Ultrasonic accumulation preparation method for amorphous/metal micro-laminated composite

A composite material and micro-lamination technology, which is applied in the direction of manufacturing tools, metal processing equipment, non-electric welding equipment, etc., can solve the problems of small critical size of amorphous materials, limited structural materials, and poor room temperature plasticity, so as to promote tight connection and bonding , good structural stability and low residual internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

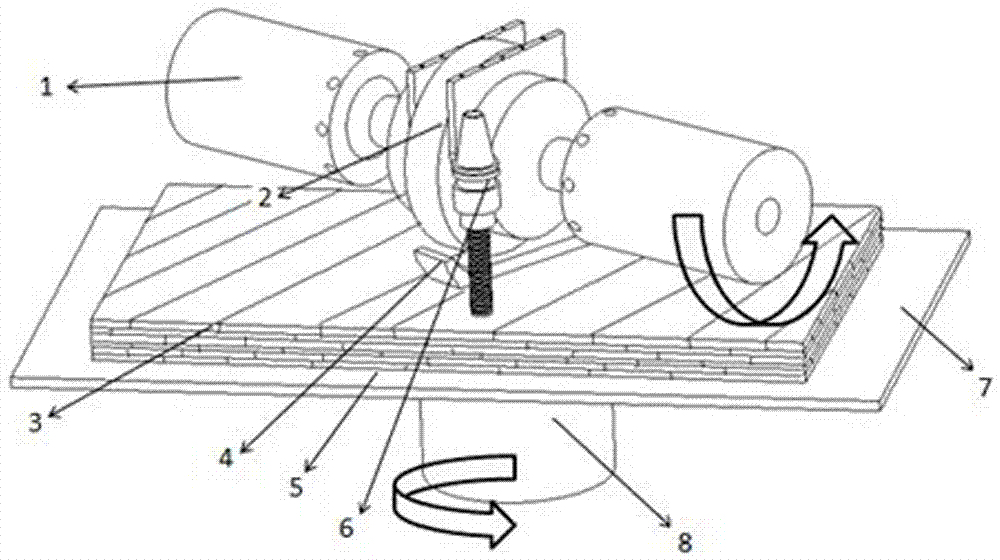

Method used

Image

Examples

Embodiment 1

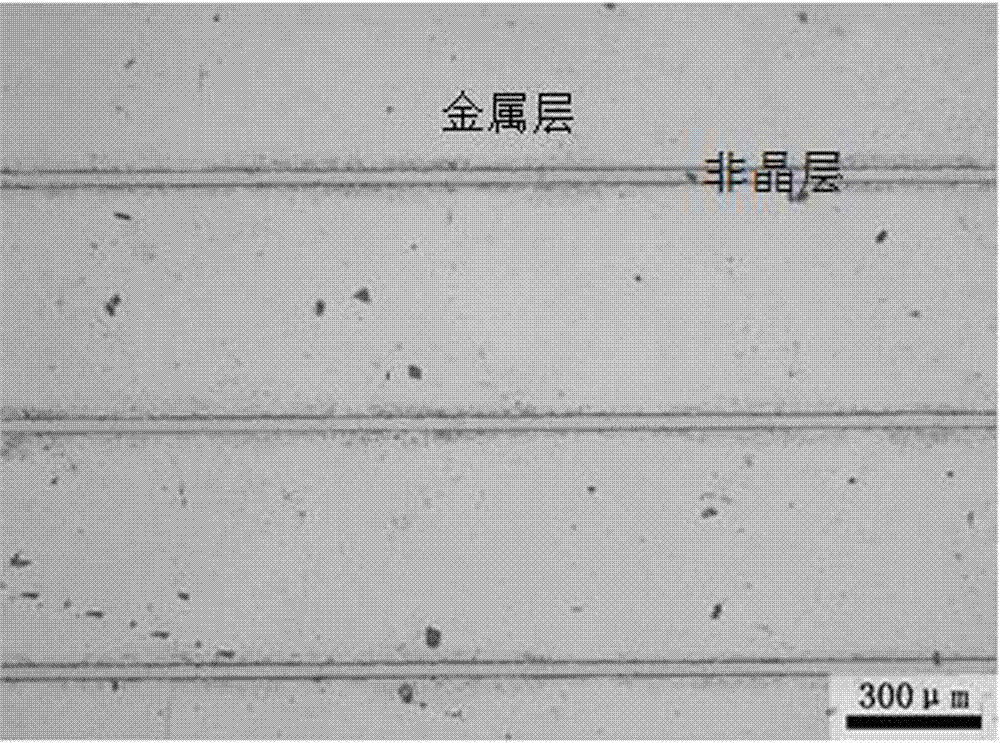

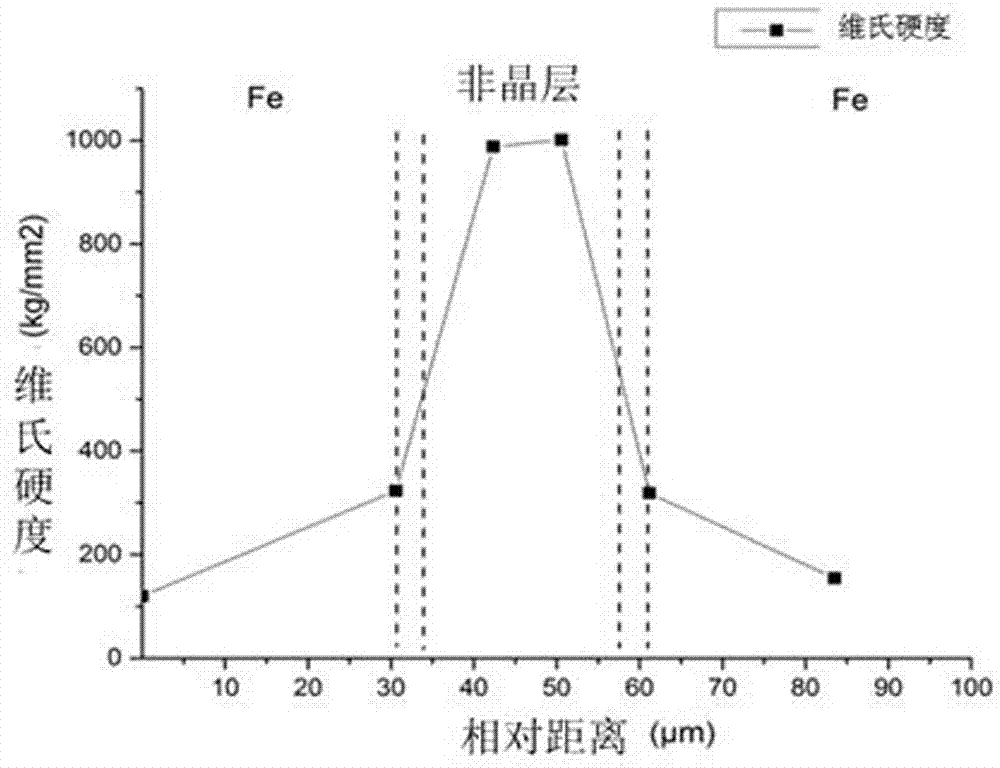

[0051] Example 1: Preparation of amorphous / iron foil micro-laminated composite material

[0052] This embodiment is a preparation method of an iron-based amorphous alloy / iron foil micro-laminated composite material, and the described amorphous alloy is made of Fe 73.5 Si 13.5 B 9.5 Cu 1 Nb 2.5 A strip with a width of 25 mm and a thickness of 30 μm is produced; the iron foil is T2 pure iron foil with a thickness of 150 mm×150 mm and a thickness of 650 μm. The concrete process of this embodiment is:

[0053] The first step, surface treatment: clean the surface of the iron foil and amorphous strip with 3% hydrochloric acid alcohol to remove the oxide film on the surface of the foil. Then, the iron foil and the amorphous strip were polished with 240#, 400#, 800#, 1000#, 1500#, 2000# sandpaper in sequence until the surface was bright, and then the foil was sanded horizontally, vertically and 45° with wool felt. Grind in the same direction, and finally place it in an ultrasoni...

Embodiment 2

[0060] Example 2: Preparation of amorphous / aluminum foil micro-laminated composite material

[0061] This embodiment is a preparation method of an iron-based amorphous alloy / aluminum foil micro-laminated composite material, and the described amorphous alloy is Fe 73.5 Si 13.5 B 9.5 Cu 1 Nb 2.5 , a strip with a width of 25 mm and a thickness of 30 μm; the iron foil is T2 pure aluminum foil with a thickness of 150 mm×150 mm and a thickness of 650 μm. The concrete process of this embodiment is:

[0062] The first step, surface treatment: the surface of the aluminum foil and the amorphous strip is cleaned with 3% hydrochloric acid alcohol to remove the oxide film on the surface of the foil. Then the aluminum foil and the amorphous strip are polished with 240#, 400#, 800#, 1000#, 1500#, and 2000# sandpaper in sequence until the surface is bright, and then the aluminum foil and the amorphous strip are polished from the horizontal, Polish in the longitudinal and 45° directions,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com