Patents

Literature

430 results about "Single crystal diamond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

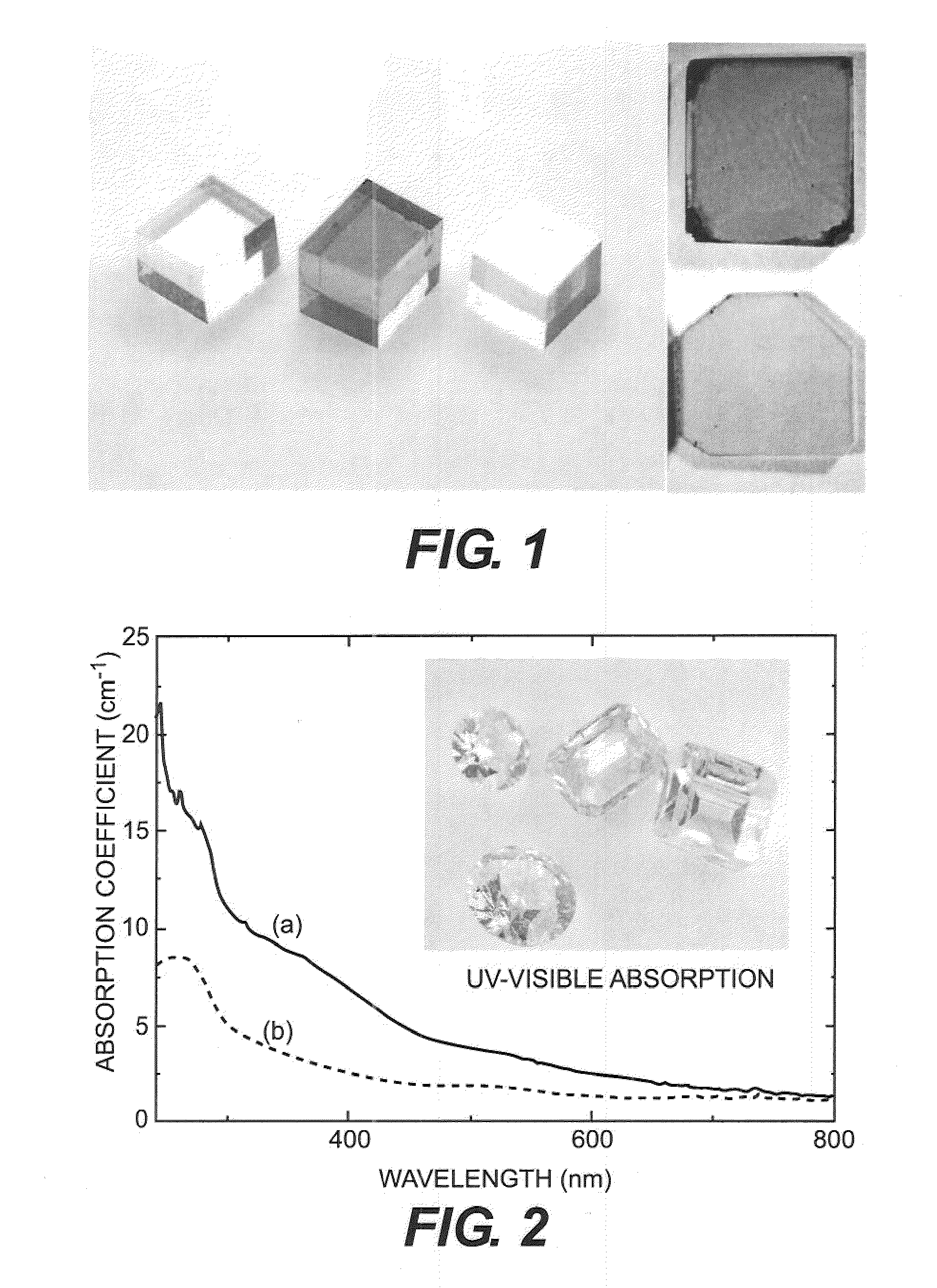

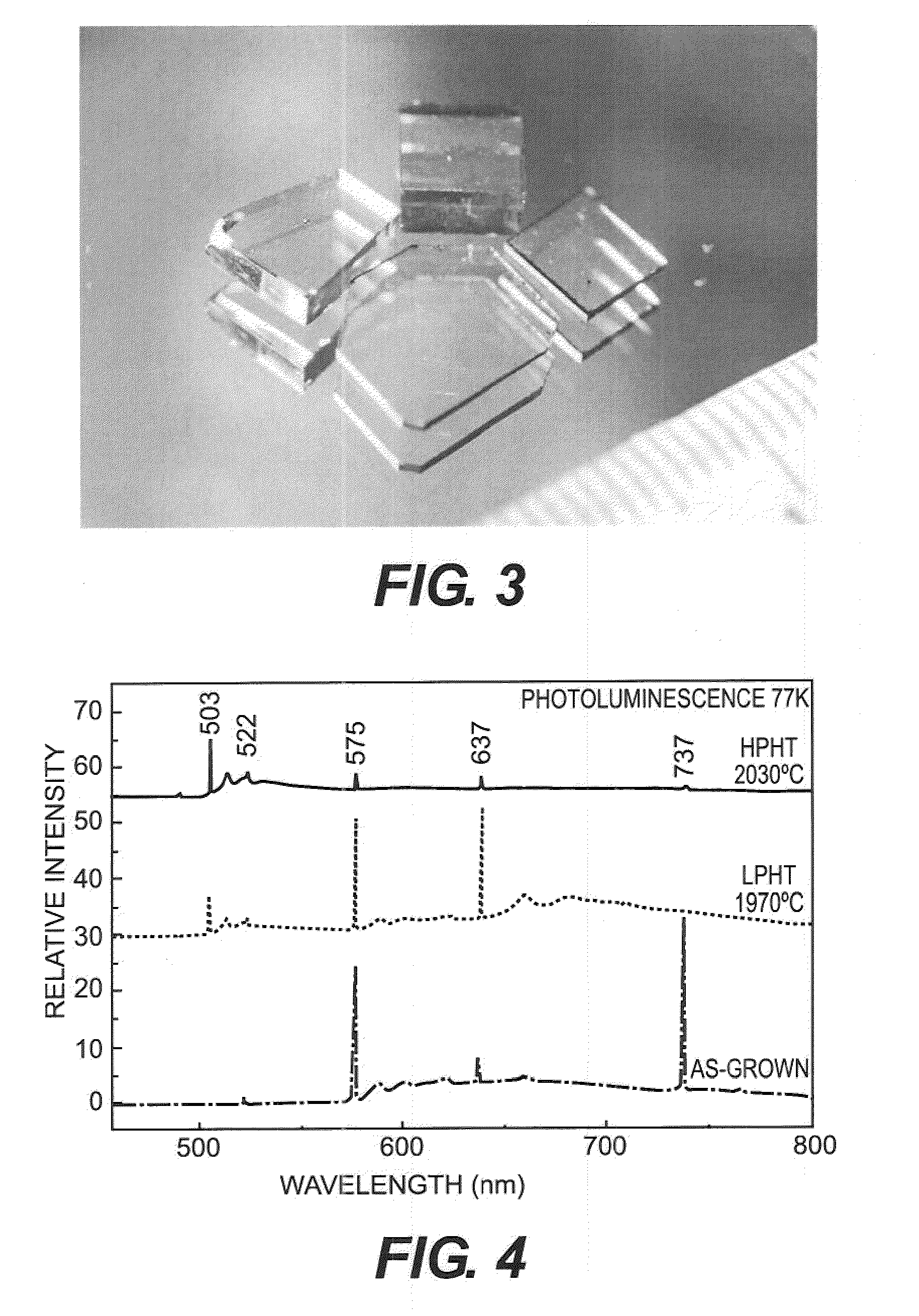

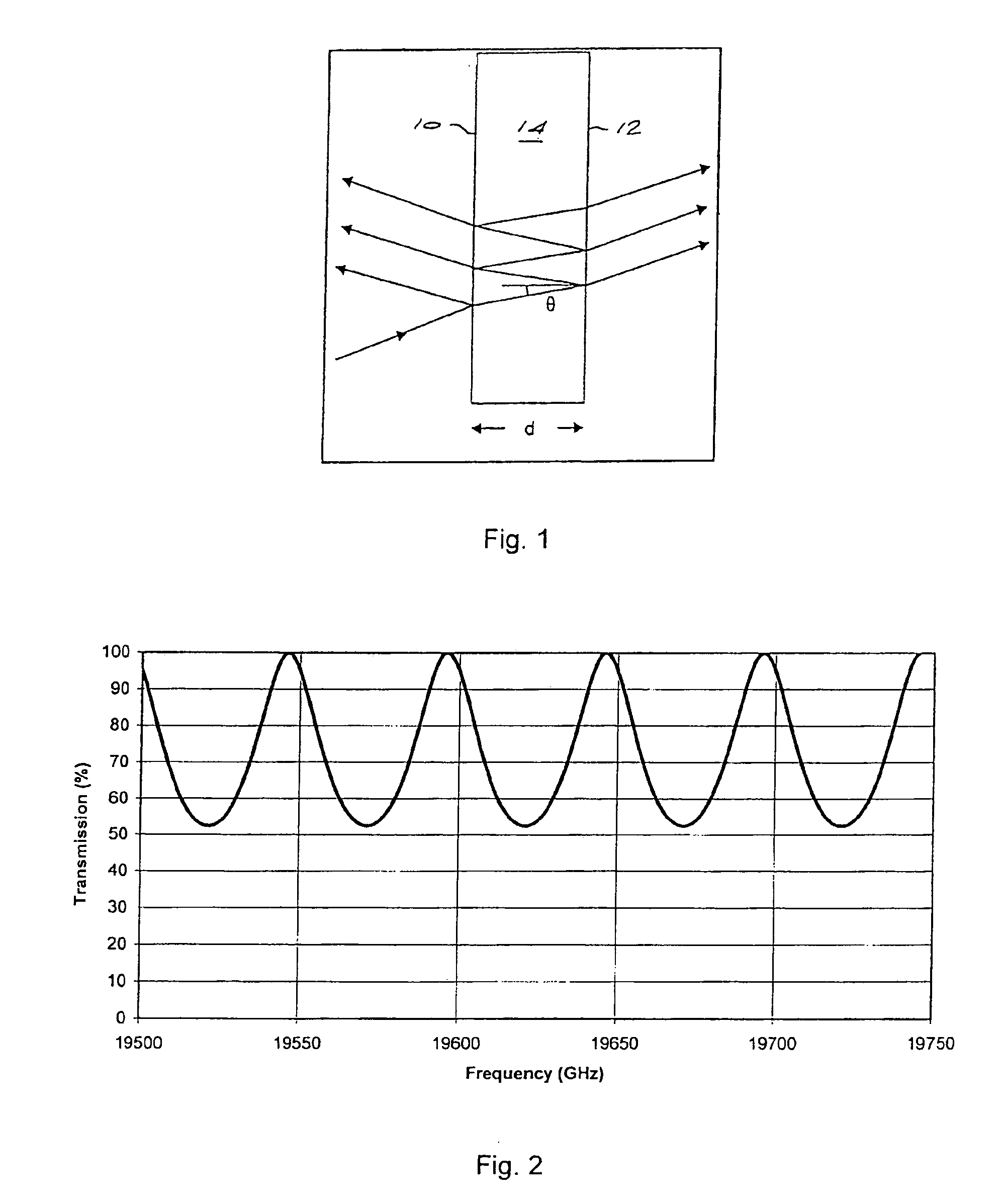

Enhanced Optical Properties of Chemical Vapor Deposited Single Crystal Diamond by Low-Pressure/High-Temperature Annealing

InactiveUS20100104494A1Good optical performanceIncrease probabilityPolycrystalline material growthCyanogen compoundsOptical propertyGas phase

The method of improving the optical properties of single crystal CVD diamond which comprises annealing the crystals at a temperature of up to 2200° C. and a pressure below 300 torr.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

Optical quality diamond material

ActiveUS7740824B2Prevent or reduce local strain generating defectsPrevent and reduce absorptionPolycrystalline material growthAfter-treatment detailsOptical reflectionGrating

Owner:ELEMENT SIX TECH LTD

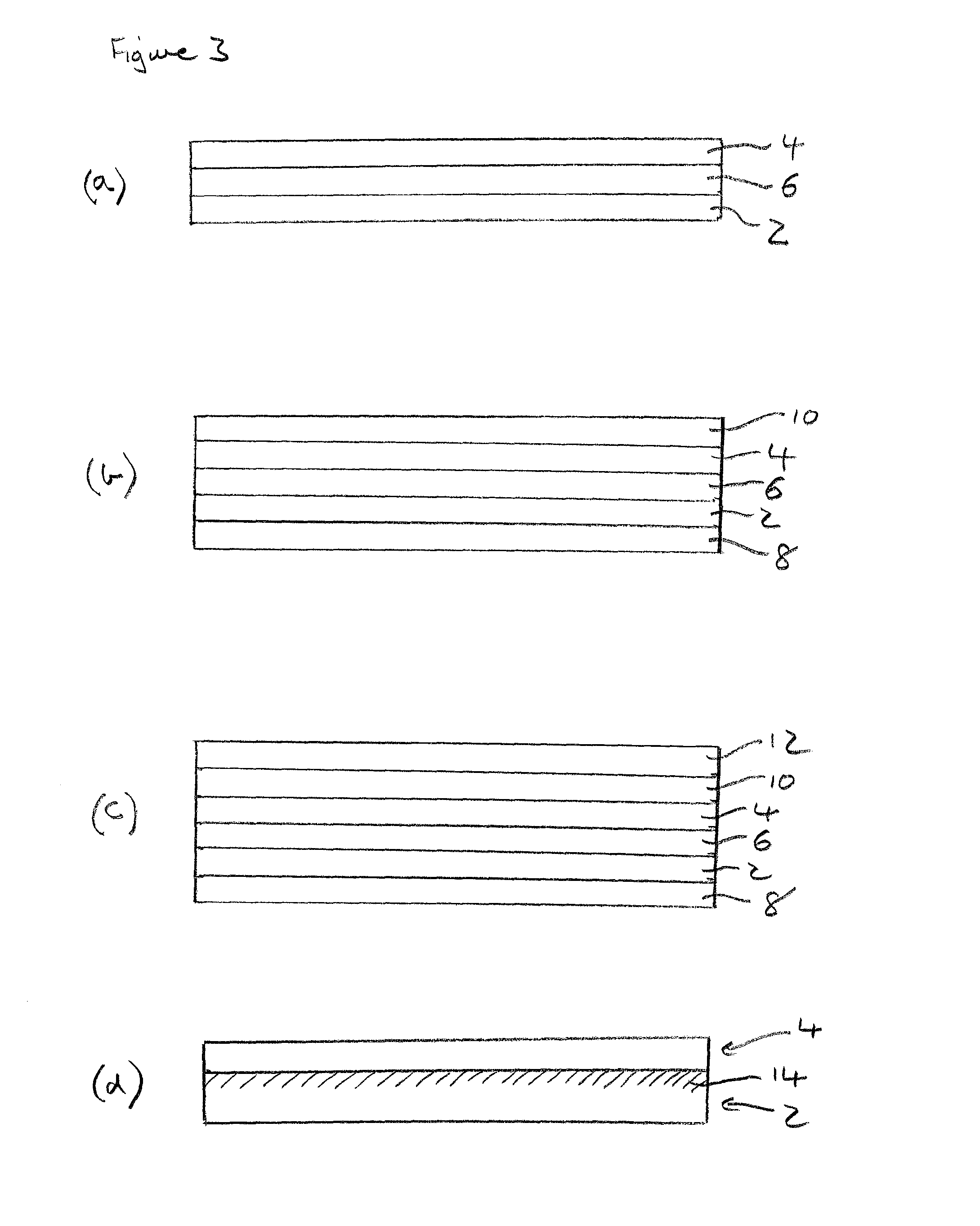

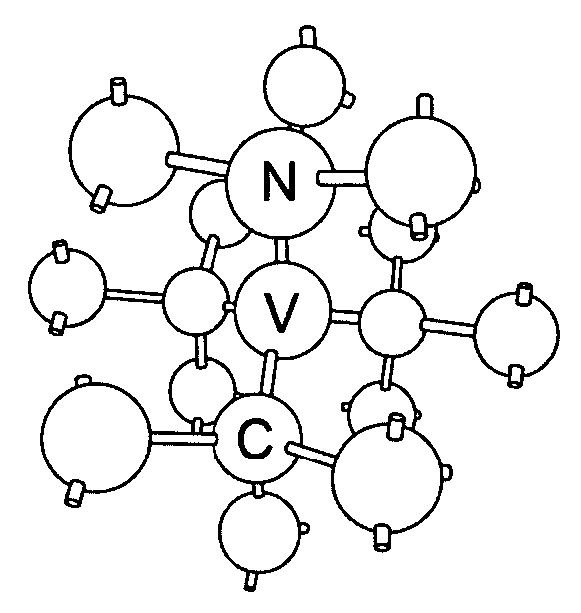

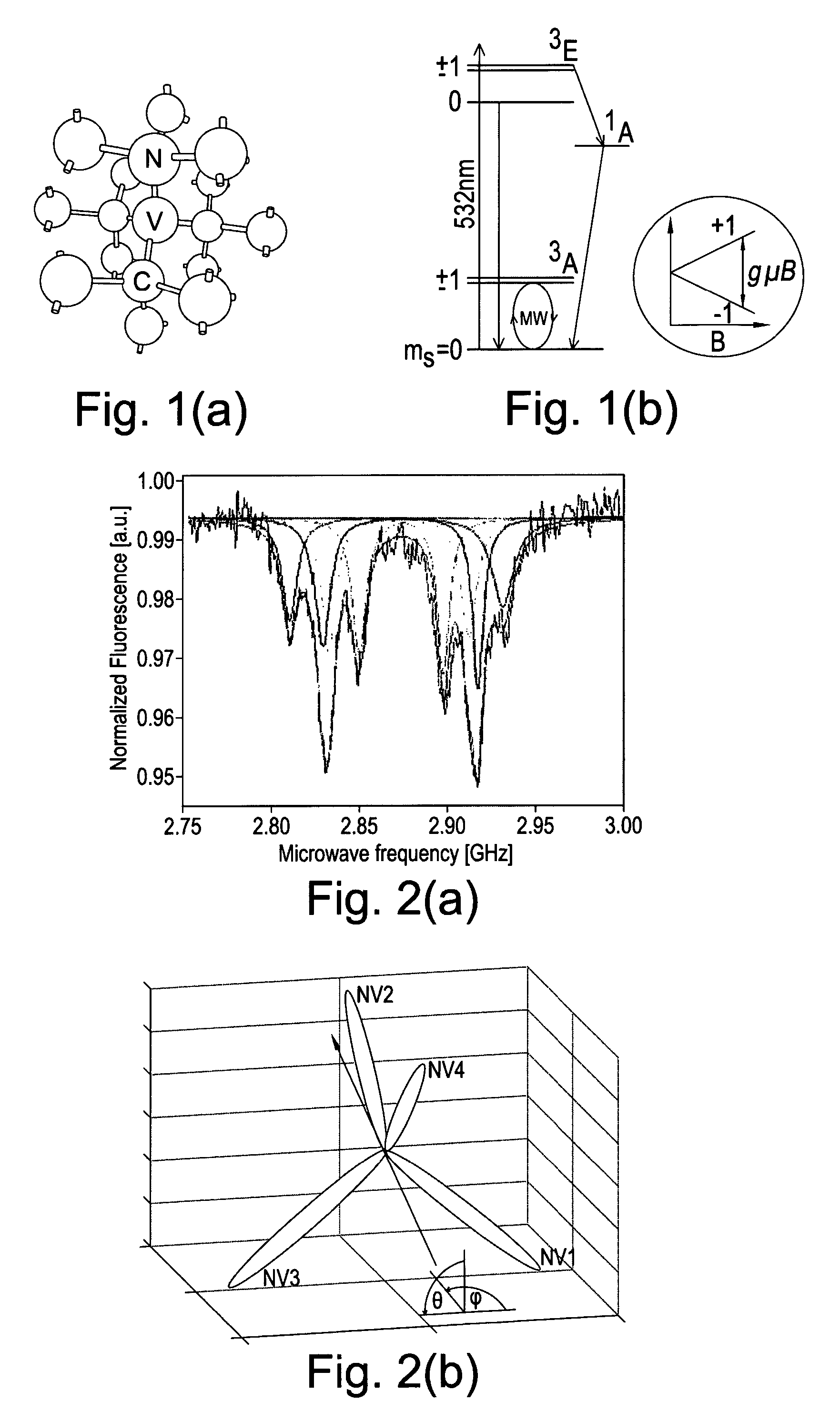

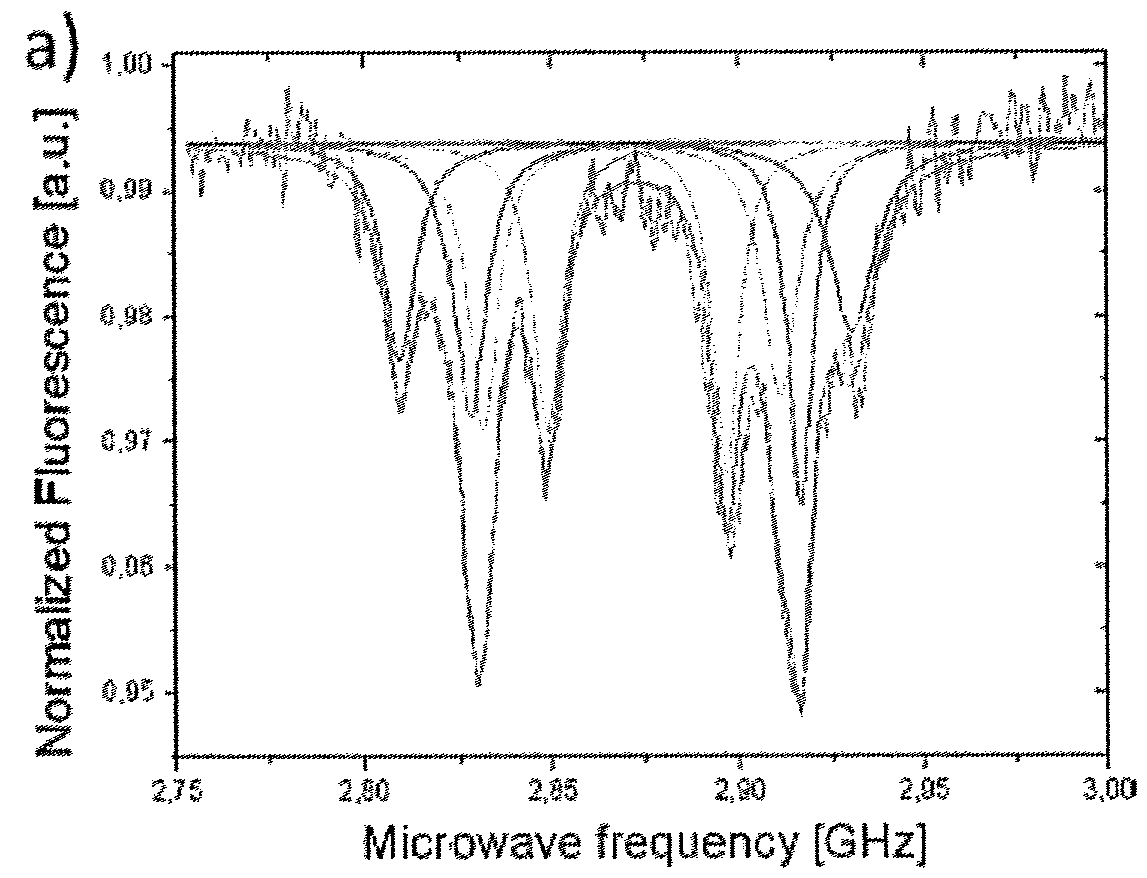

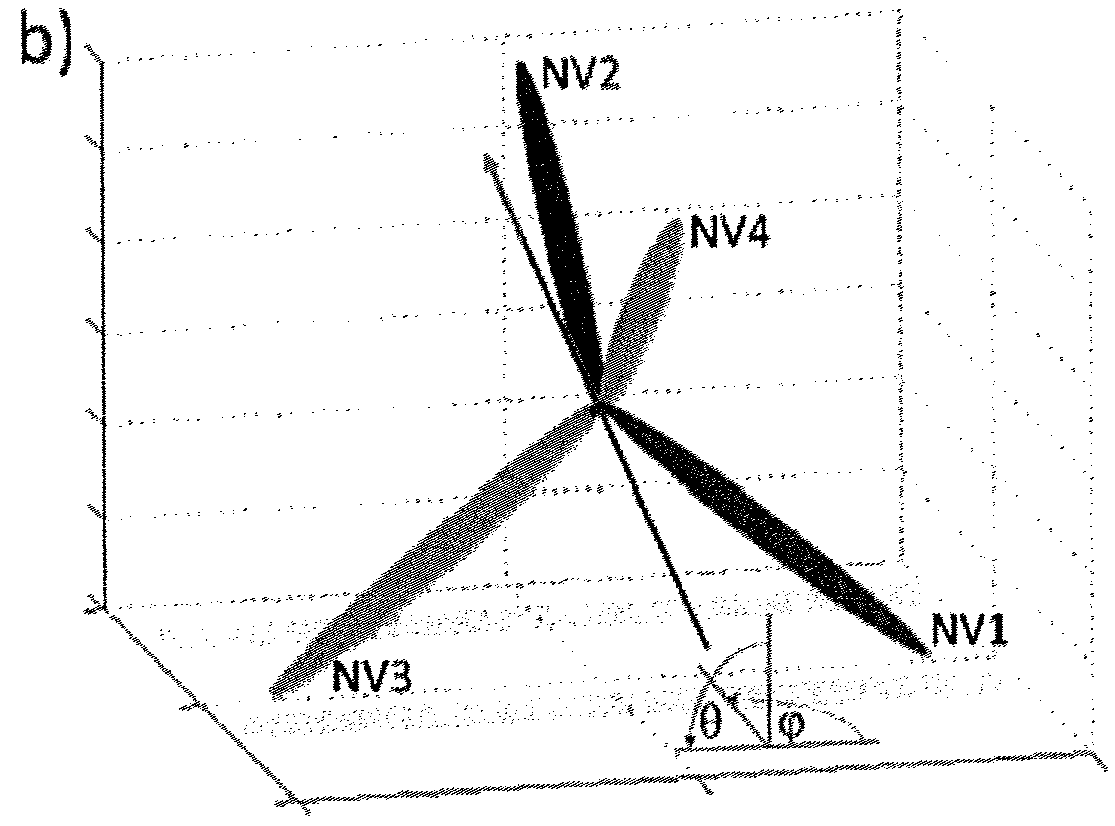

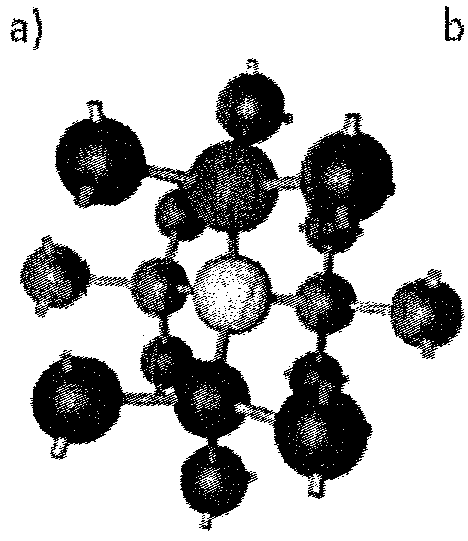

Diamond sensors, detectors, and quantum devices

ActiveUS20140037932A1High purityMinimizes strainQuantum computersPolycrystalline material growthElectron donorQuantum devices

A synthetic single crystal diamond material comprising: a first region of synthetic single crystal diamond material comprising a plurality of electron donor defects; a second region of synthetic single crystal diamond material comprising a plurality of quantum spin defects; and a third region of synthetic single crystal diamond material disposed between the first and second regions such that the first and second regions are spaced apart by the third region, wherein the second and third regions of synthetic single crystal diamond material have a lower concentration of electron donor defects than the first region of synthetic single crystal diamond material, and wherein the first and second regions are spaced apart by a distance in a range 10 nm to 100 μm which is sufficiently close to allow electrons to be donated from the first region of synthetic single crystal diamond material to the second region of synthetic single crystal diamond material thus forming negatively charged quantum spin defects in the second region of synthetic single crystal diamond material and positively charged defects in the first region of synthetic single crystal diamond material while being sufficiently far apart to reduce other coupling interactions between the first and second regions which would otherwise unduly reduce the decoherence time of the plurality of quantum spin defects and / or produce strain broaden of a spectral line width of the plurality of quantum spin defects in the second region of synthetic single crystal diamond material.

Owner:ELEMENT SIX LTD

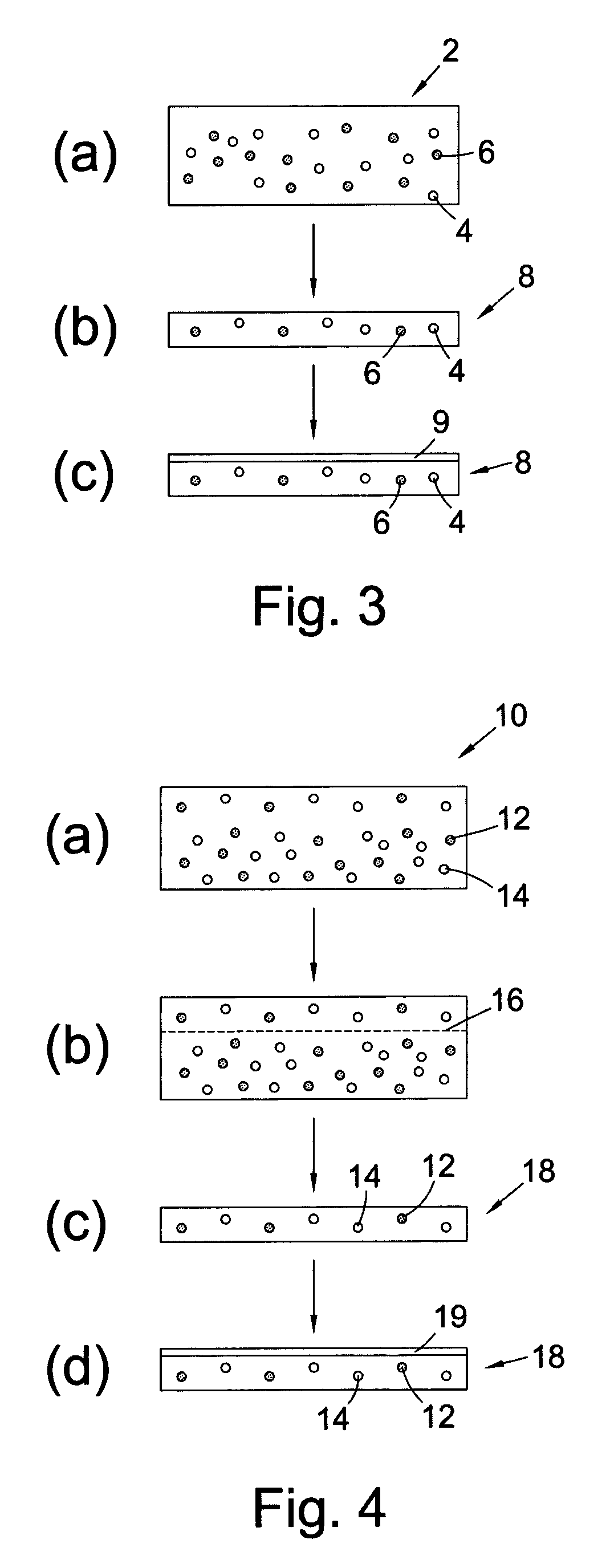

Diamond sensors, detectors, and quantum devices

ActiveUS8758509B2Improve excitation efficiencyIncrease the number ofUltra-high pressure processesNanoinformaticsBillionthSpins

A thin plate of synthetic single crystal diamond material, the thin plate of synthetic single crystal diamond material having: a thickness in a range 100 nm to 50 μιη; a concentration of quantum spin defects greater than 0.1 ppb (parts-per-billion); a concentration of point defects other than the quantum spin defects of below 200 ppm (parts-per-million); and wherein at least one major face of the thin plate of synthetic single crystal diamond material comprises surface termination species which have zero nuclear spin and / or zero electron spin.

Owner:ELEMENT SIX LTD

Diamond optical element

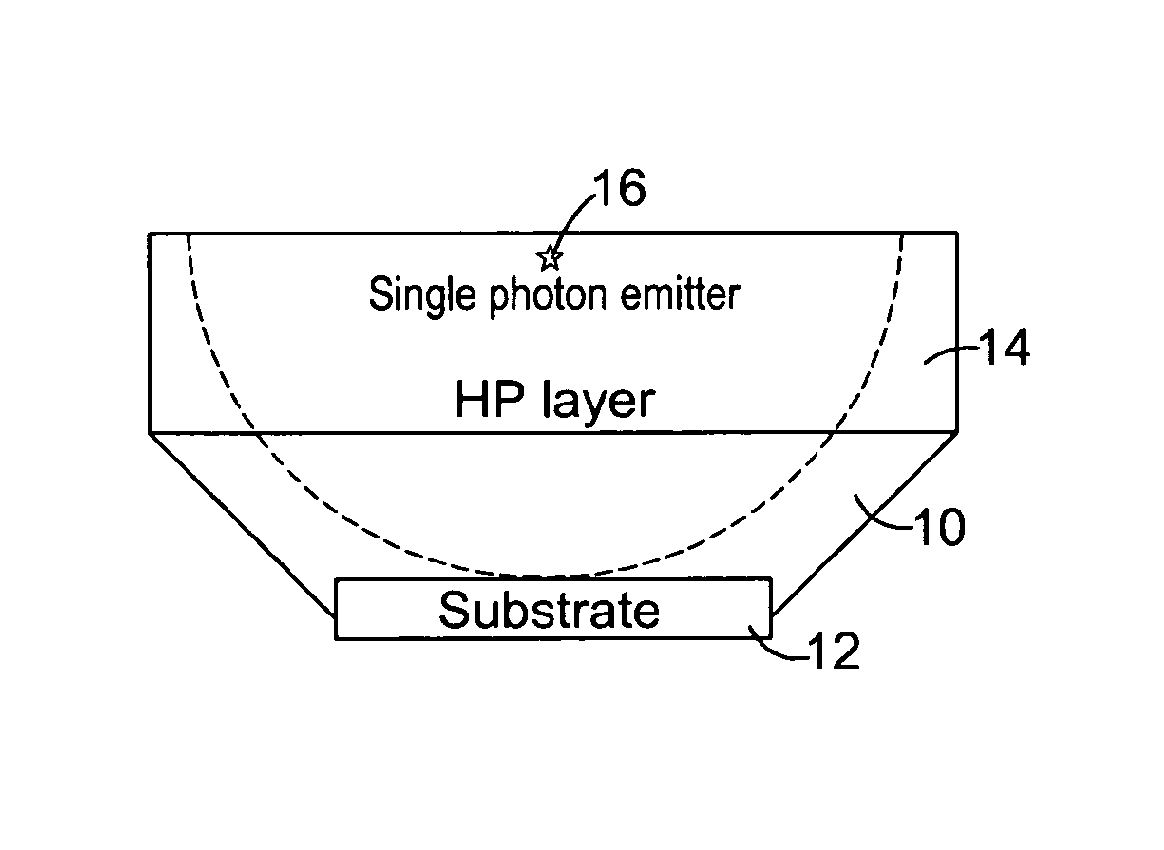

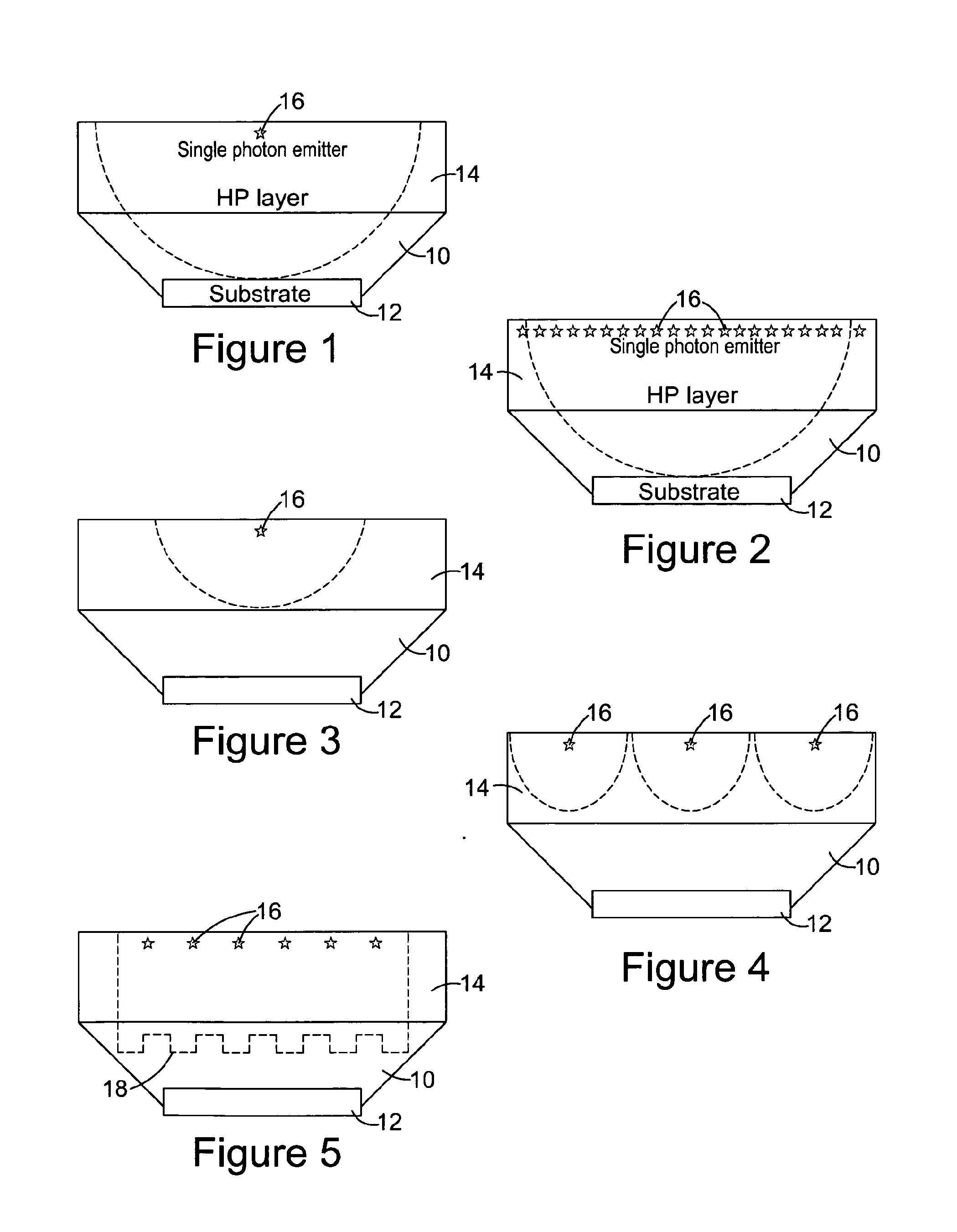

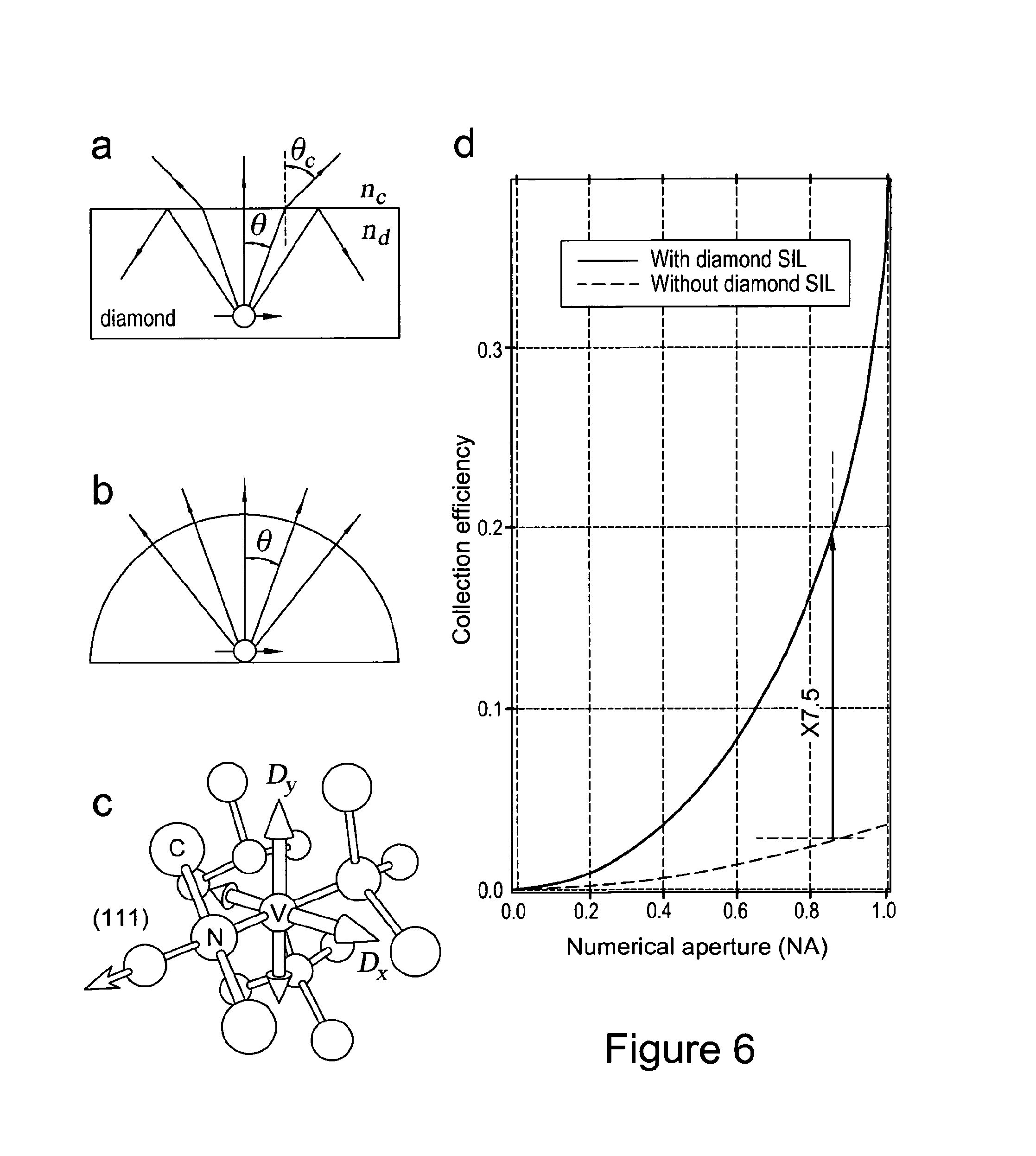

ActiveUS20130270991A1Improve light outcoupling efficiencyGas discharge lampsRecord information storageCouplingGas phase

A method of manufacturing an optical element, the method comprising: growing a first layer of single crystal diamond material via a chemical vapour deposition technique using a gas phase having a first nitrogen concentration; growing a second layer of single crystal diamond material over said first layer via a chemical vapour deposition technique using a gas phase having a second nitrogen concentration, wherein the second nitrogen concentration is lower than the first nitrogen concentration; forming an optical element from at least a portion of the second layer of single crystal diamond material; and forming an out-coupling structure at a surface of the optical element for increasing out-coupling of light.

Owner:ELEMENT SIX TECH LTD

Diamond sensors, detectors, and quantum devices

ActiveUS9249526B2Minimizes strainShorten the timeQuantum computersPolycrystalline material growthElectron donorQuantum devices

A synthetic single crystal diamond material comprising: a first region comprising electron donor defects; a second region comprising quantum spin defects; and a third region between the first and second regions. The second and third regions have a lower concentration of electron donor defects than the first region. The first and second regions are sufficiently close to allow electrons to be donated from the first region to the second region, thus forming negatively charged quantum spin defects in the second and positively charged defects in the first region, and sufficiently far apart to reduce other coupling interactions between the first and second regions which would otherwise unduly reduce the decoherence time of the plurality of quantum spin defects and / or produce strain broaden of a spectral line width of the plurality of quantum spin defects in the second region.

Owner:ELEMENT SIX LTD

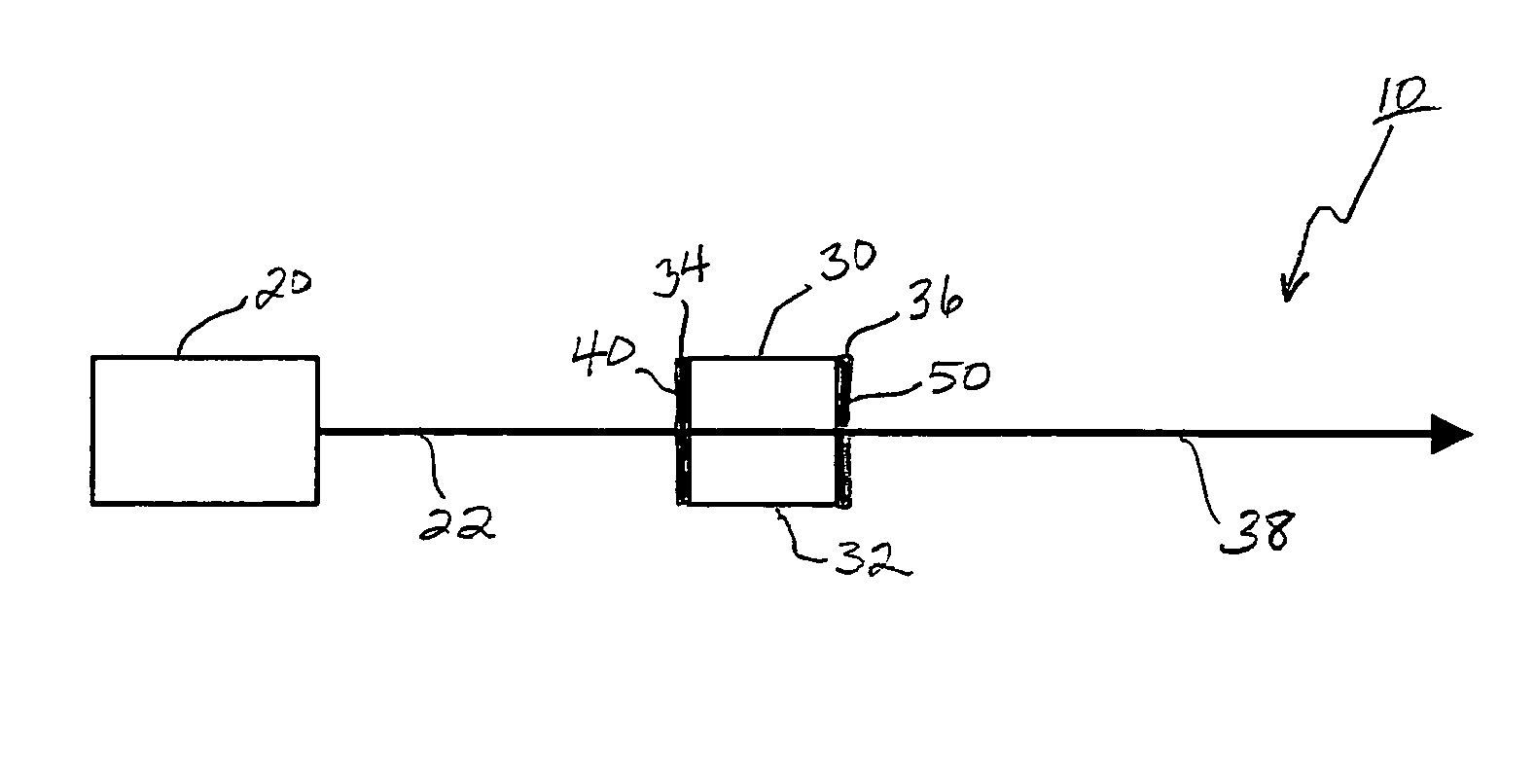

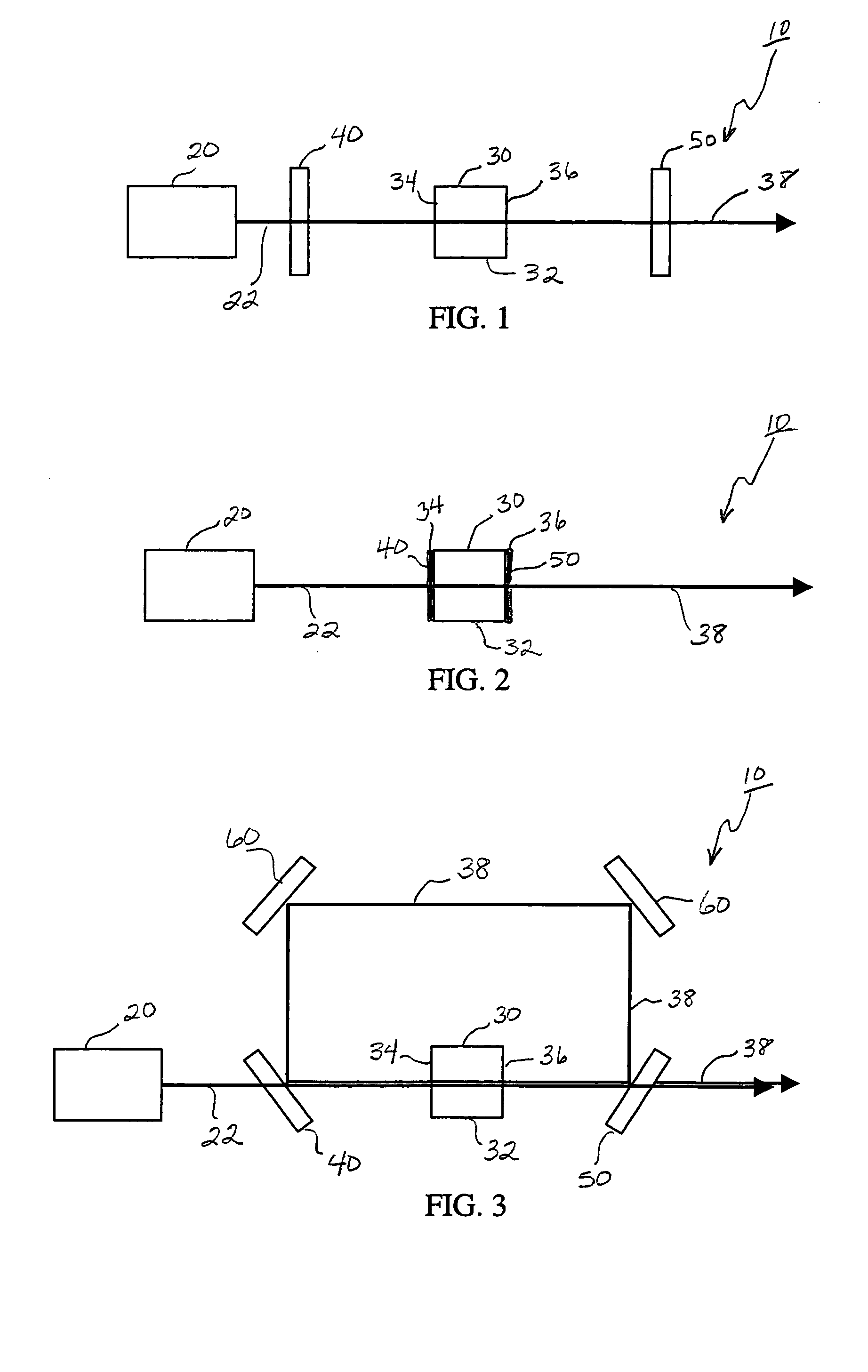

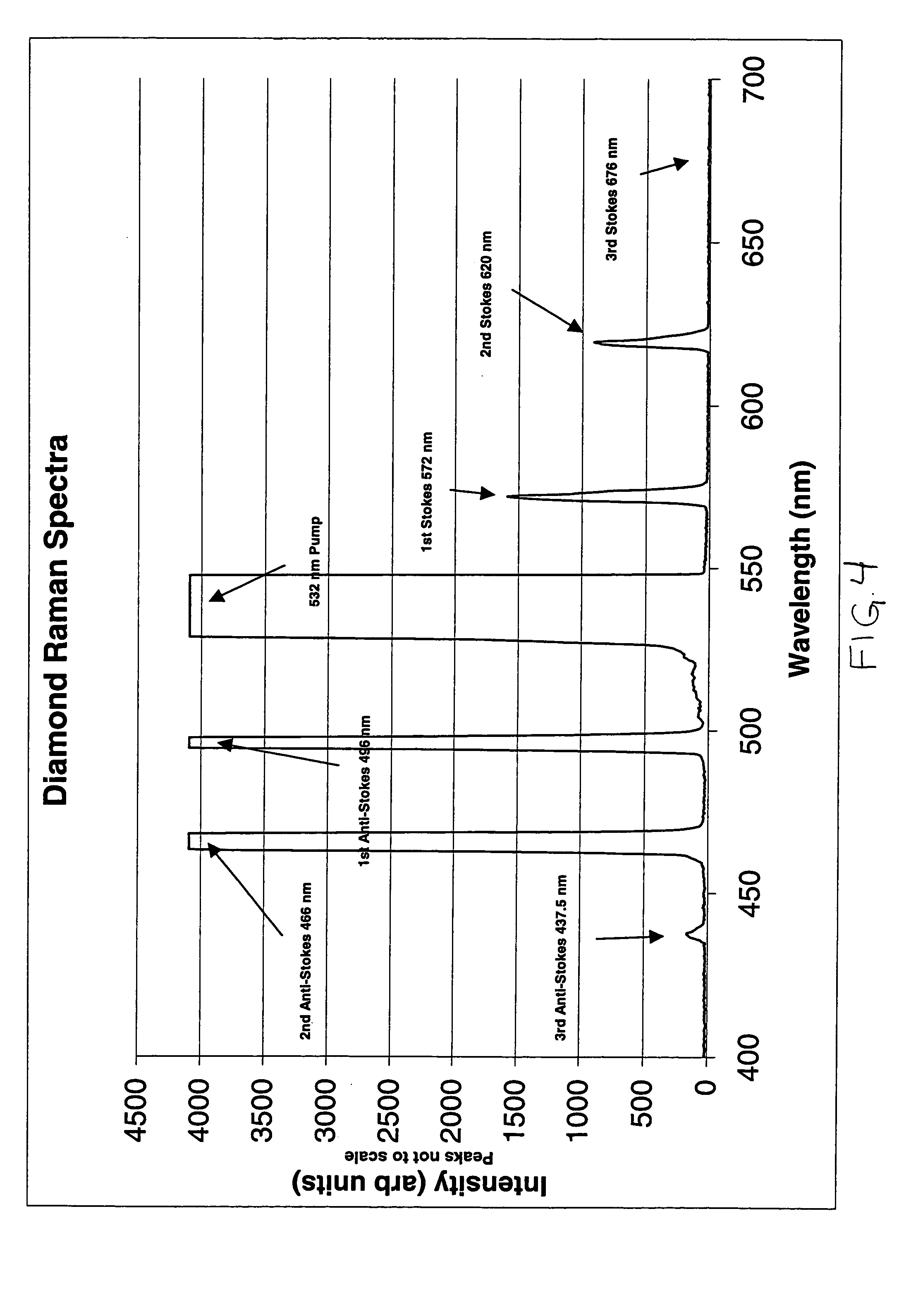

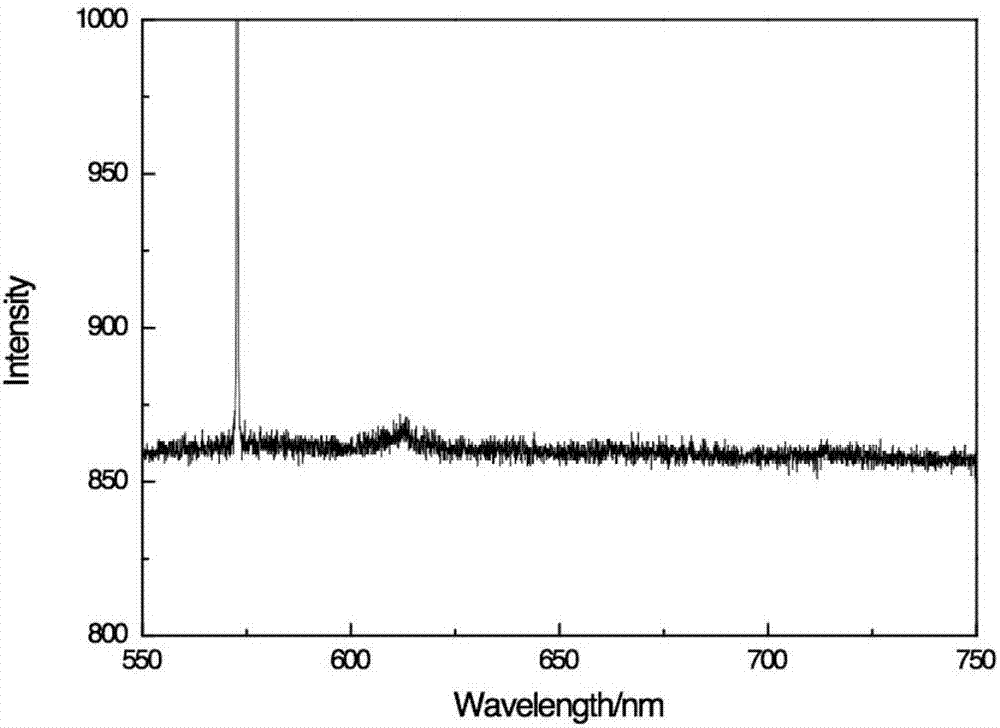

Solid state diamond Raman laser

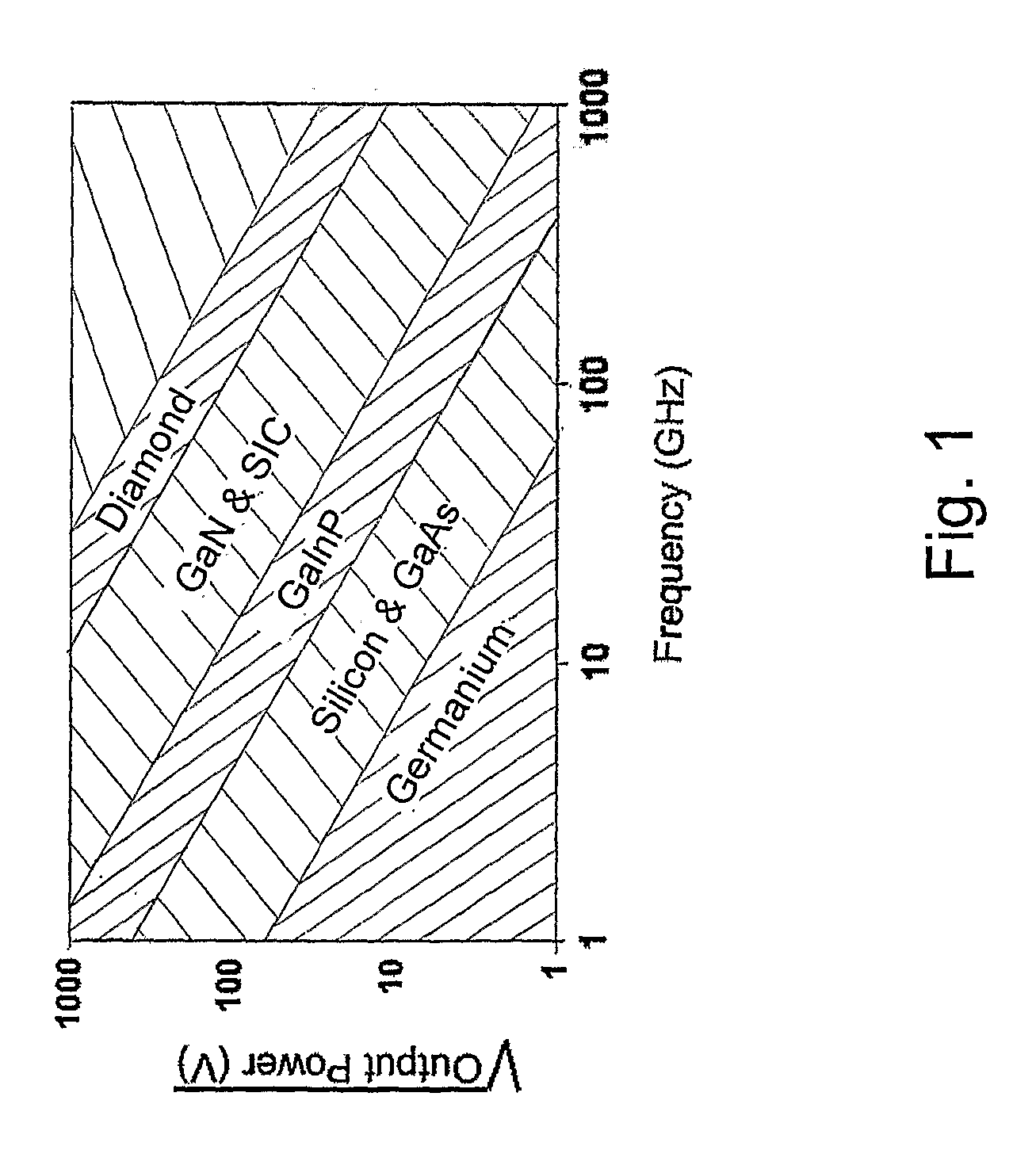

InactiveUS20050163169A1High power applicationLaser using scattering effectsActive medium materialStimulate raman scatteringSingle crystal

A solid state Raman laser includes a laser pump for producing a first radiation at a high power and at a first wavelength along an optical path, a solid Raman active medium in the optical path of the first radiation, the medium including single crystal diamond having a first surface and a second surface, where the first radiation at a high power produces stimulated Raman scattering in the medium and the medium generates a second radiation at a second wavelength, a first optical element in the optical path of the first radiation, wherein the first optical element allows the first wavelength to be transmitted and allows the second wavelength to be reflected, and a second optical element in the optical path of the first radiation, wherein the second optical element allows the first wavelength to be transmitted and allows the second wavelength to be reflected.

Owner:SPECTRA SYST CORP

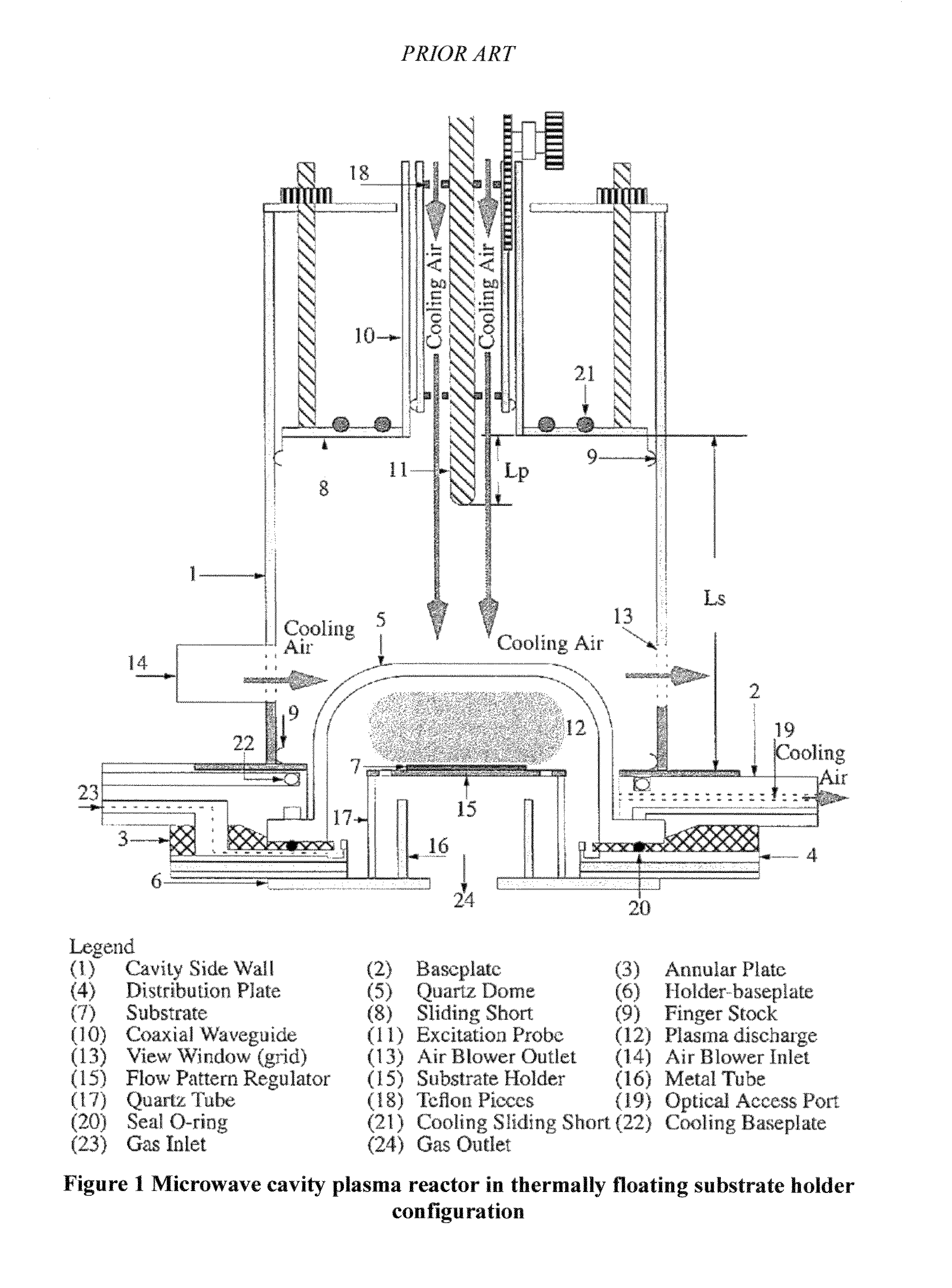

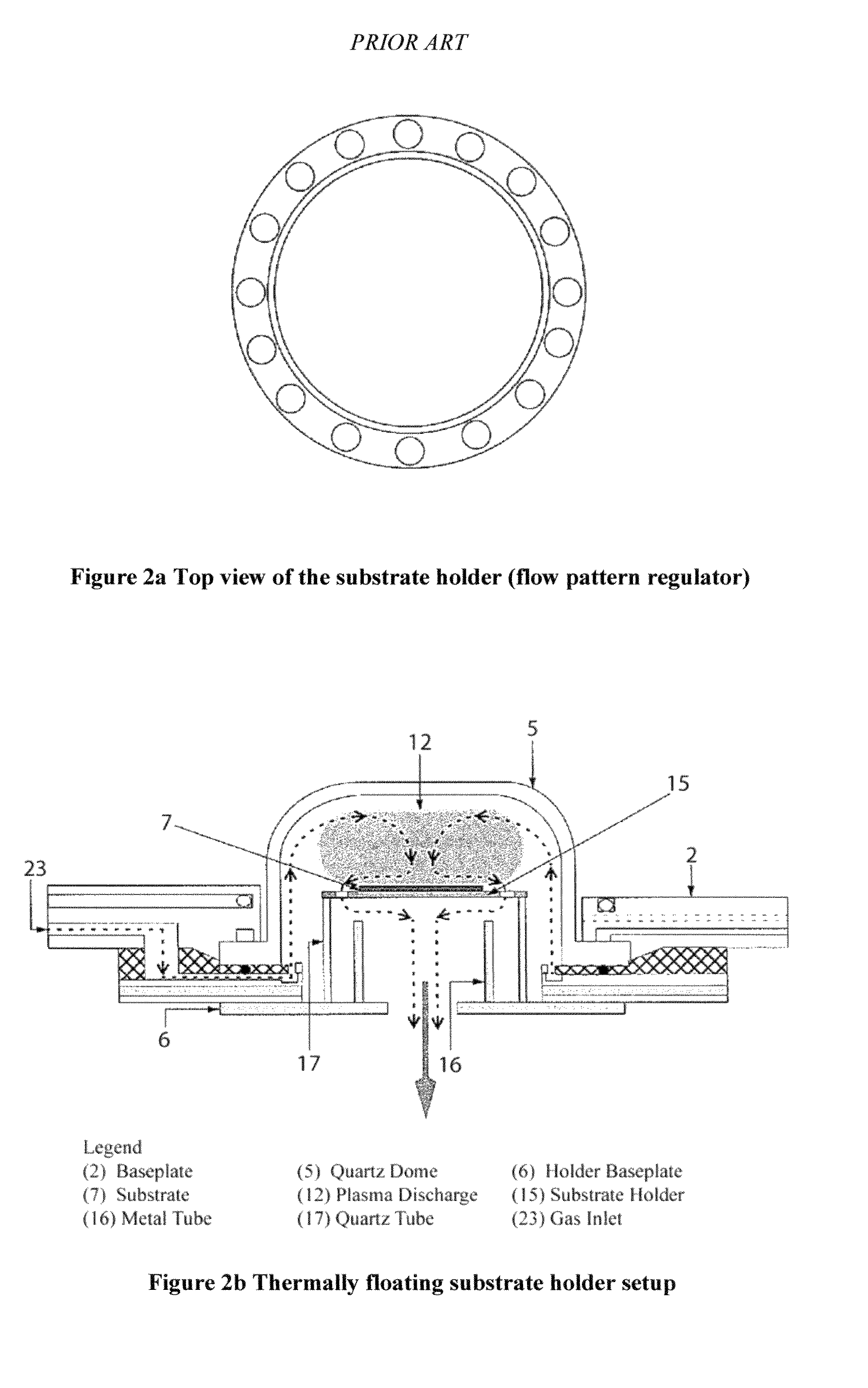

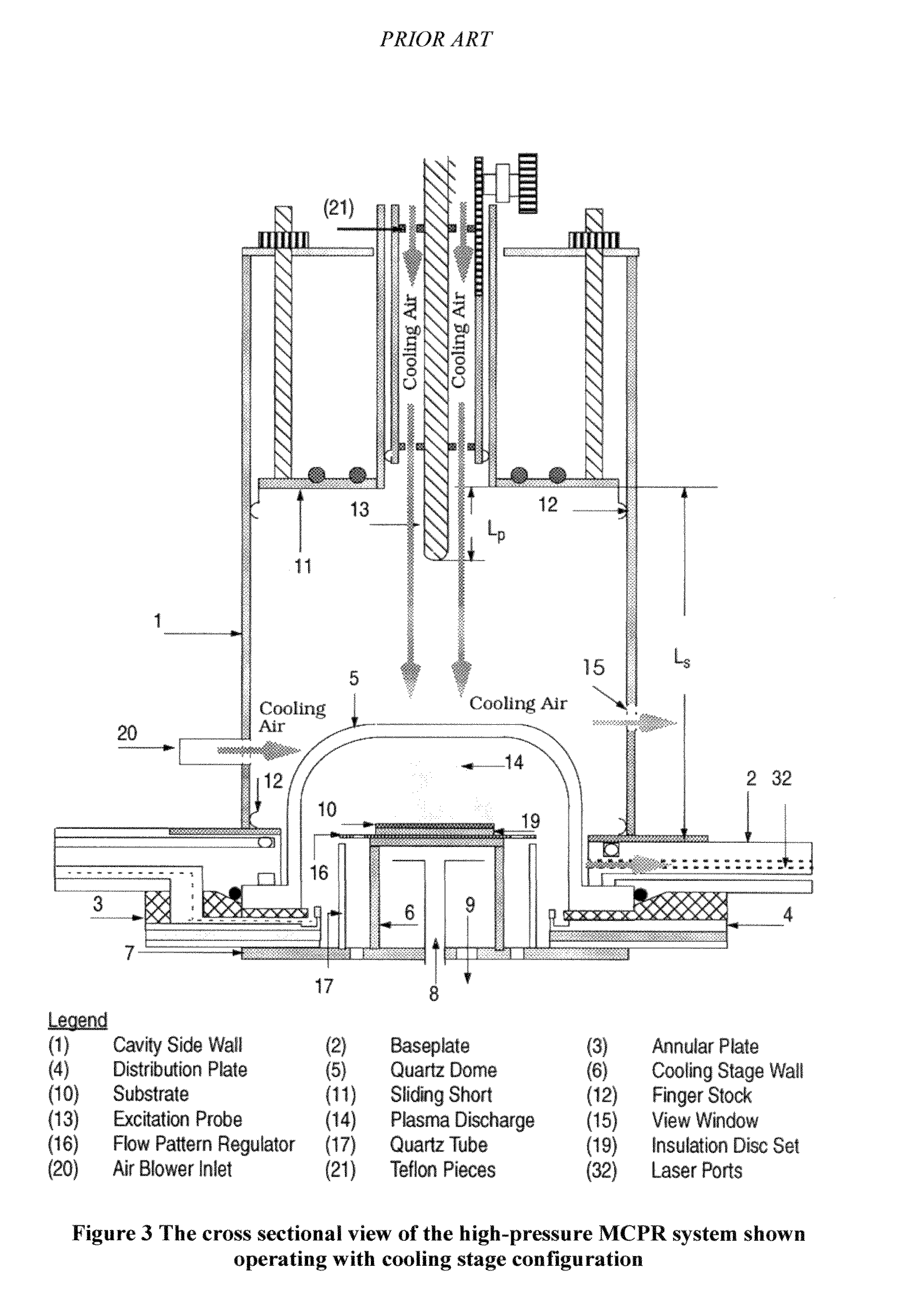

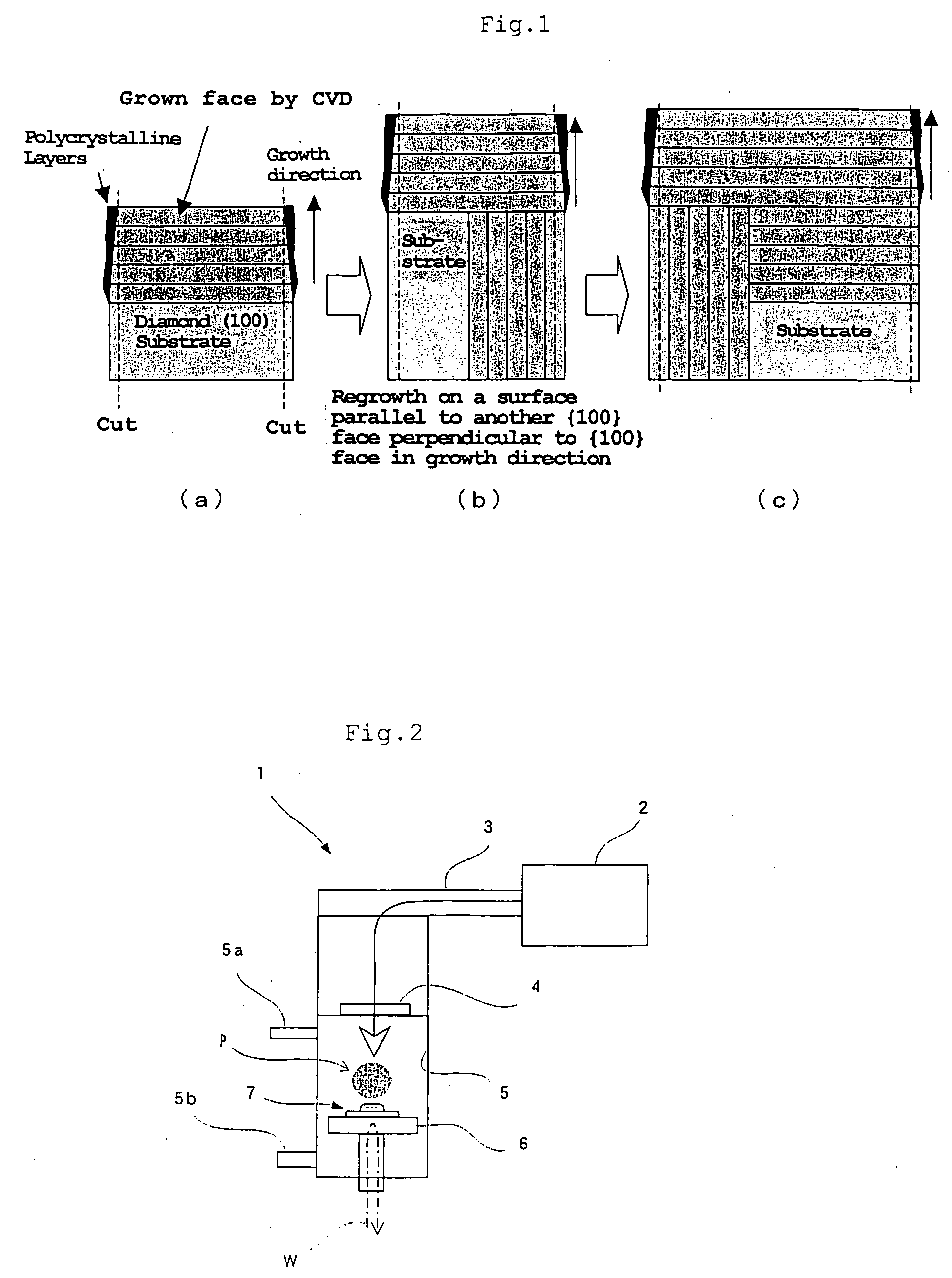

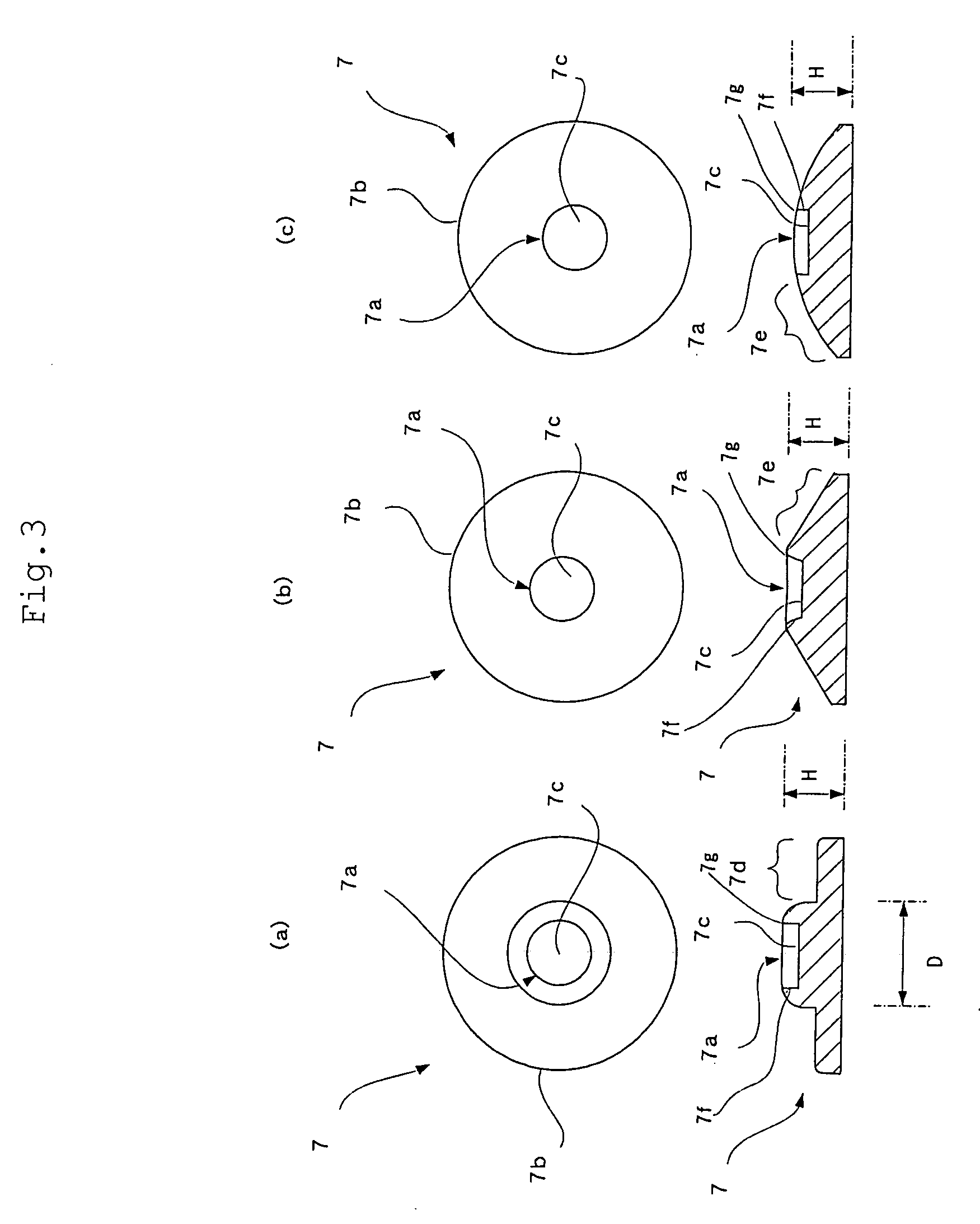

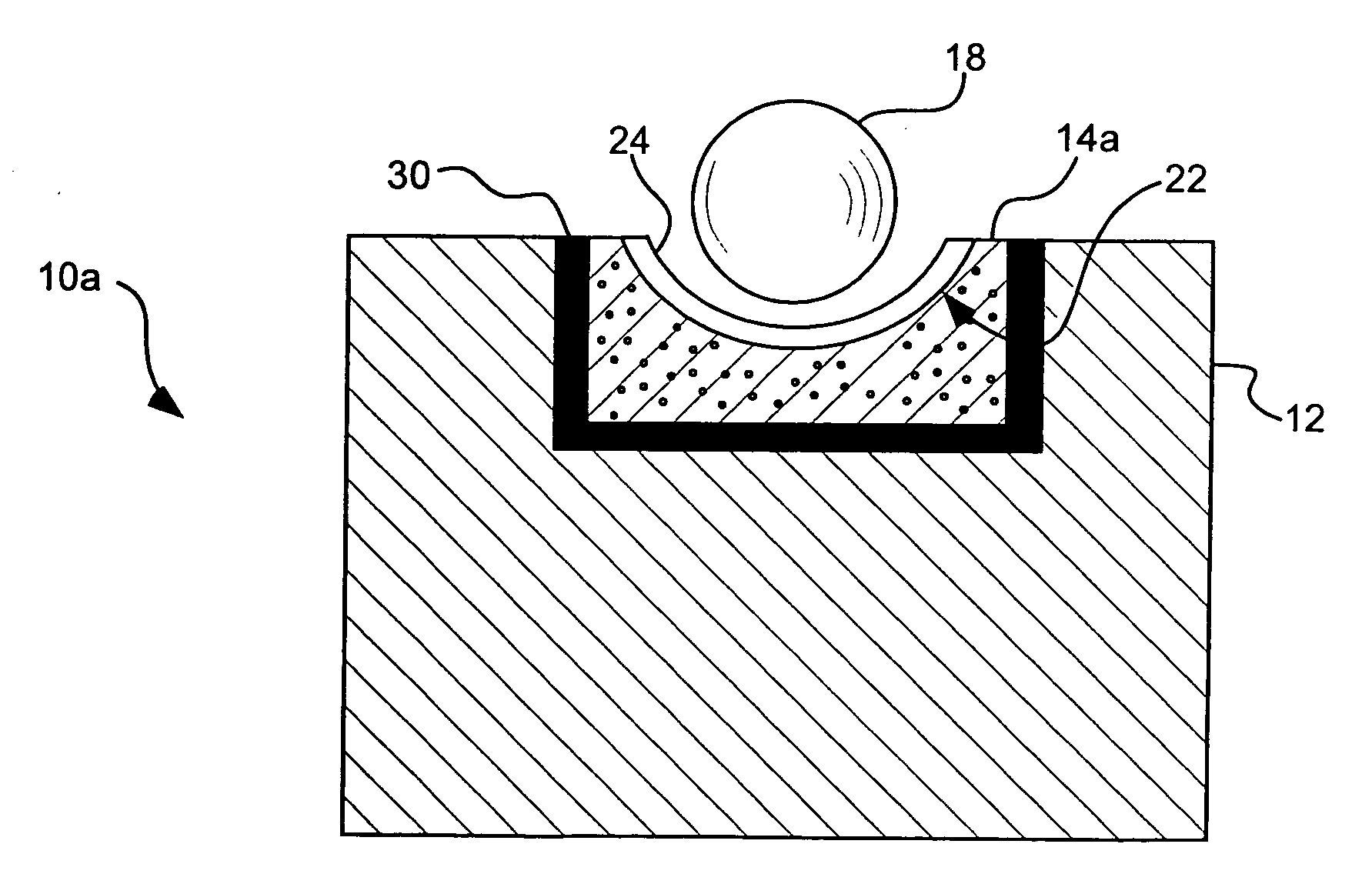

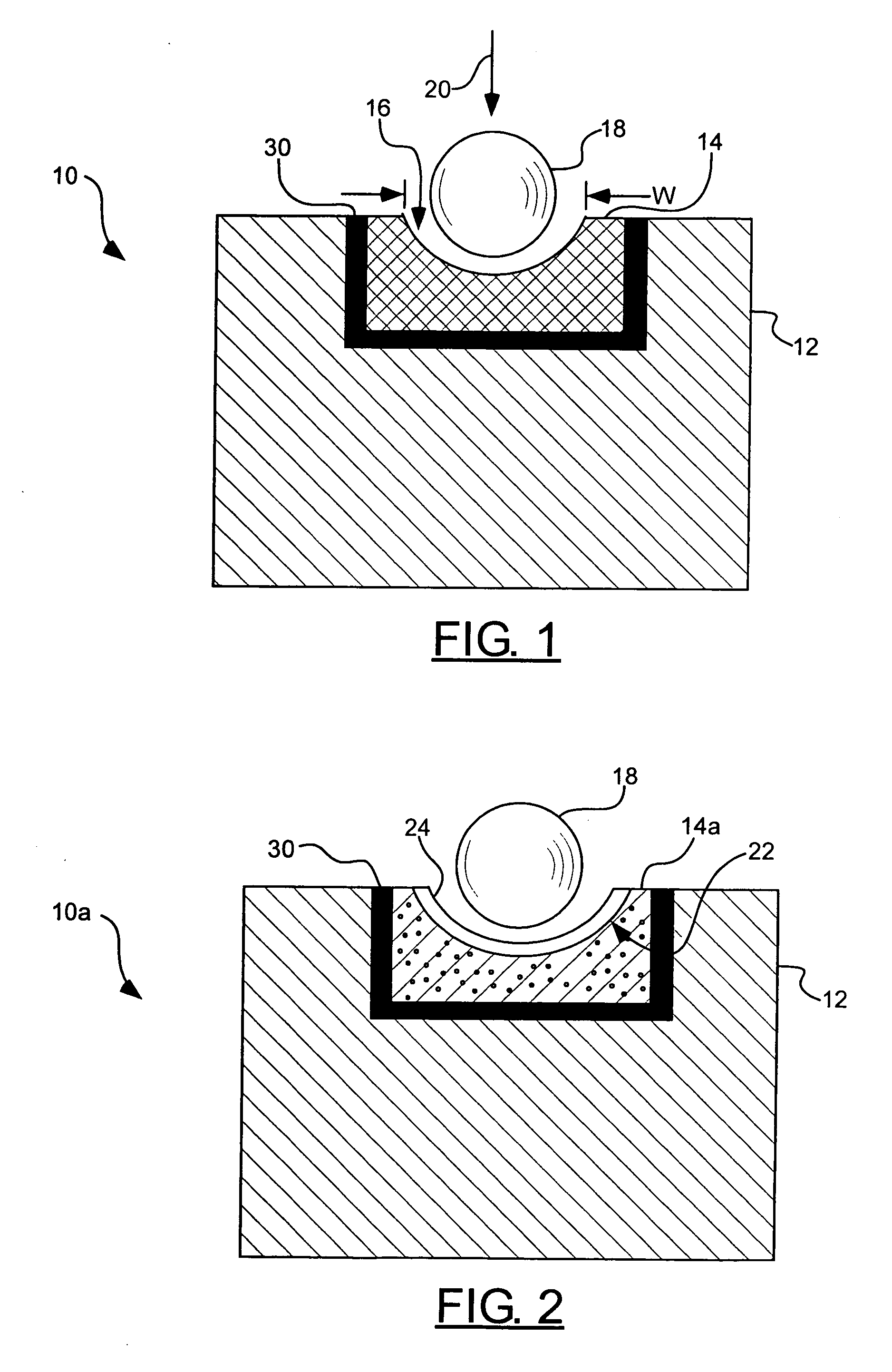

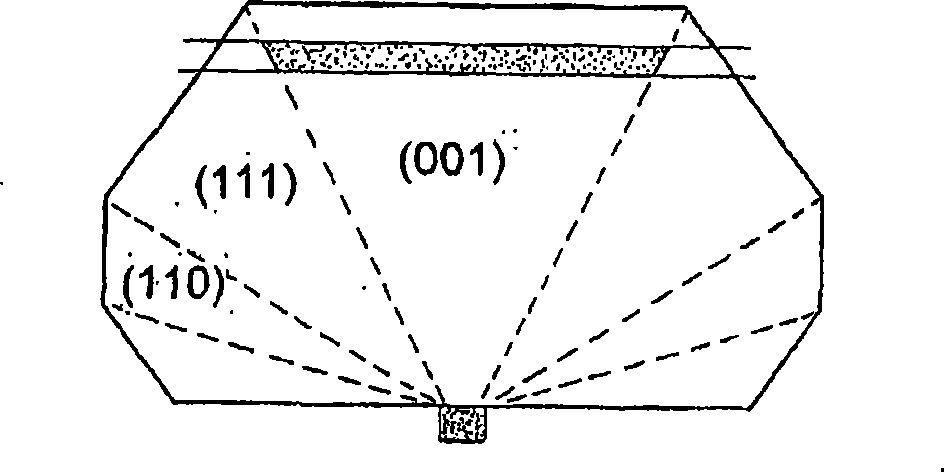

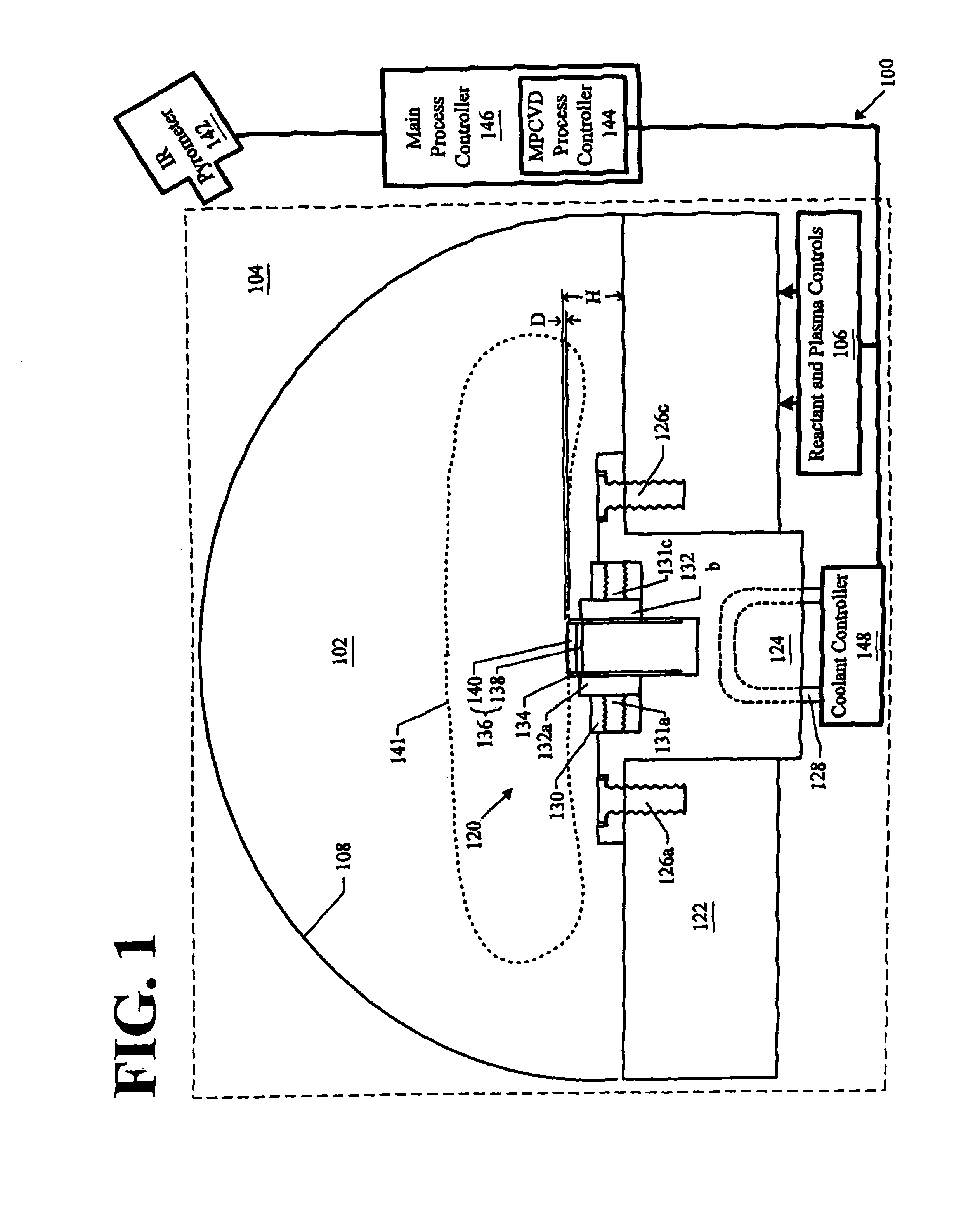

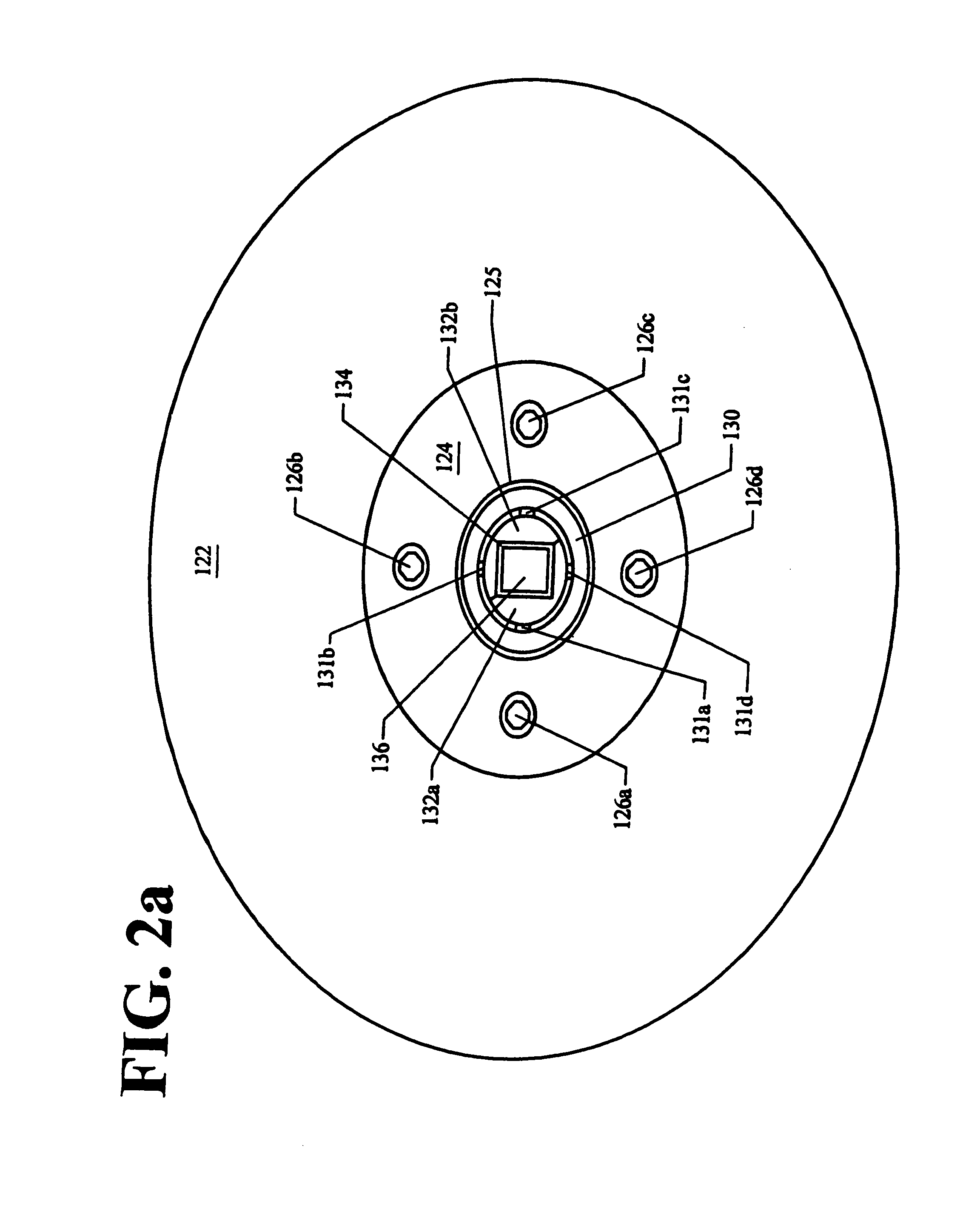

Process and apparatus for diamond synthesis

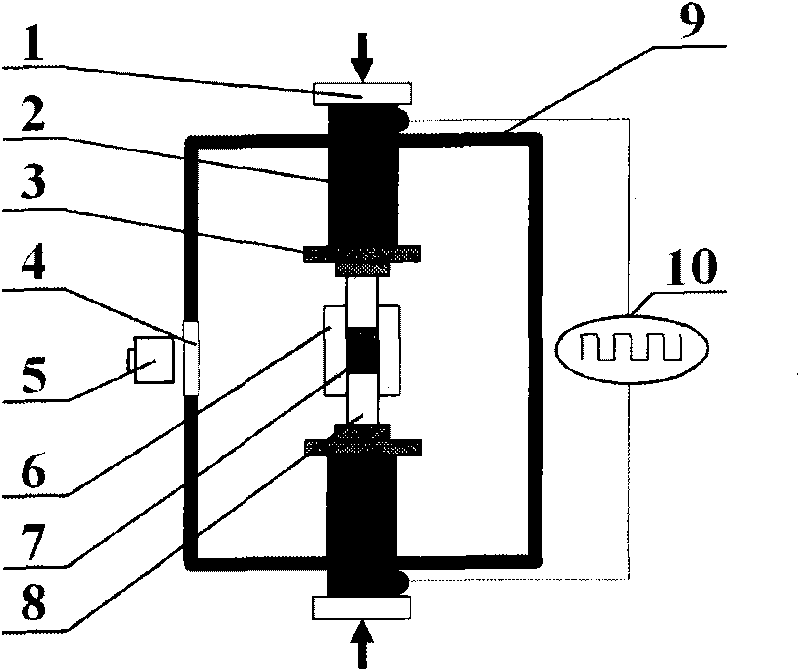

ActiveUS20090239078A1Increasing growth volume spaceIncrease growth volume spacePolycrystalline material growthElectric discharge tubesMicrowavePlasma deposition

The present invention relates to a microwave plasma deposition process and apparatus for producing diamond, preferably as single crystal diamond (SCD). The process and apparatus enables the production of multiple layers of the diamond by the use of an extending device to increase the length and the volume of a recess in a holder containing a SCD substrate as layers of diamond are deposited. The diamond is used for abrasives, cutting tools, gems, electronic substrates, heat sinks, electrochemical electrodes, windows for high power radiation and electron beams, and detectors.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV +1

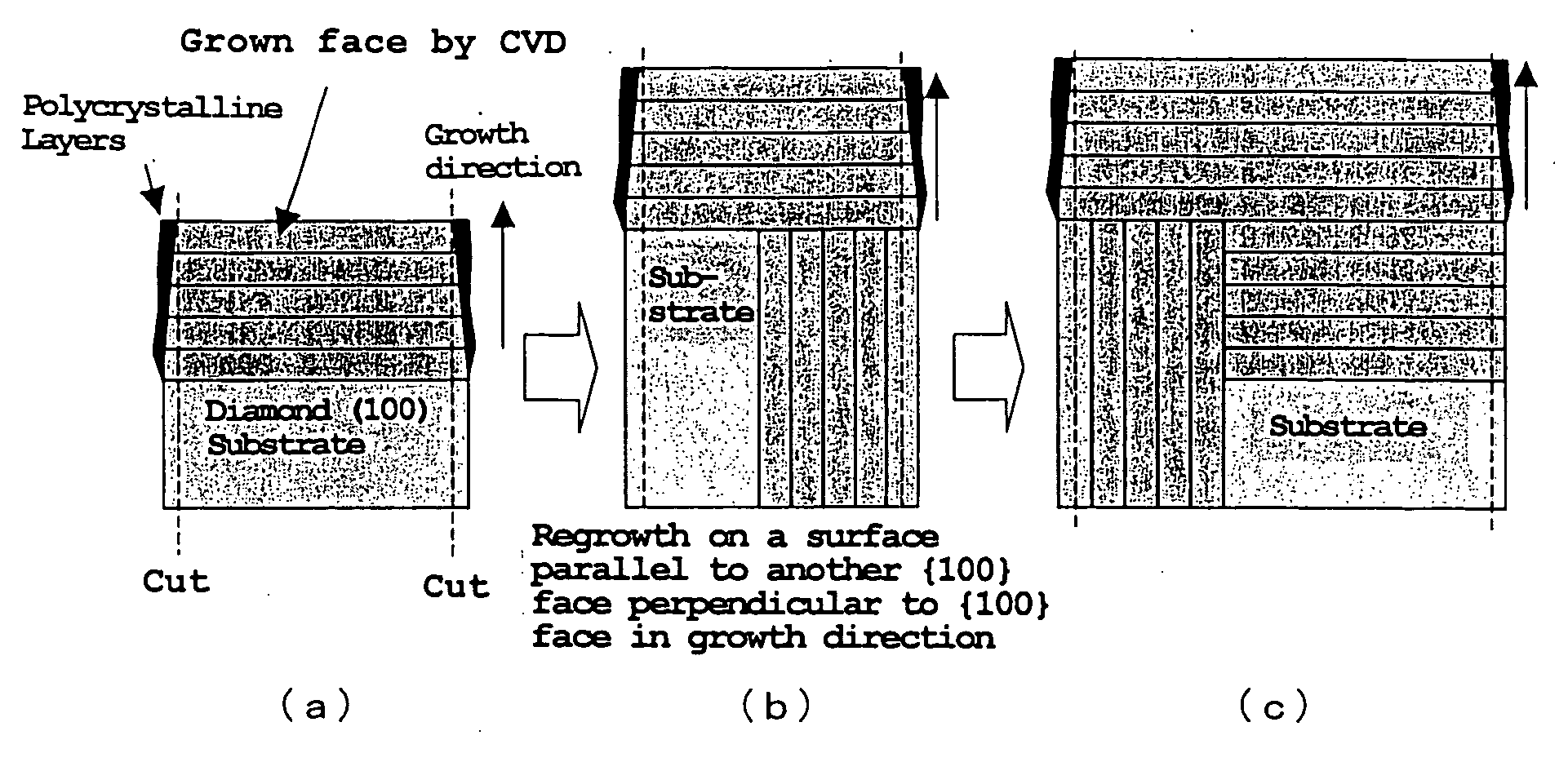

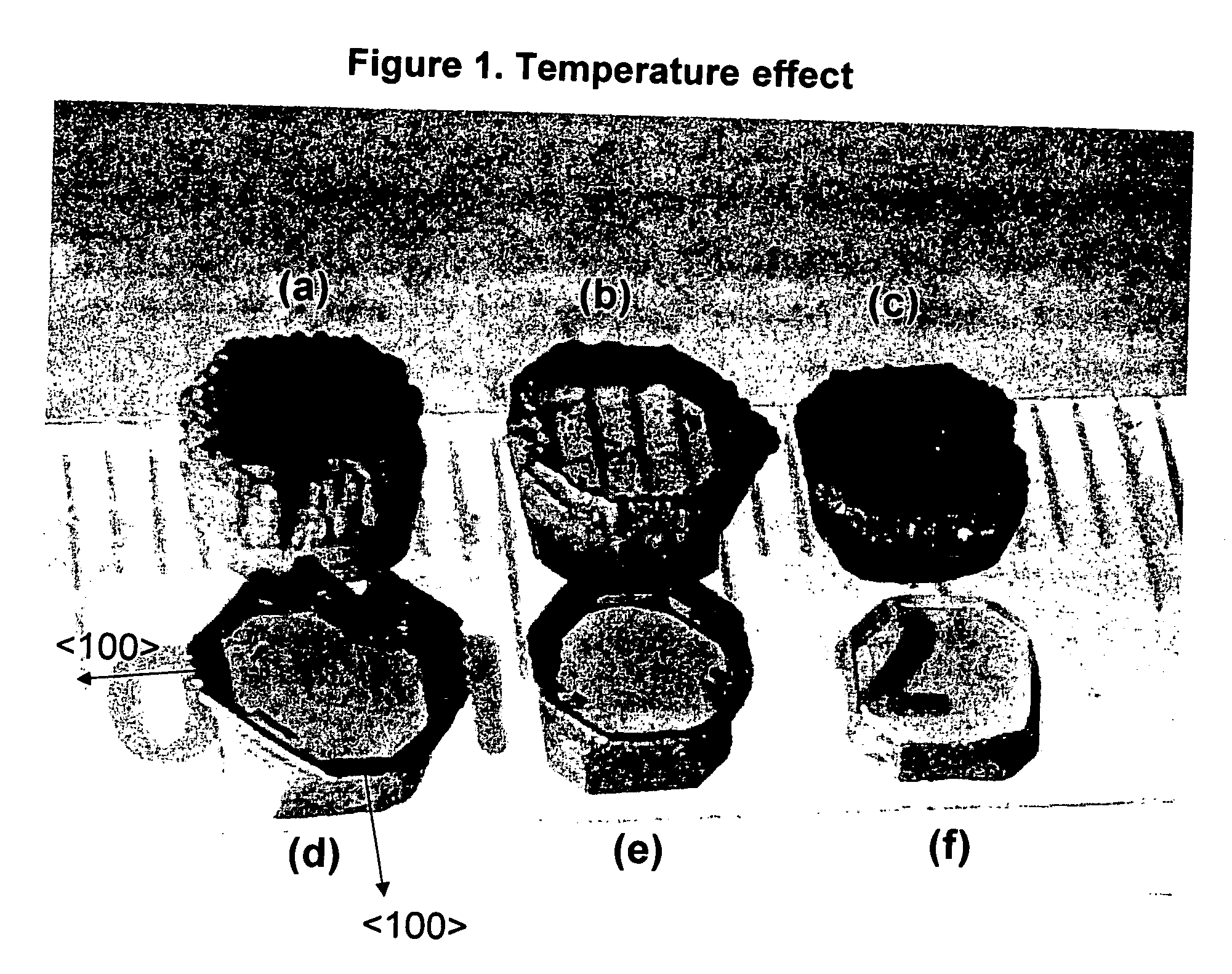

Method of producing single crystal

ActiveUS20060266279A1Low costProduce significantPolycrystalline material growthFrom normal temperature solutionsGas phaseSingle crystal

The present invention provides a method for producing a single crystals by preferential epitaxial growth of {100} face, the method comprising the steps of (1) growing the crystal on a single crystal {100} substrate; (2) forming on the side of the grown crystal a surface parallel to a {100} face different from the {100} face in the growth direction, and (3) growing the crystal on the formed {100} surface; and the steps (2) and (3) being performed once or more than once. The present invention further provides a method for producing a single-crystal diamond wherein used is a metallic holder for the single-crystal diamond having a crystal holding portion which is raised above an outer peripheral portion of the holder, is apart from the outer peripheral portion of the holder, and has a recessed shape. According to the present invention, a method for producing a single crystal by epitaxial growth, in particular a method for producing a single-crystal diamond using gaseous phase synthetic methods enable the production of a large single-crystal diamond in a comparatively short time at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

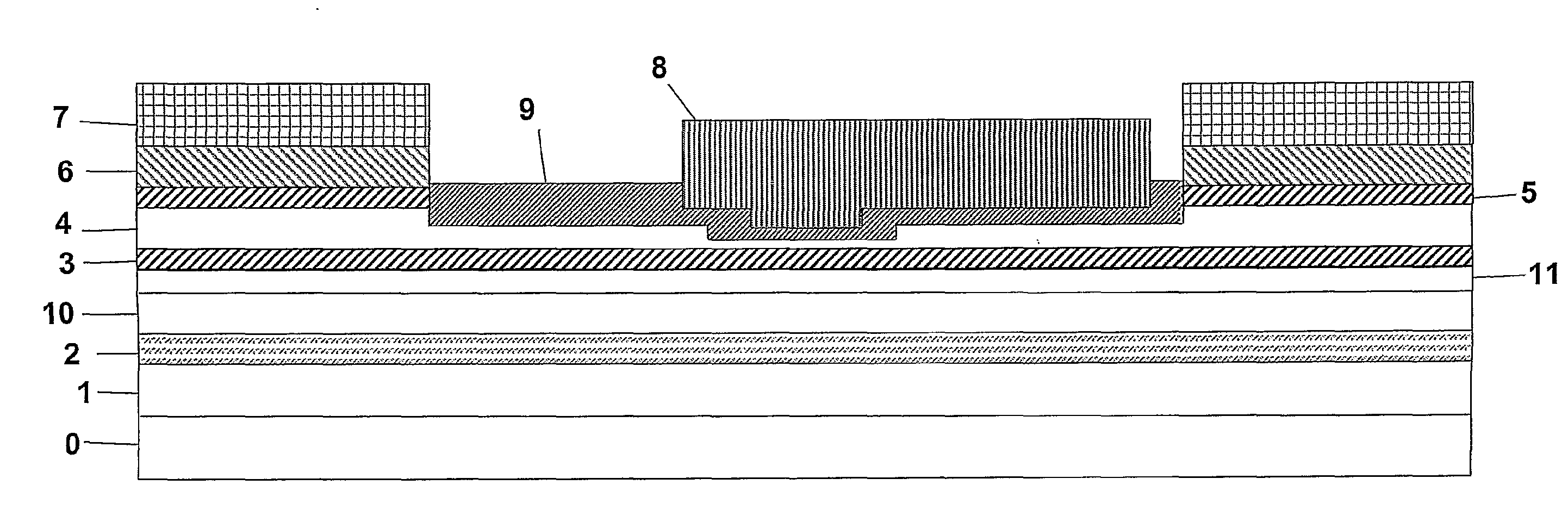

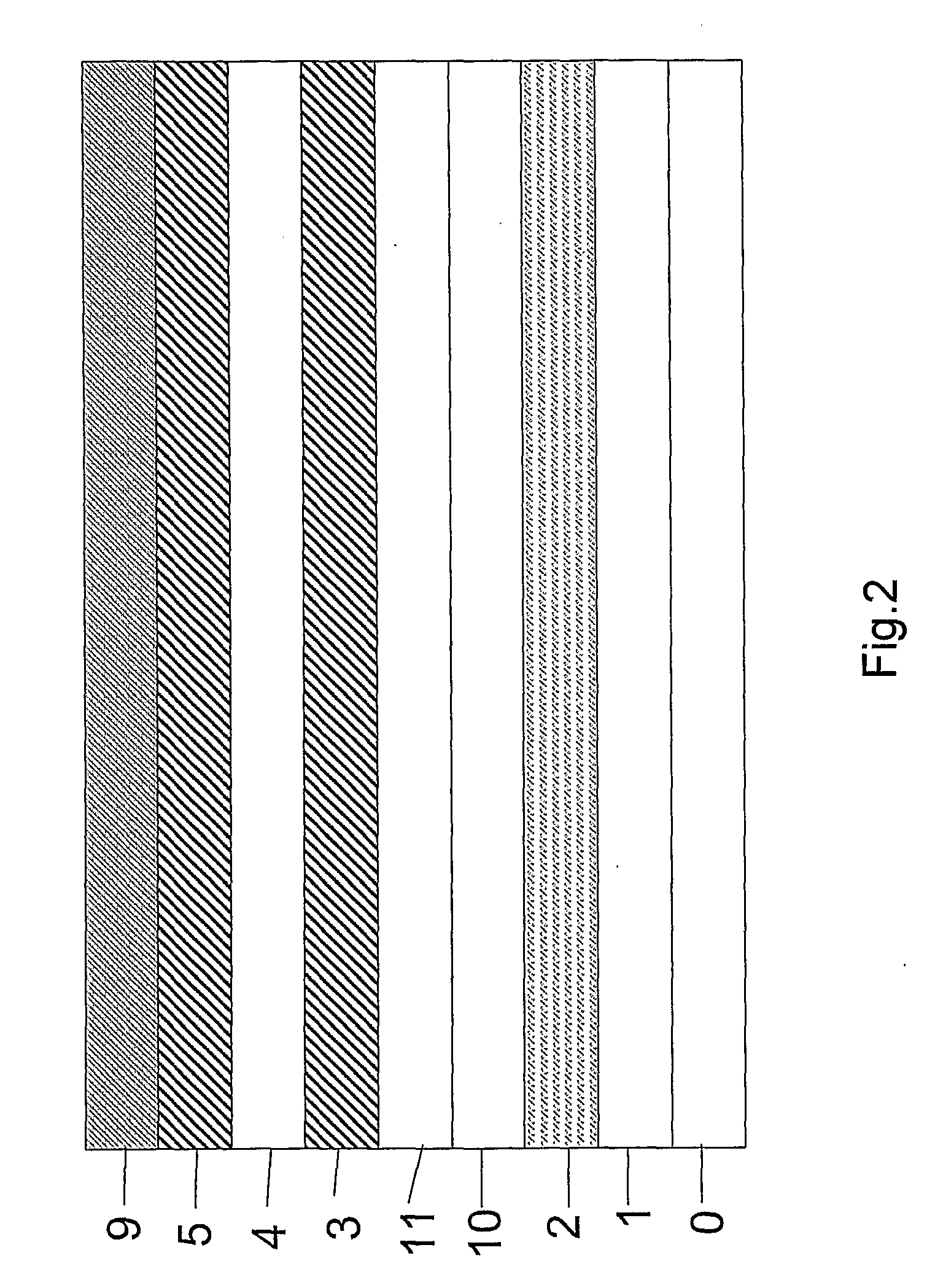

Diamond Transistor And Method Of Manufacture Thereof

InactiveUS20080099768A1Reduce surface roughnessLower step heightTransistorPolycrystalline material growthDelta dopingSingle crystal

Owner:DIAMOND MICROWAVE DEVICES

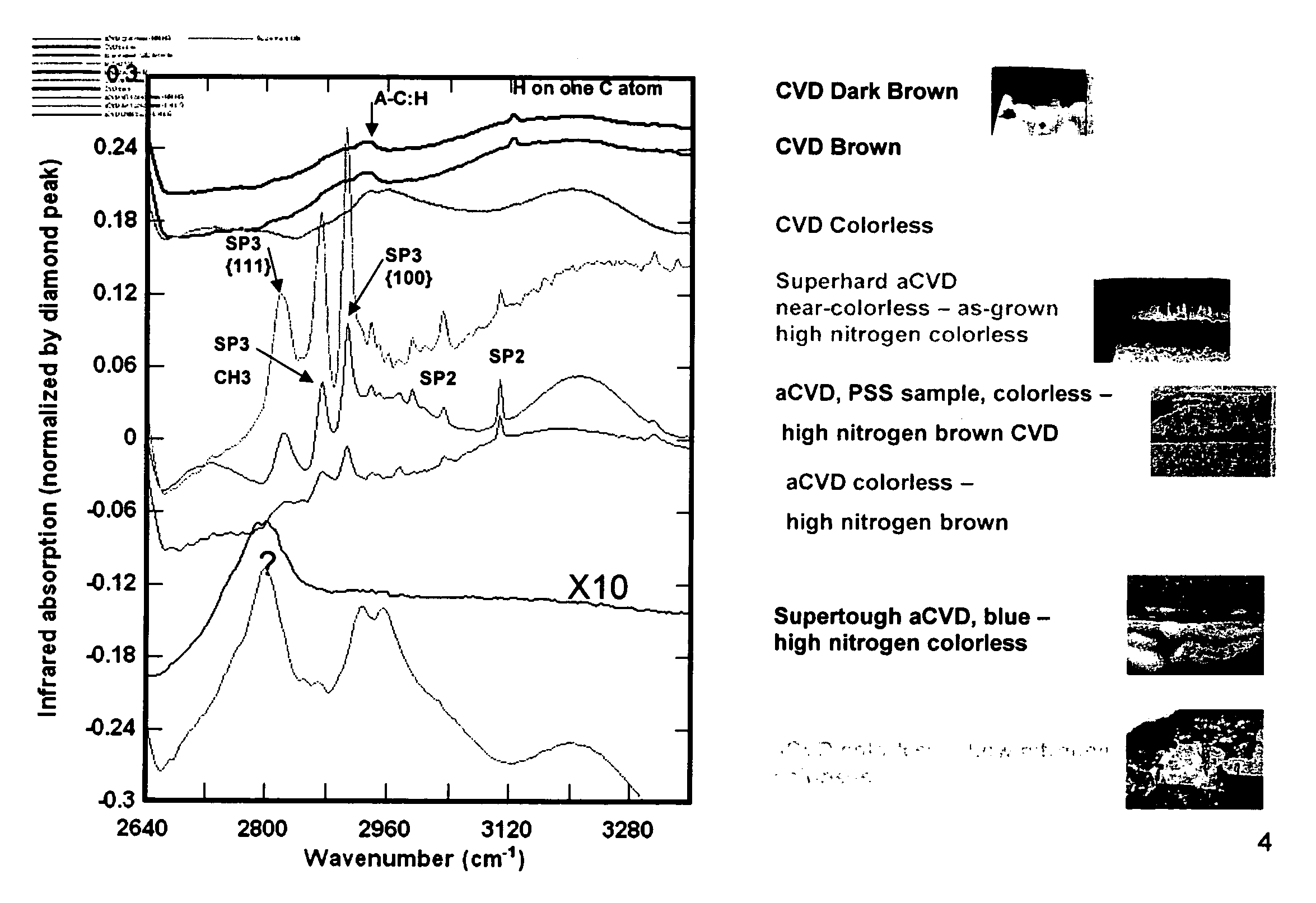

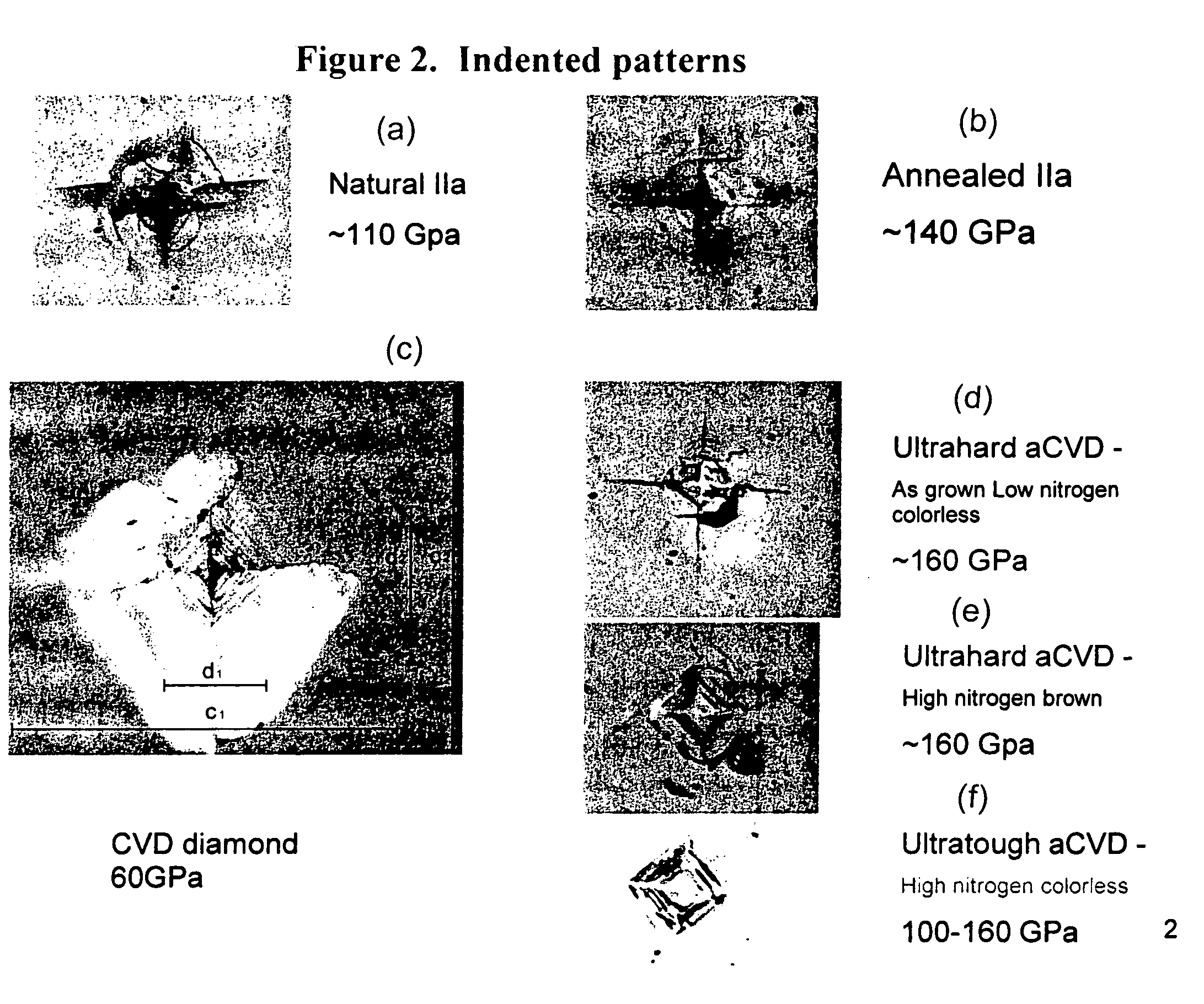

Ultratough CVD single crystal diamond and three dimensional growth thereof

ActiveUS20060065187A1Minimizes gradientHigh melting pointPolycrystalline material growthUltra-high pressure processesSingle crystalMicrowave plasma chemical vapor deposition

The invention relates to a single-crystal diamond grown by microwave plasma chemical vapor deposition that has a toughness of at least about 30 MPa m1 / 2. The invention also relates to a method of producing a single-crystal diamond with a toughness of at least about 30 MPa m1 / 2. The invetnion further relates to a process for producing a single crystal CVD diamond in three dimensions on a single crystal diamond substrate.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

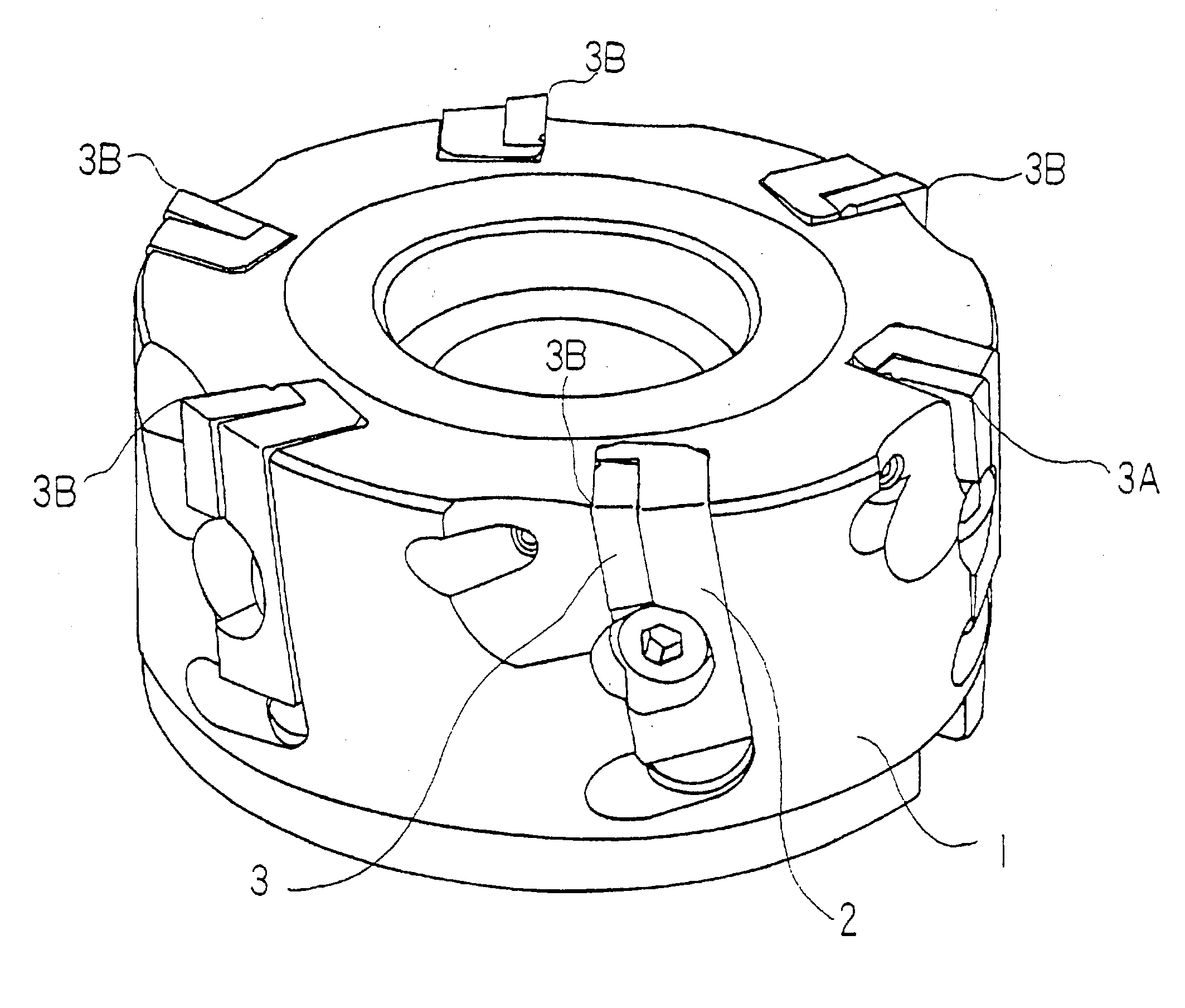

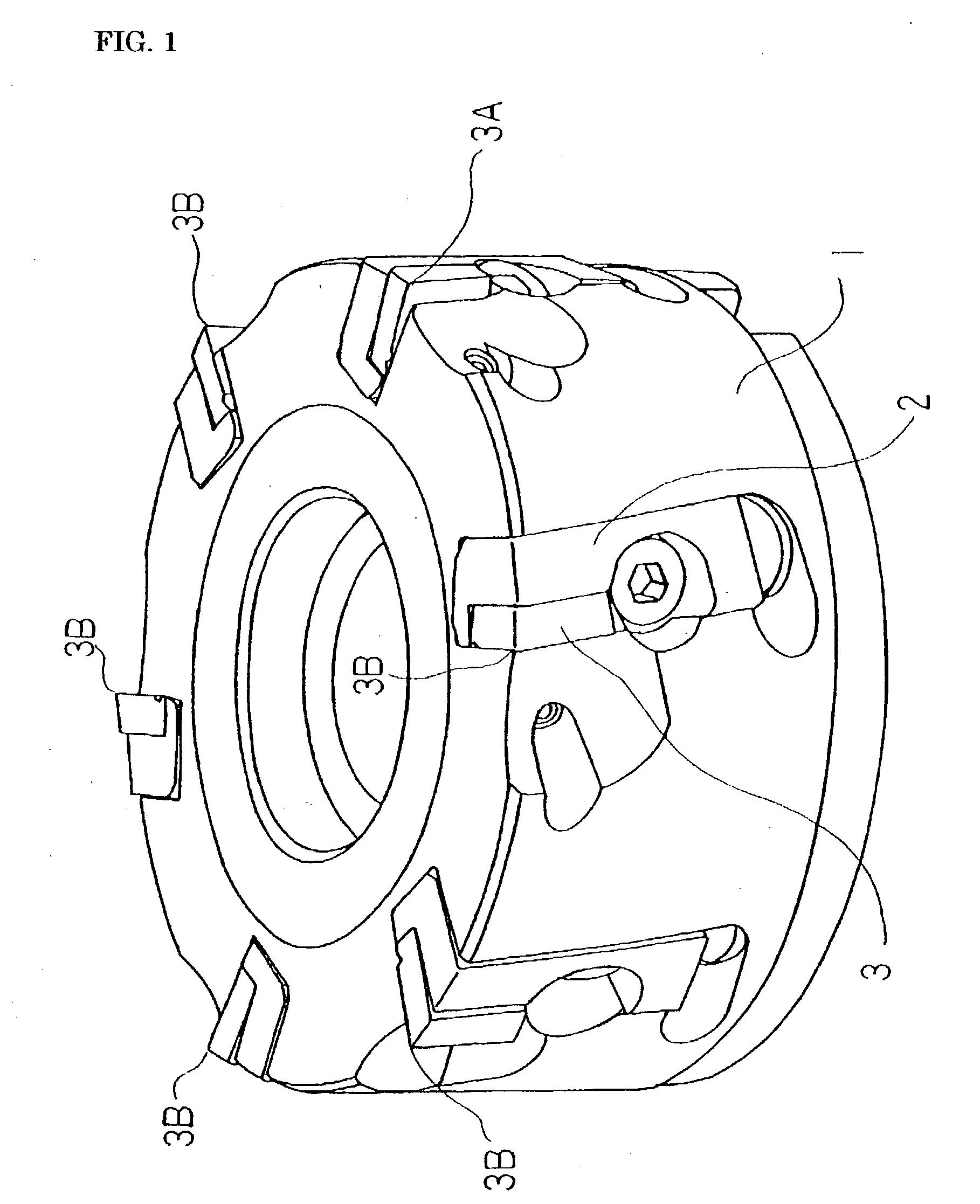

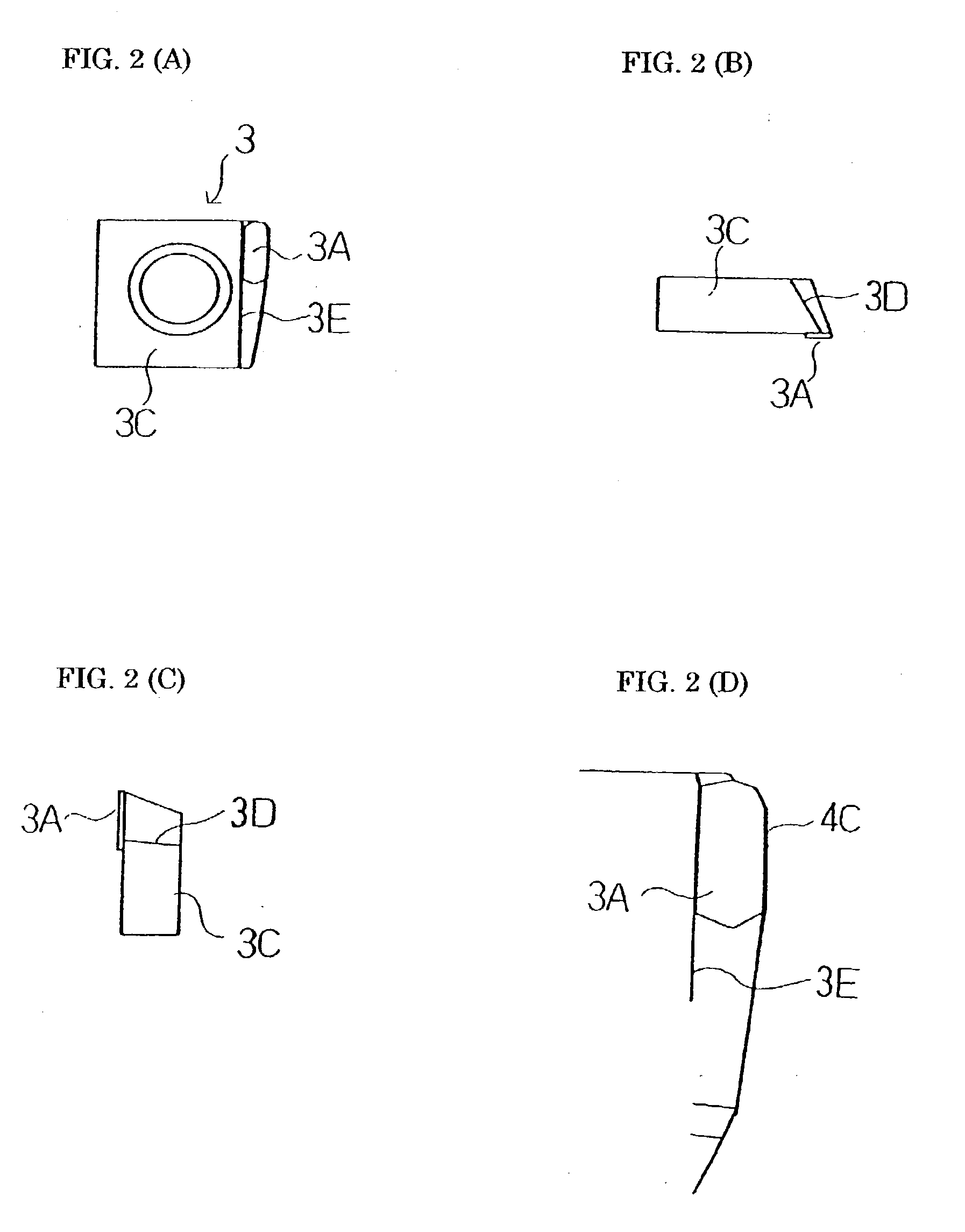

Cutting tip for rotating cutting tool and rotating cutting tool using the tip, and method of machining using the tool

InactiveUS20030133763A1Improve bottom surface roughnessUneven finished surfaceMilling cuttersWorkpiecesSingle crystalKnife blades

Owner:SUMITOMO ELECTRIC IND LTD

Method of growing a single crystal diamond

InactiveUS20050066884A1Polycrystalline material growthFrom normal temperature solutionsIsotopes of carbonSingle crystal

Synthetic monocrystalline diamond compositions having one or more monocrystalline diamond layers formed by chemical vapor deposition, the layers including one or more layers having an increased concentration of one or more impurities (such as boron and / or isotopes of carbon), as compared to other layers or comparable layers without such impurities. Such compositions provide an improved combination of properties, including color, strength, velocity of sound, electrical conductivity, and control of defects. A related method for preparing such a composition is also described., as well as a system for use in performing such a method, and articles incorporating such a composition.

Owner:SCIO DIAMOND TECHNOLOGY CORPORATION

Single crystal diamond having 12C, 13C, and phosphorous

InactiveUS20050056206A1Polycrystalline material growthFrom normal temperature solutionsIsotopes of carbonSingle crystal

Synthetic monocrystalline diamond compositions having one or more monocrystalline diamond layers formed by chemical vapor deposition, the layers including one or more layers having an increased concentration of one or more impurities (such as boron and / or isotopes of carbon), as compared to other layers or comparable layers without such impurities. Such compositions provide an improved combination of properties, including color, strength, velocity of sound, electrical conductivity, and control of defects. A related method for preparing such a composition is also described, as well as a system for use in performing such a method, and articles incorporating such a composition.

Owner:SCIO DIAMOND TECHNOLOGY CORPORATION

Method of forming an N-type doped single crystal diamond

InactiveUS20050061233A1Polycrystalline material growthUltra-high pressure processesIsotopes of carbonSingle crystal

Synthetic monocrystalline diamond compositions having one or more monocrystalline diamond layers formed by chemical vapor deposition, the layers including one or more layers having an increased concentration of one or more impurities (such as boron and / or isotopes of carbon), as compared to other layers or comparable layers without such impurities. Such compositions provide an improved combination of properties, including color, strength, velocity of sound, electrical conductivity, and control of defects. A related method for preparing such a composition is also described., as well as a system for use in performing such a method, and articles incorporating such a composition.

Owner:SCIO DIAMOND TECHNOLOGY CORPORATION

Heteroepitaxial diamond and diamond nuclei precursors

InactiveUS20040069209A1Enhance electron emissionAccelerate emissionsPolycrystalline material growthFrom solid stateGas phaseSingle crystal

A process for growing by chemical vapor deposition a heteroepitaxial single crystal diamond is disclosed. The process provides a substrate which enables the growth of single crystal diamond which is vapor coated on an iridium film. An intermediate process for producing a composite composition with diamond nuclei is also described. Further described are composite compositions of metal oxide, iridium and single crystal diamond films or diamond nuclei. Single crystal diamond is useful in a variety of electronics and acoustics fields.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

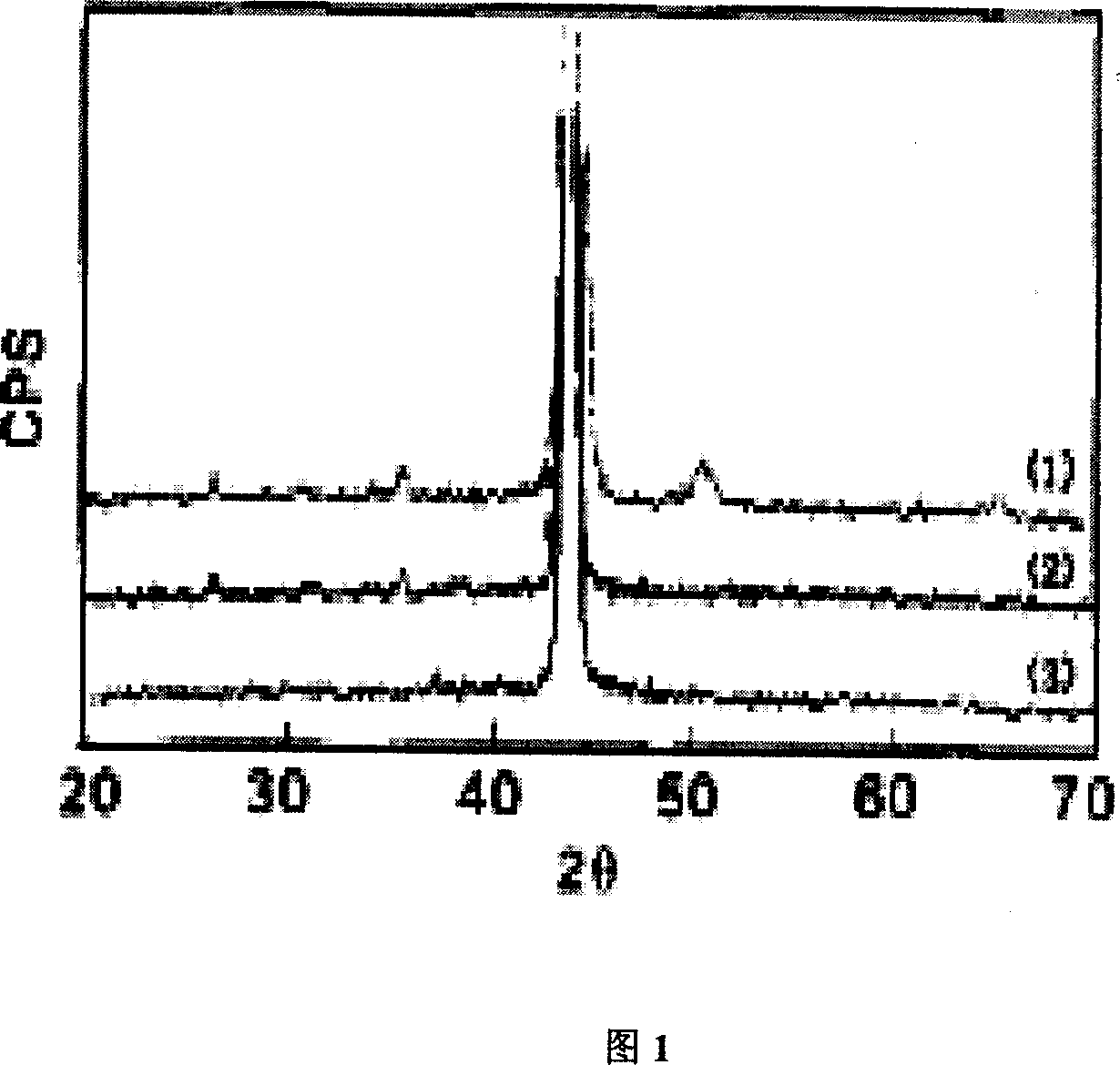

Preparation method of high-performance diamond reinforced Al-matrix electronic packaging composite material

ActiveCN101728279AHigh densityImprove thermal conductivitySemiconductor/solid-state device manufacturingSingle crystalVolumetric Mass Density

The invention relates to a preparation method of a high-performance diamond reinforced Al-matrix electronic packaging composite material, belonging to the field of metal-matrix composite materials. The preparation method is characterized by comprising the following steps: adding alloy elements into a pure Al matrix to prepare elemental mixed powder or Al alloy powder; uniformly mixing the elemental mixed powder or the Al alloy powder and diamond single crystal grains according to the volume percentage ratio of 75:25-40:60; adding the mixture into a graphite mold for carrying out spark plasma sintering, wherein the mixture is added at the heating speed of 50-100 DEG C / min until the sintering temperature is 580-800 DEG C and the sintering pressure is 30-40MPa; keeping the temperature and the pressure for 5-20min; and obtaining the high-performance diamond reinforced Al-matrix electronic packaging composite material after the sintering process finishes. The alloy elements comprise B, Si, Cr, Ti, Nb, Ag, Cu and the like. The material of the invention has the characteristics that the heat conductivity reaches 430W / m.K, the heat expansion coefficient is 6.40ppm / K, the compressive strength is 331MPa, and the density is only 3.13g / cm<3>. The invention effectively solves the problem of graphitization of single crystal diamond grains in the preparation process of the material, and has simple preparation processes and high production efficiency.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Single crystal diamond tool

InactiveUS20050056207A1Polycrystalline material growthFrom normal temperature solutionsIsotopes of carbonSingle crystal

Synthetic monocrystalline diamond compositions having one or more monocrystalline diamond layers formed by chemical vapor deposition, the layers including one or more layers having an increased concentration of one or more impurities (such as boron and / or isotopes of carbon), as compared to other layers or comparable layers without such impurities. Such compositions provide an improved combination of properties, including color, strength, velocity of sound, electrical conductivity, and control of defects. A related method for preparing such a composition is also described., as well as a system for use in performing such a method, and articles incorporating such a composition.

Owner:SCIO DIAMOND TECHNOLOGY CORPORATION

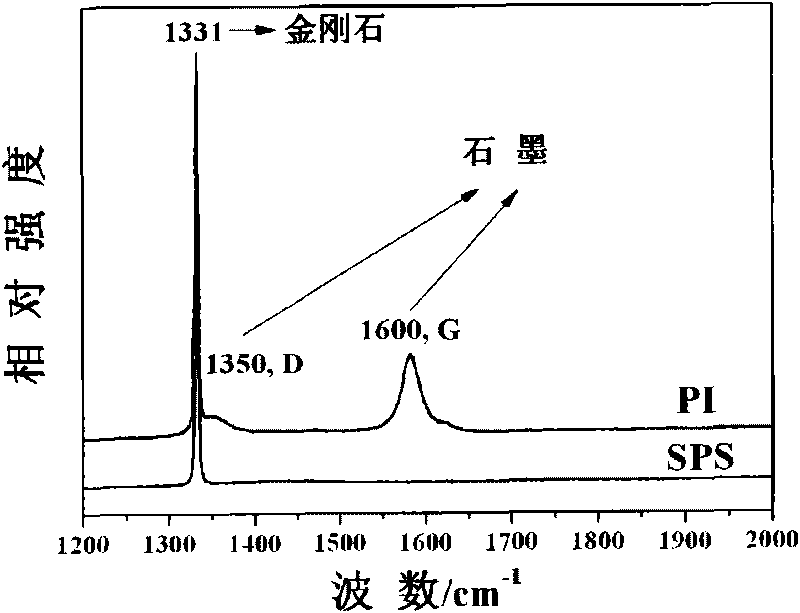

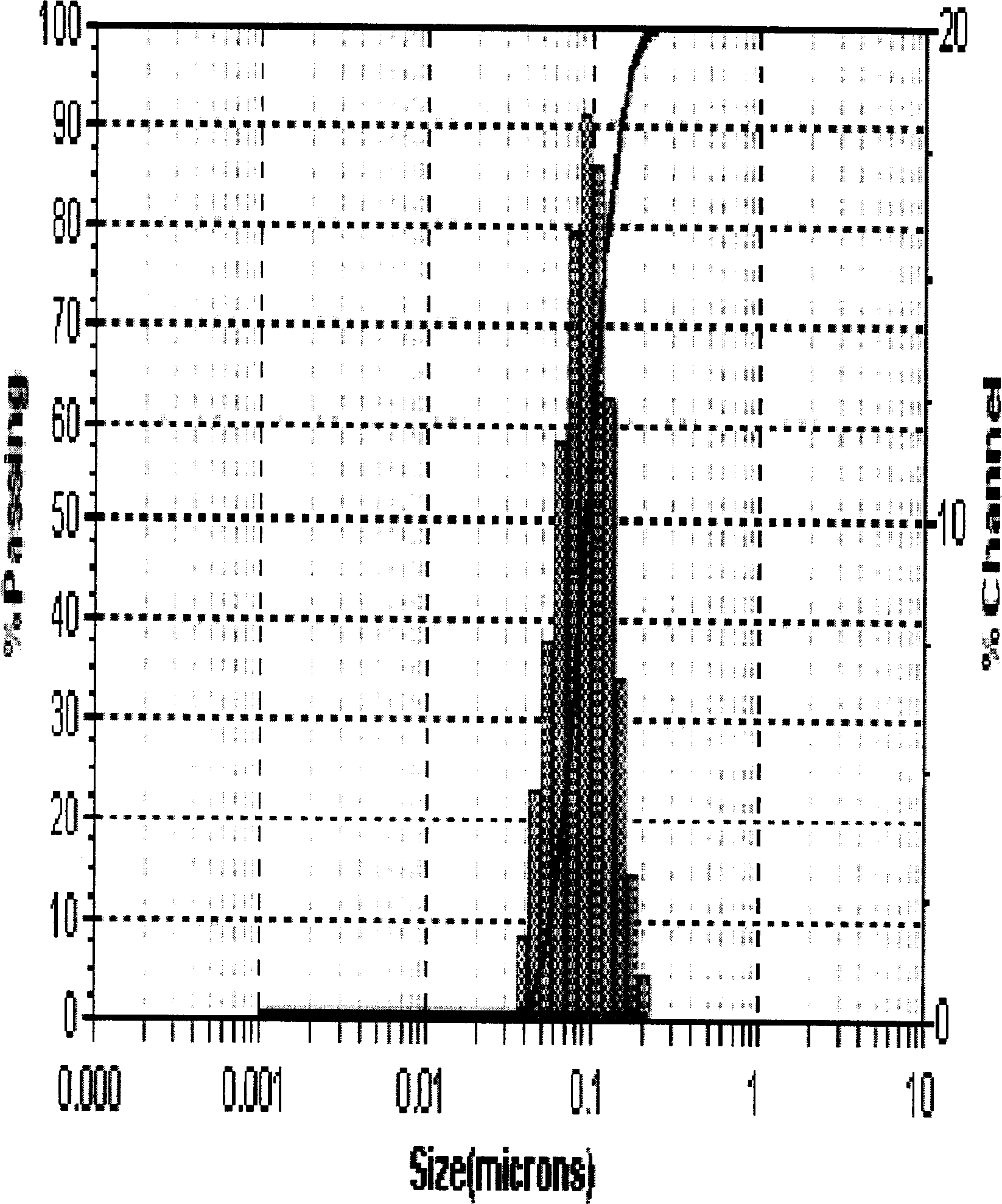

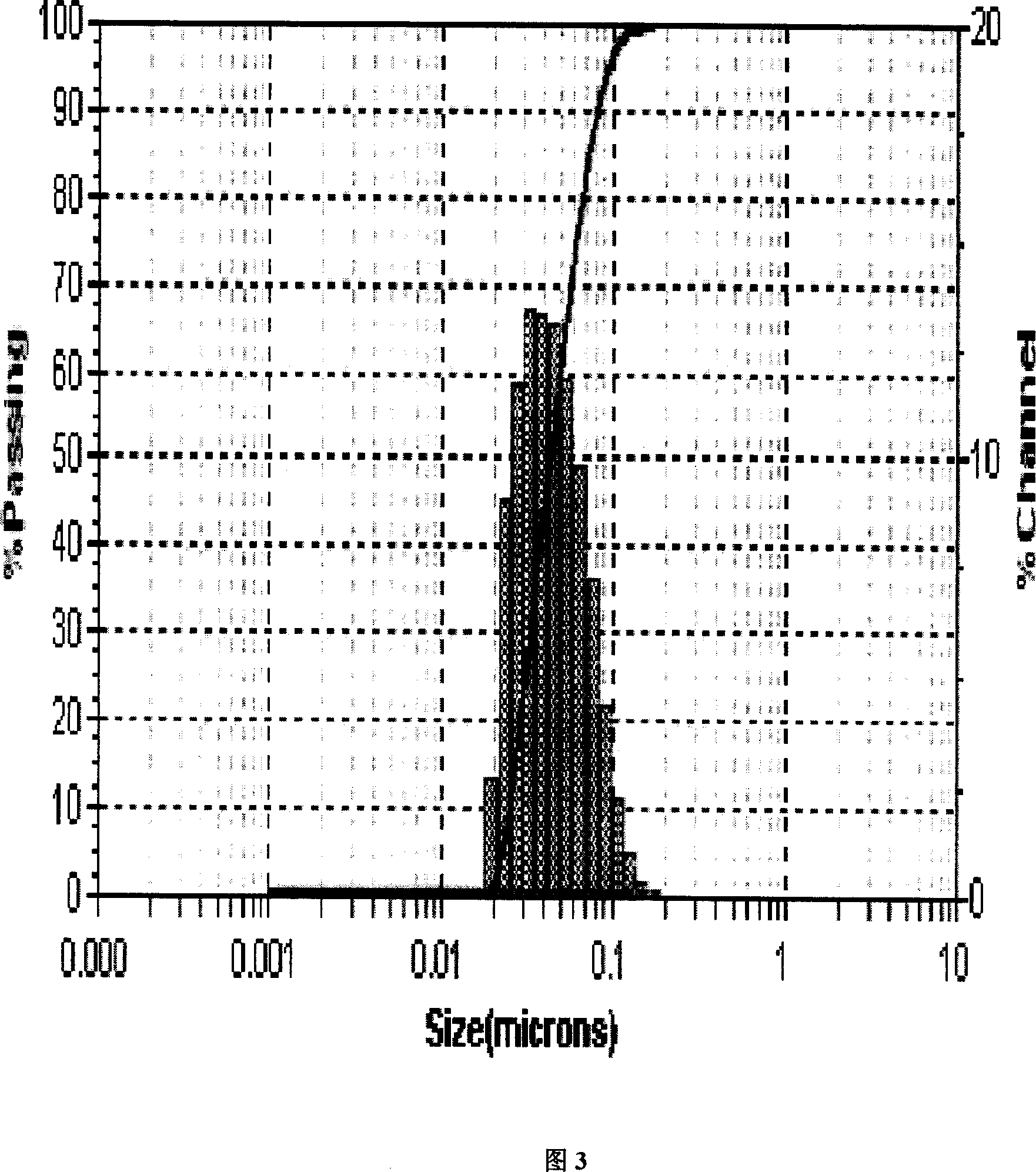

Nano monocrystalline diamond and method for making same

InactiveCN1962964AEasy to obtainReduce manufacturing costPolycrystalline material growthOther chemical processesGraphiteSingle crystal

The invention discloses a manufacturing method of nanometer single-crystal diamond, which comprise the following steps: 1. grinding the single-crystal diamond particle with grain size more than nanometer grade; obtaining the micropowder of nanometer single-crystal diamond; 2. proceeding acid and alkaline disposal for micropowder; removing metal, graphite and silicon separately; 3. utilizing multi-pipe high-speed centrifuger to grade the micropowder into different grain sizes; obtaining the even grain size at 100nm or less.

Owner:北京国瑞升精机科技有限公司

Superhard mold face for forming ele

InactiveUS20070157670A1SmoothImprove smoothnessTailstocks/centresConfectionerySingle crystalMaterials science

Mold assemblies for forming optical elements including a support material and a molding material are disclosed and described. In one aspect, the molding material can include a single crystal diamond coupled to the support material and includes a working surface defining a shape to be imparted to an optical element to be pressed in the mold assembly. In another aspect, the molding material can include a PCD compact coupled to the support material and includes a working surface defining a shape to be imparted to an optical element to be pressed in the mold assembly. In yet a further aspect, the molding material may include a cermet composite coating material which provides a gradient of one material coupled to the support material to another material at a working surface of the molding material which defines a shape to be imparted to an optical element to be molded.

Owner:SUNG CHIEN MIN

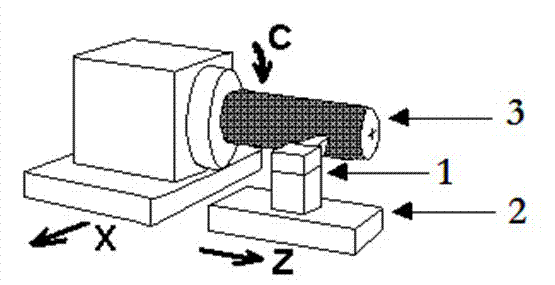

Single point diamond lathe and method for machining special-shape workpiece

The invention provides a single point diamond lathe which comprises a workpiece axial displacement guide rail shaft (Z-axis) and a transversal displacement guide rail shaft (X-axis) of a normal numerically-controlled lathe and a single crystal diamond cutter, wherein a main shaft rotary indexing shaft (C-axis) is additively arranged on a radial displacement guide rail shaft; an angle-adjustable three-dimensional knife rest is arranged on the workpiece axial displacement guide rail shaft; the single crystal diamond cutter is fixed on the three-dimensional knife rest; a workpiece to be machined is fixed on the main shaft rotary indexing shaft; and the Z-direction displacement of the workpiece to be machined is adjusted by the workpiece axial displacement guide rail shaft. The invention further provides a method for controlling the X-direction displacement of the workpiece to be machined by the transversal displacement guide rail shaft and machining the special-shape workpiece. The invention compiles 2-3 shaft linkage by the C-axis indexing function of a single crystal diamond main shaft to be capable of realizing the planing contour machining on the cylindrical surface and the spherical surface, and has the characteristic that the special-shape workpiece is precisely machined.

Owner:SHANGHAI MODERN ADVANCED ULTRA PRECISION MFG CENT

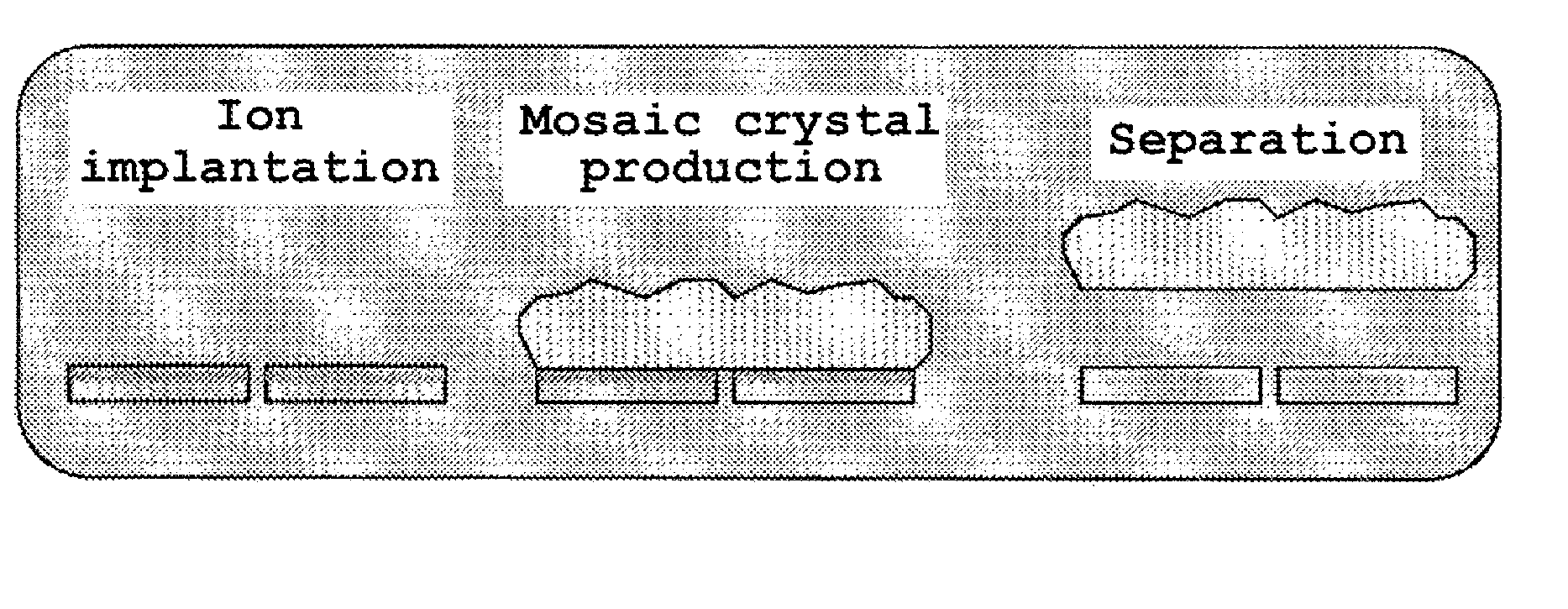

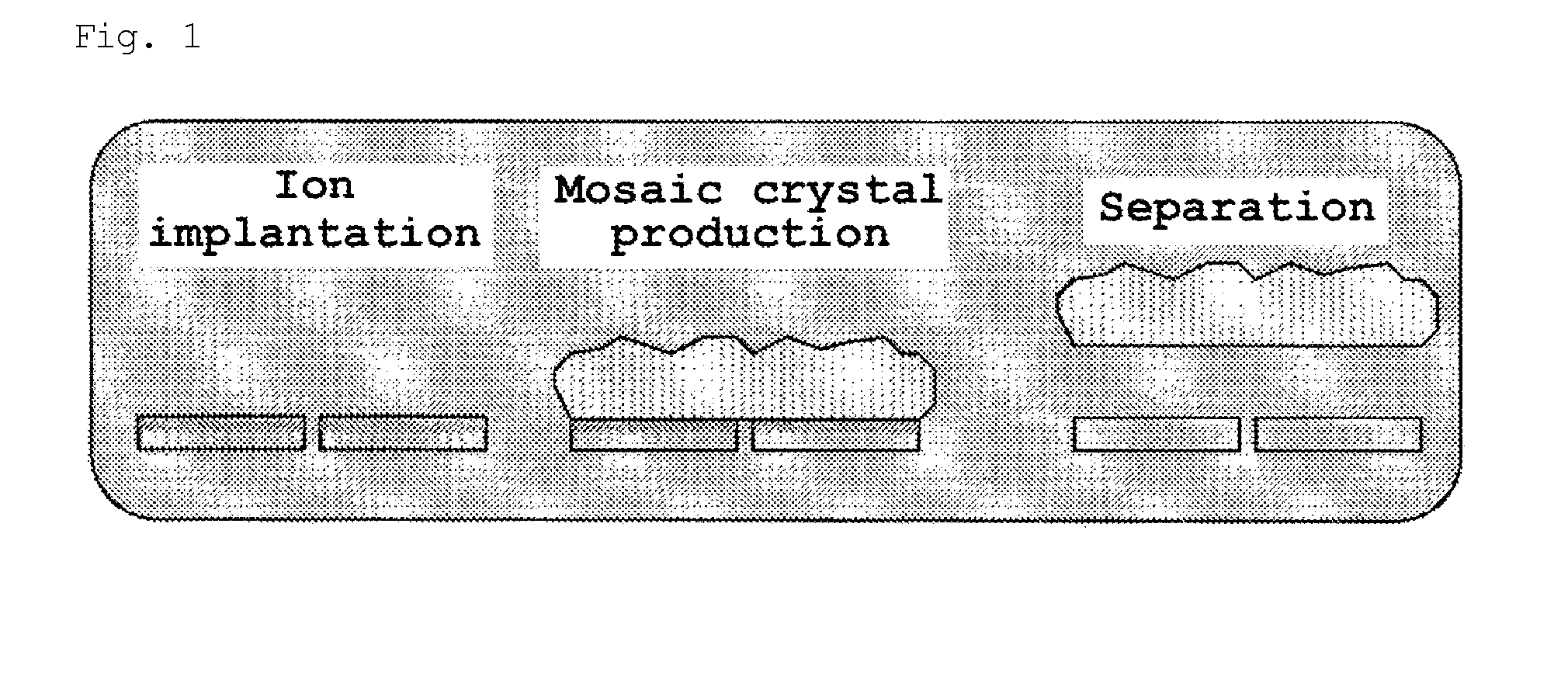

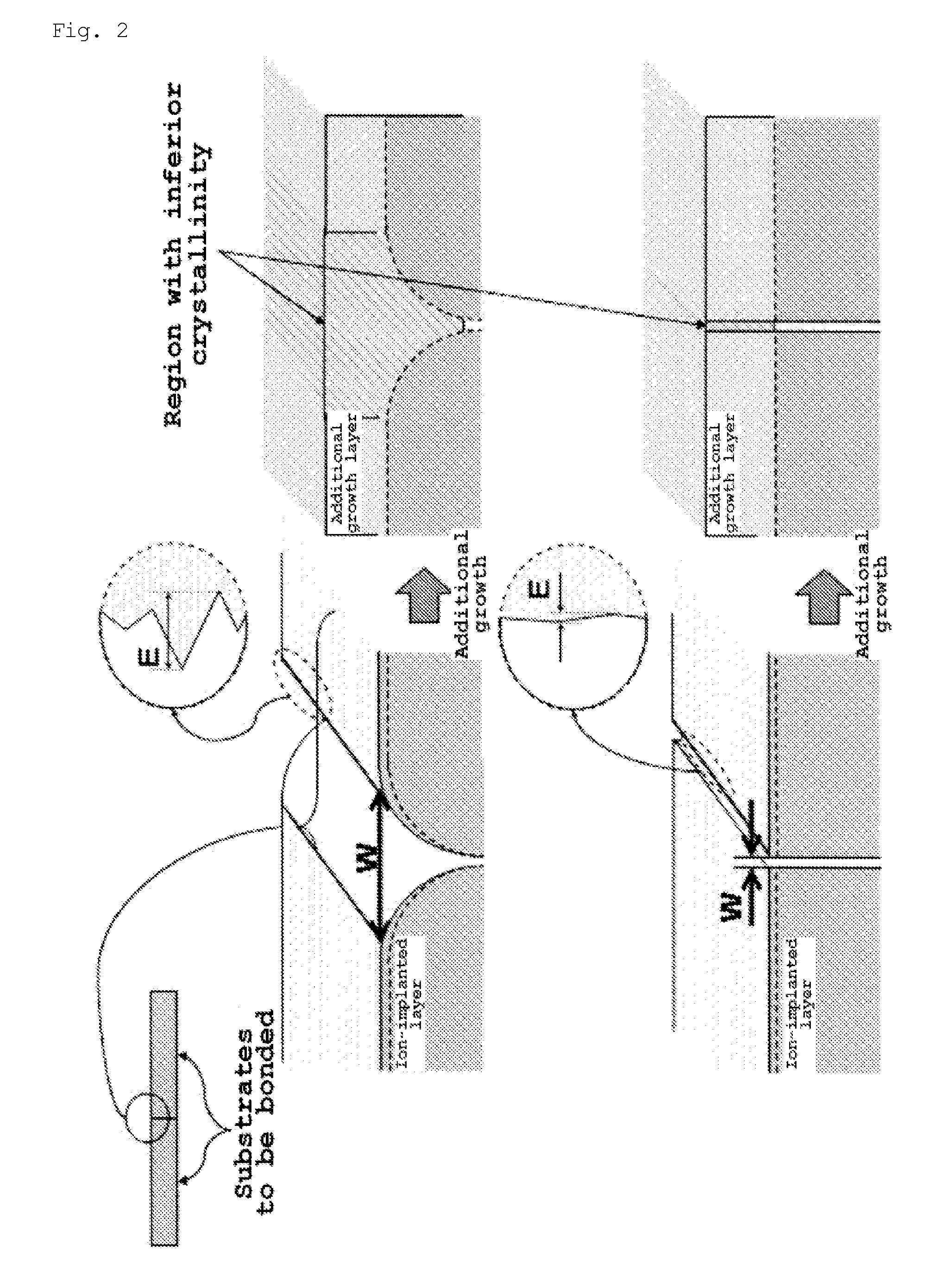

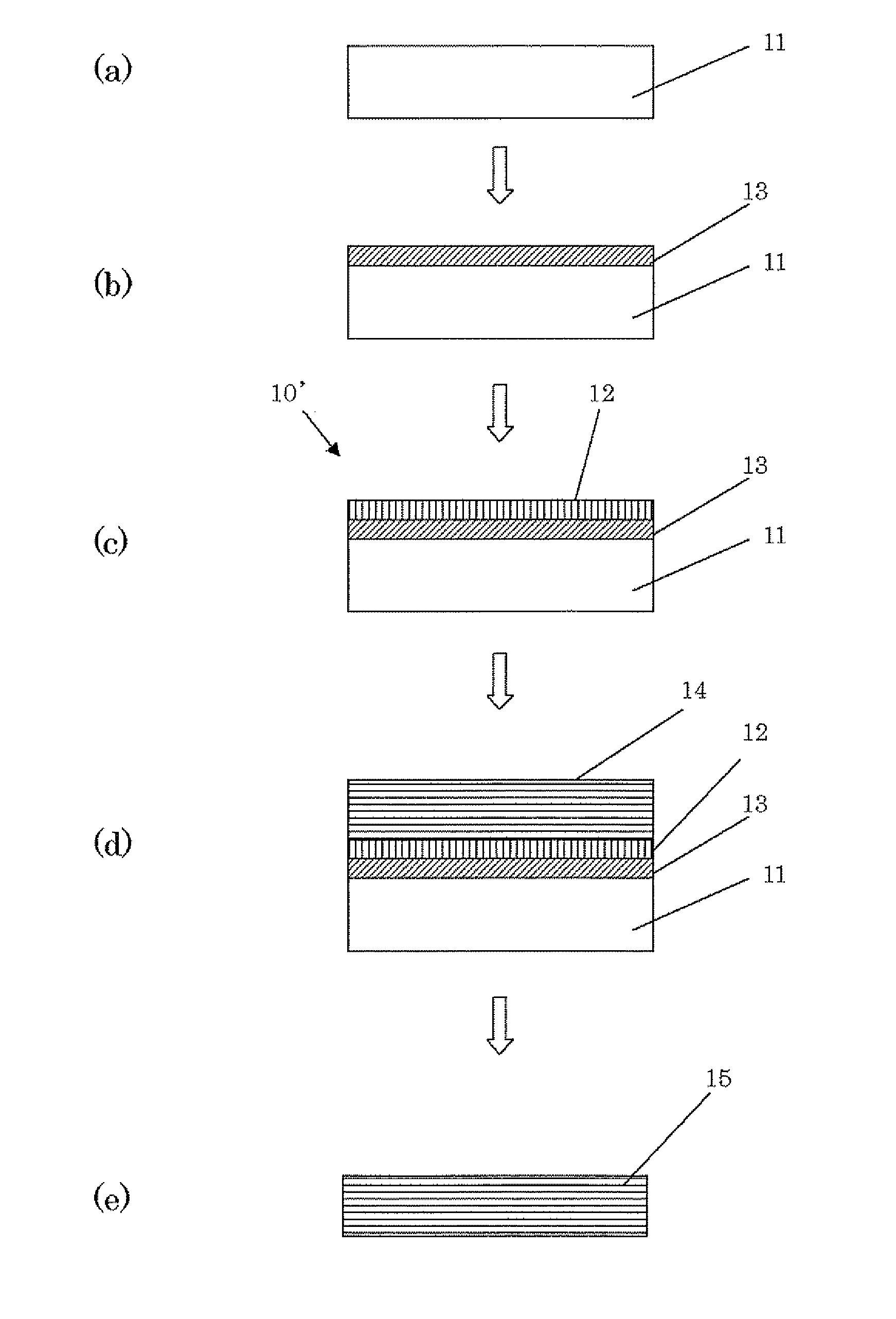

Method for producing mosaic diamond

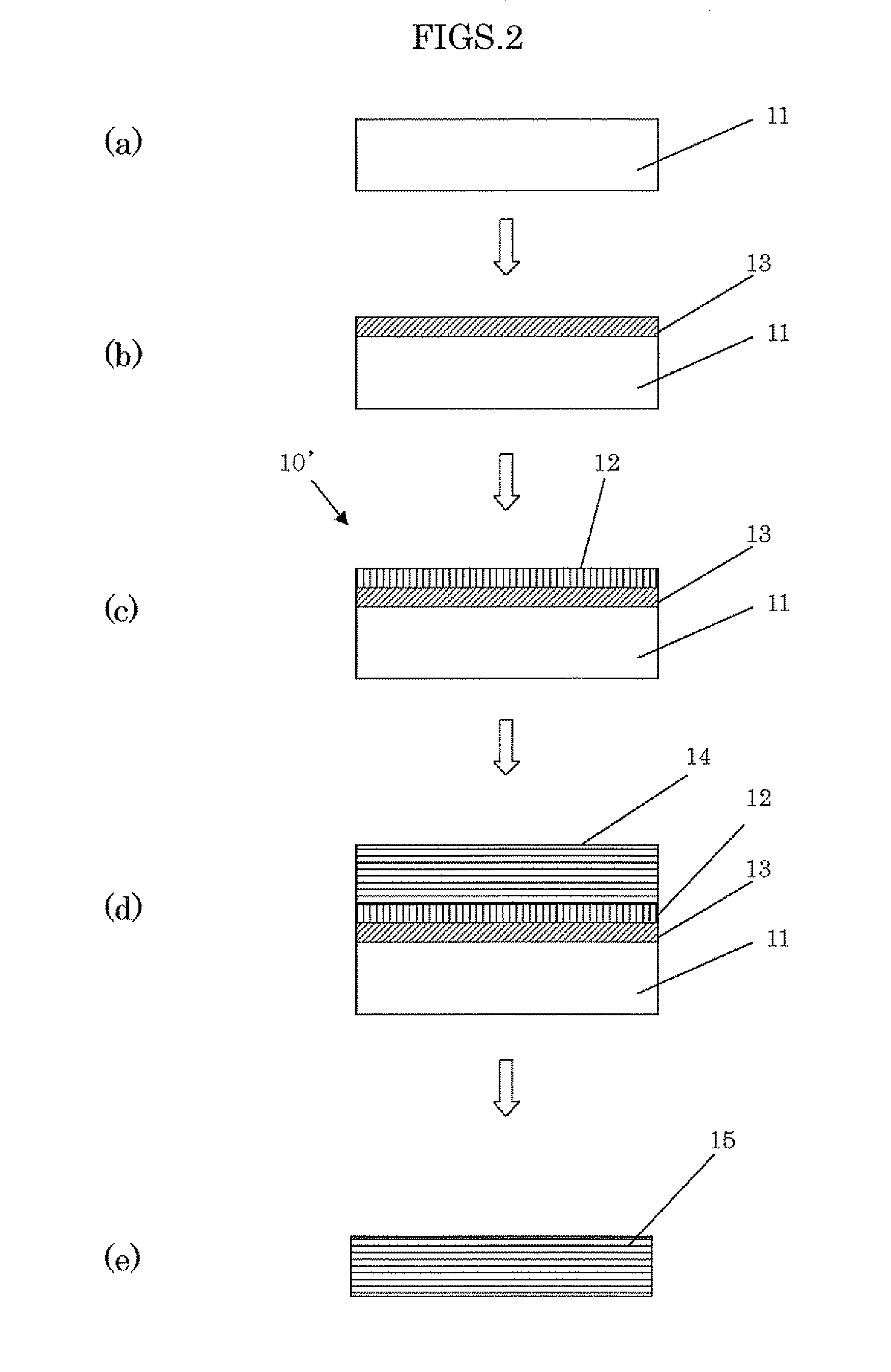

InactiveUS20120302045A1Simple processStable mass productionPolycrystalline material growthDiffusion/dopingSynthesis methodsSingle crystal

The present invention discloses a method for producing a mosaic diamond comprising implanting ions in the vicinity of the surfaces of a plurality of single-crystal diamond substrates arranged in the form of a mosaic, or in the vicinity of the surfaces of mosaic single-crystal diamond substrates whose back surfaces are bonded by a single-crystal diamond layer, so as to form non-diamond layers; growing a single-crystal diamond layer by a vapor-phase synthesis method; and separating the single-crystal diamond layer above the non-diamond layers by etching the non-diamond layers. The method of the present invention prevents the destruction of single-crystal diamond substrates by using a process that is simpler than conventional methods, thus allowing a large quantity of mosaic diamond to be produced in a stable and efficient manner.

Owner:NAT INST OF ADVANCED IND SCI & TECH

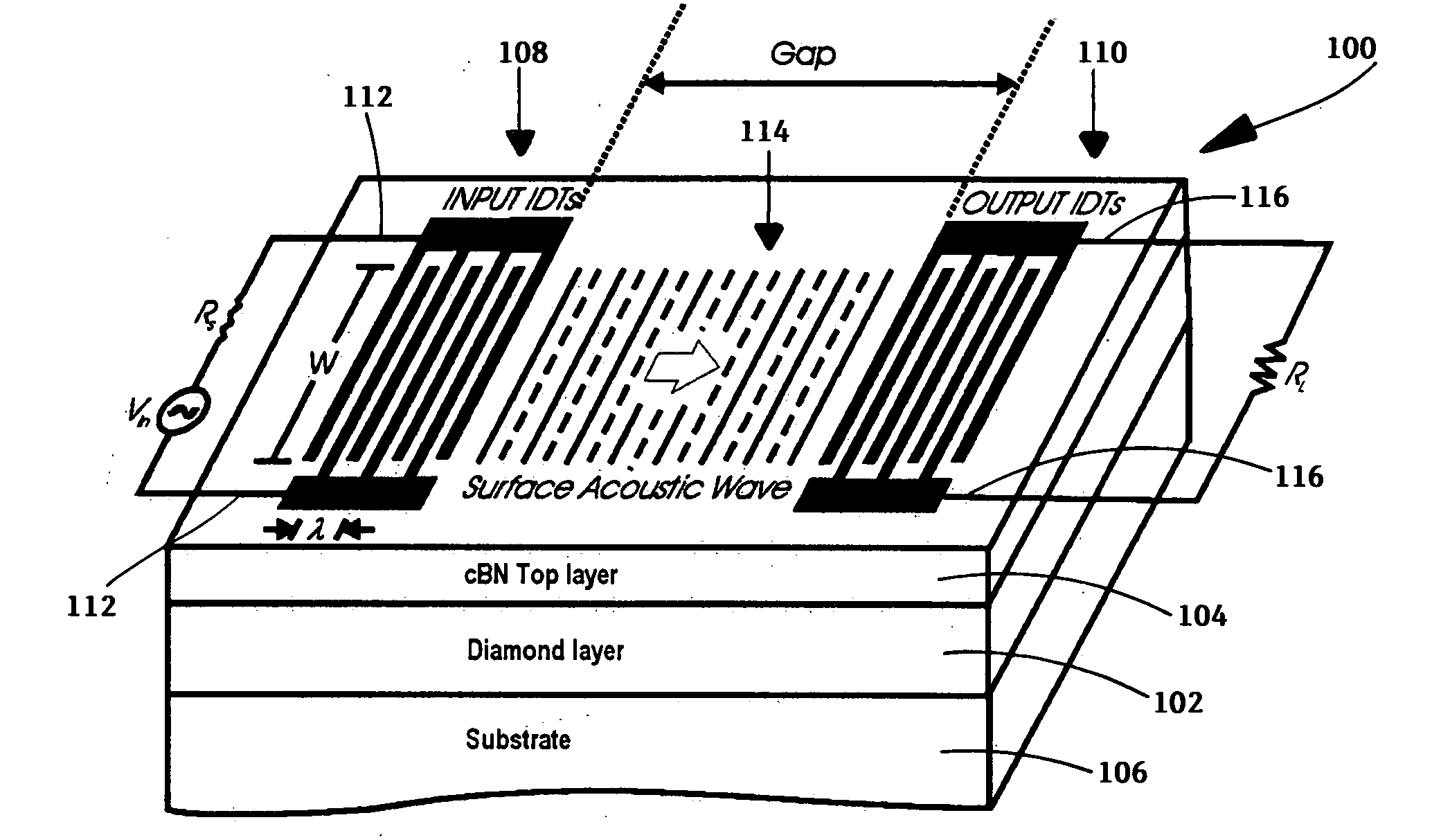

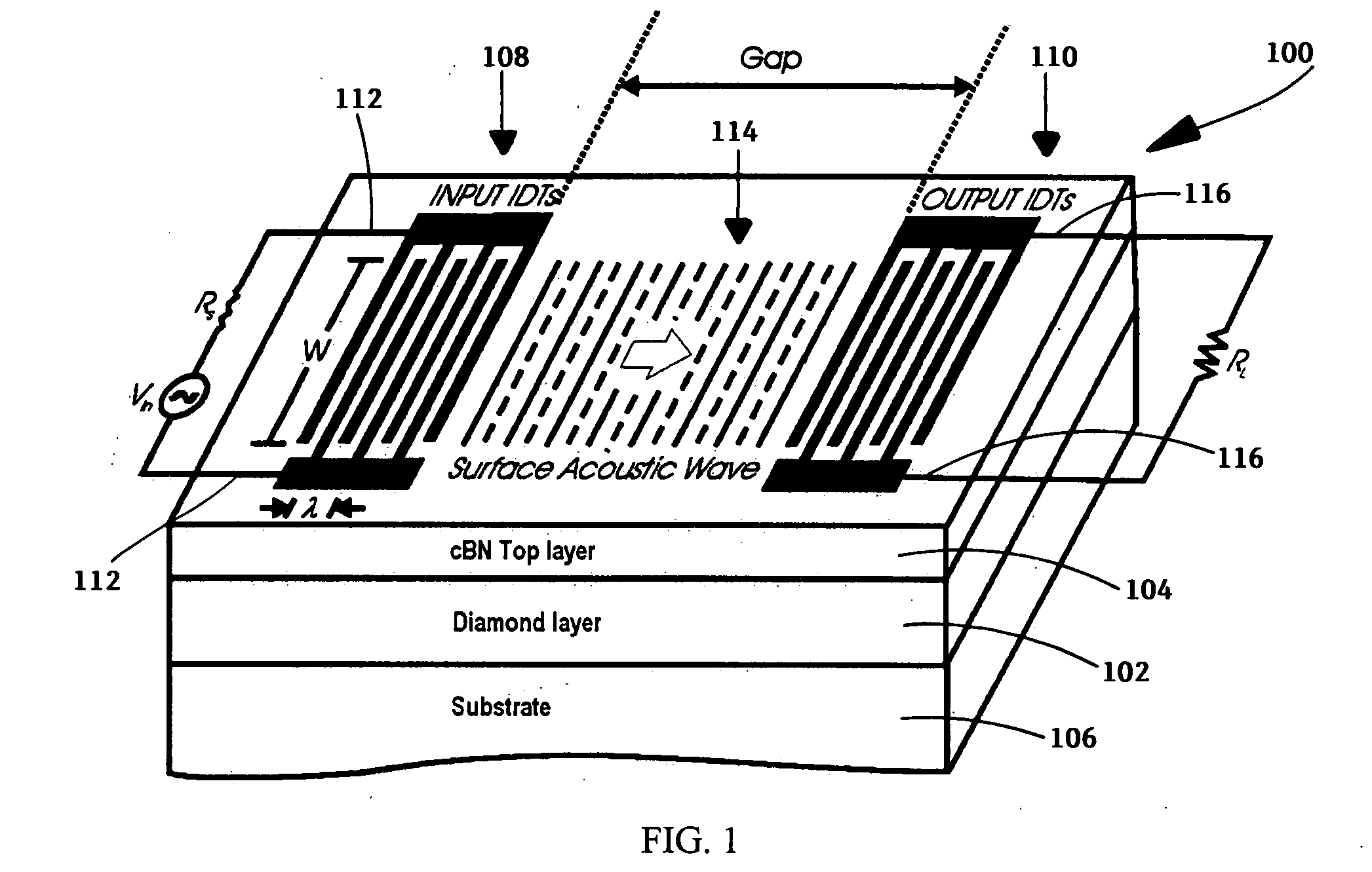

Surface acoustic wave (SAW) devices based on cubic boron nitride/diamond composite structures

ActiveUS20080303378A1Reduce surface roughnessAvoid distractionImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLow speedPolycrystalline diamond

A surface acoustic wave (SAW) device which is made of cBN / diamond composite structures and the fabrication method are disclosed. In the SAW device based on cubic boron nitride and diamond composite structures, the diamond hard layer includes randomly-oriented polycrystalline diamond (poly-D), oriented (heteroepitaxial) diamond, single-crystal diamond wafers and nanocrystalline diamond (nano-D) films. The cBN film with a sound velocity close to that of diamond serves as the piezoelectric layer, which was directly deposited on diamond hard layer without any soft sp2-BN incubation layer by ion assisted physical vapor deposition (PVD) and plasma-enhanced (or ion assisted) chemical vapor deposition (PECVD). Due to the high sound velocity and the low velocity dispersion between the cBN and diamond layered materials, the present SAW device based on cubic boron nitride and diamond composite structures can improve the device performance and operate at ultra-high frequency range.

Owner:CITY UNIVERSITY OF HONG KONG

Hot pressed and diamond impregnated drill tooth applicable to strong abrasive hard formation

The invention provides a hot pressed and diamond impregnated drill tooth applicable to a strong abrasive hard formation, which consists of a composite matrix and a natural diamond and is composed by a hot pressing and sintering process, wherein the composite matrix consists of 25-43% of WC (wolfram carbide), 15-25% of casting WC, 15-30% of Cu, 13-20% of Co, 11-17% of Ni, 1-3% of Mn, 1-2% of P and 0.5-1% of artificial single-crystal diamond powder; the natural diamond is a titanium coated natural diamond, the particle size range is 40-100 meshes, and the concentration is 75-110%; and the drill tooth is cylindrical. The drill tooth provided by the invention can be inlaid on a bit matrix in the vertical and horizontal ways and has cutting and grinding combined functions for rock breaking in the soft and hard interlaced and abrasive formation, high rock breaking efficiency and long service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

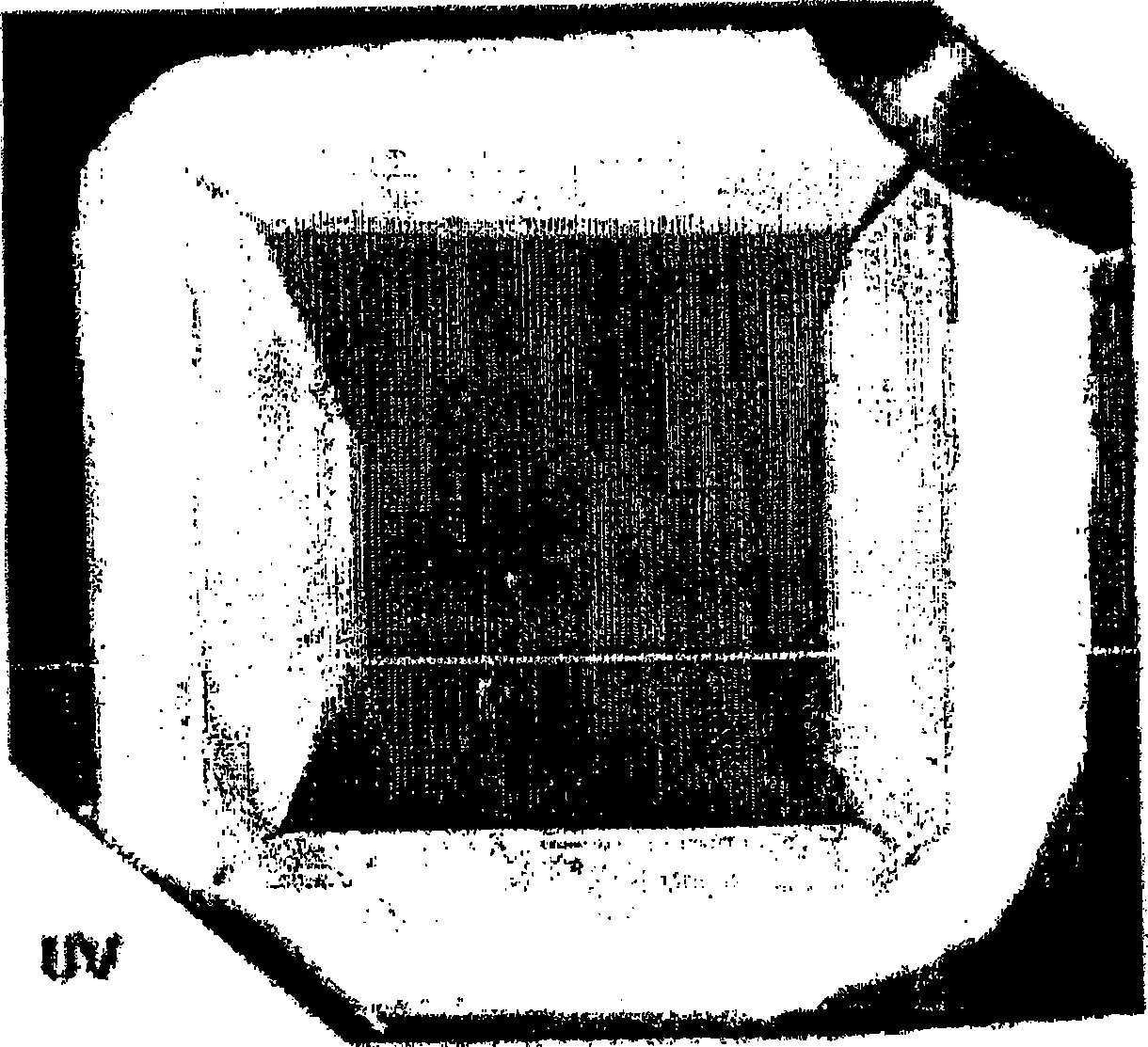

High crystalline quality synthetic diamond

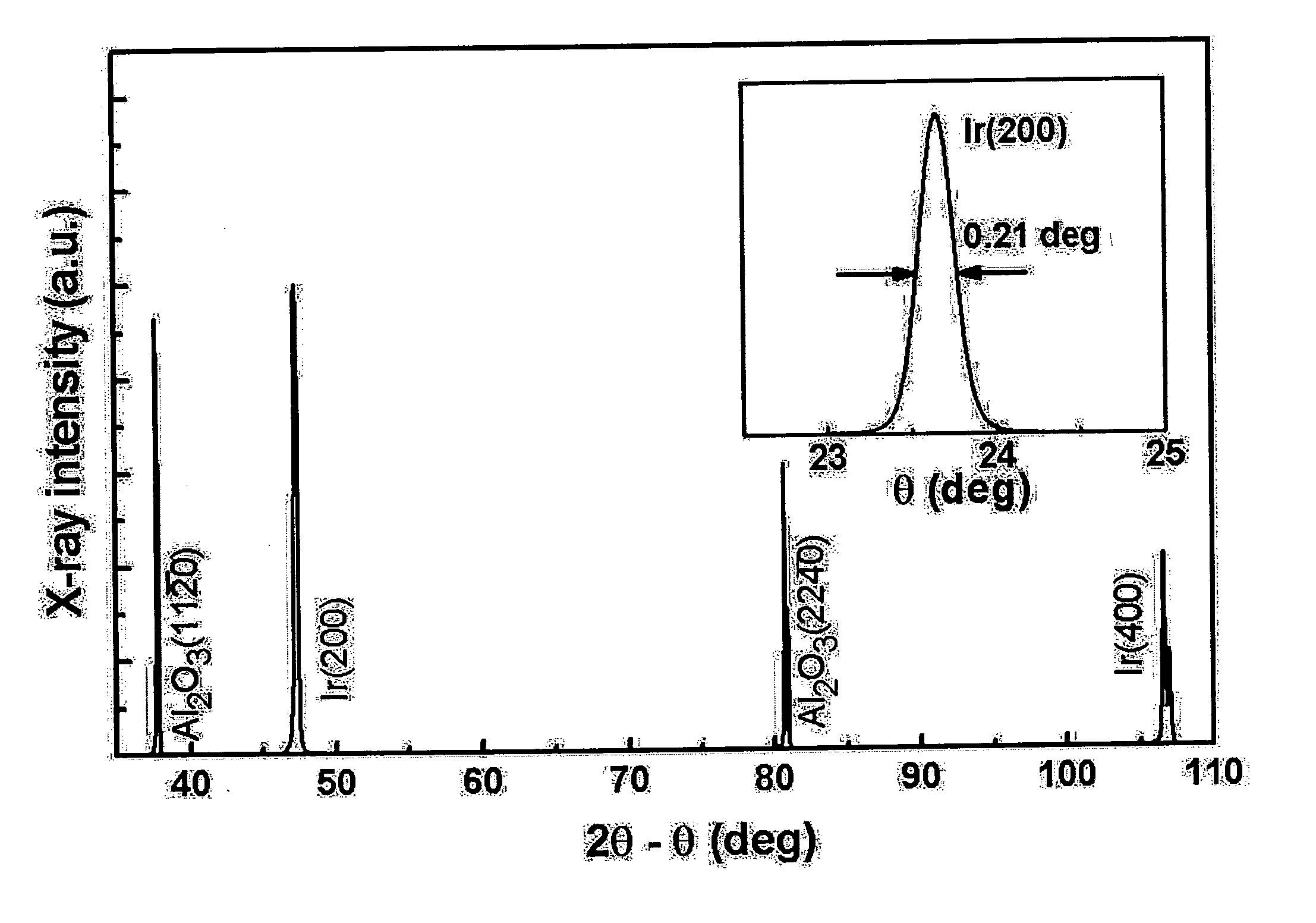

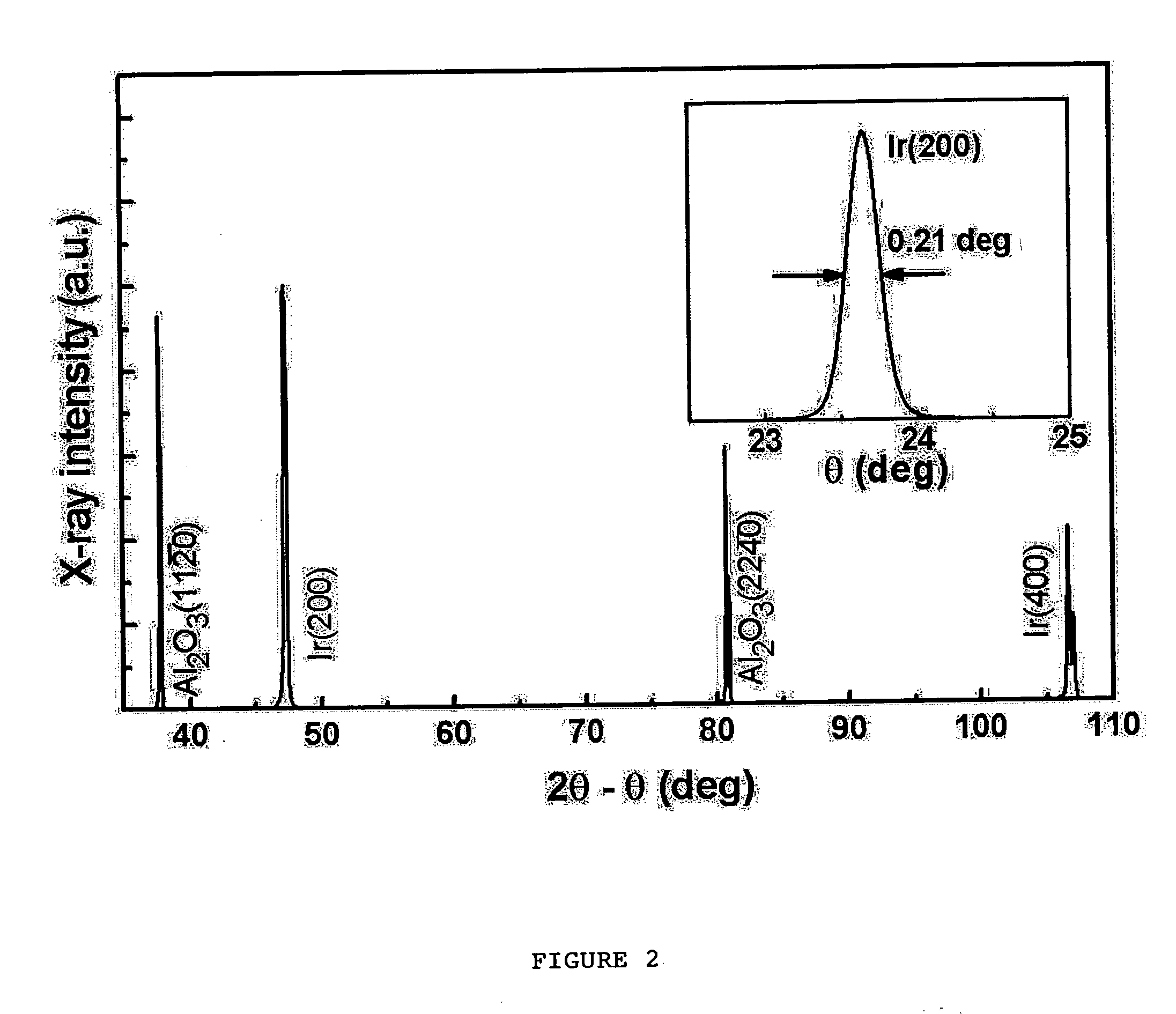

ActiveCN101443476AAvoid applying elastic strainPolycrystalline material growthFrom chemically reactive gasesRocking curveX-ray

The invention relates to a single crystal CVD diamond material, wherein the extended defect density as characterised by X-ray topography is less than 400 / cm2 over an area of greater than 0.014 cm2. The invention further relates to a method for producing a CVD single crystal diamond material according to any preceding claim comprising the step of selecting a substrate on which to grow the CVD single crystal diamond, wherein the substrate has at least one of a density of extended defects as characterised by X-ray topography of less than 400 / cm2 over an area greater than 0.014 cm2; an optical isotropy of less than 1x10-5 over a volume greater than 0.1 mm3; and a FWHM X-ray rocking curve width for the (004) reflection of less than 20 arc seconds.

Owner:EHLEMENT SIKS TECHZ PTI

Diamond single crystal, method for producing the same, and single crystal diamond tool

ActiveUS20150176155A1High hardnessEasy to processPolycrystalline material growthLayered productsGas phaseTransmittance

A method for producing a diamond single crystal includes implanting an ion other than carbon into a surface of a diamond single crystal seed substrate and thereby decreasing the transmittance of light having a wavelength of 800 nm, the surface having an off-angle of 7 degrees or less with respect to a {100} plane, and homoepitaxially growing a diamond single crystal on the ion-implanted surface of the seed substrate using a chemical vapor synthesis under synthesis conditions where the ratio NC / NH of the number of carbon-containing molecules NC to the number of hydrogen molecules NH in a gas phase is 10% or more and 40% or less, the ratio NN / NC of the number of nitrogen molecules NN to the number of carbon-containing molecules NC in the gas phase is 0.1% or more and 10% or less, and the seed substrate temperature T is 850° C. or more and less than 1000° C.

Owner:SUMITOMO ELECTRIC IND LTD

Method of preparing high-performance diamond semiconductor based on low-cost single crystal diamond

ActiveCN107275192AImprove performanceReduce technical difficultySemiconductor/solid-state device manufacturingSelf-healingHydrogen atmosphere

The invention discloses a method for preparing a high-performance diamond semiconductor based on low-cost single crystal diamond, and belongs to the technical field of novel semiconductor preparation. The process steps include a, a commercially available cheap high temperature and pressure Ib-type single crystal diamond substrate is subjected to acid pickling to remove surface inclusions and form a passivated oxygen termination surface; b, the activated diamond surface is subjected to short time treatment by microwave hydrogen plasmas to expose a fresh C-C dangling bond; c, a high-quality single crystal diamond thin film is epitaxially grown on the fresh diamond surface by microwave plasma chemical vapor deposition to achieve the diamond thin film epitaxy with low dislocation density and impurity content mainly through the introduction of oxygen atoms with a self-healing function; and d, a carbon source and a oxygen source are turned off, the epitaxially grown diamond surface is treated by the microwave hydrogen plasmas to obtain a high hydrogen termination density, and the treated diamond surface is cooled to room temperature under a hydrogen atmosphere to obtain a diamond semiconductor with high conductivity. According to the invention, the process flow is simplified, the technical difficulty and the production cost are reduced, and the production cycle is shortened.

Owner:UNIV OF SCI & TECH BEIJING

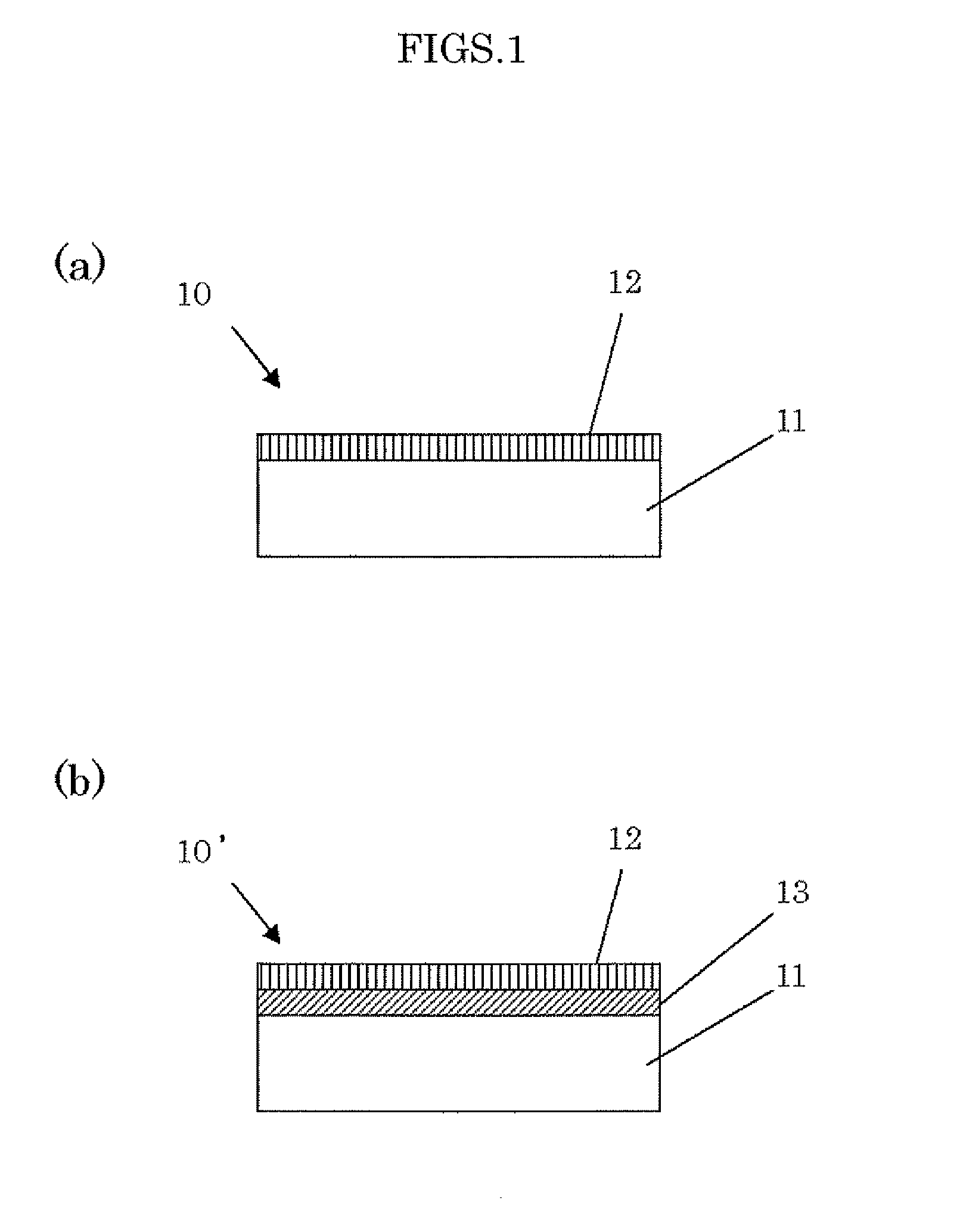

Base material for growing single crystal diamond and method for producing single crystal diamond substrate

InactiveUS20110084285A1High crystallinityLow costPolycrystalline material growthAfter-treatment detailsSingle crystalCrystallinity

The present invention is a base material for growing a single crystal diamond comprising: at least a single crystal SiC substrate; and an iridium film or a rhodium film heteroepitaxially grown on a side of the single crystal SiC substrate where the single crystal diamond is to be grown. As a result, there is provided a base material for growing a single crystal diamond and a method for producing a single crystal diamond substrate which can grow the single crystal diamond having a large area and good crystallinity and produce a high quality single crystal diamond substrate at low cost.

Owner:SHIN ETSU CHEM IND CO LTD

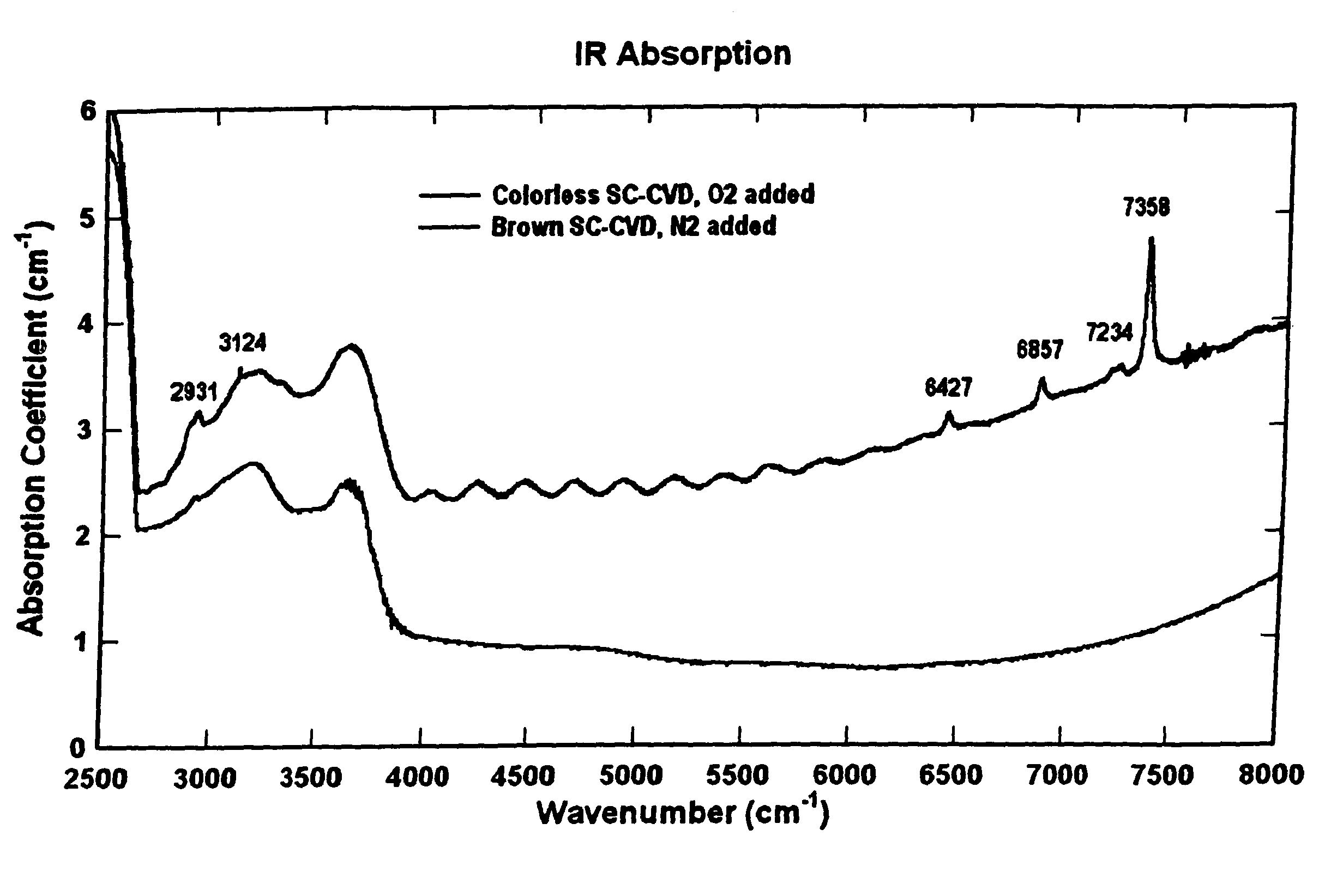

Colorless single-crystal CVD diamond at rapid growth rate

ActiveUS7883684B2Polycrystalline material growthUltra-high pressure processesSingle crystalMicrowave plasma chemical vapor deposition

The present invention relates to a method for producing colorless, single-crystal diamonds at a rapid growth rate. The method for diamond production includes controlling temperature of a growth surface of the diamond such that all temperature gradients across the growth surface of the diamond are less than about 20° C., and growing single-crystal diamond by microwave plasma chemical vapor deposition on the growth surface of a diamond at a growth temperature in a deposition chamber having an atmosphere, wherein the atmosphere comprises from about 8% to about 20% CH4 per unit of H2 and from about 5 to about 25% O2 per unit of CH4. The method of the invention can produce diamonds larger than 10 carats. Growth rates using the method of the invention can be greater than 50 μm / hour.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

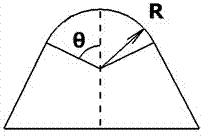

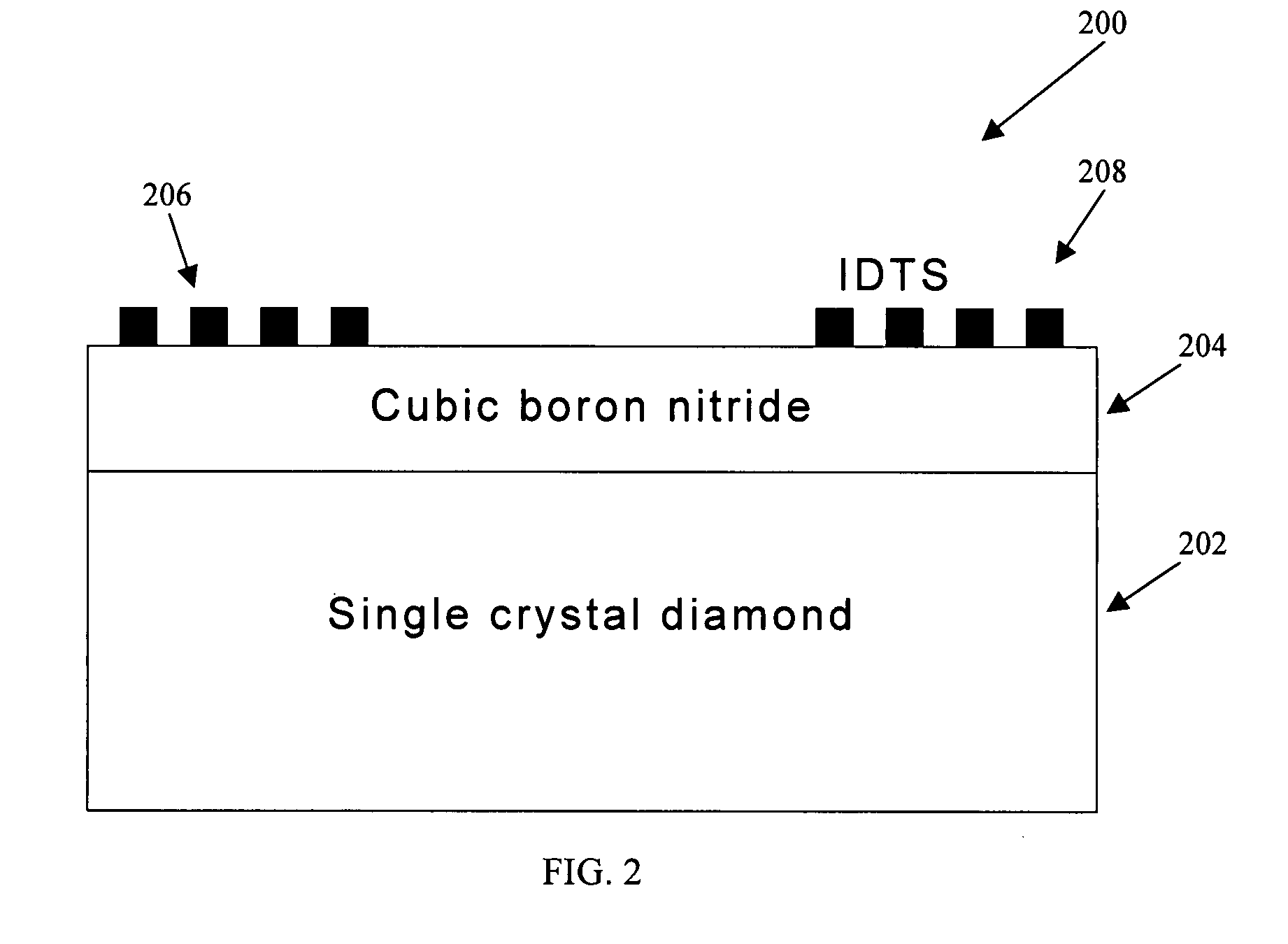

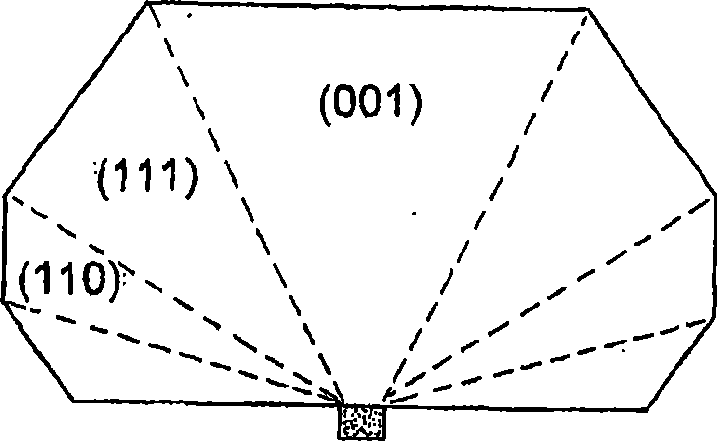

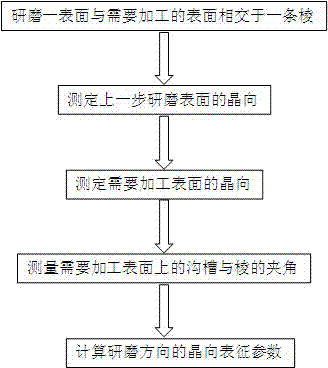

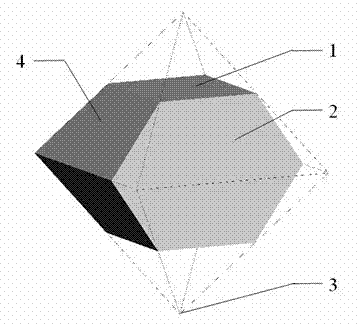

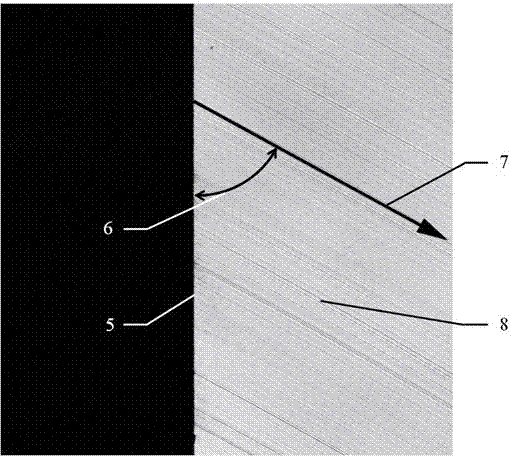

Method for confirming grinding crystal orientation of diamond

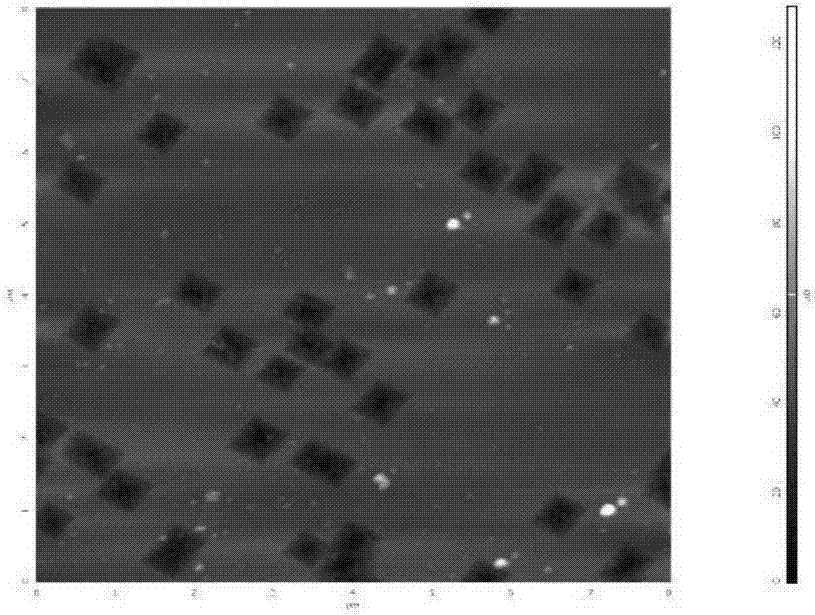

ActiveCN103616394AMaterial analysis using wave/particle radiationMaterial analysis by optical meansCrystal orientationLaser scanning

The invention relates to a method for conforming grinding crystal orientation of a diamond, belonging to the technical field of ultra-precise machining. The method comprises the steps of (1) grinding a single crystal diamond so as to obtain an abrasive surface, wherein the abrasive surface and a crystal face to be ground intersect so as to form a ridge; (2) measuring the index of the crystal surface of the obtained abrasive surface; (3) measuring the index of the crystal surface of the surface to be ground; (4) measuring the included angle between a groove left in the surface to be processed due to processing and the ridge formed in step (1); (5) calculating according to the data measured from step (2) to step (4) so as to obtain the specific crystal orientation index or direction in the grinding direction. According to the method, the abrasive surface provided in advance and the surface to be ground form the ridge which is taken as the reference crystal orientation, in subsequent abrasive machining, characterization parameters of the specific grinding direction can be measured by a laser scanning confocal microscope only by marking initial crystal orientation on the crystal surface, and the space placing position and placing gesture of the diamond workpiece do not need to be recorded, so that the method is convenient and rapid.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com