Method used for transverse bridging splicing growth of large-area monocrystal diamond

A single crystal diamond, large-area technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of relative movement of diamonds and obvious splicing seams, and reduce the risk of cracks or even cracks. The splicing is firm and the effect of stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for splicing and growing single crystal diamond comprises the steps:

[0043] 1) Select two (100) single crystal diamond substrates, the substrate size is 3×3×0.4mm 3 and 3×3×0.5mm 3 , using a standard acid-base cleaning process to clean the single crystal diamond on the substrate to remove the non-diamond phase on the surface, then clean the two single crystal diamonds with alcohol, acetone, and deionized water, and dry them with nitrogen.

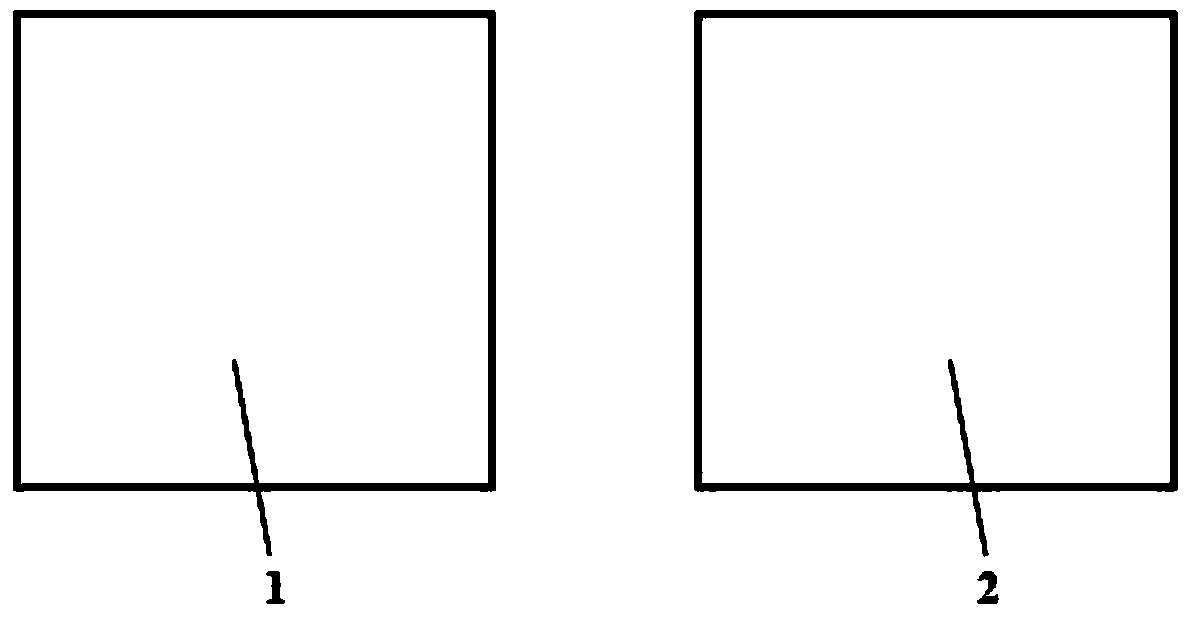

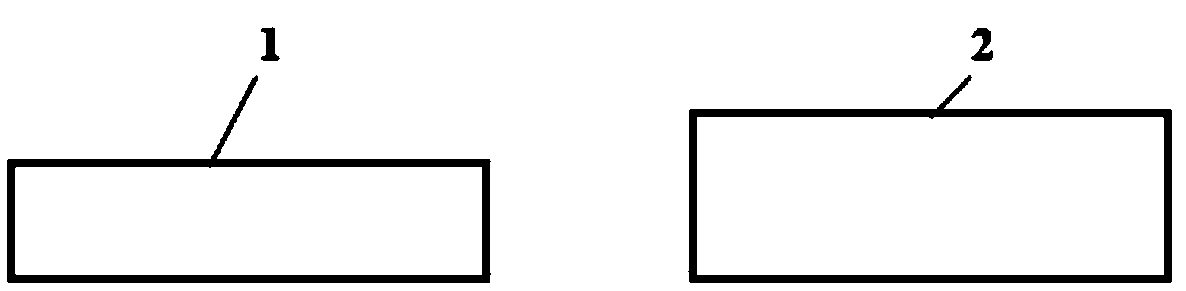

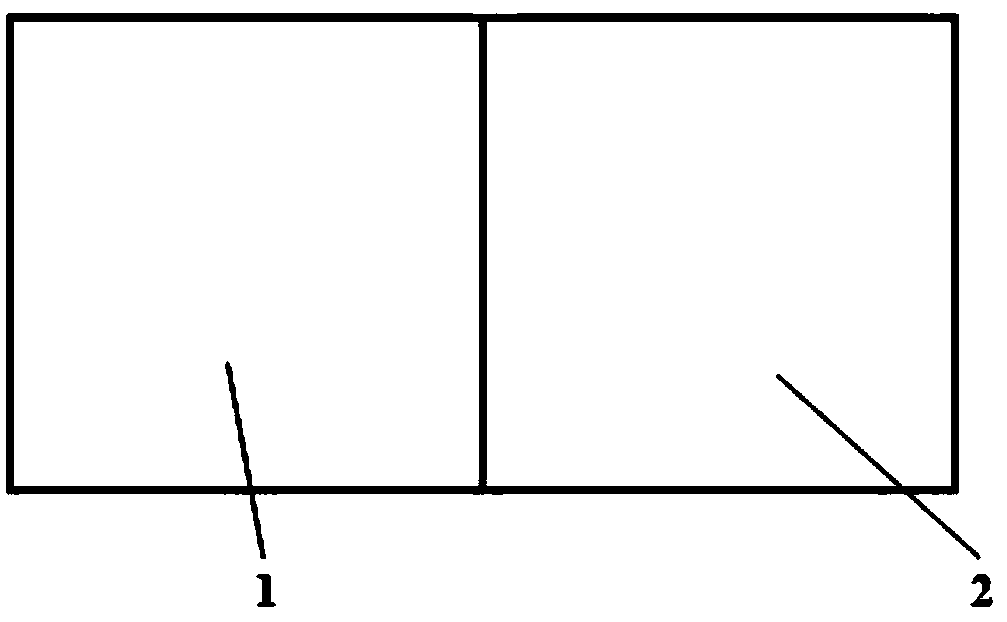

[0044] 2) Splicing two single crystal diamond substrates in a microwave plasma cavity.

[0045] 3) Microwave plasma is used to epitaxy the substrate, and under certain conditions, a lateral bridging part is grown at the seam to realize firm splicing; a complete epitaxial single crystal diamond can be obtained by continuing to grow. The diamond was grown by plasma chemical deposition technology, and the growth conditions were: methane flow rate 100 sccm, growth temperature 800°C, chamber pressure 150 Torr, and total gas f...

Embodiment 2

[0047] A method for splicing and growing single crystal diamond comprises the steps:

[0048] 1) Select two (100) single crystal diamond substrates, the substrate size is 3×3×0.4mm 3 and 3×3×0.5mm 3 , using a standard acid-base cleaning process to clean the single crystal diamond on the substrate to remove the non-diamond phase on the surface, then clean the two single crystal diamonds with alcohol, acetone, and deionized water, and dry them with nitrogen.

[0049] 2) Splicing two single crystal diamond substrates in a microwave plasma cavity.

[0050] 3) Microwave plasma is used to epitaxy the substrate, and under certain conditions, a lateral bridging part is grown at the seam to realize firm splicing; a complete epitaxial single crystal diamond can be obtained by continuing to grow. The diamond was grown by plasma chemical deposition technology, and the growth conditions were: methane flow rate 200 sccm, growth temperature 800°C, chamber pressure 150 Torr, and total gas f...

Embodiment 3

[0052] A method for splicing and growing single crystal diamond comprises the steps:

[0053] 1) Select two (100) single crystal diamond substrates, the substrate size is 3×3×0.4mm 3 and 3×3×0.5mm 3 , using a standard acid-base cleaning process to clean the single crystal diamond on the substrate to remove the non-diamond phase on the surface, then clean the two single crystal diamonds with alcohol, acetone, and deionized water, and dry them with nitrogen.

[0054] 2) Splicing two single crystal diamond substrates in a microwave plasma cavity.

[0055] 3) Microwave plasma is used to epitaxy the substrate, and under certain conditions, a lateral bridging part is grown at the seam to realize firm splicing; a complete epitaxial single crystal diamond can be obtained by continuing to grow. The diamond is grown by plasma chemical deposition technology, and the growth conditions are as follows: methane flow rate 200 sccm, growth temperature 1300° C., chamber pressure 150 Torr, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com