Variable-friction damper

A damper and variable friction technology, applied in the field of dampers and variable friction dampers, can solve the problems of large changes in stiffness and unfavorable seismic resistance of building structures, and achieve the effect of avoiding collision, simple structure and large adjustment area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

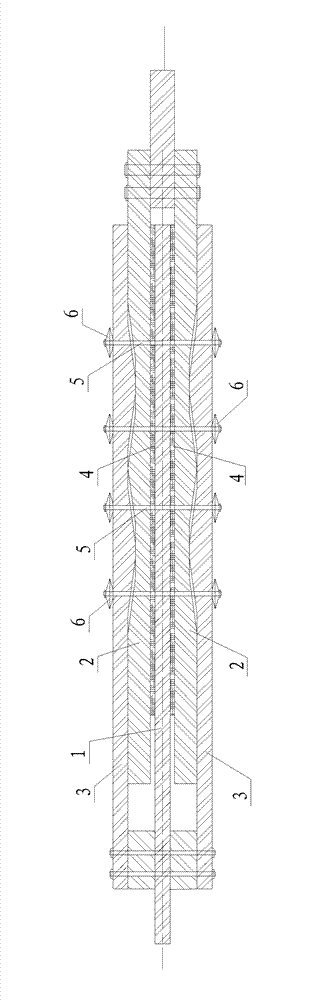

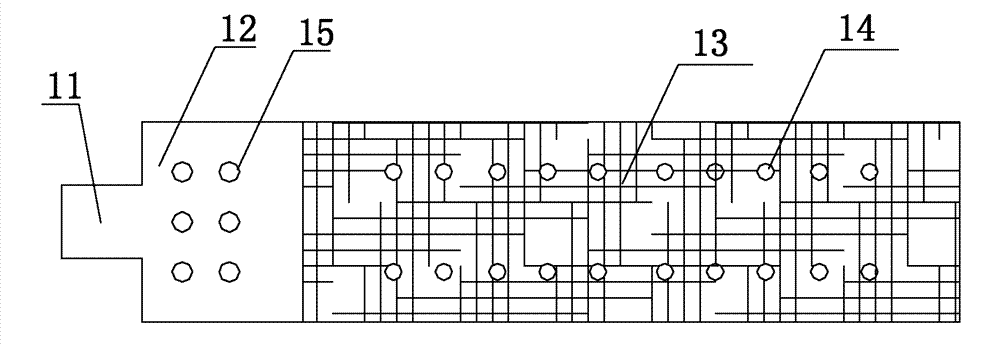

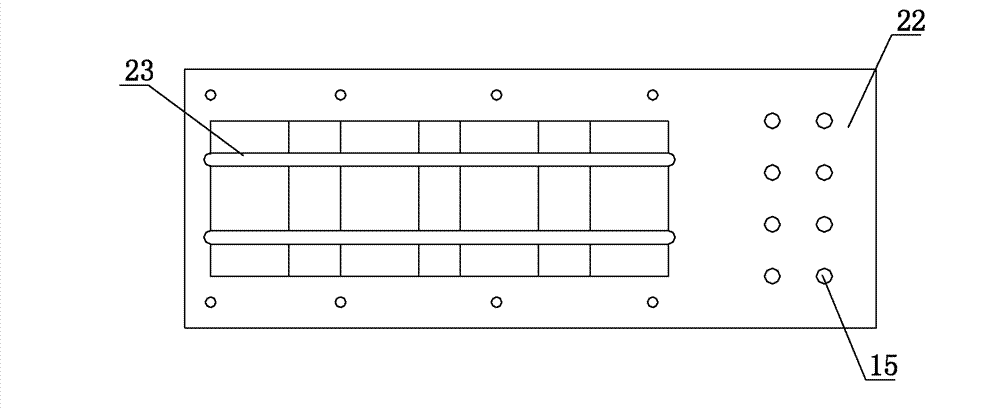

[0066] like Figure 1 to Figure 7 As shown, the first embodiment is a flat plate variable friction damper, which includes five stacked steel plates, of which the core plate 1 is located in the middle, and two first steel plates are separated on both sides of the core plate 1 2. The second steel plate 3 is located outside the first steel plate 2 .

[0067] like figure 1 , figure 2 and Figure 5 As shown, both sides of the core plate 1 are bonded with a friction material 4, and the friction material 4 is a heavy-duty friction material. One end of the core board 1 has a core board connecting part 11 connected with the building structure, and the fixing part 12 of the core board 1 is connected with the core board connecting part 11, and three rows of fixing holes 15 are arranged on the fixing part 12, and the other parts are core boards. The friction part 13 of the plate 1 is provided with two rows of connecting holes 14 (of course, the friction material 4 also has two rows o...

Embodiment 2

[0073] like Figure 8 to Figure 10 As shown, Embodiment 2 is a hinge point variable friction damper, which includes eight steel plates, such as Figure 8 As shown, among the eight steel plates, the first, third, fifth and seventh steel plates form a group, and the second, fourth, sixth and eighth steel plates form a group. Stacked together, the middle part between the fourth steel plate 100 and the fifth steel plate 101 is a slope contact, that is, a concave-convex surface contact, (same as the slope of Embodiment 1, and will not be repeated here). Friction material 102 is bonded between the remaining two adjacent steel plates. Corresponding connecting holes (not shown in the figure) are opened on the two groups of steel plates and the friction material 102 bonded thereon, and bolts 103 that hinge the eight steel plates together are pierced in the connecting holes. The other ends of the two groups of steel plates are respectively connected to different building components, a...

Embodiment 3

[0077] like Figure 11 and Figure 12 As shown, Embodiment 3 is a circular cross-section support type variable friction damper, which includes a plurality of ring-shaped steel plates that are set together, that is, the inner steel plate 200, the middle steel plate 201 and the outer steel plate 202, the inner steel plate 200 and the middle steel plate 201 The friction material 203 is bonded to the side that is attached to each other. The friction surface is formed between the middle steel plate 201 and the friction material 203, and it slides relative to each other in the working state. Contact (the structure and principle of the concave-convex surface are the same as those in Embodiment 1, and will not be repeated here). Both ends are in planar contact. Outer steel plate 202, inner steel plate 200 and the friction material 203 bonded thereon are provided with multiple sets of corresponding connecting holes (not shown in the figure), and the middle steel plate 201 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com