420MPa normalizing super-thick steel plate, and preparation method thereof

A structural steel plate and normalizing technology, applied in the field of 420MPa normalized extra-thick structural steel plate and its manufacturing, to achieve the effect of large thickness, low temperature toughness, high plasticity, mechanical properties and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

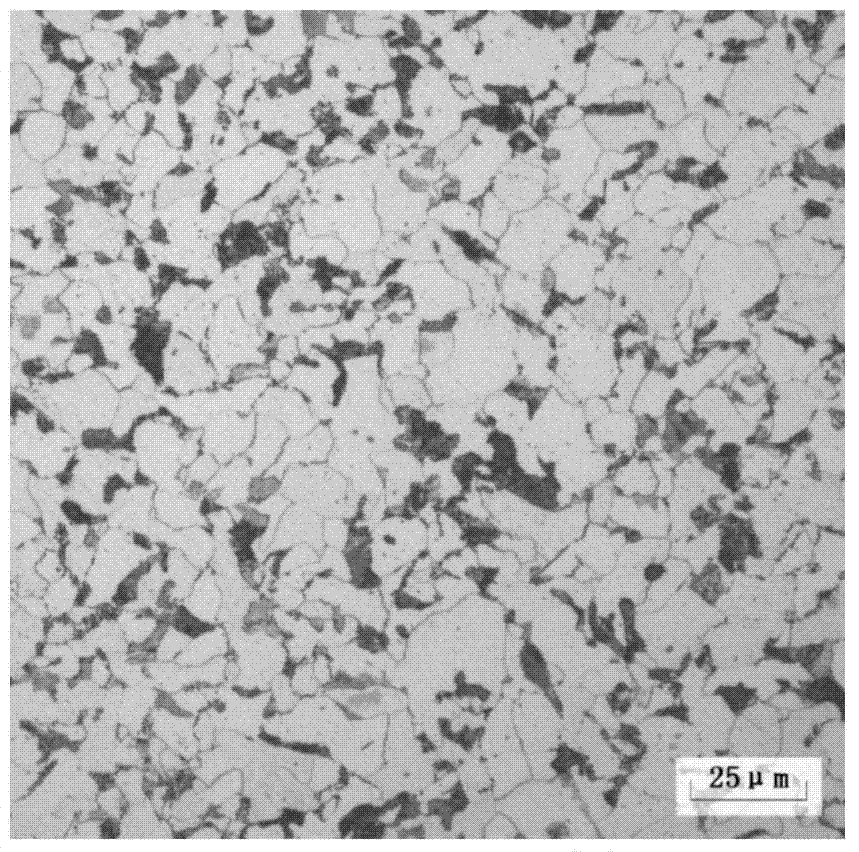

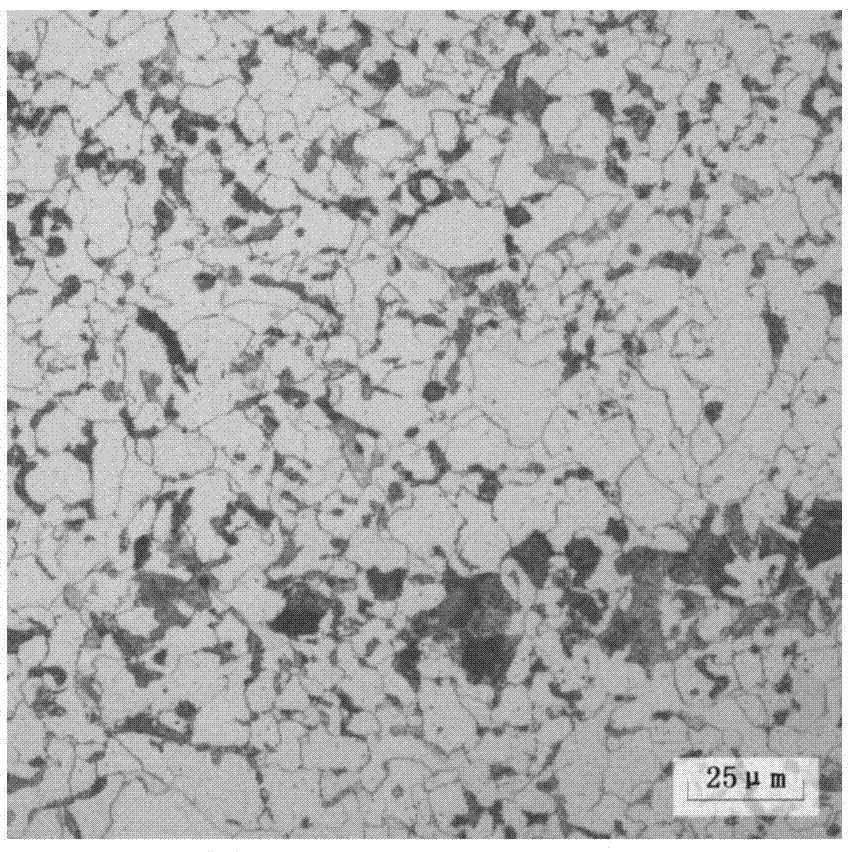

[0026] According to the composition design and production process provided by the present invention, an example of a 100mm thick steel plate is provided. In addition to what has been explained in this manual, the continuous casting slab size is 400mm×2050mm×2750mm, the finished steel plate size is 100mm×2300mm×L (length), cold-packed, the heating temperature is 1170°C, and the two-stand two-stage controlled rolling is adopted in this embodiment. , the finish rolling start temperature is 875°C, the final rolling temperature is 820°C, the thickness to be warmed is 120mm, the stack cooling is 72 hours after rolling, the normalizing temperature is 880°C, the furnace time is 150min, and the accelerated cooling temperature after the furnace is 620°C. The chemical composition of the steel plate is shown in Table 1, the mechanical properties are shown in Table 2, and the metallographic structure is shown in the appendix figure 1 and figure 2 .

[0027] Chemical composition of table...

Embodiment 2

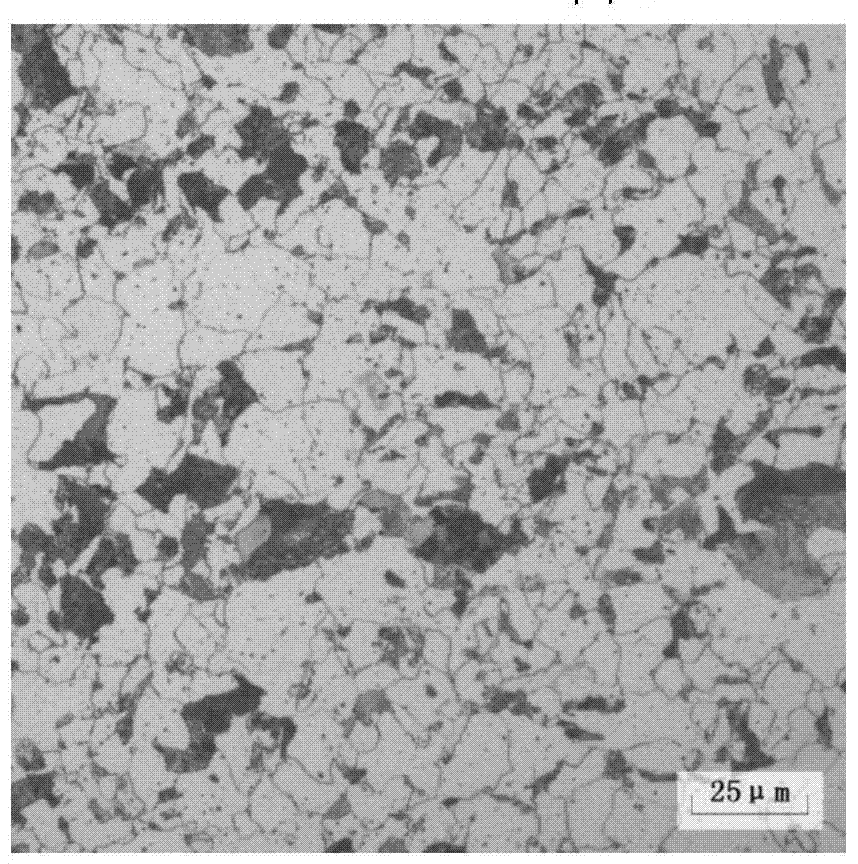

[0032] According to the composition design and production process provided by the present invention, an example of a thickness specification of 120mm is provided. In addition to what has been explained in this manual, the continuous casting slab size is 400mm×1850mm×2750mm, the finished steel plate size is 120mm×2000mm×L (length), cold loading, heating temperature 1190°C, two-stand two-stage controlled rolling , the finish rolling start temperature is 860°C, the finish rolling temperature is 820°C, the thickness to be warmed is 140mm, the stack cooling is 72 hours after rolling, the normalizing temperature is 910°C, the furnace time is 150min, and the accelerated cooling temperature after the furnace is 630°C. The chemical composition of the steel plate is shown in Table 3, the mechanical properties are shown in Table 4, and the metallographic structure is shown in the attached image 3 and Figure 4 .

[0033] Table 3 Chemical composition of 120mm steel plate (weight, %)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com