30% mineral reinforced electroplating PC/ABS alloy material and preparation method thereof

An alloy material and ABS resin technology, which is applied in the field of 30% mineral reinforced electroplating PC/ABS alloy material and its preparation, can solve the problems of decreased physical properties and synergistic improvement of mechanical properties, and achieves small residual internal stress, cost reduction, raw material easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

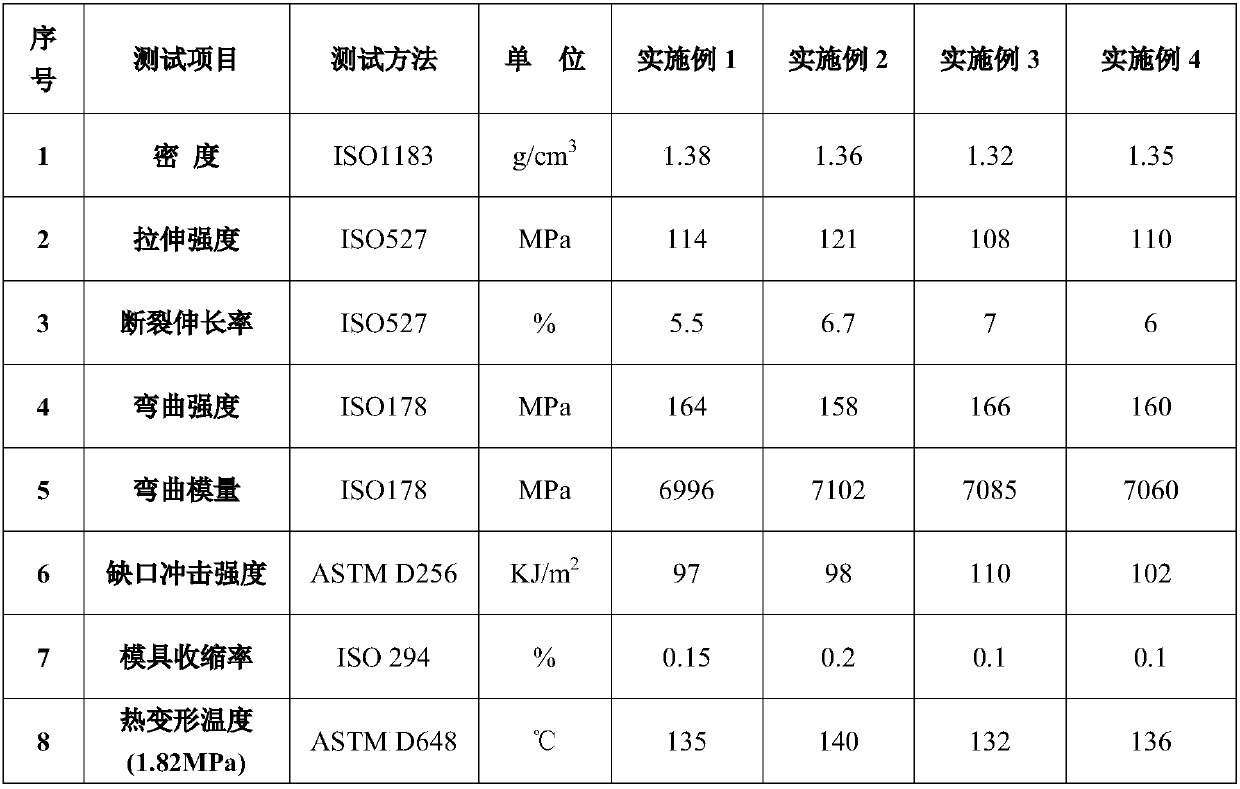

Embodiment 1

[0021] Embodiment 1: a kind of 30% mineral reinforced electroplating PC / ABS alloy material, its formula component ratio is: PC resin: 45%, ABS resin: 12%, internal stress improving agent is PS: 3%, modified mineral fiber Surface-modified calcium carbonate: 30%, toughening agent is EMA: 2%, compatibilizer is SMA-700: 3%, lubricant is paraffin oil: 3% and antioxidant is 1098 and 1076 (composite Ratio 1:1):2%. Among them, the melt index (300°C, 1.2kg) of PC resin is 20g / 10min, and the melt index (300°C, 1.2kg) of ABS resin is 10g / 10min.

[0022] Put the main ingredients PC resin and ABS resin in the above formula, as well as the internal stress improver and lubricant according to the required mass fraction, and place them in the mixer in sequence and mix them for 5 minutes to obtain the mixture; then, sequentially mix EMA, SMA-70 Add 1098 and 1076 (combining ratio 1:1) to the previously obtained mixture and continue mixing for 6 minutes; add the obtained mixture to the main feed...

Embodiment 2

[0023] Embodiment 2: a kind of 30% mineral reinforced electroplating PC / ABS alloy material, its formula component ratio is: PC resin: 40%, ABS resin: 15%, internal stress improving agent is PS: 2%, modified mineral fiber Surface-modified calcium carbonate: 32%, toughening agent: EMA: 2%, compatibilizer: SMA-700: 3%, lubricant: paraffin oil: 3% and antioxidant: 1098: 3%. Among them, the melt index of PC resin (300°C, 1.2kg) is 40g / 10min, and the melt index of ABS resin (300°C, 1.2kg) is 10g / 10min.

[0024] Put the main ingredients PC resin and ABS resin in the above formula, as well as the internal stress improver and lubricant according to the required mass fractions, and place them in the mixer in sequence and mix them for 6 minutes to obtain the mixture; then, sequentially mix EMA, SMA-70 Add 1098 and 1076 (compounding ratio 1:1) to the mixture obtained before and continue to knead for 10 minutes; add the obtained mixture to the main feeding port of the co-rotating twin-scre...

Embodiment 3

[0025] Embodiment 3: a kind of 30% mineral reinforced electroplating PC / ABS alloy material, its formula component ratio is: PC resin: 43%, ABS resin: 14%, internal stress improving agent is PS: 3%, modified mineral fiber Surface-modified calcium carbonate: 30%, toughening agent is EMA: 2%, compatibilizer is SMA-700: 3%, lubricant is paraffin oil: 3% and antioxidant is 1098 and 1010 (composite Ratio 1:1):2%. Among them, the melt index (300°C, 1.2kg) of PC resin is 20g / 10min, and the melt index (300°C, 1.2kg) of ABS resin is 10g / 10min.

[0026] Put the main ingredients PC resin and ABS resin in the above formula, as well as the internal stress improver and lubricant according to the required mass fraction, and place them in the mixer in sequence and mix them for 5 minutes to obtain the mixture; then, sequentially mix EMA, SMA-70 Add 1098 and 1010 (combining ratio 1:1) to the mixture obtained before and continue mixing for 6 minutes; add the obtained mixture to the main feed por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com