Sulfide and oxy-sulfide glass and glass-ceramic films for batteries incorporating metallic anodes

a technology of glassceramic films and metallic anodes, which is applied in the direction of cell components, electrochemical generators, manufacturing tools, etc., can solve the problems of difficult formation and vulnerable to cell failure, and achieve the effect of improving glass formability and/or stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

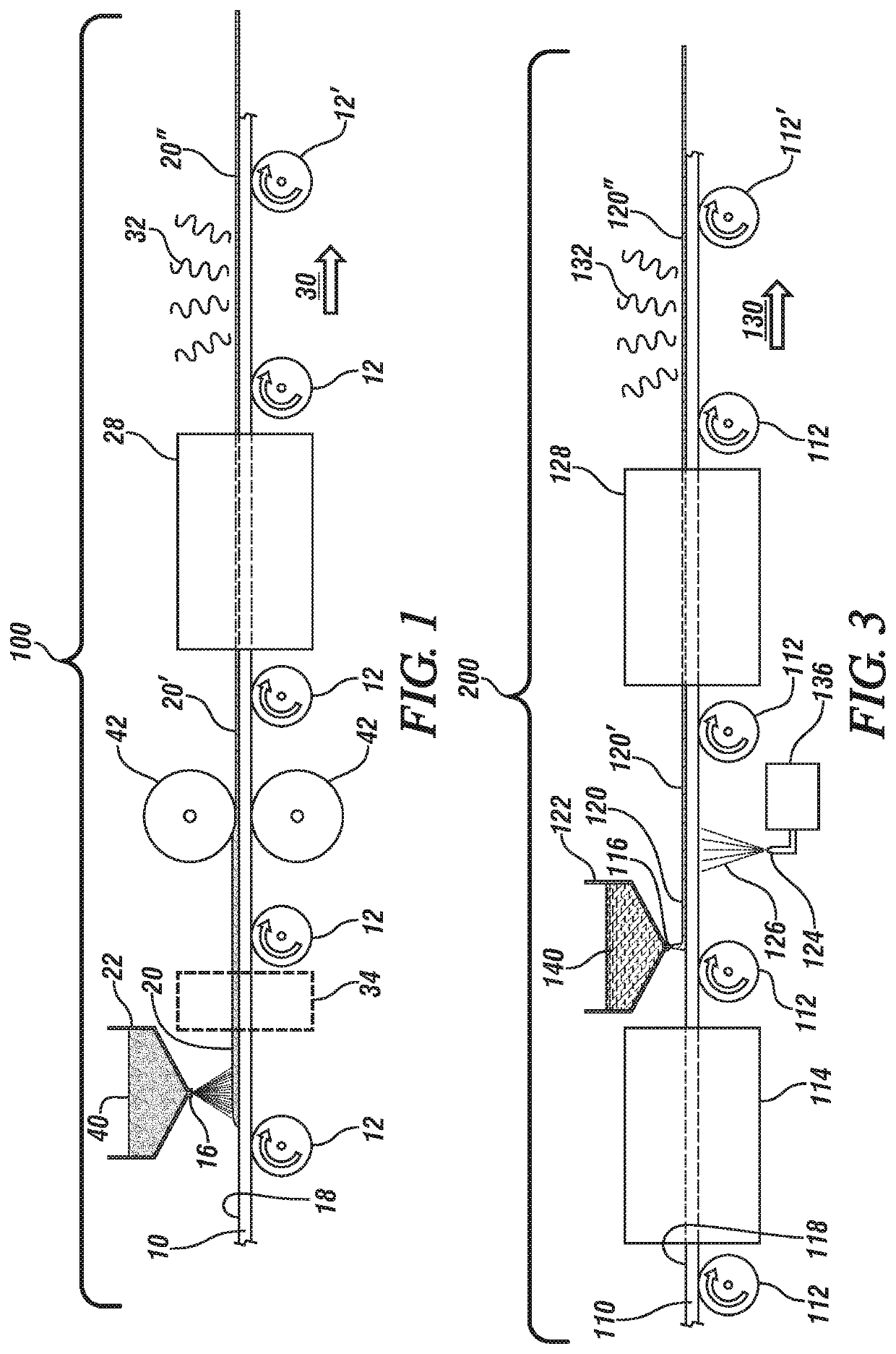

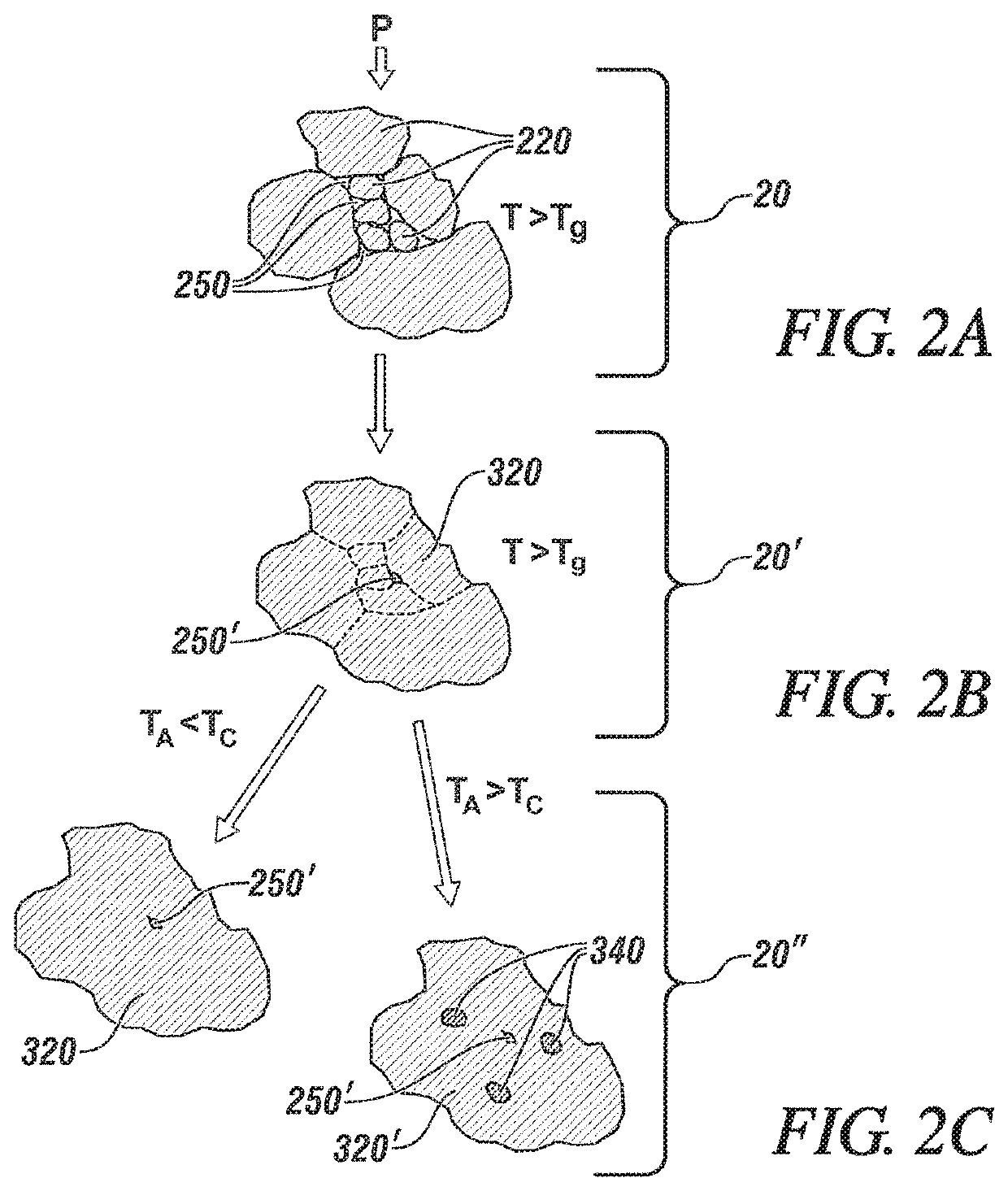

[0022]Sulfide-based or oxy-sulfide-based glasses containing lithium ions offer promise as solid electrolytes in electrochemical cells which employ an alkali metal, particularly lithium or sodium, as an anode. For convenience, the following description will detail methods for forming a thin layer of a lithium ion-conducting solid electrolyte for use in cells comprising a metallic lithium anode, but similar methods may be practiced to prepare sodium ion-conducting electrolytes by substituting sodium-based compositions for the corresponding lithium-based compositions.

[0023]Suitably thin films or sheets of these sulfide or oxy-sulfide compositions may be interposed between the lithium metal anode, possibly in conjunction with a liquid, lithium-conducting electrolyte, and an opposing cathode and serve to separate these opposing electrodes and prevent direct electrical interconnection of anode and cathode in such cells.

[0024]The separator function of the film is as important as its electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com