Environment-friendly bamboo wood adhesive and bamboo wood dip-coating method

An environmentally friendly, adhesive technology, applied in adhesives, epoxy resin glue, adhesive additives, etc., can solve the problems that the adhesive strength cannot be exerted to the maximum effect, and the adhesive is applied unevenly, etc., to achieve Achieve automation integration, clean and tidy bottom surface, and overcome poor water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

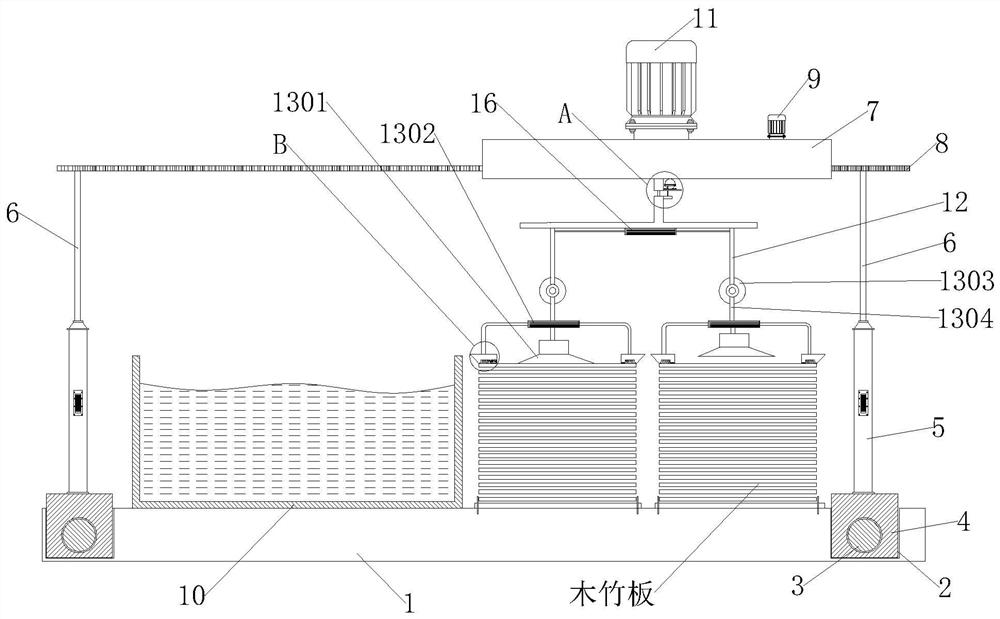

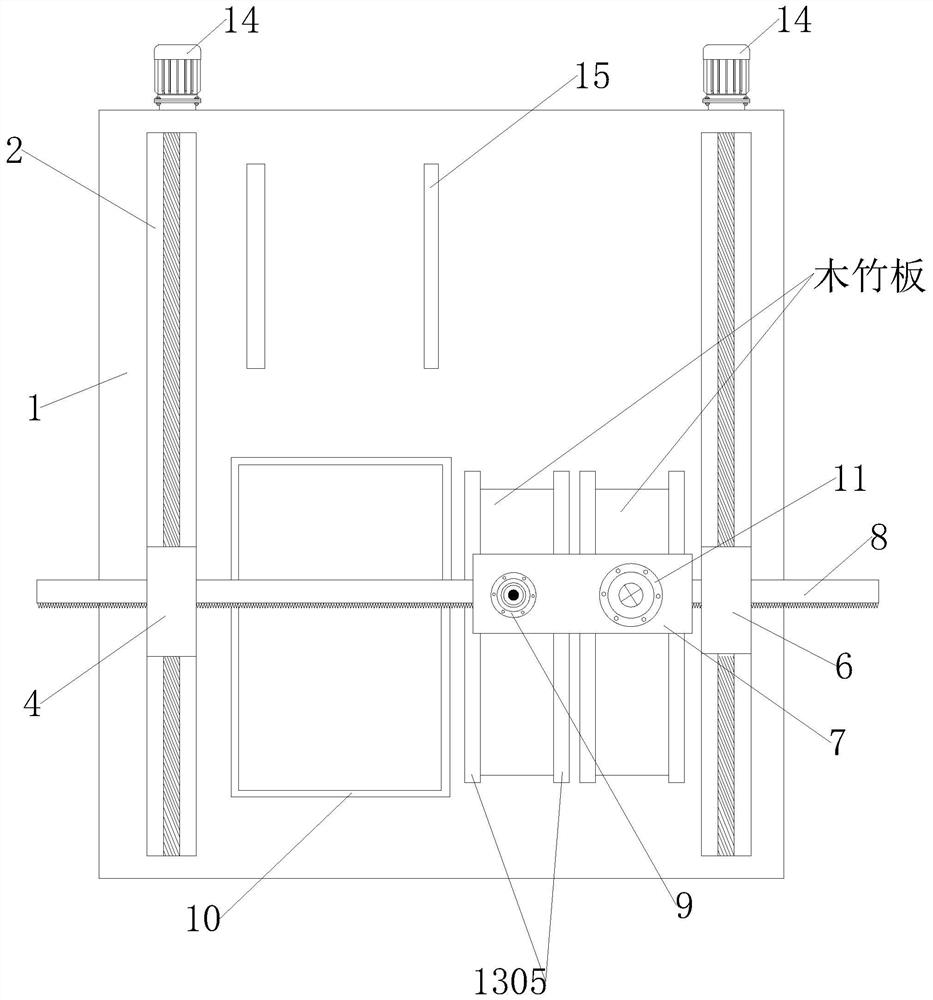

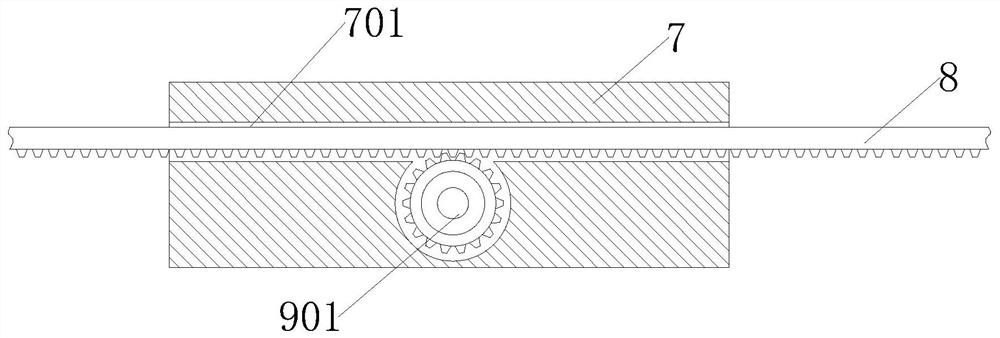

[0047] see Figure 1-9 , is a schematic diagram of the overall structure of an environment-friendly bamboo-wood adhesive and a bamboo-wood dip-coating method;

[0048] An environment-friendly bamboo wood adhesive, including water, vegetable protein, modifier, crosslinking agent, curing agent, filler and additives; each component is made according to the following mass parts: water: 100 parts, vegetable protein: 20-40 parts, modifier: 0.1-5 parts, cross-linking agent: 20-40 parts, curing agent: 2-20 parts, filler: 1-5 parts, additive: 3 parts; wherein, the vegetable protein The raw material is defatted soy flour with a protein content of not less than 50%; the modifying agent is a combination of sodium hydroxide and sodium lauryl sulfate or urea or sodium sulfite; the crosslinking agent is sodium silicate and Epoxy resin modified polyvinyl alcohol solution, wherein the mass parts of each component is sodium silicate: 16 parts, epoxy resin: 2 parts, and mass concentration is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com