Patents

Literature

259 results about "Microwave plasma chemical vapor deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

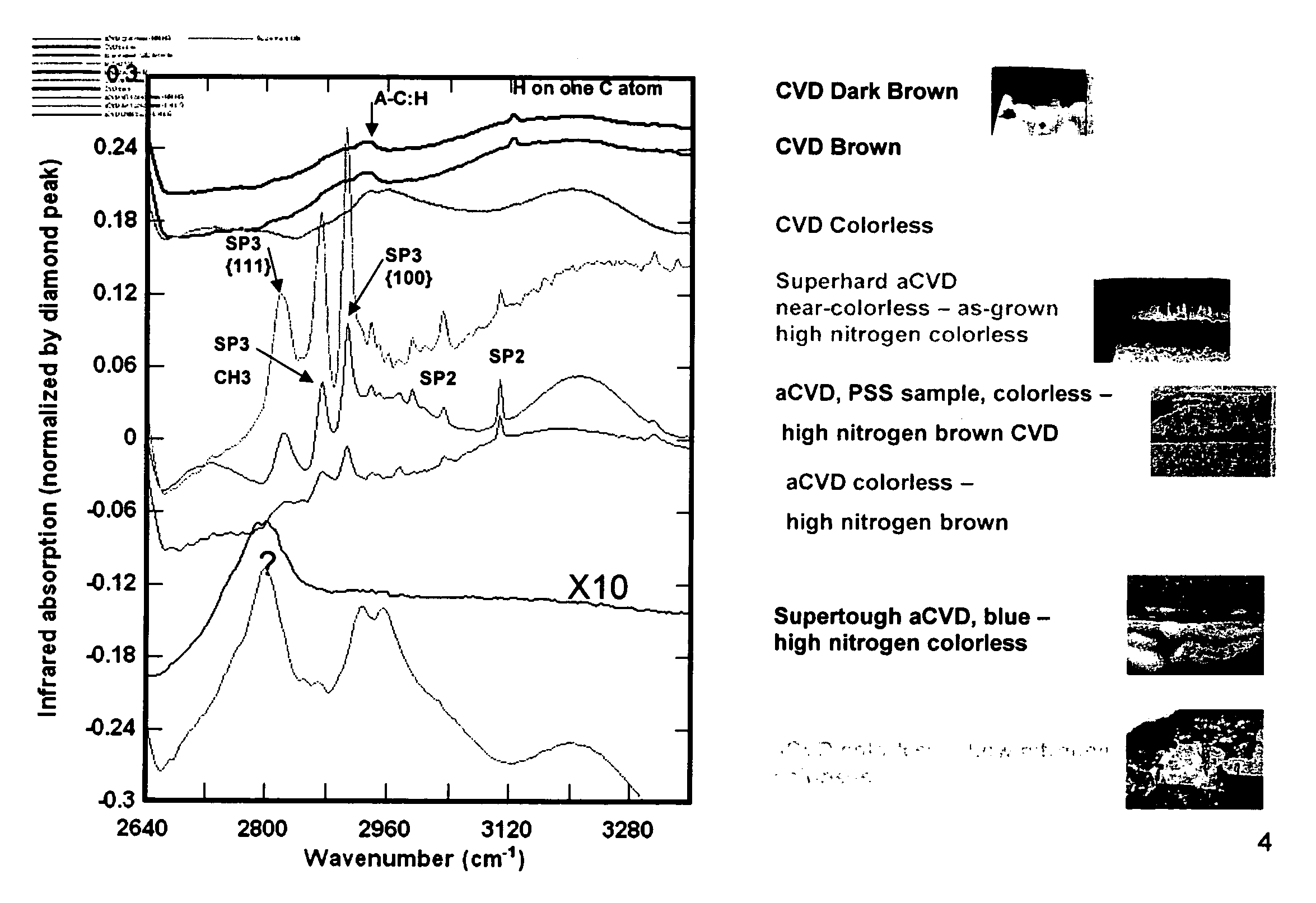

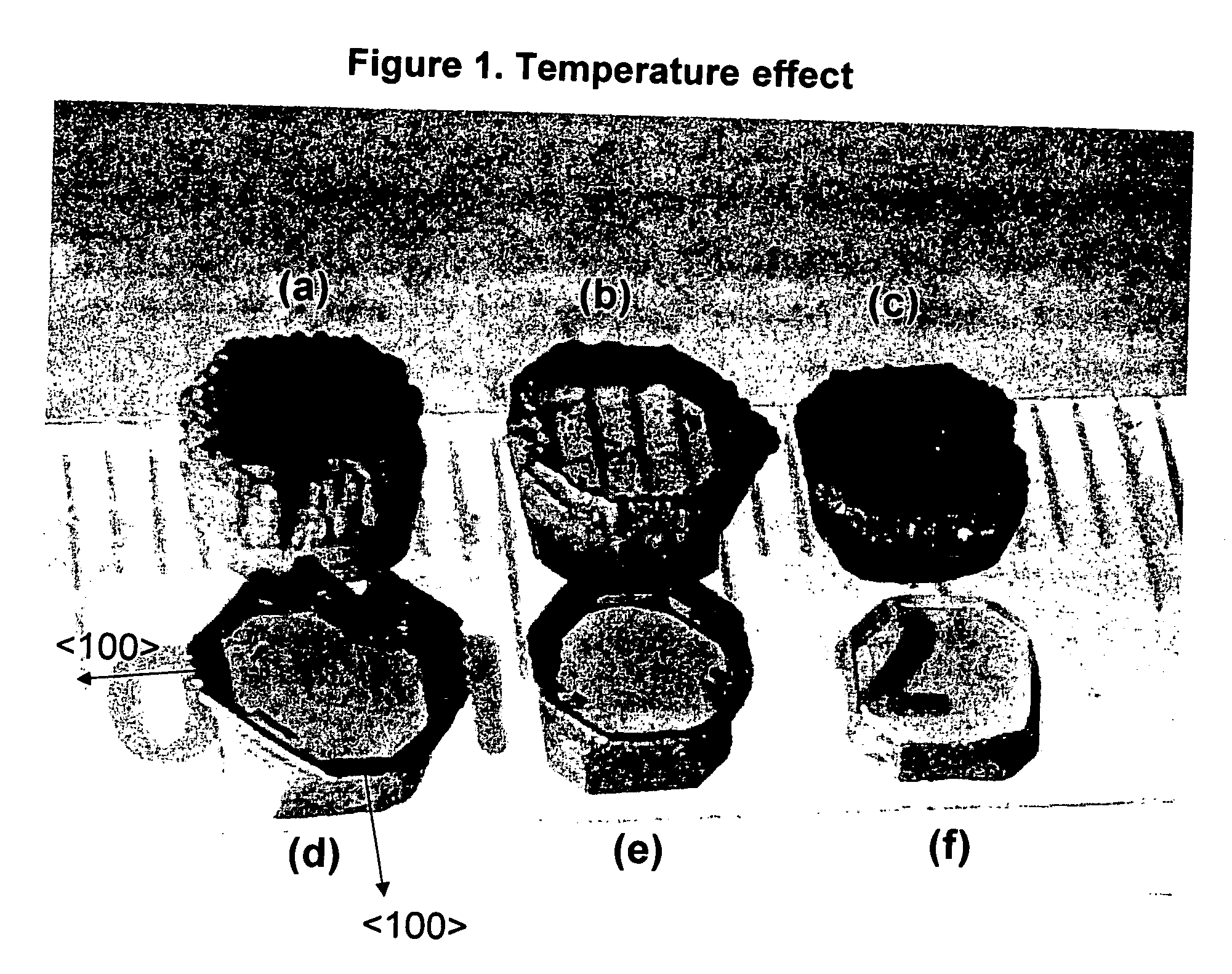

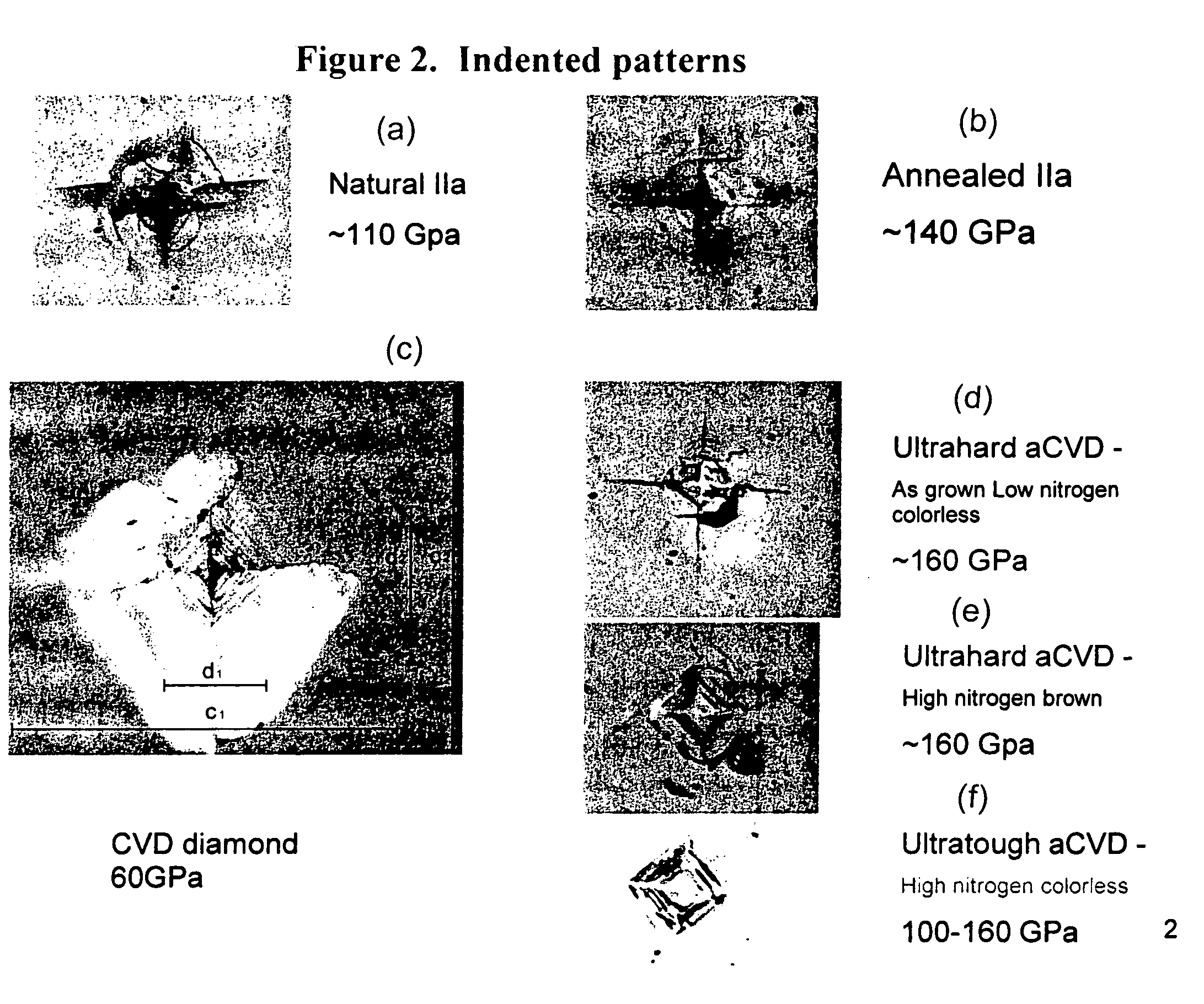

Ultratough CVD single crystal diamond and three dimensional growth thereof

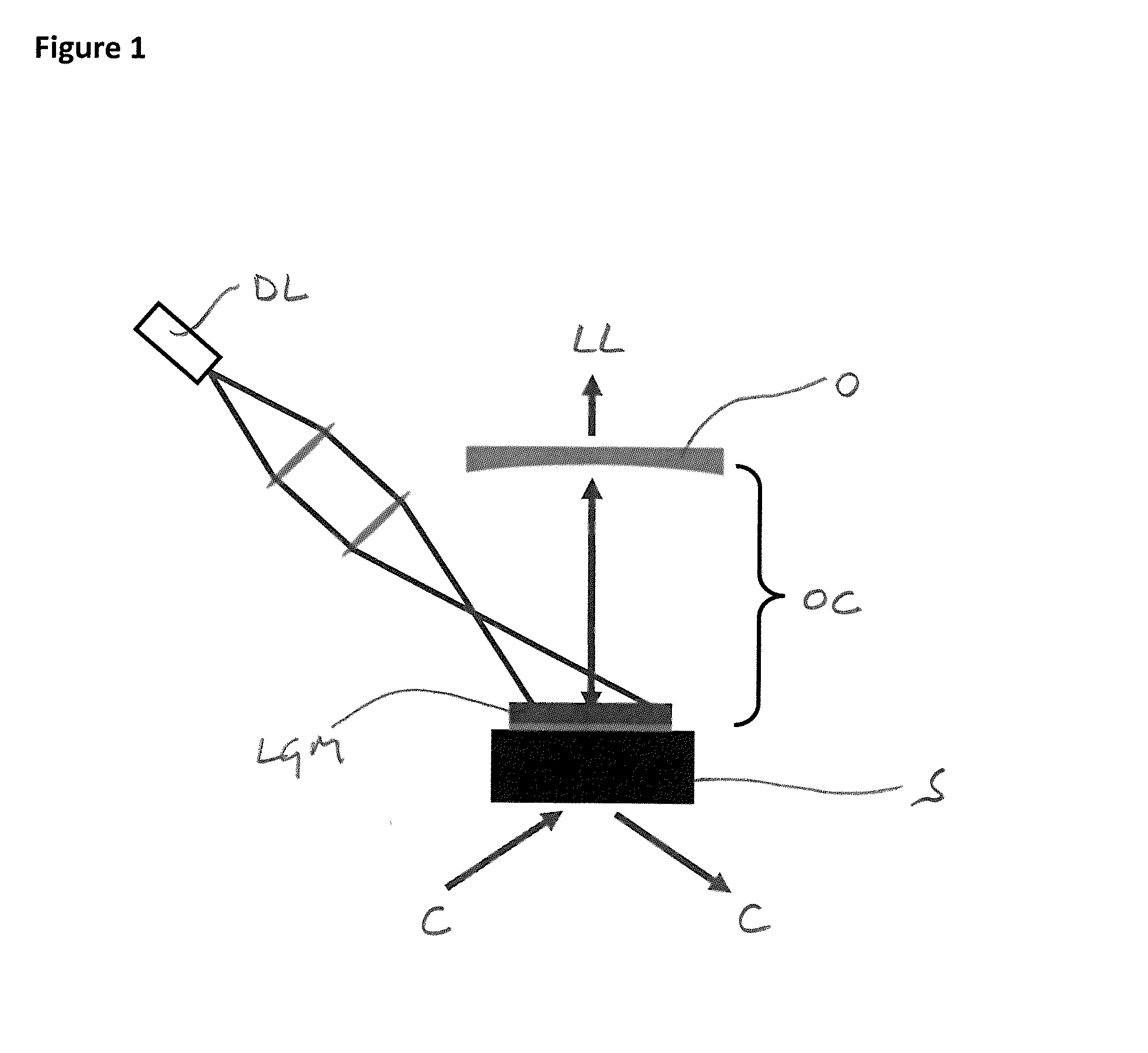

ActiveUS20060065187A1Minimizes gradientHigh melting pointPolycrystalline material growthUltra-high pressure processesSingle crystalMicrowave plasma chemical vapor deposition

The invention relates to a single-crystal diamond grown by microwave plasma chemical vapor deposition that has a toughness of at least about 30 MPa m1 / 2. The invention also relates to a method of producing a single-crystal diamond with a toughness of at least about 30 MPa m1 / 2. The invetnion further relates to a process for producing a single crystal CVD diamond in three dimensions on a single crystal diamond substrate.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

Thick polycrystalline synthetic diamond wafers for heat spreading applications and microwave plasma chemical vapour depositon synthesis techniques

ActiveUS20150222087A1Low costNegating economic benefitPolycrystalline material growthLaser detailsMolecular nitrogenGas concentration

A method of fabricating a polycrystalline CVD synthetic diamond material having an average thermal conductivity at room temperature through a thickness of the polycrystalline CVD synthetic diamond material of at least 2000 Wm−1K−1, the method comprising: loading a refractory metal substrate into a CVD reactor; locating a refractory metal guard ring around a peripheral region of the refractory metal substrate, the refractory metal guard ring defining a gap between an edge of the refractory metal substrate and the refractory metal guard ring having a width 1.5 mm to 5.0 mm; introducing microwaves into the CVD reactor at a power such that the power density in terms of power per unit area of the refractory metal substrate is in a range 2.5 to 4.5 W mm−2; introducing process gas into the CVD reactor wherein the process gas within the CVD reactor comprises a nitrogen concentration in a range 600 ppb to 1500 ppb calculated as molecular nitrogen N2, a carbon containing gas concentration in a range 0.5% to 3.0% by volume, and a hydrogen concentration in a range 92% to 98.5% by volume; controlling an average temperature of the refractory metal substrate to lie in a range 750° C. to 950° C. and to maintain a temperature difference between an edge and a centre point on the refractory metal substrate of no more than 80° C. growing polycrystalline CVD synthetic diamond material to a thickness of at least 1.3 mm on the refractory metal substrate; and cooling the polycrystalline CVD synthetic diamond material to yield a polycrystalline CVD synthetic diamond material having a thickness of at least 1.3 mm, an average thermal conductivity at room temperature through the thickness of the polycrystalline CVD synthetic diamond material of at least 2000 Wm−1K−1 over at least a central area of the polycrystalline CVD synthetic diamond material, wherein the central area is at least 70% of a total area of the polycrystalline CVD synthetic diamond material, a single substitutional nitrogen concentration no more than 0.80 ppm over at least the central area of the polycrystalline CVD synthetic diamond material, and wherein the polycrystalline CVD synthetic diamond material is substantially crack free over at least the central area thereof such that the central area has no cracks which intersect both external major faces of the polycrystalline CVD synthetic diamond material and extend greater than 2 mm in length.

Owner:ELEMENT SIX TECH LTD

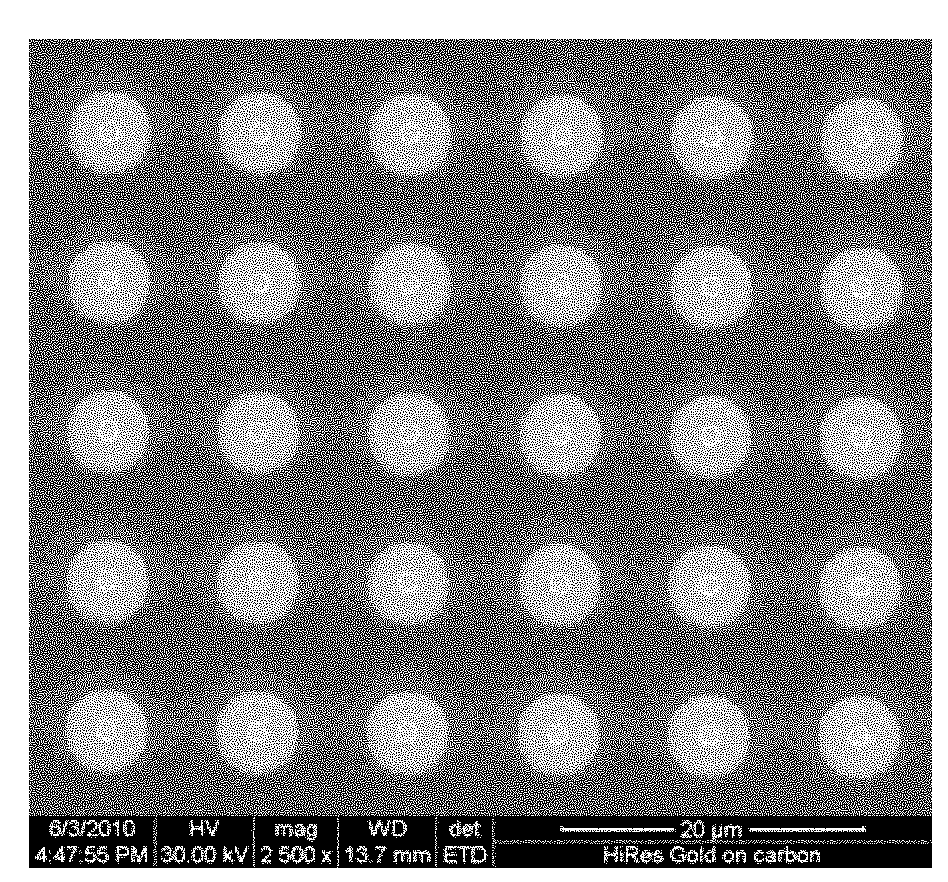

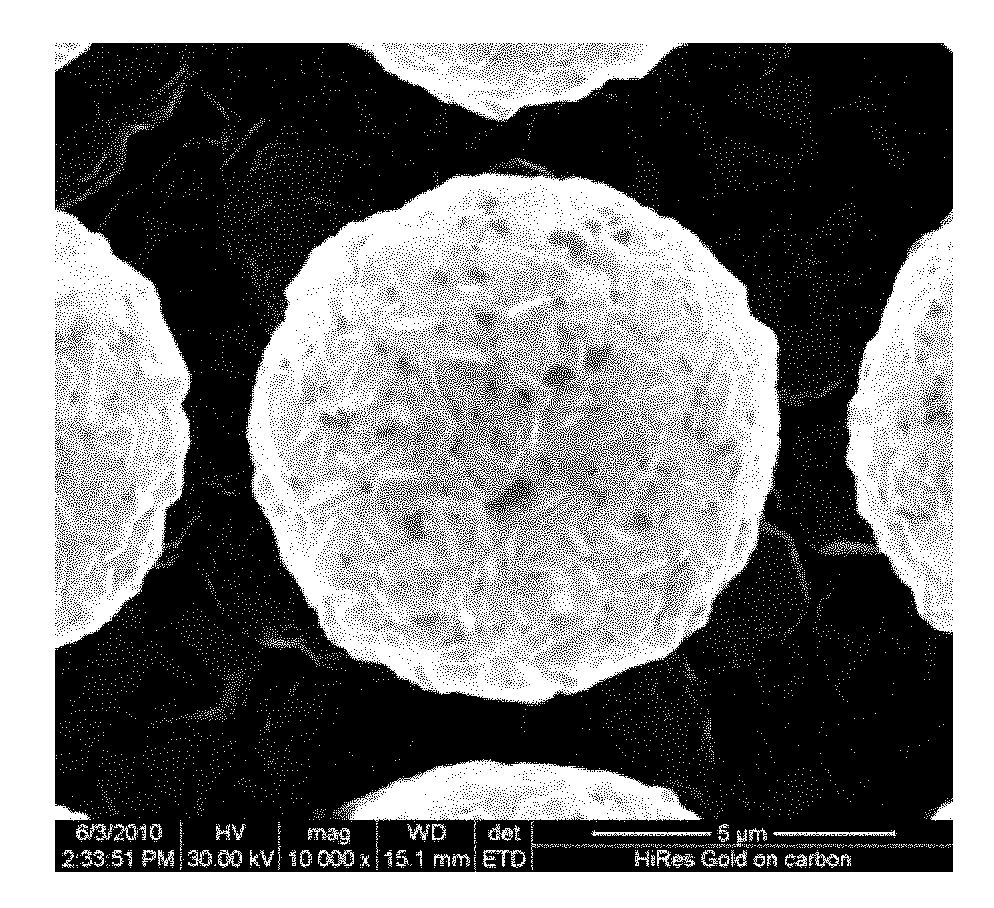

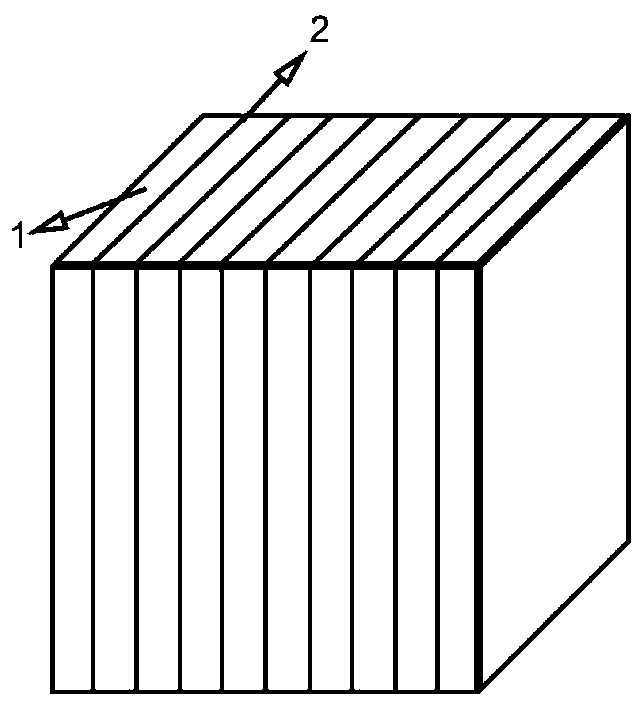

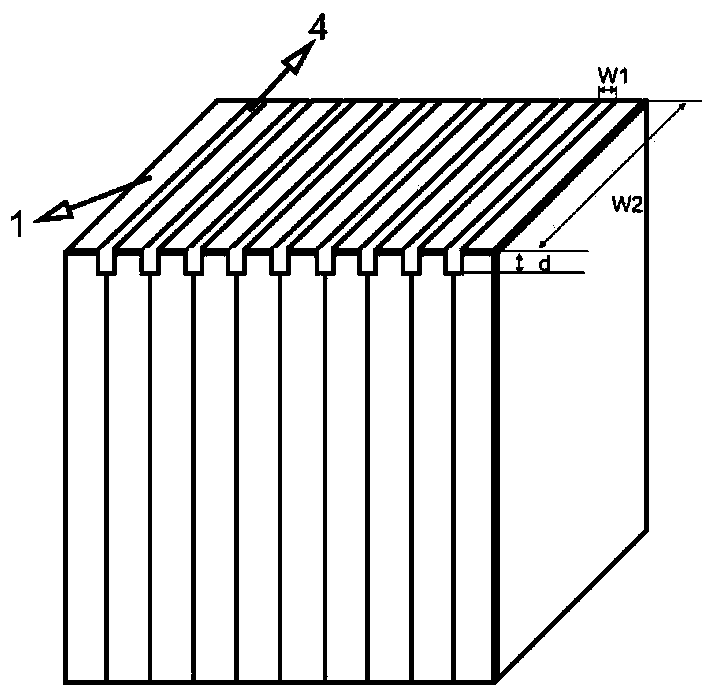

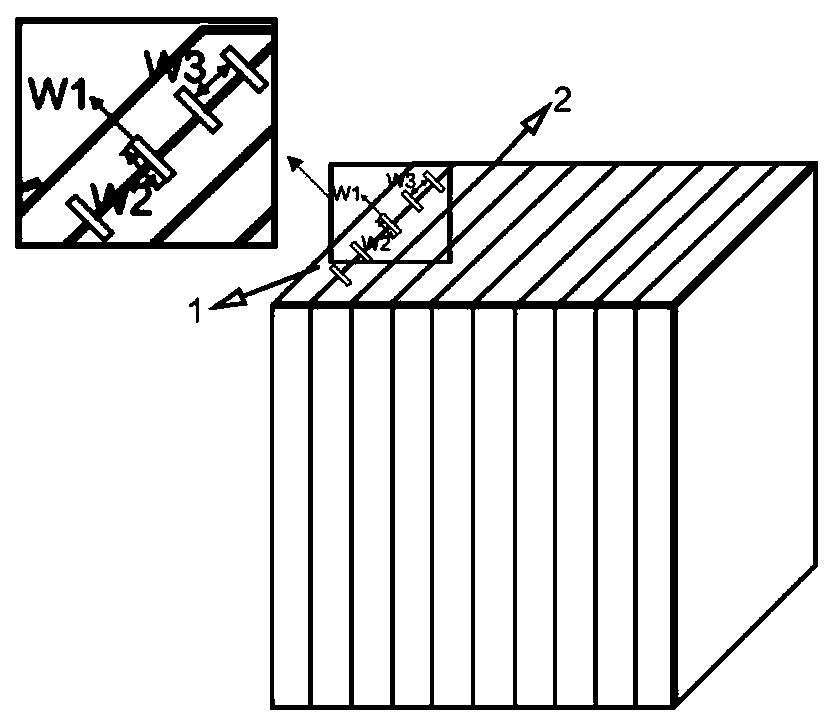

Boron-doped diamond micro-nano material with columnar array structure and preparation method thereof

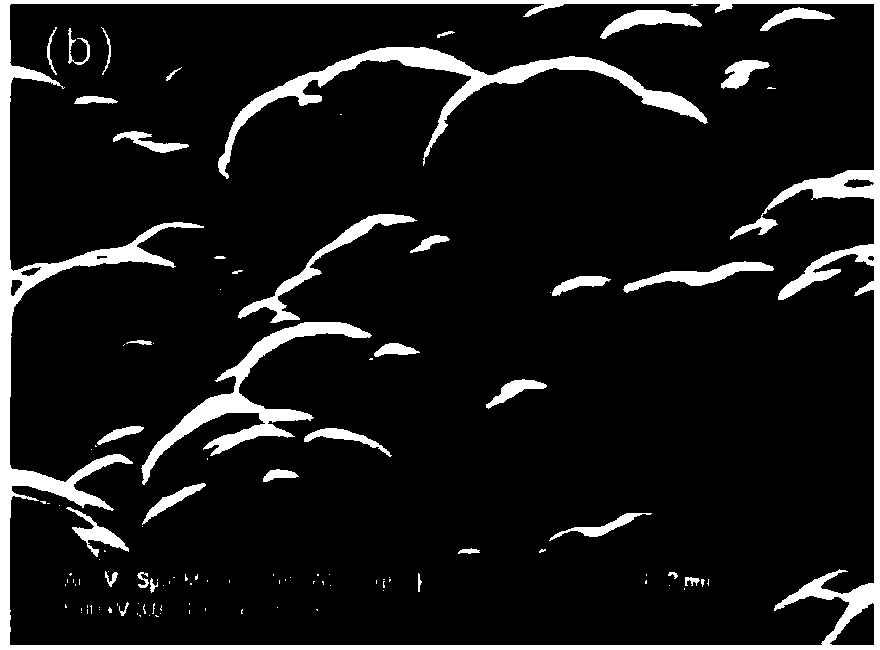

The invention relates to a boron-doped diamond micro-nano material and a preparation method thereof, belonging to the technical field of micro-nano materials. The boron-doped diamond micro-nano material with a columnar array structure, provided by the invention, is prepared on a silicon substrate and is characterized in that the silicon substrate is of a columnar array structure formed on siliconby adopting a photoetching technology, wherein the height of a single column is 5-20 mum, the diameter of the column is 1-10 mum, and the distance from one column to the other column is 2-10 mum. Thepreparation method comprises the following steps of: firstly, ultrasonically inoculating a diamond seed on the silicon substrate; then forming a boron-doped diamond film with the thickness of 0.5-2 mum by adopting a microwave plasma chemical vapor deposition method; and forming the ordered columnar array structure because the boron-doped diamond columns are mutually parallel in the axial direction, wherein the height of a single boron-doped diamond column is 5.5-22 mum, the diameter of the single boron-doped diamond column is 2-14 mum, and the distance from one boron-doped diamond column to the other boron-doped diamond column is 0.4-8 mum. The boron-doped diamond micro-nano material provided by the invention has large specific surface area and can be used on the aspects such as electrochemistry detection and the like.

Owner:DALIAN UNIV OF TECH

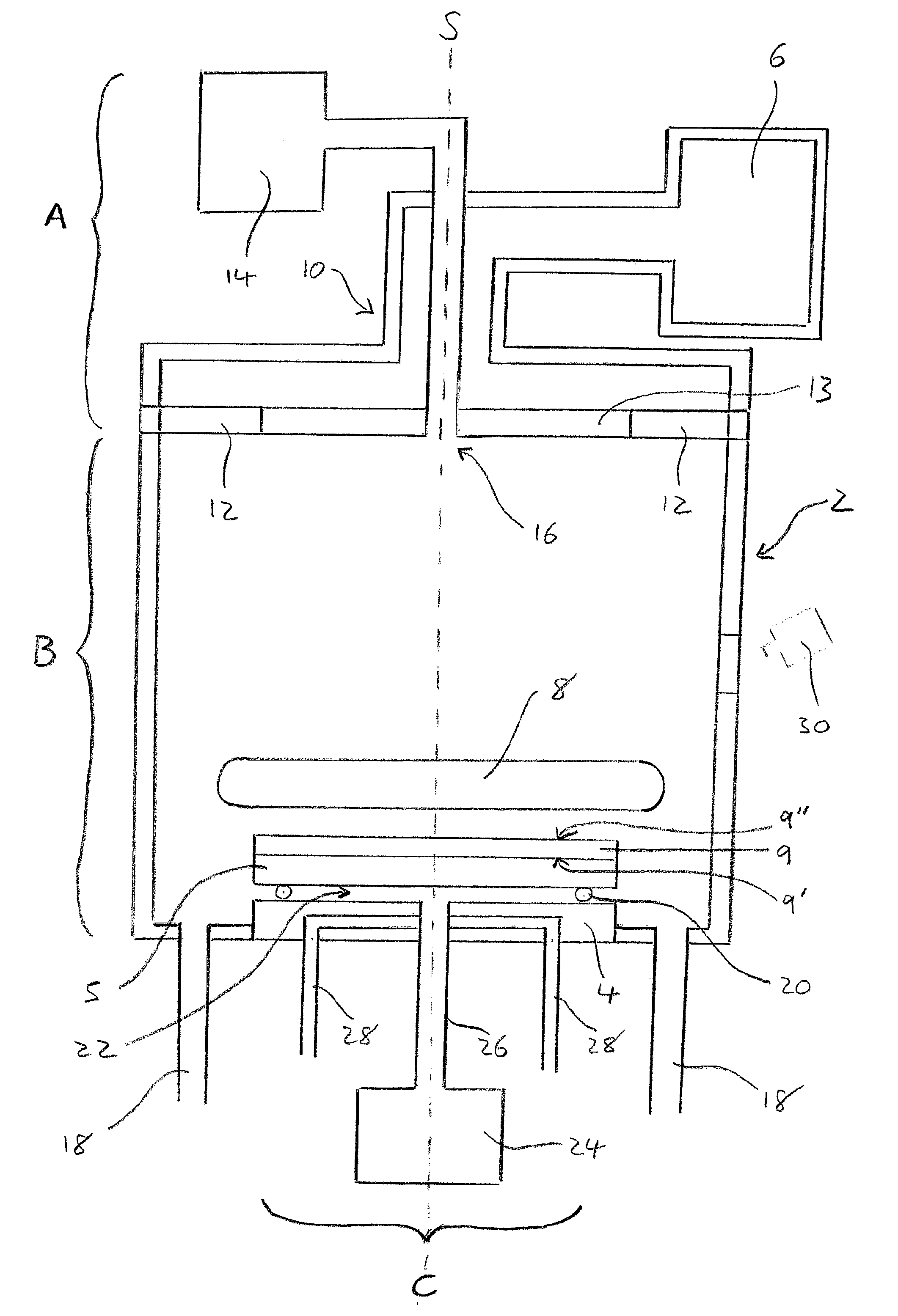

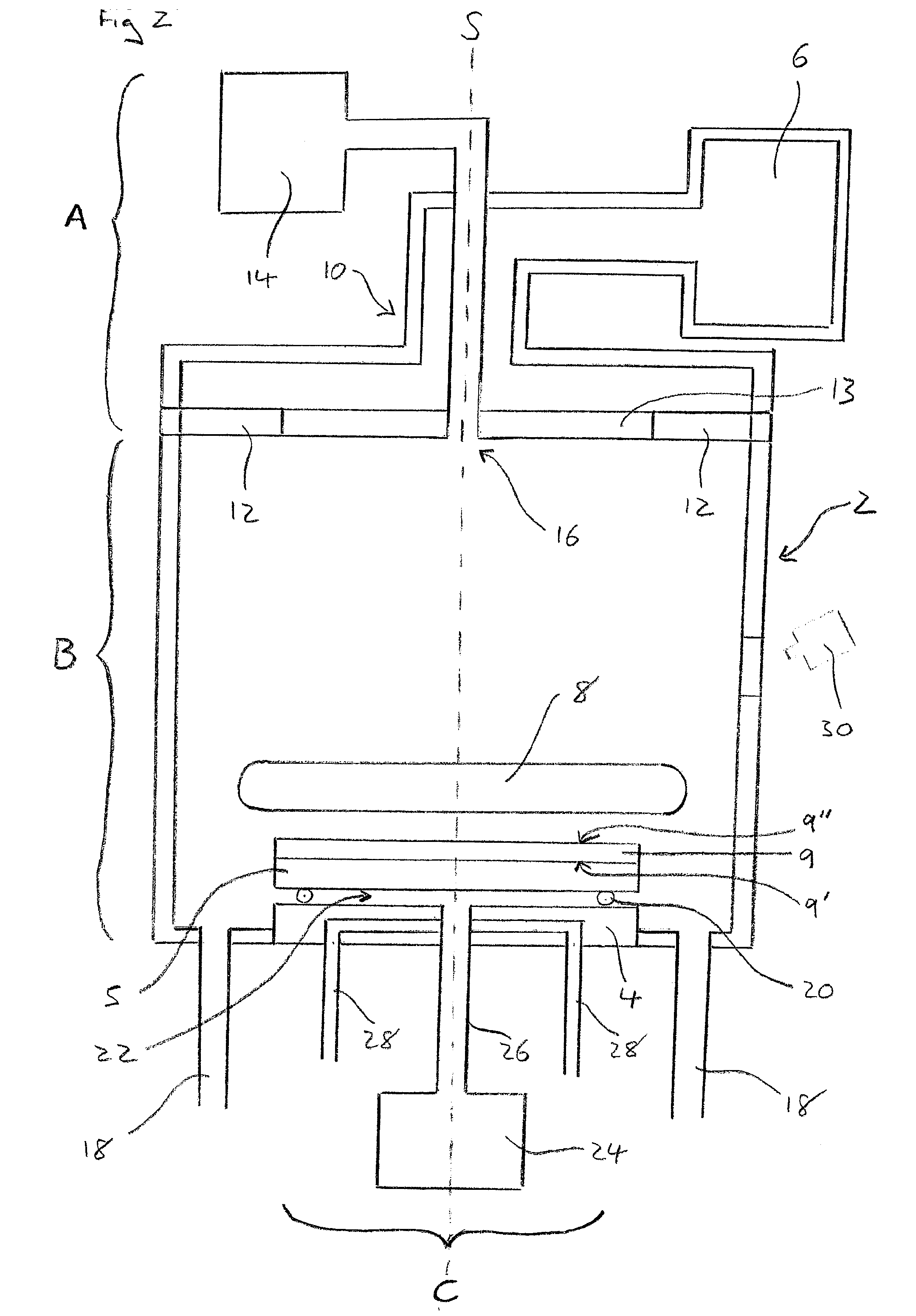

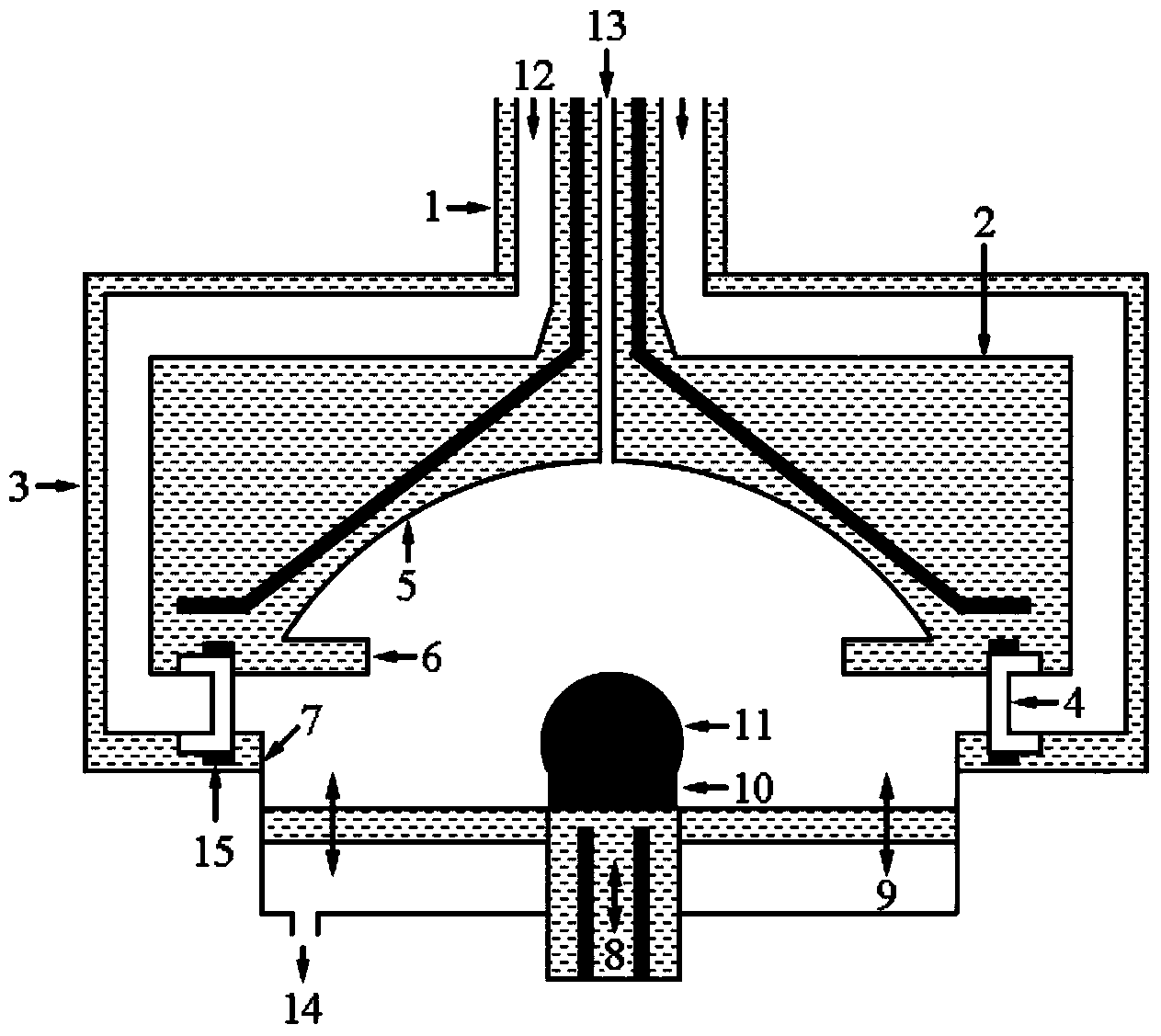

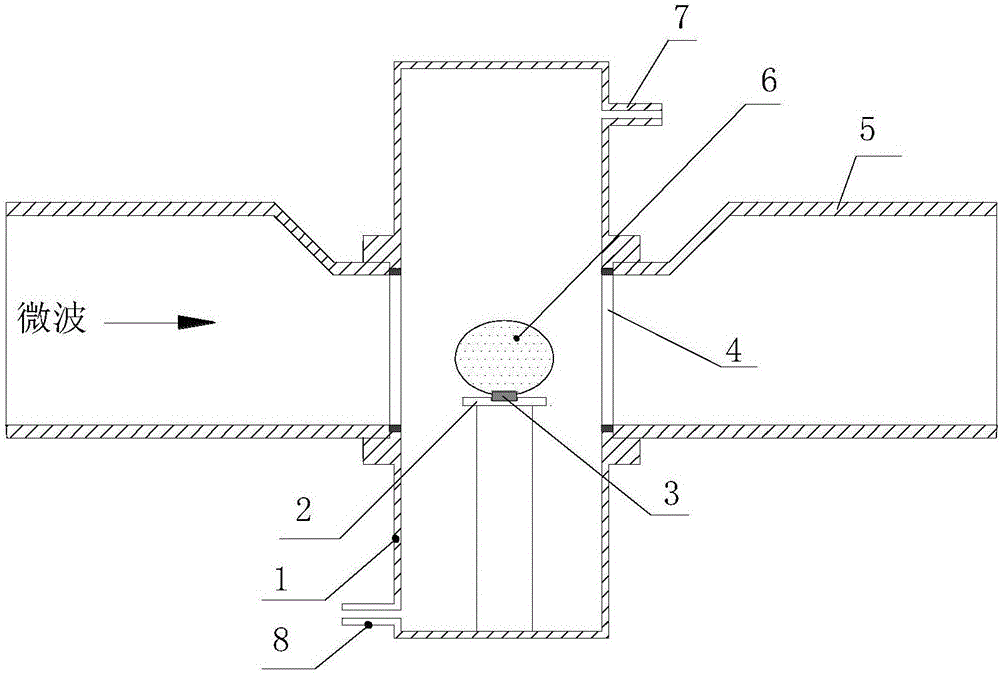

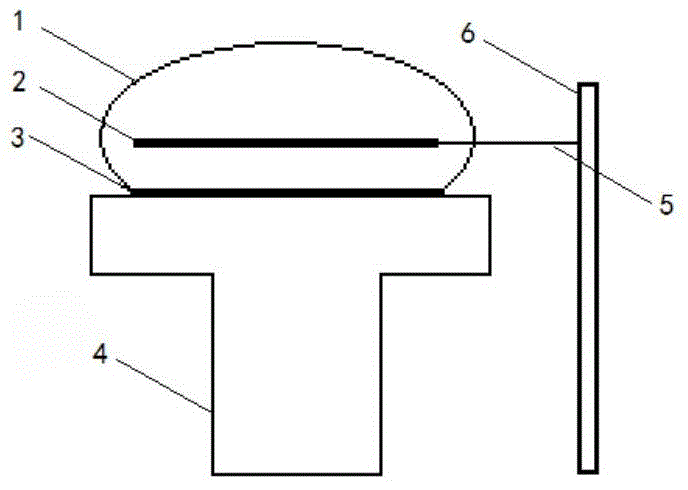

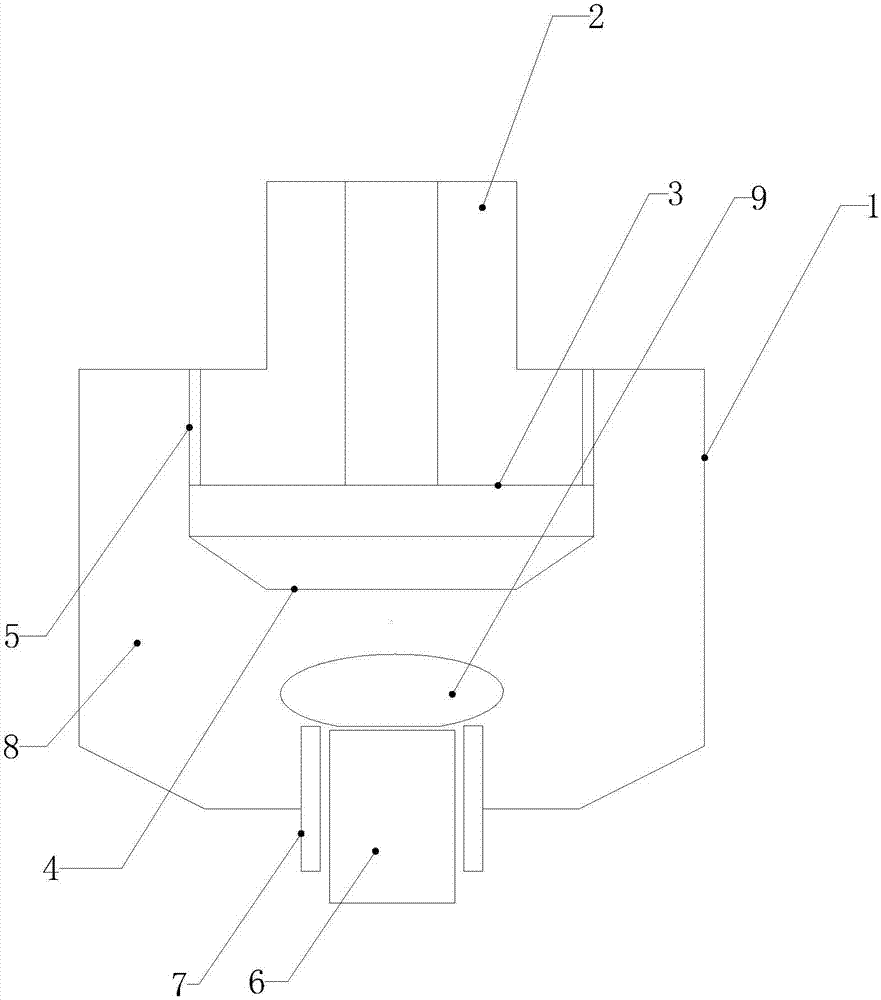

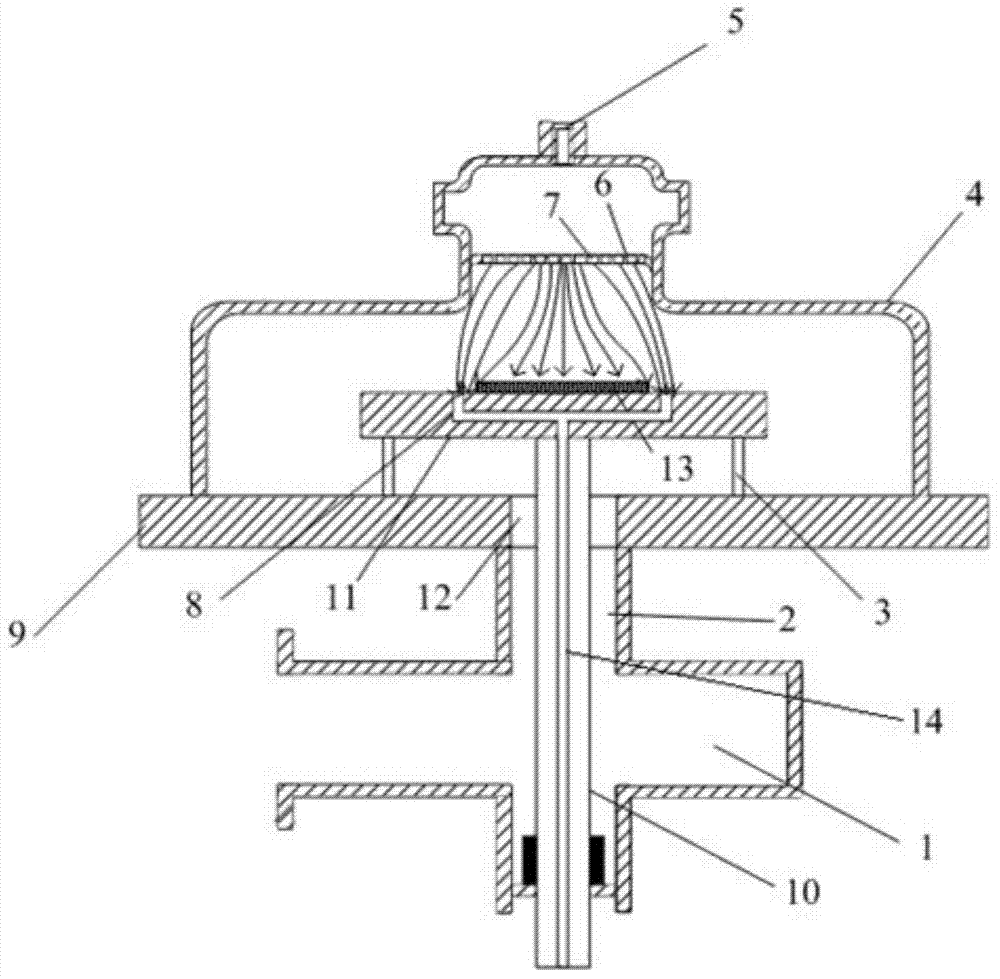

High power microwave plasma chemical vapor deposition device for diamond film

ActiveCN103305816ADeposition high speedHigh microwave powerChemical vapor deposition coatingResonant cavityHigh density

The invention relates to a high power microwave plasma chemical vapor deposition device for a diamond film, and belongs to the technical field of preparation of diamond films. The device comprises an upper cylinder and a lower cylinder of a resonant cavity, a deposition table for depositing the diamond film and a resonant cavity main body formed by semi-ellipsoidal microwave reflectors. The semi-ellipsoidal microwave reflectors are in smooth transition with the upper cylinder of the resonant cavity in shape, thus, guaranteeing that microwave entering into the resonant cavity is not scattered. At the same time, the semi-ellipsoidal microwave reflectors are arranged, so that the resonant cavity has strong focusing capacity of a microwave electric field for the convenience of focusing microwave energy above the deposition table so as to form a strong electric field area and high-density plasmas. The positions of the semi-ellipsoidal microwave reflectors are adjusted to adjust the resonant cavity of the device, so that distribution of the microwave electric field and plasmas in the device are optimized in real time. At the same time, a quartz glass window in the device is located below the diamond film deposition table, and other main parts of the device are far from the plasmas and can be directly cooled by water better.

Owner:HEBEI PLASMA DIAMOND TECH

Vertical graphene/manganese dioxide composite material as well as preparation method and application thereof

InactiveCN110993908AHigh specific capacityImprove cycle lifeMaterial nanotechnologySecondary cellsElectrical batteryElectric capacity

The invention discloses a vertical graphene / manganese dioxide composite material, a preparation method of the vertical graphene / manganese dioxide composite material and an application of the verticalgraphene / manganese dioxide composite material as a positive electrode material of a zinc ion battery. The method comprises the steps of reacting for 1-2 hours at the temperature of 750-850 DEG C to generate a carbon cloth loaded vertical graphene sheet according to a microwave plasma chemical vapor deposition method; through a hydrothermal method, taking potassium permanganate and water as reaction sources, reacting for 1-6 hours at the temperature of 120-160 DEG C, taking out and drying to obtain the vertical graphene / manganese dioxide composite material, and uniformly loading the manganese dioxide nanosheets on the surface of the vertical graphene to form a core-shell structure. The vertical graphene / manganese dioxide composite material provided by the invention has high specific capacitance, high rate capability and long cycle life, and has the wide application prospects in the fields of mobile communication, electric vehicles, aerospace and the like.

Owner:ZHEJIANG UNIV

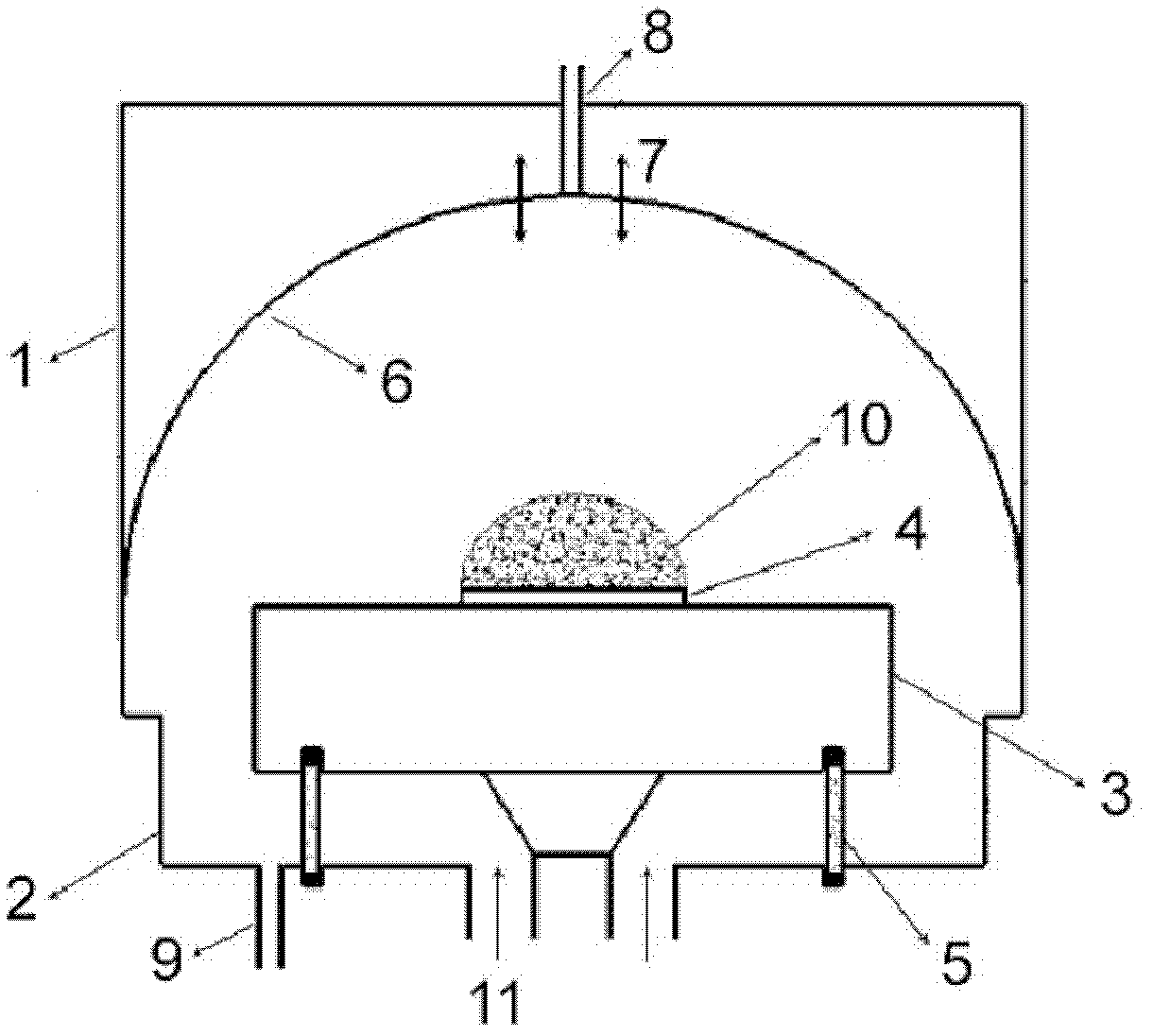

Domical microwave plasma chemical vapor deposition diamond film device

ActiveCN103668127AGood vacuum tightnessAid in depositionElectric discharge tubesChemical vapor deposition coatingResonant cavityPhysical chemistry

The invention relates to a domical microwave plasma chemical vapor deposition diamond film device which is suitable for quick preparation of a high-quality diamond film in the presence of high-power microwave input. A resonant cavity main body is composed of a domical reflecting body, a metal sheet reflecting body, a quartz ring window, a cylindrical reflecting body and a deposition platform, wherein the metal sheet reflecting body can block spreading of microwave to the top of the resonant cavity, so that more microwave can be accumulated above a substrate; the deposition platform is divided into a central deposition platform and a marginal deposition platform, and the independent vertical moving functions of the central deposition platform and the marginal deposition platform are beneficial to realize quick optimization of a plasma state; and the quartz ring window is hidden in a slit formed by the wall of the resonant cavity, thus avoiding etching of plasma and being beneficial to improve the vacuum performance of the resonant cavity. Besides, the favorable design of a water cooling system ensures the high-power operating safety of the equipment. So many advantages are combined, so that the domical microwave plasma chemical vapor deposition device has a capability of depositing a high-quality diamond film at high speed under a high power level.

Owner:HEBEI PLASMA DIAMOND TECH

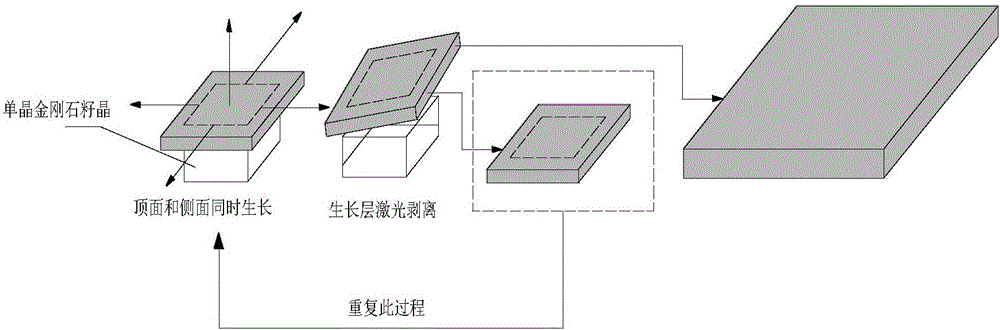

Two-dimensional expansion method for CVD monocrystal diamond

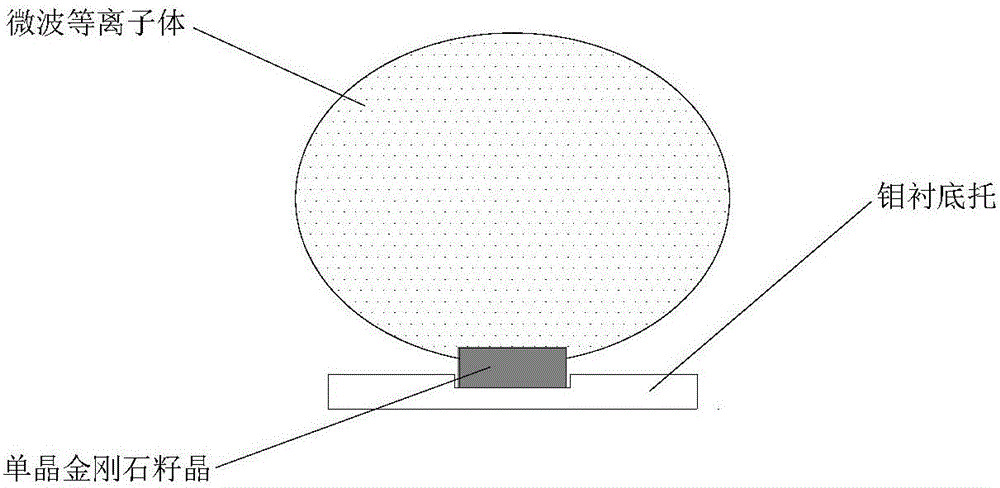

InactiveCN106012003ASmall sizePolycrystalline material growthFrom chemically reactive gasesVacuum pumpSeed crystal

The invention relates to a manufacturing method for a monocrystal diamond material, especially to a two-dimensional expansion method for CVD monocrystal diamond. The two-dimensional expansion method is characterized by comprising the following steps: a, placing a seed crystal of monocrystal diamond into a substrate support with a hole in the center so as to allow the seed crystal of monocrystal diamond to be exposed, wherein the substrate support is made of metal molybdenum; b, putting the substrate support with the seed crystal of monocrystal diamond into a deposition chamber and carrying out vacuum-pumping on the deposition chamber; c, generating plasma by using a microwave plasma chemical vapor deposition method, i.e., introducing hydrogen and methane into the deposition chamber, adjusting gas flow, microwave power and air pressure and allowing gas in the deposition chamber to absorb microwave energy and excite and generate plasma, thereby allowing monocrystal diamond to grow on a top surface and four side surfaces at the same time and realizing two-dimensional expansion of monocrystal diamond; and d, carrying out peeling so as to obtain large-size monocrystal diamond. The method realizes two-dimensional growth of monocrystal diamond on a monocrystal diamond substrate via the microwave plasma chemical vapor deposition method, so the size of monocrystal diamond is enlarged.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

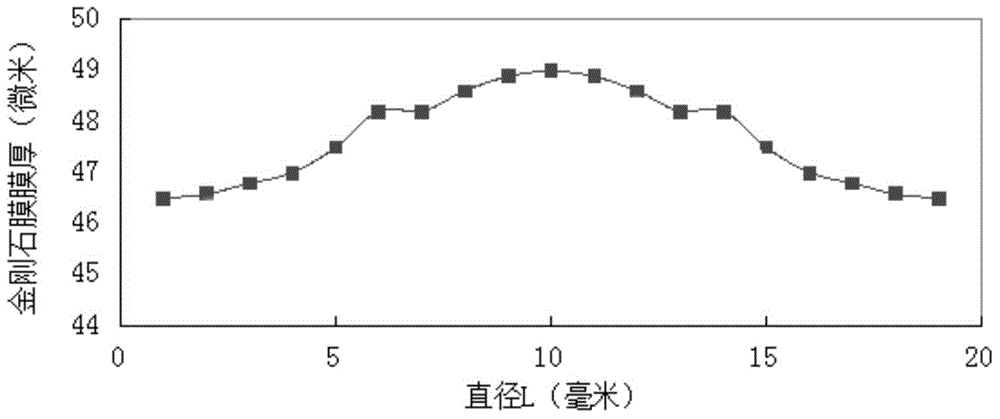

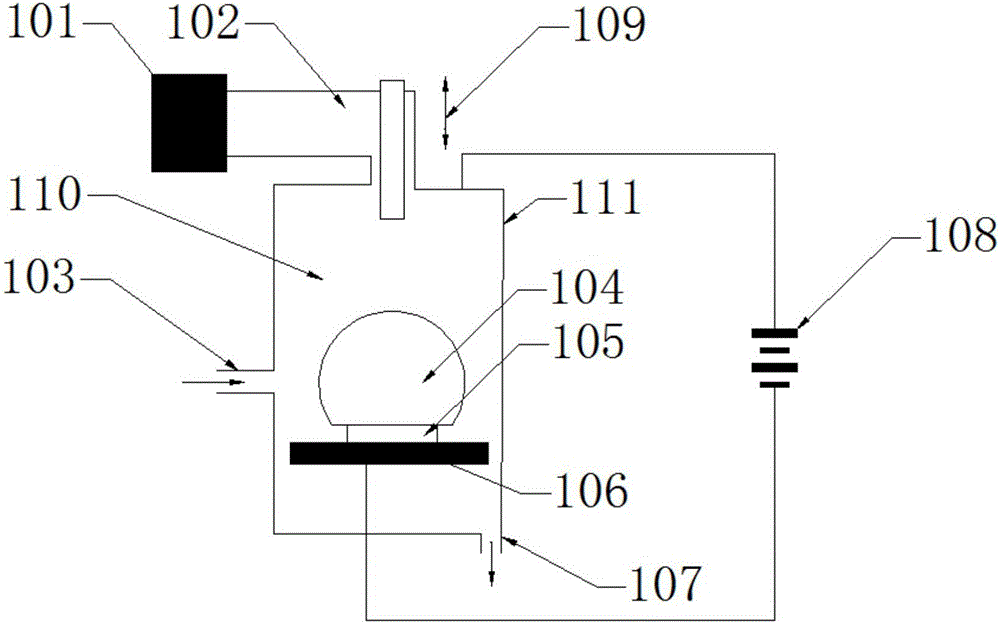

Preparation apparatus for diamond film and method for preparing diamond film by using apparatus

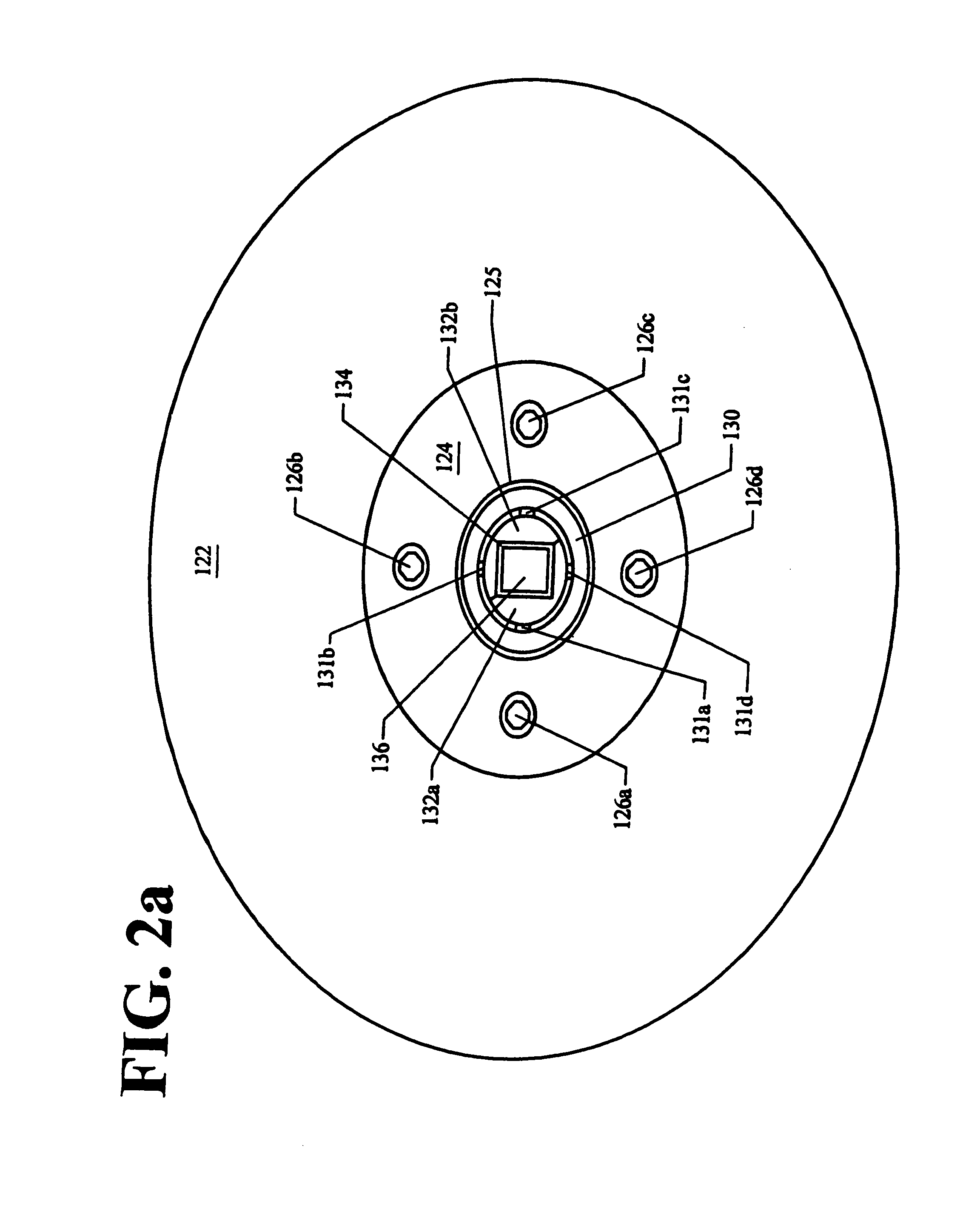

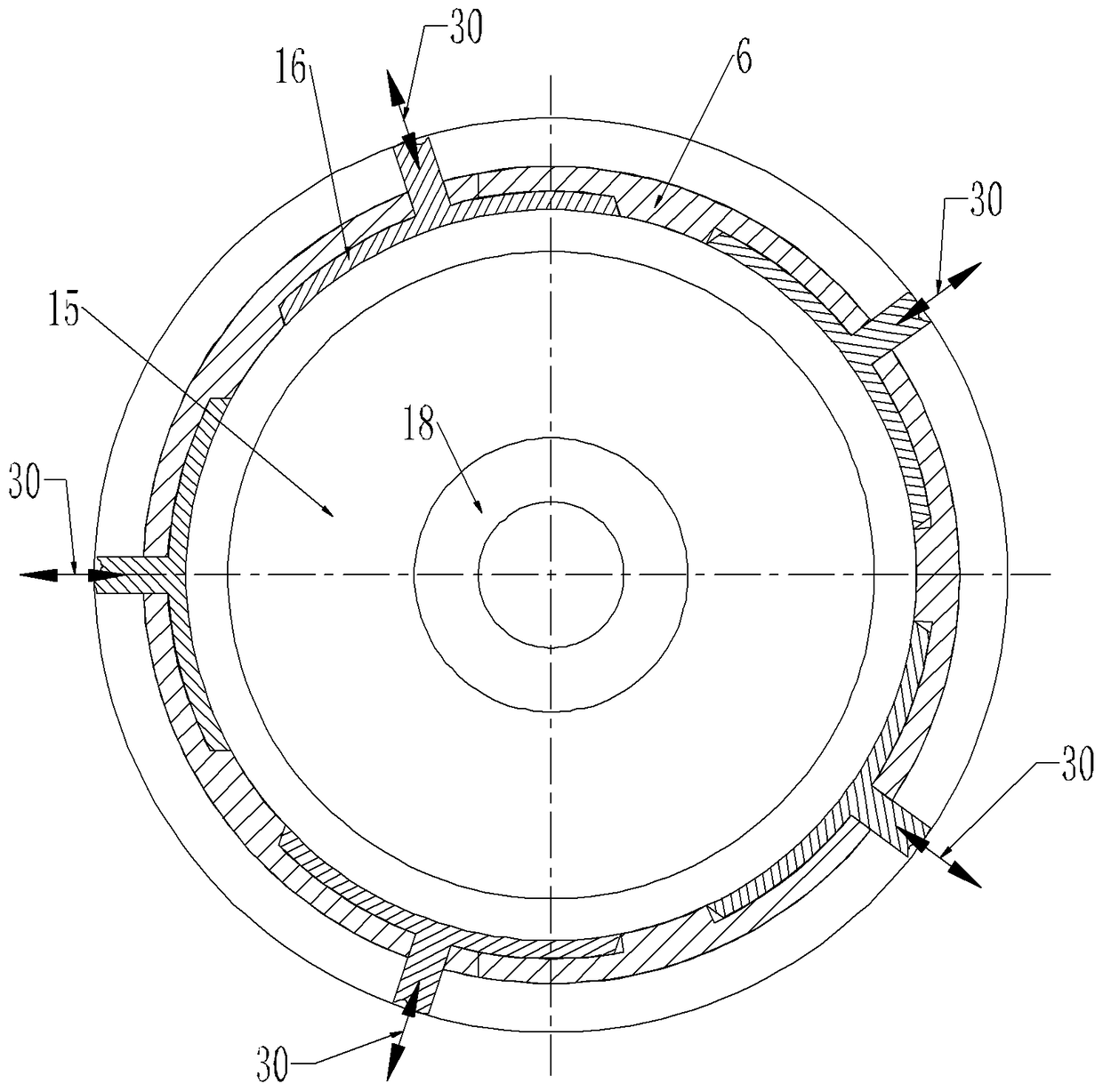

ActiveCN103911596AChange density distributionImprove deposition uniformityChemical vapor deposition coatingMicrowavePlasma reaction

The invention provides a preparation apparatus for a diamond film. The apparatus employs a microwave plasma chemical vapor deposition device and comprises a microwave system, a vacuum system, a gas supply system and a plasma reaction chamber, wherein an autogyration substrate table is arranged in the plasma reaction chamber, microwaves generated by the microwave system during working enter into the plasma reaction chamber and excite gas supplied by the gas supply system above the autogyration substrate table to generate a plasma ball, and a refractory metal circular ring is arranged above the autogyration substrate table and located in the lower half part of the plasma ball.

Owner:SHANGHAI ZHENGSHI TECH CO LTD

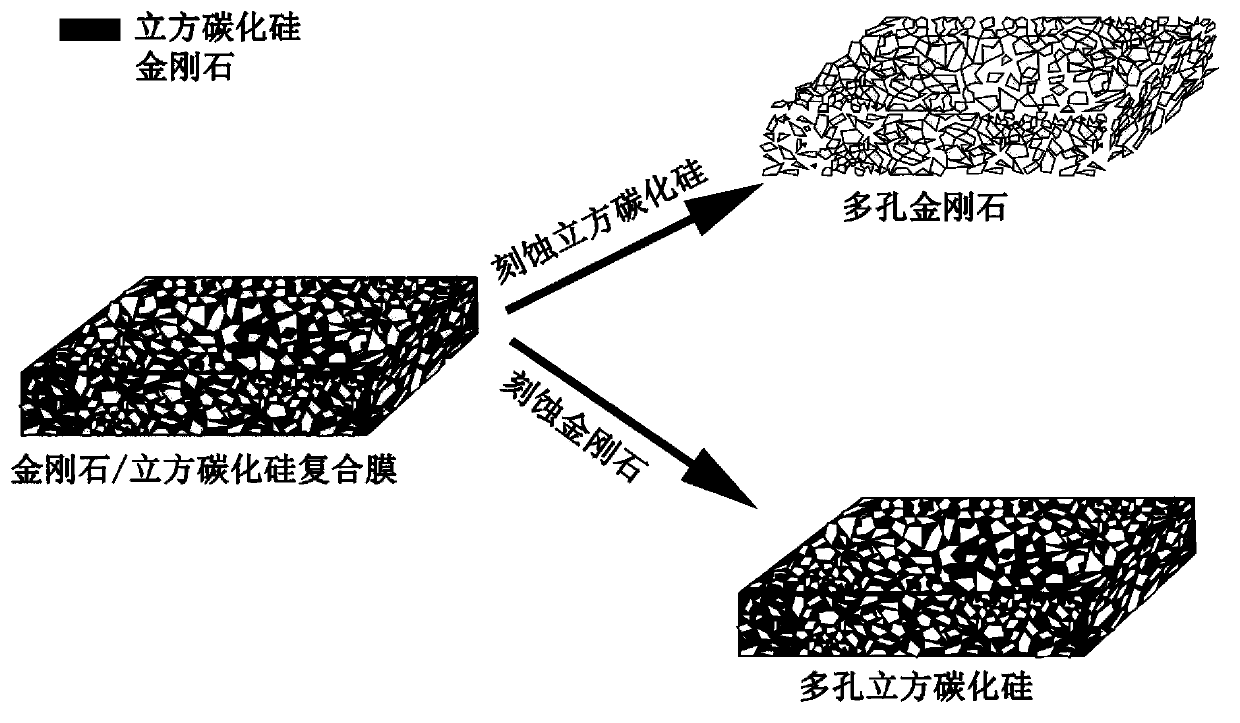

Method for manufacturing porous diamond or porous cubic silicon carbide self-supporting film

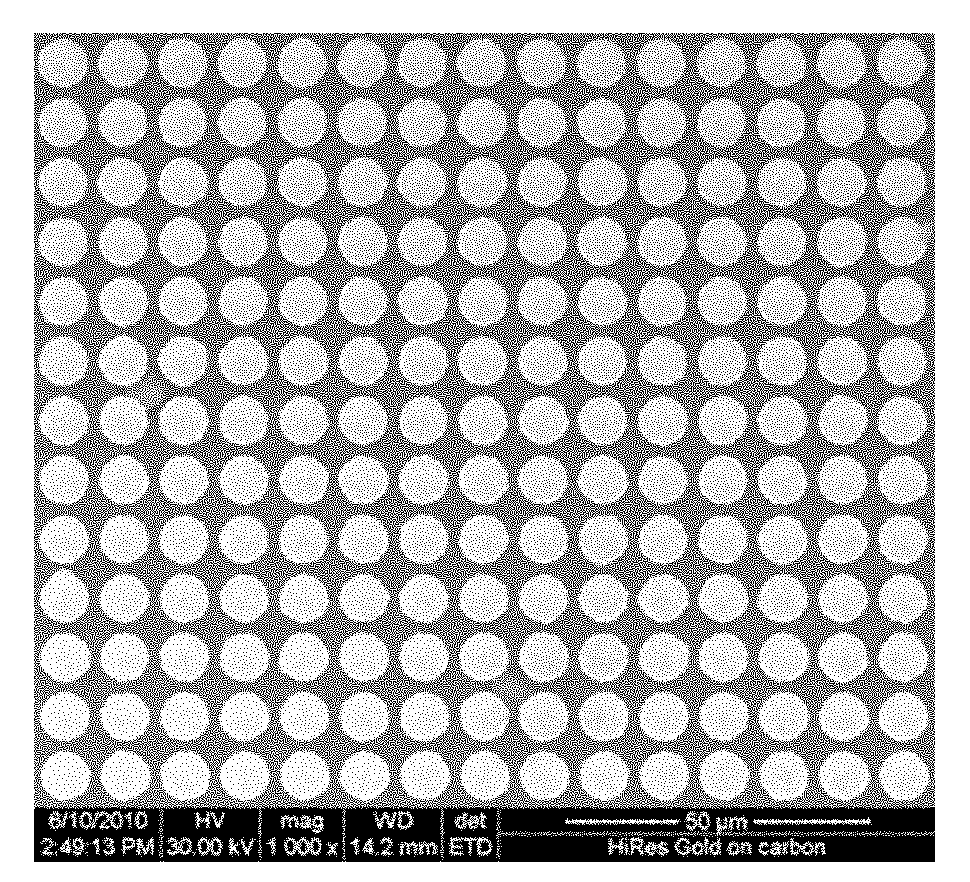

ActiveCN104178745AImprove stabilityControllable distributionChemical vapor deposition coatingPorosityComposite film

The invention discloses a method for manufacturing a porous diamond or porous cubic silicon carbide self-supporting film. The method comprises the steps that a base material is provided, and surface of the base material is pretreated to obtain a higher diamond-shaped nuclei rate; the pretreated base material is put into a microwave plasma chemical vapor deposition or hot filament chemical vapor deposition reactor, and at the temperature of 600 DEG C to 900 DEG C, a diamond / cubic silicon carbide composite film is manufactured; selective etching is performed on the obtained composite film, at the temperature above 70 DEG C, the composite film is etched in mixed corrosion liquid of hydrofluoric acid and nitric acid, and the porous diamond self-supporting film is obtained, at the temperature above 500 DEG C, the composite film is heated in the air containing oxygen gas, and the porous cubic silicon carbide self-supporting film is obtained. Under the condition that any template and any electrode material are not used, the obtained porous diamond self-supporting film and the porous cubic silicon carbide self-supporting film have the controllable aperture, the controllable porosity and the controllable thickness, and the method is suitable for industrial application and fundamental research.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing large-size CVD (Chemical Vapor Deposition) diamond crystal

InactiveCN109161964AQuality assuranceUniform growth orientationPolycrystalline material growthFrom chemically reactive gasesSurface cleaningDiamond crystal

The invention discloses a method for preparing a large-size CVD (Chemical Vapor Deposition) diamond crystal. The method comprises the following steps: (1) cutting a single diamond crystal grown by using an HPHT (High Temperature and High Pressure) method so as to obtain single HPHT diamond crystal sheets; (2) carrying out surface cleaning; (3) throwing a photoresist to the single HPHT diamond crystal sheets, and carrying out membrane hardening so as to obtain design patterns; (4) depositing a medium membrane by using a CVD method; (5) removing the photoresist and the medium membrane outside the design patterns so as to obtain design medium membrane patterns; (6) splicing the single HPHT diamond crystal sheets in CVD equipment, and carrying out plasma etching so as to obtain a new surface;(7) growing a thick-layer CVD single diamond crystal on the new surface by using a microwave plasma chemical vapor deposition method; (8) cutting and removing the spliced single HPHT diamond crystal sheets, thereby obtaining the self-supported large-size CVD diamond crystal. By adopting the method, growth defects at crystal boundaries and parts nearby of spliced single diamond crystals grown by using the CVD method can be avoided, the quality of the crystal can be ensured, and the self-supported large-size CVD diamond crystal can be prepared.

Owner:JINAN ZHONGWU NEW MATERIALS CO LTD

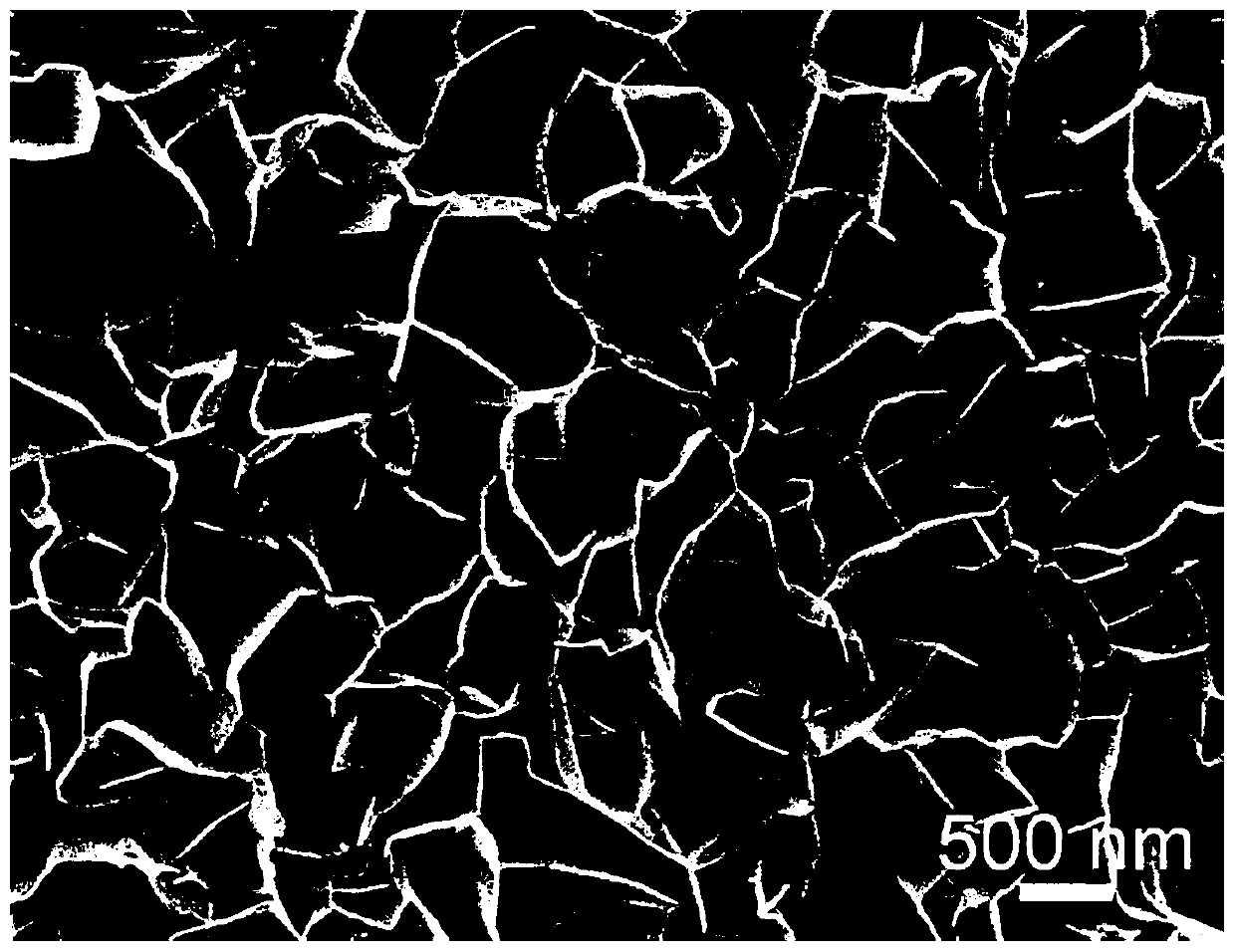

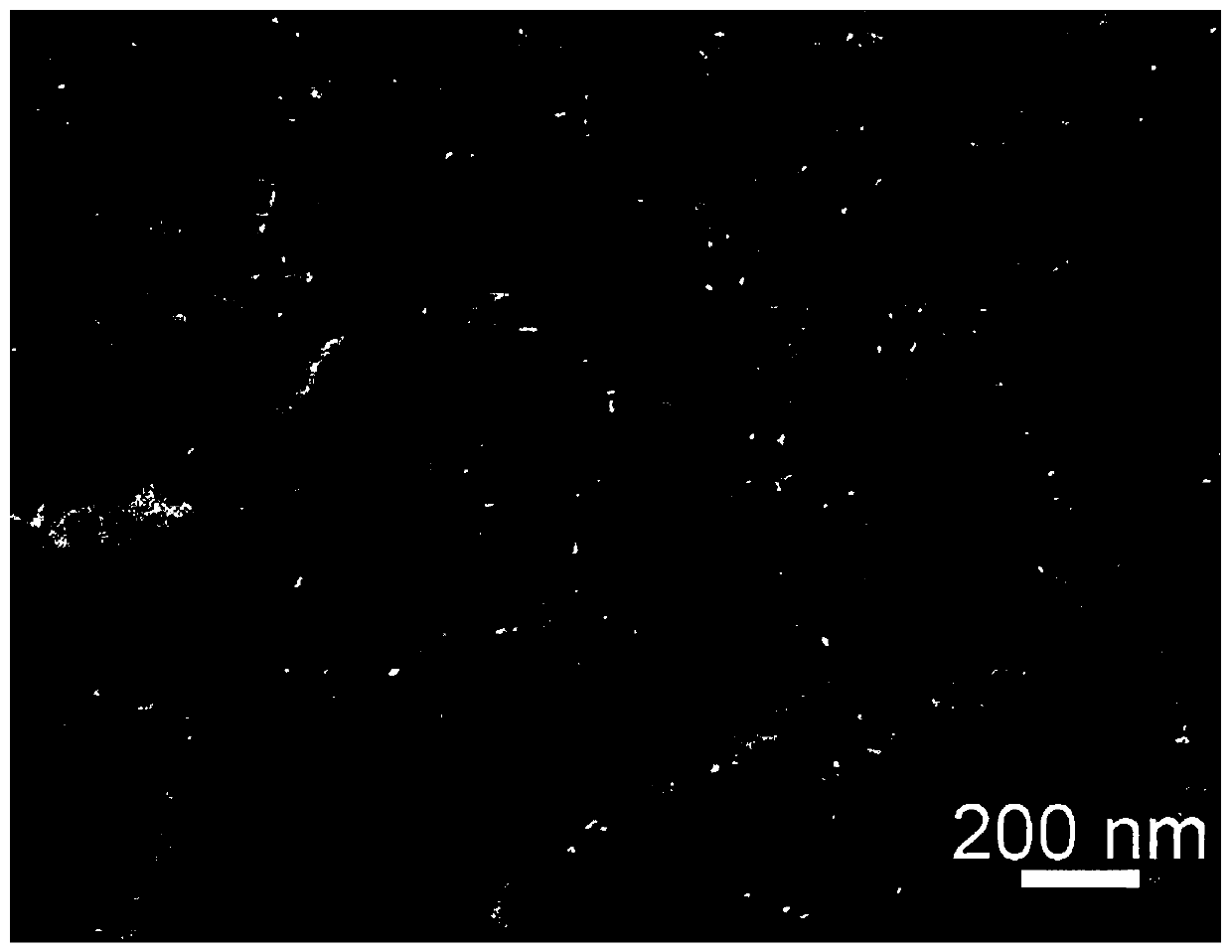

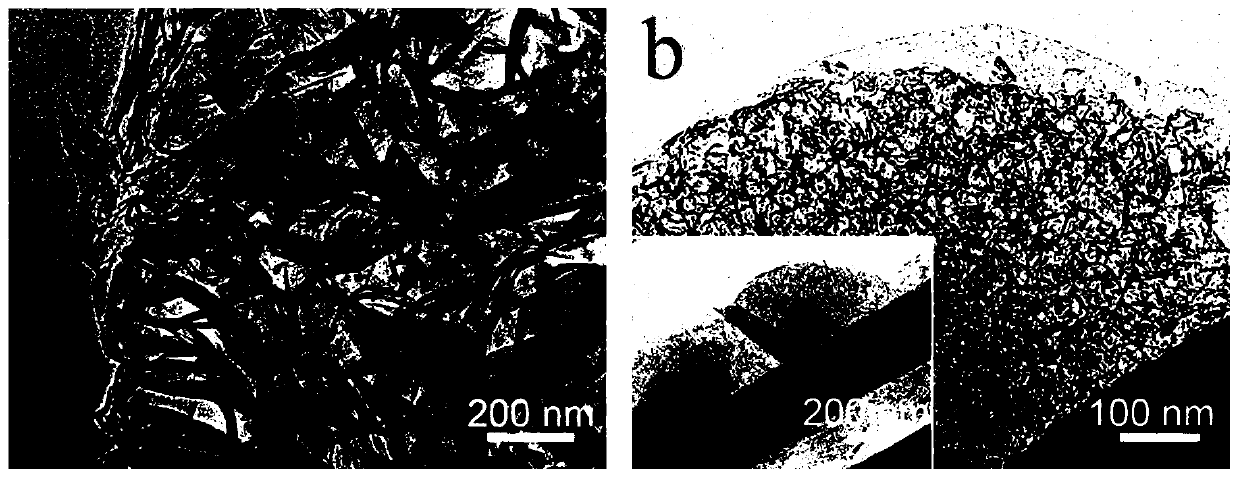

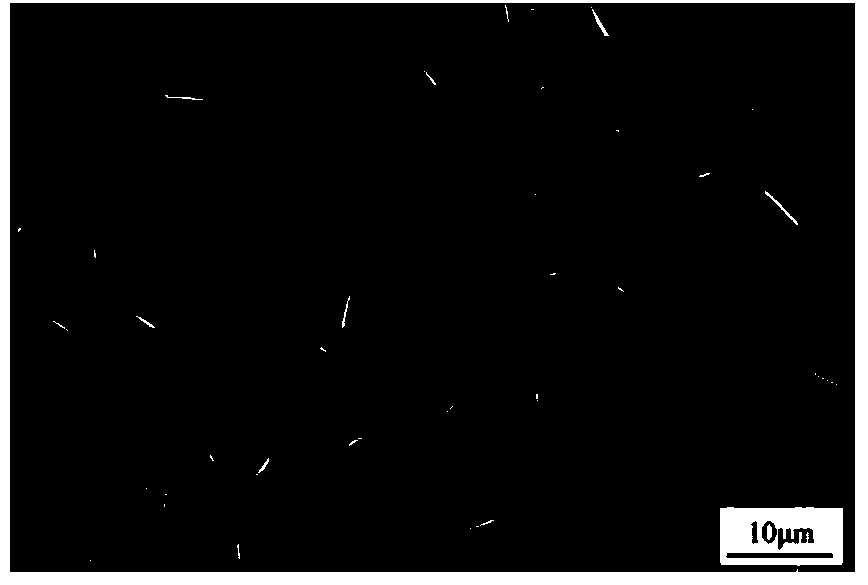

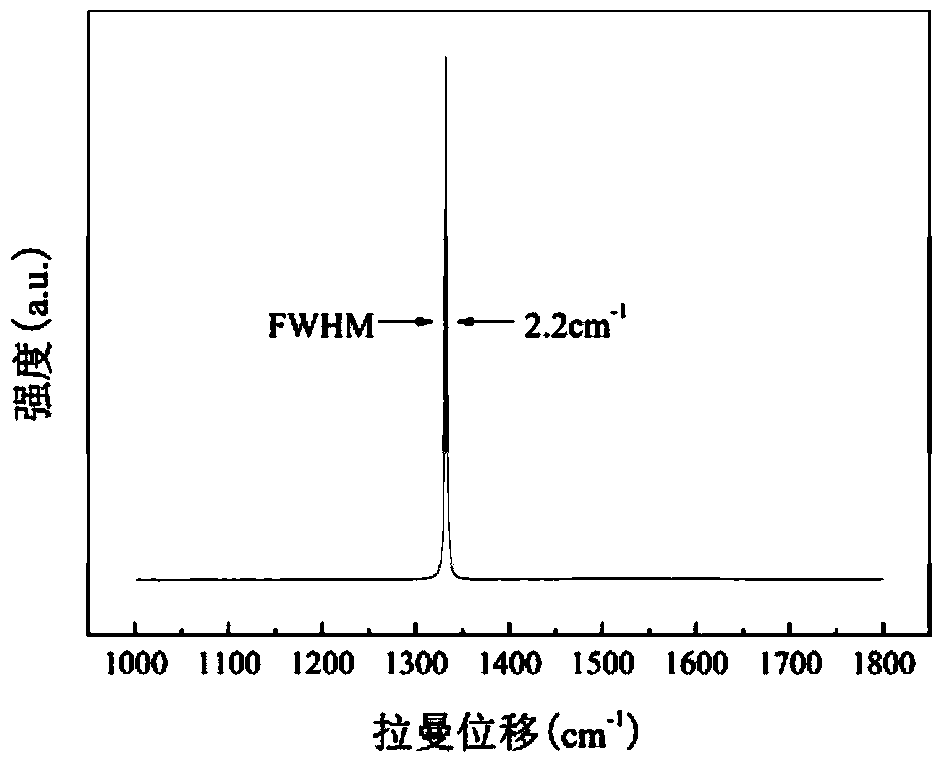

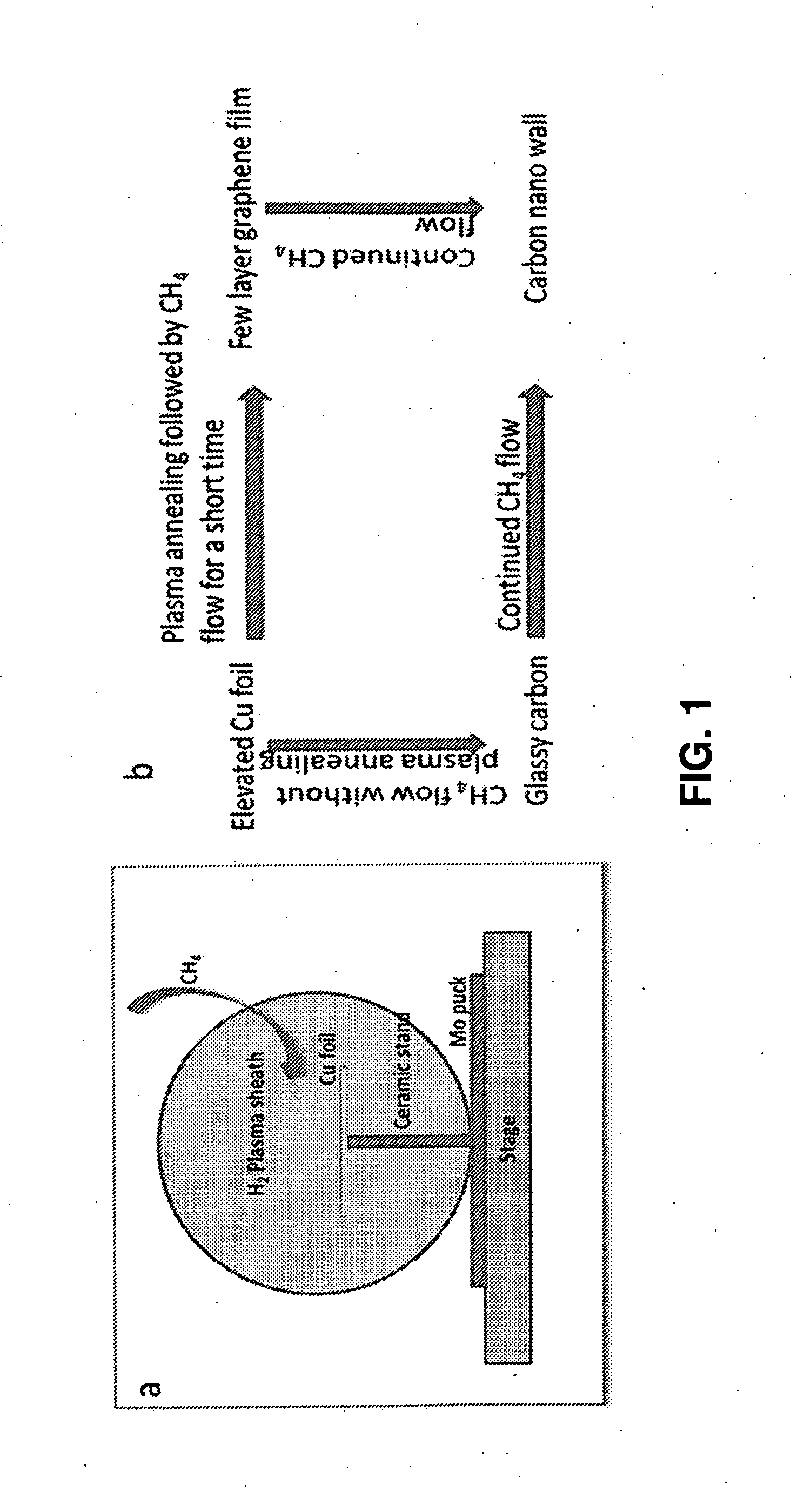

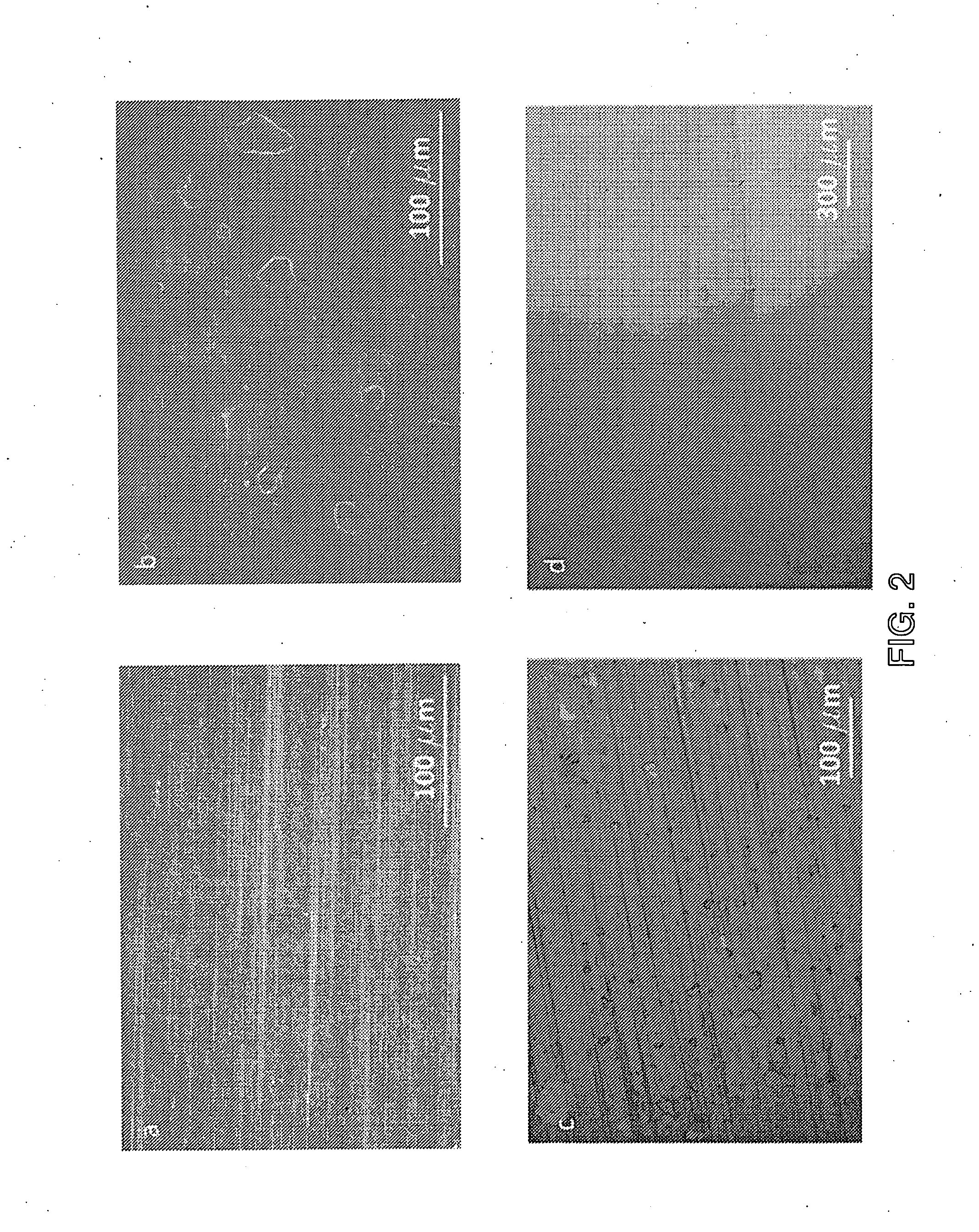

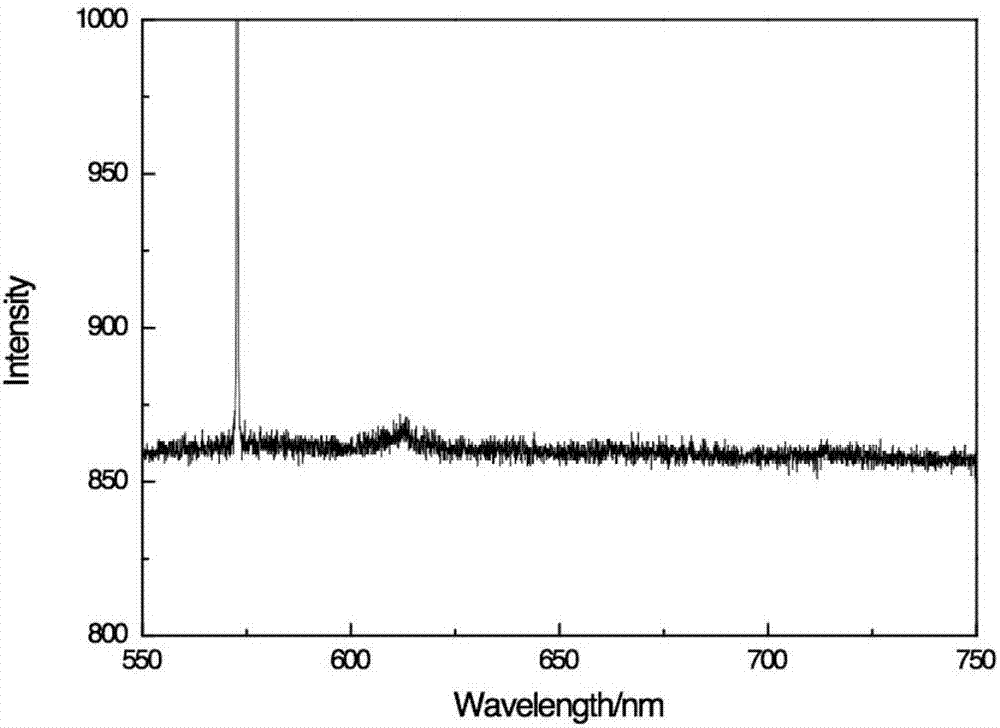

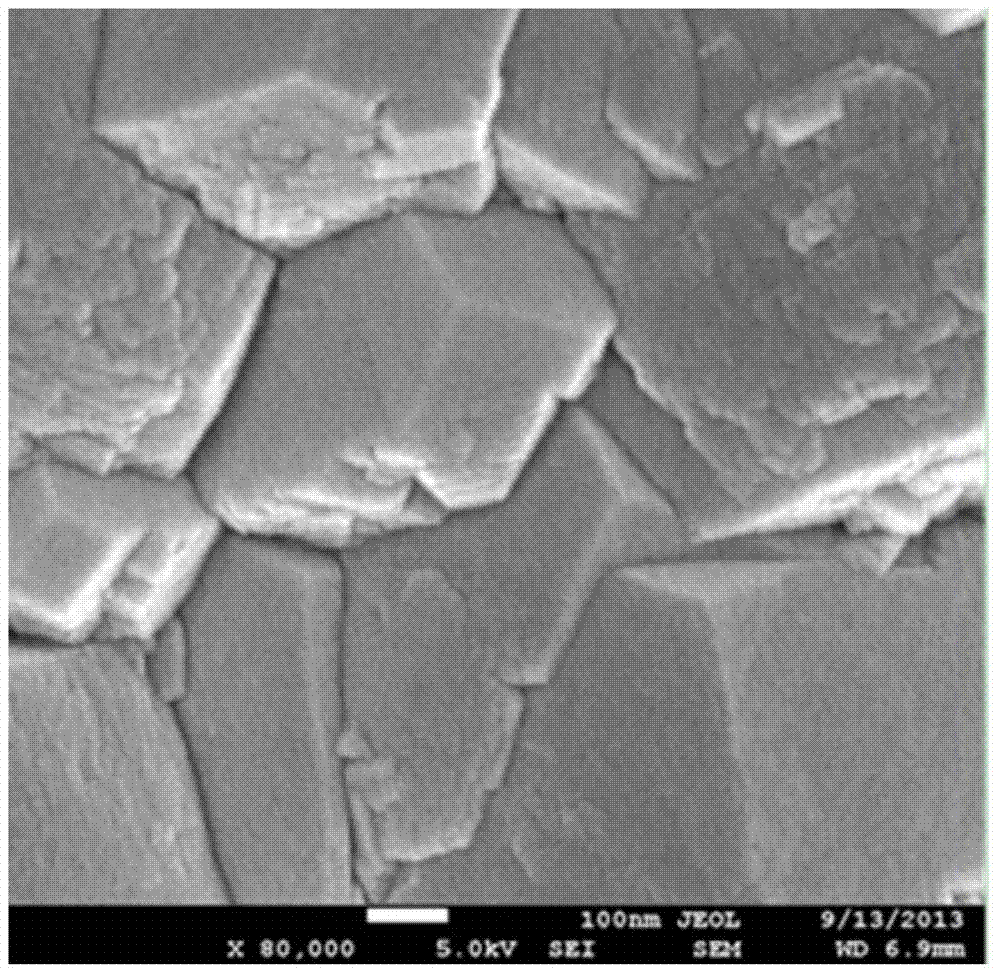

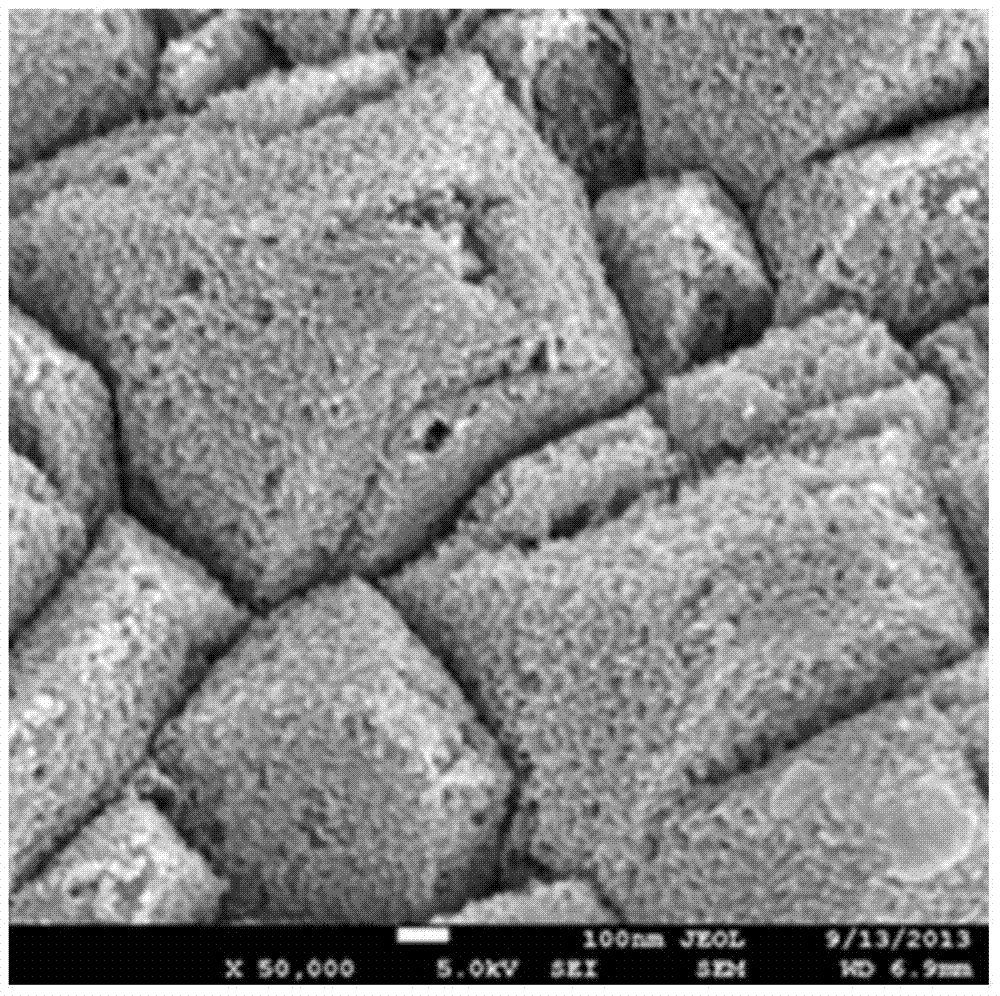

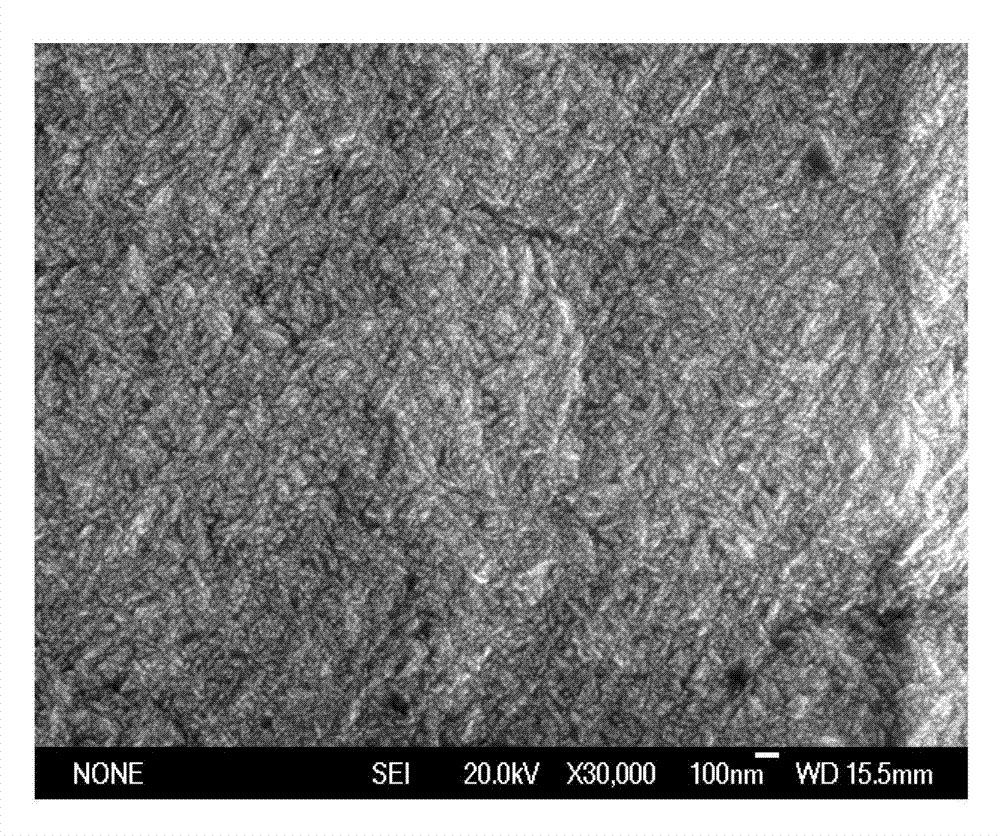

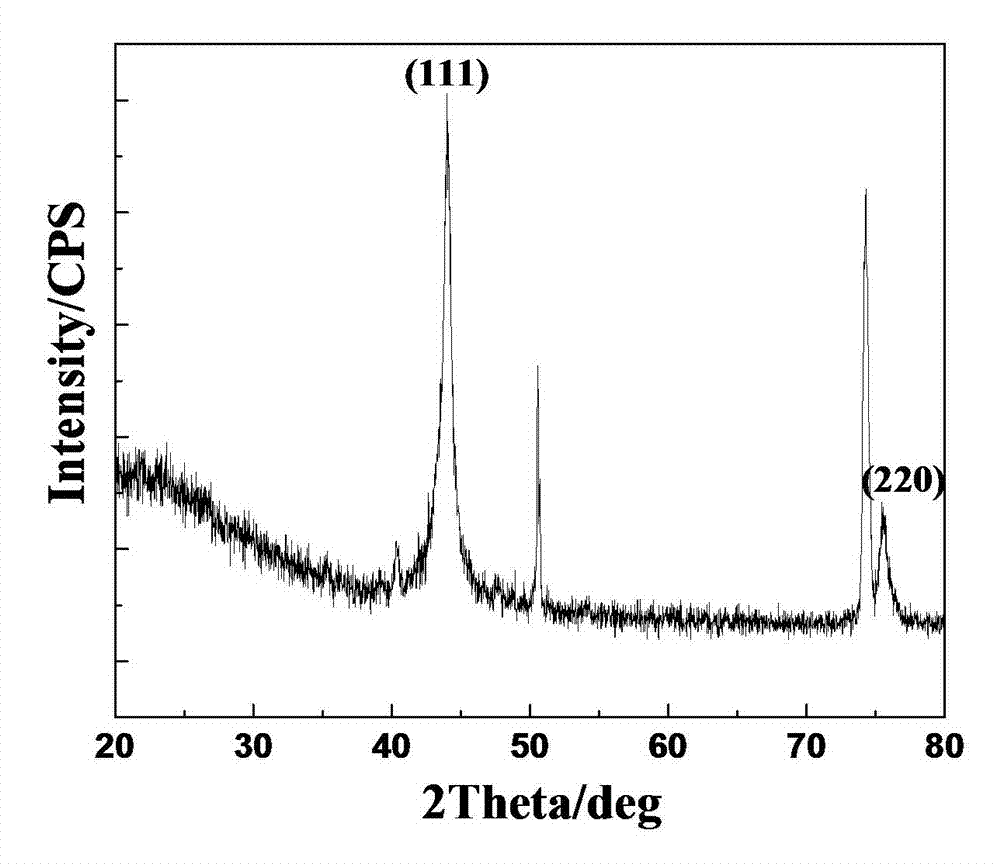

Rapid synthesis of graphene and formation of graphene structures

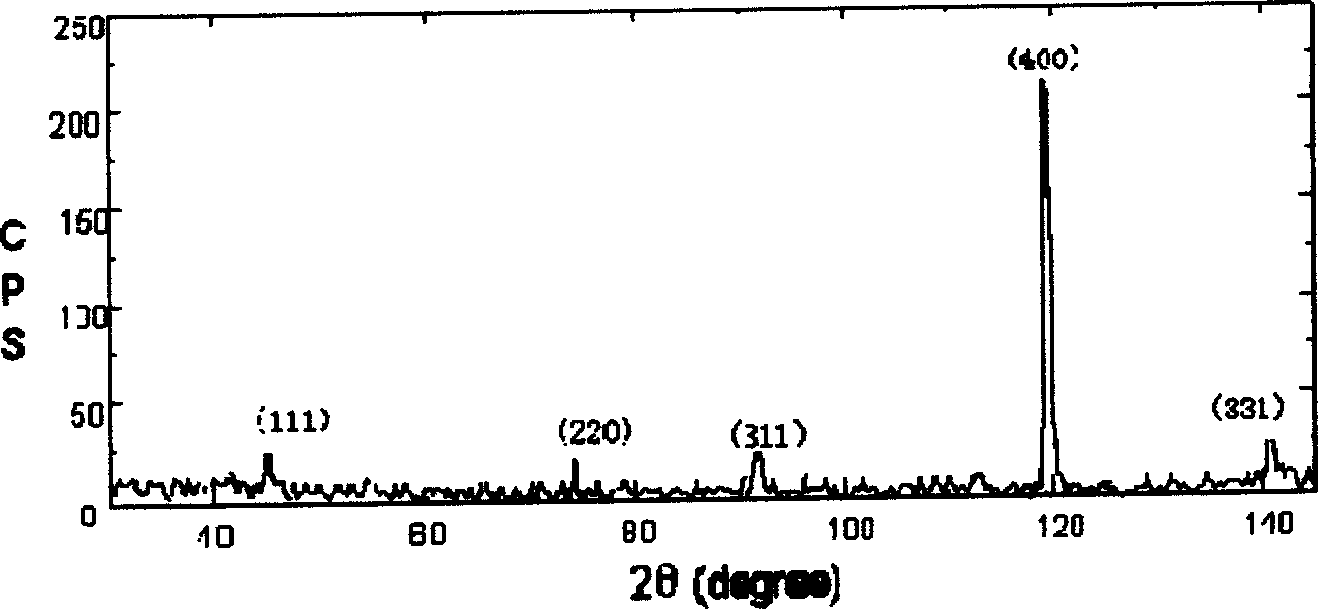

ActiveUS20150037515A1Shorten the timeReduce the temperatureMaterial nanotechnologyGrapheneDoped grapheneX-ray

A process for rapid synthesis of few-layer graphene films on Cu foil by microwave plasma chemical vapor deposition (MPCVD). The plasma / metal interaction can be useful for a rapid synthesis of such thin films. The process can produce films of controllable quality from amorphous to highly crystalline by adjusting plasma conditions during growth processes of ˜100 sec duration and with little or no supplemental substrate heating. Films have been characterized using Raman spectroscopy, scanning electron microscopy, transmission electron microscopy and X-ray photoelectron spectroscopy. The results help to identify the stages involved in the MPCVD deposition of thin carbon films on Cu foil. In yet other embodiments, the films are doped during synthesis by introduction of nitrogen gas in the reactor. Raman spectroscopy, X-ray photoelectron spectroscopy, transmission electron microscopy and scanning tunneling microscopy reveal crystal structure and chemical characteristics. Nitrogen concentrations up to approximately 2 atomic % are observed. The growth process requires only a few minutes without supplemental substrate heating and offers a promising path toward large-scale synthesis of nitrogen-doped graphene films.

Owner:PURDUE RES FOUND INC

Method of preparing high-performance diamond semiconductor based on low-cost single crystal diamond

ActiveCN107275192AImprove performanceReduce technical difficultySemiconductor/solid-state device manufacturingSelf-healingHydrogen atmosphere

The invention discloses a method for preparing a high-performance diamond semiconductor based on low-cost single crystal diamond, and belongs to the technical field of novel semiconductor preparation. The process steps include a, a commercially available cheap high temperature and pressure Ib-type single crystal diamond substrate is subjected to acid pickling to remove surface inclusions and form a passivated oxygen termination surface; b, the activated diamond surface is subjected to short time treatment by microwave hydrogen plasmas to expose a fresh C-C dangling bond; c, a high-quality single crystal diamond thin film is epitaxially grown on the fresh diamond surface by microwave plasma chemical vapor deposition to achieve the diamond thin film epitaxy with low dislocation density and impurity content mainly through the introduction of oxygen atoms with a self-healing function; and d, a carbon source and a oxygen source are turned off, the epitaxially grown diamond surface is treated by the microwave hydrogen plasmas to obtain a high hydrogen termination density, and the treated diamond surface is cooled to room temperature under a hydrogen atmosphere to obtain a diamond semiconductor with high conductivity. According to the invention, the process flow is simplified, the technical difficulty and the production cost are reduced, and the production cycle is shortened.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of porous diamond film

ActiveCN104498894AImprove hydrophilicityIncrease contentChemical vapor deposition coatingAir atmosphereMicrowave

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

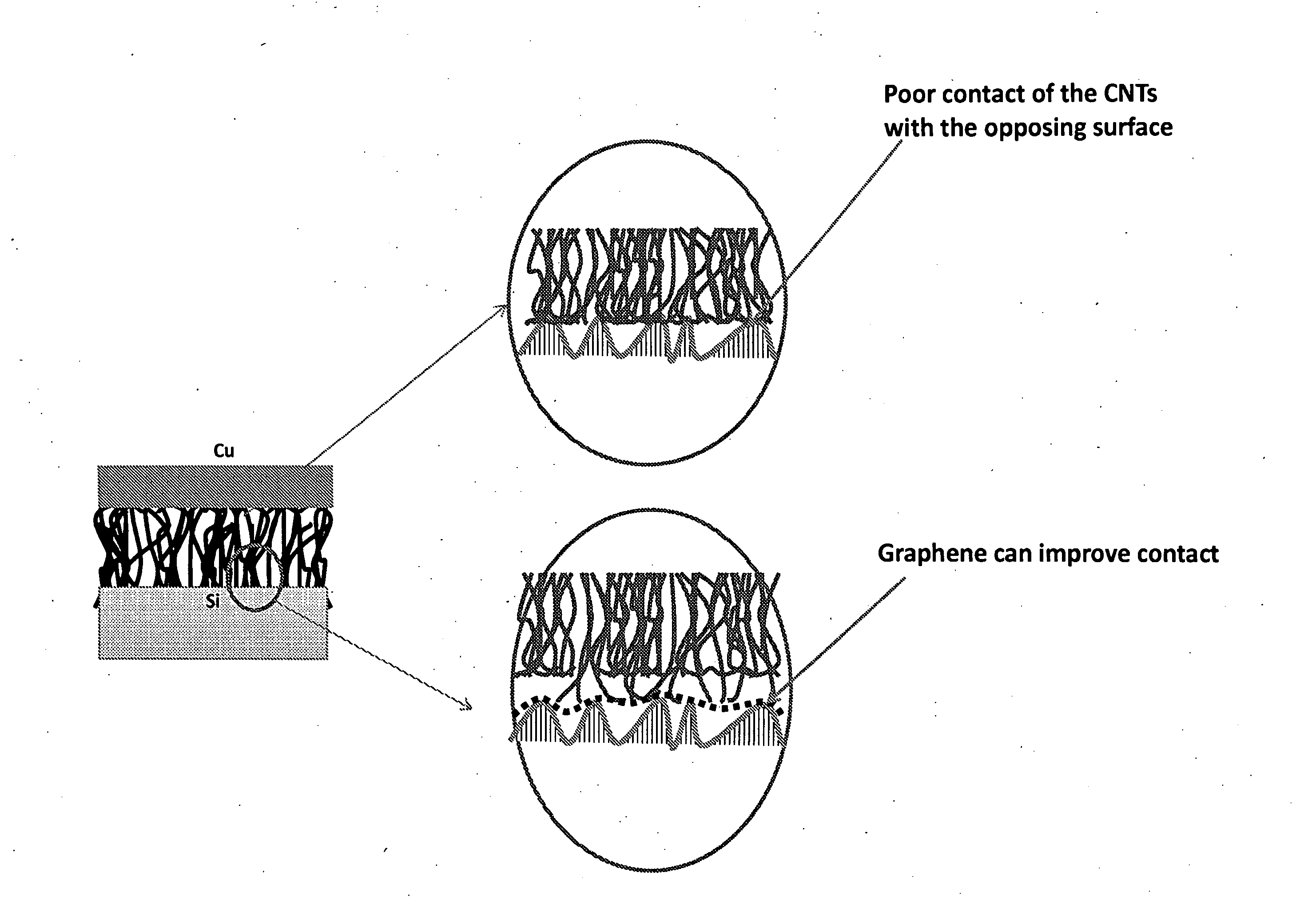

Preparation method of high-performance lithium ion battery based on three-dimensional graphene bracket structure

InactiveCN103956520AAchieve ballistic transportStress reliefFinal product manufactureElectrolyte accumulators manufactureMethyl carbonateLithium-ion battery

The invention provides a preparation method of a high-performance lithium ion battery based on a three-dimensional graphene bracket structure. The method comprises the steps of carrying out ultrasonic cleaning on a nickel piece, a copper piece or a nickel-copper alloy piece by acetone, alcohol and deionized water respectively in sequence, drying and then putting the dried piece into a microwave plasma chemical vapor deposition chamber; heating, filling the microwave plasma chemical vapor deposition chamber with methane, and carrying out plasma treatment by hydrogen to form a three-dimensional graphene bracket; after that, putting the three-dimensional graphene bracket into a magnetron sputtering cavity, filling the magnetron sputtering cavity with argon, and carrying out sputtering with a lithium ion battery electrode material as a target; and finally, assembling in an argon-filled glove box to obtain the battery, wherein multi-space polypropylene is taken as a diaphragm, and LiPF6 and mixed liquid of ethylene carbonate, dimethyl carbonate and diethyl carbonate is taken as electrolyte. After the method is adopted, the high-quality three-dimensional graphene structure is obtained for the first time, and three-dimensional graphene is high in electrical conductivity, is a flexible material, and is capable of effectively relieving stress caused by lithium ions in the charge and discharge processes and greatly increasing the transport rate of electrons and lithium ions.

Owner:QUANZHOU NORMAL UNIV

Colorless single-crystal CVD diamond at rapid growth rate

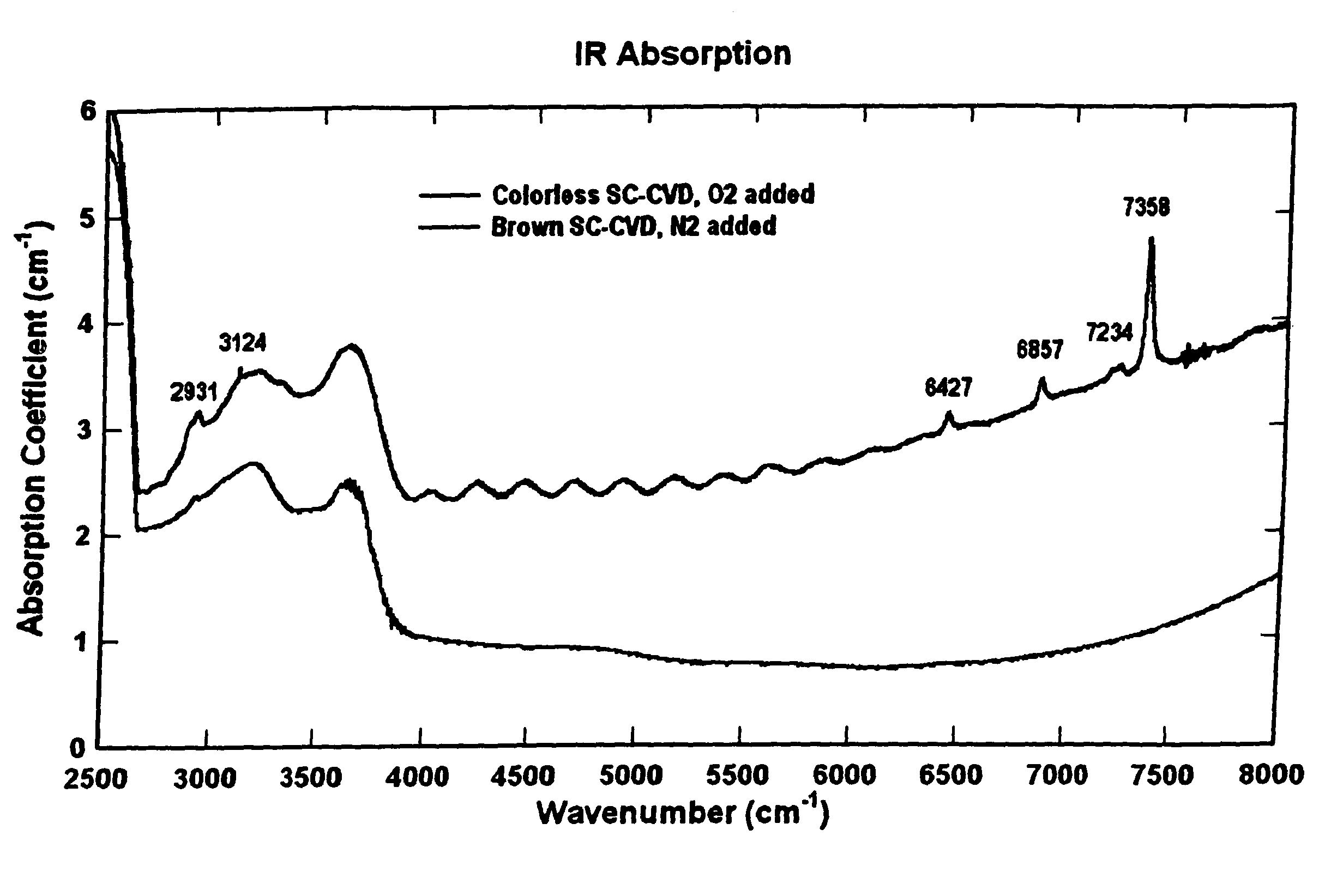

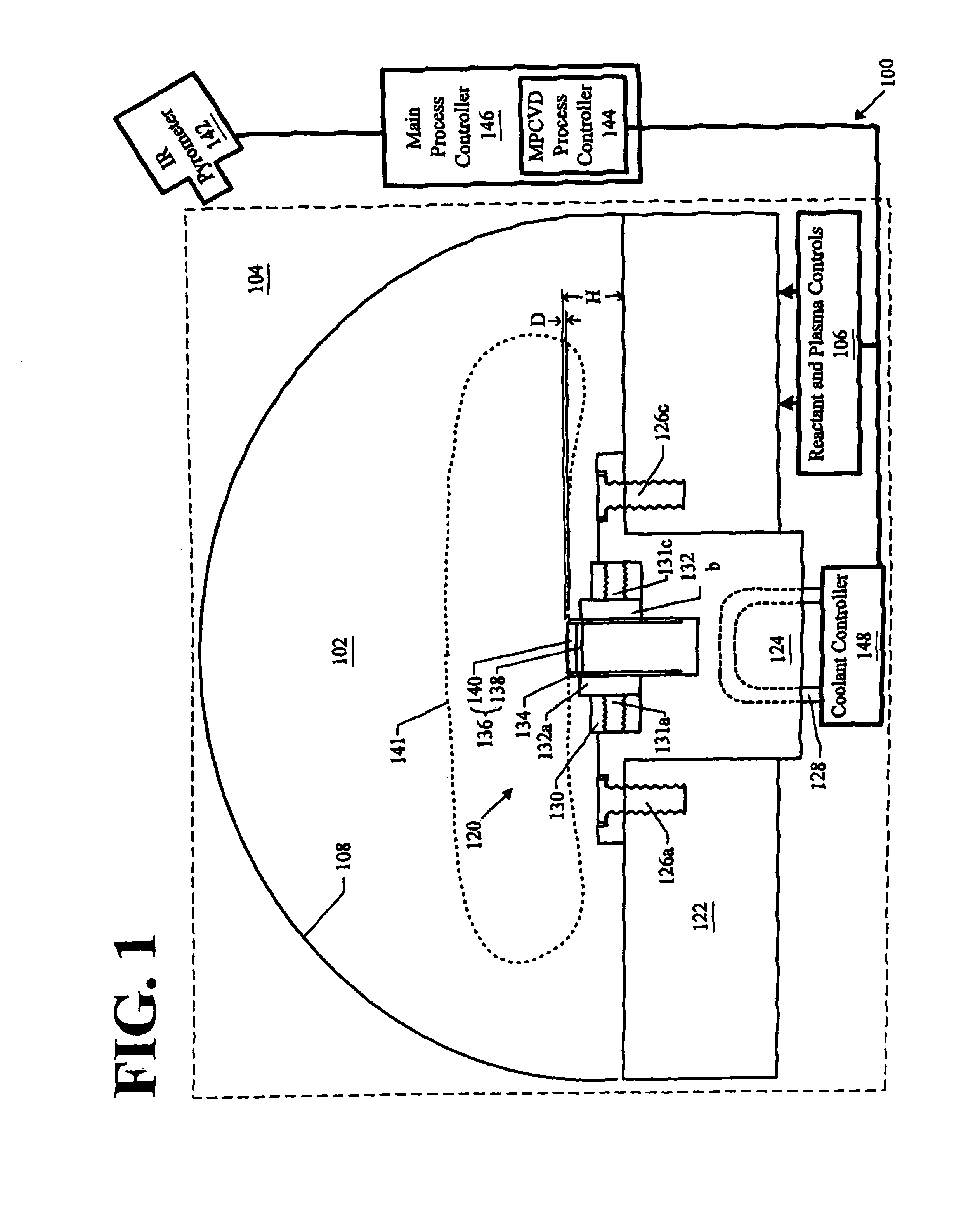

ActiveUS7883684B2Polycrystalline material growthUltra-high pressure processesSingle crystalMicrowave plasma chemical vapor deposition

The present invention relates to a method for producing colorless, single-crystal diamonds at a rapid growth rate. The method for diamond production includes controlling temperature of a growth surface of the diamond such that all temperature gradients across the growth surface of the diamond are less than about 20° C., and growing single-crystal diamond by microwave plasma chemical vapor deposition on the growth surface of a diamond at a growth temperature in a deposition chamber having an atmosphere, wherein the atmosphere comprises from about 8% to about 20% CH4 per unit of H2 and from about 5 to about 25% O2 per unit of CH4. The method of the invention can produce diamonds larger than 10 carats. Growth rates using the method of the invention can be greater than 50 μm / hour.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

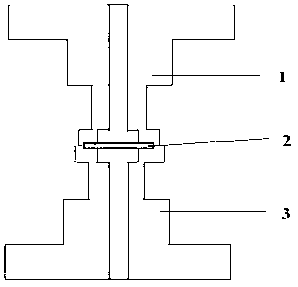

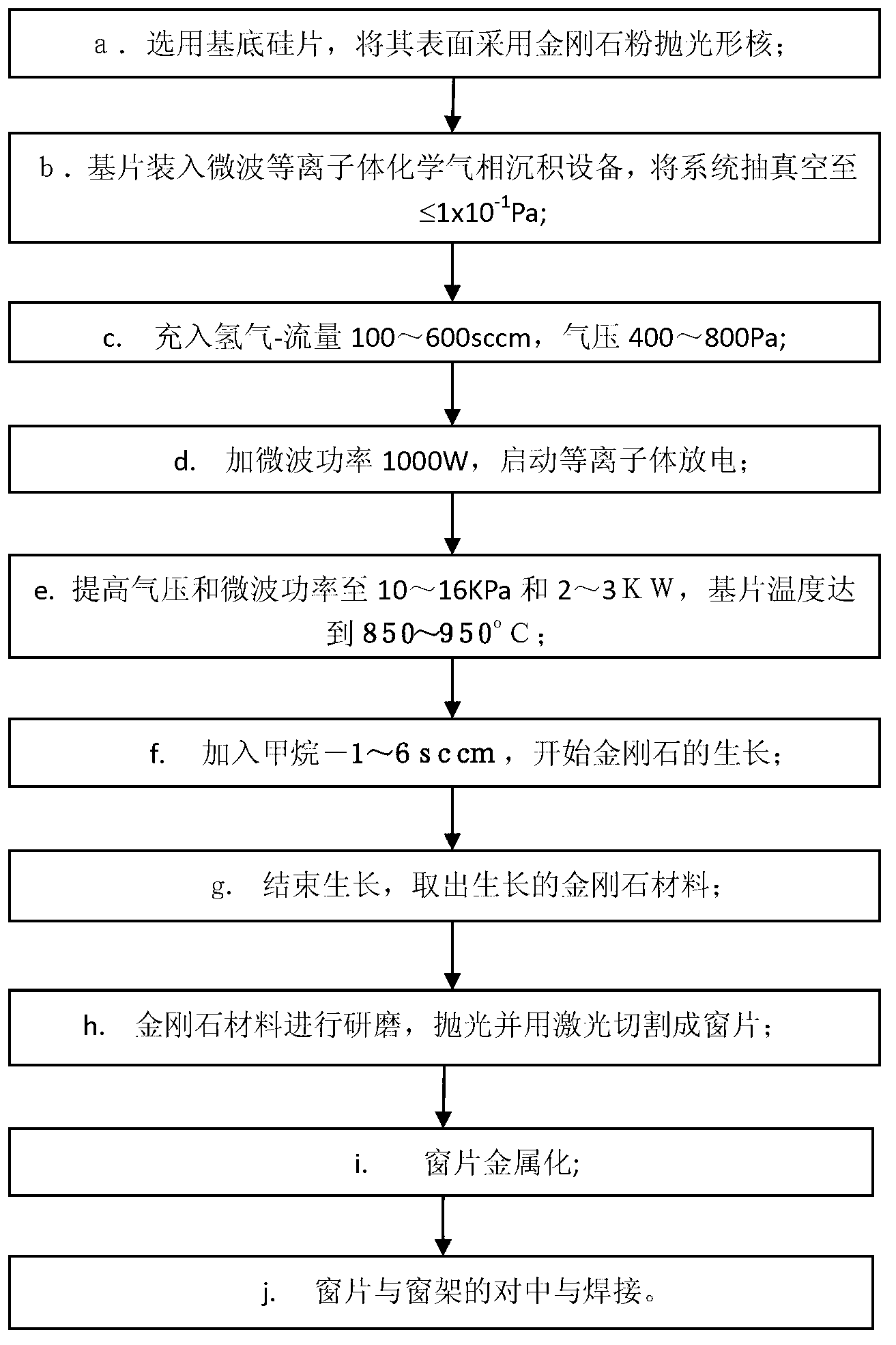

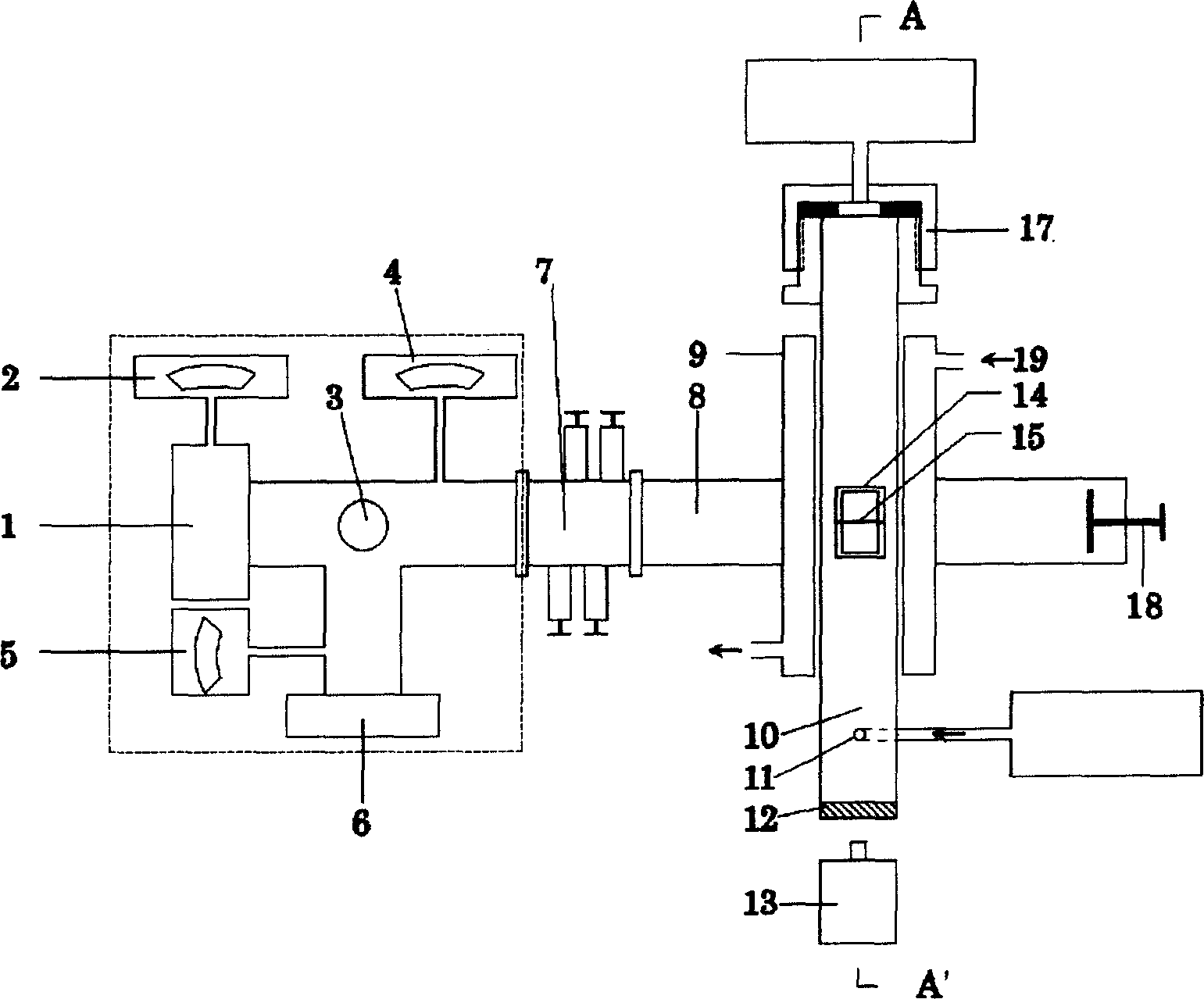

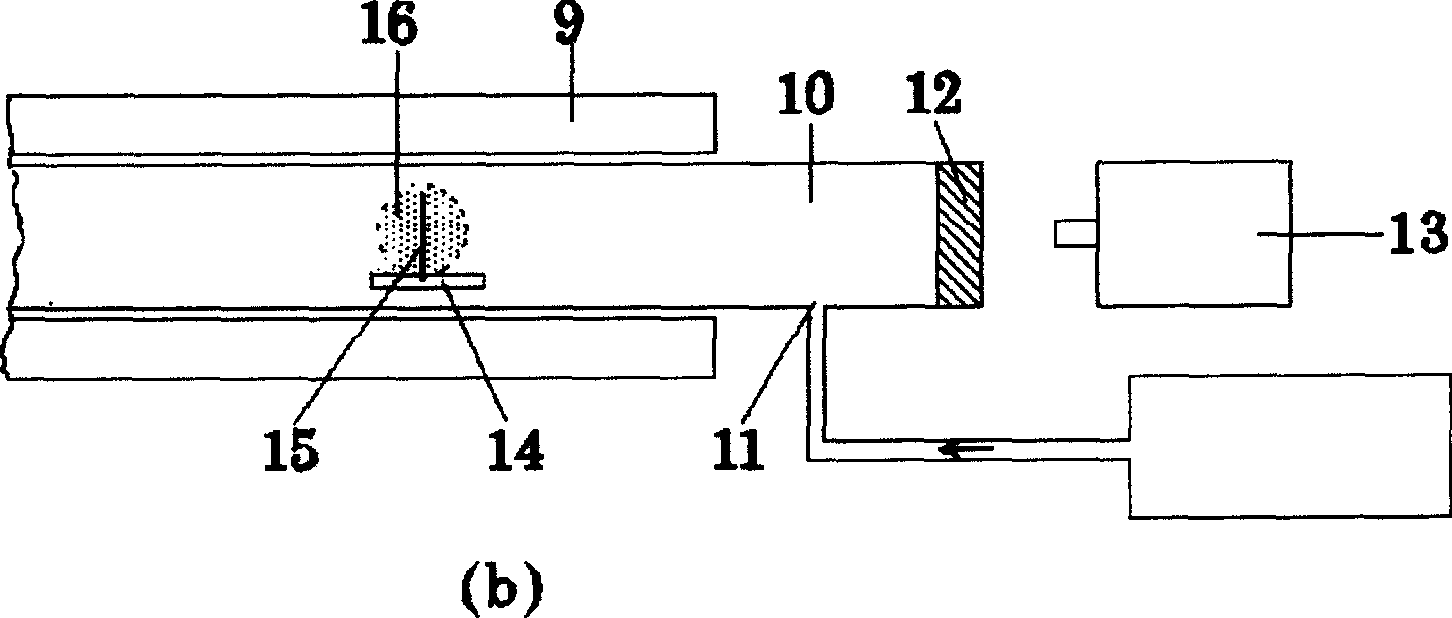

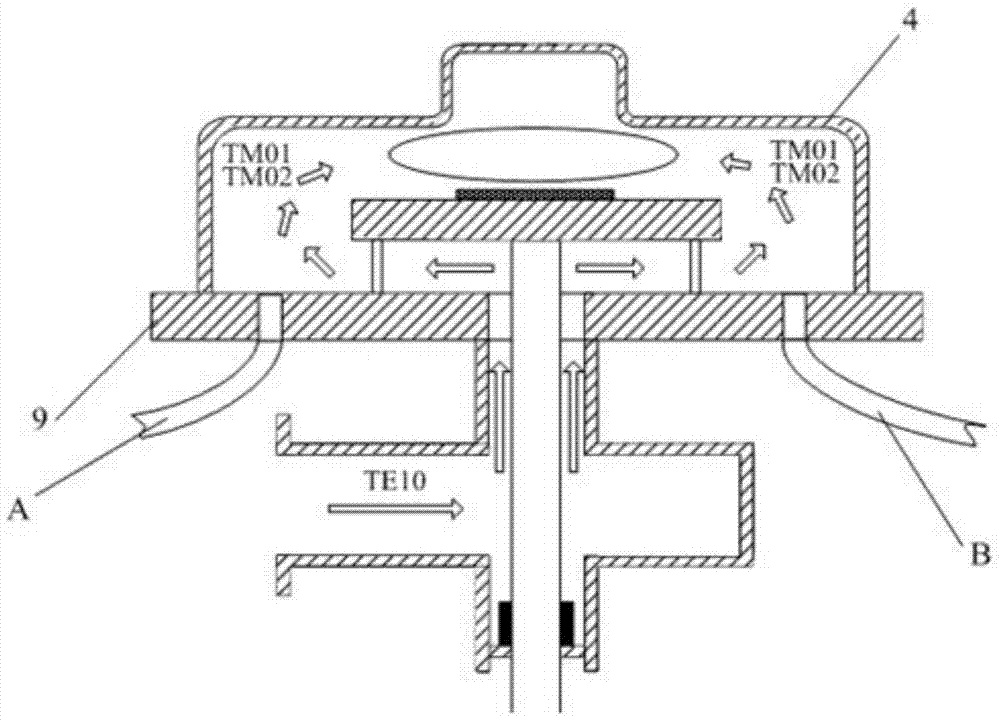

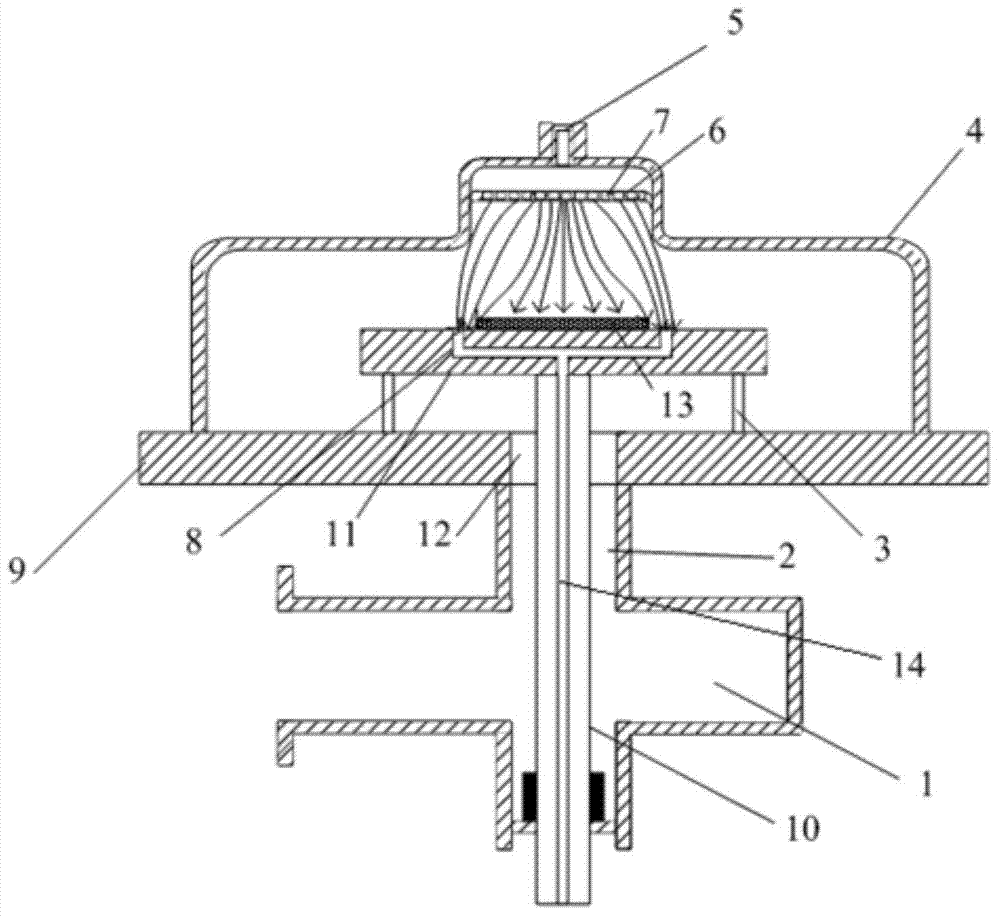

Diamond energy transmission window for short millimeter wave traveling tubes and manufacturing method of diamond energy transmission window

ActiveCN103236390AIncrease output powerSuppression of reflection oscillationsTransit-tube coupling devicesCold cathode manufactureSapphire windowEngineering

The invention discloses a diamond energy transmission window for short millimeter wave traveling tubes and a manufacturing method of the diamond energy transmission window and belongs to the technical field of vacuum electronics. The diamond energy transmission window comprises an energy transmission window leaf, a connecting wave guide and sealing window frames. The sealing window frames connected with the waveguide are symmetrically arranged on the upper and lower portion of the diamond energy transmission window, and the diamond window leaf is hermetically clamped between the window frames. The manufacturing method of the diamond energy transmission window includes: a, selecting a substrate silicon wafer; b, installing the substrate silicon wafer in a microwave plasma chemical vapor deposition device; c, inflating hydrogen gas; d, starting plasma discharging; e, increasing air pressure and microwave power and increasing substrate temperature to 850-950 DEG C; f, adding methane and starting growing diamond; g, finishing growing and taking out of diamond materials; h, grinding, polishing and cutting to obtain the window leaf by laser; i, metalizing the window leaf; and j, welding the window leaf and the window frames by centering. The diamond energy transmission window is superior to sapphire windows in both matching performance and transmission loss.

Owner:NO 12 RES INST OF CETC

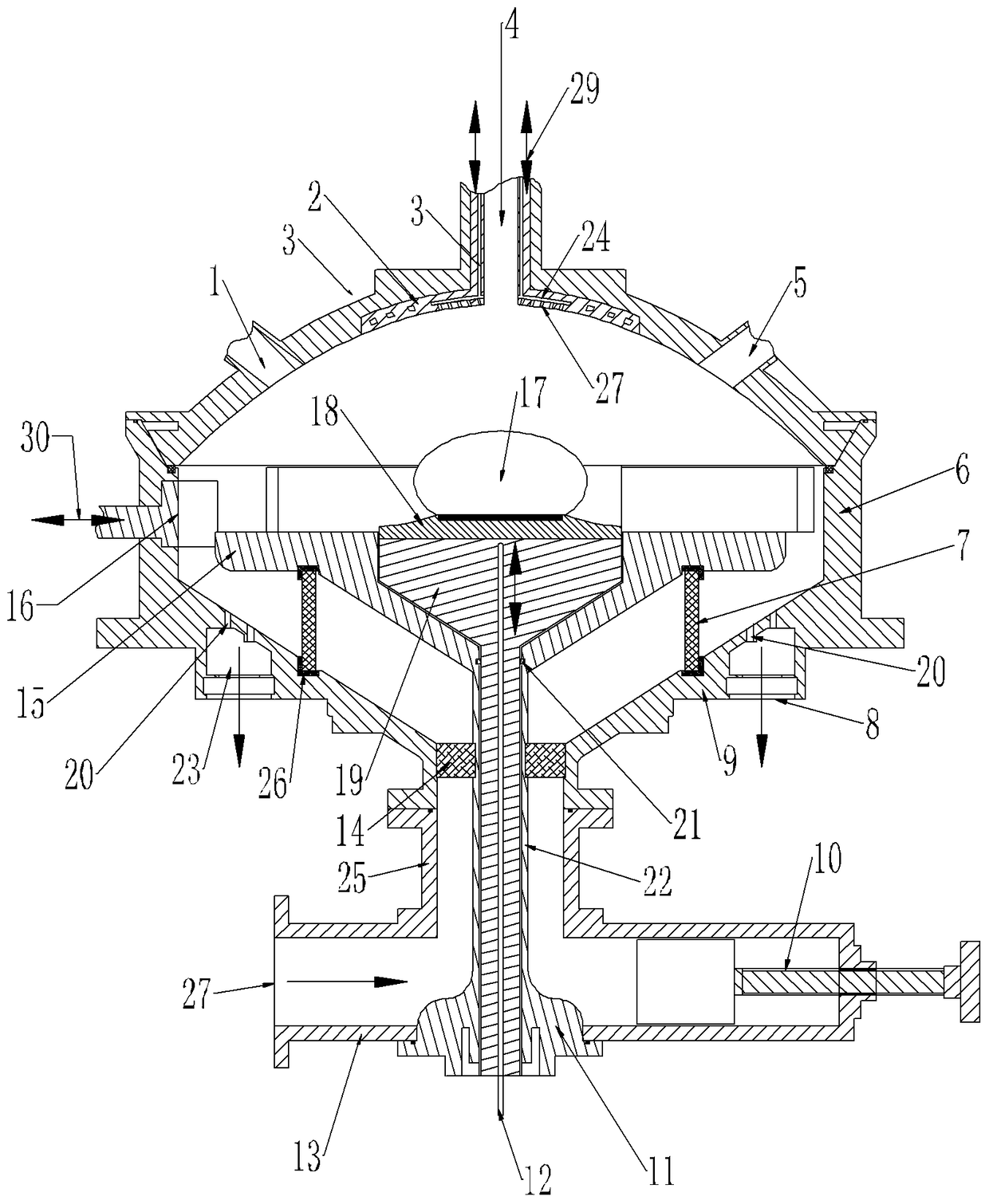

Tunable rounding cavity type high-power microwave plasma chemical vapor deposition device

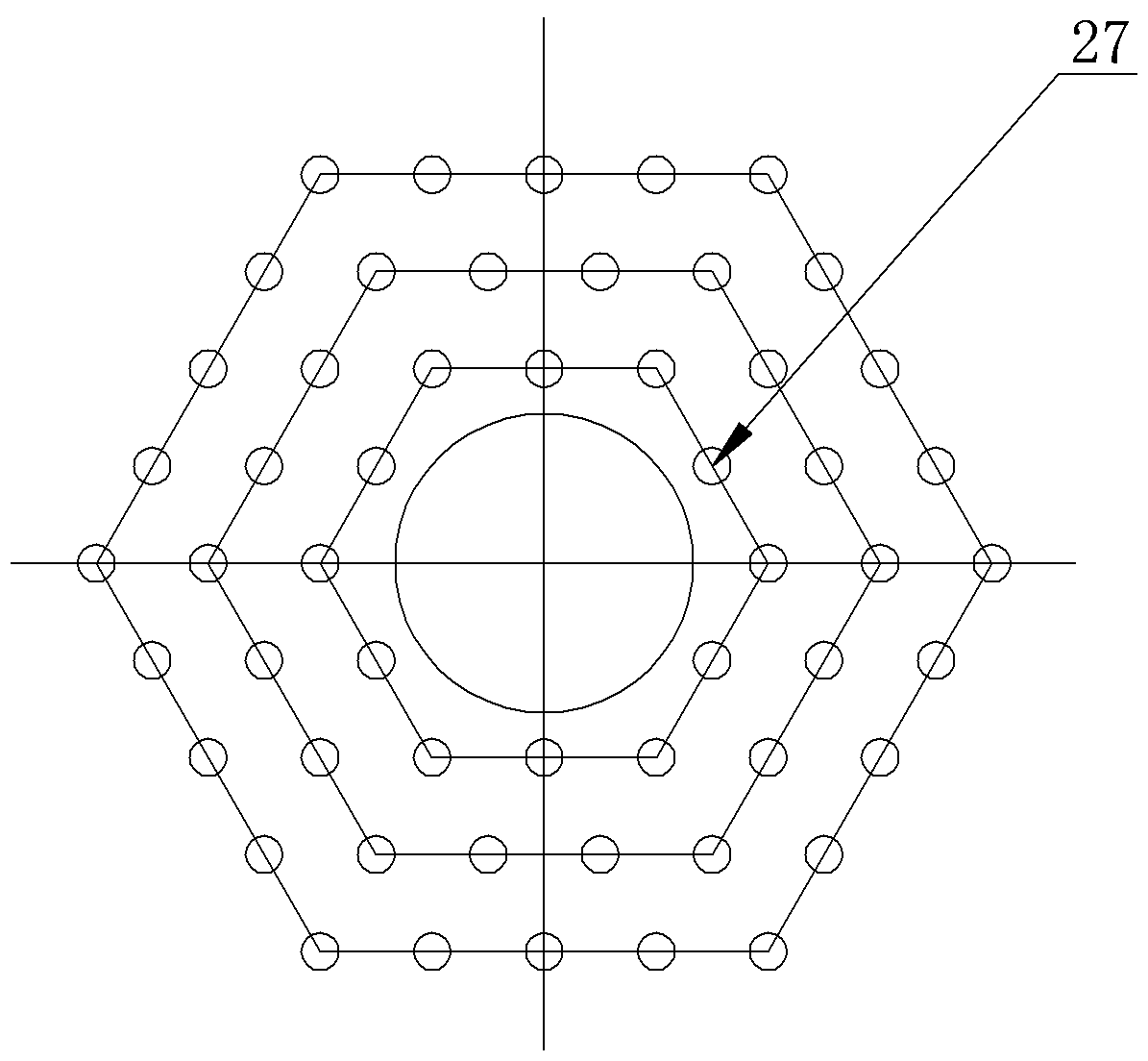

ActiveCN108624870AEnhanced couplingImprove feedFinal product manufactureChemical vapor deposition coatingDistributed structureMicrowave resonance

The invention discloses a tunable rounding cavity type high-power microwave plasma chemical vapor deposition device which is composed of a microwave resonance cavity main body, a mode converter and amicrowave electric field adjusting system. According to the chemical vapor deposition device, by means of the rounding cavity type cavity, a sample table, the mode converter and an adjusting structurethereof, the problems of low microwave input power, the poor focusing ability, shortage of perfect adjusting measures and the too close distance between a unifying part and plasma existing in variousexisting devices can be effectively solved, gas is input from the top and output from the bottom, the multi-hole array distributing structure of a flow uniformizing ring and a buffering bin is adopted, uniformity of gas flow and distribution in a resonance cavity and on the surface of a base piece can be effectively is improved, and deposition efficiency and uniformity of a deposition diamond film are further improved. The device can achieve efficient deposition of large-area and high-quality diamond film under high power.

Owner:CHENGDU NEWMAN HERUI MICROWAVE TECH CO LTD

Method for oriented growth of diamond film on aluminium oxide ceramic

The present invention relates to microwave plasma chemical vapor deposition process of oriented diamond film on alumina ceramic. The technological process includes the following steps: implanting carbon ion to alumina ceramic before deposition; microwave plasma high-temperature annealing of the alumina ceramic under mixed nitrogen and hydrogen atmosphere; and the oriented deposition of diamond film on the alumina ceramic. During the oriented deposition, the alumina ceramic is set inside the quartz tube reactor with microwave plasma radiation, the reactor is vacuum pumped, inflated with mixed gas of hydrogen and methane, and diamond film of oriented crystal grains is formed through vapor deposition under specific technological condition.

Owner:SHANGHAI UNIV

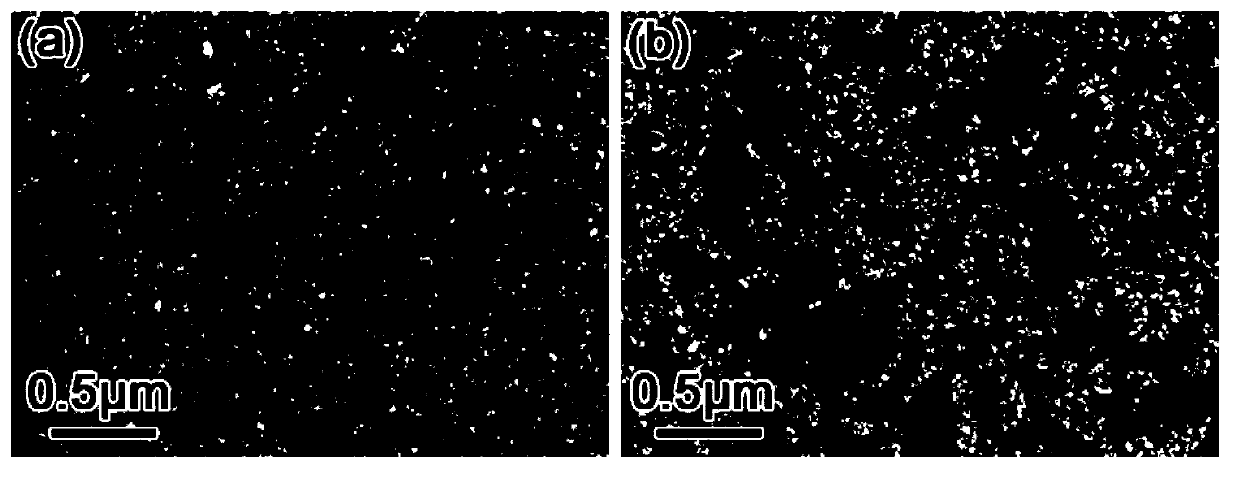

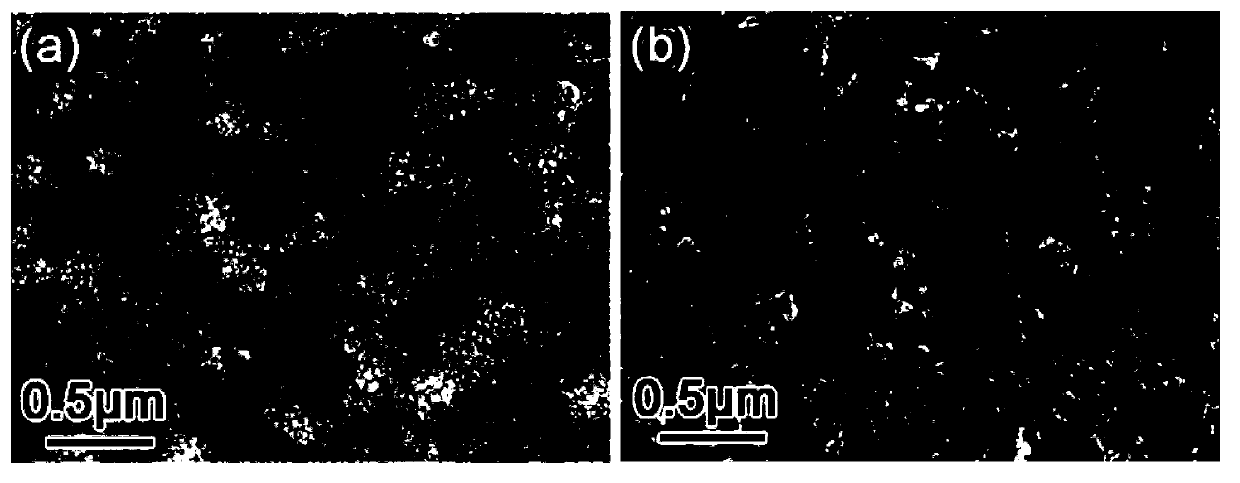

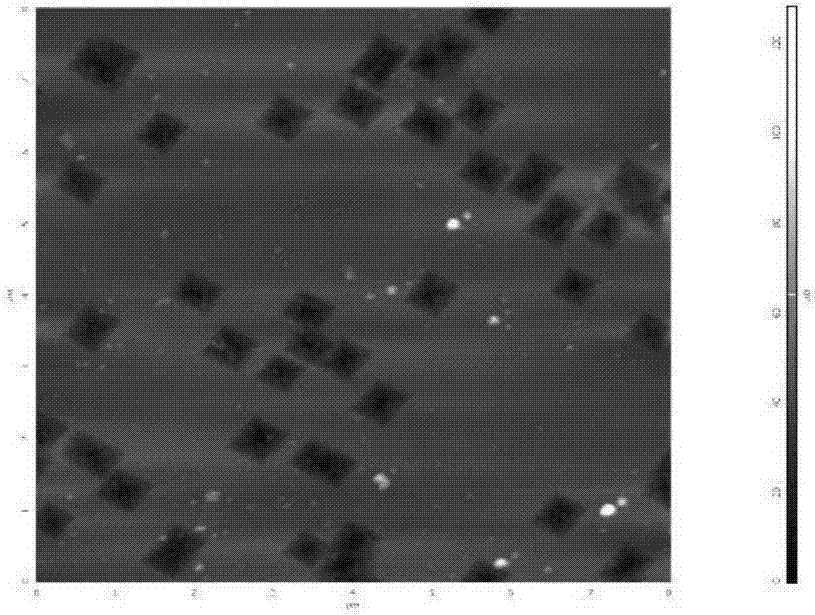

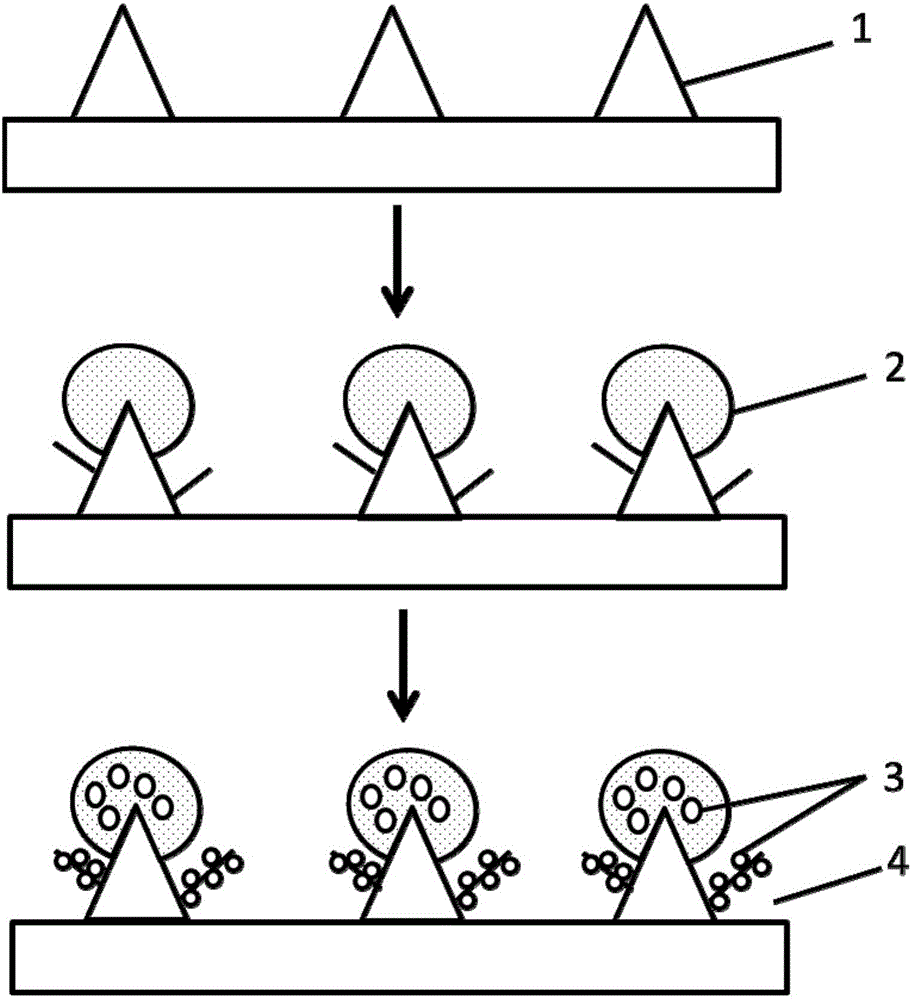

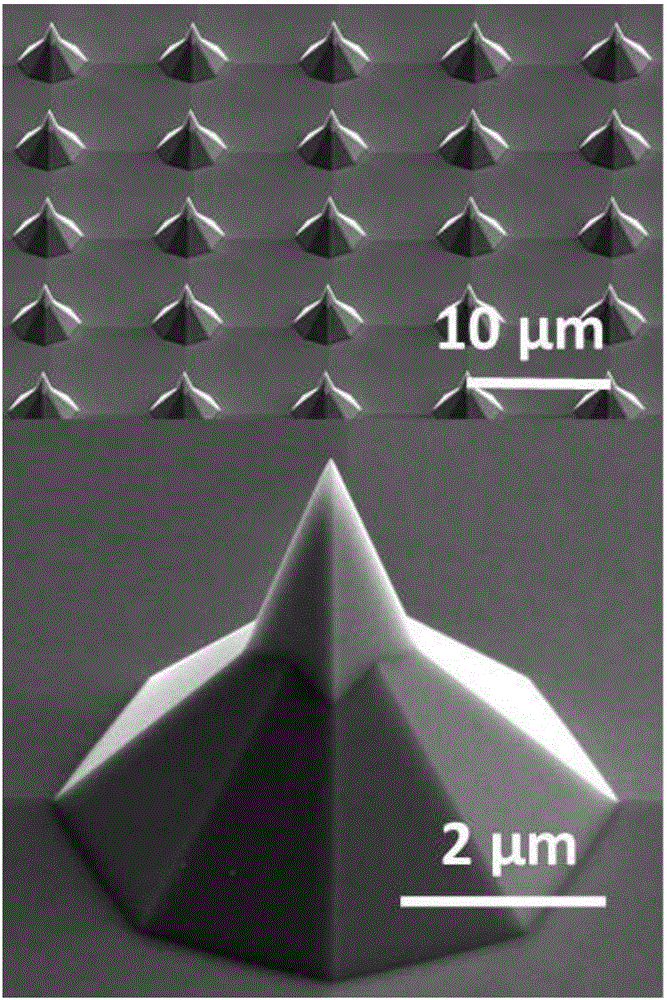

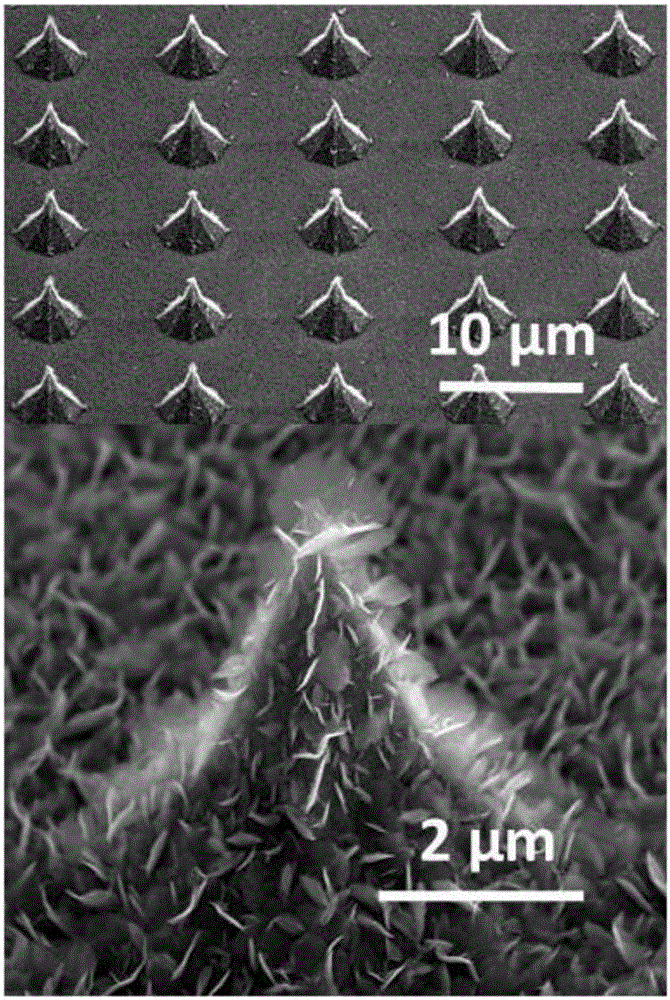

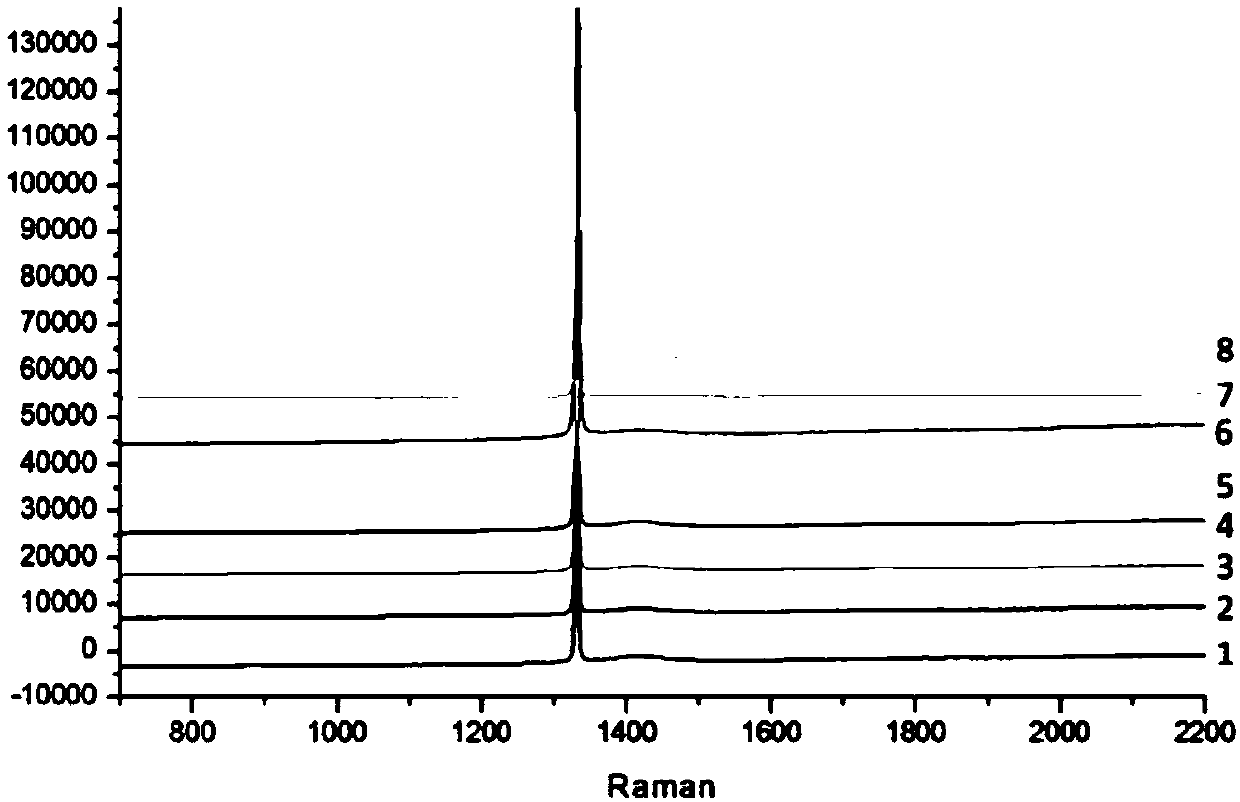

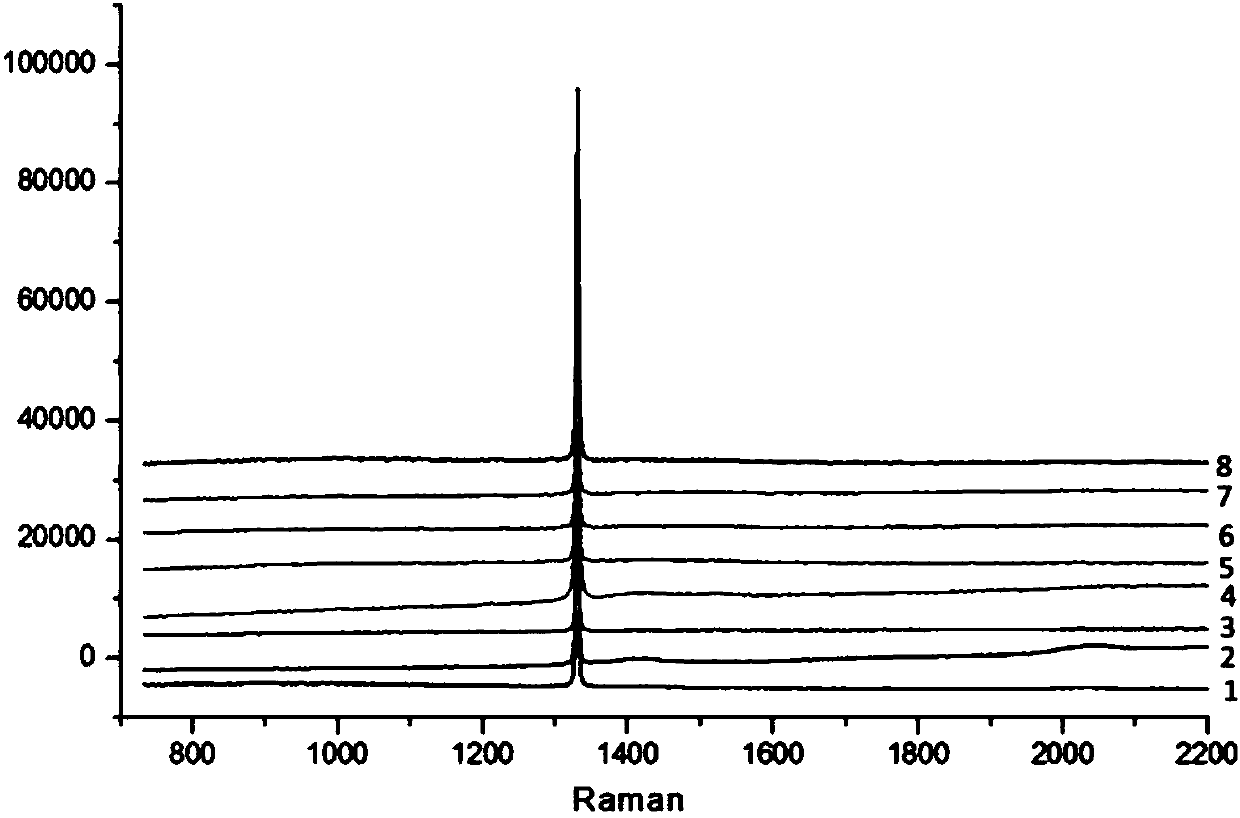

Preparation method for surface-enhanced Raman substrate and surface-enhanced Raman substrate structure

The invention provides a preparation method for a surface-enhanced Raman substrate and a surface-enhanced Raman substrate structure, belonging to the field of preparation of micro-nano structures. The preparation method comprises the following steps: selecting a silicon substrate and etching the silicon substrate to produce a silicon pyramid array; putting the silicon pyramid array into a microwave plasma chemical vapor deposition system for growth of a graphene nanoflake; and coating the surface of the graphene nanoflake with a layer of metal particles so as to obtain the surface-enhanced Raman substrate. The surface-enhanced Raman substrate structure is prepared by using the preparation method. The preparation method in the invention can prepare the uniform surface-enhanced Raman substrate with a large area and ensure the metal particles to be pure and free of contaminations. Meanwhile, the preparation method is simple and convenient, and is low in cost. The surface-enhanced Raman substrate prepared in the invention has strong Raman enhancement characteristics and high sensitivity.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

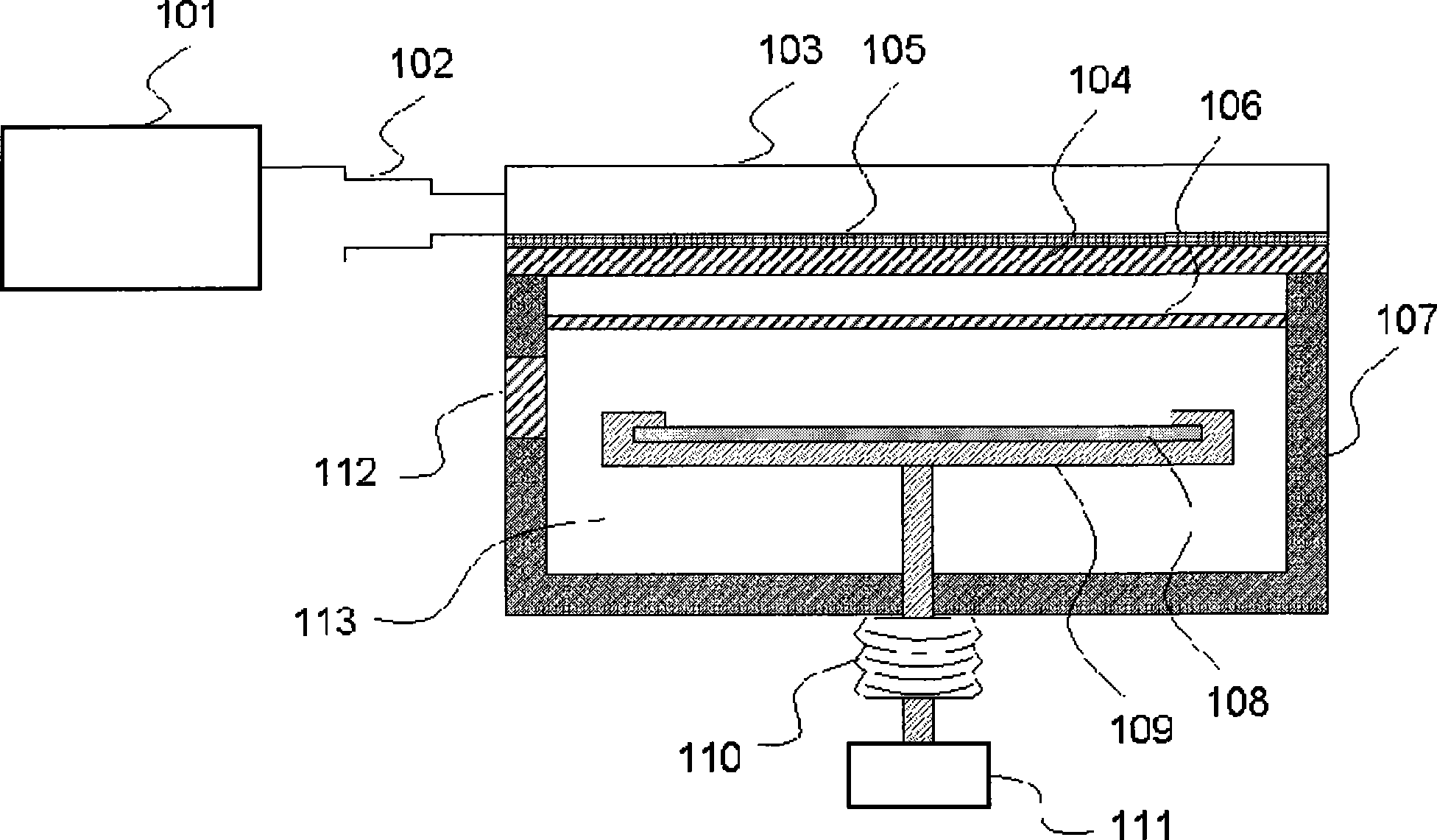

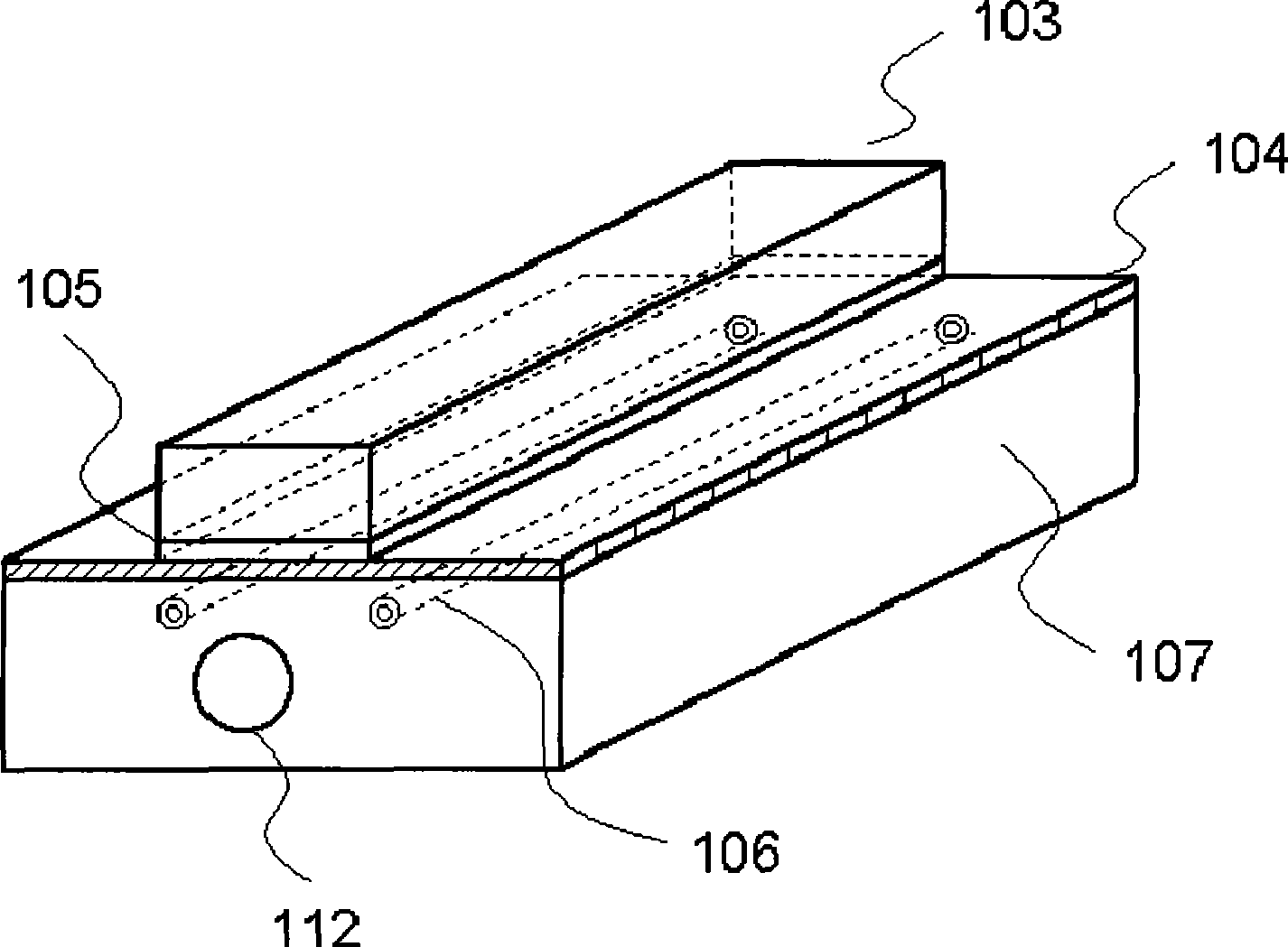

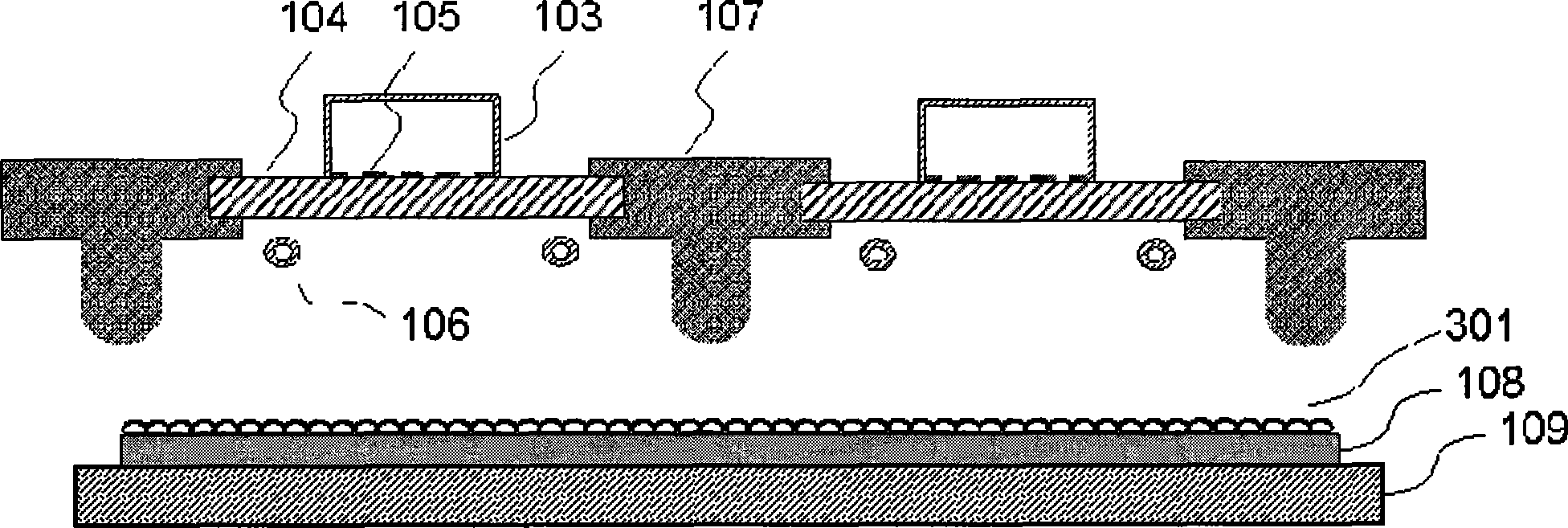

Large area microwave plasma CVD device

The invention relates to a large-area microwave plasma chemical vapor deposition device, in particular to the filed of solar batteries and panel display by using the film preparation device to quickly deposit amorphous silicon and microcrystallizing silicon films on a substrate. The device comprises a microwave source, a tapered wave pipe and a rectangle wave pipe; the tapered wave pipe is connected with the microwave source and the rectangle wave pipe; a main cavity with one upper end that is sealed by a quartz glass plate is arranged below the rectangle wave pipe; a microwave feed-in window is positioned between and adheres to the rectangle wave pipe and the quartz glass plate; at least one gas distribution pipe is disposed inside the main cavity; and the main cavity is internally provided with an object load device for loading the substrate and a vacuum system connected with the main cavity body. The rectangle wave pipe is disposed to correspond to the substrate. A large area of uniform plasma is produced by using parallel distribution of pipes, and the device in the invention can realize the homogenization of the large-area film deposition.

Owner:上海拓引数码技术有限公司

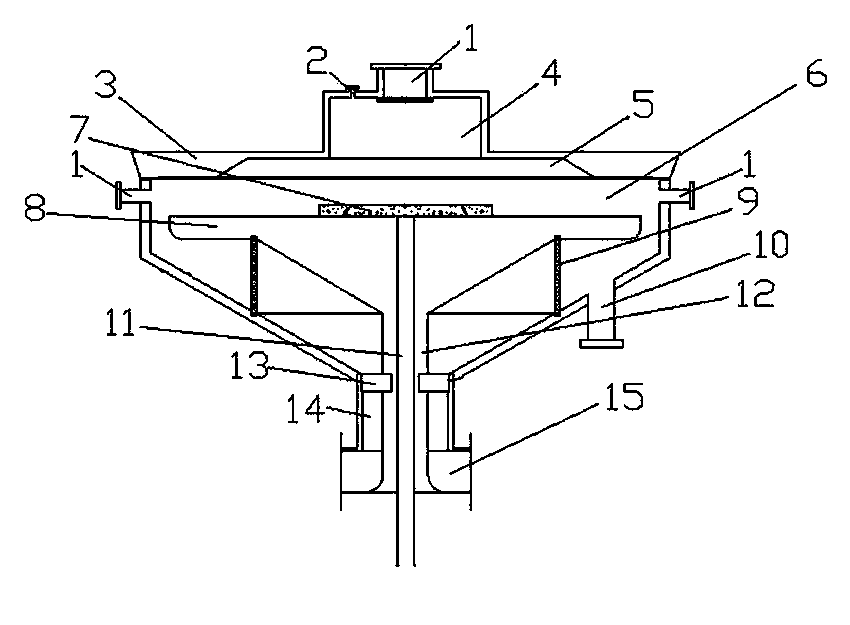

Large-area microwave plasma chemical vapor deposition system

The invention belongs to the microwave plasma chemical vapor deposition system field, and mainly relates to a microwave plasma chemical vapor deposition system for preparation of a large-area high-quality diamond film. The system mainly includes a vacuum part and a microwave lead-in part, the vacuum part includes a vacuum chamber and a vacuum chamber upper cover, two concave parts with different specific sizes are formed on the center-side surface of the vacuum chamber upper cover, so that the vacuum chamber is a multi-mode chamber body, two large-area even-energy plasma spheres produced by two modes are formed above a substrate table, the microwave lead-in part mainly includes, from bottom to top, a waveguide, a quartz ring and a mode transforming antenna, the substrate table combines the lower part of the chamber body so as to clamp the quartz ring to maintain the vacuum, the mode transforming antenna leads microwave into the vacuum chamber, and the vacuum chamber, the mode transforming antenna and the water-cooled substrate table are fixed by a ceramic ring to maintain strict centring.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

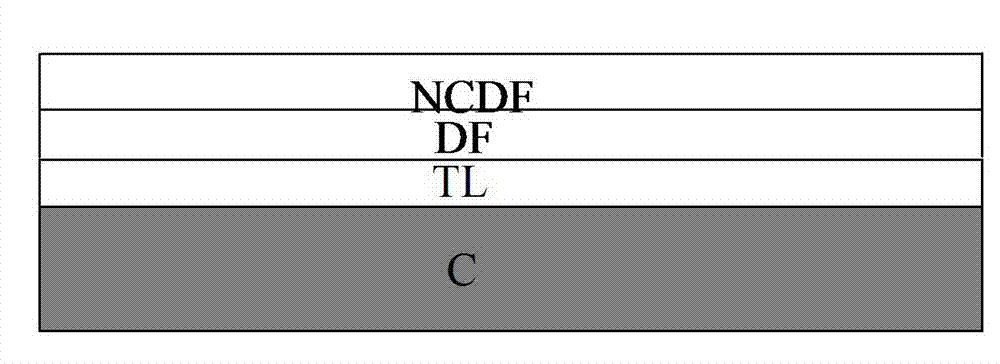

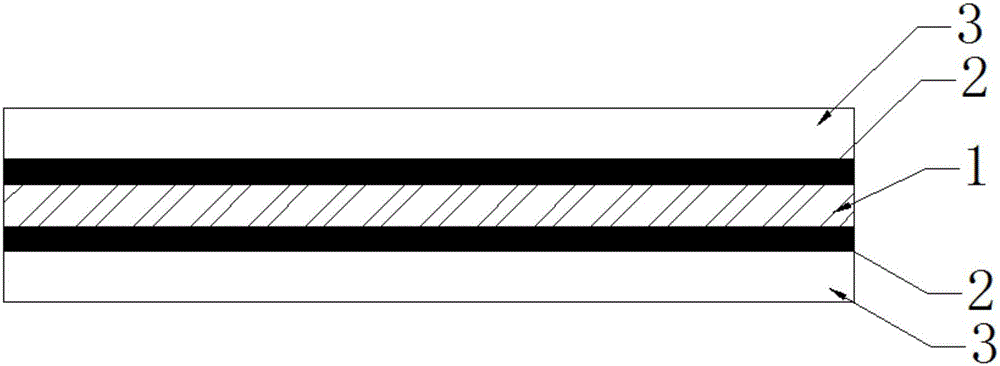

Flexible substrate nanometer diamond film and preparation method thereof

InactiveCN102965666AIncrease nucleation rateImprove adhesionVacuum evaporation coatingSputtering coatingHydrogen treatmentControllability

The invention relates to a flexible substrate nanometer diamond film and a preparation method thereof. The flexible substrate nanometer diamond film comprises a metal flexible substrate layer, a Ni transition layer, a diamond film layer and a nanometer diamond film layer. According to the preparation method, Ni is used as the transition layer, and the diamond film and the nanometer diamond film are prepared by a microwave plasma chemical vapor deposition (MPCVD) method, so that the adhesive force is enhanced, and the adhesive force of the film base is further enhanced by regulating the following key processing steps: (1) carrying out hydrogen treatment on the Ni transition layer to enhance the binding force between the transition layer Ni and the substrate and etch redundant Ni; (2) depositing the diamond film at high methane concentration to improve the nucleation rate of the subsequent nanometer diamond film; (3) depositing the nanometer diamond film at low methane concentration with Ar gas introduced; and (4) insulating and annealing. The flexible substrate nanometer diamond film is low in surface roughness and smooth in surface, and can be used for substituting polishing powder, so that the shortage of the conventional polishing process is effectively overcome, and the application range is widened. The preparation method is simple and easy to realize, and has high controllability and generality.

Owner:ZHENGZHOU UNIV

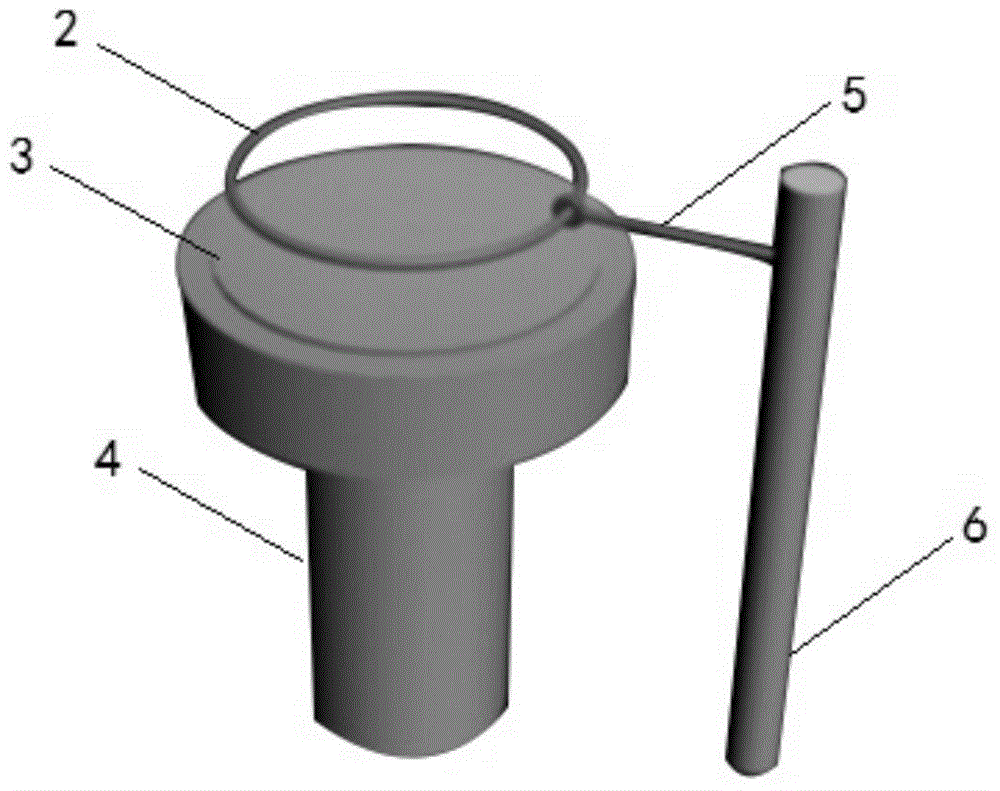

Microwave plasma chemical vapor deposition device and production method thereof

InactiveCN107227450ASimple structureReduce processing costsChemical vapor deposition coatingMicrowaveEngineering

The invention relates to a microwave plasma chemical vapor deposition device, which comprises a casing, a microwave input port is arranged on the upper surface of the casing, a substrate is arranged below the microwave input port, a loop antenna is arranged on the bottom surface of the substrate, and the connection between the substrate and the casing is A tubular microwave window made of microwave dielectric material is arranged in between, and a deposition platform is provided at the bottom of the shell, which is located below the loop antenna, and the deposition platform can move up and down driven by the first lifting device, and the deposition platform A plasma stabilizing ring with a tubular structure is arranged on the outer surface, and a closed resonant cavity is formed surrounded by the deposition table, the plasma stabilizing ring, the shell, the tubular microwave window and the substrate. The microwave plasma chemical vapor deposition device of the invention has the advantages of simple structure, low processing cost, high production efficiency and high quality of finished products. In addition, the present invention also designs the production method of the microwave plasma chemical vapor deposition device.

Owner:无锡远稳烯科技有限公司

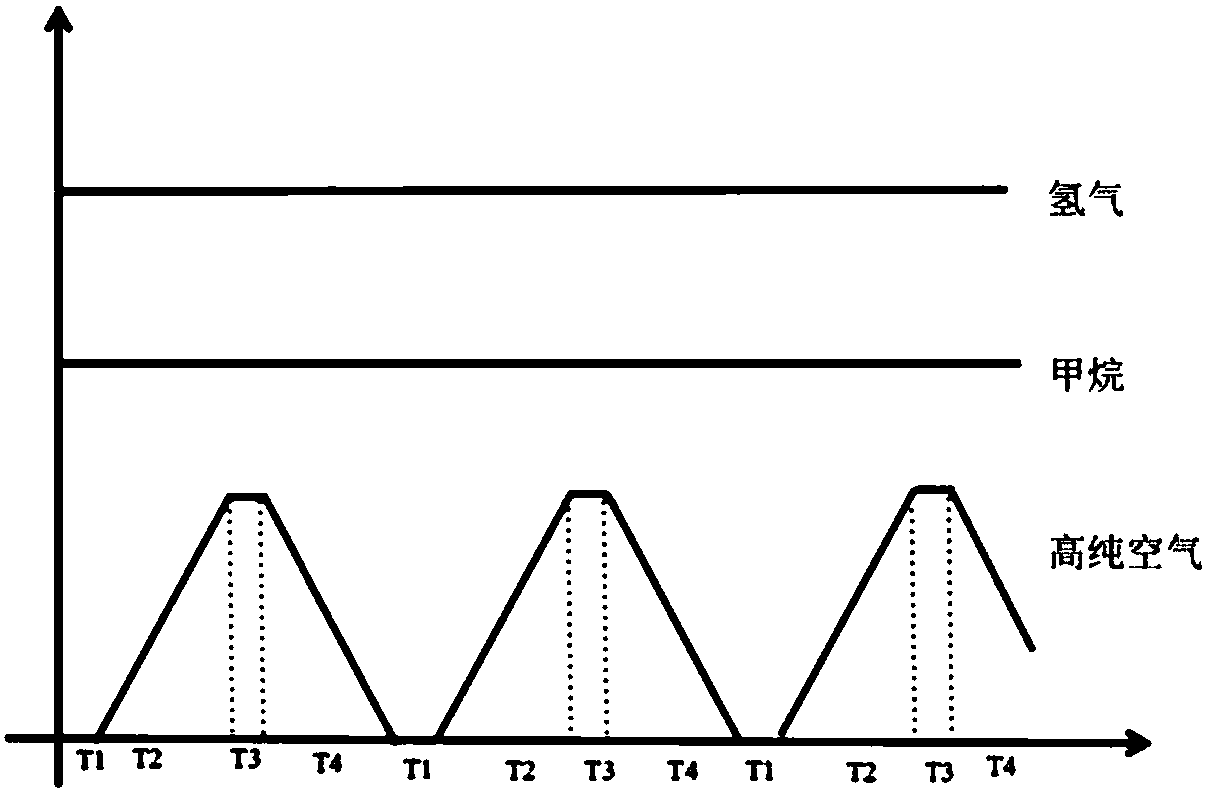

Gradient monocrystalline diamond and preparation method thereof

ActiveCN107740184AFast growthHigh hardnessPolycrystalline material growthFrom chemically reactive gasesHydrogenNitrogen

The invention relates to the field of growth of monocrystalline diamonds through a microwave plasma chemical vapor deposition method and in particular relates to a gradient monocrystalline diamond anda preparation method thereof. Microwave plasma chemical vapor deposition equipment is adopted and high-purity air is introduced in a hydrogen and methane mixed gas source according to a continuous gradient concentration, so as to realize alternating deposition of a high-quality monocrystalline diamond layer without nitrogen and a nitrogen-containing diamond layer; then the gradient monocrystalline diamond with high quality, high strength and good toughness is prepared.

Owner:湖北碳六科技有限公司

Method for preparation of large size CVD diamond by vertical splicing and cutting

ActiveCN110230091AAchieve preparationThe prepared diamond size achievedPolycrystalline material growthFrom chemically reactive gasesLaser etchingMaterials preparation

Belonging to the field of diamond material preparation, the invention discloses a method for preparation of large size CVD diamond by vertical splicing and cutting. Specifically, epitaxial growth of large size CVD diamond is carried out on the sides of a plurality of vertically and tightly arranged monocrystal diamond seed crystals, and then the seed crystals and epitaxial diamond are separated bylaser cutting process in order to obtain large size CVD diamond. The process steps include: a. conducting precision mechanical polishing treatment on the upper surfaces of the plurality of verticallyand tightly arranged monocrystal diamond seed crystals to obtain seed crystals with a height difference within 10microm and surface roughness less than 1nm; b. conducting patterned grooving treatmenton the seams of all the seed crystals by laser etching, electron beam lithography, ICP etching, focused ion beam bombardment or other methods; c. employing microwave plasma chemical vapor deposition(MPCVD) method for epitaxial growth of the seed crystals' sides subjected to grooving treatment; and d. separating the seed crystals from the epitaxial large size diamond by laser side cutting in order, thus obtaining the large-size and high-quality monocrystal diamond.

Owner:UNIV OF SCI & TECH BEIJING

Microwave plasma chemical vapor deposition device

ActiveCN103668121AEvenly distributedDischarge in timeChemical vapor deposition coatingCoaxial waveguidesMicrowave plasma chemical vapor deposition

The invention discloses a microwave plasma chemical vapor deposition device. The device comprises a reaction chamber consisting of a reaction chamber upper cover and a reaction table, wherein a rectangular waveguide and a coaxial waveguide which are connected with each other are arranged below the reaction chamber; a center shaft of the coaxial waveguide extends into the reaction chamber, and a sample table for placing a substrate is coaxially and fixedly connected above the center shaft; a gas guide inlet is formed in the center of the reaction chamber upper cover, a horizontal baffle in which a plurality of small inlet holes are formed is also arranged at the neck of the reaction chamber upper cover, a gas buffering and mixing chamber is formed between the horizontal baffle and the top of the reaction chamber upper cover, and exhaust paths are evenly and circumferentially distributed in positions, which are next to the outer side of the edge of the substrate, of the sample table. According to the device, the problem that gases in the reaction chamber cannot be evenly distributed around the substrate is solved.

Owner:西安德盟特半导体科技有限公司

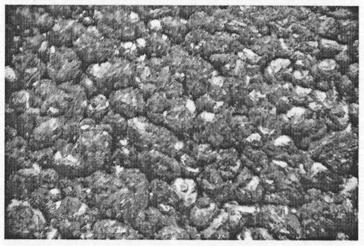

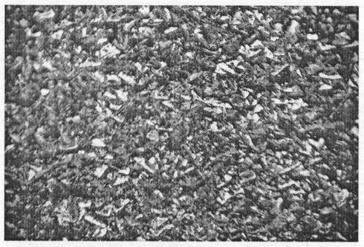

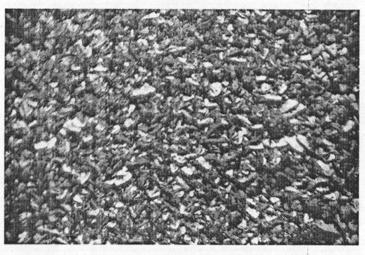

Method for growing polycrystalline diamond piece by using microwave plasma chemical vapor deposition method

InactiveCN109911894AInhibition of growing phenomenaInhibition of growthDiamondSurface finishPolycrystalline diamond

The invention discloses a method for growing a polycrystalline diamond piece by using a microwave plasma chemical vapor deposition method and relates to the field of artificial diamond. The method specifically comprises the following steps: (1) pretreating a substrate in microwave plasma chemical vapor deposition equipment; (2) forming a core for 0.4-0.6 hour on the pretreated substrate accordingto common polycrystalline diamond piece growth process, controlling growth time according to a final growth thickness, and carrying out power-off, grinding and polishing for multiple times for repeated multi-time growth. The self-support thickness of the polycrystalline diamond piece grown by using the method can be a millimeter grade or greater, the phenomenon that diamond granules are continuously increased along with increase of thicknesses can be effectively inhibited, then the purposes that the diamond granules are refined while thickness requirements are met, and the density, the mechanical strength and the surface smoothness after polishing of the diamond piece are improved, are achieved, and effects of a CVD (Chemical Vapor Deposition) polycrystalline diamond material can be sufficiently taken into play.

Owner:河北地质大学

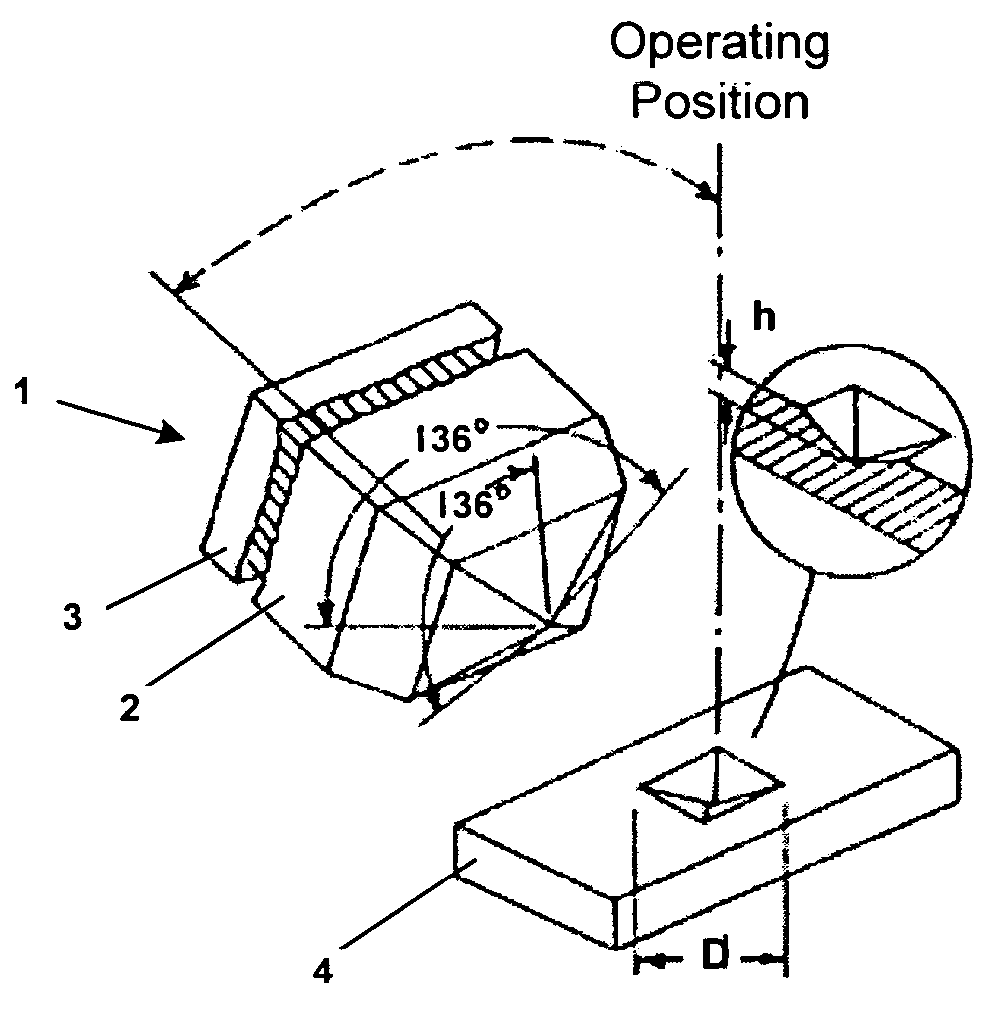

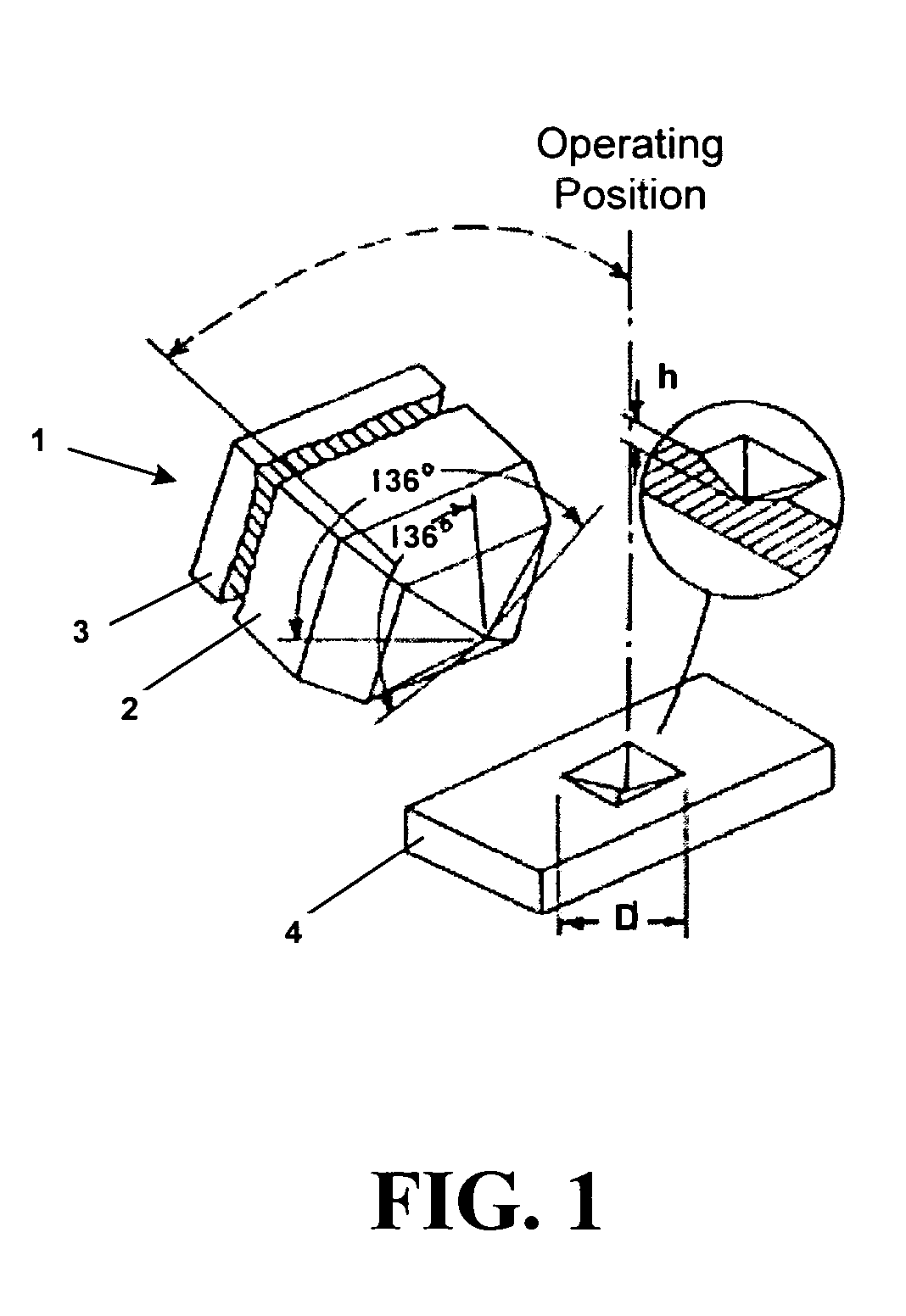

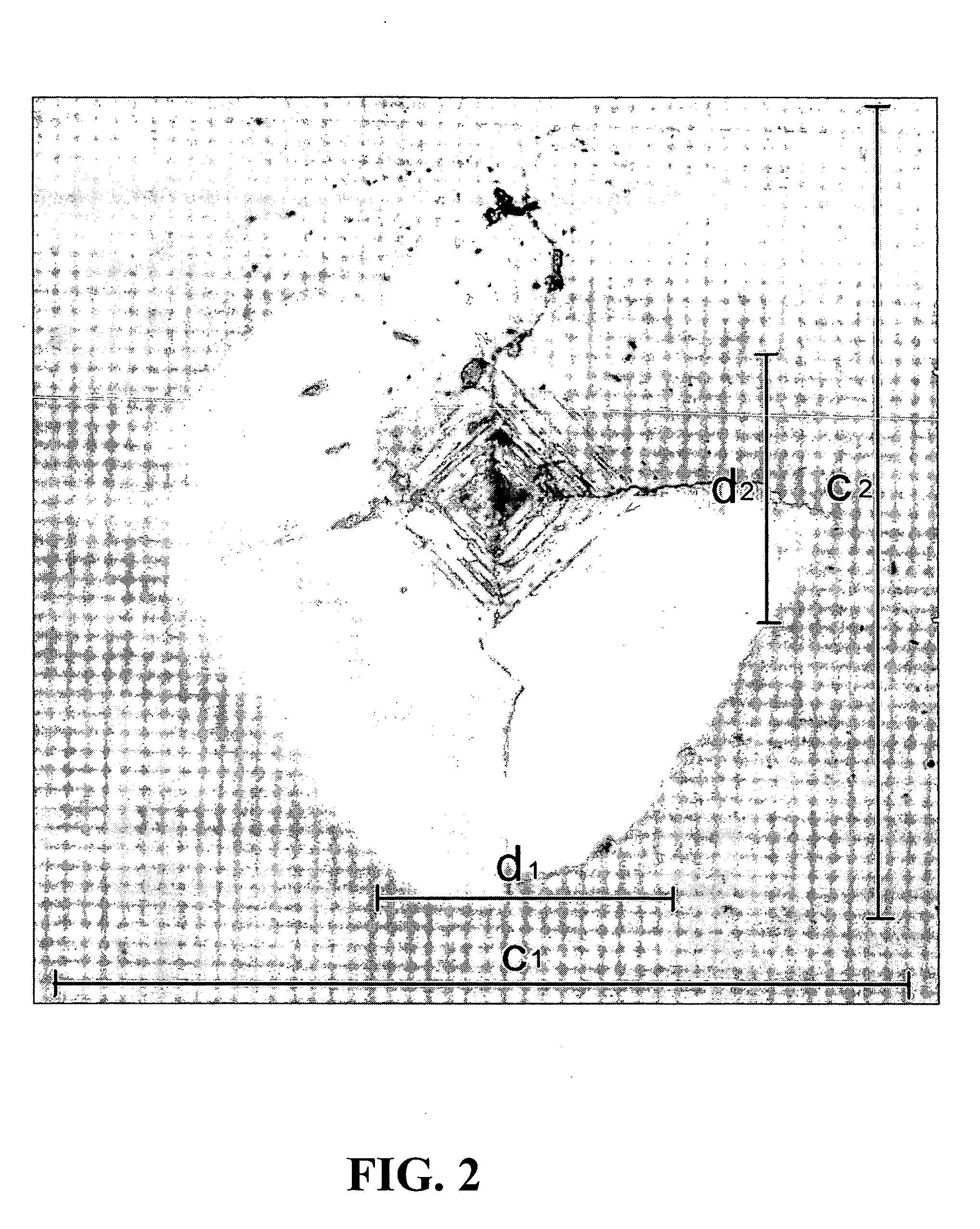

Tough diamonds and method of making thereof

InactiveUS20050011433A1Improve fracture toughnessTelevision system detailsDisc-shaped record carriersSingle crystalHardness

A single crystal diamond grown by microwave plasma chemical vapor deposition has a hardness of 50-90 GPa and a fracture toughness of 11-20 MPa m1 / 2. A method for growing a single crystal diamond includes placing a seed diamond in a holder; and growing single crystal diamond at a temperature of about 1000° C. to about 1100° C. such that the single crystal diamond has a fracture toughness of 11-20 MPa m1 / 2.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

Current collector for lithium ion battery positive electrode and battery with current collector

InactiveCN106159316AImprove electronic conductivityImproved High Power Discharge PerformanceElectrode carriers/collectorsSecondary cellsElectrical batteryGraphene

The invention relates to a current collector for a lithium ion battery positive electrode and a battery with the current collector, in particular to a high-power lithium ion battery, and belongs to the technical field of secondary batteries. The current collector comprises an aluminum foil base, and a graphene layer is deposited on at least one surface of the aluminum foil base by a microwave plasma chemical vapor deposition method. By the aid of microwave plasma chemical vapor deposition, a low-temperature graphene film can be prepared, an aluminum foil current collector of the lithium ion battery positive electrode can be modified, the graphene layer and the aluminum foil base are excellently adhered, electrical conductivity of the current collector is improved, electrode service life is prolonged, adhesive force of the current collector and an electrode active material is greatly improved by the graphene layer, interface contact resistance between the current collector and the active material is reduced, so that high-power discharge capacity of the lithium ion battery is improved.

Owner:中直新能源科技(大连)有限公司

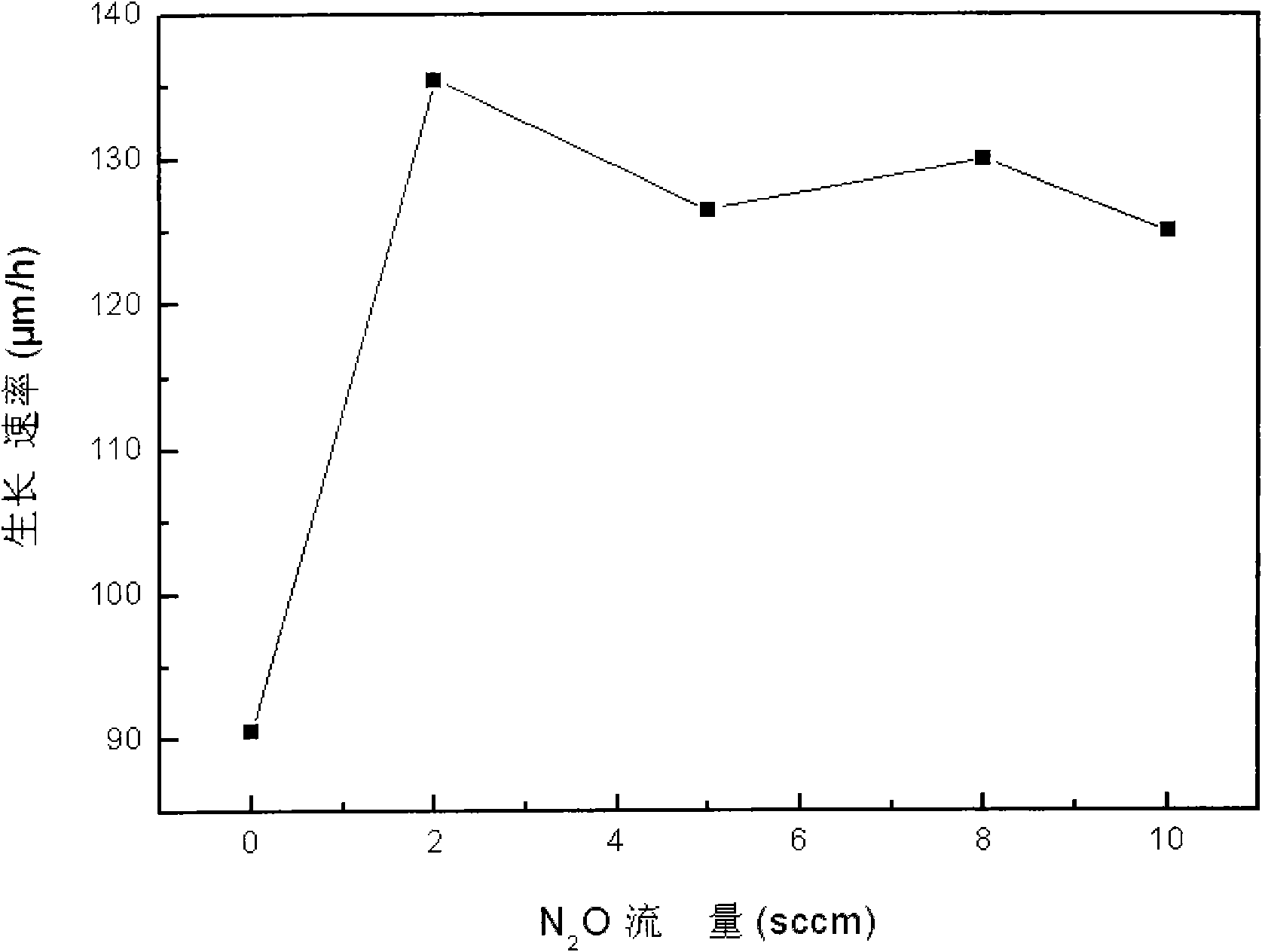

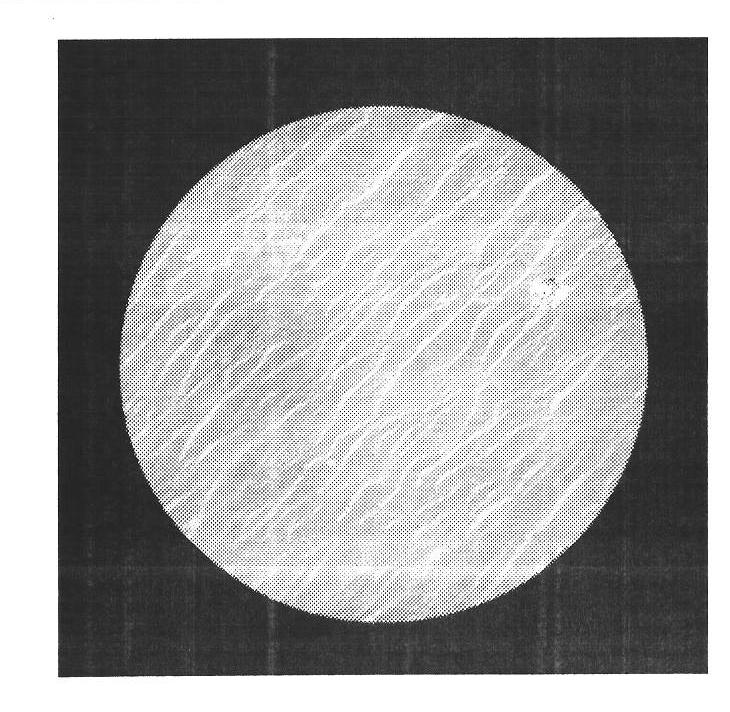

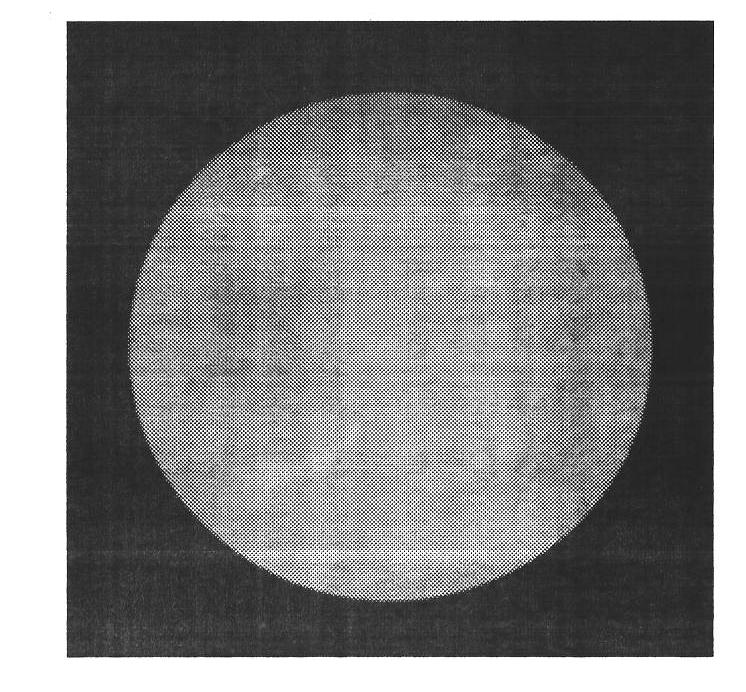

Chemical vapor deposition method for preparing diamond single crystal by adding N2O gas

ActiveCN102021649AQuality assuranceQuality improvementPolycrystalline material growthFrom chemically reactive gasesSingle crystalChemical vapor deposition

The invention discloses a chemical vapor deposition method for preparing diamond single crystal by adding N2O gas, and belongs to the technical field of diamond single crystal materials and preparation methods thereof. A microwave plasma chemical vapor deposition system is adopted. The method comprises the following steps of: putting a polished and ultrasonic cleaned single crystal diamond substrate into a deposition chamber, and introducing hydrogen, methane and laughing gas into the deposition chamber, wherein the flow ratio of H2: CH4: N2O is 750: 75-90: 2-10; and growing the diamond single crystal under microwave power of between 2 and 2.5kw, at the substrate temperature of between 900 and 1,100 DEG C and under air pressure of between 13 and 40kPa. The method is simple, and has the advantages of good quality, low cost, low pollution and the like; and under the condition that the increased N2O concentration affects the global climate warming effect remarkably increasingly, the method makes use of the waste gas, saves energy, reduces emission and promotes the production of diamond.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com