Rapid forming method of semi-transparent concrete plates

A concrete slab and forming method technology, which is applied in ceramic forming machines, chemical instruments and methods, clay preparation devices, etc., can solve the problems of unsuitable prefabrication, industrial production, high cost, and time-consuming, and achieve simple and efficient formwork splicing , the surface is smooth and tidy, the plate is beautiful and generous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

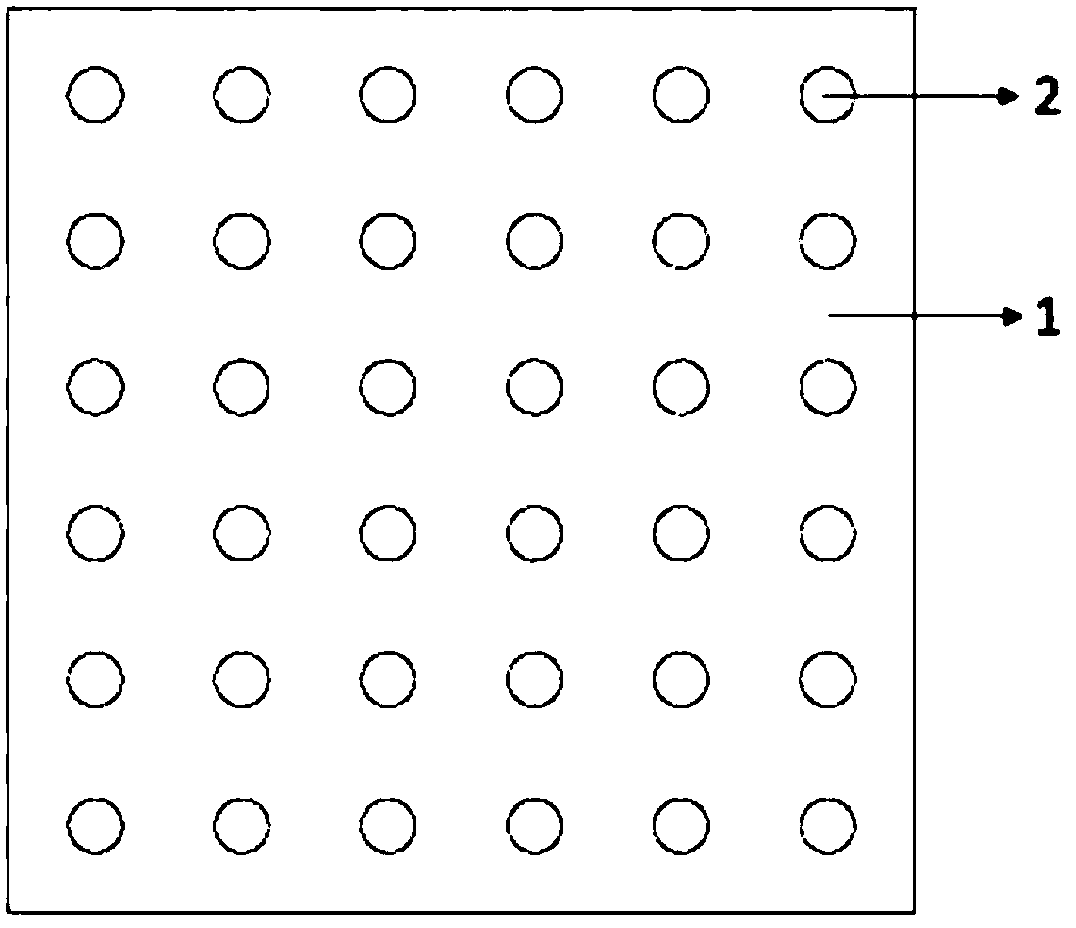

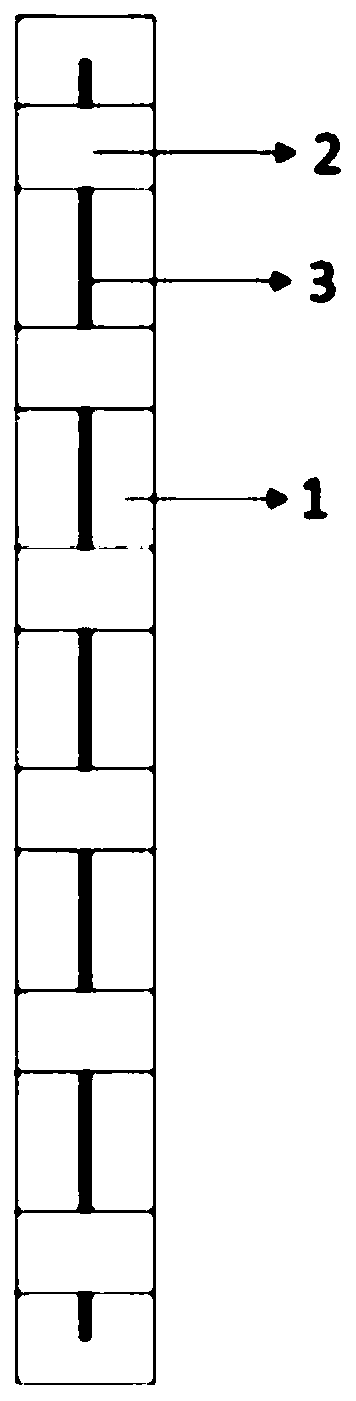

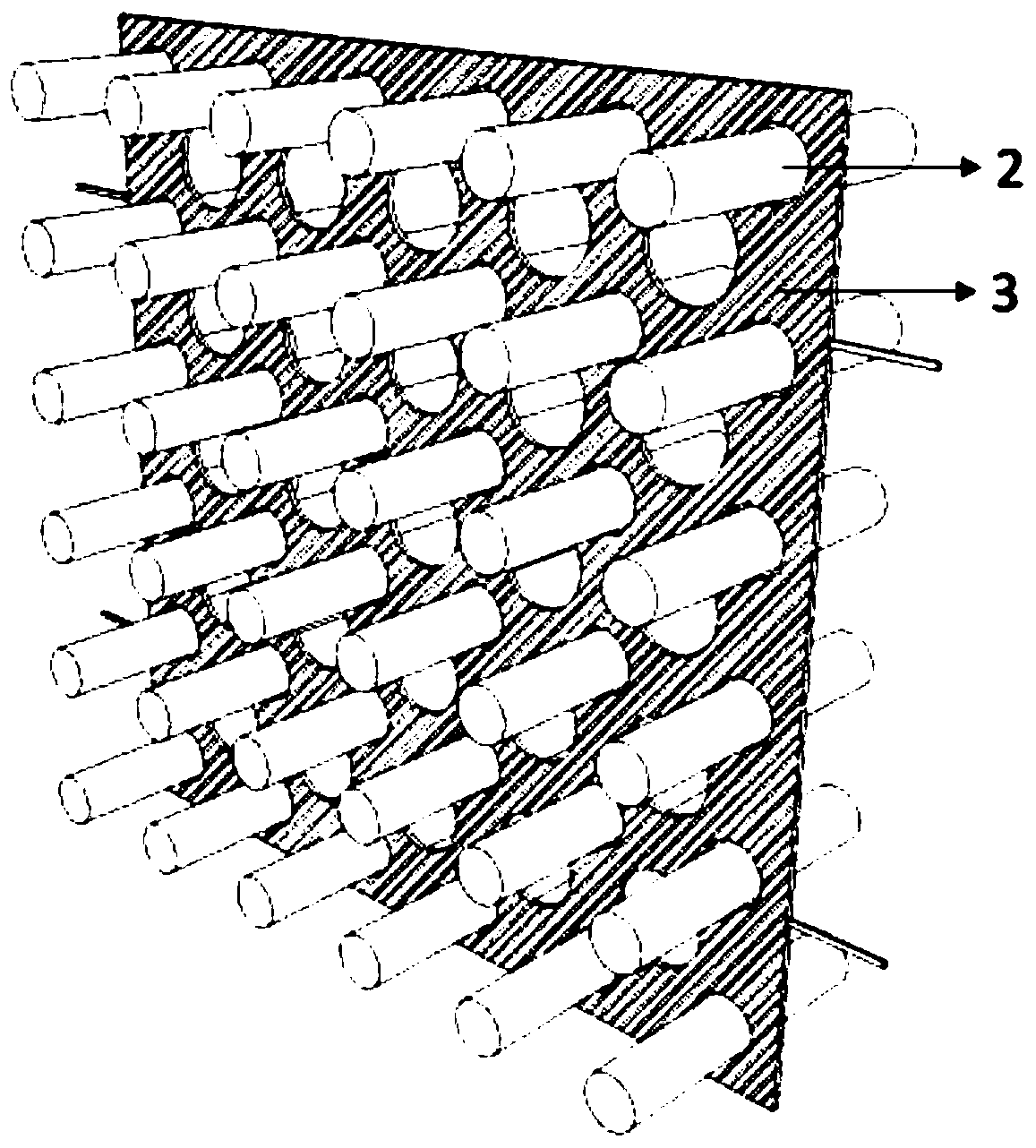

[0031] Such as Figure 1~5 Shown: the translucent concrete slab made by the present invention includes light guide element 2, perforated steel plate 3 and concrete material 1, wherein light guide element 2 adopts such as optical fiber, glass rod, plastic rod, etc. to realize the light guide function of the plate, Concrete material 1 uses various concrete additives such as hollow microspheres, silica fume, and plastics to realize the excellent thermal insulation performance of the board. Multi-layer perforated steel plates can also be used to meet the needs of light guide element layout and bearing capacity.

[0032] The formwork used in the present invention comprises formwork plate 4 and anchors 5, 6, 7, wherein formwork plate 4 adopts steel plate, plexiglass plate etc., and anchorage is divided into anchor bolt 5 of anchor formwork, self-tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com