Nano monocrystalline diamond and method for making same

A single crystal diamond and nano-single crystal technology, applied in the direction of single crystal growth, single crystal growth, manufacturing tools, etc., can solve the problems of high cost, impossibility of application, easy aggregation of nanoparticles, etc., and achieve low production cost and reliable technical support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

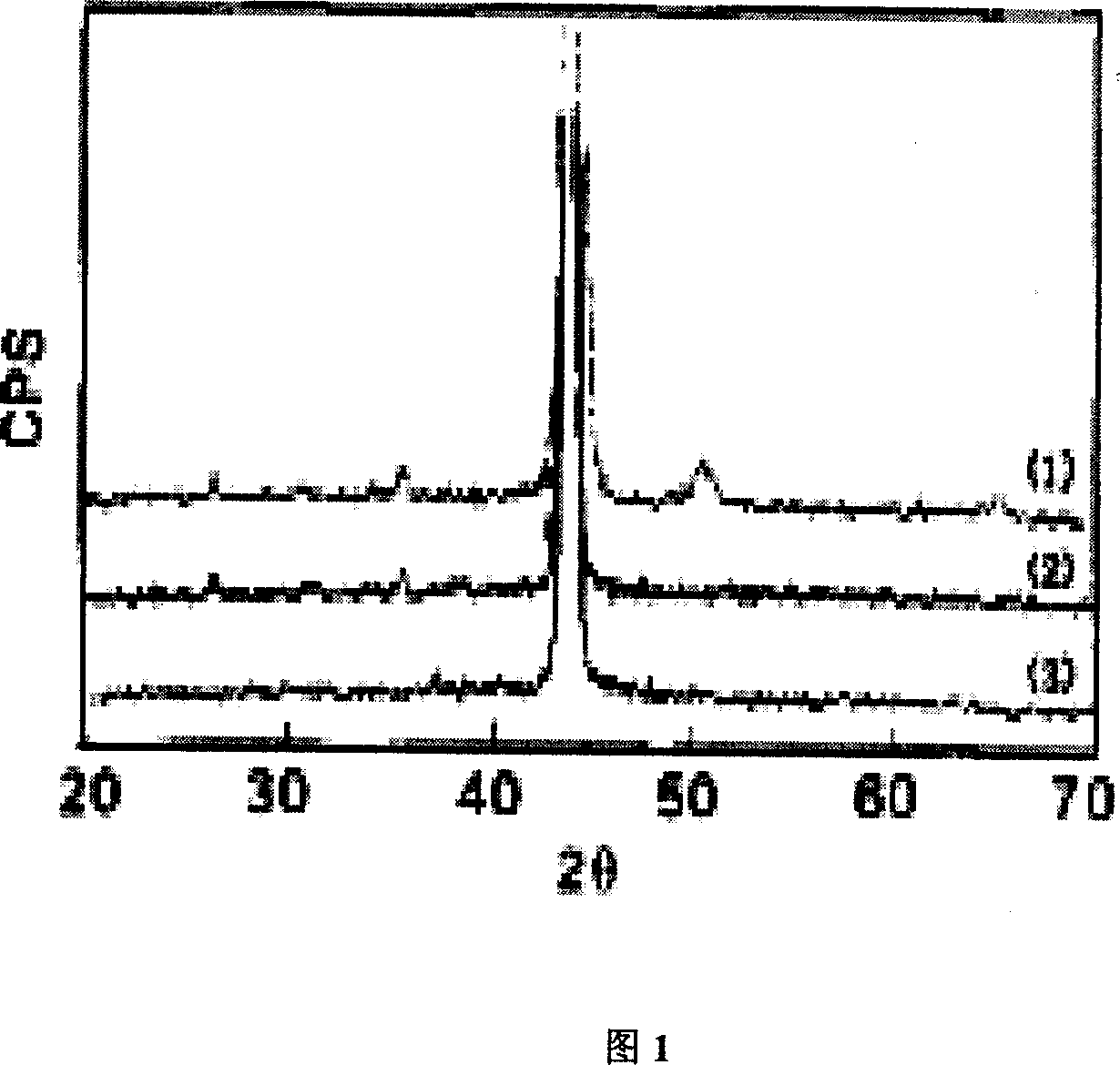

Embodiment 1

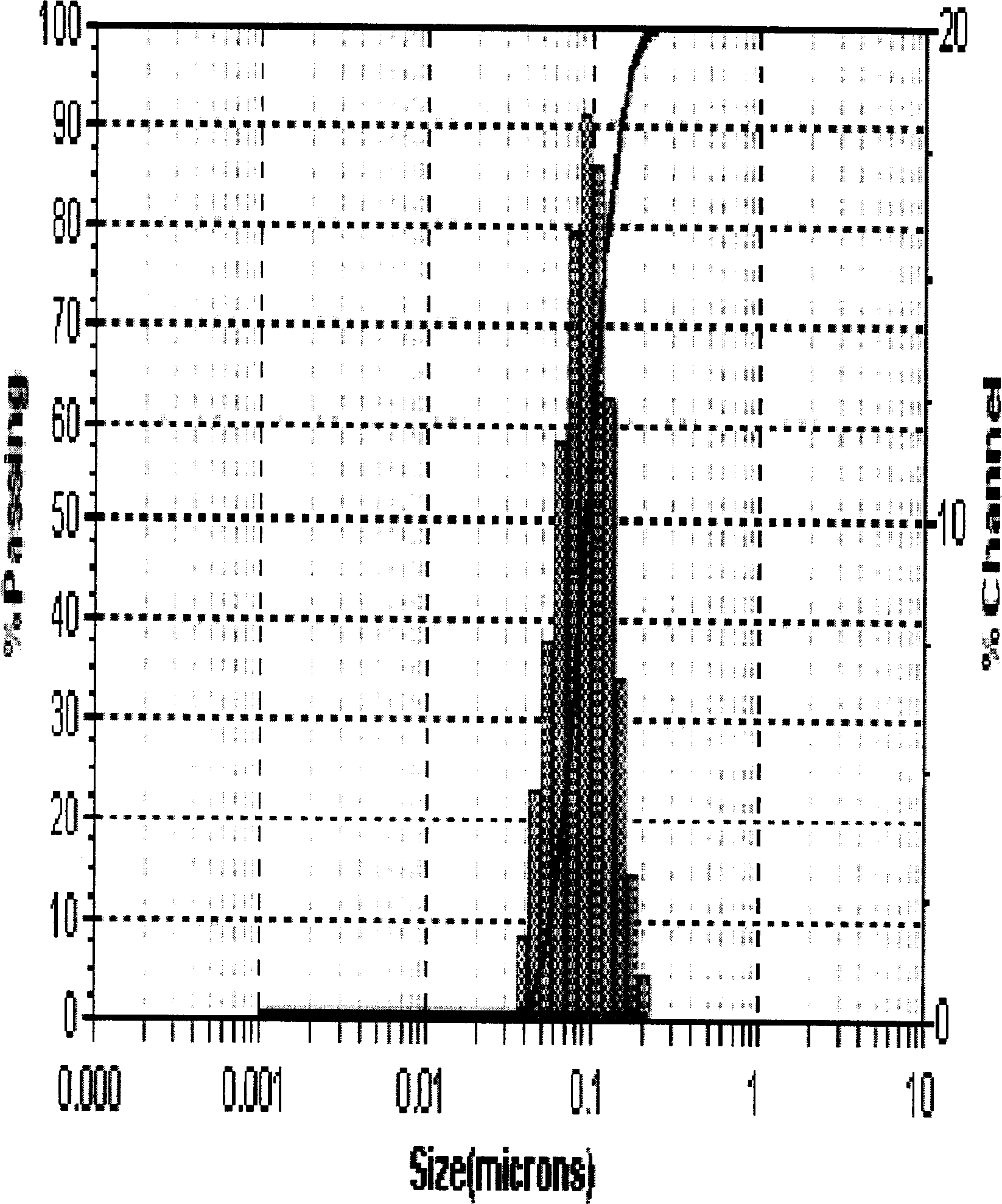

[0060] Micro-grinding and centrifugal classification are performed on single crystal diamond particles with a nominal particle size of 4--8um. For the pulverization step, a steel ball mill jar with a diameter and length of 150 mm was used. 100 grams of the above-mentioned original diamond powder are loaded, and 6 kg of steel balls with a diameter of 12 mm, 8 mm and 6 mm are respectively loaded in a ratio of 1: 2: 4, and the ball mill jar is operated at 90 n / min for 120 hours. The pulverized powder is taken out from the tank, put into 1000ml of 10% dilute hydrochloric acid solution, heated and reacted for 1 hour, the components of metal impurities are removed by dissolving, and then fully washed with water until the pH value is about 6.5. Dehydration and drying, and then put the powder in 1000ml of mixed acid solution of perchloric acid and sulfuric acid (perchloric acid: sulfuric acid = 1: 2) and heat treatment for 1.5 hours. When the color does not change, stop heating, centr...

Embodiment 2

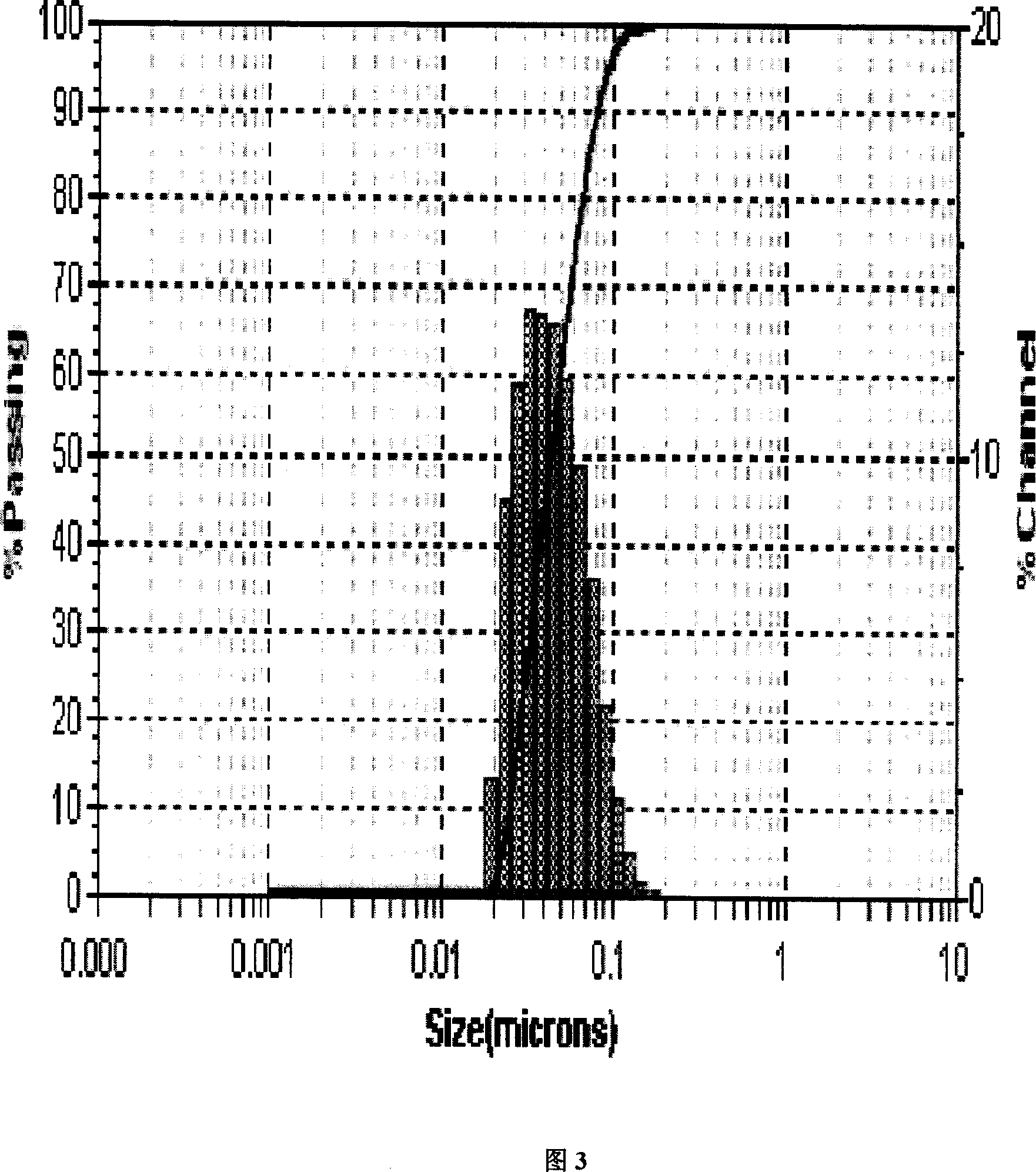

[0062] Crush and centrifugally classify single crystal diamond particles with a nominal particle size of 2-4um. Load 100 grams of the above-mentioned raw diamond powder. Load 5kg of steel balls with diameters of 10mm, 6mm and 4mm in a ratio of 1:4:6 , the ball mill tank was operated at 80n / min (rpm) for 72 hours, the pulverized powder was taken out from the tank, put into 1000ml of 20% dilute hydrochloric acid solution, and heated for 0.5 hours to remove metal impurities by dissolution, and then fully rinsed with water To a pH value of about 6.5. Dehydration and drying, then place the powder in 1000ml of mixed acid solution of perchloric acid and sulfuric acid (perchloric acid: sulfuric acid = 1:1) and heat treatment for 1.5 hours. When the color does not change, stop heating, centrifugal washing, pH = 4, dehydrated and dried. Then, according to the ratio of material: alkali = 1: 3, put it in a nickel tongs pot. Keep it warm at 400 degrees for 2 hours. After it cools down, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com