Flexible substrate nanometer diamond film and preparation method thereof

A nano-diamond and flexible substrate technology, applied in the field of polishing and abrasive materials, can solve the problems of complex production and preparation process, low bonding force between the diamond film and the substrate, etc., and achieves improved nucleation rate, strong controllability and versatility , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

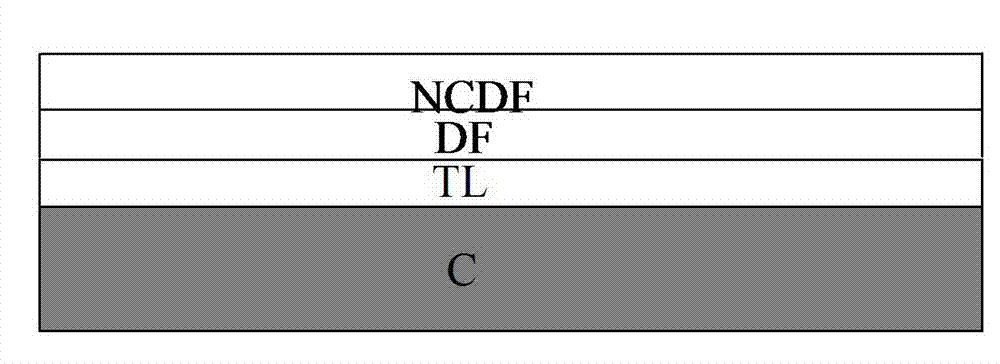

[0025] Embodiment 1 A kind of preparation method of flexible substrate nano-diamond film:

[0026] (1) Substrate copper foil (10×10×0.2mm) is surface treated, and the treatment process is: polishing → ultrasonic cleaning in acetone solution for 10 minutes → deionized water cleaning for 5 minutes → soaking in 10% dilute sulfuric acid for 10 hours → acetone solution Ultrasonic cleaning for 10 minutes → deionized water cleaning for 2 minutes;

[0027] (2) Preparation of transition layer: C-S magnetron sputtering was used for the preparation of Ni transition layer. The specific conditions for sputtering deposition were as follows: sputtering current 0.9A, sputtering temperature 310°C, sputtering deposition time 18min, Ar gas flow 38sccm, during the entire sputtering process, the sample holder rotates continuously to make the film layer uniform;

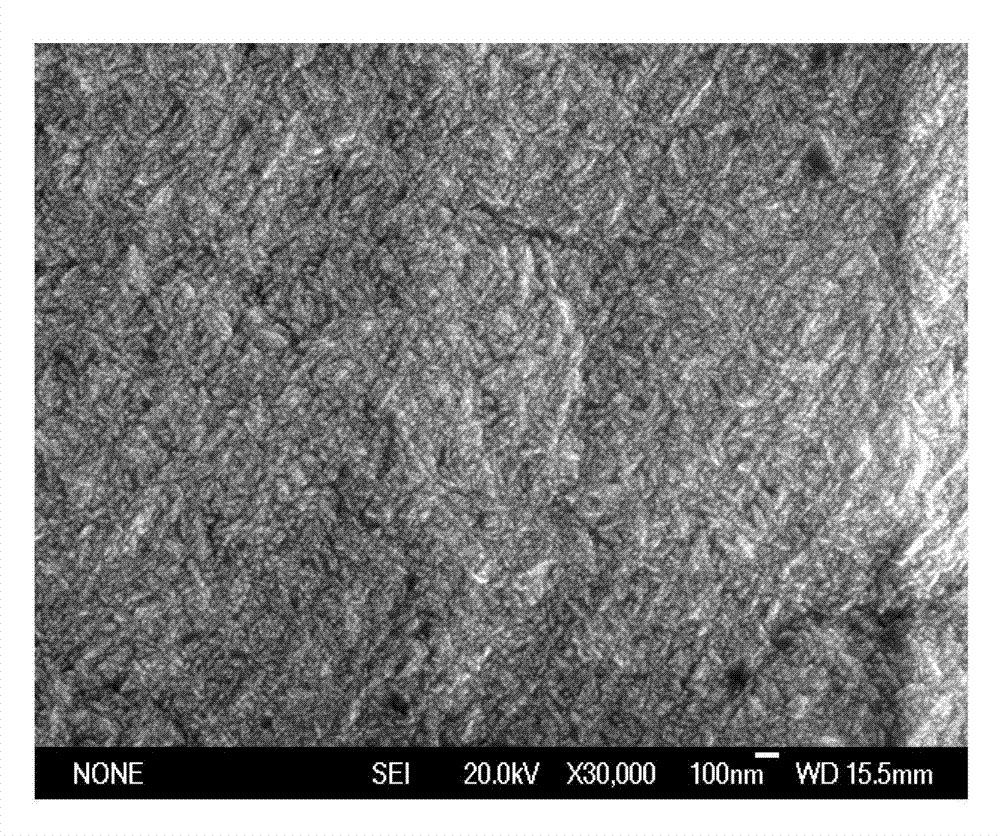

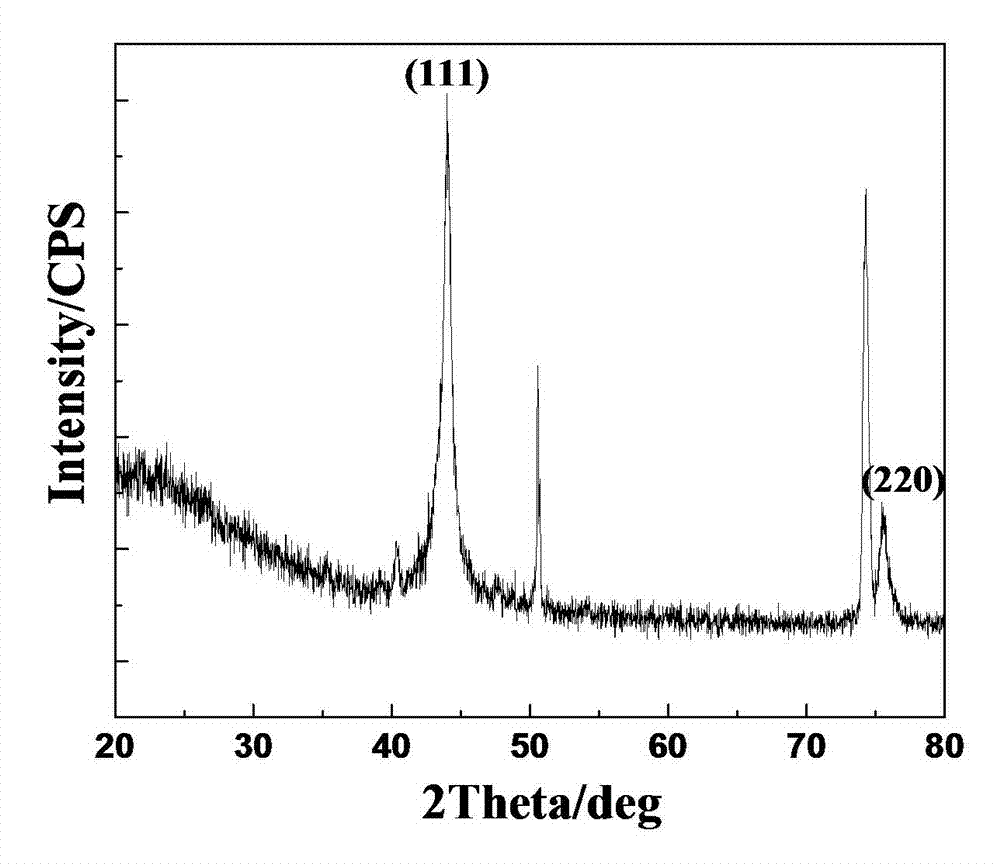

[0028] (3) The sample obtained in step 2 was ultrasonically cleaned with diamond micropowder acetone solution for 10 minutes, ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com