Ultra-thin stone plate capable of fast assembling dry hanging and manufacturing method thereof

A technology of ultra-thin stone and stone slabs, which is applied in the field of building decoration materials, can solve the problems of affecting the overall appearance, labor-intensive, waste of limited natural resources, etc., and achieve the effect of firm combination and increased commodity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

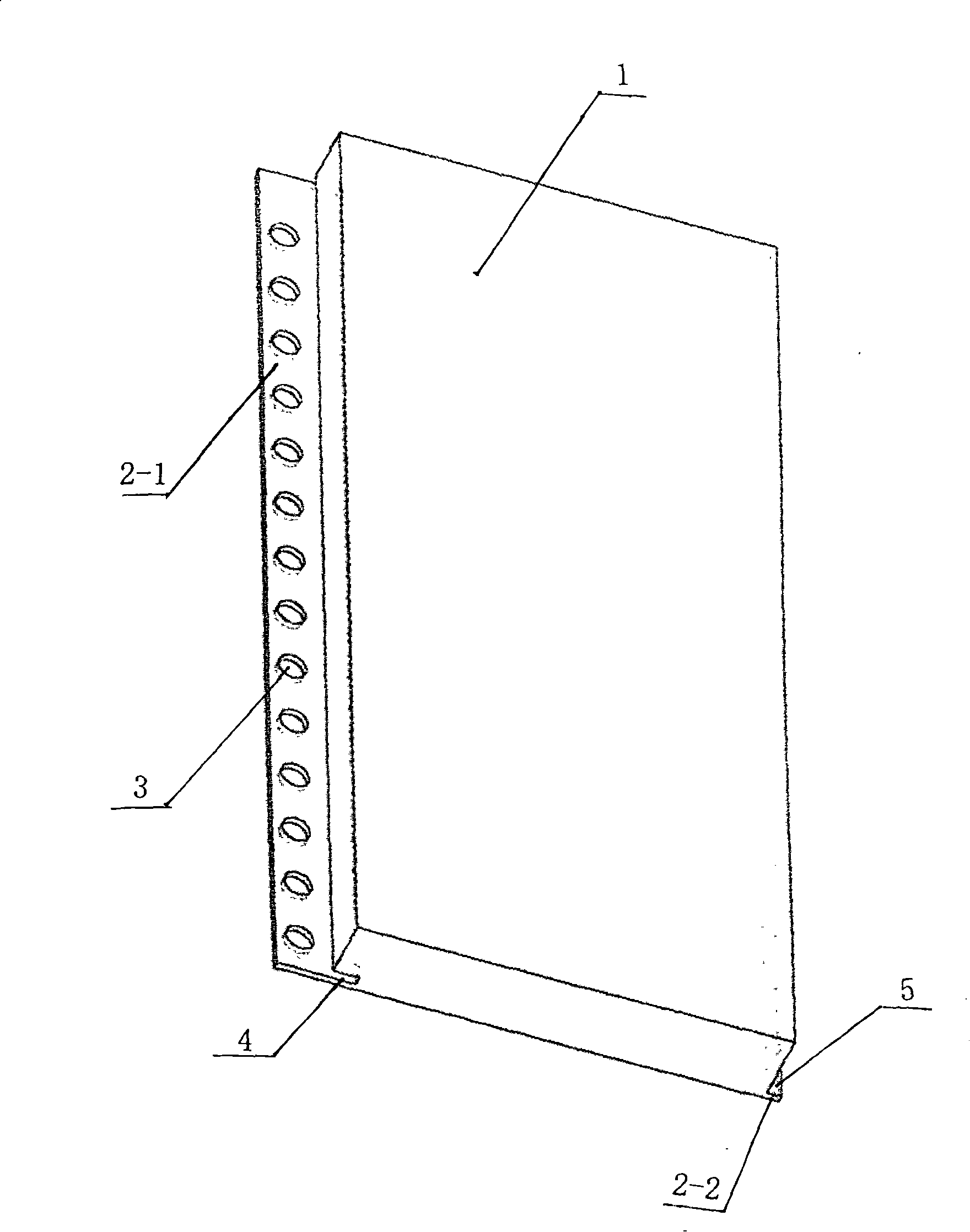

[0024] The invention can quickly assemble dry-hanging ultra-thin stone slabs. Since the stone slab body and the angle steel bars solidified together with the stone slab and the cured product are composed, the production method includes the following steps:

[0025] 1. Prepare the stone plate to be cut, with a thickness of 2.1cm and a length of 100cm;

[0026] 2. Set grooves at the upper and lower left and right edges of the stone plate to be cut;

[0027] 3. Prepare stainless steel angle steel strips 2-1 and 2-2. The rectangular surfaces of the two angle steels are uniformly wide and narrow, and through holes 3 are arranged on the two rectangular surfaces, wherein the narrow rectangular surfaces of 2-2 are embedded in the groove of the stone plate After the middle, the other right-angled surface is flat with the surface of the stone slab, and the edge exceeds the edge of the stone slab to form a male tenon 5. After the narrow side of the stainless steel angle steel bar 2-1 is ...

Embodiment 2

[0033] On the left and right sides of the back side of the stone slab body 1, three sections of stainless steel angle steel bars are arranged at intervals, each length is 15 cm, and the rest are the same as in Embodiment 1. This embodiment can save stainless steel materials and reduce costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com