Plate-type friction-changing damper

A variable friction and damper technology, which is applied to friction dampers, building components, shockproof, etc., can solve the problems of complex devices and difficult implementation, and achieve the effect of easy material acquisition, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

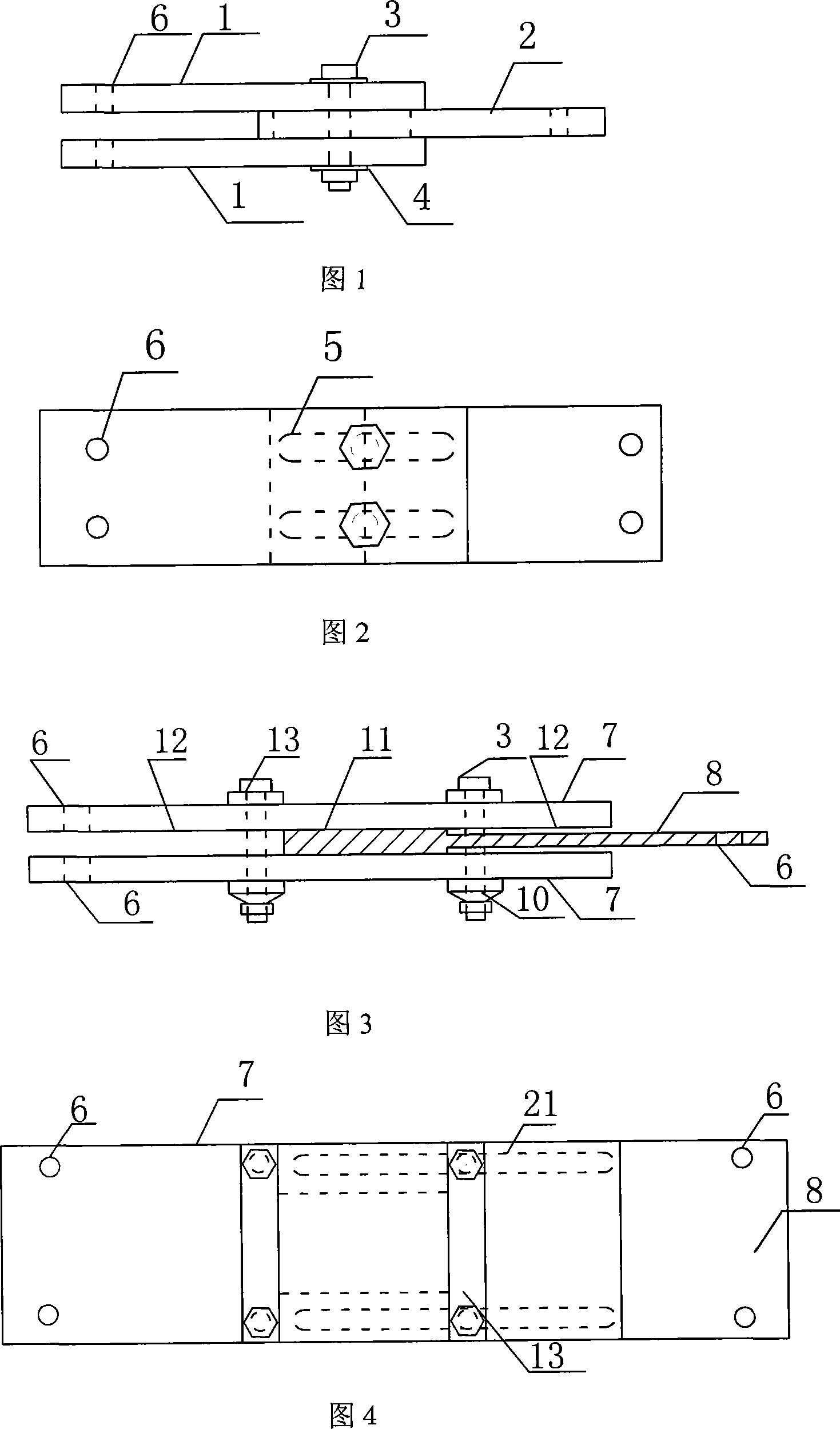

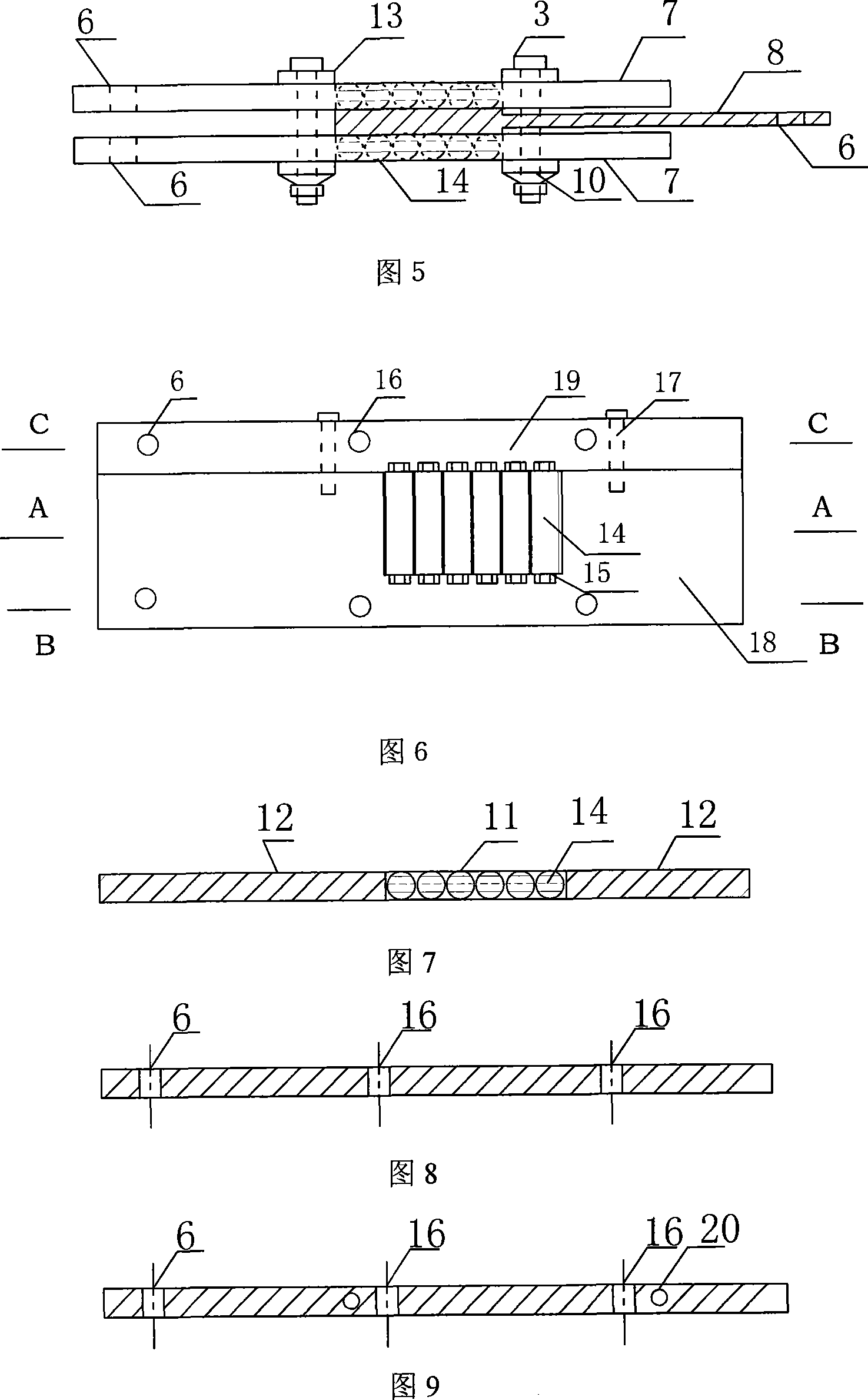

Embodiment 1

[0041] In this embodiment, the difference between the friction coefficients of the middle friction surface and the friction surfaces on both sides is realized by using the difference between the steel-steel rolling friction coefficient and the sliding friction coefficient. The structure of embodiment 1 is shown in Figure 5, mainly including cover plate 7, sliding plate 8, pre-tightening bolt 3, disc spring 10 and spacer 13, sliding plate 8 is located between two cover plates, slides relative to the cover plate; Tighten the bolt 3 to press the two cover plates to provide a positive pressure between the contact surface of the sliding plate 8 and the cover plate 7; the size of the positive pressure is controlled by changing the compression amount of the disc spring 10, and the spacer 13 enhances the rigidity of the cover plate The structure of the cover plate is as shown in Figures 6-9, consisting of steel plates 18, strip plates 19, rollers 14 and bearings 15, the bearings 15 are...

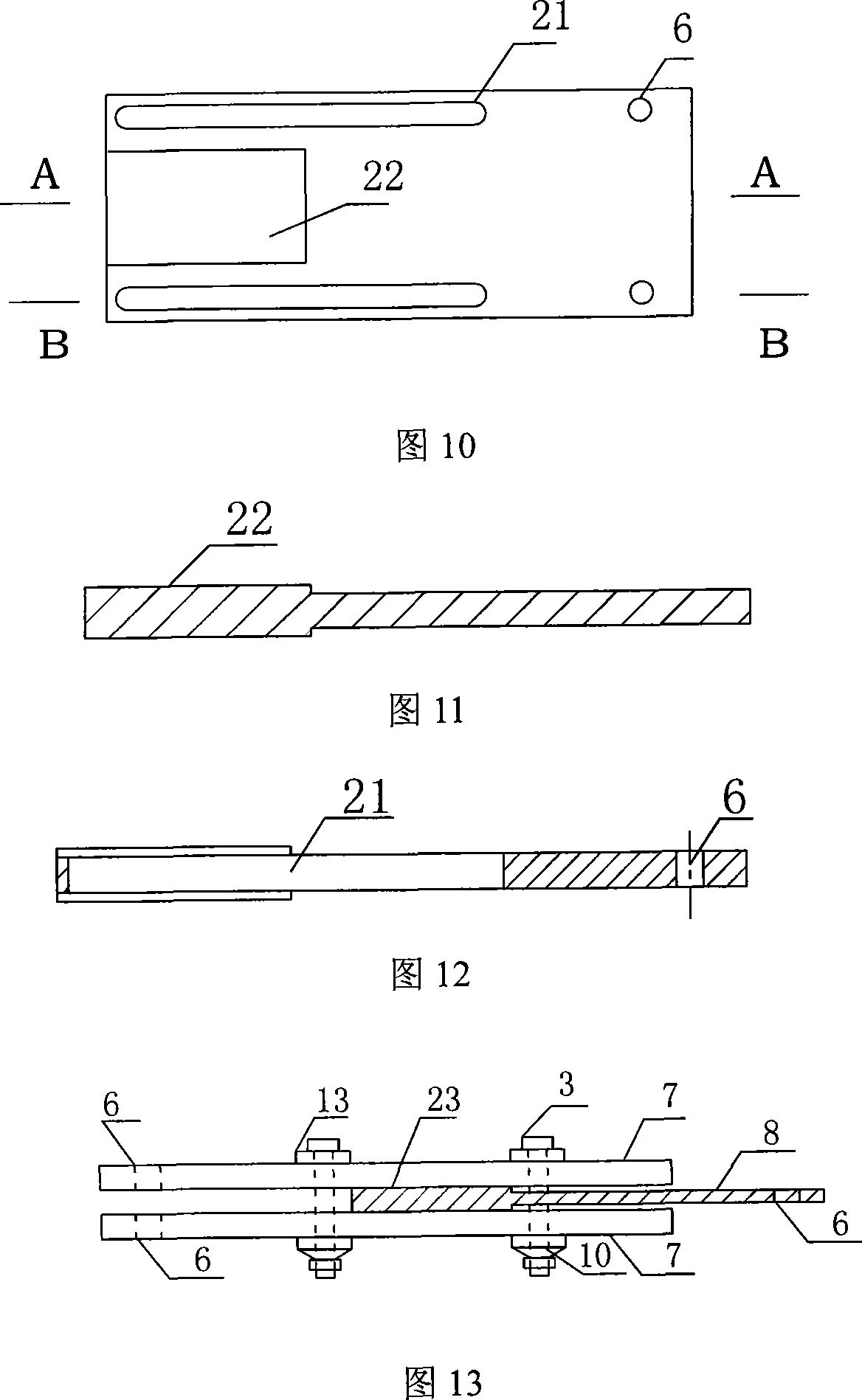

Embodiment 2

[0043]In this embodiment, the Teflon coating can greatly reduce the friction coefficient to realize the difference in the friction coefficient between the middle friction surface and the friction surfaces on both sides. Embodiment 2, as shown in Figure 13, mainly includes a cover plate 7, a sliding plate 8, a pre-tightening bolt 3 and a disc spring 10. The sliding plate 8 is located between the cover plates and slides relative to the cover plate; the high-strength pre-tightening bolt presses the cover plate , to provide a positive pressure between the sliding plate and the contact surface of the cover plate; the size of the positive pressure is controlled by changing the compression amount of the disc spring. The middle third of the friction surface of the cover plate 7 is plated with Teflon coating. Since the thickness of Teflon is only tens of microns, the local plating of Teflon on the steel plate will not cause the friction surface to be uneven. The structure of the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com