Method for controlling electroslag melting casting by added transient magnetic field and electroslag smelting casting device

A transient magnetic field and electroslag casting technology, applied in the field of electroslag casting, can solve the problems of slag entrainment, slag entrainment danger, low energy density of static magnetic field, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

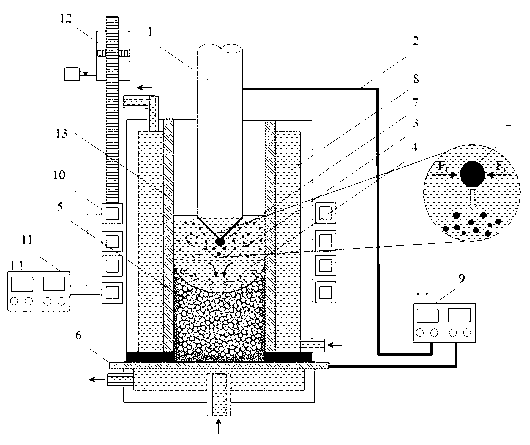

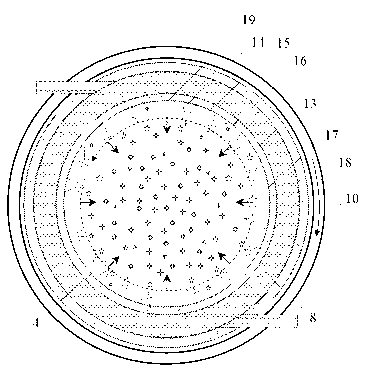

[0035] see figure 1 and figure 2 The electroslag melting and casting device realizing the method of controlling electroslag melting and casting by adding a transient magnetic field according to the present invention is formed by combining an electroslag remelting device and a die casting device, including a metal consumable electrode 1, a cable 2, a melting power supply 9, a crystallization Device 13, bottom electrode plate 6, crystallizer water cooling jacket 8, bottom electrode cooling device. The molten slag liquid is located in the inner copper tube cavity of the crystallizer 13, forming a molten slag pool 3, and the lower part of the metal melt 4 below the molten slag pool 3 is solidified to form an ingot 5, and the upper surface of the bottom electrode plate 6 is directly supported Taking the bottom of the ingot 5, the metal self-consumable electrode 1 and the bottom electrode plate 6 are connected to the smelting power supply 9 respectively through the cable 2, and t...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, especially in that:

[0046] In this embodiment, the transient magnetic field coil 10 is arranged inside the crystallizer water cooling jacket 8, which can directly cool the transient magnetic field coil 10 to form an effectively cooled water-cooled coil, which is convenient for outputting a stable and effective magnetic field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com