Thin strip of alloy containing initial ultrafine crystals and method for cutting same, and thin strip of nanocrystalline soft-magnetic alloy and magnetic part employing same

A technology of ultrafine crystals and thin strips, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of cracks on the cut surface, failure to obtain a rectangular cross section, and inability to accurately evaluate the magnetic flux density, etc., to achieve high versatility, The effect of less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

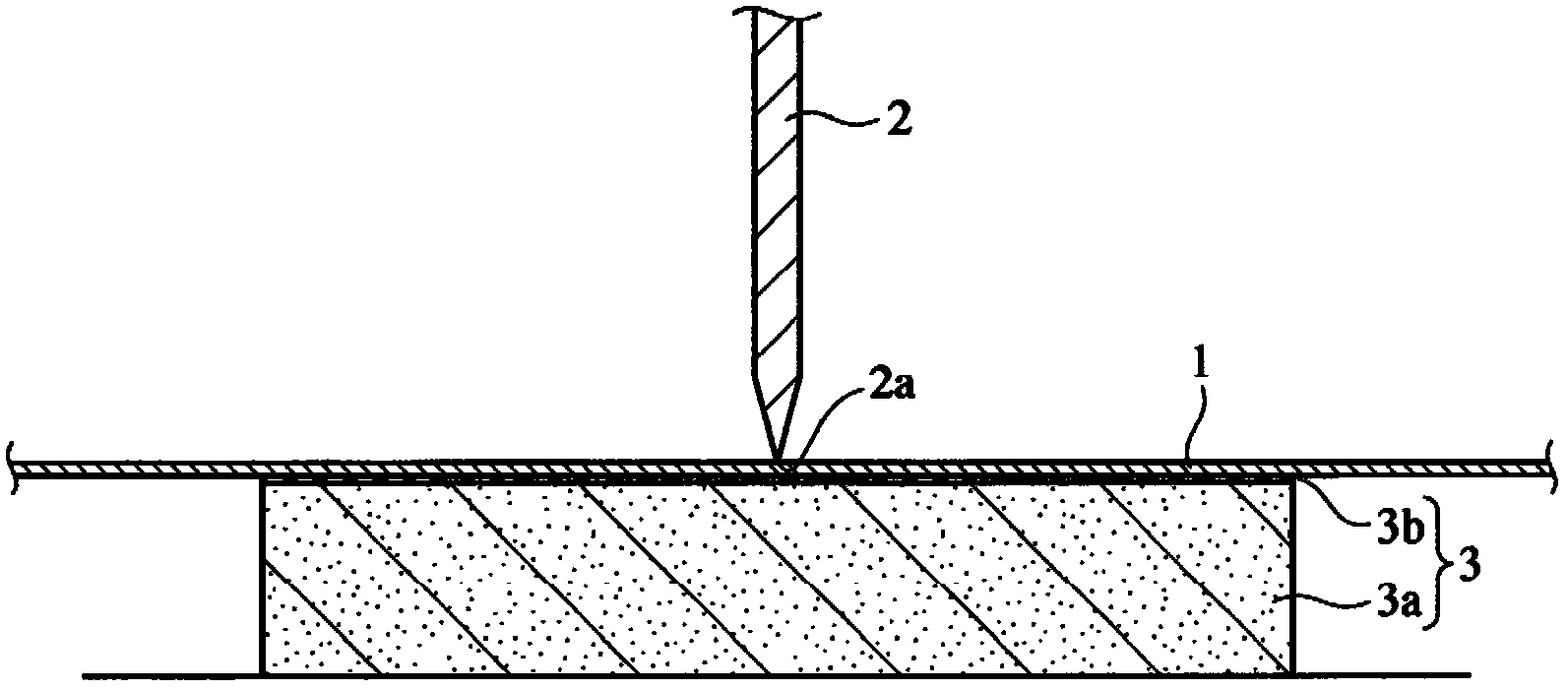

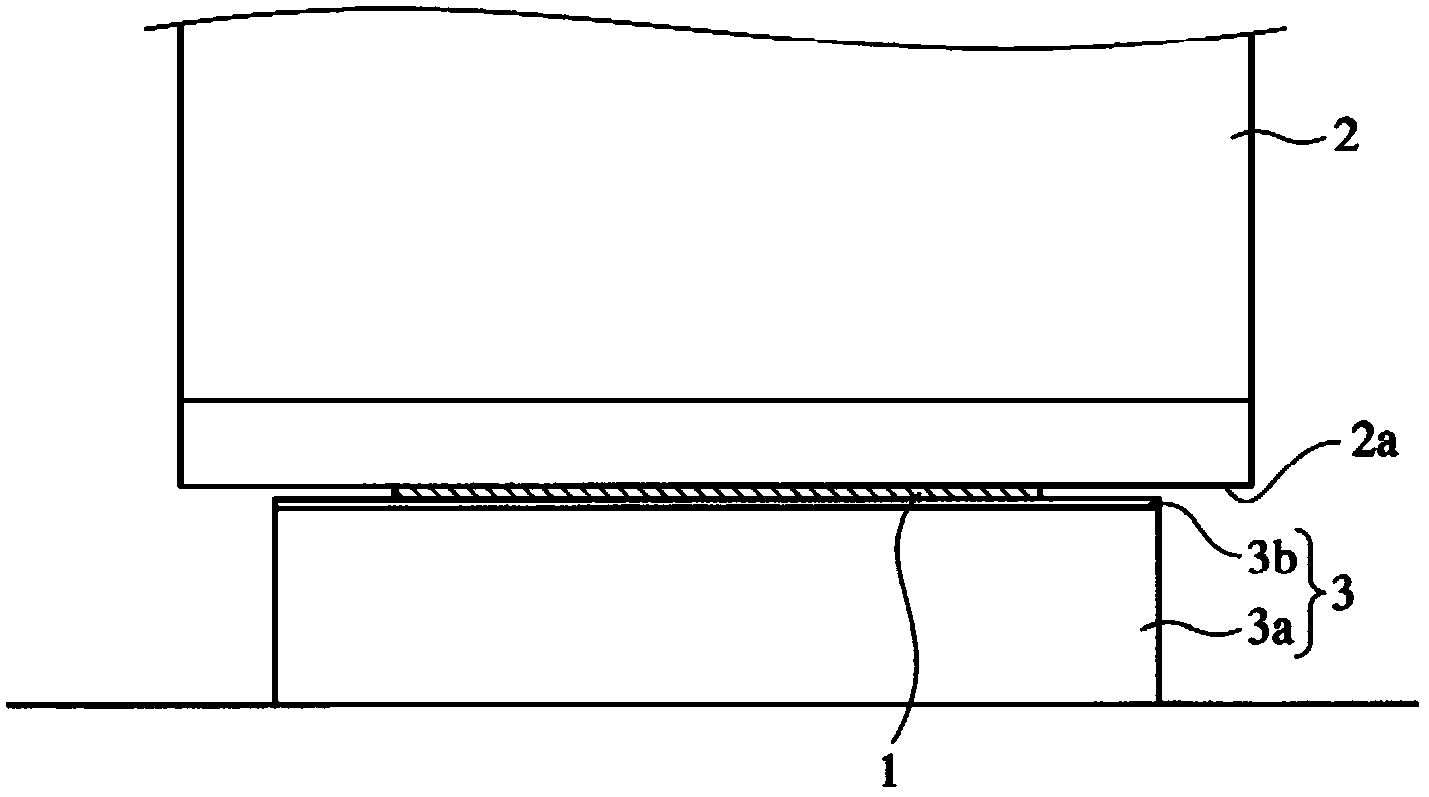

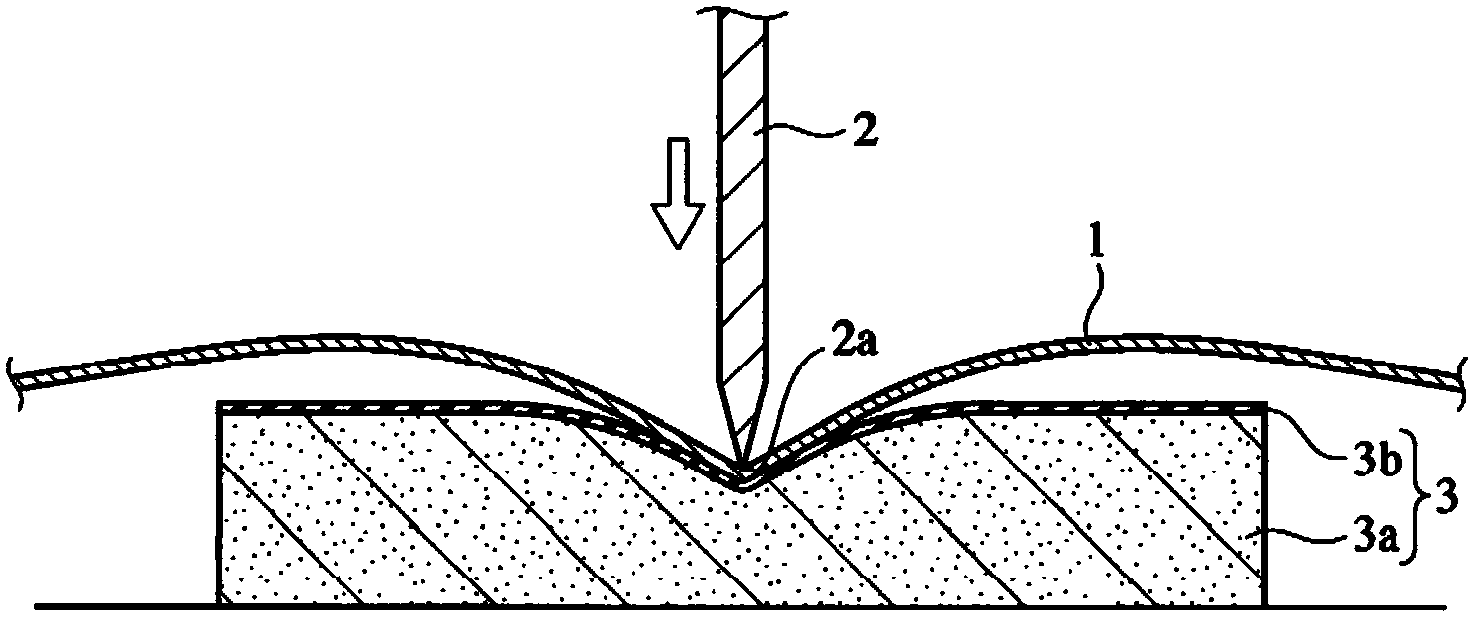

[0131] By the single-roll method using a cooling roll made of copper alloy, the alloy melt (1300°C) having the composition shown in Table 1 was rapidly quenched in the air, and peeled from the roll at a ribbon temperature of 250°C to produce Initial ultrafine crystal alloy strips with a width of 25mm (Examples 1-5) and 50mm (Examples 6-8). In order to adjust the average particle size and volume fraction of ultrafine crystal grains, and the Vickers hardness Hv of the initial ultrafine crystal alloy ribbon, the gap between the nozzle and the cooling roll and the circumference of the roll during casting were changed as shown in Table 1. Speed (27 ~ 36m / s).

[0132] Such as Figure 5 As shown, the thickness and Vickers hardness Hv of each initial ultrafine crystal alloy thin strip at each measurement point row 1 to 5 were measured. The average thickness is the average of the thicknesses measured at the measurement point rows 1 to 5, and the thickness difference is the differen...

Embodiment 8

[0175] In the alloy melt of Example 8, since the Cu content is as high as 1.6 at%, a relatively thin primary ultrafine crystal alloy ribbon can be formed. Even for such a thin ribbon, the Vickers hardness Hv of the central part and the end part is also in the range of 850 to 1150, and the hardness difference is 70. Therefore, in the cutting by the linear pressing method of the present invention, the initial ultrafine The crystalline alloy ribbon was cut approximately linearly (crack mode), and the ratio of the defect portion was reduced to 4.2%.

[0176] In Comparative Example 9, the gap between the nozzle and the cooling roll during casting was 310 μm, and the peripheral speed of the roll was 35 m / s. Table 11 shows the Vickers hardness and thickness of the primary ultrafine crystal alloy ribbons measured in the same manner as in Example 1 at the first to fifth positions of each measurement point row. The Vickers hardness Hv of the central portion and the end portion of the a...

Embodiment 9

[0180] In order to study the relationship between the proportion of the defect and the gap without the influence of the thickness, the Fe bal. Cu 1.4 Si 4 B 14 The composition (atomic %) of the alloy melt was changed as shown in Table 12, except that the gap was changed as shown in Table 12, and the peripheral speed of the roll was changed so that the thickness was constant at 21 μm. In the same manner as in Example 1, initial ultra-thin alloys with a width of 25 mm and 50 mm were produced. Microcrystalline alloy thin ribbon. It was confirmed that each thin ribbon has a structure in which ultrafine crystal grains with an average particle diameter of 30 nm or less are dispersed in the amorphous matrix at a ratio of 5 to 30% by volume. Next, the hardness difference between the center portion and the end portion of each ribbon, the thickness difference in the width direction, and the ratio of the defect portion when cut by the linear pressing method of the present invention we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com