Patents

Literature

229results about How to "Stable splicing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing cellular ceramic-metal composite vertical mill roller

ActiveCN104439192AAvoid the disadvantages of not being able to useImprove yieldGrain treatmentsMetal matrix compositeCeramic metal

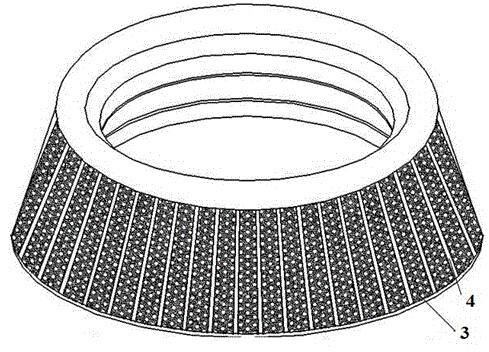

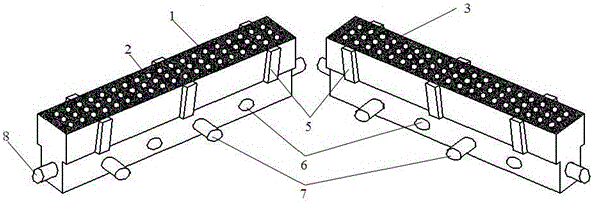

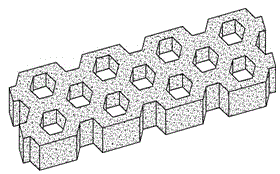

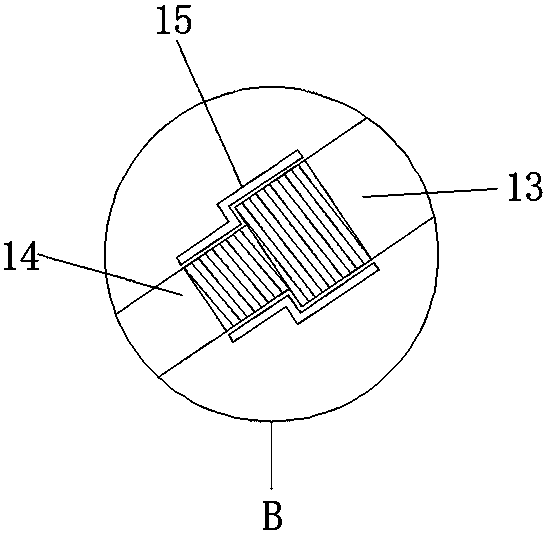

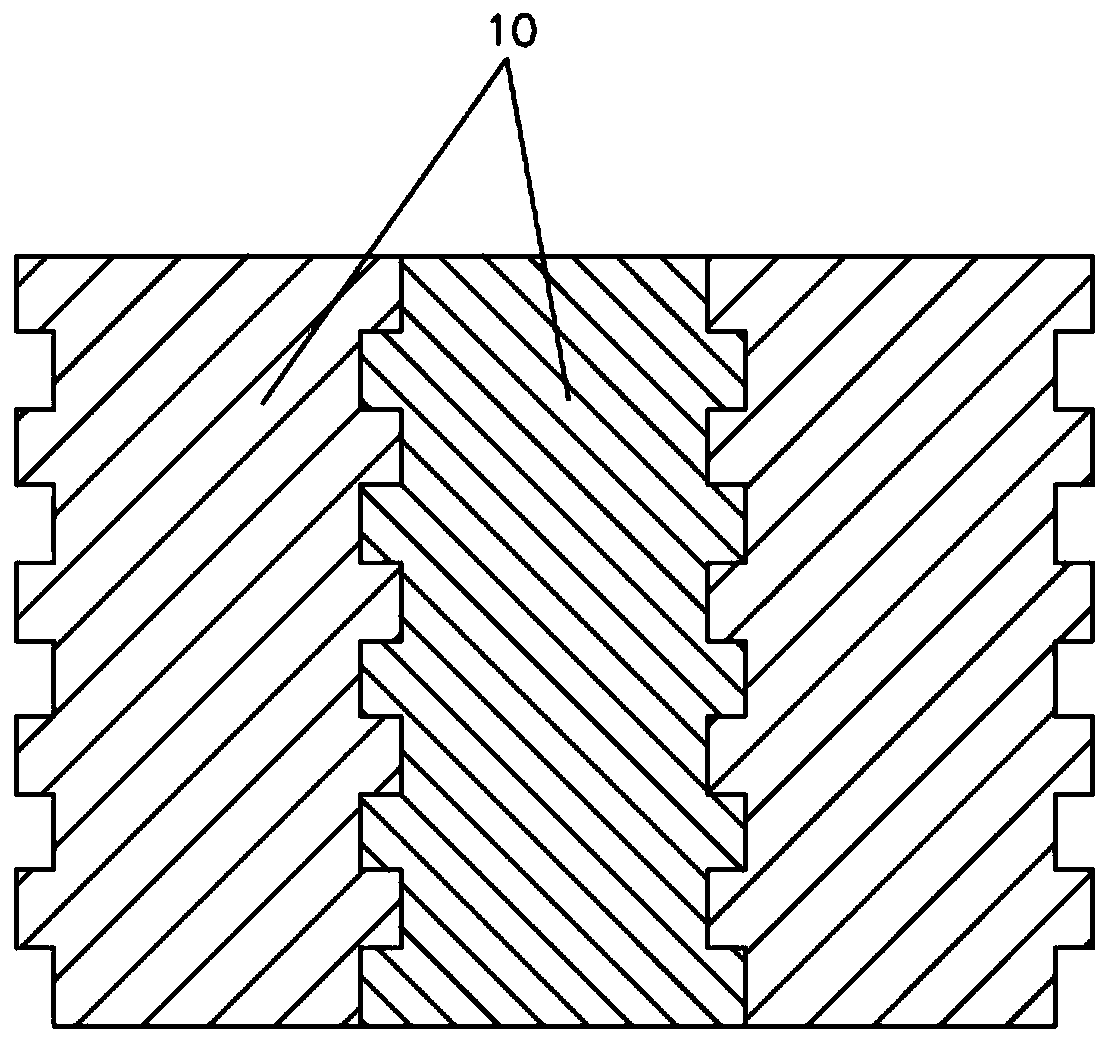

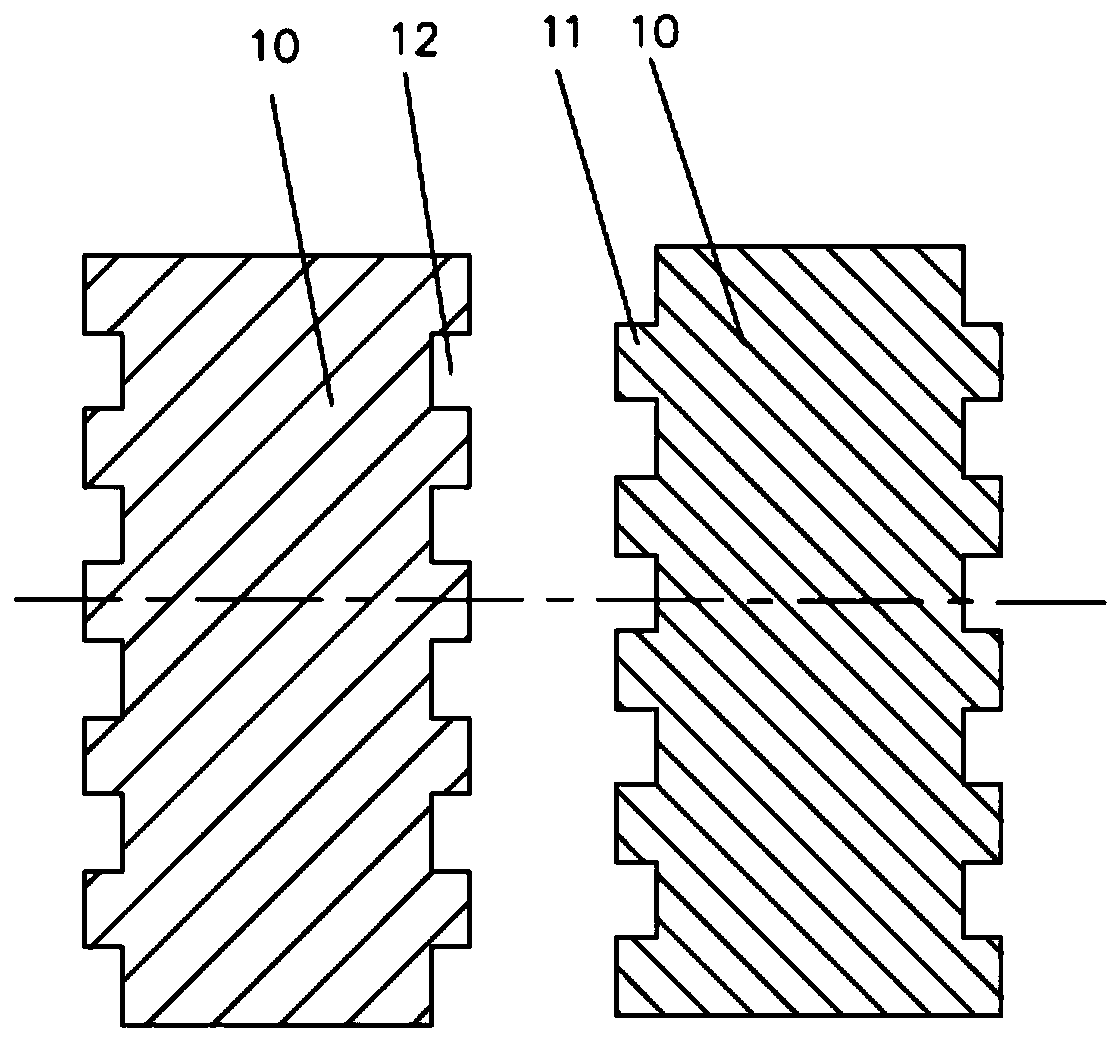

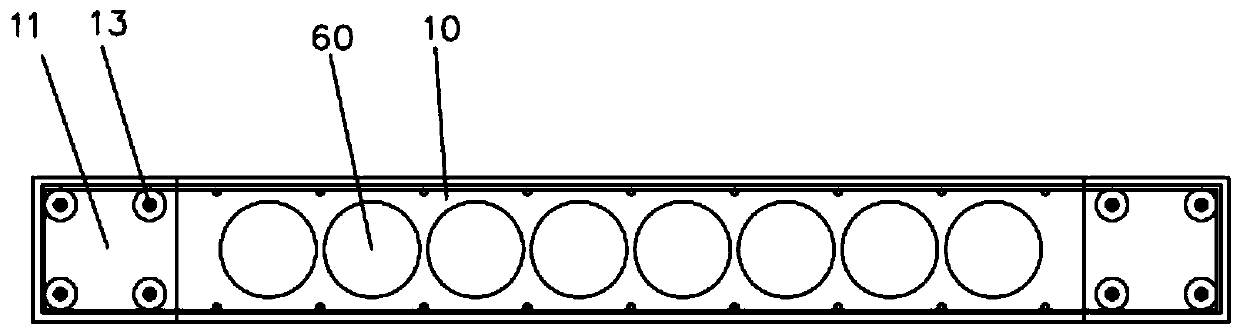

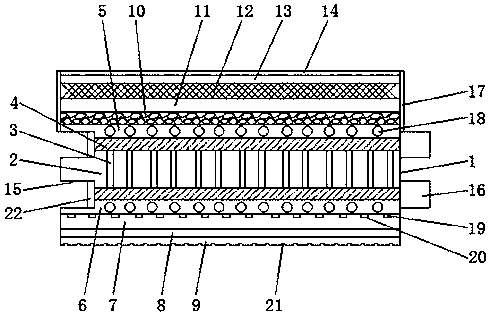

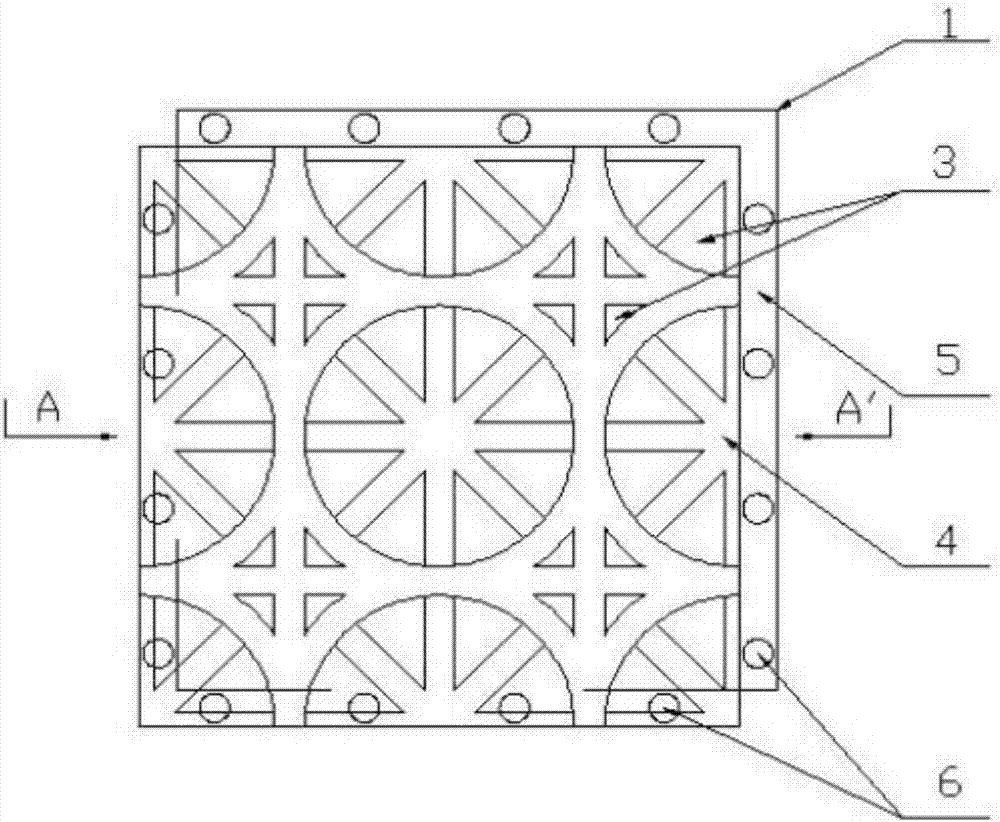

The invention relates to a method for manufacturing a cellular ceramic-metal composite vertical mill roller and belongs to the technical field of metal-matrix composites. The method comprises the steps that firstly, a cellular porous ceramic preform is manufactured and then made into a cellular ceramic-metal composite wear-resisting insert, wherein the cellular ceramic-metal composite wear-resisting insert is provided with clearance ribs, insert holes and insert columns; heat treatment is conducted on the cellular ceramic-metal composite wear-resisting insert, the outer surfaces of the insert holes and the insert columns are coated with fireproof coatings, and the insert columns of the wear-resisting insert are inserted into the insert holes in pair, so that the wear-resisting inserts are firmly spliced; the cellular ceramic-metal composite wear-resisting insert is placed in a vertical mill roller sand mould, molten tough metal is poured, after the molten tough metal is solidified completely, the composite vertical mill roller is formed, overall heat treatment is conducted on the composite vertical mill roller, and then the cellular ceramic-metal composite vertical mill roller is obtained. According to the method, the wear-resisting composite insert does not need an external clamp, it is only required that insert columns are inserted into the insert holes and can be firmly spliced.

Owner:KUNMING UNIV OF SCI & TECH

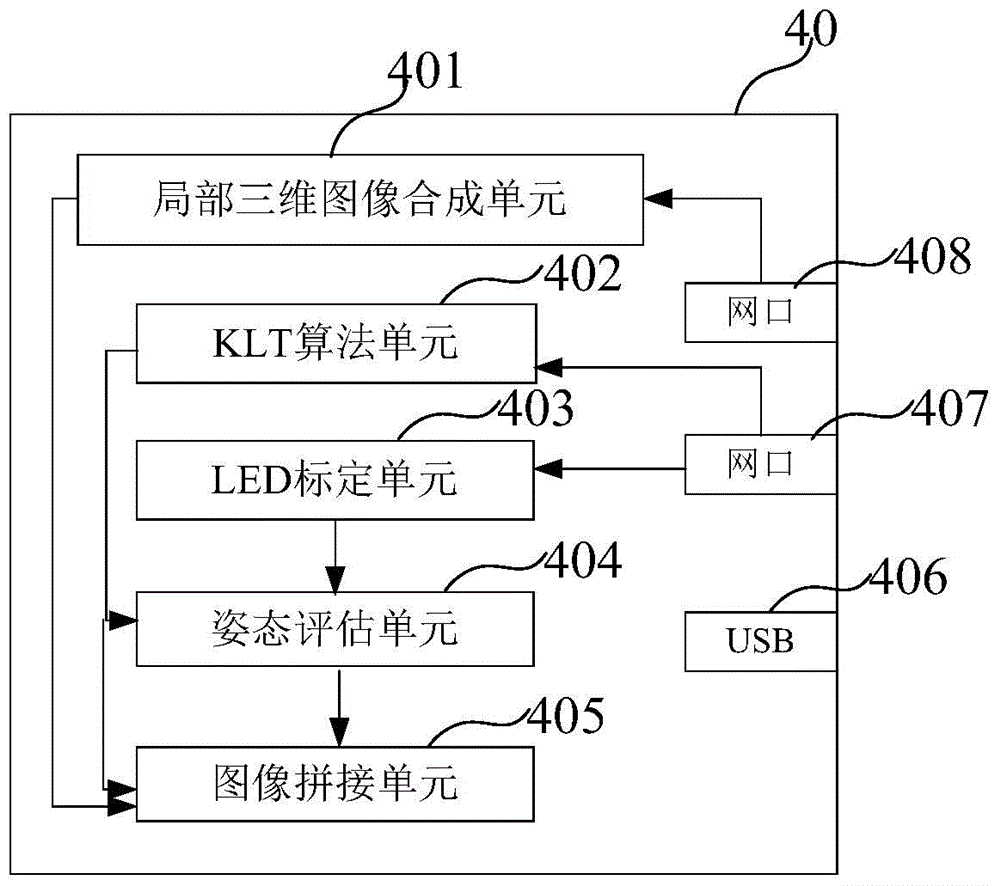

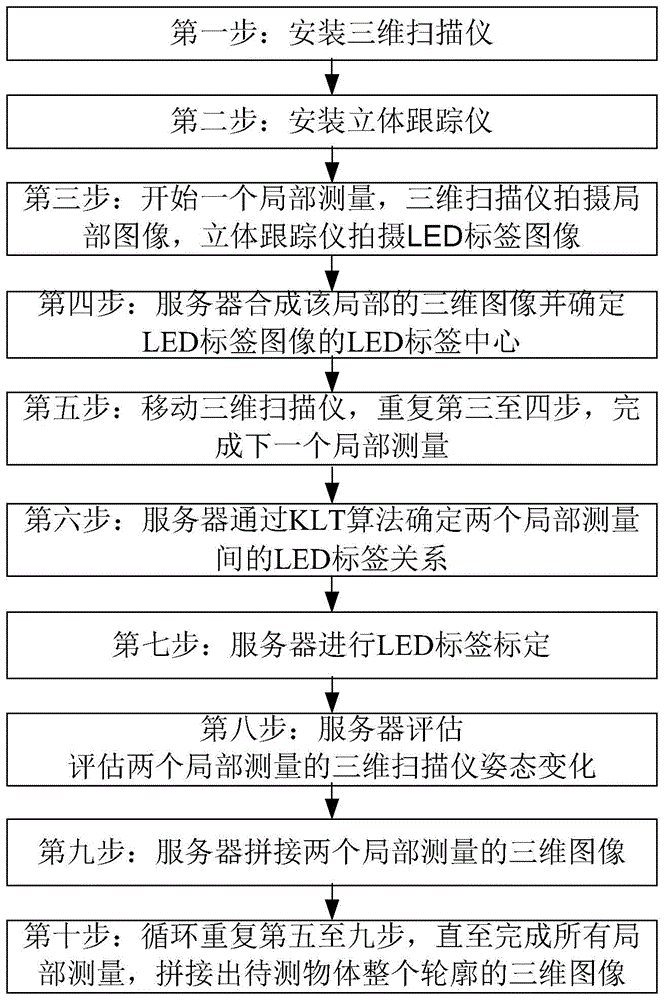

Three-dimensional geometrical measurement method and three-dimensional geometrical measurement system based on LED tag tracking

InactiveCN104976968AFlexible block measurementConvenient block measurementUsing optical meansThree dimensional measurement3d scanning

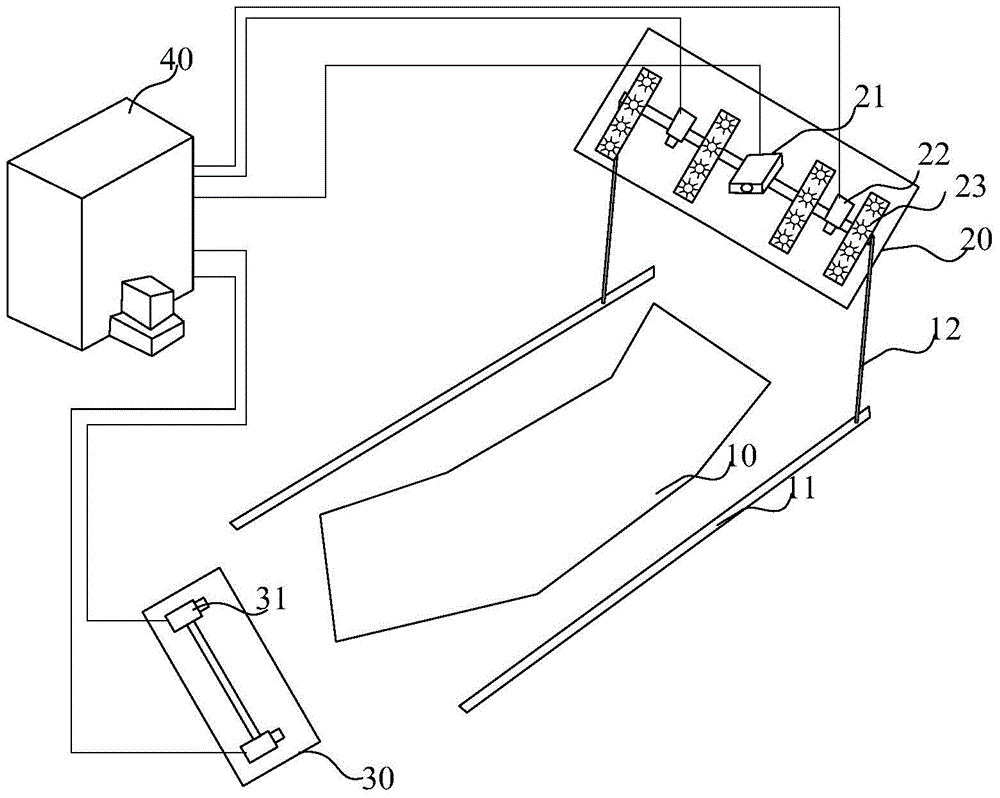

The invention provides a three-dimensional geometrical measurement method and a three-dimensional geometrical measurement system based on LED tag tracking. A three-dimensional scanner is arranged such that the three-dimensional scanner can move along a track and is close to an object to be measured, and blocked local measurement is flexibly and conveniently carried out on a large-scale object by a structured light method to obtain a high-resolution local image. Meanwhile, as the light of an LED tag is bright enough, even when the distance between a stereoscopic tracker and the LED tag increases, the stereoscopic tracker can quickly and accurately track the LED tag to ensure that a server can precisely locate the center position of the LED tag and the position of the LED tag in the coordinate system of the three-dimensional scanner, precisely obtain the LED tag relationship between two local measurements, accurately evaluate the attitude change of the three-dimensional scanner and realize precise stitching of local measurement results. Moreover, three-dimensional measurement of the whole contour of a large-scale object can be completed conveniently, stably and accurately without the need for tedious switching between multiple projectors.

Owner:JIANGSU UNIV OF SCI & TECH

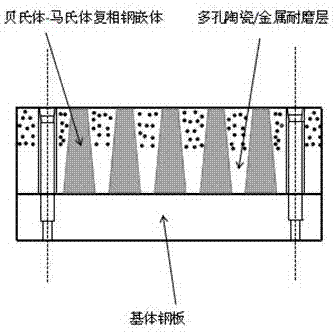

Ceramic/metal composite material wear-resistant lining plate and preparation method thereof

PendingCN107336484AImprove impact resistanceStrong economic applicabilityMetal layered productsWear resistantCost savings

The present invention relates to a ceramic / metal composite material wear-resistant lining plate and a preparation method thereof, and belongs to the technical field of materials. The ceramic / metal composite material wear-resistant lining plate comprises bainite-martensite complex-phase steel inlays, a porous ceramic / metal wear-resistant layer and a fixed base steel plate, wherein the porous ceramic / metal wear-resistant layer is provided with embedding holes, the bainite-martensite complex-phase steel inlays are fixedly embedded into the intermittent holes of the porous ceramic / metal wear-resistant layer, and the porous ceramic / metal wear-resistant layer is fixedly connected to the base steel plate. According to the present invention, the ceramic / metal composite material wear-resistant lining plate has advantages of good impact resistance, good wear resistance, long service life, convenient maintenance, simple production process and cost saving, can be adapted to different impact loads such as the high impact load, the medium impact load and the low impact load, and can effectively reduce the problems of the incapable provision of the characteristics of the material due to the inapparent high-manganese steel processing hardening effect and the great defect generated by the base body material due to the too high stress of the processed and hardened structure.

Owner:KUNMING UNIV OF SCI & TECH

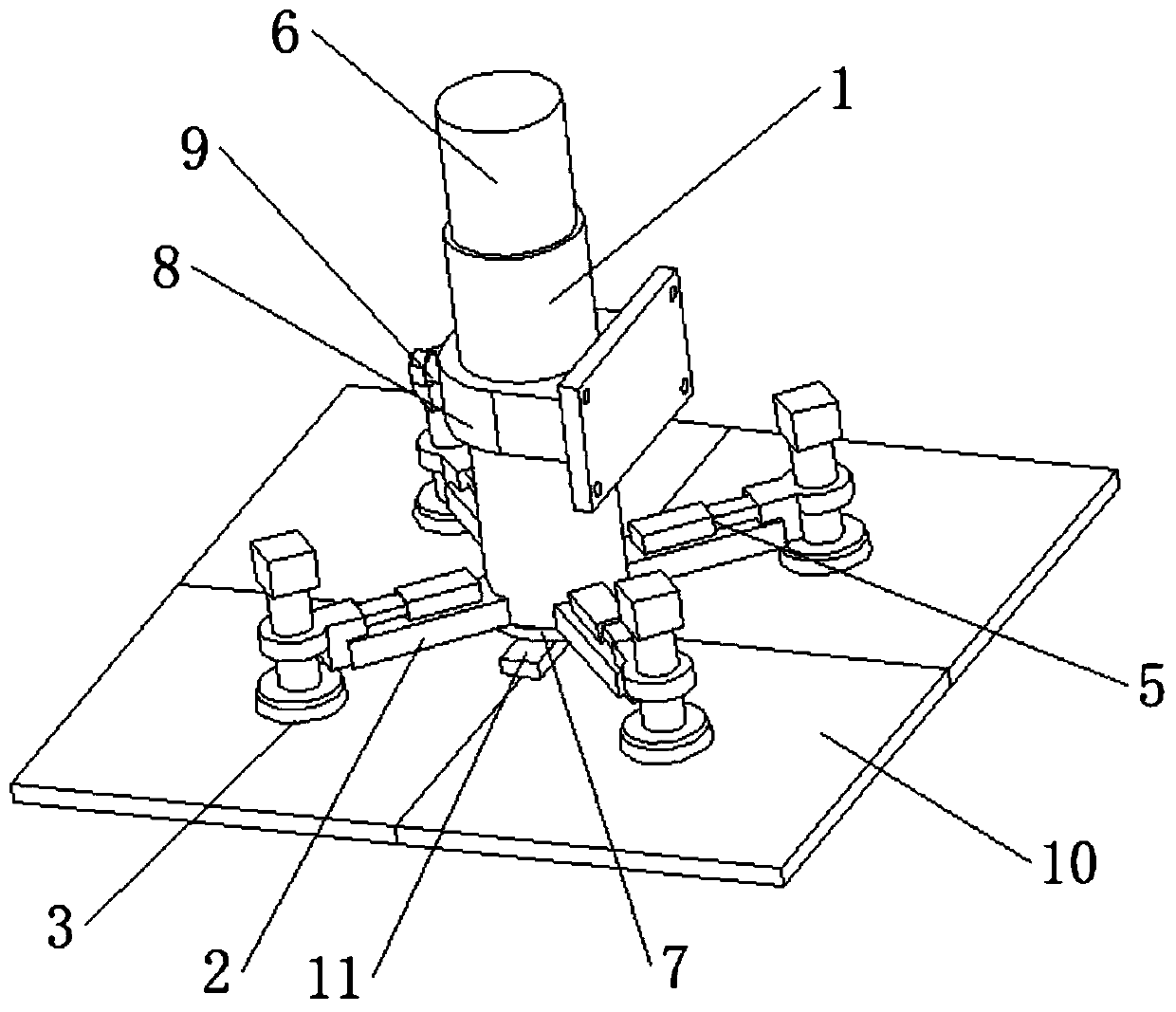

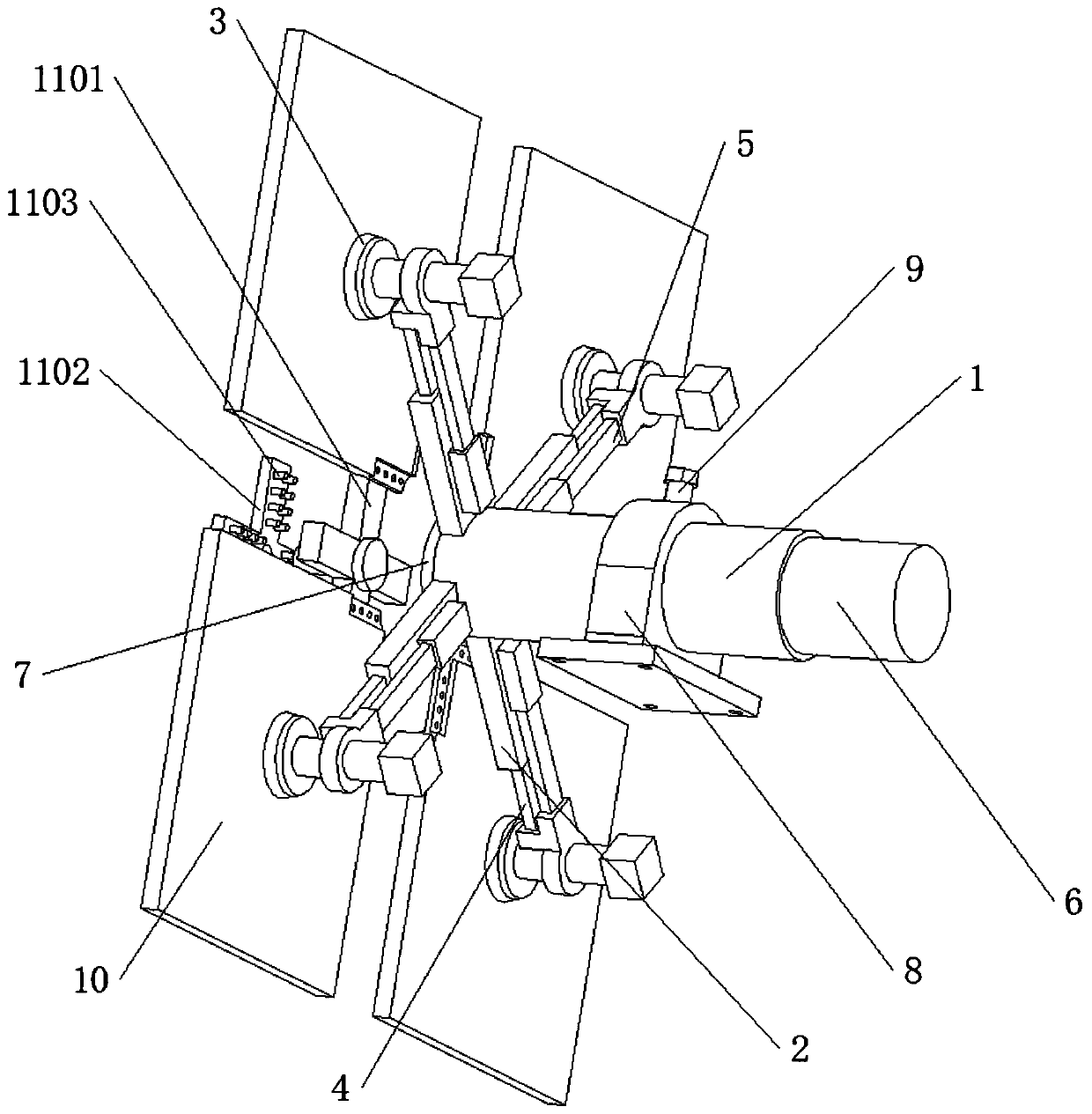

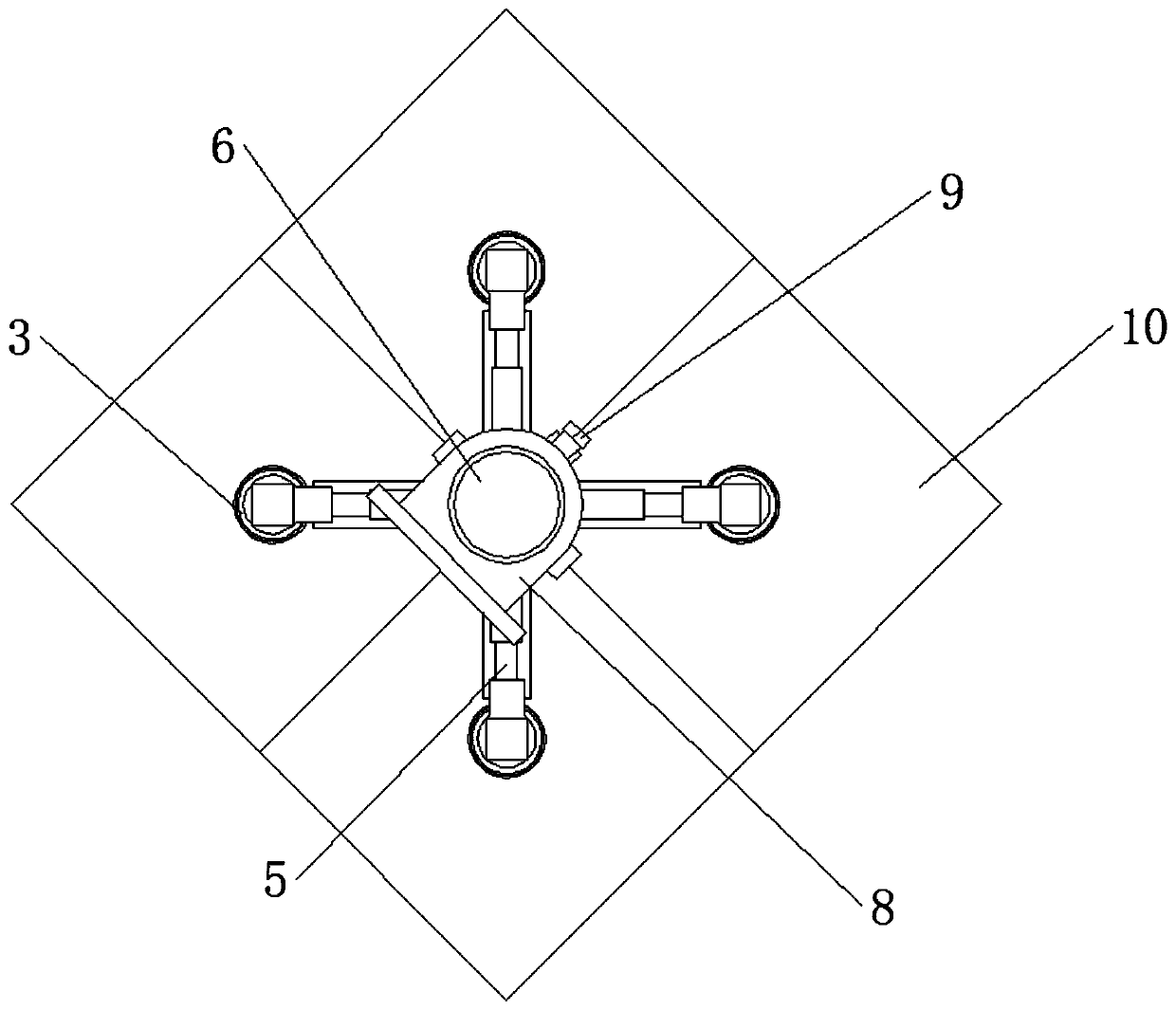

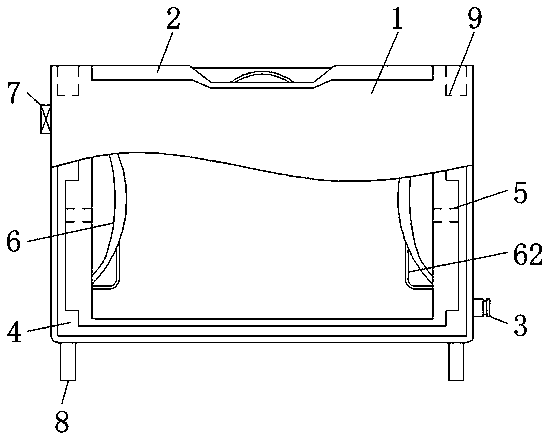

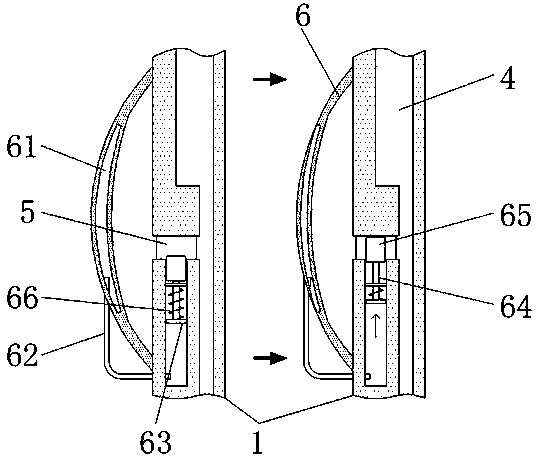

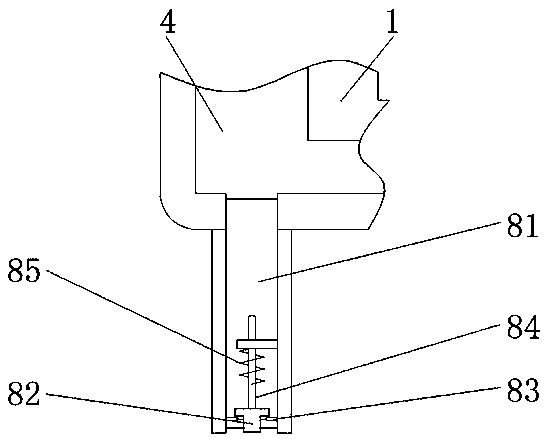

Splicing device of building curtain wall aluminum plate and splicing method thereof

The invention discloses a splicing device of a building curtain wall aluminum plate and a splicing method thereof, and belongs to the field of curtain wall splicing devices. The splicing device of thebuilding curtain wall aluminum plate comprises a shaft barrel, two pairs of extension plates are fixed to the lower end of the shaft barrel, sliding grooves are formed in one ends, away from the shaft barrel, of the extension plates, positioning rods are slidably connected in the sliding grooves, vacuum suckers are fixedly connected to the positioning rods, the vacuum suckers are connected with curtain wall aluminum plate bodies, air cylinders are connected between the vacuum suckers and the extension plates, an electromotor is fixedly connected to the upper end of a connecting piece, the power output end of the electromotor is fixedly connected with a transmission shaft, the transmission shaft is in threaded connection with a threaded sleeve, the threaded sleeve is slidably connected inthe shaft barrel, the lower end of the threaded sleeve is fixedly connected with a push plate matched with the vacuum suckers, and the push plate is provided with the connecting piece matched with thecurtain wall aluminum plate bodies, thus, the aluminum plate can be guaranteed to be tightly spliced, the splicing work is all carried out on one device, and the working efficiency is easy to improve.

Owner:徐宁

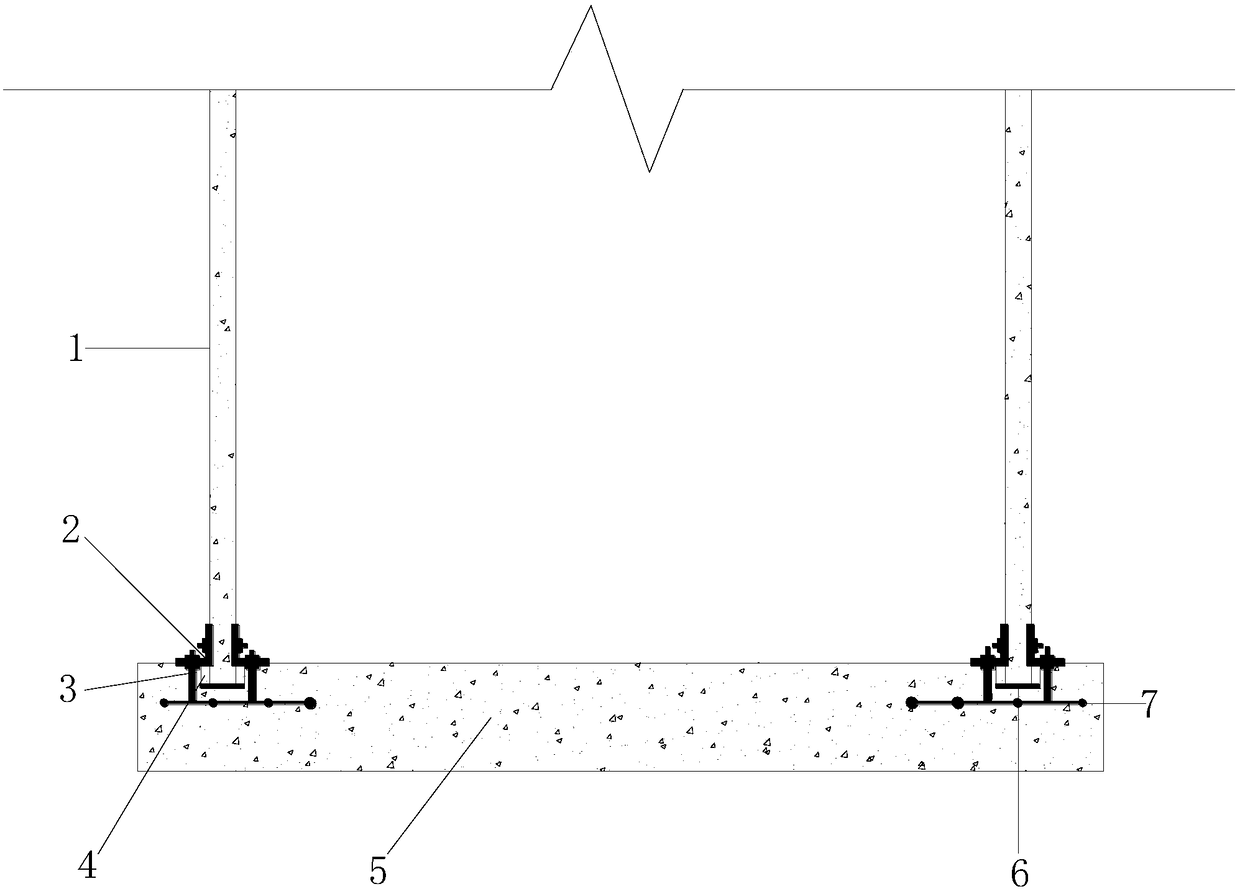

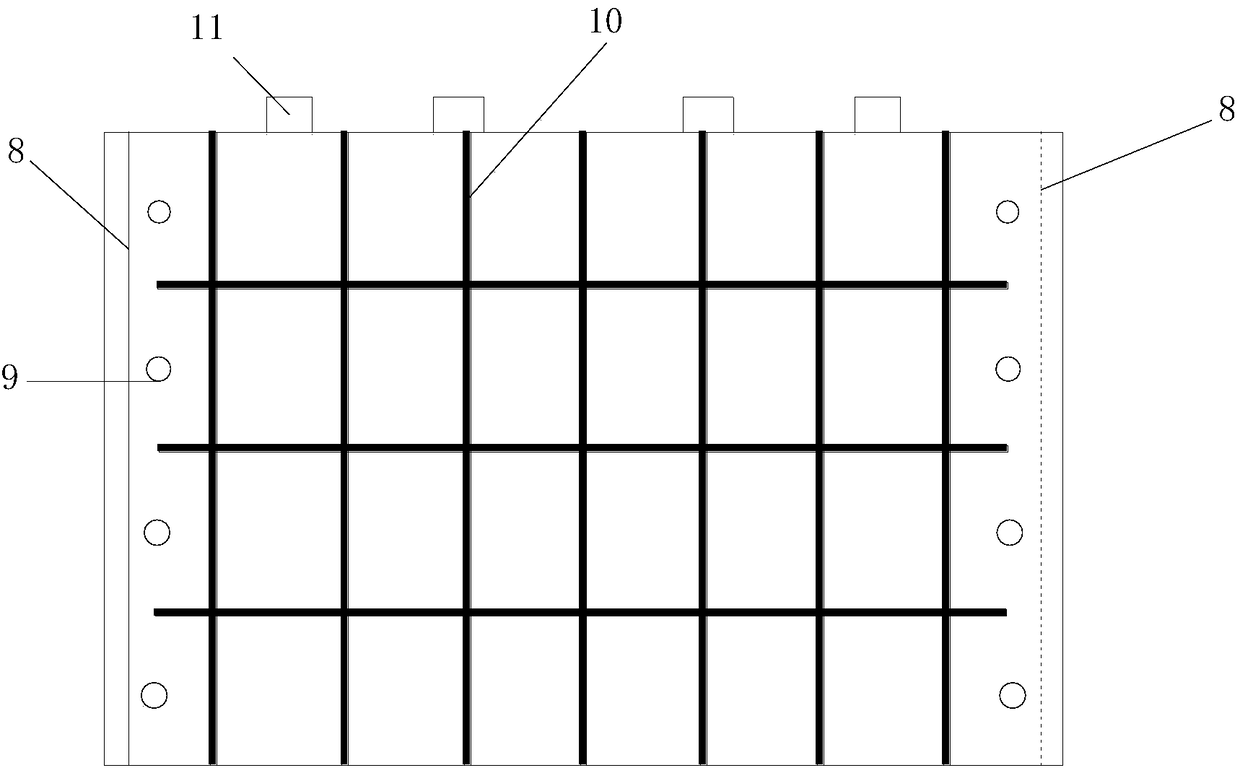

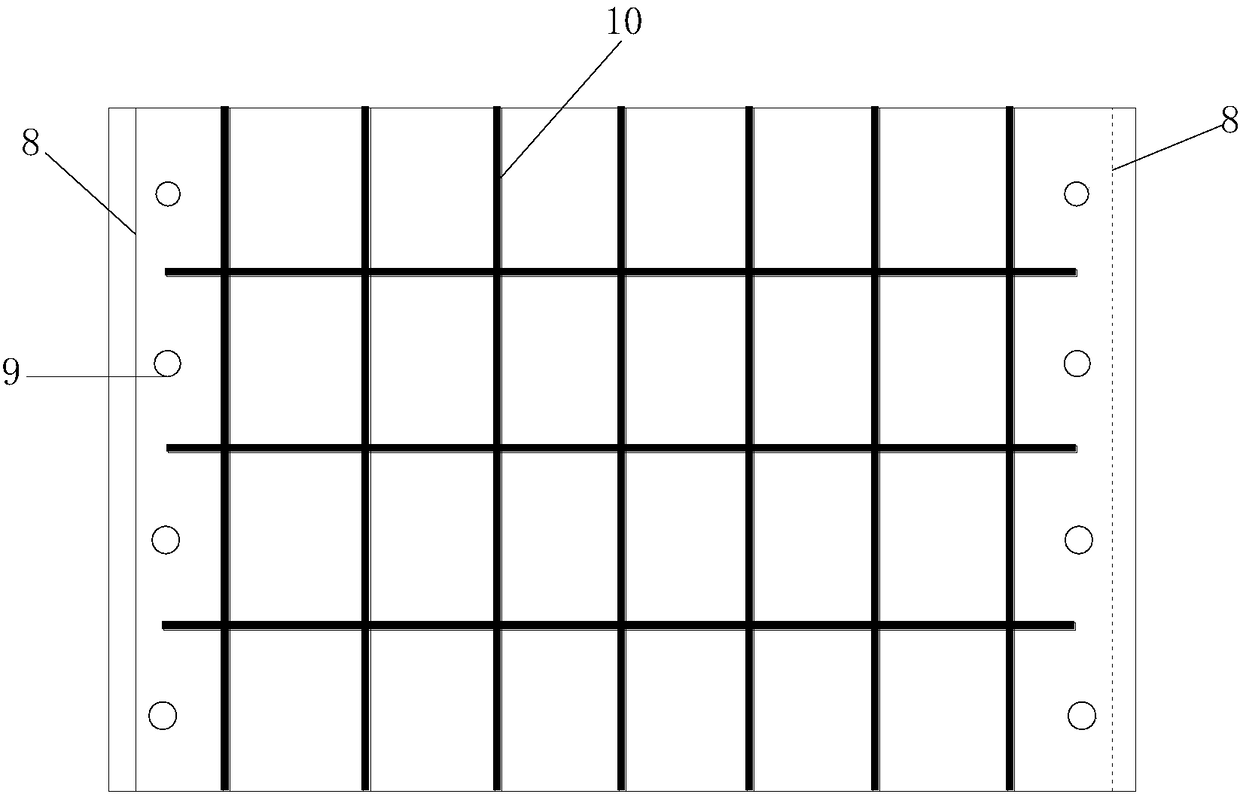

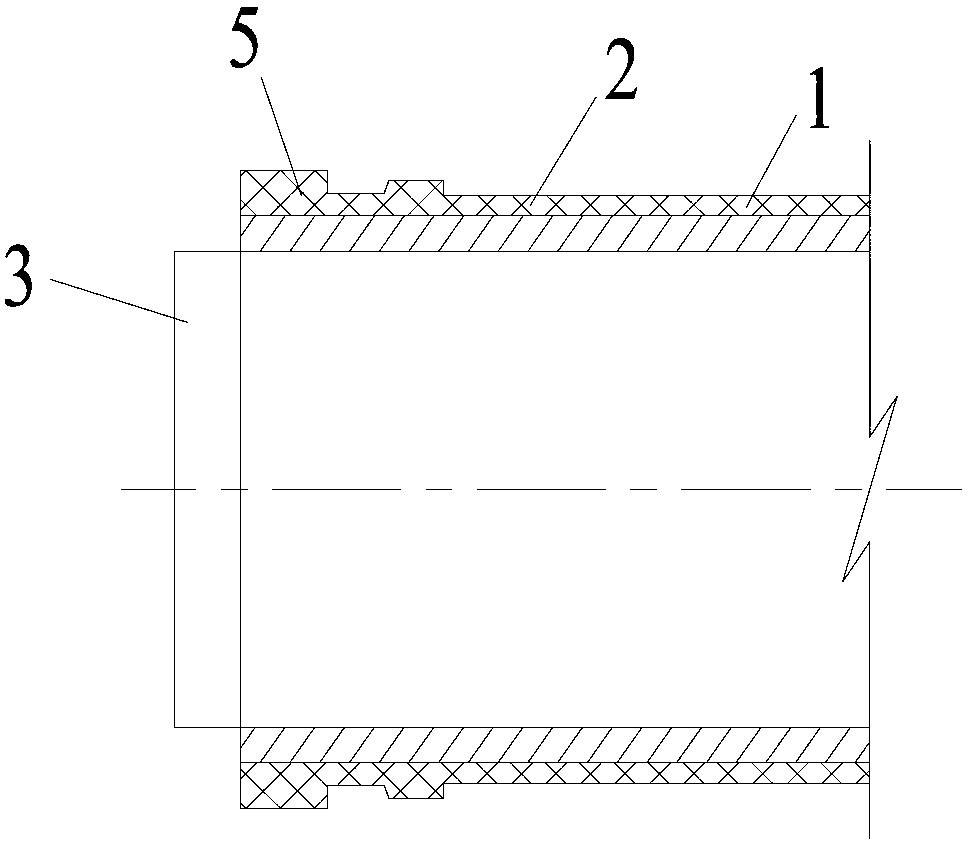

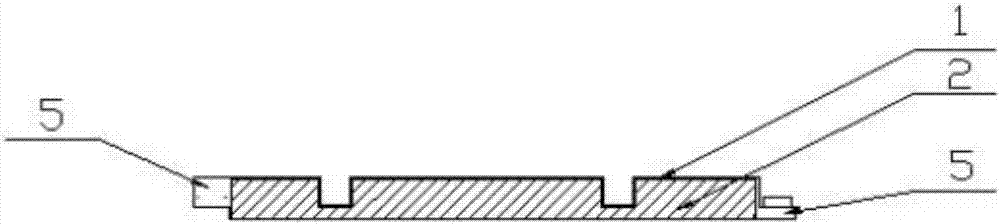

Prefabricated thin concrete slab formwork structure and construction method

InactiveCN108265738ABottom firmly fixedPrecise Positioning and PerpendicularityFoundation engineeringThin slabGrout

The invention relates to a prefabricated thin concrete slab formwork structure. The prefabricated thin concrete slab formwork structure comprises prefabricated thin concrete slabs, a cushion layer, grooves, integrally-embedded connecting screws, angle iron, leveling base grout layers and cast-in-situ bored piles. The prefabricated thin concrete slabs adopt rabbets for connection, are provided withscrew holes and connected through the evenly-distributed angle iron. The connecting angle iron on the inner side is of an embedded type. The angle iron is provided with lead screw through holes connected with the integrally-embedded connecting screws. Grid cloth anti-crack tapes are arranged in seams between the prefabricated thin concrete slabs. Connecting studs are evenly welded to the angle iron on the inner sides of the prefabricated thin concrete slabs. Lugs are evenly arranged at the tops of the prefabricated thin concrete slabs. The prefabricated thin concrete slab formwork structure has the beneficial effects that an inner formwork of a sliding formwork system is evenly divided into cavities at equal intervals, adjustable sand partition plates are arranged in the cavities to forma limiting balance weight frame, and bags between the partition plates are filled with sand to achieve regional ballasting; and a plate vibrator and a vibrating leveling beam are arranged on a lower panel of a sliding formwork, so that the slope concrete pouring quality is further improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

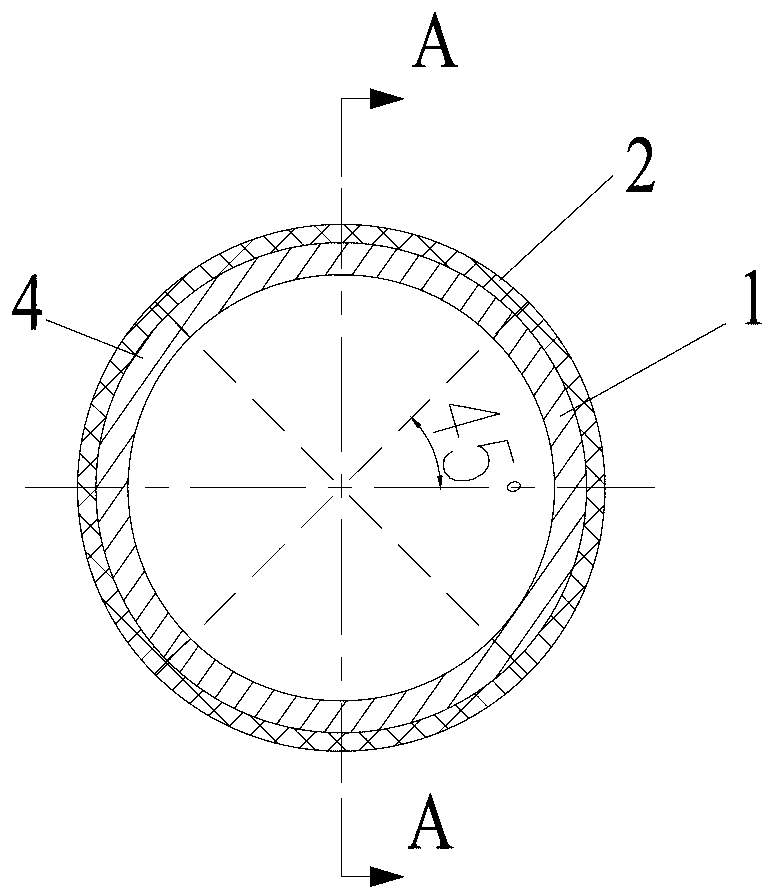

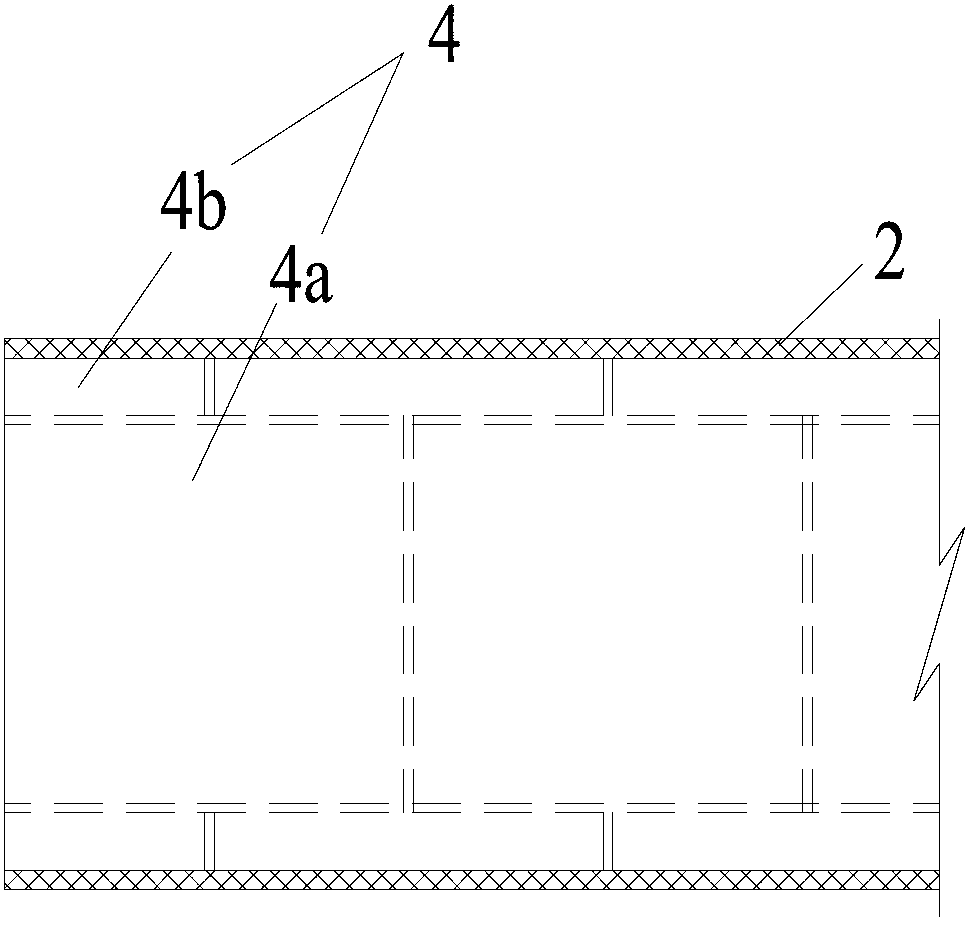

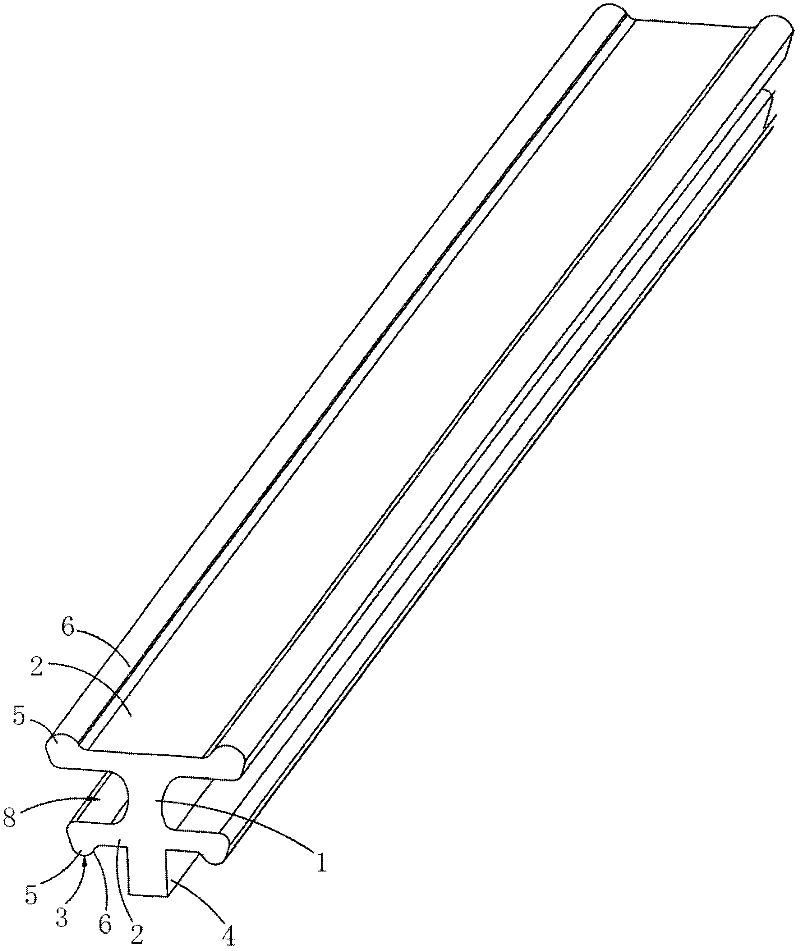

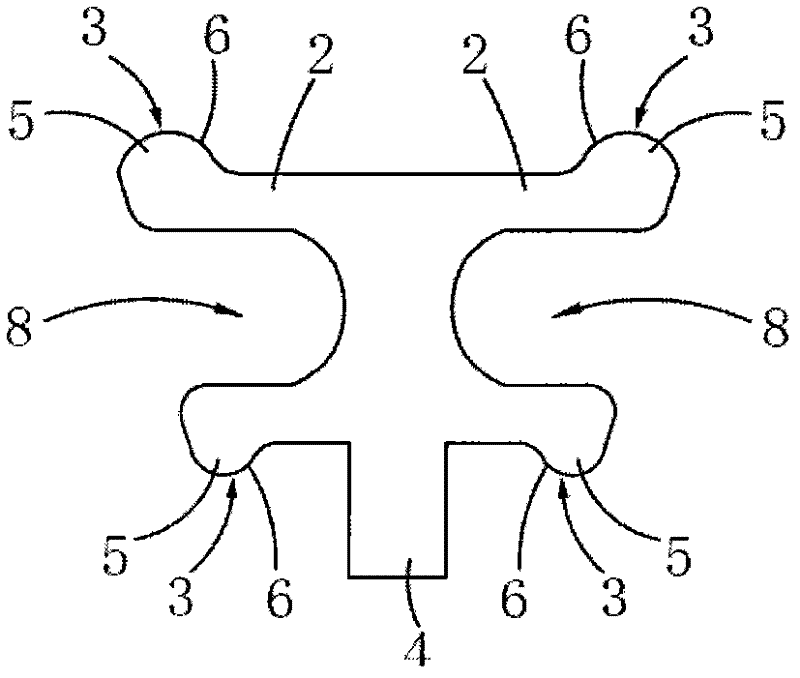

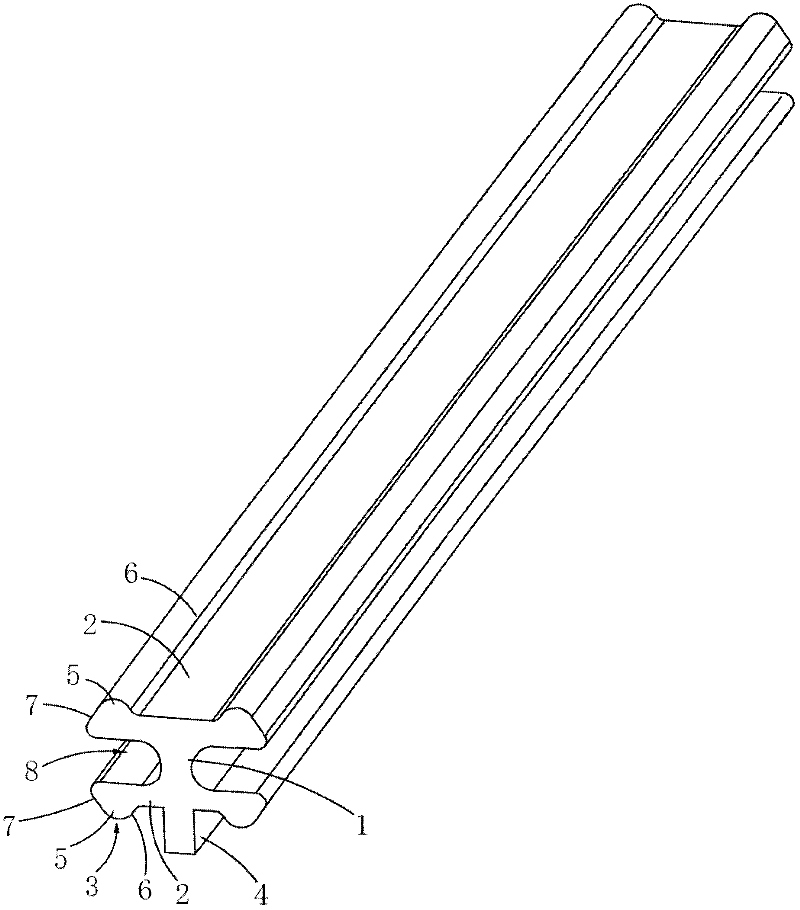

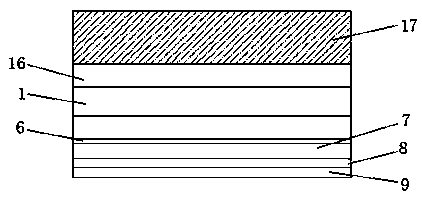

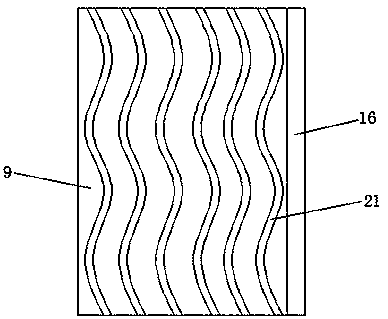

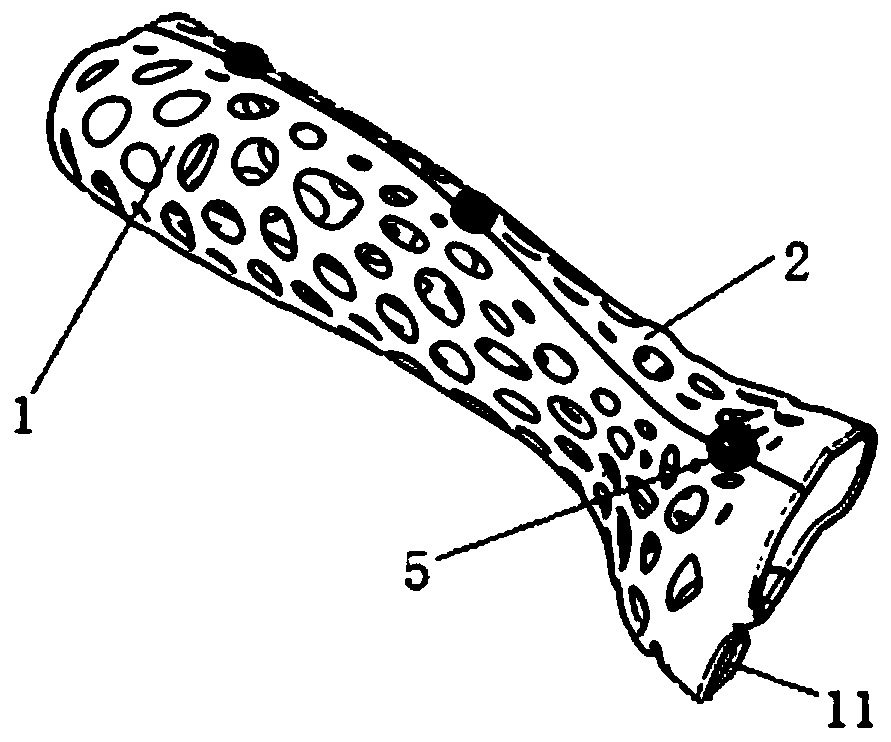

Composite tube and preparation method thereof

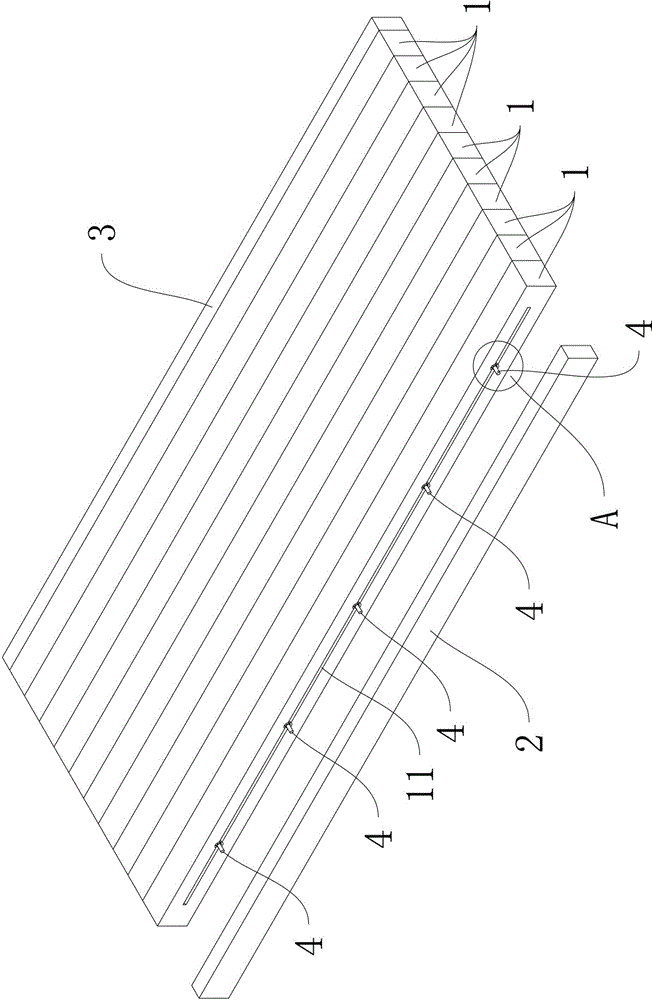

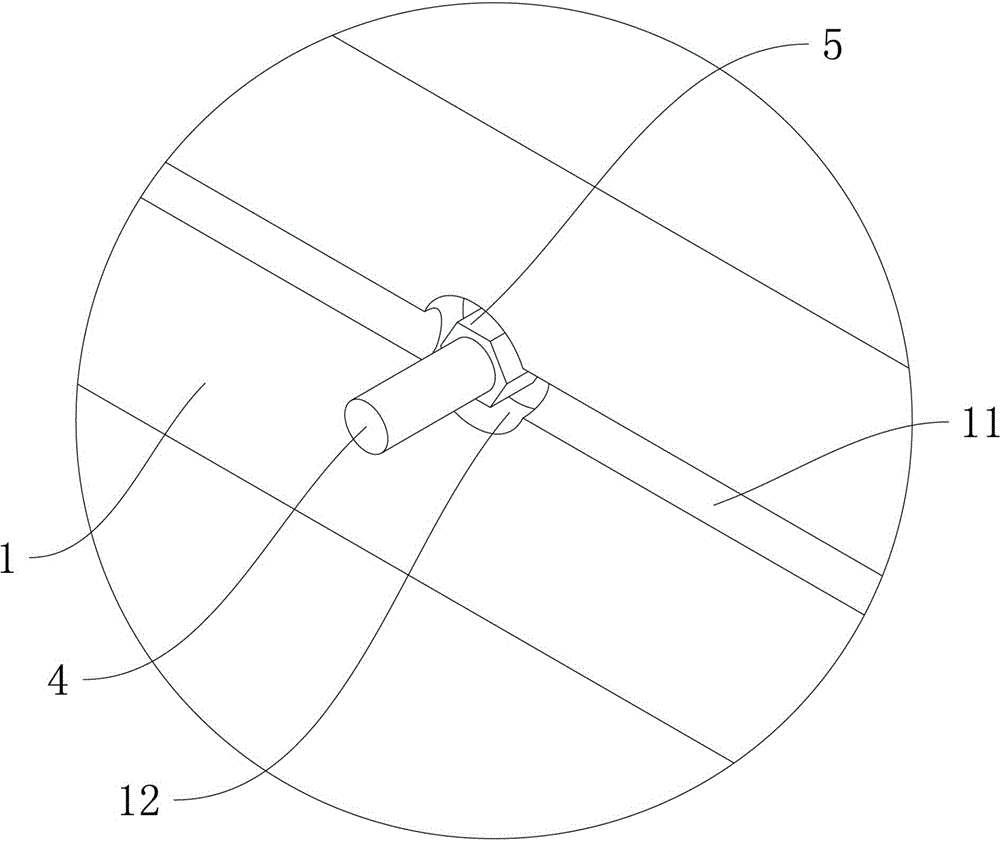

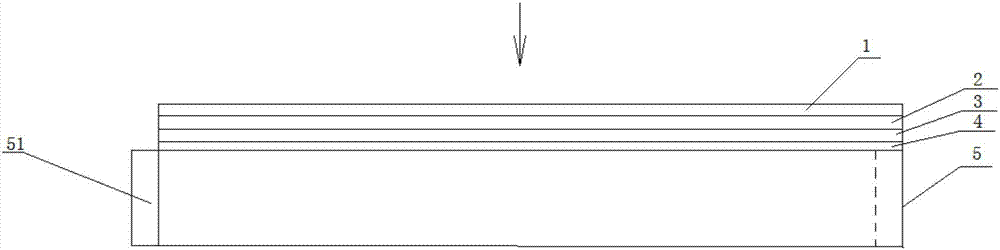

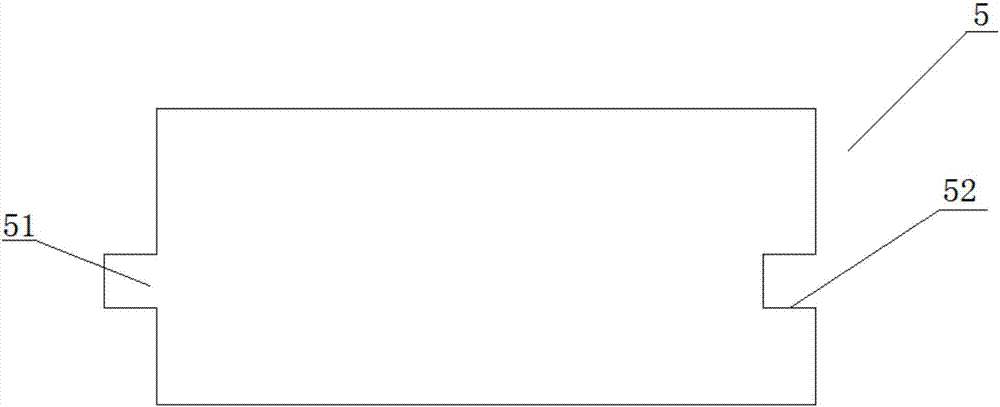

The invention discloses a composite tube and a preparation method thereof. The composite tube comprises an inner tube (1) and an outer tube (2), wherein the inner tube (1) is formed by splicing of ceramic pieces (4), and the outer tube (2) is arranged on the outer side of the inner tube (1) in a tensioned mode. On one hand, the ceramic pieces are spliced to form the inner tube, the size and quality of the ceramic pieces can be precisely controlled, and the ceramic pieces can be conveniently spliced to form the inner tube; on the other hand, the outer tube is arranged on the outer side of the inner tube in the tensioned mode, tensioning force can be exerted on the inner tube by the outer tube, additional pressure stress is exerted on the ceramic pieces, therefore splicing of the ceramic pieces is more firm, and falling of the ceramic pieces is avoided.

Owner:ZOOMLION HEAVY IND CO LTD

Method used for transverse bridging splicing growth of large-area monocrystal diamond

PendingCN108677246ASimple stitchingStable splicingPolycrystalline material growthFrom chemically reactive gasesSingle crystalDiamond substrate

The invention discloses a method used for transverse bridging splicing growth of large-area monocrystal diamond. According to the method, monocrystal diamond substrate I and monocrystal diamond substrate II are subjected to splicing, growth of a bridge-shaped connection part at the joint part is realized, and a complete large-area monocrystal diamond layer is obtained through continuous epitaxialgrowth; wherein the thickness of the monocrystal diamond substrate I at the joint part is lower than that of the monocrystal diamond substrate II at the joint part. The method is capable of solving problems in the prior art that the joint part is obvious, and diamond relative movement is easily caused in diamond splicing growth, and cracking risk at the joint part is reduced.

Owner:西安德盟特半导体科技有限公司

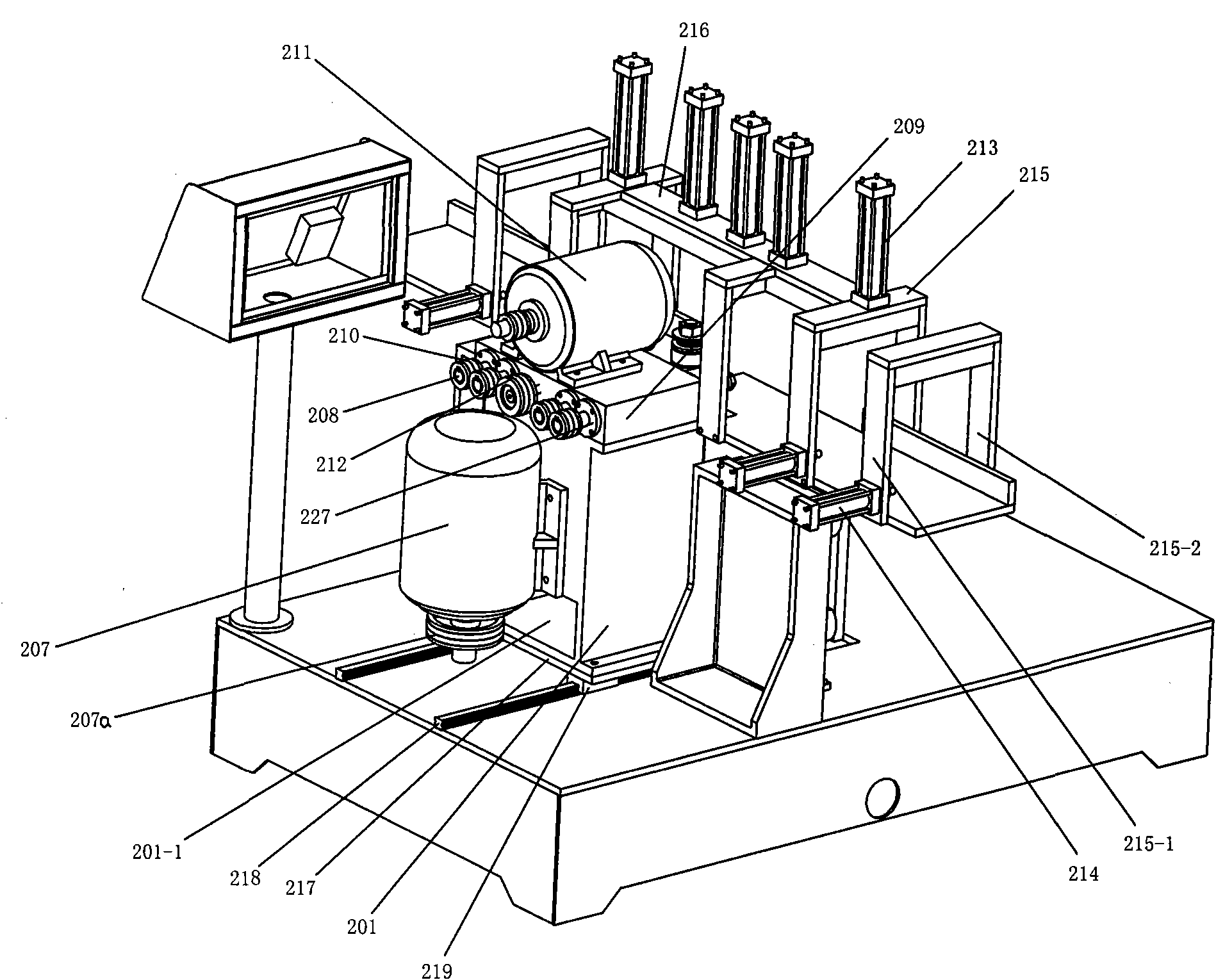

Constant tension jointing device for strip-shaped non-woven fabric substrate

ActiveCN1621329AStable splicingConstant tension automatic splicing speed is highWebs handlingEngineeringNonwoven fabric

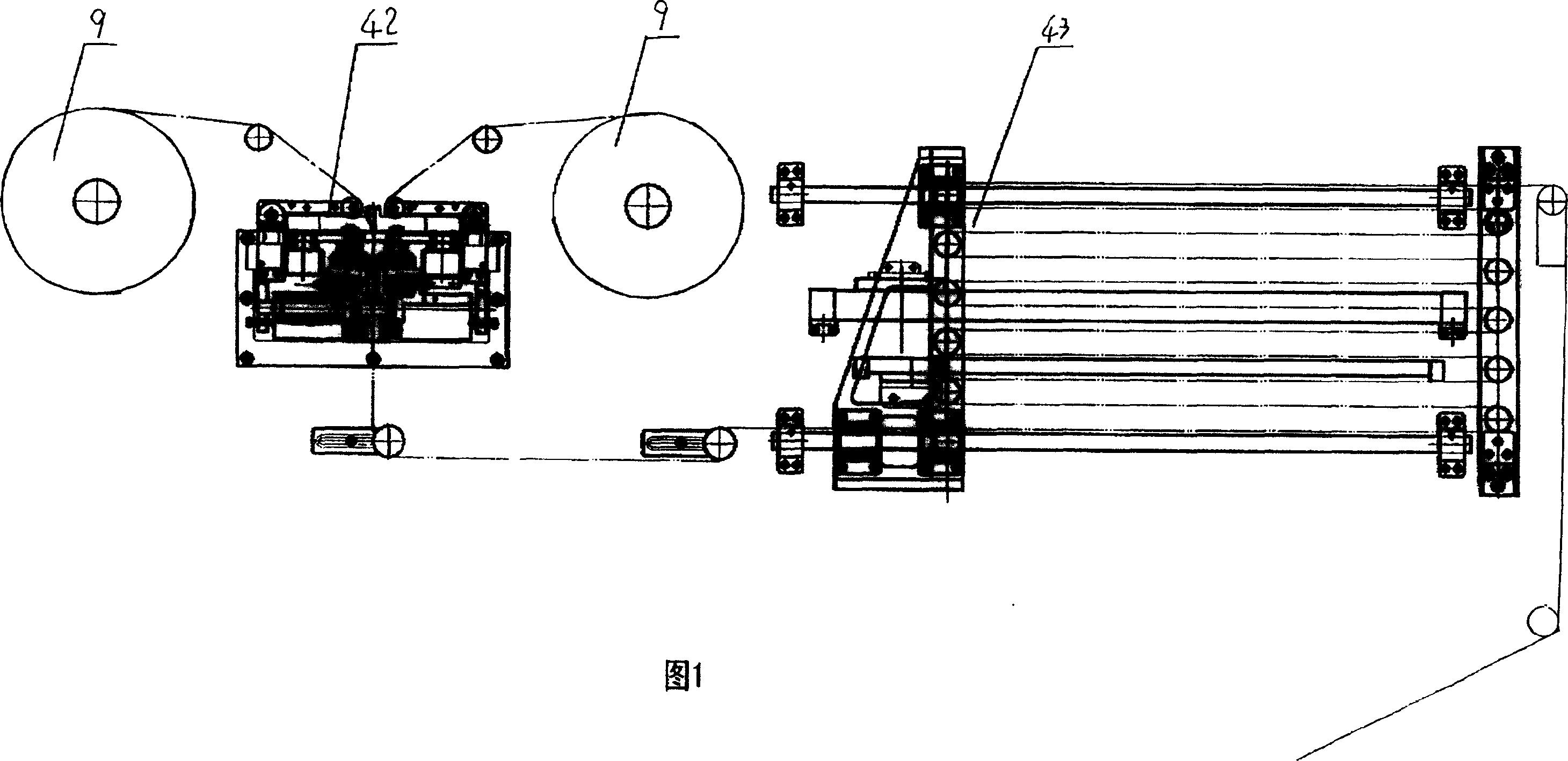

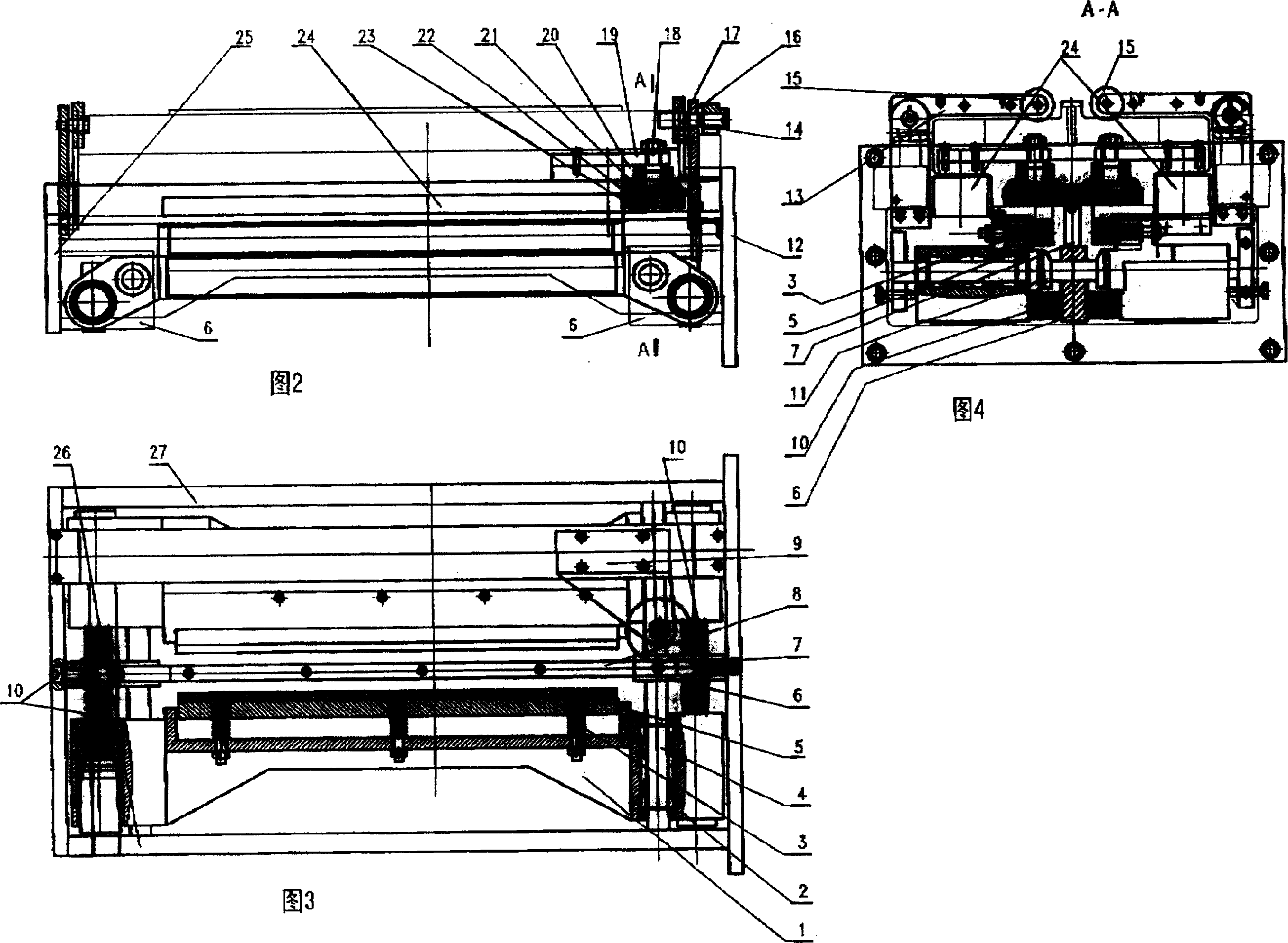

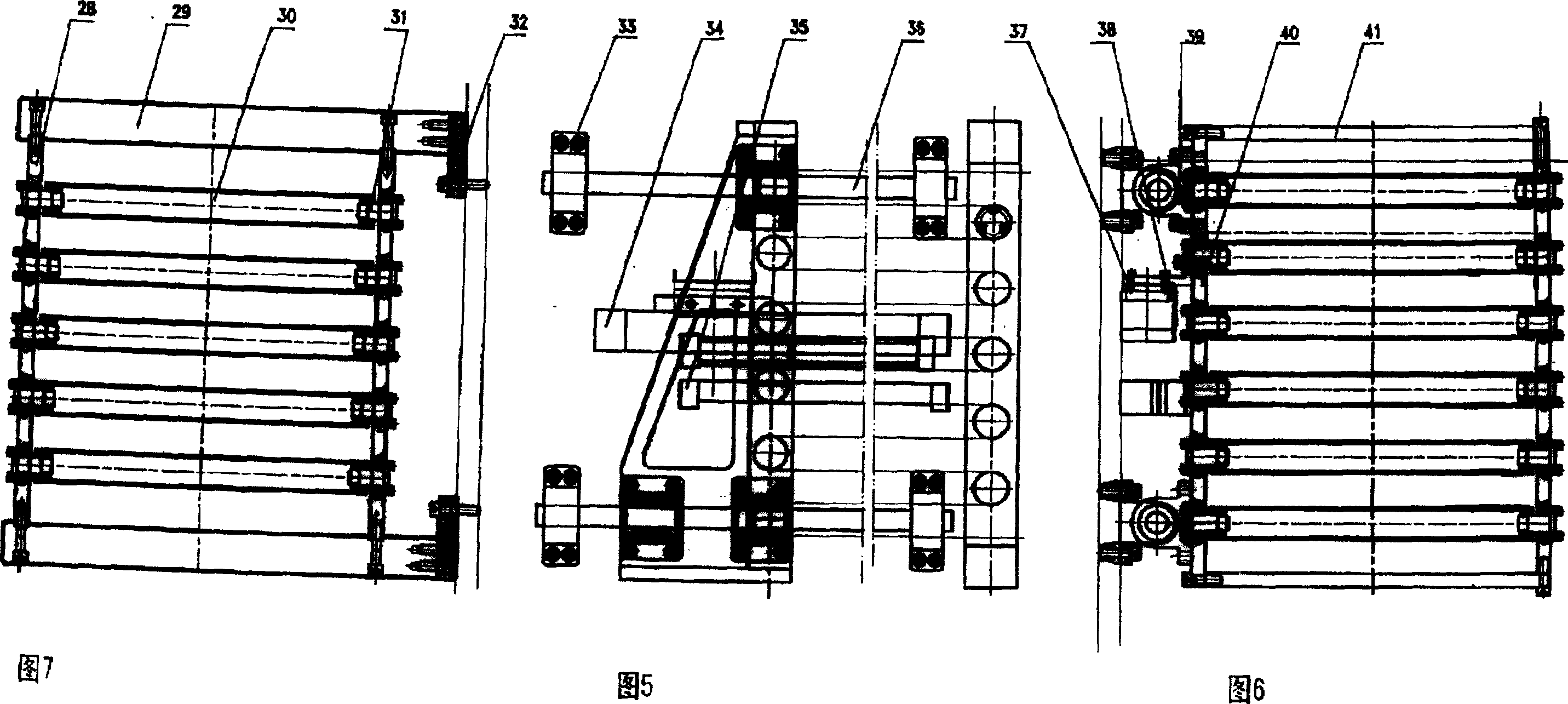

The present invention is constant-tension splicing apparatus for strip non-woven fabric base material. The present invention features that the constant-tension splicing apparatus includes splicing mechanism, constant-tension mechanism and vertical plate frame. The splicing mechanism includes frame, anvil assembly, moving rack assembly, cutter assembly and safety door assembly; and the constant-tension mechanism includes fixed tension wheel frame, movable tension wheel frame, tension wheel, guide shaft, potentiometer and horizontal cylinder. The present invention has high automatic constant-tension splicing speed up to 200 m / min, stable splicing, high splicing quality and high production efficiency.

Owner:ANQING HENG CHANG MACHINERY

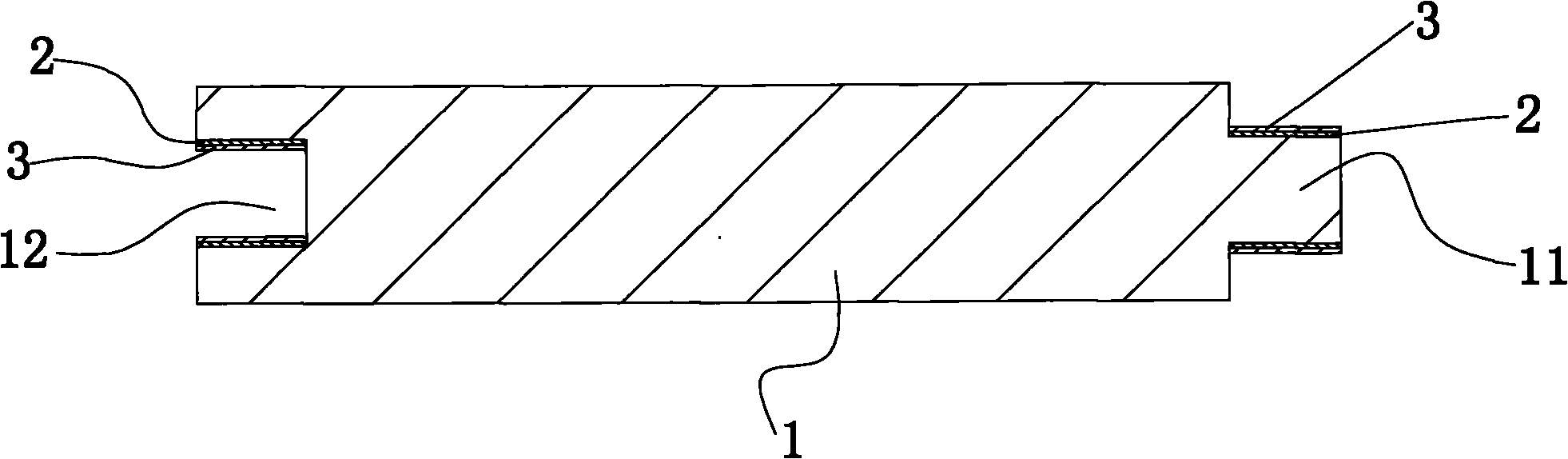

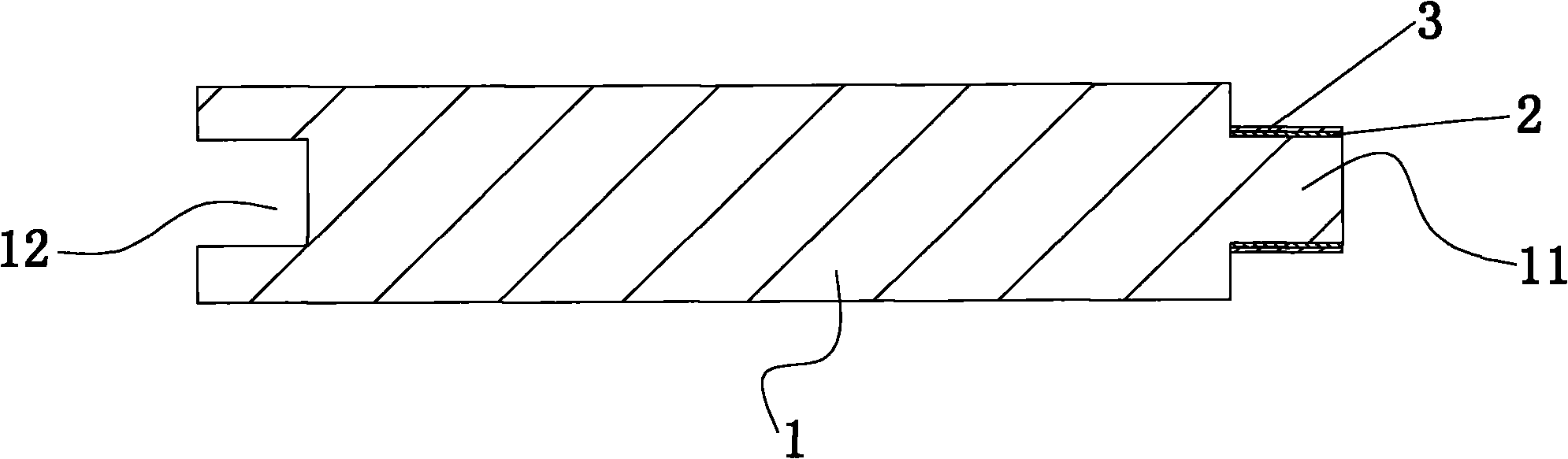

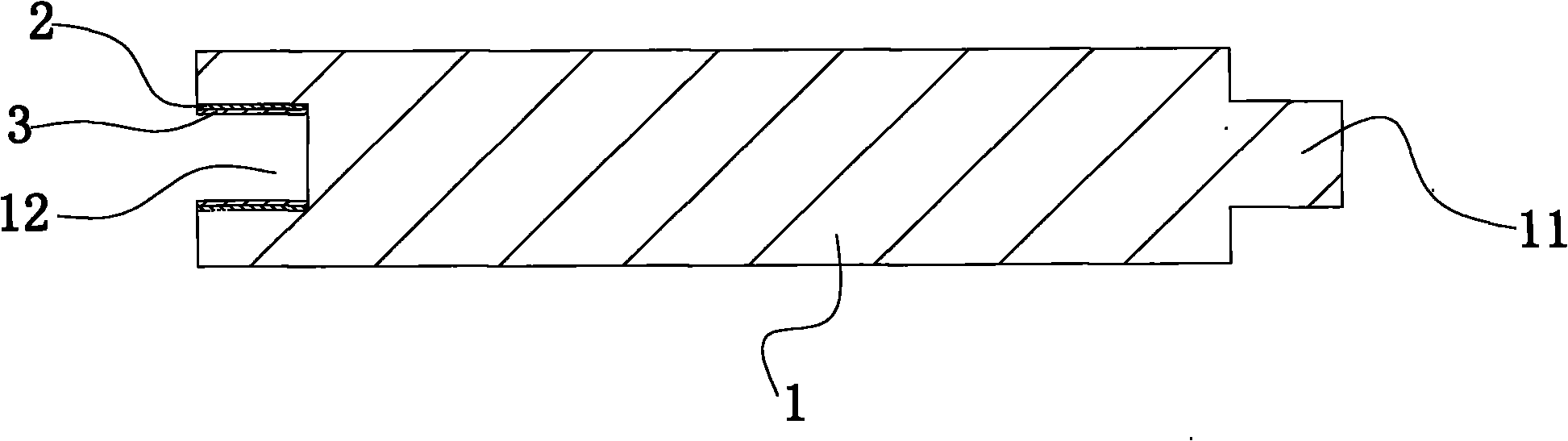

Glued groove-and-tongue floor

InactiveCN102080438AImproving the gluing installation processStable splicingFlooringEngineeringTongue and groove

The invention discloses a glued groove-and-tongue floor, which comprises a floor body, wherein the floor body is provided with a joint tongue and a joint groove. The glued groove-and-tongue floor is characterized in that: a pressure sensitive glue layer is coated on the joint tongue and / or the joint groove. The glued groove-and-tongue floor has the advantages that: 1, the pressure sensitive glue layer is pre-coated on the joint tongue and / or the joint groove, namely the tongued and grooved positions, of the floor so as to greatly improve a floor gluing mounting process and the mounting efficiency, save time, avoid the surface of the floor being polluted and achieve higher environmental friendliness; 2, adjacent floor blocks can be separated without any damage after being glued and spliced by pressure sensitive glue, so the floor is convenient to disassemble and rearrange after faults are produced in arrangement and pavement, and the after-service cost of the product is reduced; and 3, the adhesive power of the pressure sensitive glue can greatly strengthen an interlocking force between tongues and grooves of the floors and make securer and more stable the splicing of the floor, thereby greatly reducing the problem of contraction joint deformation of the paved floor as well as noises caused by friction between the tongues and grooves of the floors and greatly improving the mounting quality of the floor.

Owner:GUANGDONG YINGRAN WOOD IND

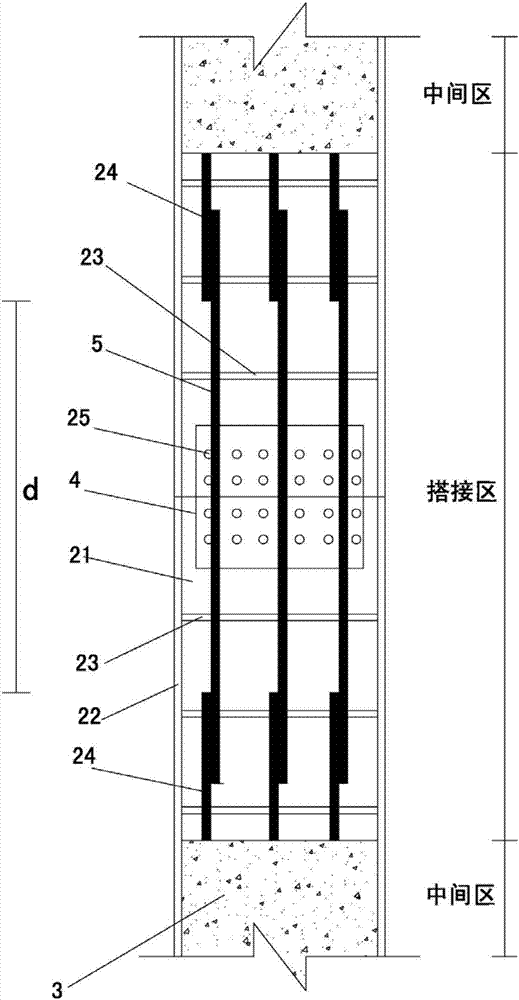

Splicing method for partial composite prefabricated columns

The invention relates to a splicing method for partial composite prefabricated columns. The splicing method comprises the following technological steps that (1), the H-shaped steel-concrete partial composite columns are prefabricated; (2), concrete is not poured in the partial composite columns at a lap joint area in advance, and bolt holes are formed in webs of the lap joint area; (3), longitudinal bars in the spliced prefabricated columns stretch out of respective intermediate areas to the lap joint area, but sections of distances d are left on the stretch-out longitudinal bars of the spliced columns; (4), the two sliced columns are subjected to bolt-welding connection in the lap joint area; (5), in the lap joint area, lap joint steel bars are adopted to be connected with the longitudinal bars in the spliced columns in a welding mode; and (6), after the steps from the step (2) to the step (5) are completed, the concrete is poured in the lap joint area. The splicing method for the partial composite prefabricated columns has the multiple advantages that construction is convenient and splicing is firm, and the domestic blank in partial composite column splicing is filled.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Controlling method for coil contacting of hot rolling coiling machine unloading trolley

ActiveCN110064659AStable splicingReduce accident rateRoll mill control devicesMetal rolling arrangementsLow speedStrip steel

The invention relates to a controlling method for coil contacting of a hot rolling coiling machine unloading trolley. The controlling method comprises the following steps that 1), a calibrating procedure is made to calculate the speed of low-speed rising-and-falling and high-speed rising of an unloading trolley; 2), when strip steel is coiled, the unloading trolley firstly pre-rises to a pre-rising position, of 300mm-500mm under the maximum coiling diameter of a coiling machine for waiting; 3) when the time that the strip steel tail reaches the coiling machine is less than the time required bythe unloading trolley rising from the pre-rising position to contact a steel coil at a low speed, the unloading trolley rises in a low speed to contact the steel coil; and 4), after the steel coil contacts with the unloading trolley and is discharged from the coiling machine, the unloading trolley falls down at a low speed, when the time that the unloading trolley falls down is more than the timethat the unloading trolley from the coil contacting position reaches to a coil unloading fixing beam, the unloading trolley returns to the lowest position at a high speed, and all unloading actions are completed. According to the controlling method, the unloading trolley can stably connect with the steel coil, and the accident rate is reduced.

Owner:ANGANG STEEL CO LTD

Pure log spliced board and aluminum-wood composited spliced board device using same

InactiveCN105113702AWon't swellWon't archConstruction materialCovering/liningsAdhesiveMechanical engineering

The invention relates to a pure log spliced board and an aluminum-wood composited spliced board device using the same. The pure log spliced board comprises a plurality of pure log boards, a first pure log side board, a second pure log side board, a plurality of screws and a plurality of nuts, each pure log board is made to have a splicing lateral side, an extensible groove slit and multiple screw holes are formed in each splicing lateral side, an adhesive is coated on each splicing lateral side, the pure log boards are arranged, spliced and pressed to form an integrated pure log spliced board body, each screw is penetratingly nested in the corresponding screw hole of the corresponding pure log board, two ends of each screw are tightened and locked by using the nuts, and the pure log side boards are arranged on the splicing lateral sides on two sides of the pure log spliced board body respectively to hide the ends of the screws and the nuts in the spliced board. The pure log spliced board is simple in structure, convenient to assemble and easy to realize, unfavorable factors like material cracking and deforming caused by thermal expansion and cold contraction of pure log are prevented effectively, and a log product is more attractive, more environment friendly and longer in service life.

Owner:彭志军

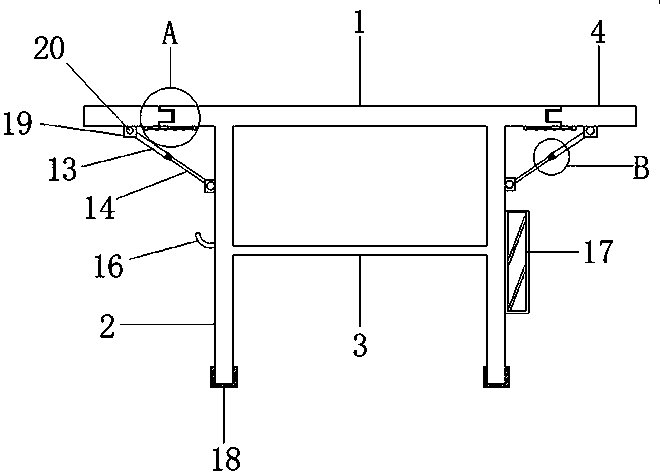

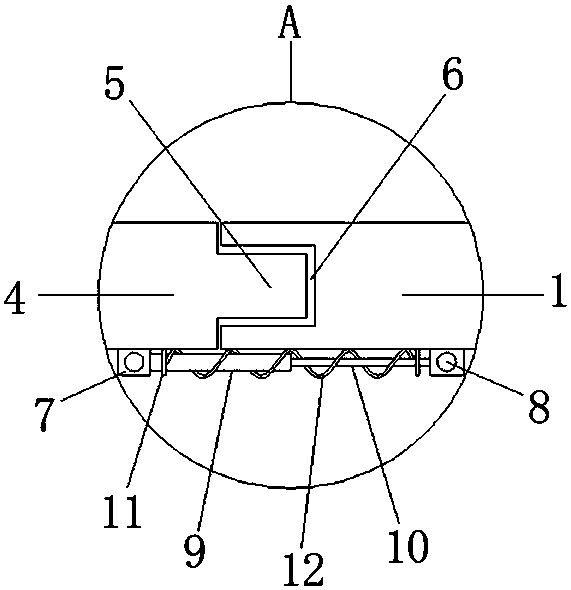

Desk with expandable desktop

InactiveCN108378565ASolve the shortcomings of insufficient use areaImprove functionalityExtensible tablesFurniture partsEngineeringApplication areas

The invention discloses a desk with an expandable desktop. The desk comprises a panel, four desk legs are symmetrically arranged on the bottom wall of the panel, and drawers are arranged on the side walls of the four desk legs; two expansion plates are symmetrically arranged at the two sides of the panel, multiple insertion plates are arranged on the side walls of the sides, close to the panel, ofthe two expansion plates, and insertion grooves matched with the insertion plates are formed in the side walls of the two sides of the panel; each insertion plate is inserted into the corresponding insertion groove, two first mounting plates are arranged on the bottom wall of each expansion plate, and a first rotation rod is rotatably connected between the two first mounting plates at the same side. The desk with the expandable desktop is simple in structure and convenient to use, compared with an existing desk, the desktop can be easily and stably expanded, the defect of insufficient application area of the desk is overcome, the function of placing water cups, fountain pens and other goods is added at the same time, and the functionality of the desk is improved.

Owner:李奕萱

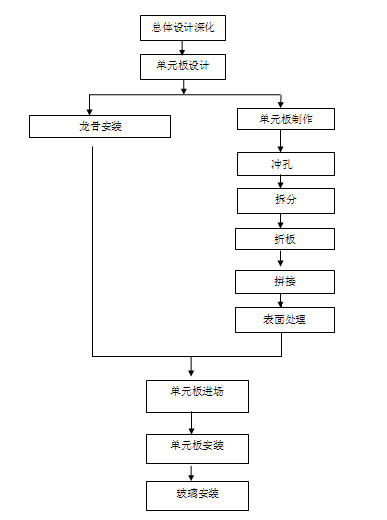

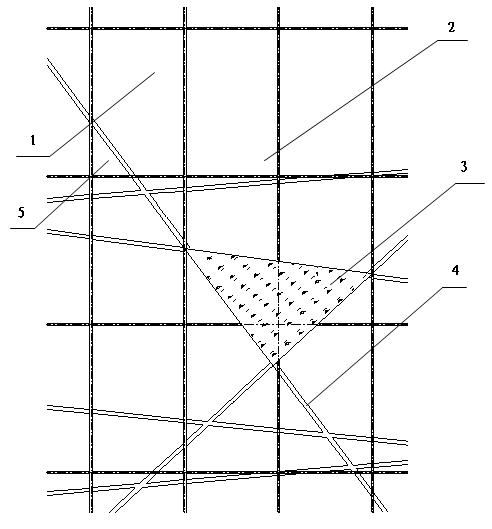

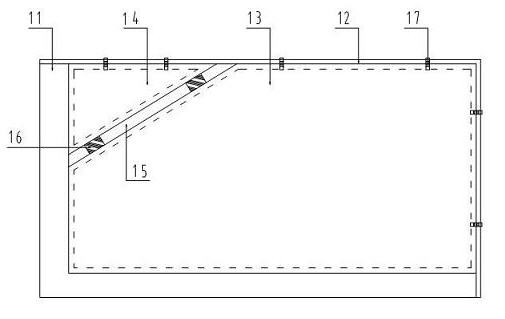

Construction method of complex puzzle unit type curtain wall

InactiveCN102661052AScientific and reasonable designAccurate block shapeWallsBuilding material handlingEngineeringUnit type

The invention relates to a construction method of a complex puzzle unit type curtain wall. The construction method comprises the following steps: using a computer to perform auxiliary design and calculation according to the overall design and the field actual situations of an elevation puzzle of the curtain wall, performing unit grid division, arrangement of a framework and unified numbering of unit plates, splitting the unit plates to puzzle plates according to puzzle lines and drawing a processing diagram of the unit plates; performing processing, shaping and splicing on the puzzle plates according to the processing diagram of the unit plates for forming the regular unit plates which are connected firmly; and finally performing field installation of the curtain wall. According to he construction method disclosed by the invention, the unit plates are scientific and reasonable in design, accurate in manufacturing, strict in installation process; the complex puzzle lines are straight and smooth, plate shape is accurate, falsehood and reality are combined smartly and the effect of the complex puzzle perforated curtain wall is given a full play. the construction method has the characteristics of advanced process, precision in manufacturing, convenience in installation, and high efficiency in construction.

Owner:常熟市华丽坚装饰工程有限公司

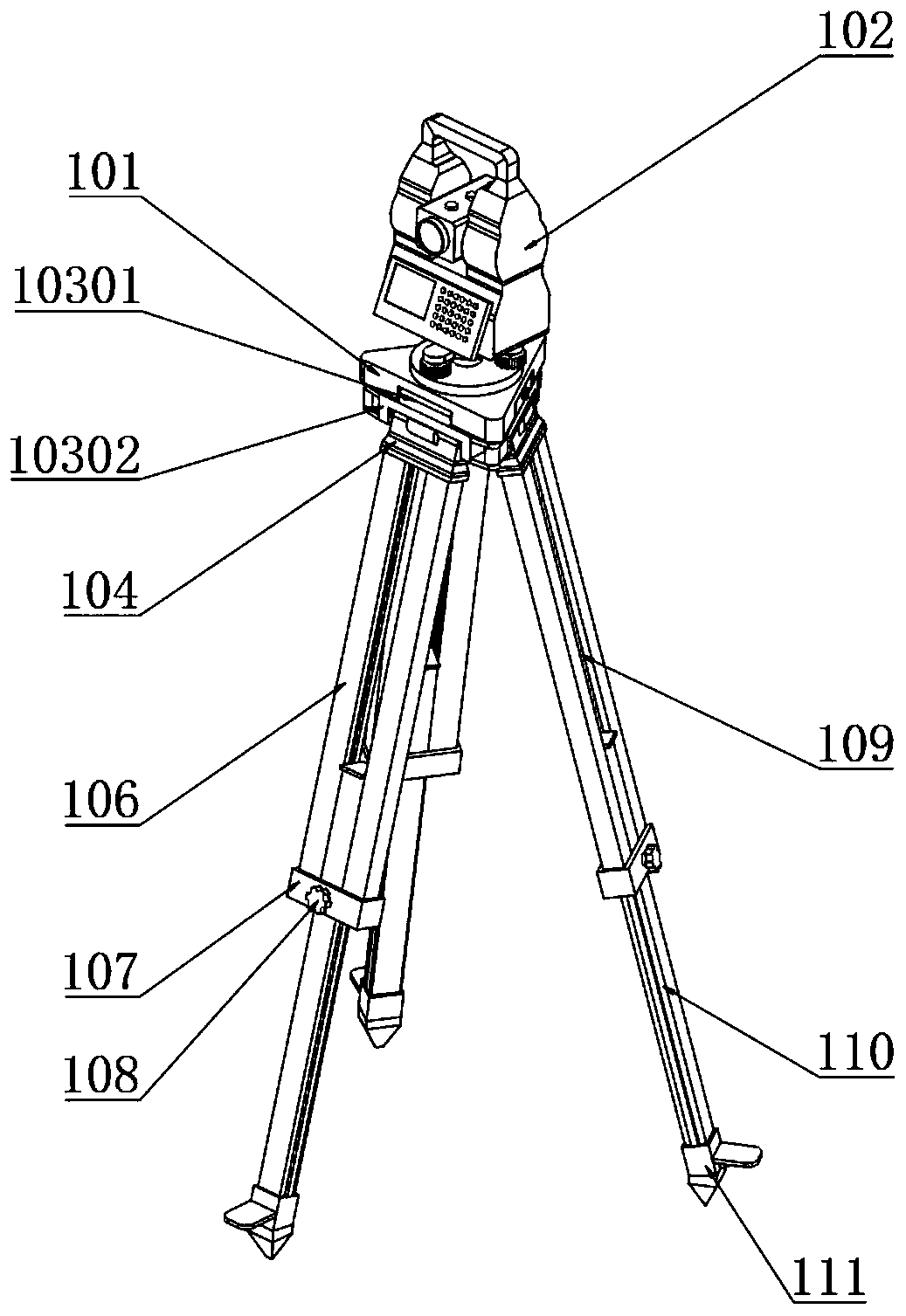

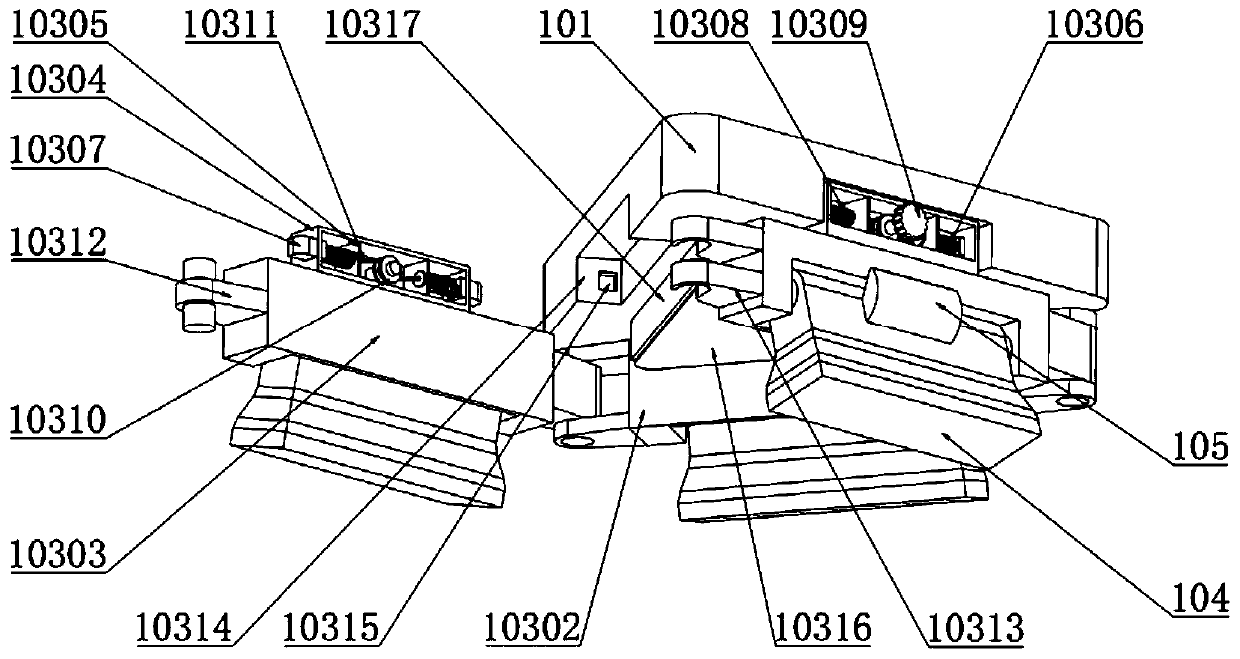

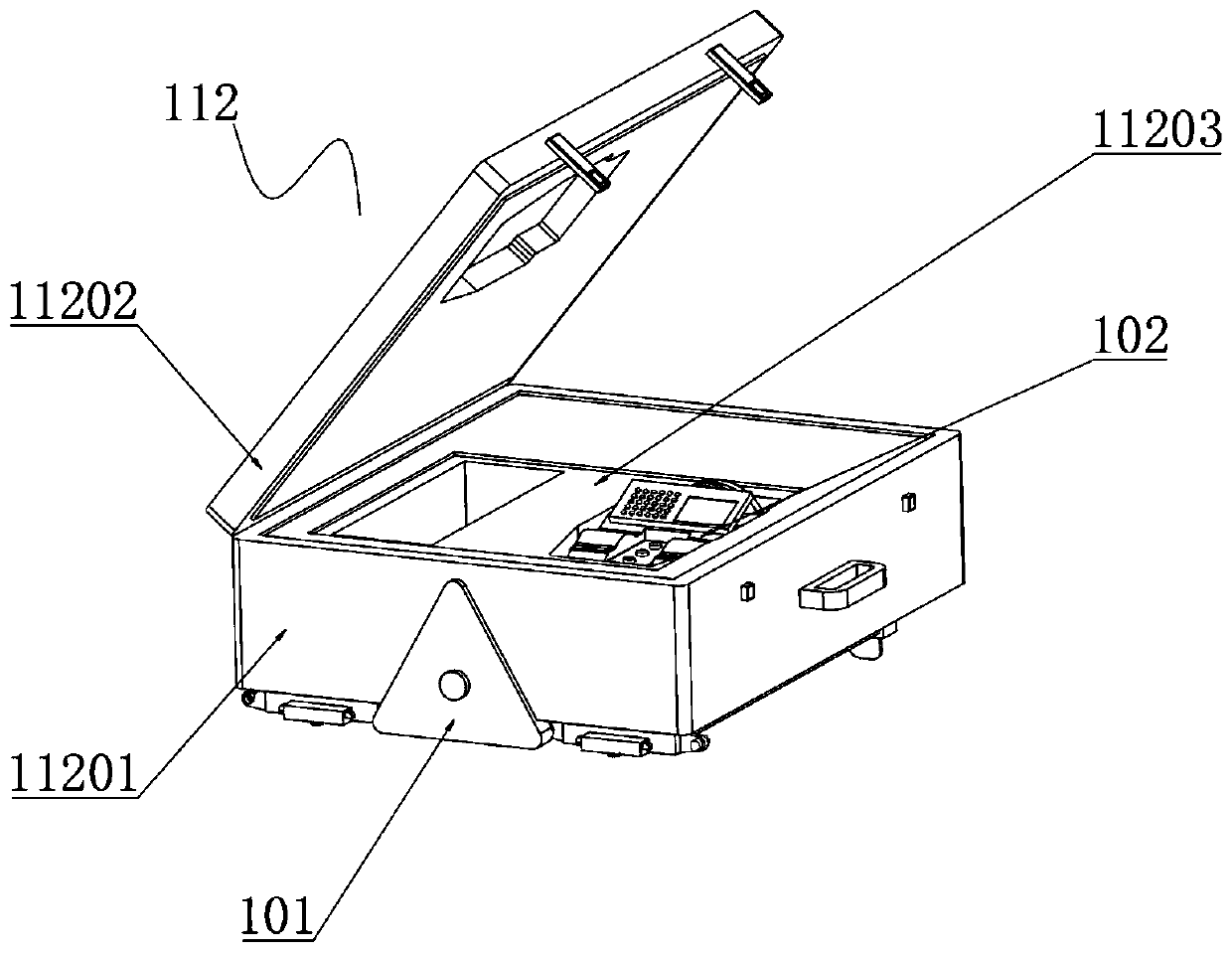

Engineering surveying instrument and lens pollution prevention machine tool for processing surveying instrument

ActiveCN111397588AImprove user experienceQuick disassemblyOptical surface grinding machinesSurveying instrumentsClassical mechanicsStructural engineering

The invention discloses an engineering surveying instrument and a lens pollution prevention machine tool for machining the surveying instrument. A surveying instrument is fixedly connected to the middle of the top end of the triangular bottom plate. A splicing mechanism is rotationally connected to the edge part of one side of the triangular bottom plate. The splicing mechanism comprises a connecting rotating block, a middle connecting square block, a side connecting square block, a buckle square box, an installation guide plate, a guide sliding rod, a sliding clamping block, a reset spring, adriving pin, a take-up reel, a limiting clamping block, a rectangular storage groove, a buckle groove, a triangular middle block and a limiting rubber pad. The side connecting square blocks are manually pulled to be far away from the triangular middle block. After the side surfaces of the middle connecting square block and the side connecting square blocks are parallel, rotation is stopped. Therefore, the surveying instrument support is deformed into the flat plate type from the cylindrical shape, the surveying instrument support can effectively utilize the storage space in the storage process, meanwhile, the flat plate type structure is more stable, the support is effectively prevented from shaking and rolling in the carrying process, and the use experience of the side surveying instrument is improved.

Owner:广西壮族自治区河池水利电力勘测设计研究院

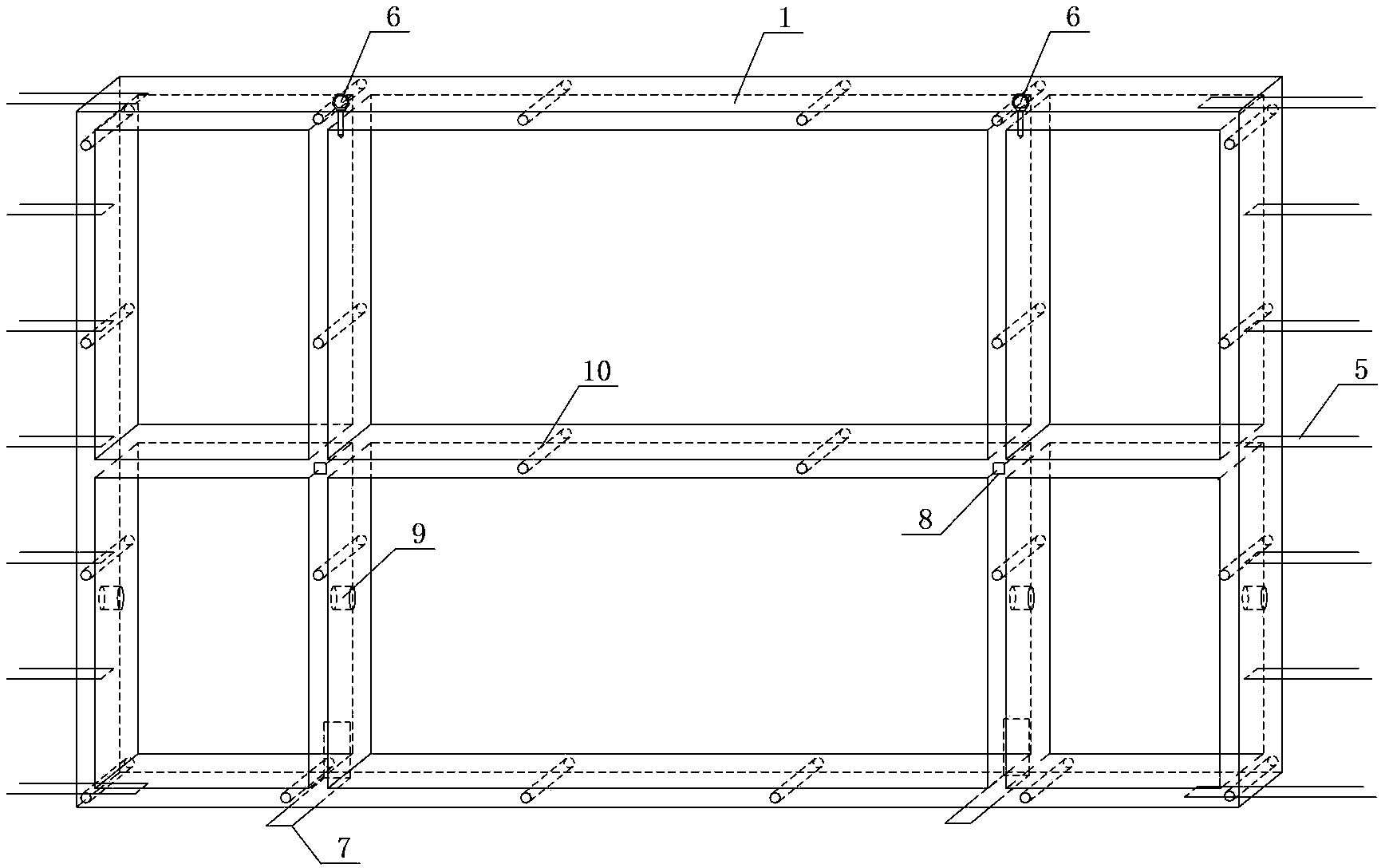

Assembly-type building and assembling method thereof

PendingCN111155651AImprove structural strengthImprove seismic performanceBuilding constructionsFloor slabButt joint

The embodiment of the invention discloses an assembly-type building and an assembling method thereof, and belongs to the technical field of housing construction. According to the following technical scheme, the assembly-type building comprises a plurality of wallboards and floor slabs. Every two adjacent wallboards are connected through a prefabricating piece. The wallboards comprise a plurality of prefabricated slabs. A plurality of lugs are arranged on one sides of the prefabricated slabs, and a plurality of grooves are formed in the other sides of the prefabricated slabs. After the two prefabricated slabs are in butt joint, each lug is inserted into the corresponding groove, and first reinforcing steel bars are provided in a penetrating manner. The floor slabs comprise first prefabricated plates and second prefabricated plates. A plurality of mounting blocks are arranged at the two ends of the first prefabricated plates and the two ends of the second prefabricated plates. The two ends of the first prefabricated plates are overlapped into the positions between the opposite wallboards. The two ends of the second prefabricated plates are overlapped onto two wallboards of adjacent rooms. The mounting blocks on the second prefabricated plates are clamped into the positions between every two mounting blocks of the first prefabricated plates. The problems that an assembly-type building is tedious and troublesome in the splicing process in the prior art, and the structural strength of the spliced building is low are solved.

Owner:段风雷

Environment-friendly floor and manufacture method thereof

InactiveCN106948573AExtend purification lifeReduce lossSynthetic resin layered productsLaminationWood veneerHigh density

The invention belongs to the technical field of construction materials, and particularly relates to an environment-friendly floor and a manufacture method thereof. The environment-friendly floor comprises a nanometer air photocatalyst material layer, an abrasive-resistant hardened layer, a pattern layer and a base material layer which are arranged sequentially from the top to bottom and combined with one another. A negative oxygen ion layer is laid on the side face of the base material layer, a bacteriostasis and mould proof layer is arranged on the lower surface of the base material layer, the pattern layer is one of a printed pattern plate, a wood veneer plate, a thermal transfer layer and a 3D printing player, and when the pattern layer is the printed pattern plate or the wood veneer plate, a glue layer is arranged between the base material layer and the pattern layer. The environment-friendly floor is not liable to deform, high in purification efficiency, low in manufacture cost and using cost, and high in stability and firmness; the manufacture method can save consumption of negative oxygen ion powder and air photocatalyst materials, and by adoption of the manufacture method, the floor has high density and strength.

Owner:北京正菱环保科技发展有限公司

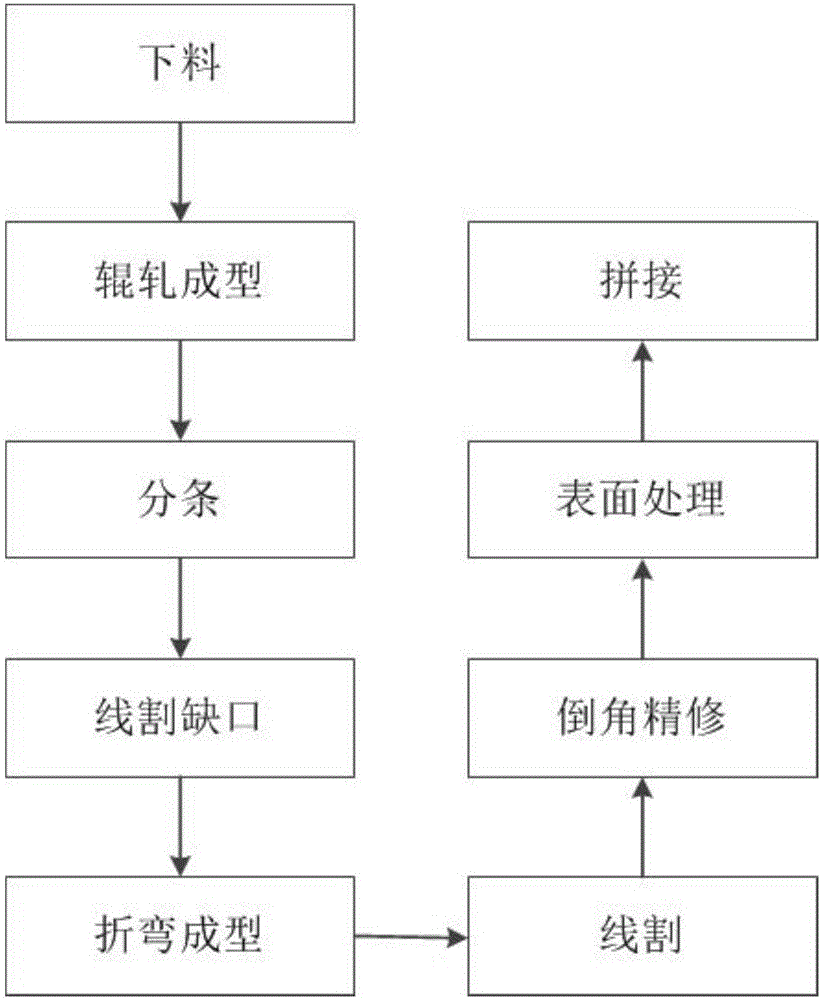

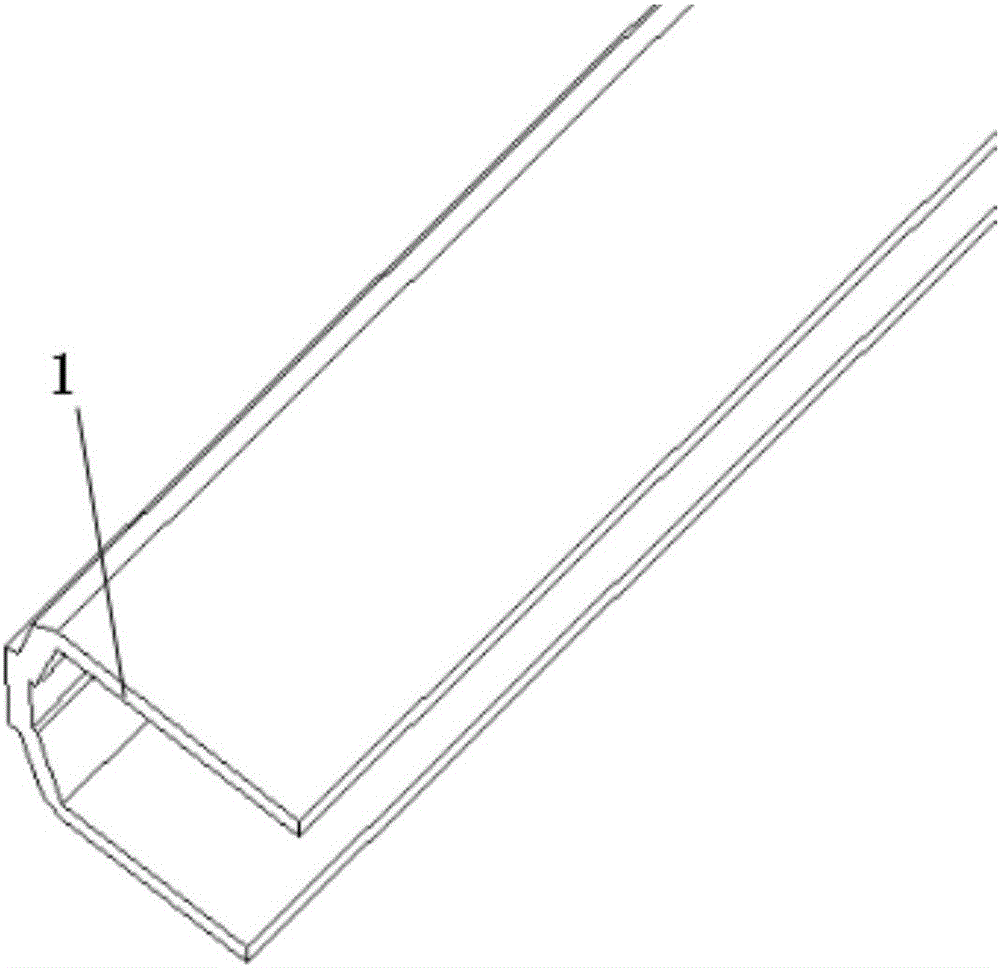

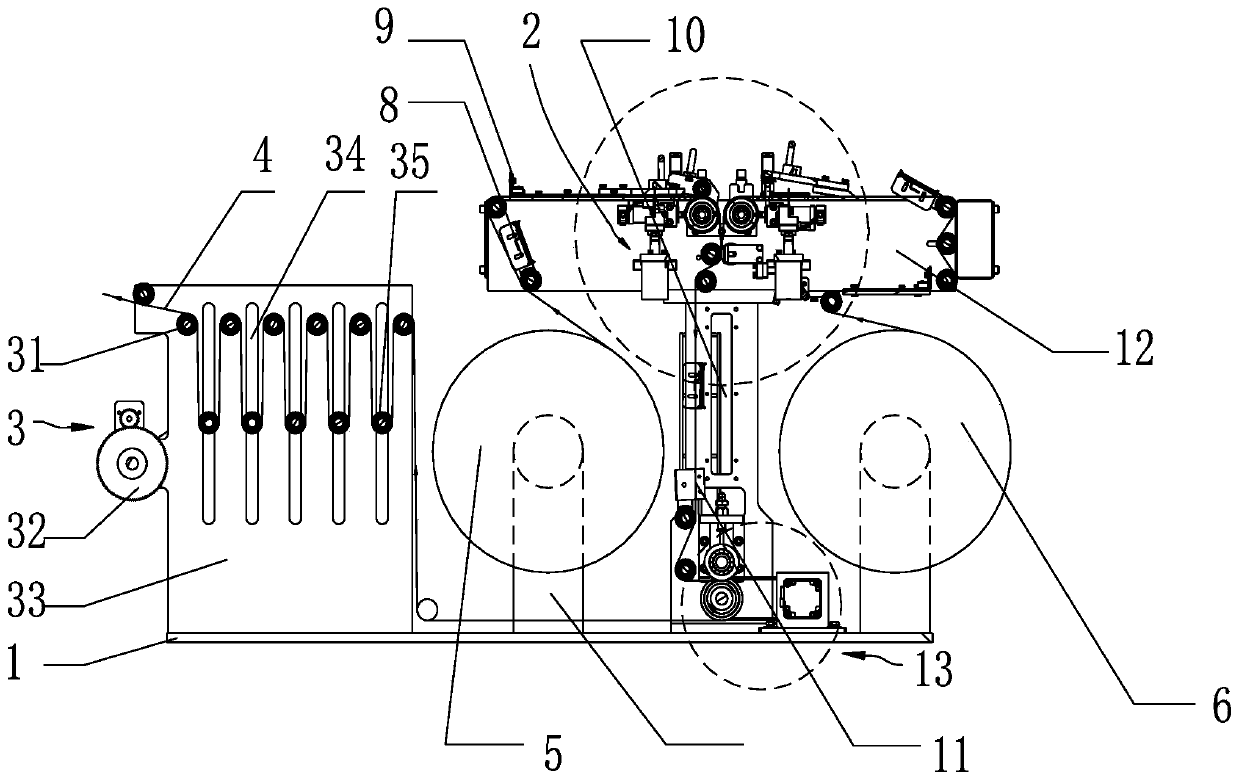

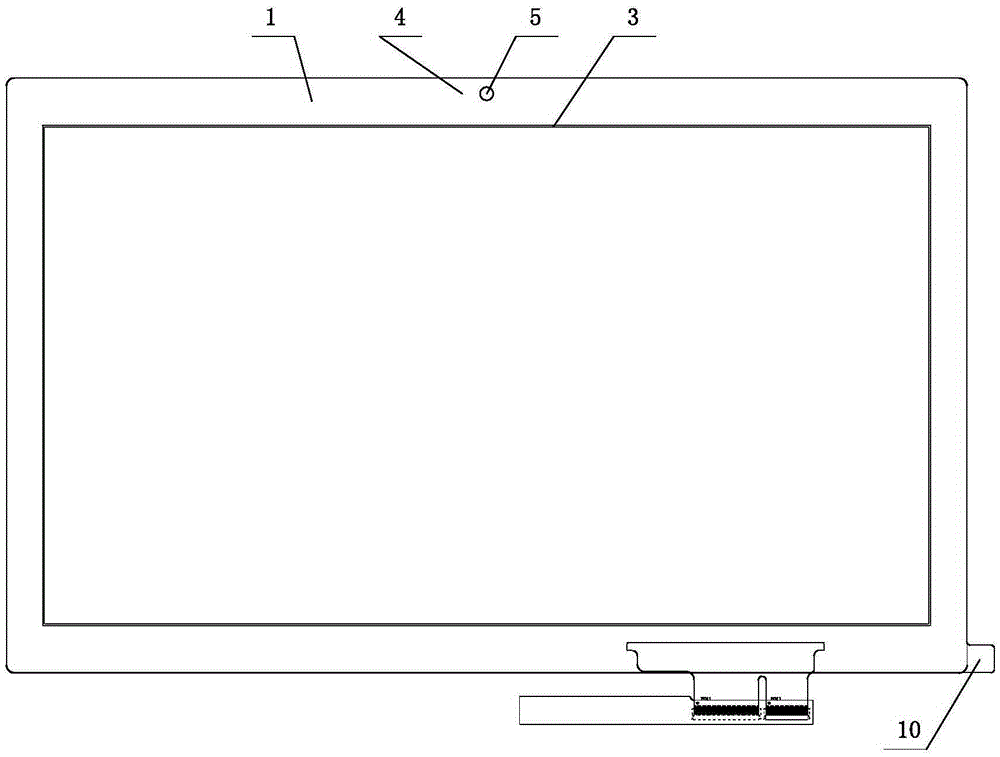

Metal front frame for display product and manufacturing method thereof

PendingCN106371237AReasonable structureSimple stitchingNon-linear opticsConvex structureWire cutting

The invention discloses a metal front frame for a display product and relates to the technical field of electronic and electronic products. The metal front frame comprises an A group frame strip and a B group frame strip which each has a cross section of a U-shaped structure. The two ends of the A group frame strip are provided with clamping convex structures, the two ends of the B group frame strip are provided with clamping grooves structures, and the clamping convex structures are matched with the clamping grooves structures to cause the A group frame strip and the B group frame strip to be spliced sequentially. The invention further discloses a method for manufacturing the metal front frame. The method comprises the steps of discharging; rolling forming; striping; wire cutting of a notch; bending forming; wire cutting; chamfering fine trimming; surface treatment; and splicing. The metal front frame is reasonable in structure and simple to splice, is spliced firmly and is formed by processes such as rolling forming an wire cutting, so that the display product is easier to manufacture, lower in cost and more attractive in appearance. Compared with conventional machining, according to the manufacturing method, a complex die structure is avoided, the rejection rate of the product is reduced, working efficiency is improved, and machining precision and strength of the metal front frame are ensured.

Owner:洪鸿莎

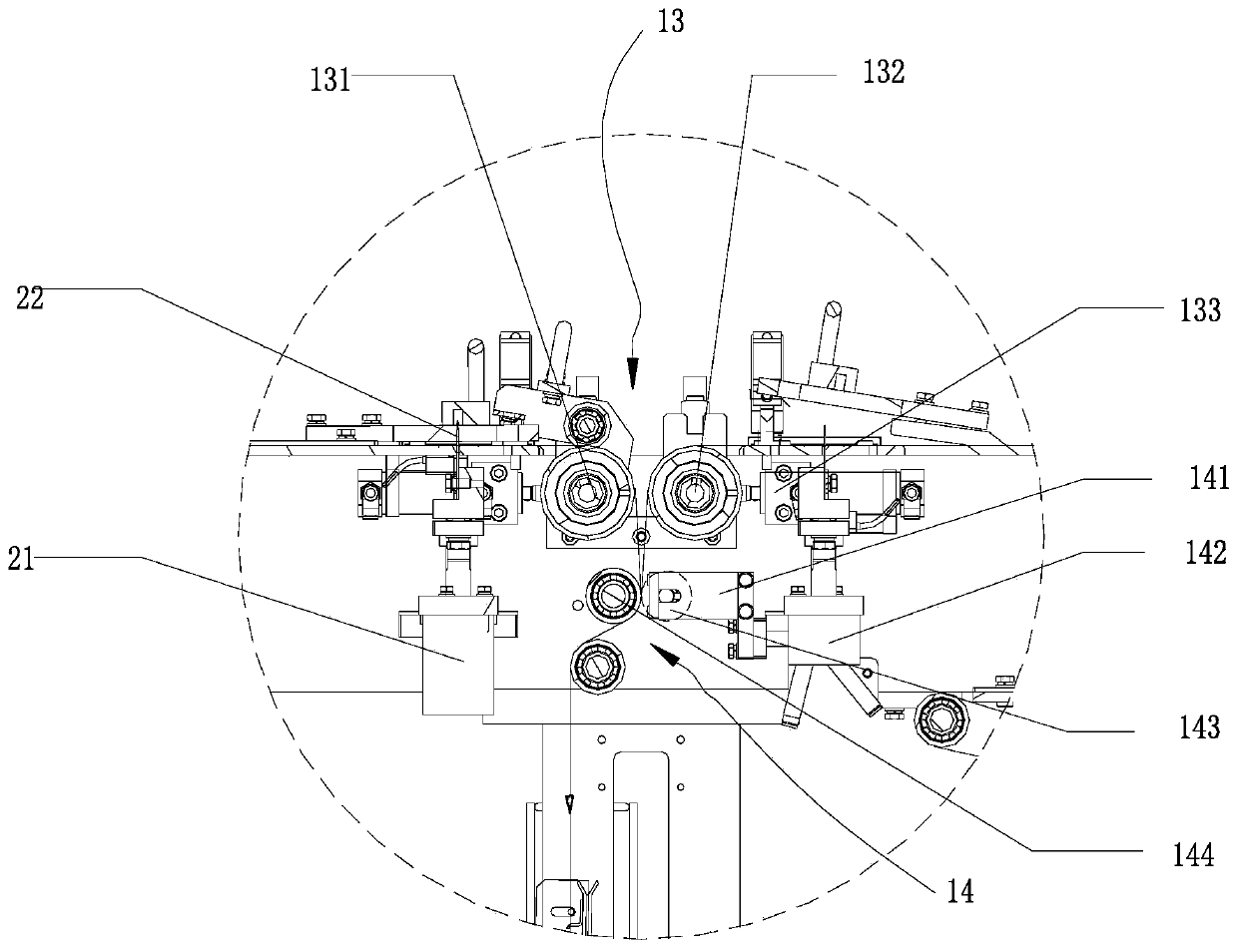

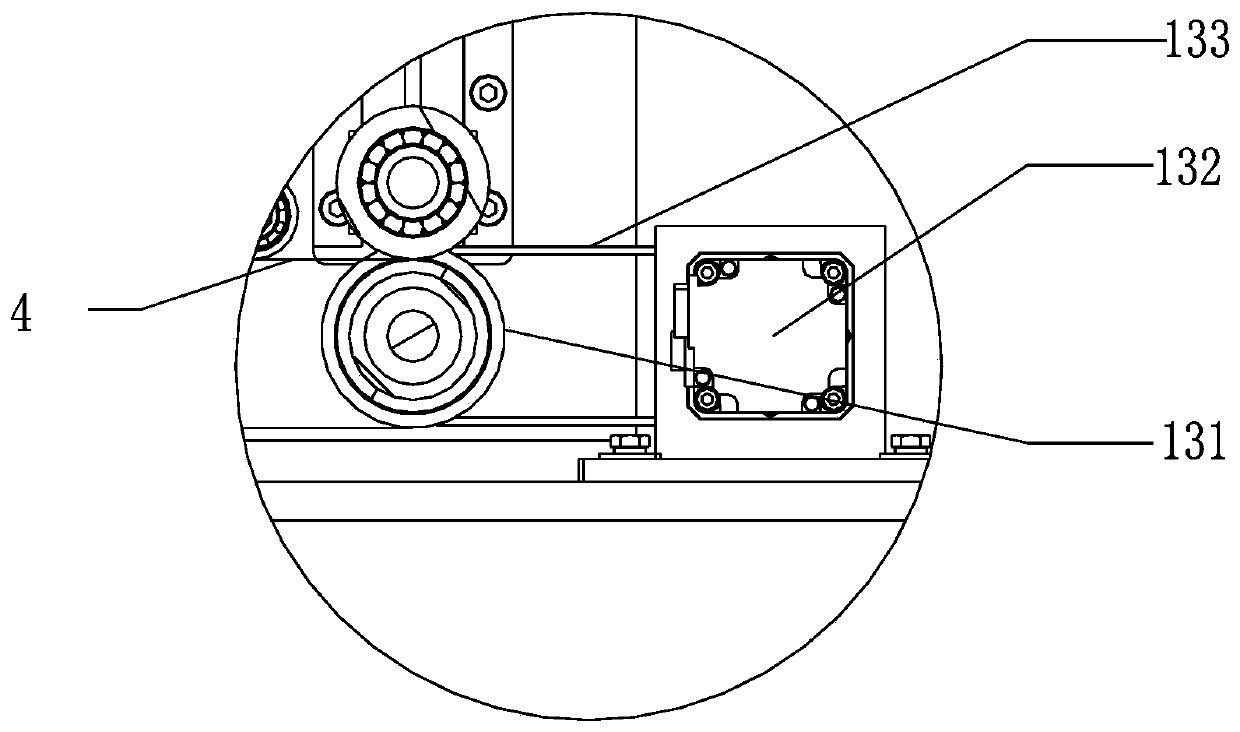

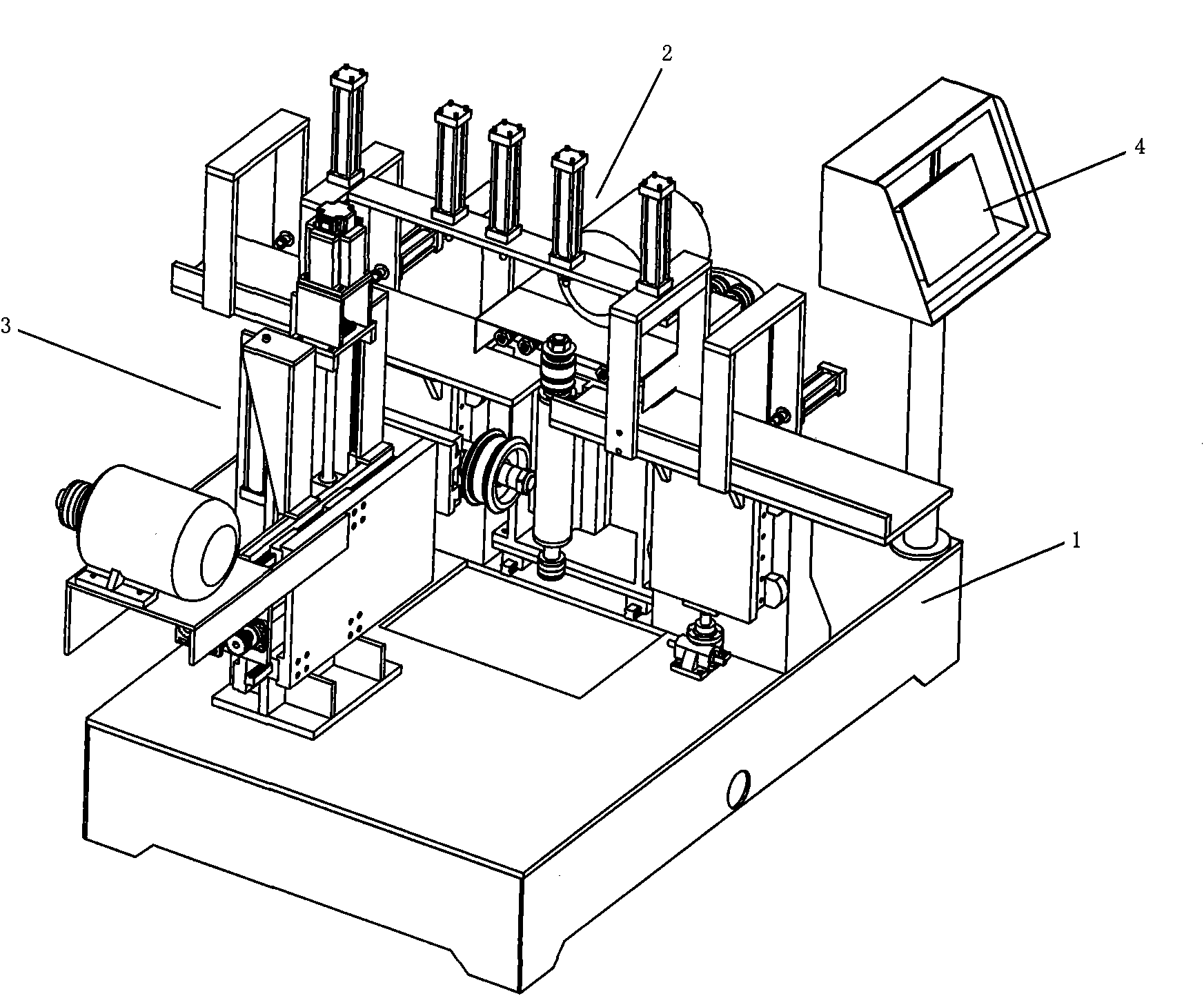

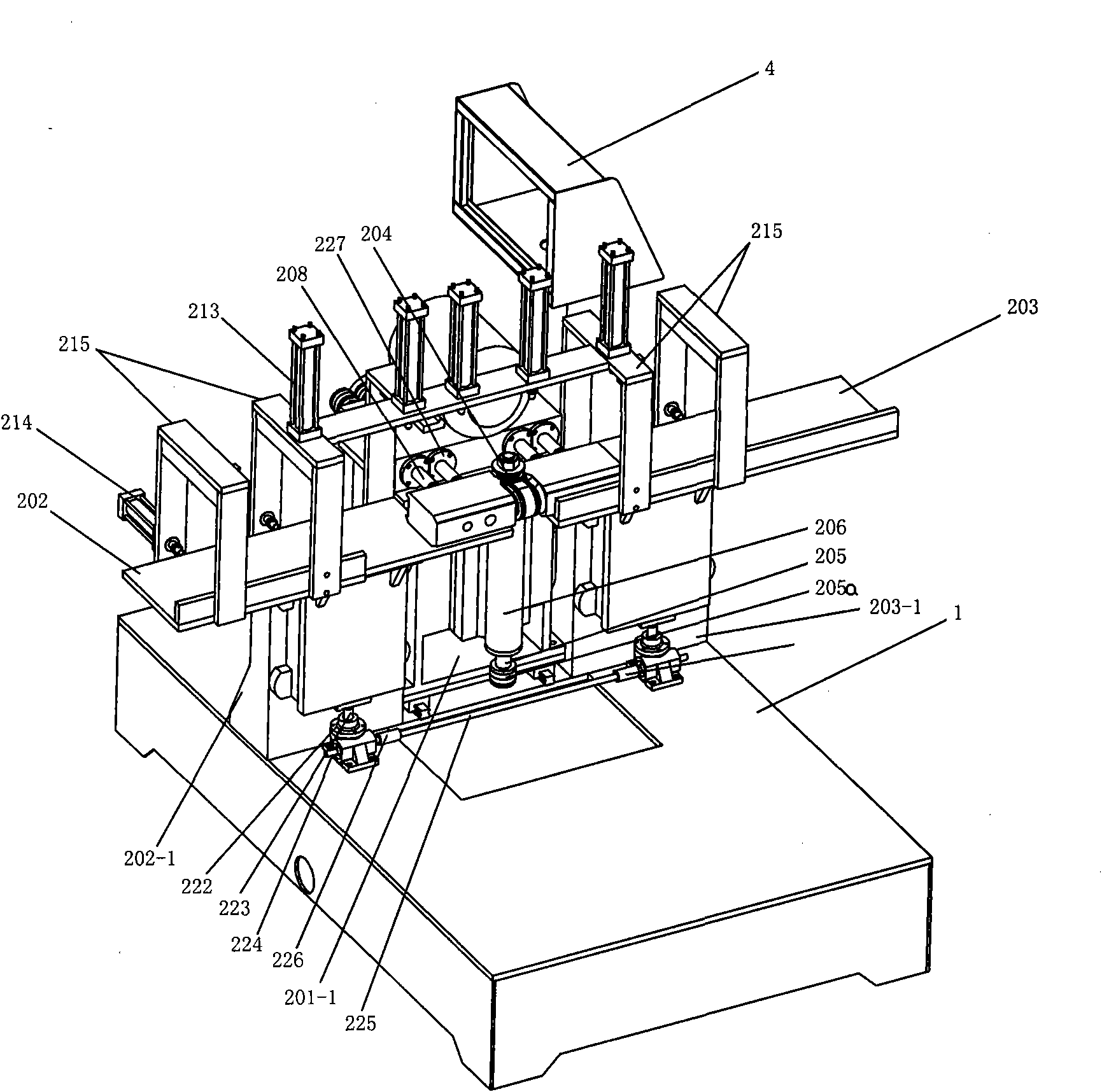

Strip automatic assembly device for packing machine and assembly method thereof

The invention discloses a strip automatic assembly device for a packing machine and an assembly method thereof. The device comprises a base; and the base is provided with a buffer part, a first drum and a second drum. The device further comprises a strip cutting mechanism, a strip assembly mechanism and an assembly reinforcing mechanism; the buffer part comprises multiple fixed pulleys and movablepulleys; the movable pulleys can slide up and down along chutes formed in a support panel; the strip cutting mechanism comprises a cutting cylinder and a cutter; the cutter is arranged perpendicularto strips; the strip assembly mechanism comprises a first roller and a second roller; and the assembly reinforcing mechanism comprises a metal roller, a rubber roller and a reinforcing cylinder. The device further comprises a strip ending sensor, an abnormal film breakage detecting sensor, a pattern detecting sensor, an assembly failure sensor and a buffer detecting sensor for acquiring signals; and the acquired signals are sent to a PLC. The device can achieve precise and reliable assembly of the strips, and achieves a certain intelligence level.

Owner:JOYEA CORP

Numerical control wood house tenon machine

The invention relates to a numerical control wood house tenon machine. A machine body is provided with a drilling and milling device, a horizontal milling device with an air cylinder stabilizing mechanism, and a numerical control device. The wood house tenon machine with the structure has high automation degree, is precisely and compactly structured, effectively improves the processing precision of a tenon and makes the connection of the wood house tenons more compact and solid.

Owner:黄丽汶

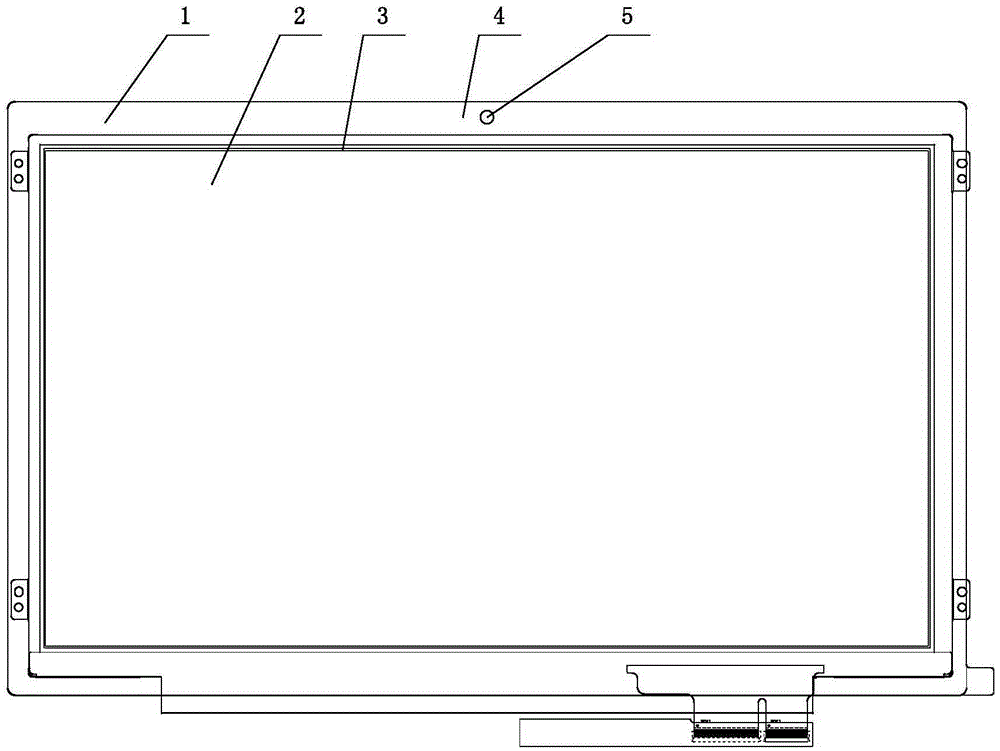

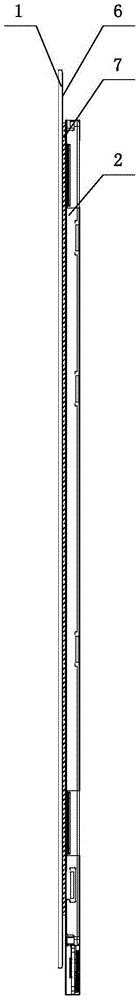

Frame lamination technology for touch screens

PendingCN105404427AFit tightlyNo bubblesInput/output processes for data processingScreen printingFoam rubber

The invention discloses a frame lamination technology for touch screens. The frame lamination technology for touch screens comprises the steps of machining a TFT liquid crystal screen module (2), pasting a film on an OGS touch screen (1), and laminating the OGS touch screen (1) onto the TFT liquid crystal screen module (2). During the step of pasting the film on the OGS touch screen, the silk-screen printing process of a wire frame (3) and an indicating lamp position hole (5) is conducted at the same time. Meanwhile, an explosion-proof film (6) is pasted onto the back surface of the OGS touch screen (1) before the step of laminating the OGS touch screen (1) onto the TFT liquid crystal screen module (2). The explosion-proof film (6) and the TFT liquid crystal screen module (2) are adhered together via the foam rubber (7). Based on the above structure, the OGS touch screen and the TFT liquid crystal screen module are adhered together more firmly without any air bubbles, and the adhesion quality thereof is better. Meanwhile, one step is saved, so that the production efficiency is increased. At the same time, the cost is saved. The explosion-proof film is firstly broken through, so that the pressure of the external force is relieved. Therefore, the explosion is avoided.

Owner:JIANGXI HOLITECH TECH

Splicing type packaging box for cold-chain logistics and low-temperature storage method thereof

ActiveCN111516965AStable splicingPlace stableShock-sensitive articlesRigid containersCold chainLogistics management

Owner:肇庆高新区得宝食品有限公司

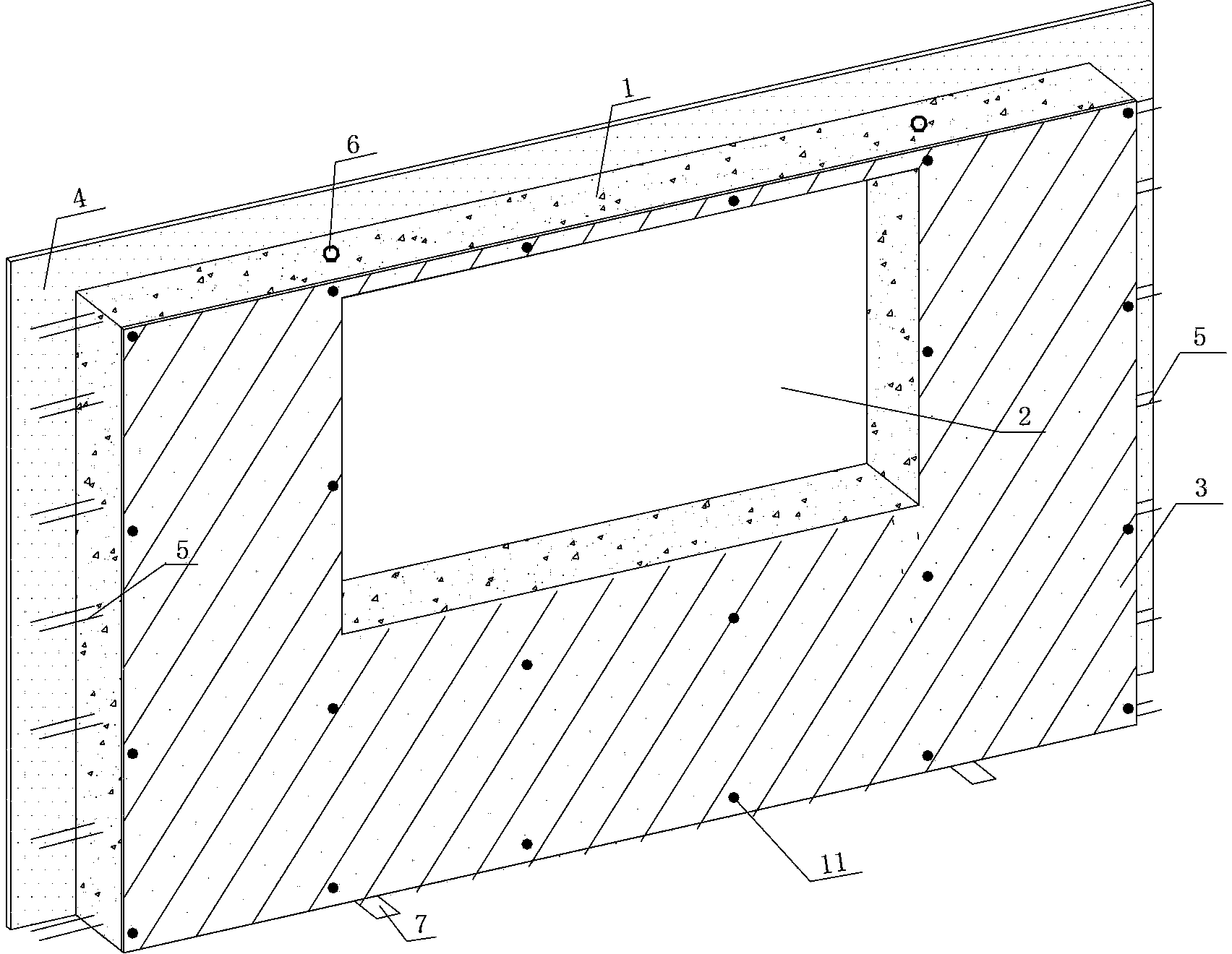

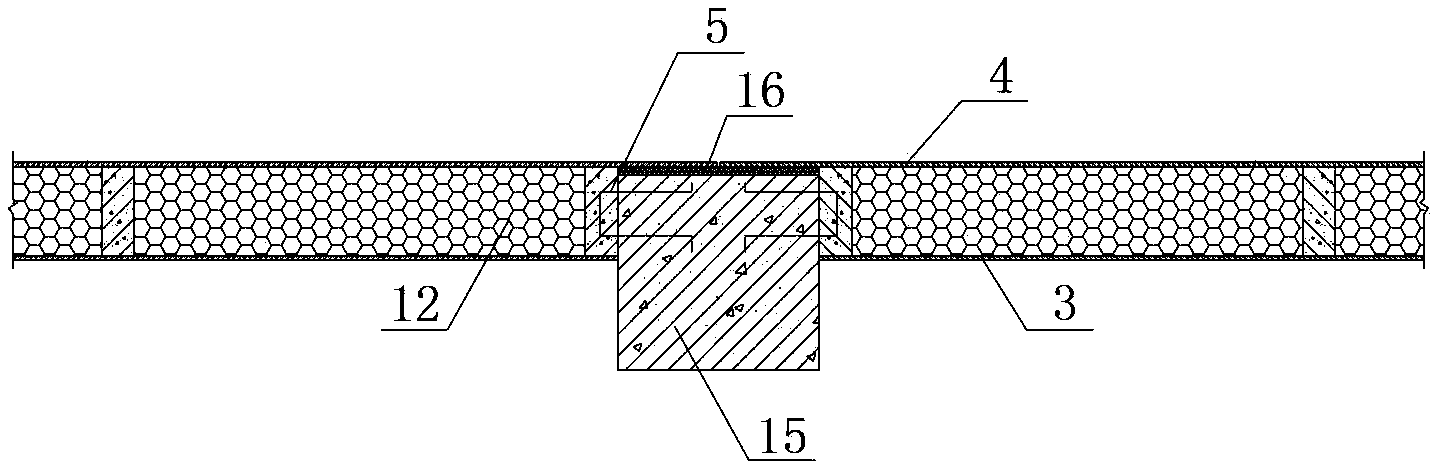

Assemble type multifunctional outer wall body and production and installation method thereof

The invention discloses an assemble type multifunctional outer wall body and a production and installation method thereof. An assemble type outer wall body mainly takes lightweight section as a keel, takes expanded polystyrene (EPS) thermal mortar as a heat preservation interlayer and is mainly applied to steel structure construction at present. The existing assemble type outer wall body has the problems that durability is bad, thermal bridge effect is notable, manufacturing cost is high, adaptability with a reinforced concrete structure is bad and the like. The assemble type multifunctional outer wall body is a frame interlayer composite structure and takes a fine stone reinforced concrete frame as the keel. Cellular concrete is filled in bars of the frame, and a window opening is reserved in the frame. Cement fiber panels are respectively fixedly installed on the inner side and the outer side of the fine stone reinforced concrete frame, and decorating layers are arranged on the cement fiber panels. The assemble type multifunctional outer wall body is suitable for assembling an integrated type structure building or a cast-in-place concrete building, split joint of the assemble type multifunctional outer wall body and a building main body structure is firm, and thus integrity is good. The assemble type multifunctional outer wall body has the integrated functions of protection, heat preservation, decoration, water proofing and the like, all working procedures are settled in one step, an outer scaffold does not need to be arranged in the process of installation, and thus construction speed is fast.

Owner:浙江省建筑科学设计研究院有限公司

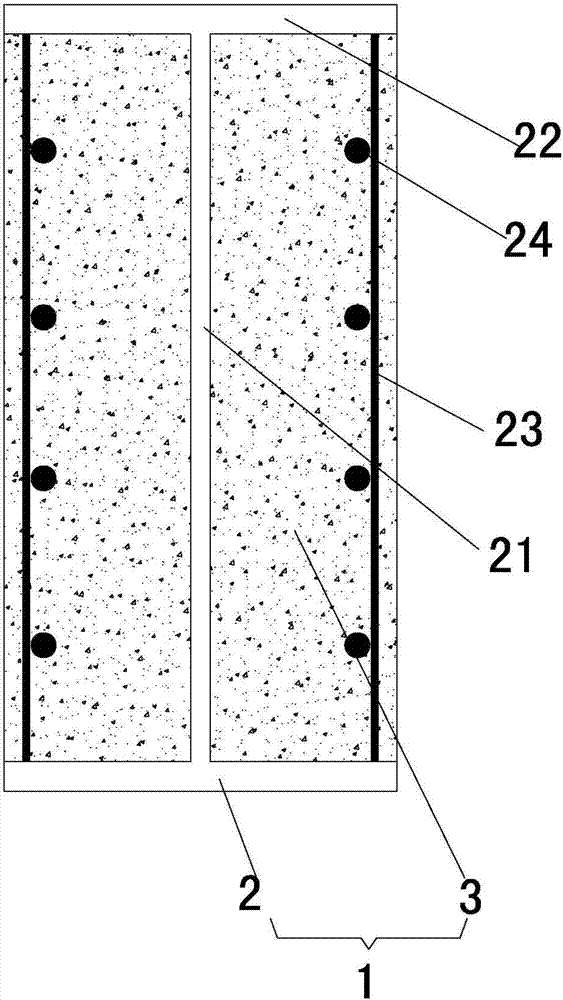

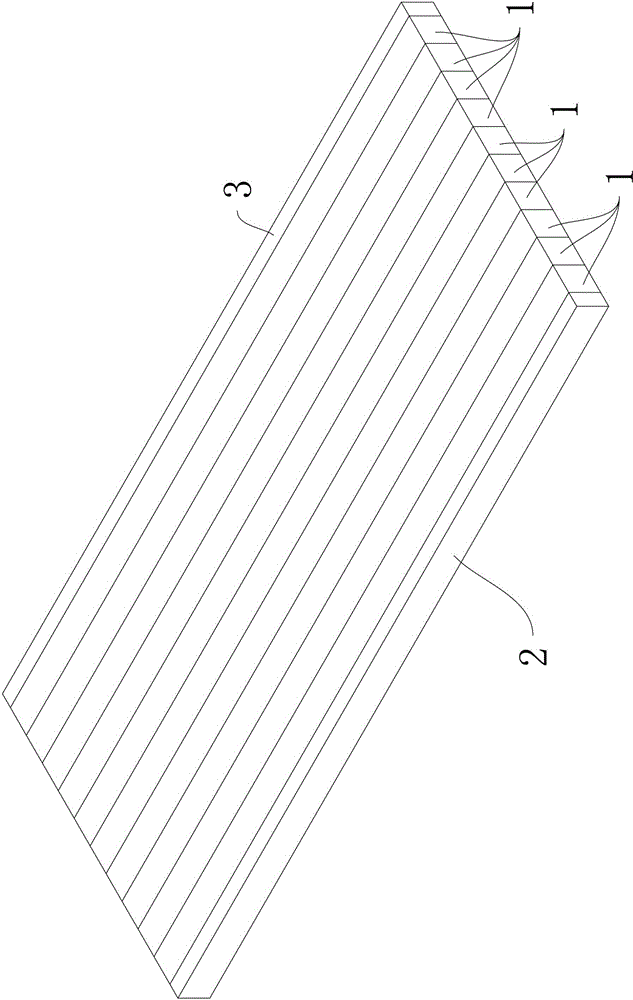

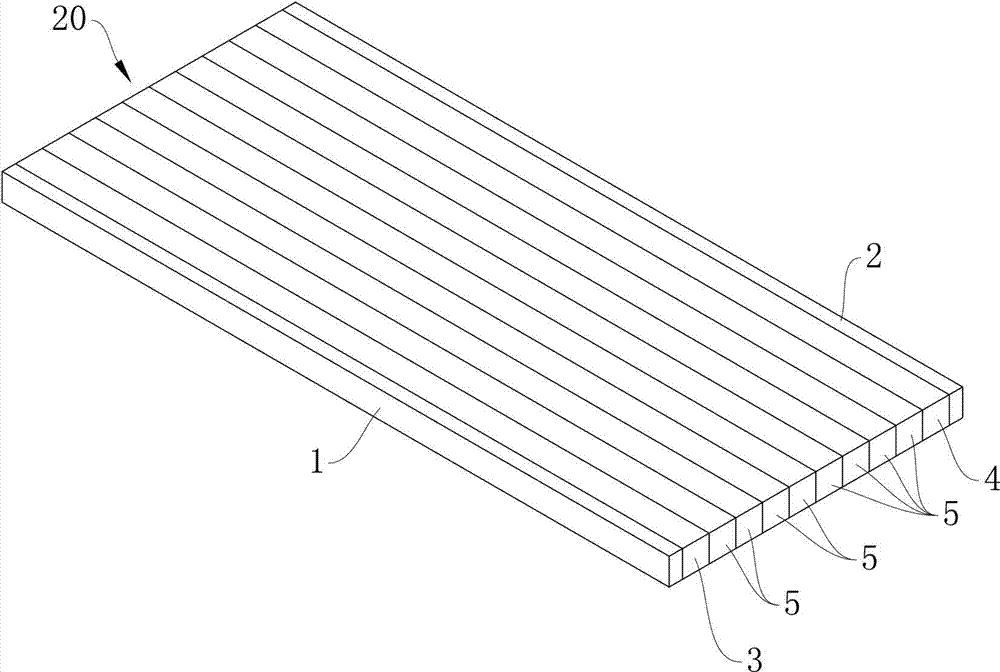

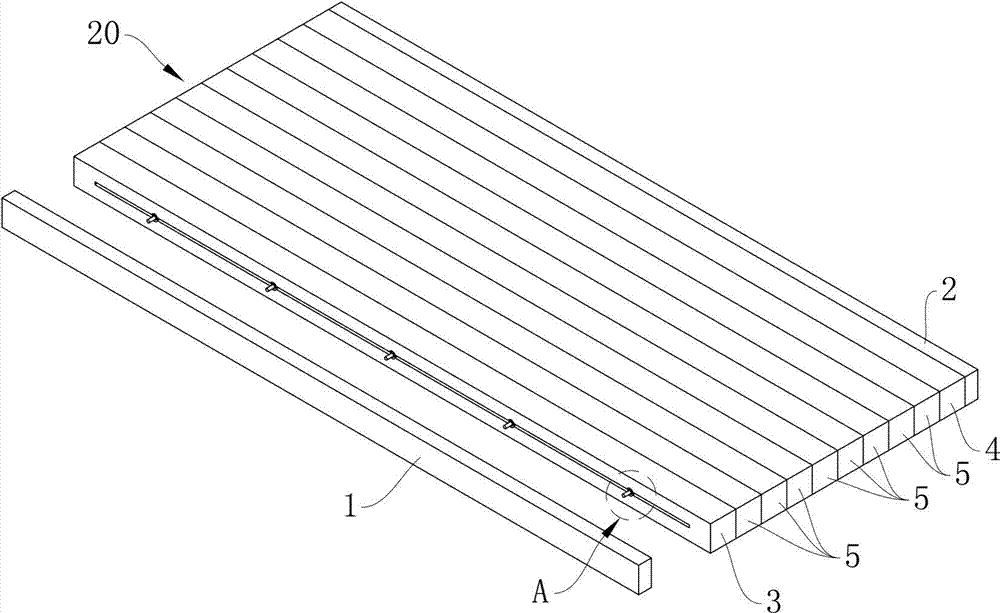

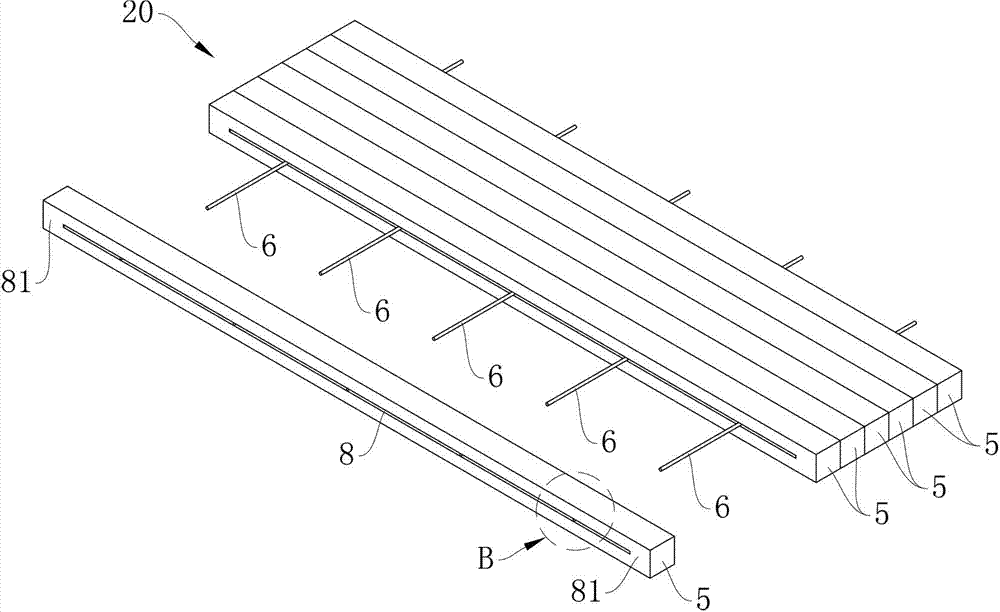

Log spliced board structure

ActiveCN103934868APrevents swelling from archingPrevent shrinkage crackingWood veneer joiningEngineeringExpansion joint

The invention relates to a log spliced board structure. The log spliced board structure is characterized by being mainly composed of a batten piece on the left outermost side, a batten piece on the right outermost side, a batten piece on the left second outer side, a batten piece on the right second outer side, a plurality of middle batten pieces, a plurality of screws connected in series, a plurality of nuts and the like. The design of expansion slits, the screws, the nuts, screw holes and nut holes is mainly adopted, the spliced wood board is not prone to expansion arching or shrinkage crack when weather changes, and the quality and the attractive appearance of the spliced wood board are greatly ensured. The splicing reliability and firmness of the batten pieces are greatly guaranteed, expansion deformation or cracking can be completely eradicated, and the quality of the spliced wood board is effectively guaranteed.

Owner:彭志军

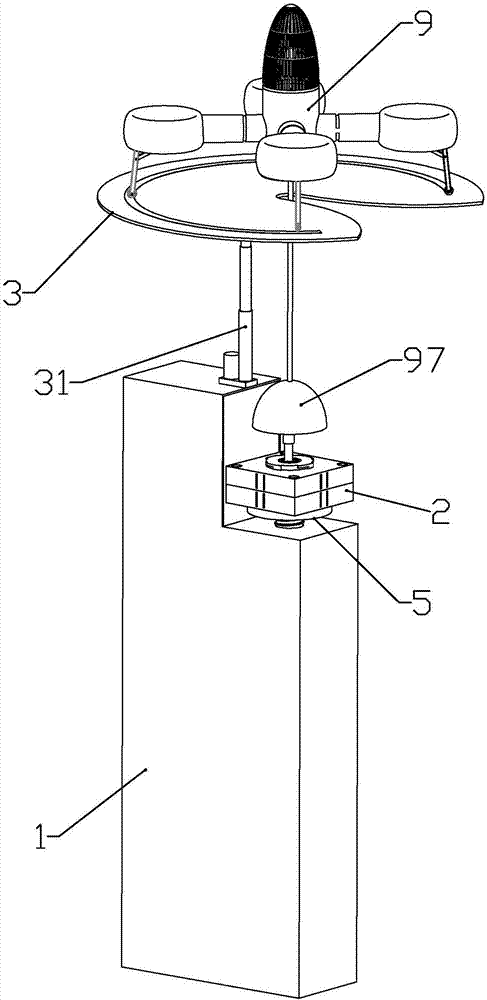

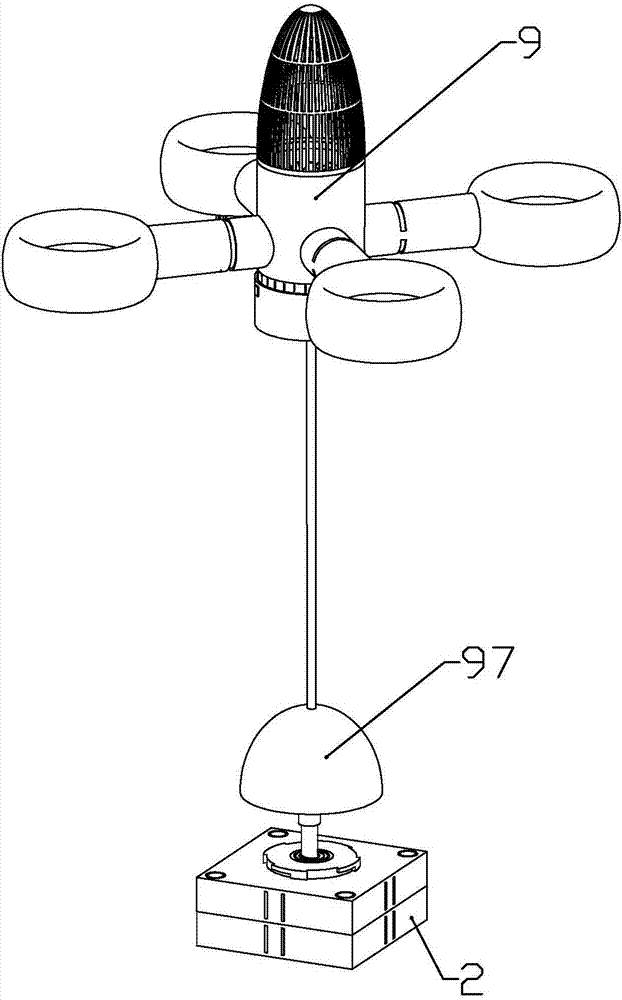

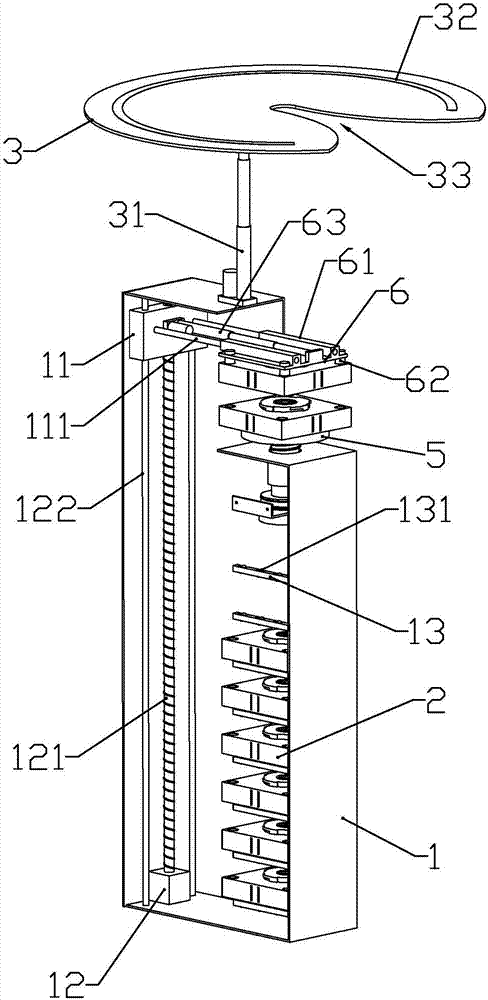

New-energy charging pile for electric cars

InactiveCN107264334AIncrease profitReduce energy consumptionAircraft componentsCharging stationsElectrical batteryNew energy

The invention discloses a new-energy charging pile for electric cars. The pile includes a cuboid shell, a plurality of battery supporting shelves, battery units, a battery dismounting base and conveying mechanisms, wherein the battery supporting shelves are installed on one side of the interior of the shell and arranged lengthwise at equal intervals; the battery units are placed on the battery supporting shelves for charging; the battery dismounting base is positioned on the top of the shell and above the battery supporting shelves; the conveying mechanisms are installed inside the shell and used for conveying the battery units between each battery supporting shelf and the battery dismounting base. By loading multiple battery units inside the shell of the charging pile, the battery units can be assembled into an integral battery module on the battery dismounting base, so that according to the predicted driving distance of different electric cars, required electric quantity can be roughly estimated and the required number of battery units is determined, and one or more battery units are conveyed to the place where an electric car is located through an air vehicle for supplying power to the electric cars.

Owner:浙视传媒(温州)有限公司

Waterproof and moisture-proof PVC floor

The invention discloses a waterproof and moisture-proof PVC floor. The waterproof and moisture-proof PVC floor comprises a PVC base plate, wherein a support plate is arranged in the center of an innercavity of the PVC base plate, support columns are uniformly installed inside the support plate in an embedded mode, and the support columns are vertically arranged. Buffer layers are separately connected to the top and bottom surfaces of the support plate in a glued mode, and the top and bottom portions of the buffer layers are separately connected with an upper reinforcing plate and a lower reinforcing plate. The upper reinforcing plate and the lower reinforcing plate are separately located at the top and the bottom of the PVC base plate, and the bottom of the lower reinforcing plate is connected with a reinforcing supporting plate. The waterproof and moisture-proof PVC floor is simple in structure, stable and reliable, easy to install, convenient to use, good in integrity, flame retardant and wear-resistant and waterproof and stain-resistant, can increase the overall strength, prevents deformation and collapse, prolongs the service life, can be waterproof at the bottom and joints ofthe floor, has good waterproof and moisture-proof effects, can be stably and closely spliced and installed, prevents slipping, improves the stability of floor laying, and has broad application prospects.

Owner:WUJIANG YOUXIN NEW MATERIAL TECH

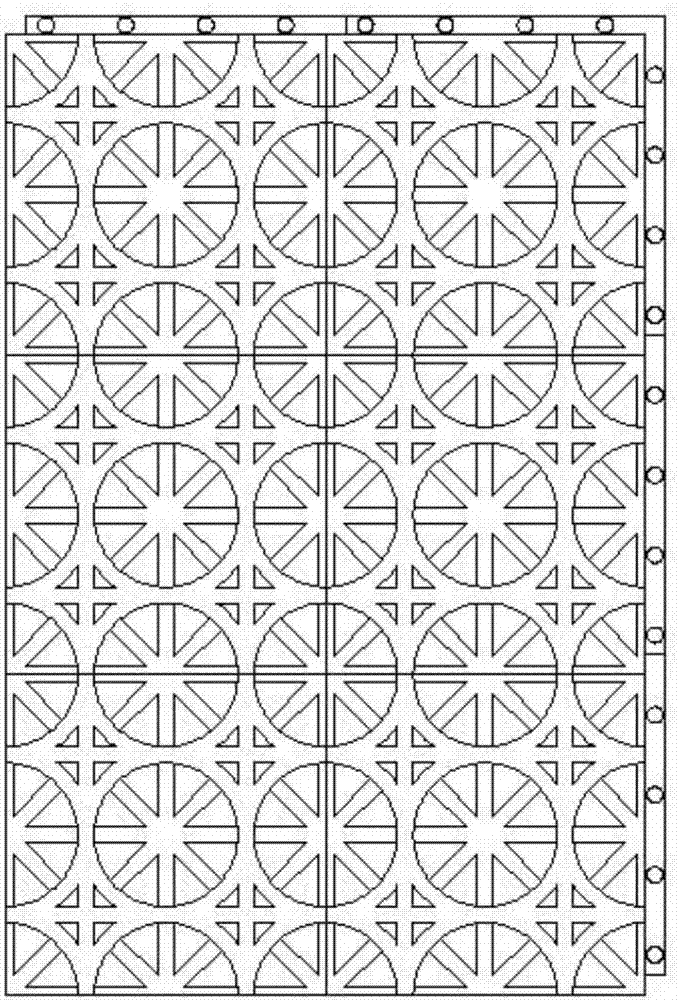

Novel floor heating modules

InactiveCN107190944AImprove stress resistanceEase of mass productionCovering/liningsLighting and heating apparatusHeat conductingEngineering plastic

The invention discloses novel floor heating modules. Each novel floor heating modules comprises a main body outer layer and a thermal insulating inner layer; the main body outer layer is internally filled with the thermal insulating inner layer, and the thermal insulating inner layer is a thermal insulating material; a plurality of protrusions are arranged on the surface of the main body outer layer and are used for fixing floor heating pipelines, and a plurality of heat conducting grooves are evenly formed in the protrusions; a splicing structure is arranged on the outer wall around the main body outer layer; and the splicing structure is provided with an external buckle and an internal buckle, and the external buckle and the internal buckle are engaged with each other. According to the novel floor heating device, pressure bearing is done by the main body outer layer and the thermal insulating inner layer together, and anti-pressure ability is high; the main body outer layer, the protrusions, the heat conducting grooves and the splicing structure are formed by one-time injection molding from engineering plastics, so that the anti-pressure ability of the floor heating modules is further enhanced, and meanwhile, mass production is conveniently achieved; and the thermal insulating material with a low heat conducting coefficient is adopted by the thermal insulating inner layer, the floor heating modules are closely connected under the cooperation of the splicing structure, so that downward loss of heat is prevented, and the thermal insulating effect is good.

Owner:WUHAN KINGBULL ECONOMIC DEV

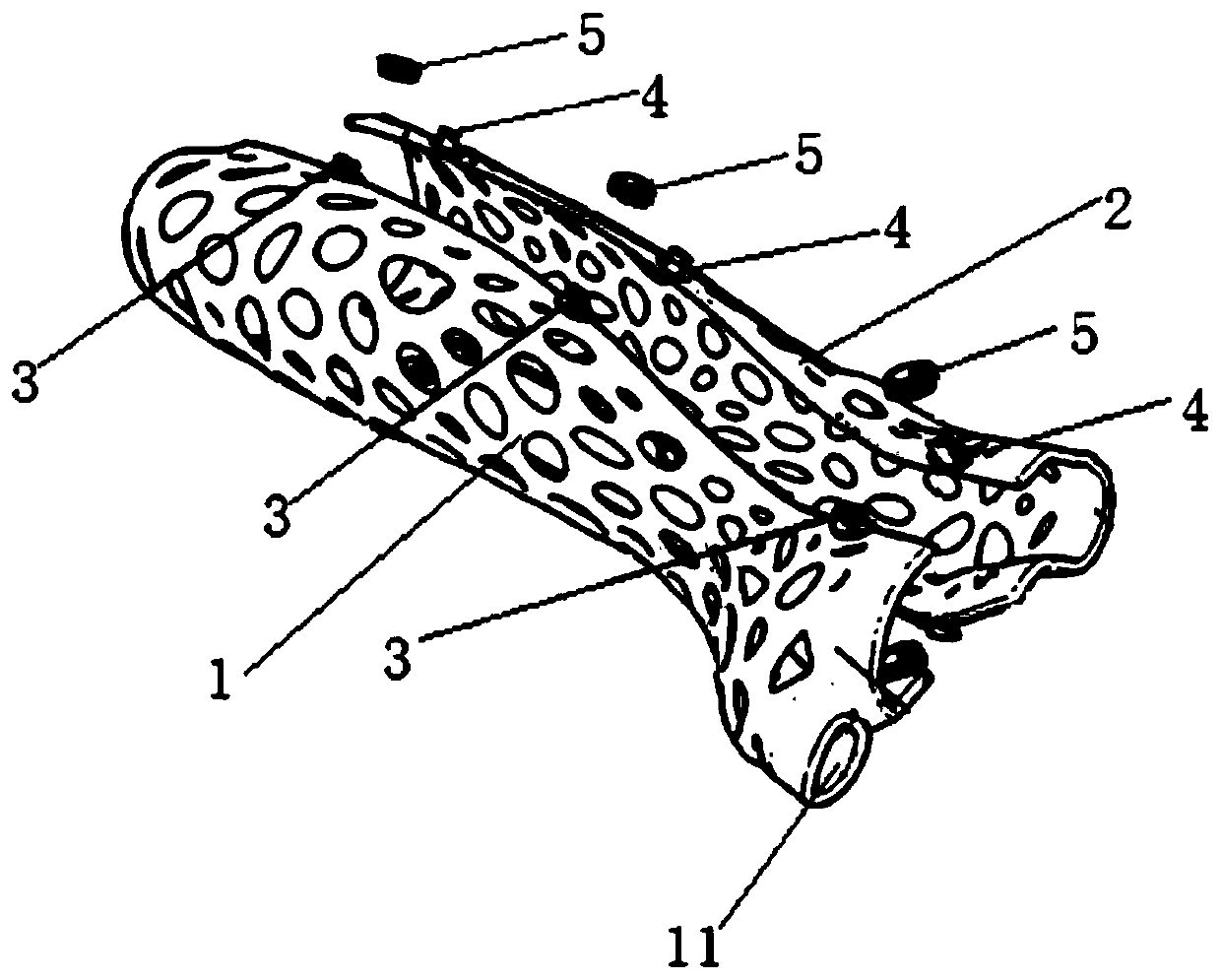

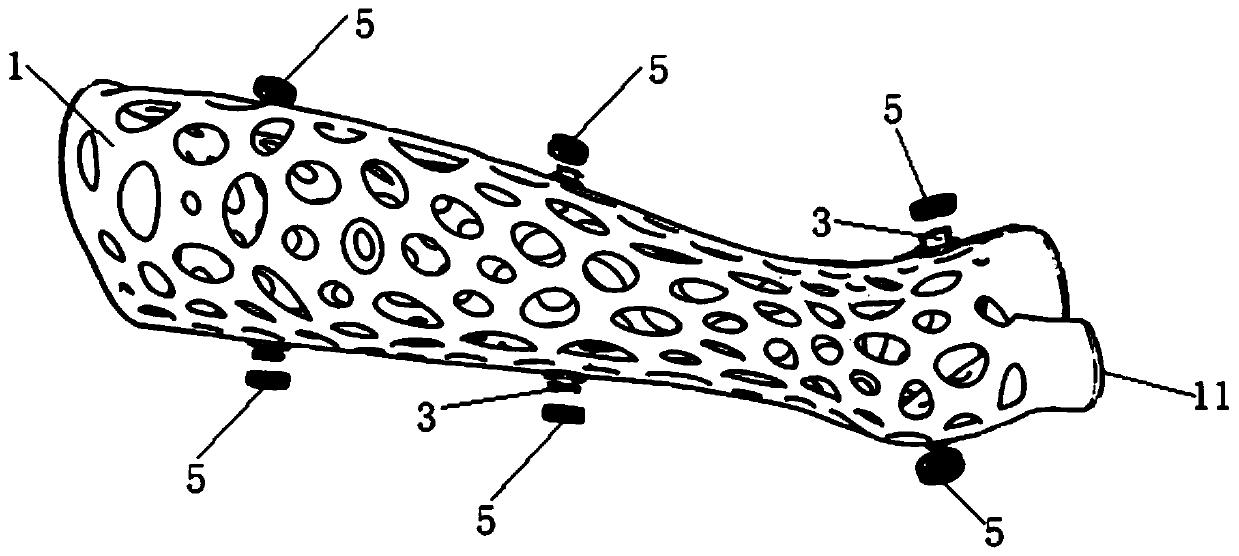

Three-dimensional printing protection device and printing method thereof

PendingCN110115652AGood fitReduce weightAdditive manufacturing apparatusFractureEngineering3 dimensional printing

The invention belongs to a medical rehabilitation protection device and a manufacturing method thereof, and particularly relates to a three-dimensional printing protection device and a printing methodthereof. The problem that existing protection devices are inconvenient to adjust according to the change of the affected part can be solved. The protection device is formed by splicing two parts of main bodies based on additive manufacturing, the two main bodies cooperate with each other through fixing rings and locking columns and are used for connecting fixation and limitation, the shape can bedesigned according to the affected part of a patient, the fitting degree is high, the weight is low, the strength is high, and the protection performance is good. Particularly, a fixing device is formed by the fixing rings and the locking columns, thelocking columns of the two parts can be jacked tightly to complete fixation simply by sleeving and rotating the fixing rings, mounting and dismounting are convenient, and the use is convenient; in addition, the elastic adjustment can be carried out in cooperation with different fixing rings according to the swelling degree of the affected part indifferent stages, and bone displacement and other problems are effectively prevented. The whole protection device is accurate to splice and position, a malposition phenomenon does not easily occur, the affected part is fastened more reliably, and the protection device has the advantage of being suitable for various affected parts.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Rapid construction method of pipe jacking working well in upper soft and lower hard stratum

The invention discloses a quick construction method of a pipe jacking working well in an upper soft and lower hard stratum. A site is smoothed, staking out in survey is carried out, the position of apile hole is positioned; a rotary drilling machine is used for drilling in an upper soil layer, every time a certain distance is drilled, a drill head of the rotary drilling machine exits out of the pile hole, and a pile casing is put into the pile hole; the method is repeated until drilling is carried out into a lower base rock layer, and all the pile casings are anchored in the upper soil layer;the rotary drilling machine is continuously used for drilling in the lower base rock layer until drilling is carried out to a specified elevation; transverse excavation is carried out in the hole wall at the bottom of the pile hole to form a pipe jacking operation space, wherein the pipe jacking operation space is provided with an opening into which the pipe jacking to be constructed can enter; ajacking device is installed in the pipe jacking operation space; and at the bottom of the pile hole and at the position of the pipe jacking construction, the lower base rock layer is excavated transversely, and jacking construction is carried out on the pipe jacking through the jacking device. The quick construction method reduces the construction workload, reduces the construction difficulty, shortens the construction period and reduces the impact on the environment.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com