Laser welding method for amorphous matrix material

A technology for laser welding and amorphous substrates, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult welding of amorphous substrates and stainless steel, high equipment requirements, etc., achieve high welding strength and reduce equipment requirements, the effect of expanding the field of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

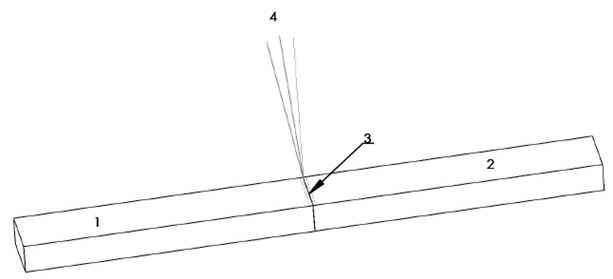

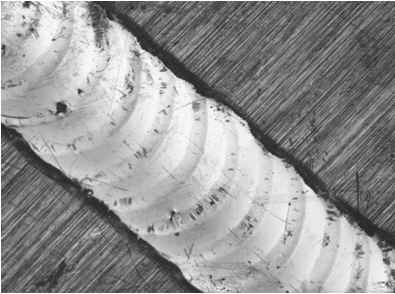

[0033] Butt two amorphous alloys with a thickness of 1.5mm, and the width of the joint is 6mm. Under the protection of argon, the laser equipment PB300 is used to set the square wave pulse to radiate at the joint of the two amorphous alloys, and the two amorphous alloys are connected. Welding, welding conditions include: laser power 1.4KW, spot diameter 0.27mm, light output frequency 8Hz, argon gas pressure 0.15MPa, argon flow rate 10mL / min, pulse laser moving speed 8mm / s, single The pulse width of the pulse is 3.5ms.

Embodiment 2

[0035] Two pieces of amorphous alloys were butt welded using the same method as in Example 1, except that the moving speed of the pulsed laser was 15 mm / s, and the duration of a single pulse was 10 ms.

Embodiment 3

[0037]Lap the stainless steel with a thickness of 0.15mm on the amorphous alloy with a thickness of 1.5mm. Under the protection of nitrogen, use the laser equipment PB300 to set the square wave pulse to aim at the surface of the stainless steel for radiation, and perform lap spot welding of the stainless steel and the amorphous alloy. The conditions include: the laser power is 2KW, the spot diameter is 0.64mm, the light output frequency is 8Hz, the nitrogen gas pressure is 0.15MPa, the nitrogen gas flow rate is 10mL / min, the pulse width of a single pulse is 8ms, and the number of solder joints is 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com