High-density metal target material preparation process

A metal target material and preparation process technology, which is applied in the direction of metal material coating process, fusion spraying, coating, etc., can solve the problems of high material loss, uneven grain, high cost, etc., and achieve high energy, high density, The effect of low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

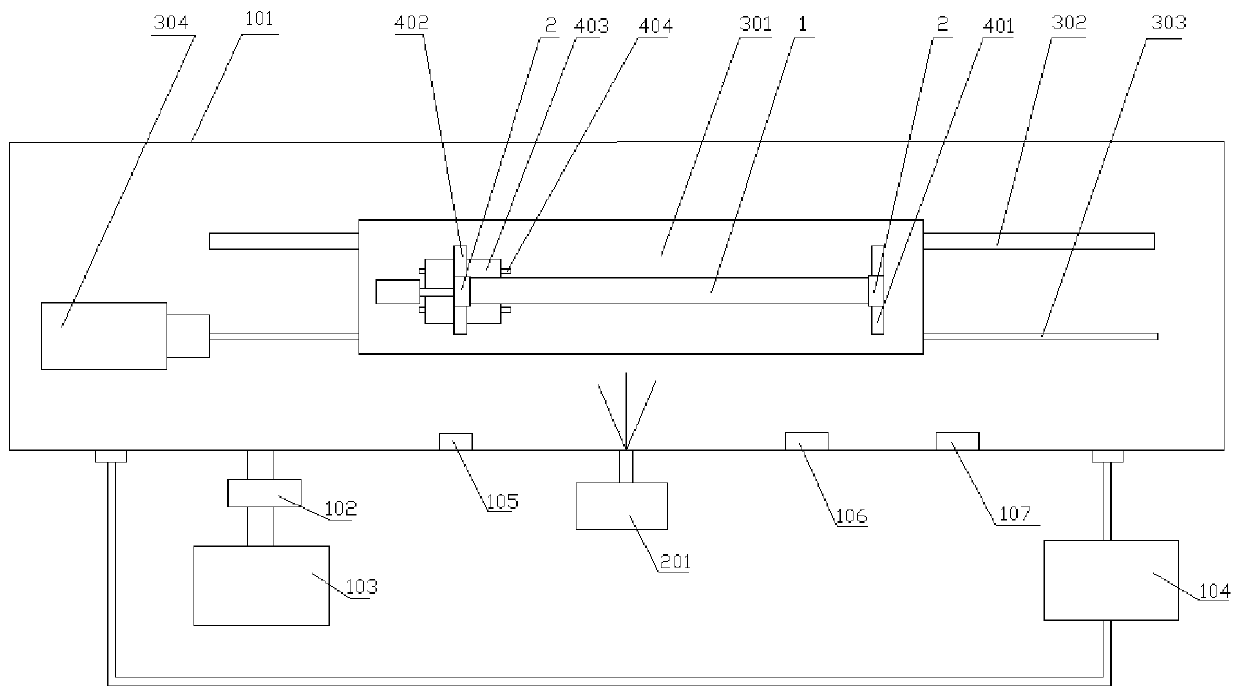

[0021] The present invention relates to a high-density metal target preparation process. The process is as follows: after the target 1 is placed on the target drive assembly, the spraying sealing cabin 101 is first vacuumed so that a sealed chamber with a pressure of 2Pa is formed in the cabin. Vacuum environment; then, the target drive assembly starts, drives the target to rotate and translate left and right, at the same time, the spray gun of the plasma spray gun system 201 starts spraying and sprays the target 1; and in the process of spraying, the infrared temperature sensor 106 monitors the surface temperature of the target 1 in real time. When the temperature deviates from the set point, the power of the plasma spray gun system 201 and its wire feeding speed are adjusted accordingly, so that the surface of the target 1 is always kept in a slightly fused state and the internal friction is reduced. Void, enhance density.

[0022] At the same time, when spraying, the dust s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com