Ultrasonic accumulation manufacturing method of amorphous/metal micro-laminated composites

A composite material and micro-lamination technology, used in manufacturing tools, metal processing equipment, non-electric welding equipment, etc., can solve the problems of limited structural materials, poor room temperature plasticity, small critical dimensions of amorphous materials, etc., to promote tight connection and bonding. , the effect of good structural stability and low residual internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

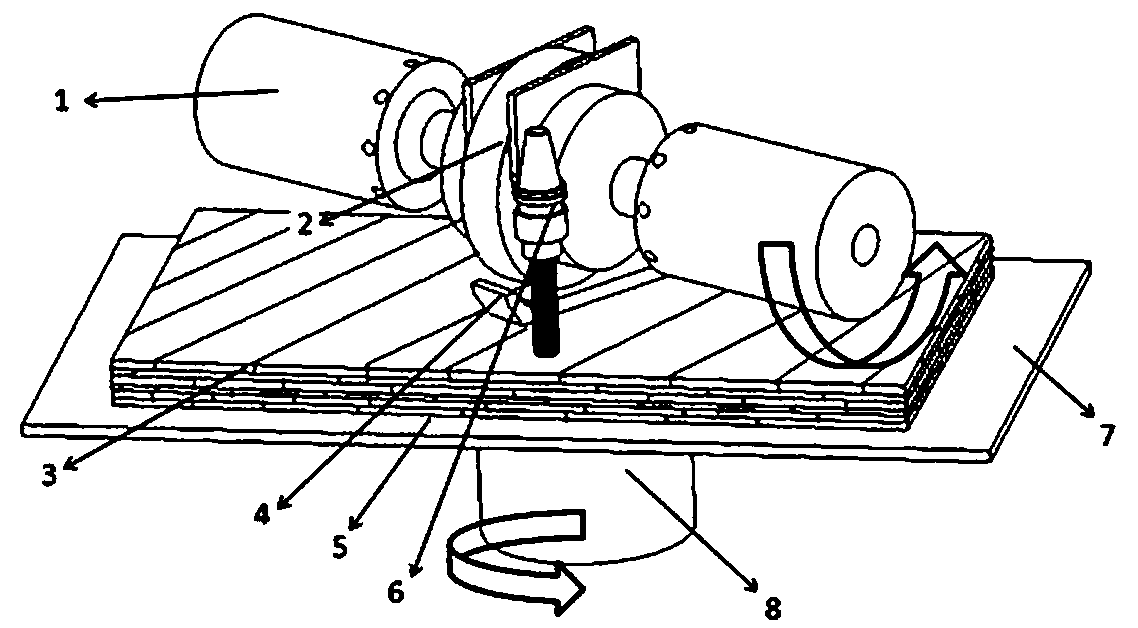

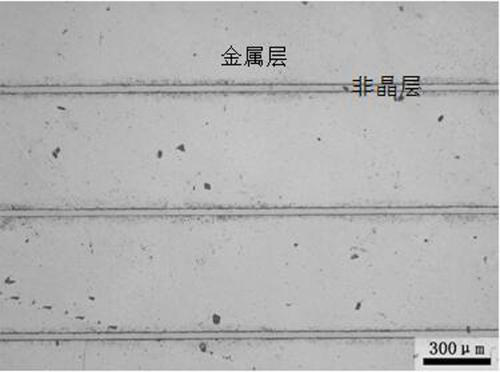

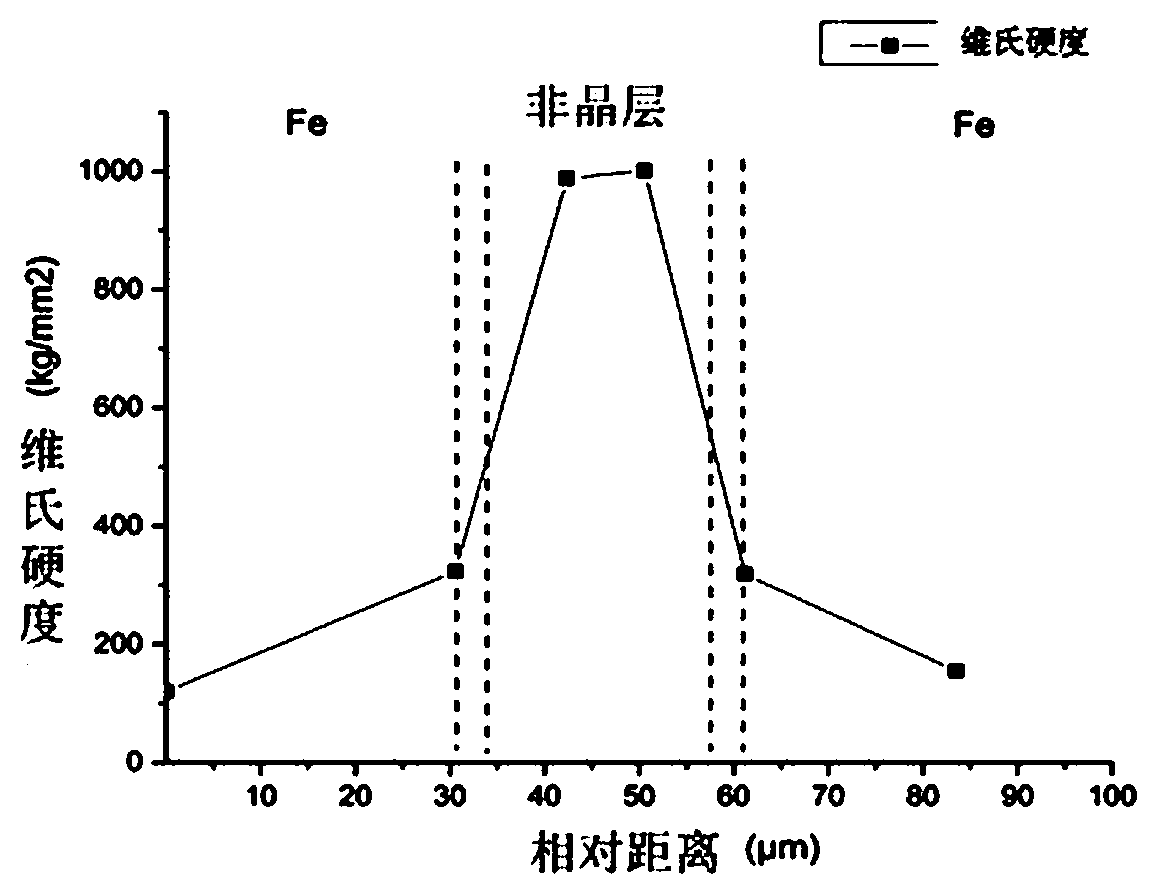

[0051] Example 1: Preparation of amorphous / iron foil micro-laminated composite material

[0052] This embodiment is a method for preparing an iron-based amorphous alloy / iron foil micro-laminated composite material. The amorphous alloy is made of Fe 73.5 Si 13.5 B 9.5 Cu 1 Nb 2.5 The finished strip has a width of 25mm and a thickness of 30μm; the iron foil is a T2 pure iron foil with a thickness of 150mm×150mm and a thickness of 650μm. The specific process of this embodiment is:

[0053] The first step, surface treatment: clean the surface of the iron foil and amorphous strip with a concentration of 3% hydrochloric acid alcohol to remove the oxide film on the surface of the foil. Afterwards, the iron foil and amorphous strips were polished with 240#, 400#, 800#, 1000#, 1500#, 2000# sandpaper to a bright surface, and then wool felt was used to grind the foil from the horizontal, vertical and 45° directions. Polish in the direction, and finally place it in an ultrasonic cleaning mach...

Embodiment 2

[0060] Example 2: Preparation of amorphous / aluminum foil micro-laminated composite material

[0061] This embodiment is a method for preparing an iron-based amorphous alloy / aluminum foil micro-laminated composite material. The amorphous alloy is Fe 73.5 Si 13.5 B 9.5 Cu 1 Nb 2.5 , The finished strip is 25mm in width and 30μm in thickness; the aluminum foil is 150mm×150mm and T2 pure aluminum foil with a thickness of 650μm. The specific process of this embodiment is:

[0062] The first step is the surface treatment: the surface of the aluminum foil and the amorphous strip is cleaned with 3% hydrochloric acid alcohol to remove the oxide film on the surface of the foil. Afterwards, the aluminum foil and amorphous strips were polished with 240#, 400#, 800#, 1000#, 1500#, 2000# sandpaper to a bright surface, and then wool felt was used to separate the aluminum foil and amorphous strips from the horizontal and Grind longitudinally and 45°, and finally place it in an ultrasonic cleaner f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com