Patents

Literature

425 results about "Ultrasonic attenuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic attenuation, which is the sum of the absorption and the scattering, is mainly dependent upon the damping capacity and scattering from the grain boundary in the material. However, to fully characterize the attenuation required knowledge of a large number of thermo-physical parameters that in practice are hard to quantify.

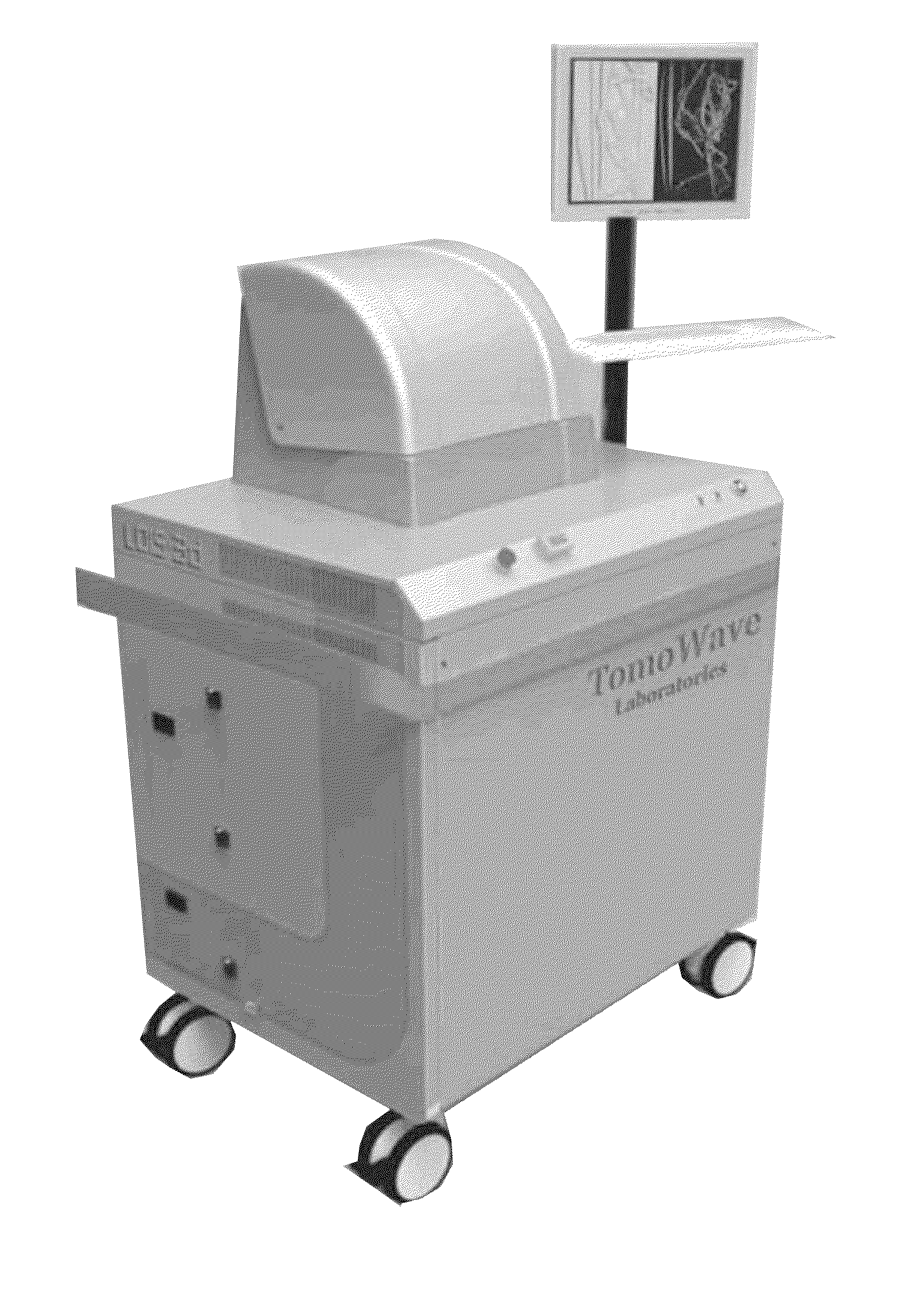

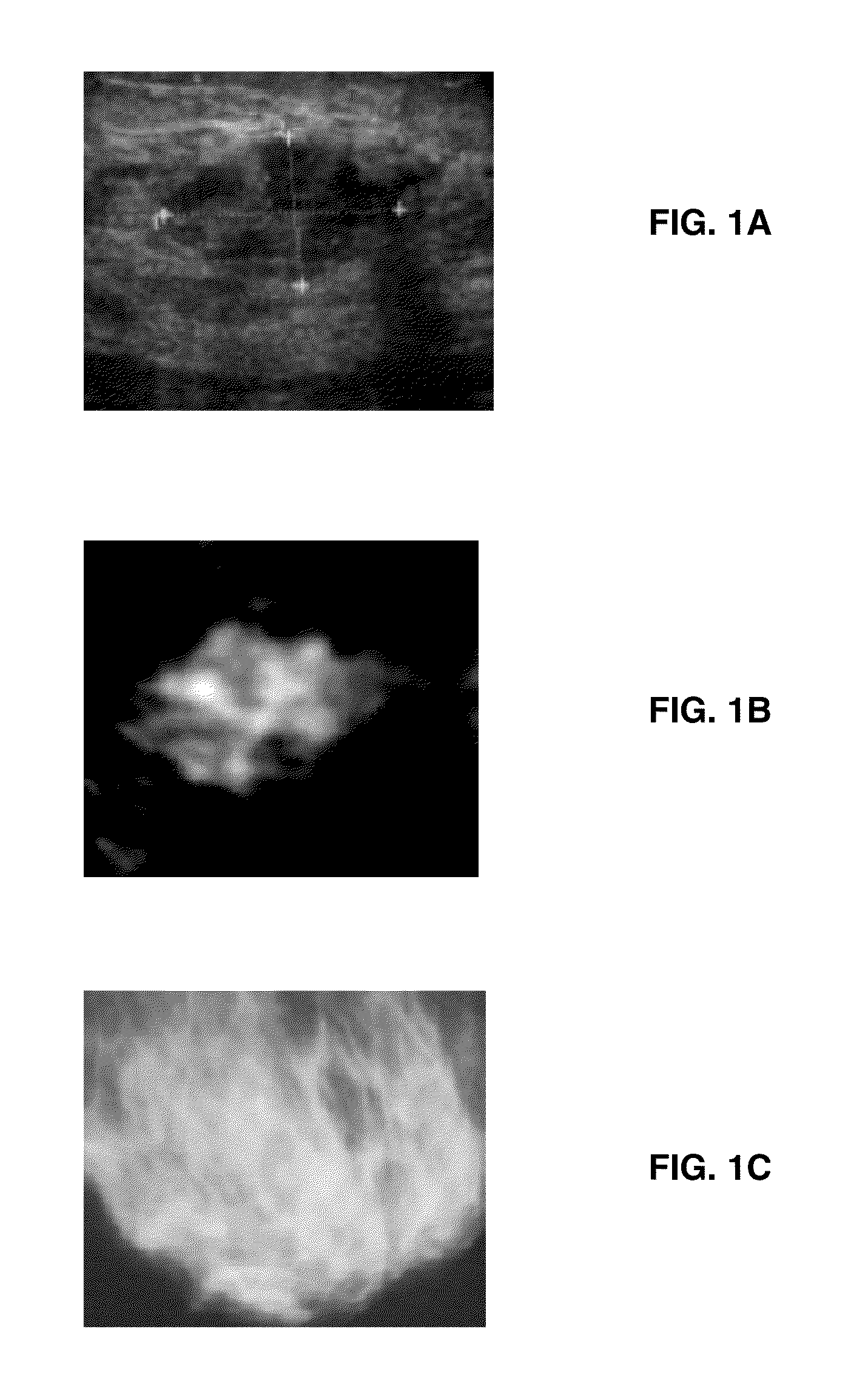

Laser Optoacoustic Ultrasonic Imaging System (LOUIS) and Methods of Use

ActiveUS20130190595A1Increase contrastImprove resolutionUltrasonic/sonic/infrasonic diagnosticsMedical imagingHelical computed tomographyContrast resolution

Provided herein are the systems, methods, components for a three-dimensional tomography system. The system is a dual-modality imaging system incorporates a laser ultrasonic system and a laser optoacoustic system. The dual-modality imaging system has means for generate tomographic images of a volume of interest in a subject body based on speed of sound, ultrasound attenuation and / or ultrasound backscattering and for generating optoacoustic tomographic images of distribution of the optical absorption coefficient in the subject body based on absorbed optical energy density or various quantitative parameters derivable therefrom. Also provided is a method for increasing contrast, resolution and accuracy of quantitative information obtained within a subject utilizing the dual-modality imaging system. The method comprises producing an image of an outline boundary of a volume of interest and generating spatially or temporally coregistered images based on speed of sound and / or ultrasonic attenuation and on absorbed optical energy within the outlined volume.

Owner:TOMOWAVE LAB INC

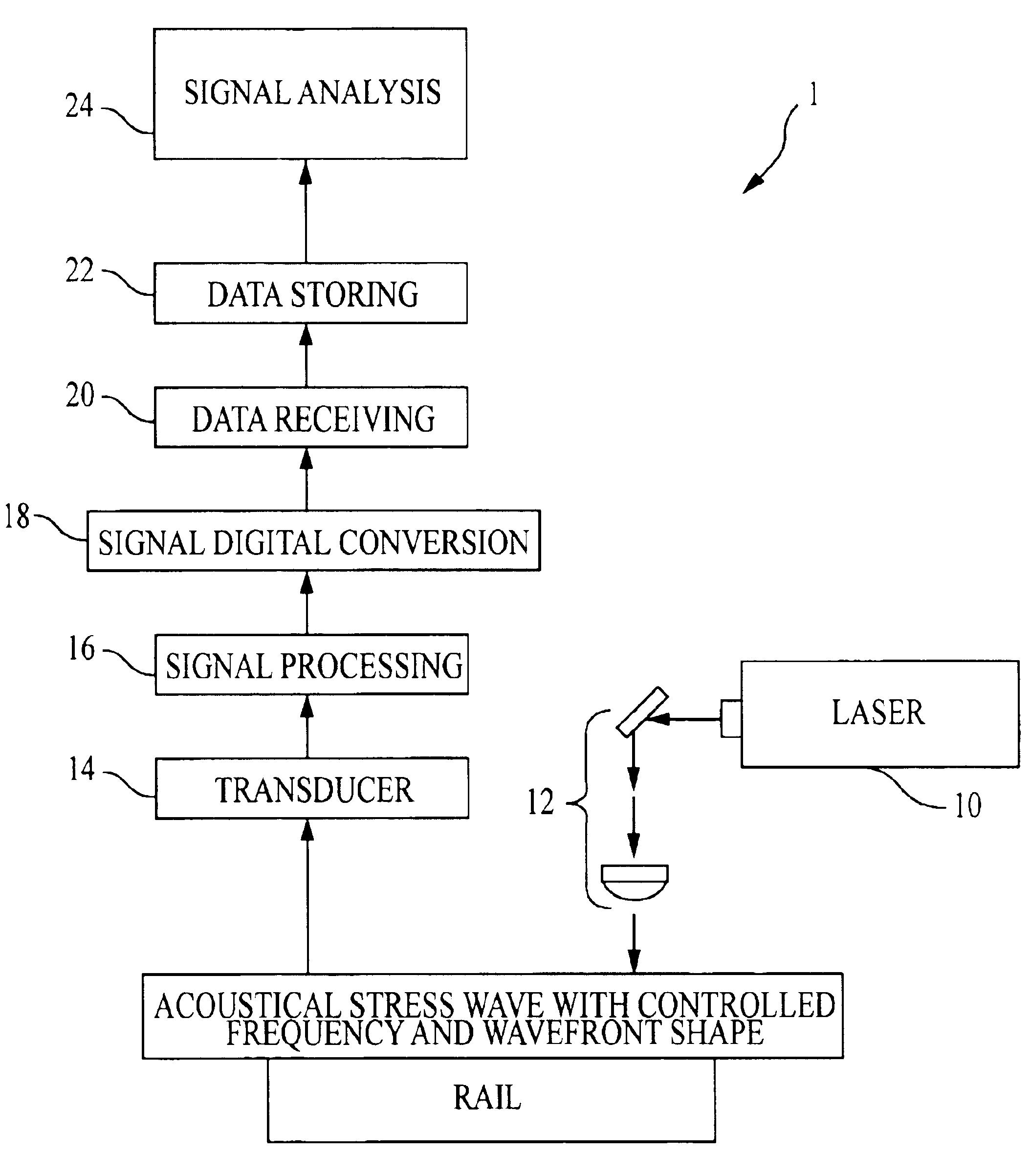

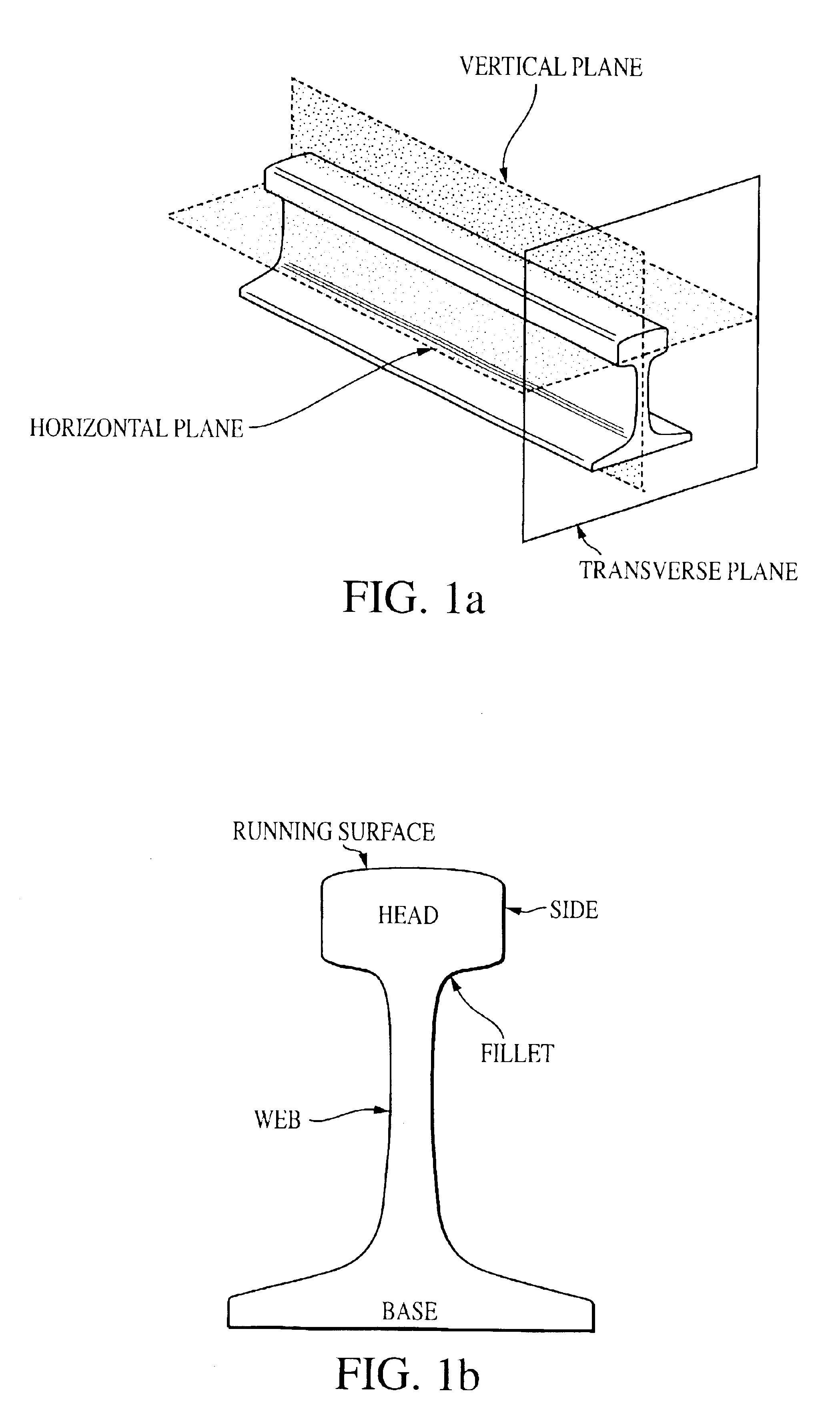

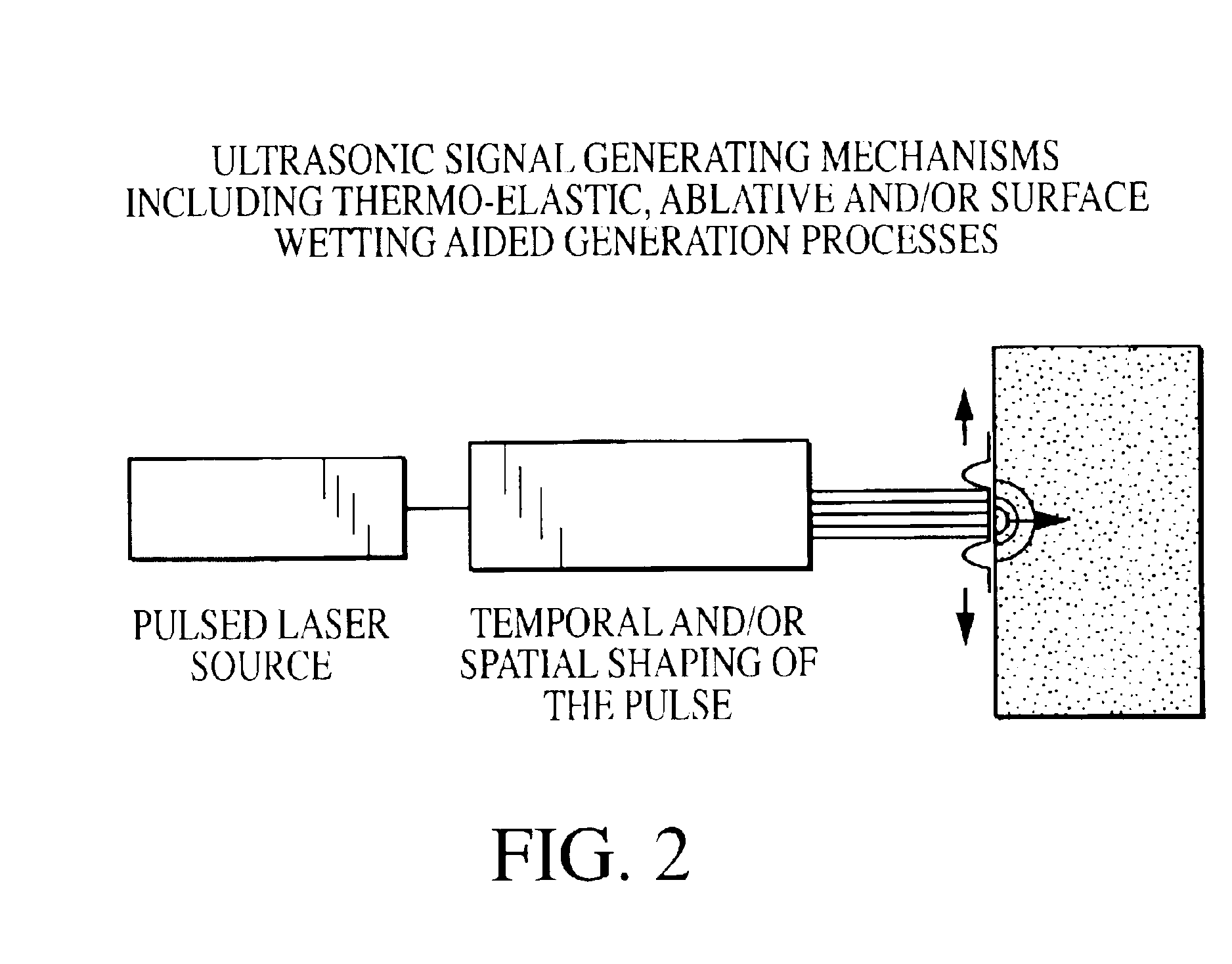

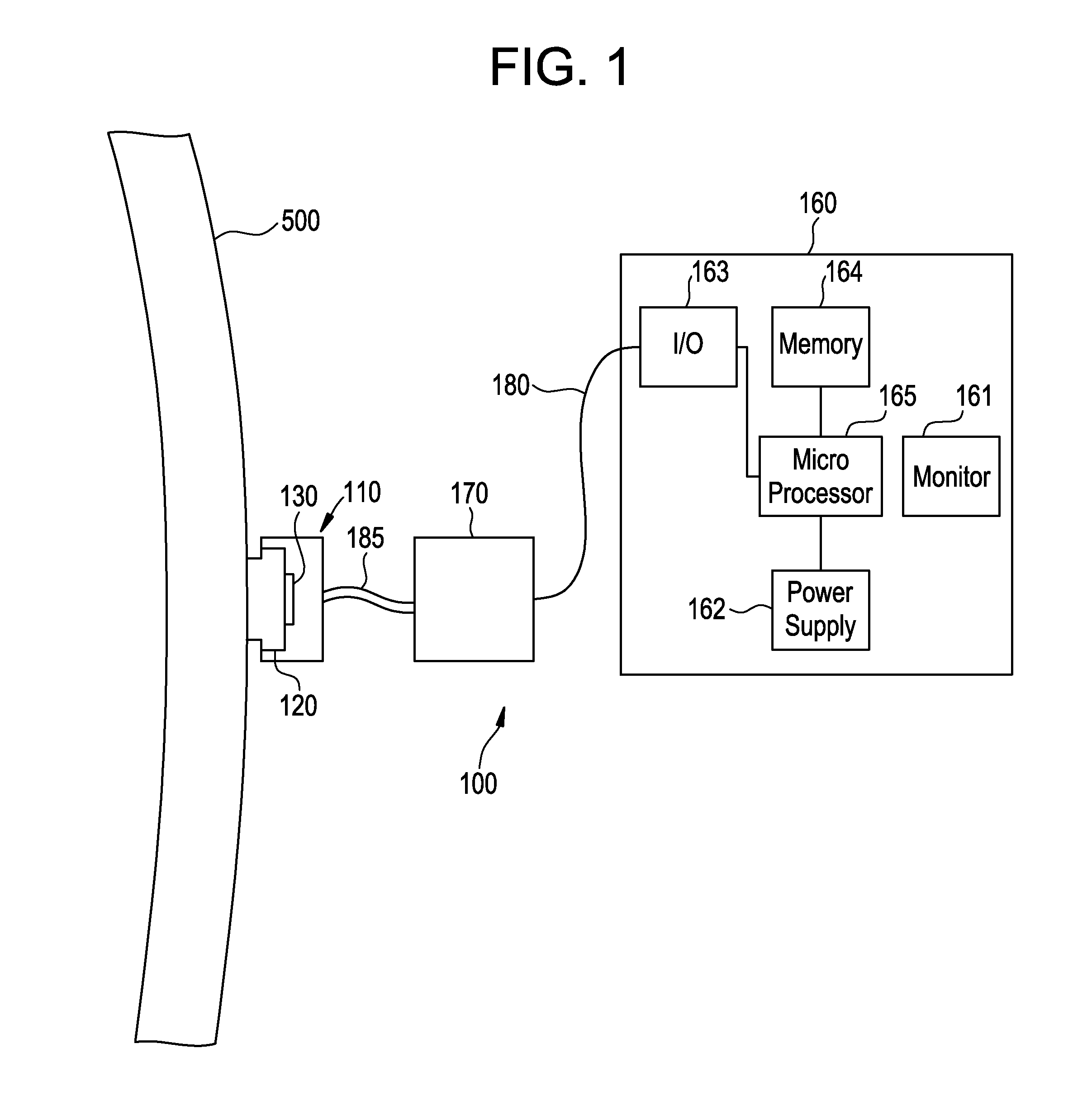

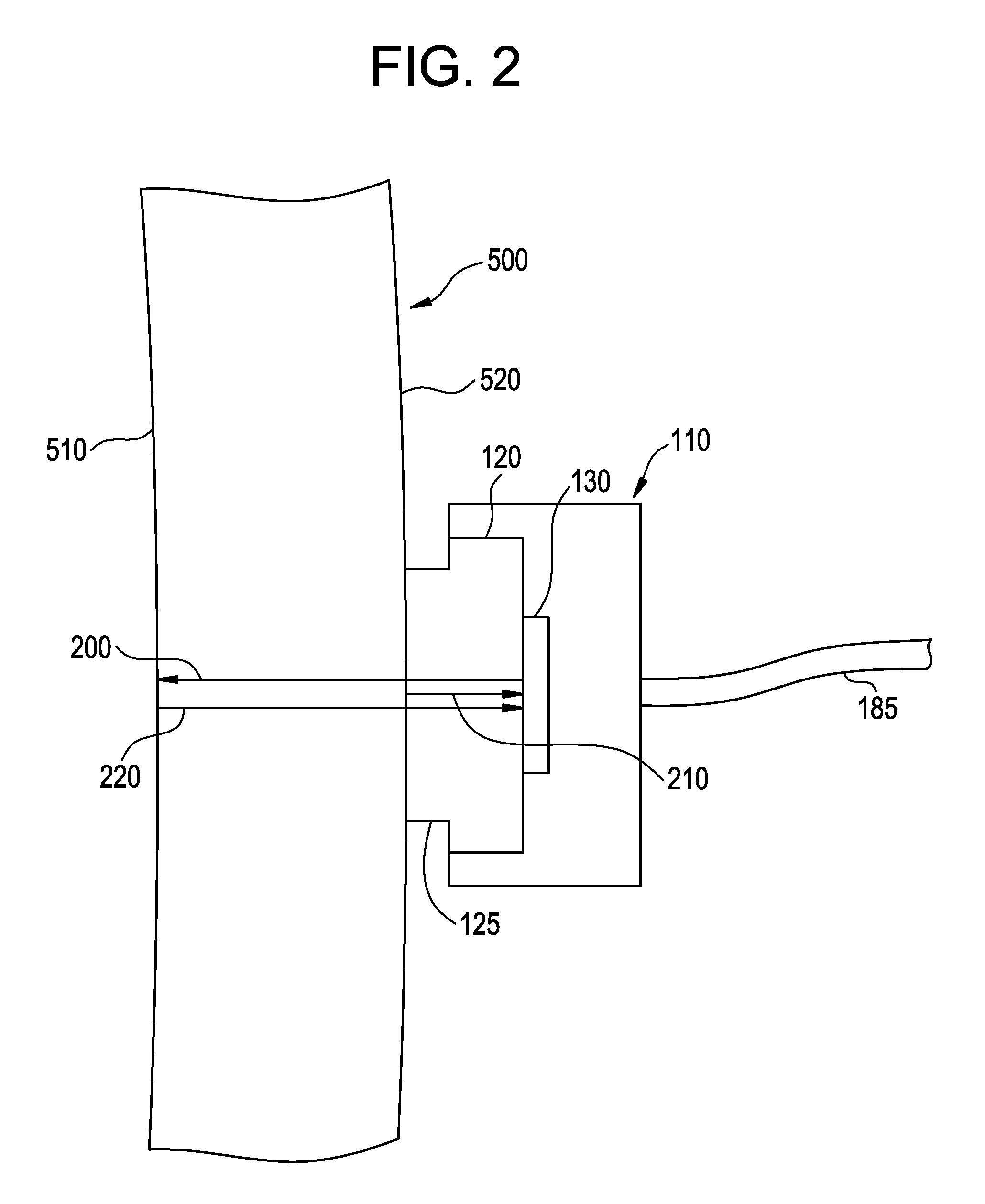

Laser-air, hybrid, ultrasonic testing of railroad tracks

InactiveUS6945114B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesRailroad industryWavefront

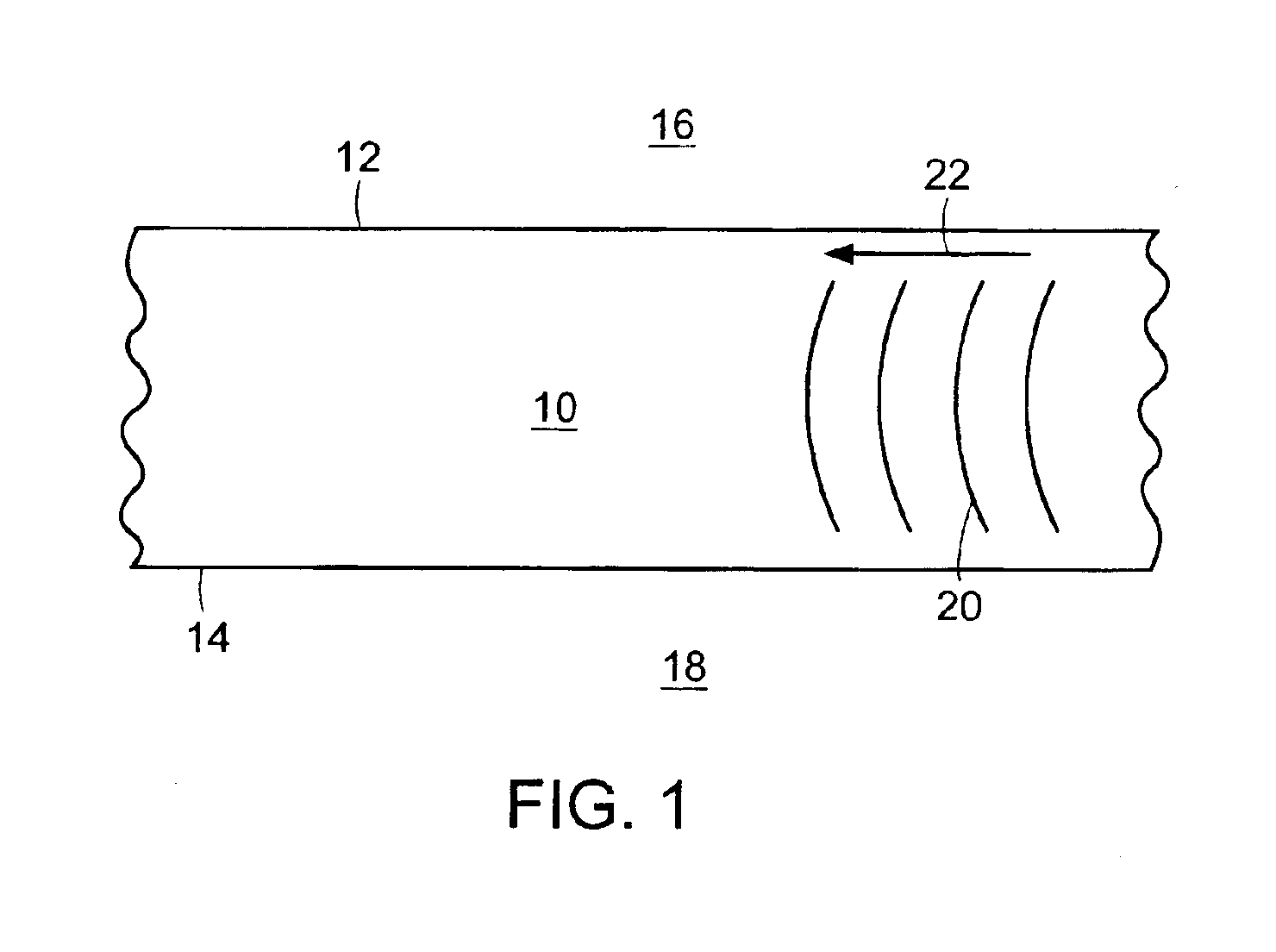

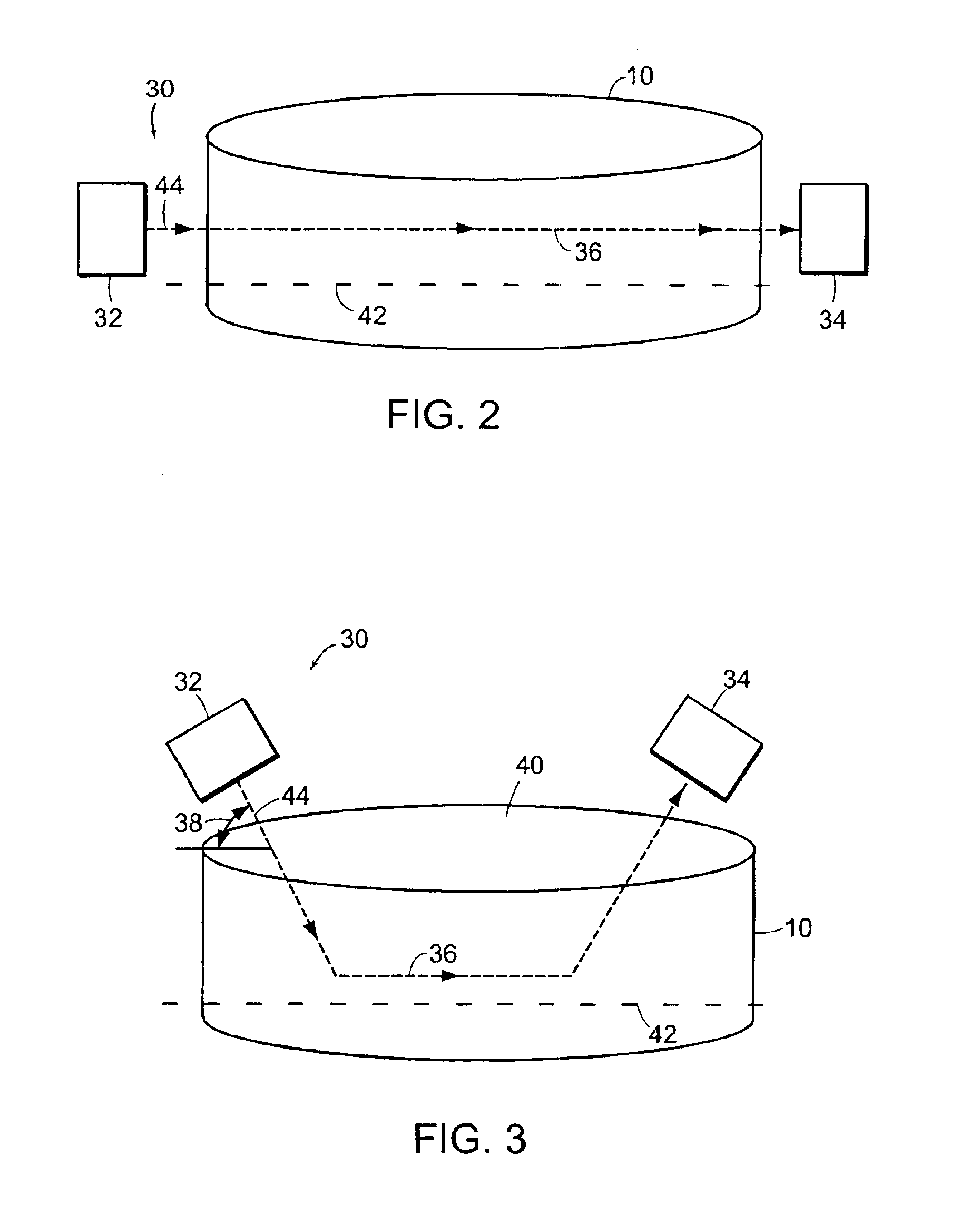

Formed Laser Sources (FLS) using pulsed laser light for generation of ultrasonic stress waves are combined with air-coupled detection of ultrasound to provide for the hybrid non-contact, dynamic and remote ultrasonic testing of structural materials, especially railroad tracks. Using this hybrid technique, multimode and controlled frequency and wavefront surface acoustic waves, plate waves, guided waves, and bulk waves are generated to propagate on and within the rail tracks. The non-contact, remote nature of this methodology enables high-speed, fill access inspections of rail tracks. The flexibility and remote nature of this methodology makes possible the detection of critical cracks that are not easy, or impossible to detect, with current inspection techniques available to the railroad industry.

Owner:MATERIALS & SENSORS TECH

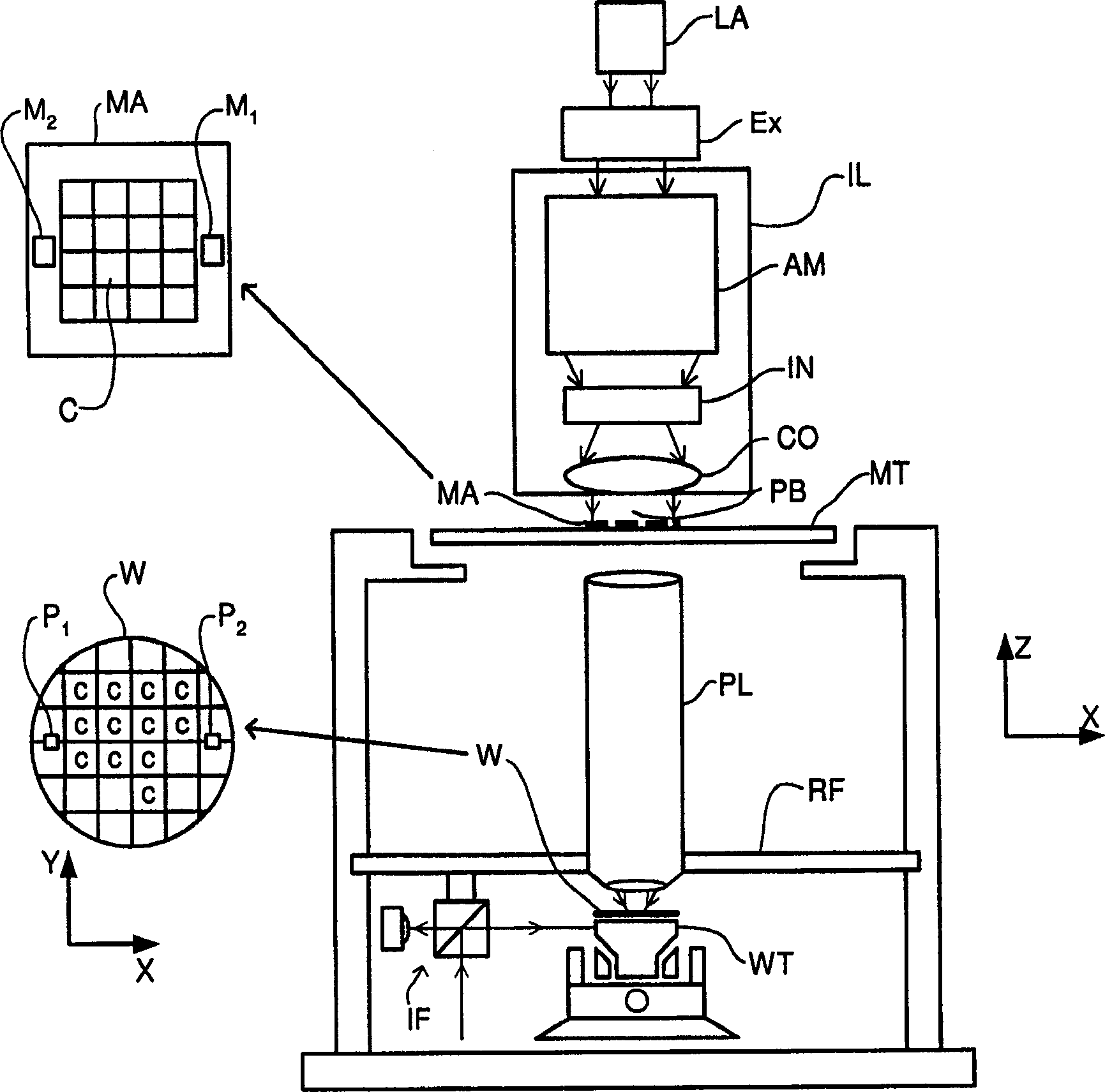

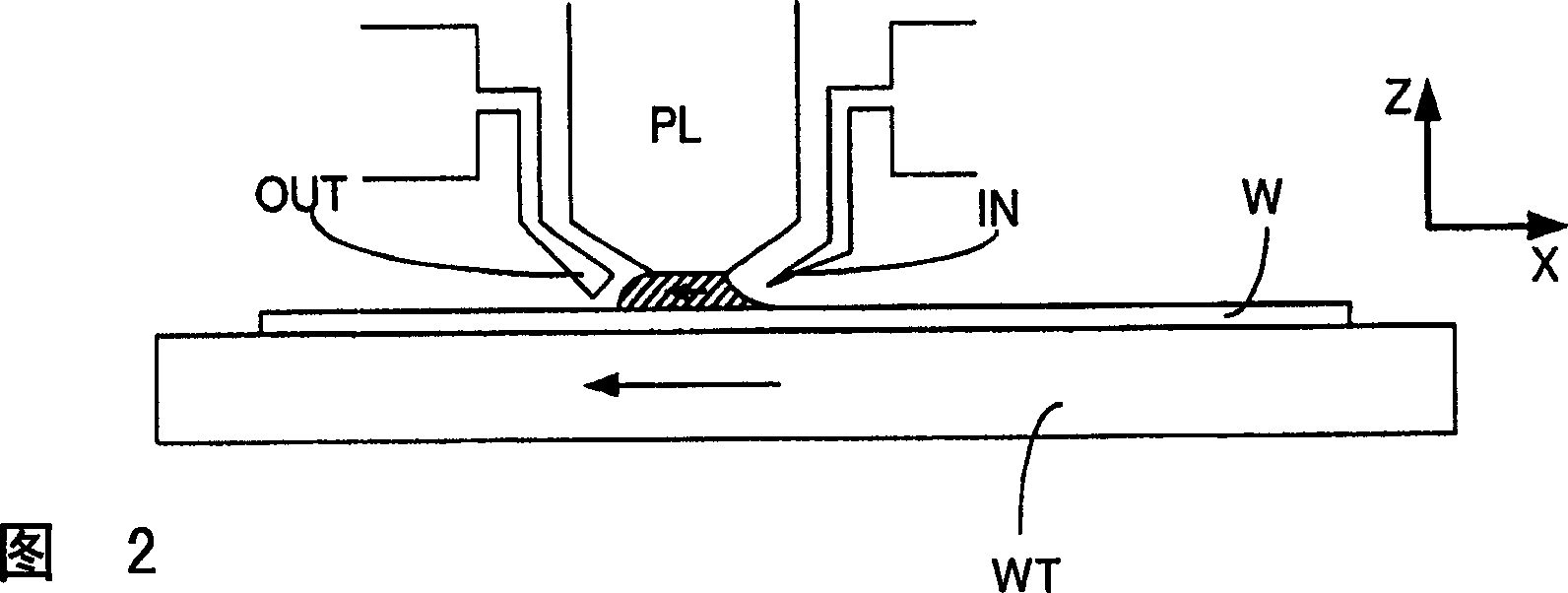

Lithographic apparatus and device manufacturing method

ActiveCN1637608ASemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusAtmospheric airUltrasonic attenuation

A lithographic apparatus and device manufacturing method using a high refractive index liquid confined in a container (13) which at least partially fills the imaging region between the final element of the projection lens and the substrate. Bubbles formed in a liquid in which atmospheric gases are dissolved or outgassed from a device element exposed to the liquid are detected and removed so that the bubbles do not interfere with exposure to cause print defects on the substrate. Detection is performed by measuring frequencies related to ultrasonic attenuation in liquids, by degassing and pressurizing liquids, isolating liquids from the atmosphere, using liquids with low surface tension, providing continuous flow of liquid through the imaging area, and phase shifting Ultrasonic standing wave nodal pattern for air bubble removal.

Owner:ASML NETHERLANDS BV

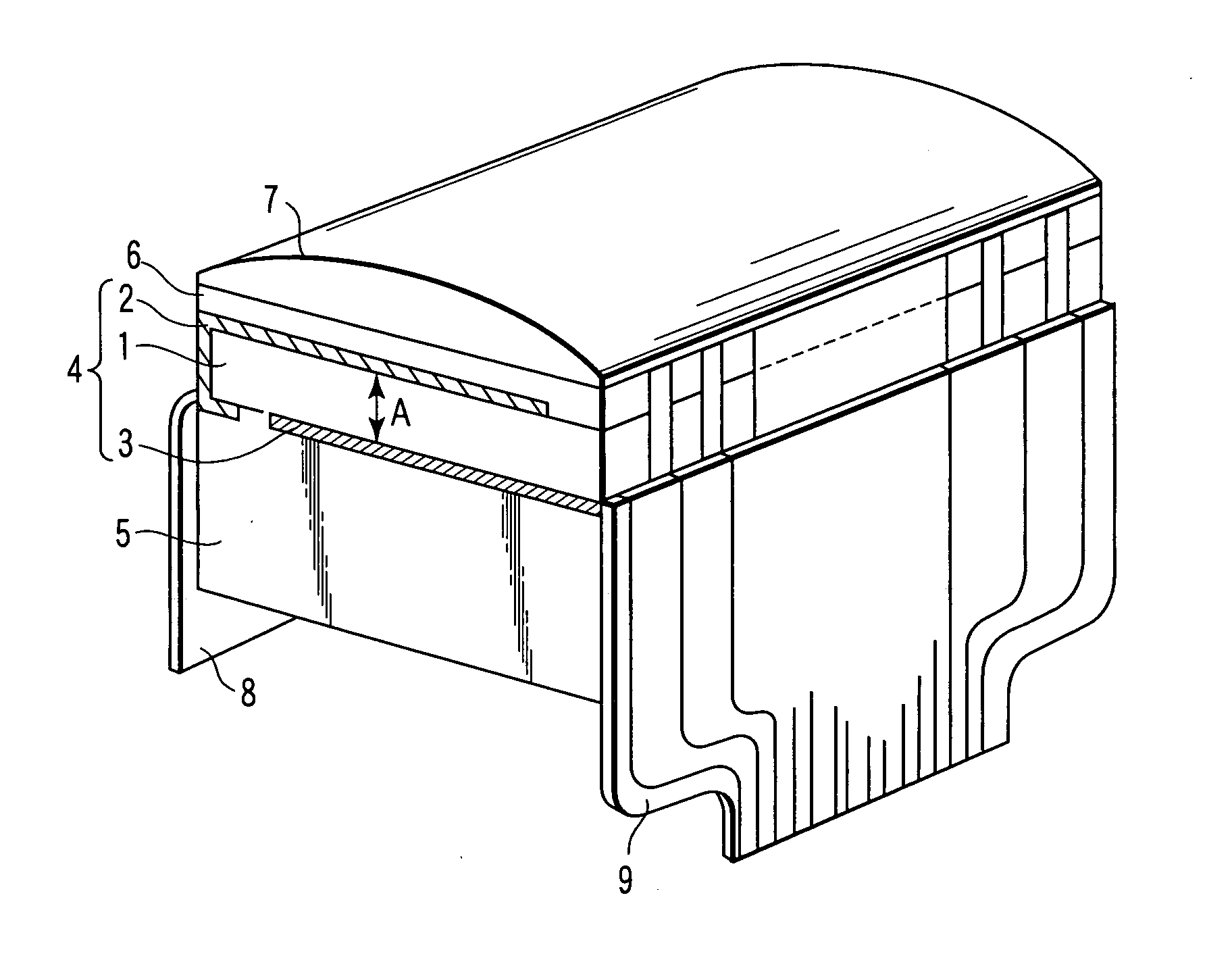

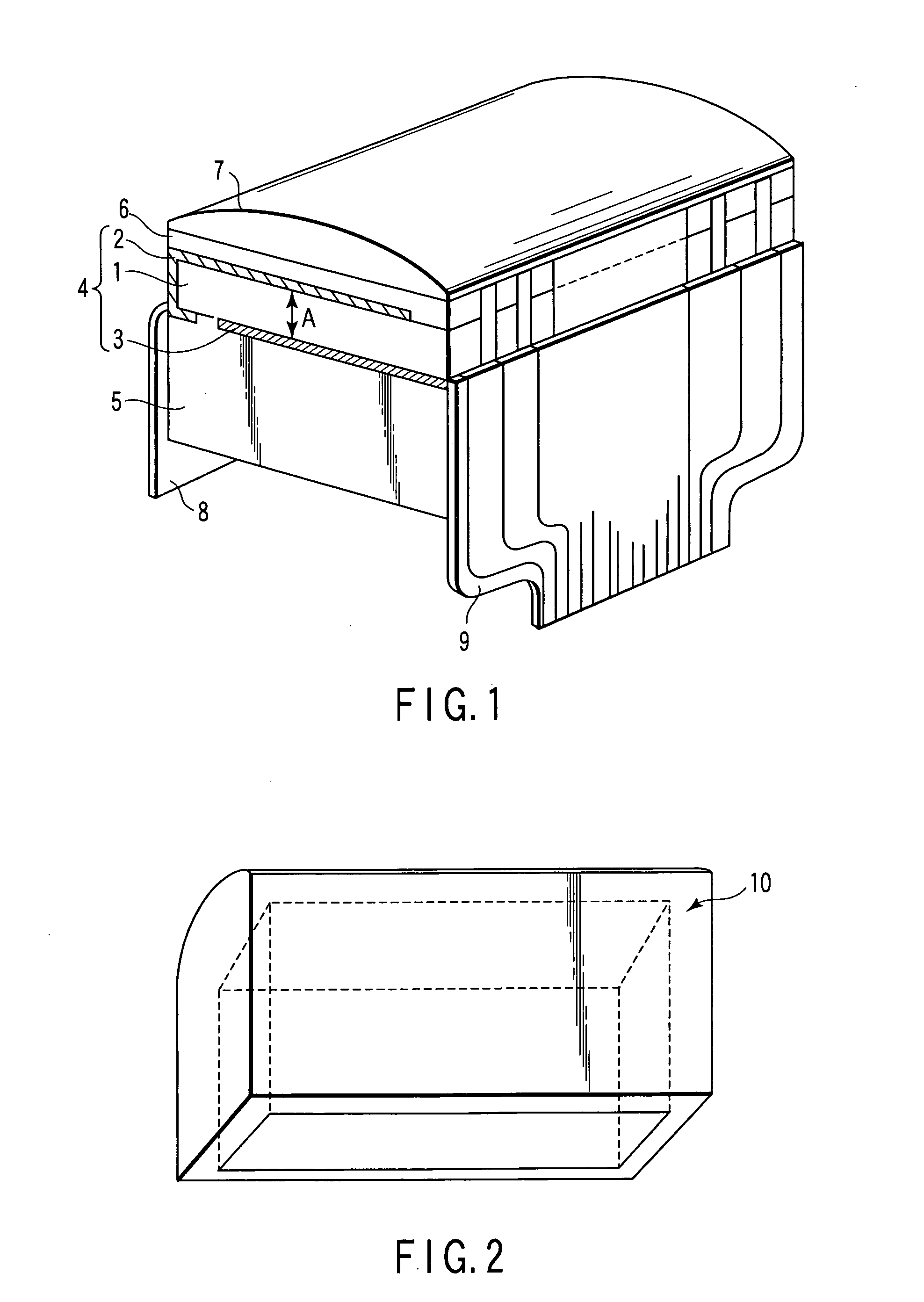

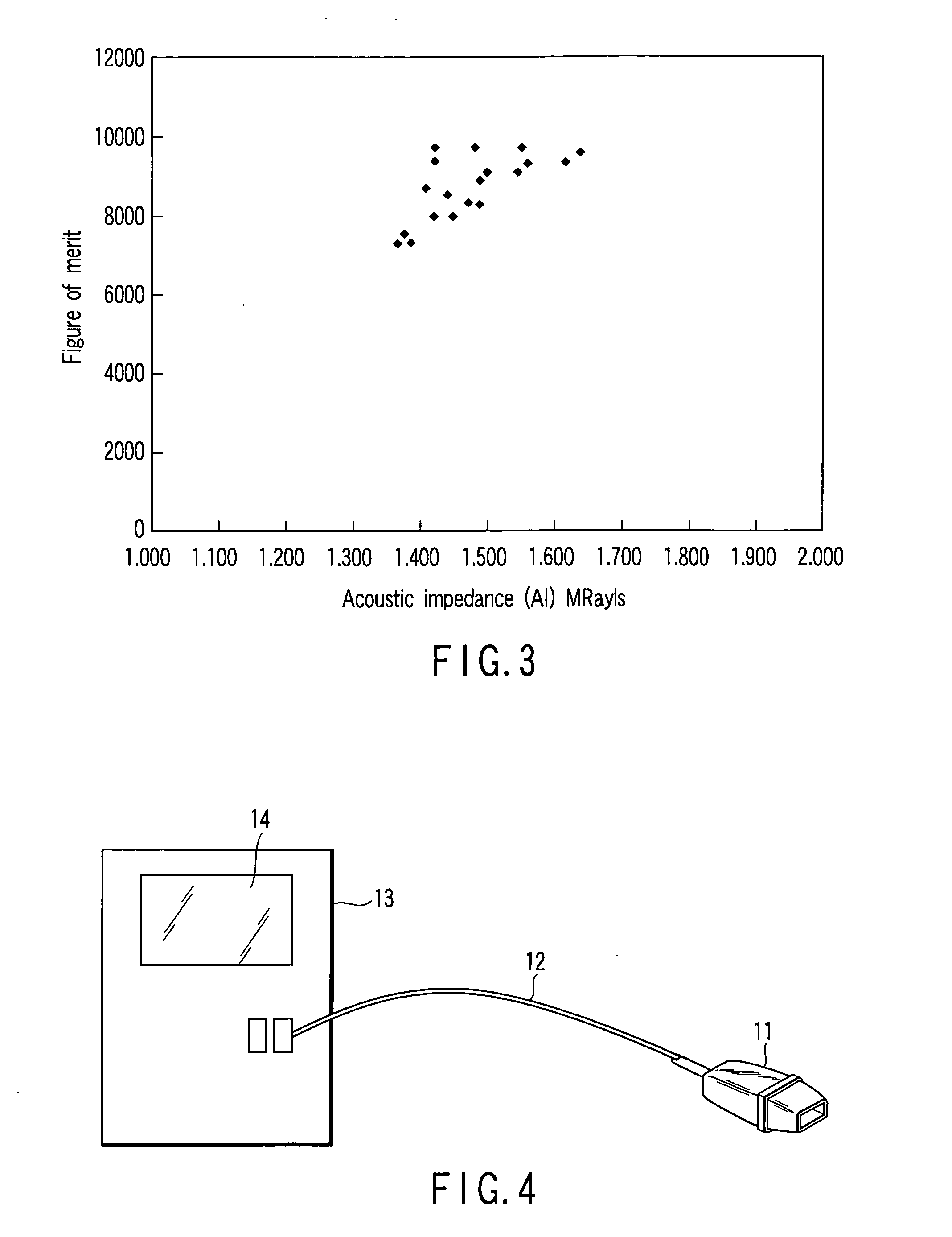

Acoustic lens composition, ultrasonic probe, and ultrasonic diagnostic apparatus

InactiveUS20050070801A1Ultrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic attenuationAcoustic lens

Provided is an acoustic lens composition which comprises 40 wt % or more of silicone rubber and 15 to 60 wt % of a zinc oxide powder, suppresses ultrasonic attenuation, and has superior molding properties.

Owner:KK TOSHIBA

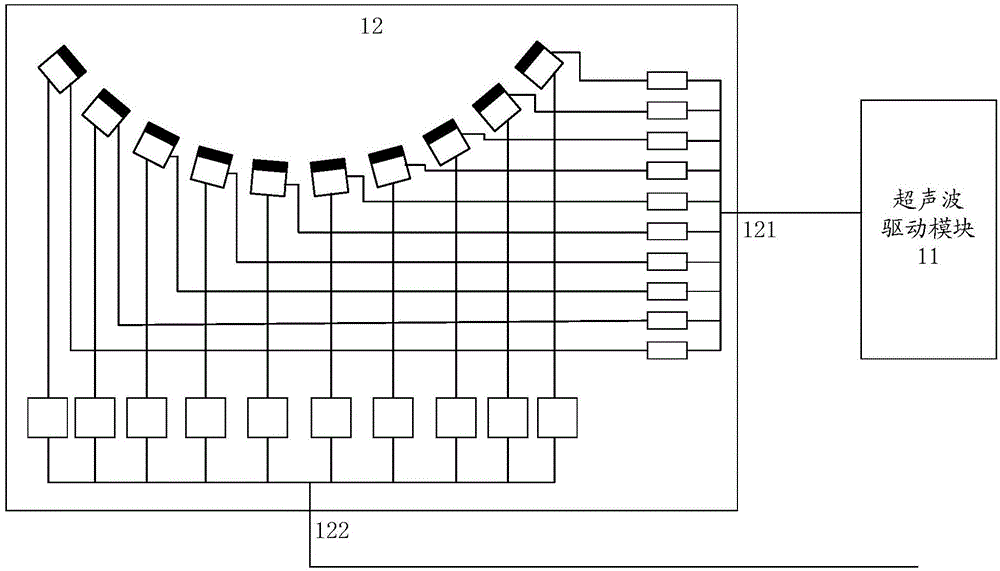

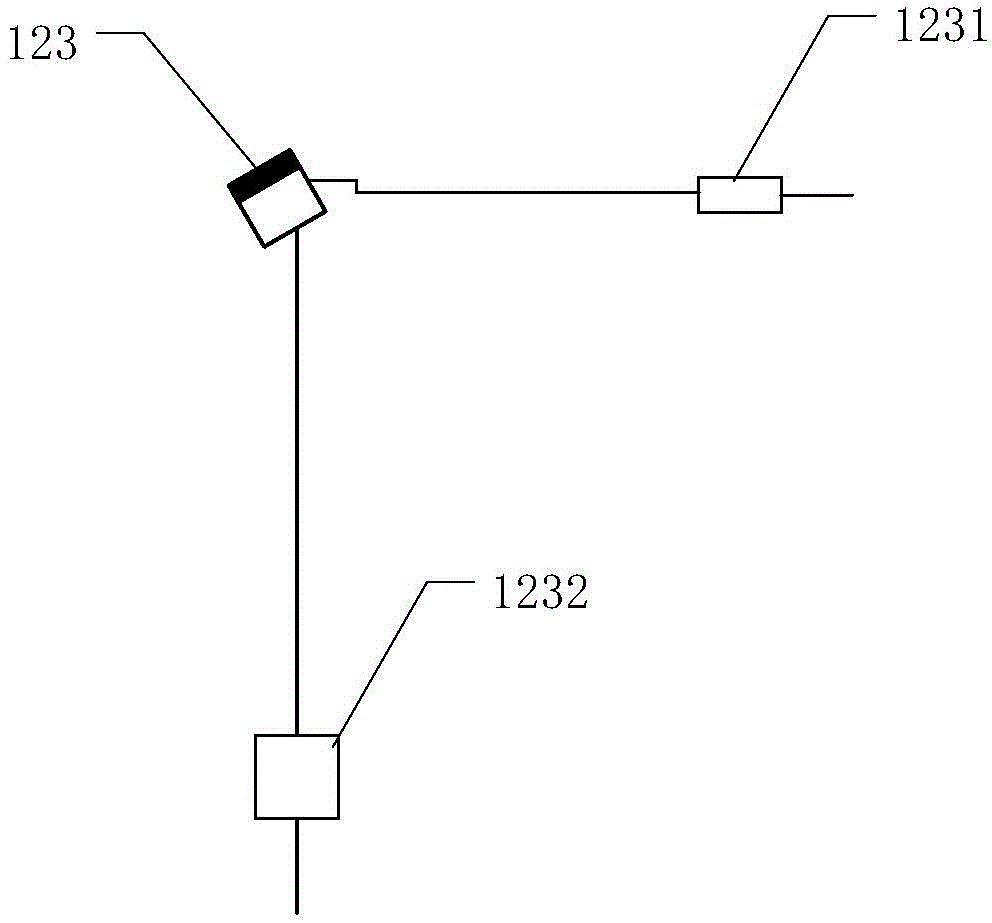

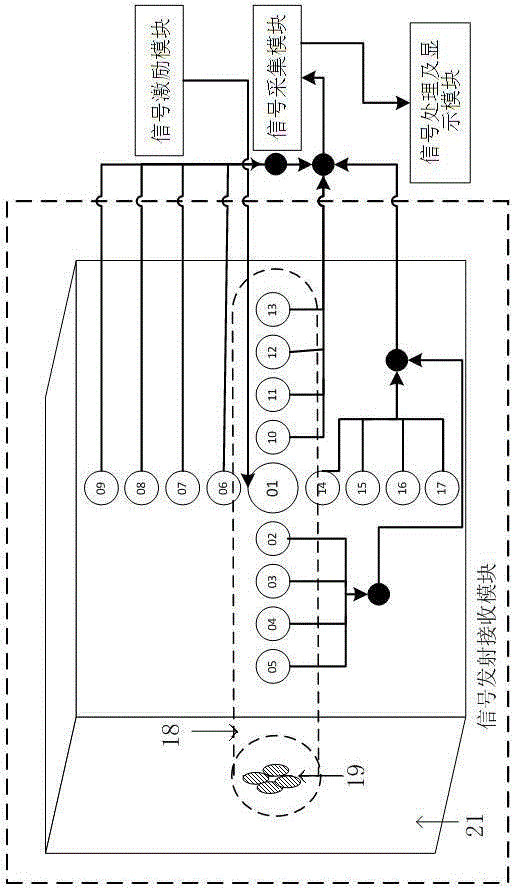

Device for ultrasonic stimulation of neural tissue

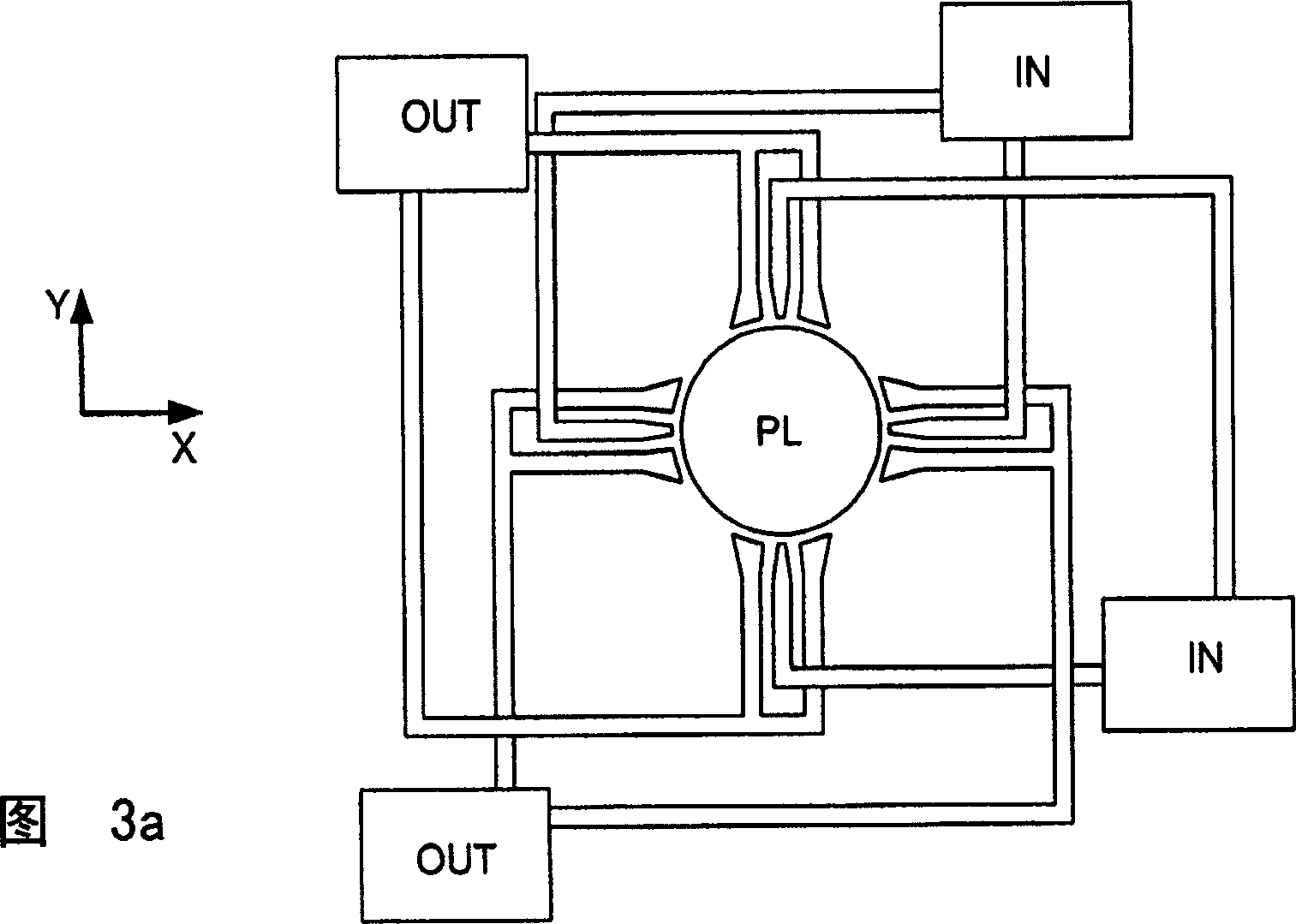

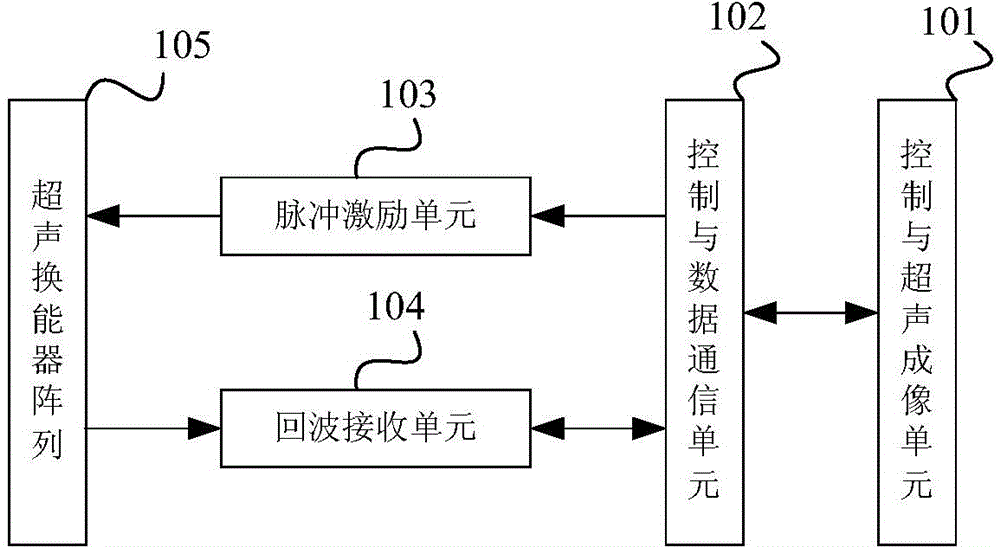

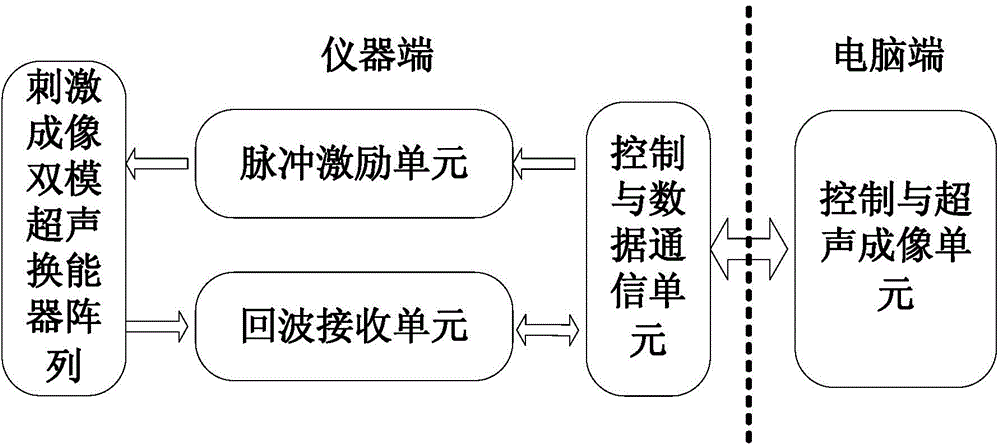

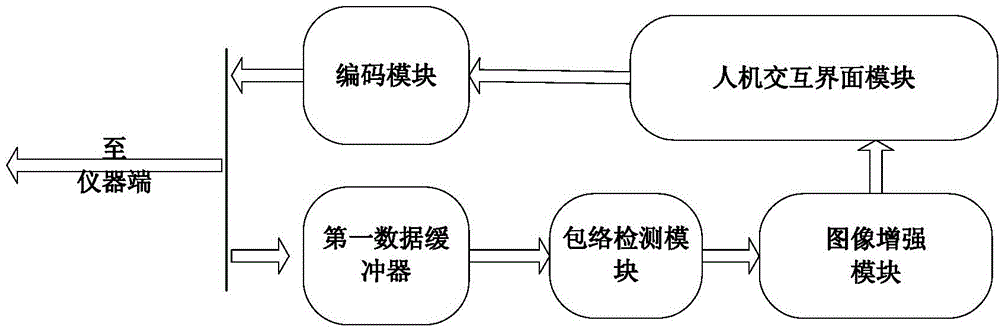

ActiveCN104826243AHigh precisionIncrease flexibilityUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationPulse parameter

The present invention relates to a device for the ultrasonic stimulation of a neural tissue. A control and data communication unit receives a control command to generate a pulse parameter and a beam-forming parameter. The ultrasonic echo radio frequency data outputted by an echo receiving unit is received and is transmitted to a control and ultrasonic imaging unit. A pulse excitation unit generates a high voltage pulse sequence according to the pulse parameter. The echo receiving unit composes ultrasonic echo radio frequency data according to the beam-forming parameter by using ultrasonic echo. The control and ultrasonic imaging unit emits a control command according to a user operation. The ultrasonic imaging of a target neural tissue scanning area is carried out according to the ultrasonic echo radio frequency data. An ultrasonic transducer array is controlled to be in a neural simulation state or an ultrasonic imaging state according to the high voltage pulse sequence. According to the technical scheme of the utility model, a method of sharing the ultrasonic transducer array by ultrasonic stimulation and ultrasonic imaging is employed, the real-time visualization of an ultrasonic neural stimulation process is realized, and the dynamic adjustment of stimulation target position and stimulation effect evaluation is helped.

Owner:GREEN VALLEY BRAINTECH SHENZHEN MEDICAL TECH CO LTD

Ultrasonic detection of porous medium characteristics

InactiveUS6959602B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesPorous mediumUltrasonic attenuation

Plate waves are used to determine the presence of defects within a porous medium, such as a membrane. An acoustic wave can be propagated through a porous medium to create a plate wave within the medium. The plate wave creates fast compression waves and slow compression waves within the medium that relate to the material and structural properties of the medium. The fast compression wave provides information about the total porosity of a medium. While the slow compression wave provides information about the presence of defects in the medium or the types of materials that form the medium.

Owner:MILLIPORE CORP

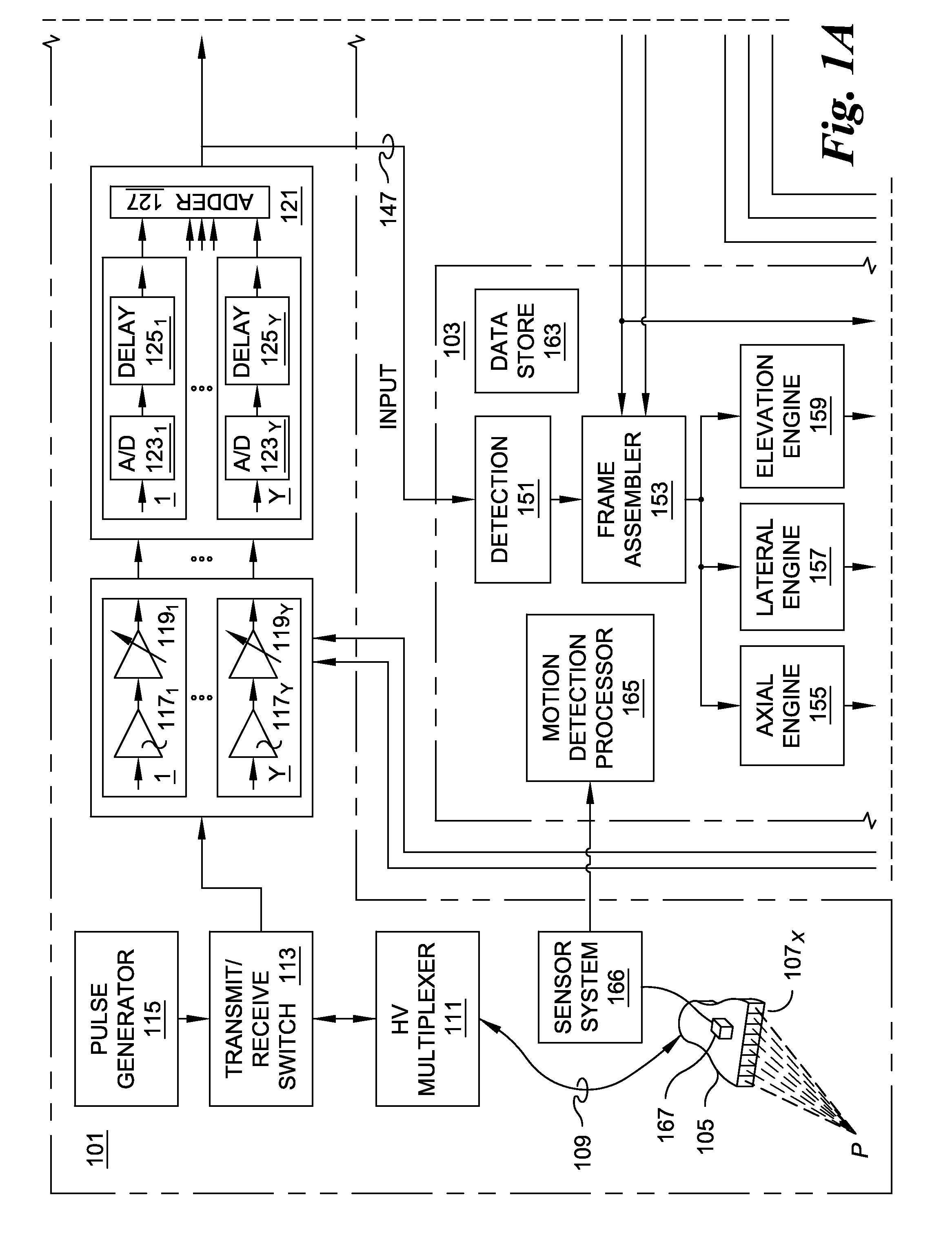

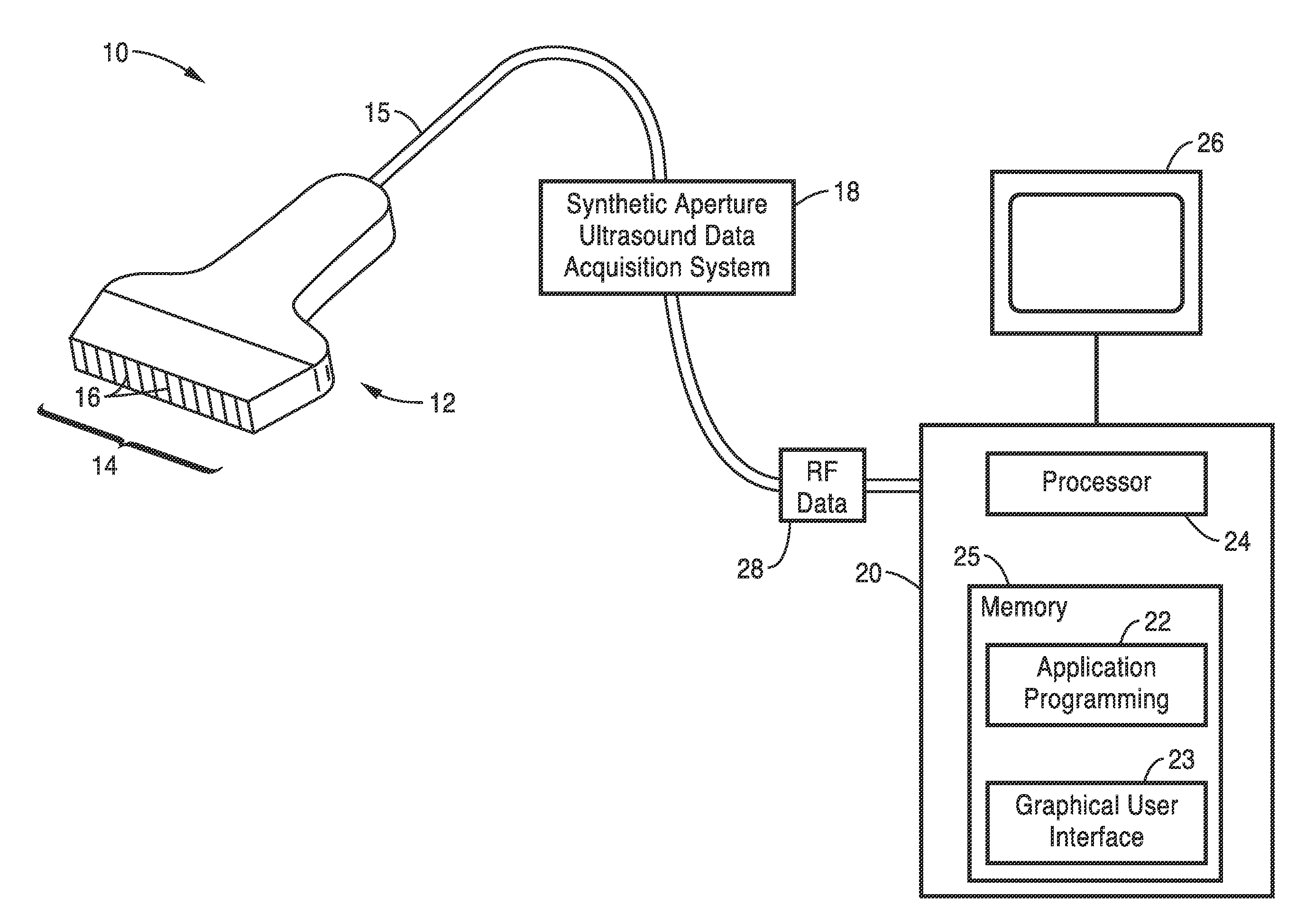

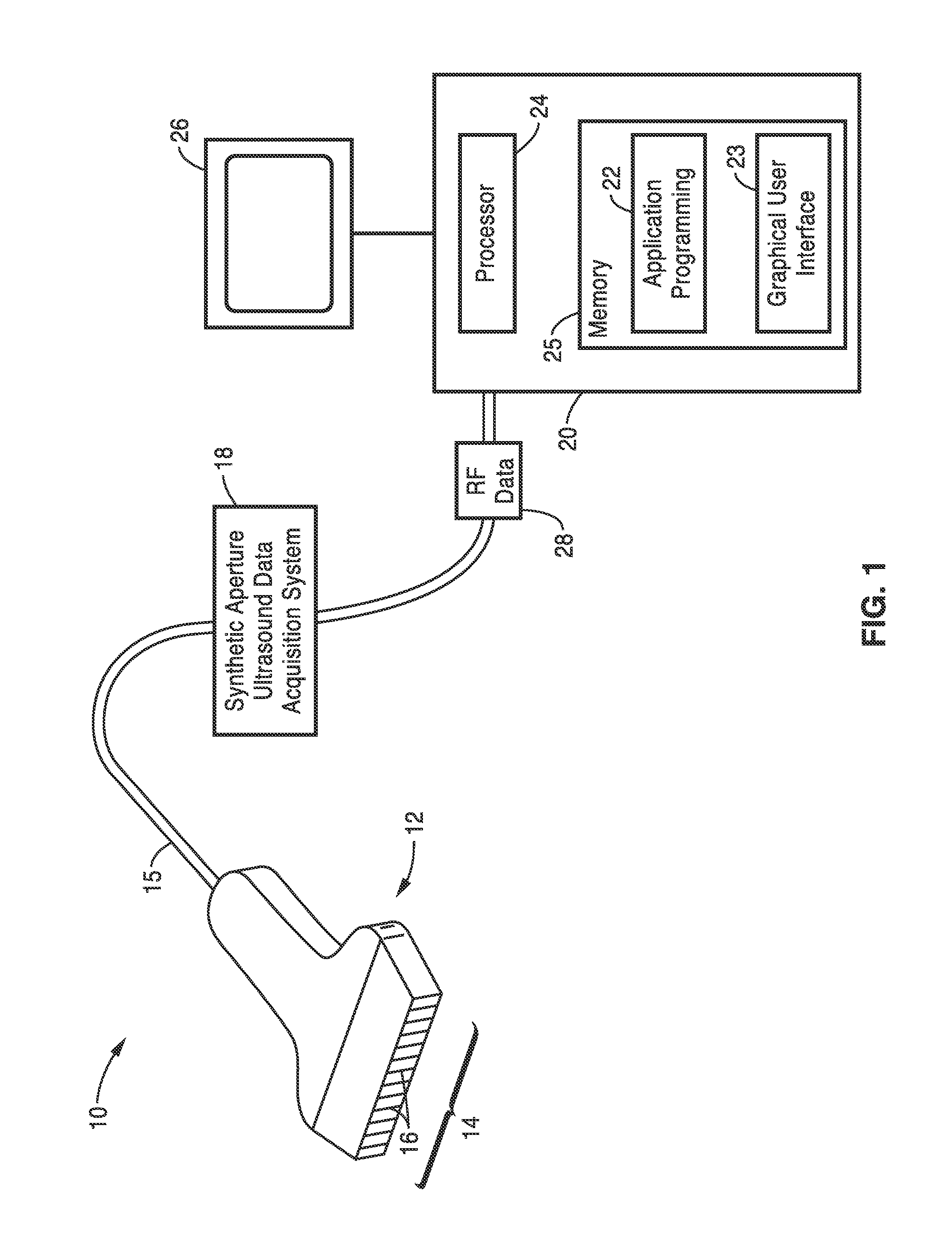

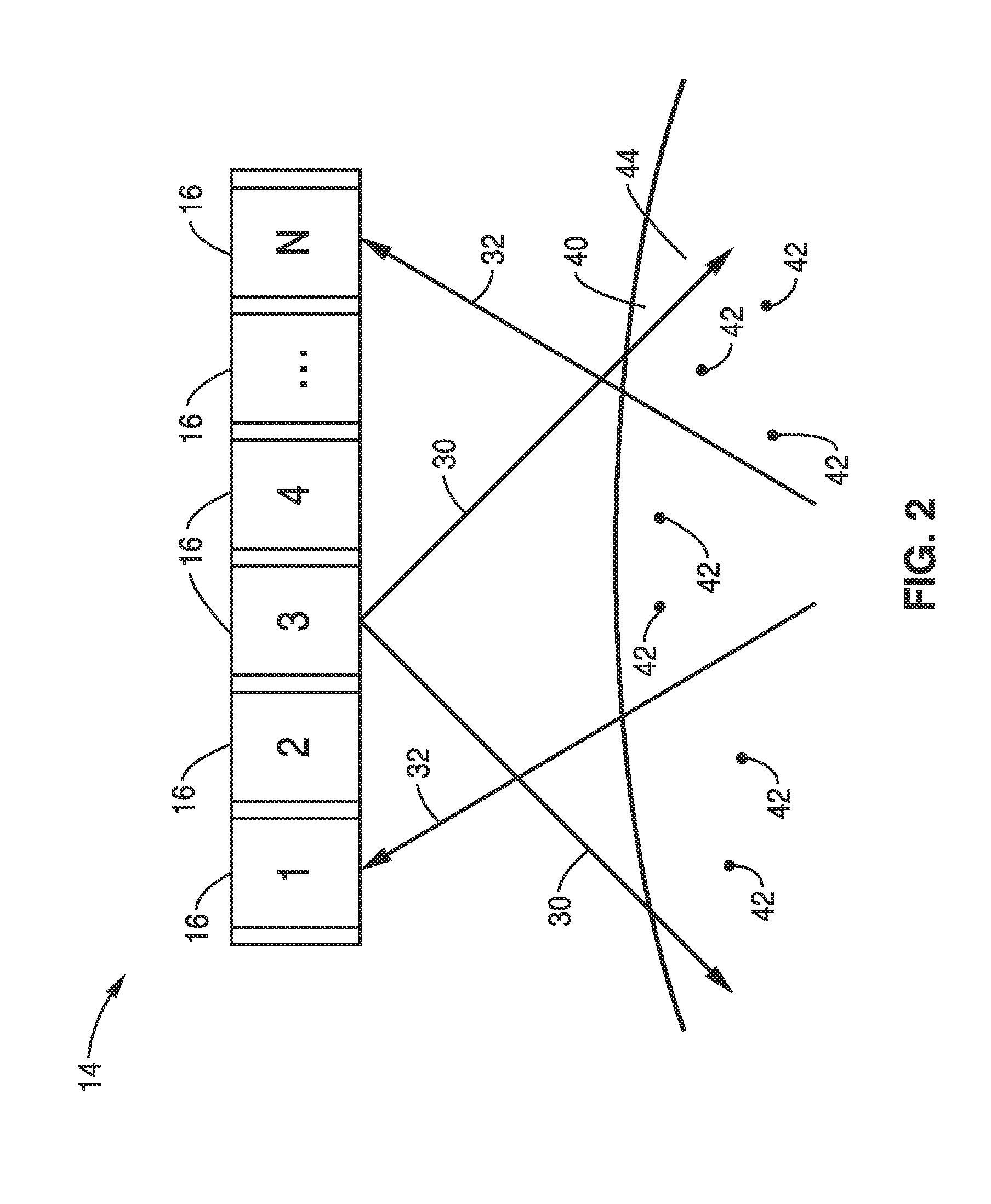

Methods and apparatus for ultrasound imaging

ActiveUS20070230759A1Reduce variationAccurate gainUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound imagingUltrasound attenuation

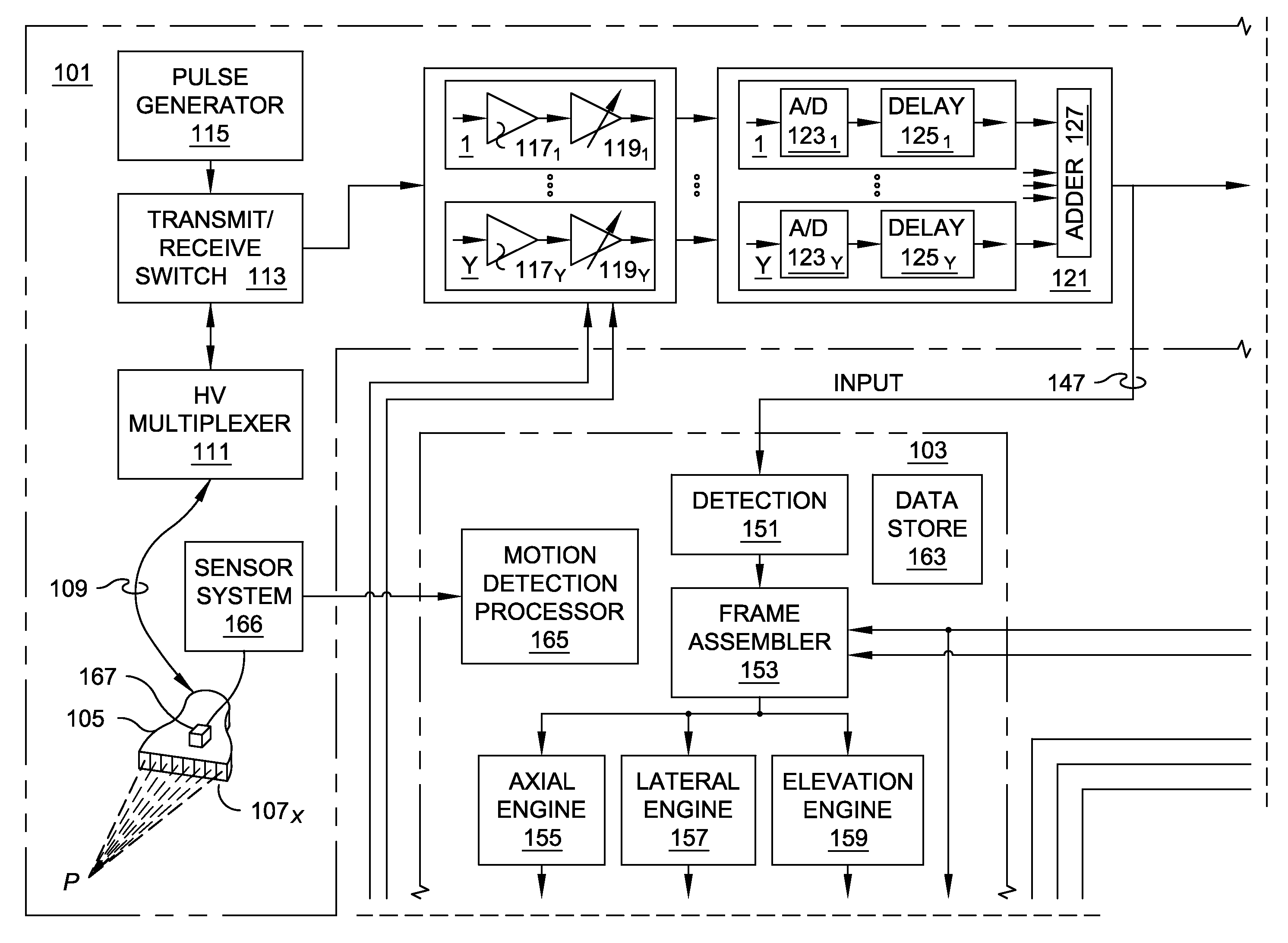

Actual ultrasound attenuation in tissue is used to calculate gain compensation profiles which are used to create a uniform image. Axial, lateral, elevation gain profiles are used to correct the attenuation and ultrasound variation in each direction. In addition, automatic activation of the automatic gain compensation is described.

Owner:HITACHI LTD

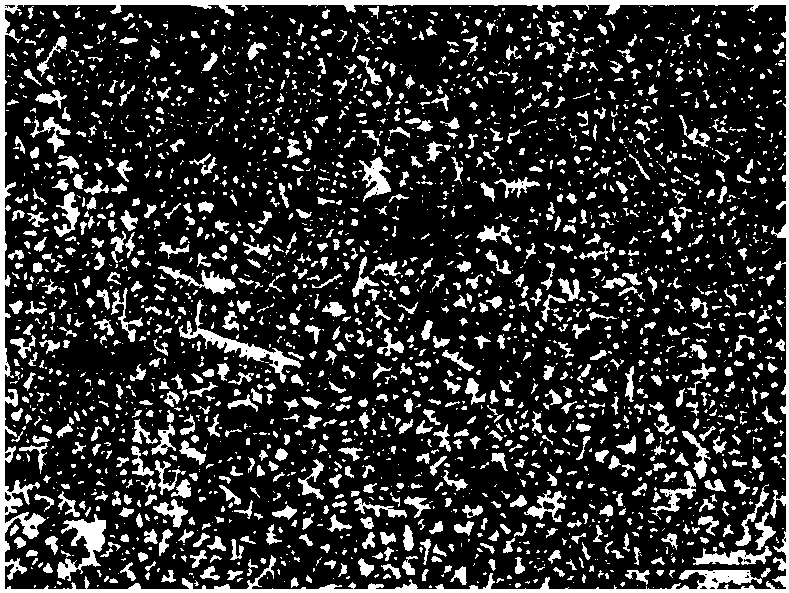

Manufacturing method of porosity reference block for composite material

ActiveCN104407060AUniform porosity distributionSmall sizeMaterial analysis using sonic/ultrasonic/infrasonic wavesNon destructivePorosity

The invention provides a manufacturing method of a porosity reference block for a composite material. The manufacturing method comprises the following steps: (1) overlays of a prepreg are designed according to thickness requirements of the porosity reference block, and glass microspheres are uniformly sprayed on each overlay; (2) a paved workpiece is put into an autoclave to be solidified, the solidified workpiece undergoes trimming to form the reference block, the reference block undergoes ultrasonic non-destructive testing, and an ultrasonic decay signal of the reference block is determined; (3) a porosity test panel with real pore flaws is prepared, the test panel is detected by an ultrasonic fault detector, an area which is the same with the ultrasonic decay signal of the reference block in the Step (2) is found out in the test panel, and the area is marked; and (4) the selected area in the Step (3) undergoes metallographic microscopic analysis and numerical value of porosity is determined.

Owner:SHANGHAI AIRCRAFT MFG +1

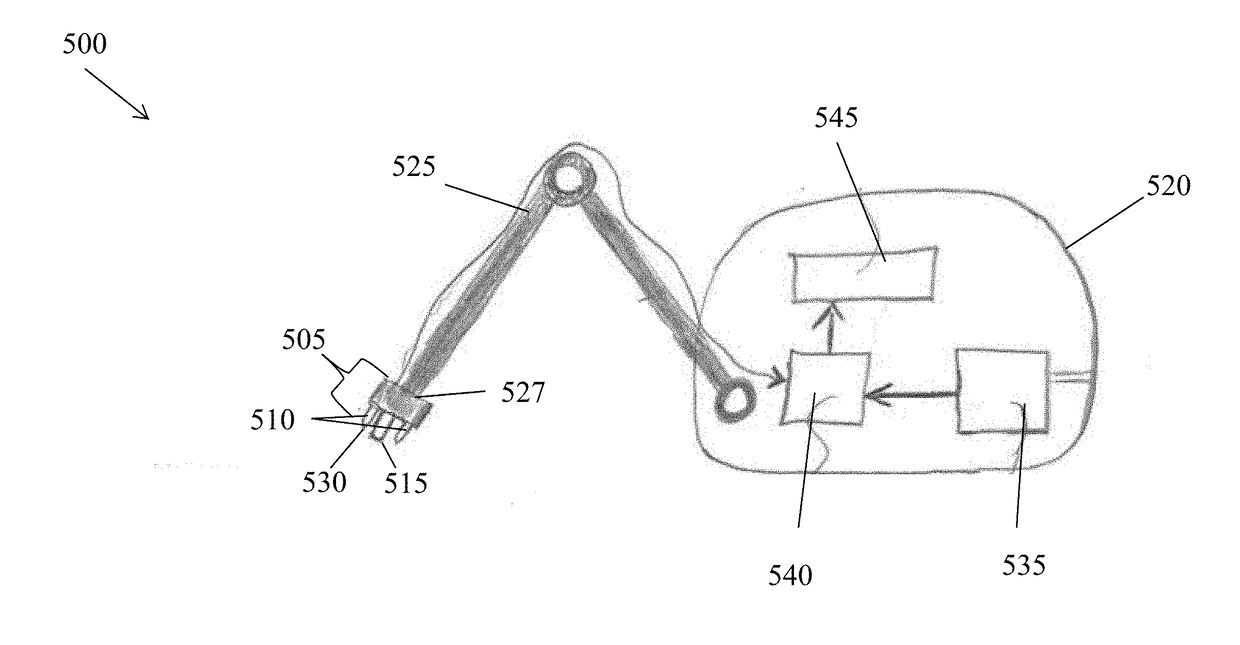

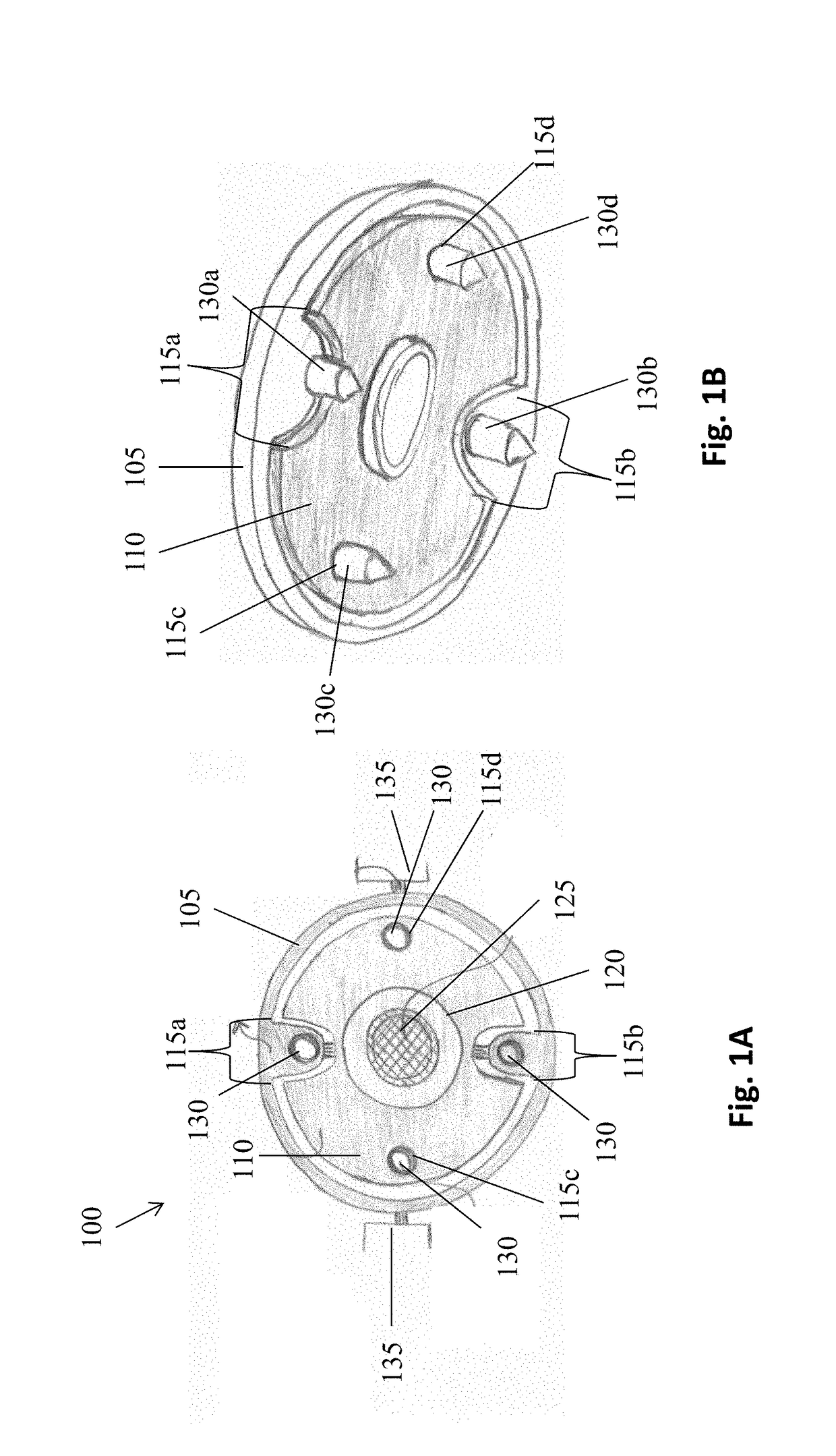

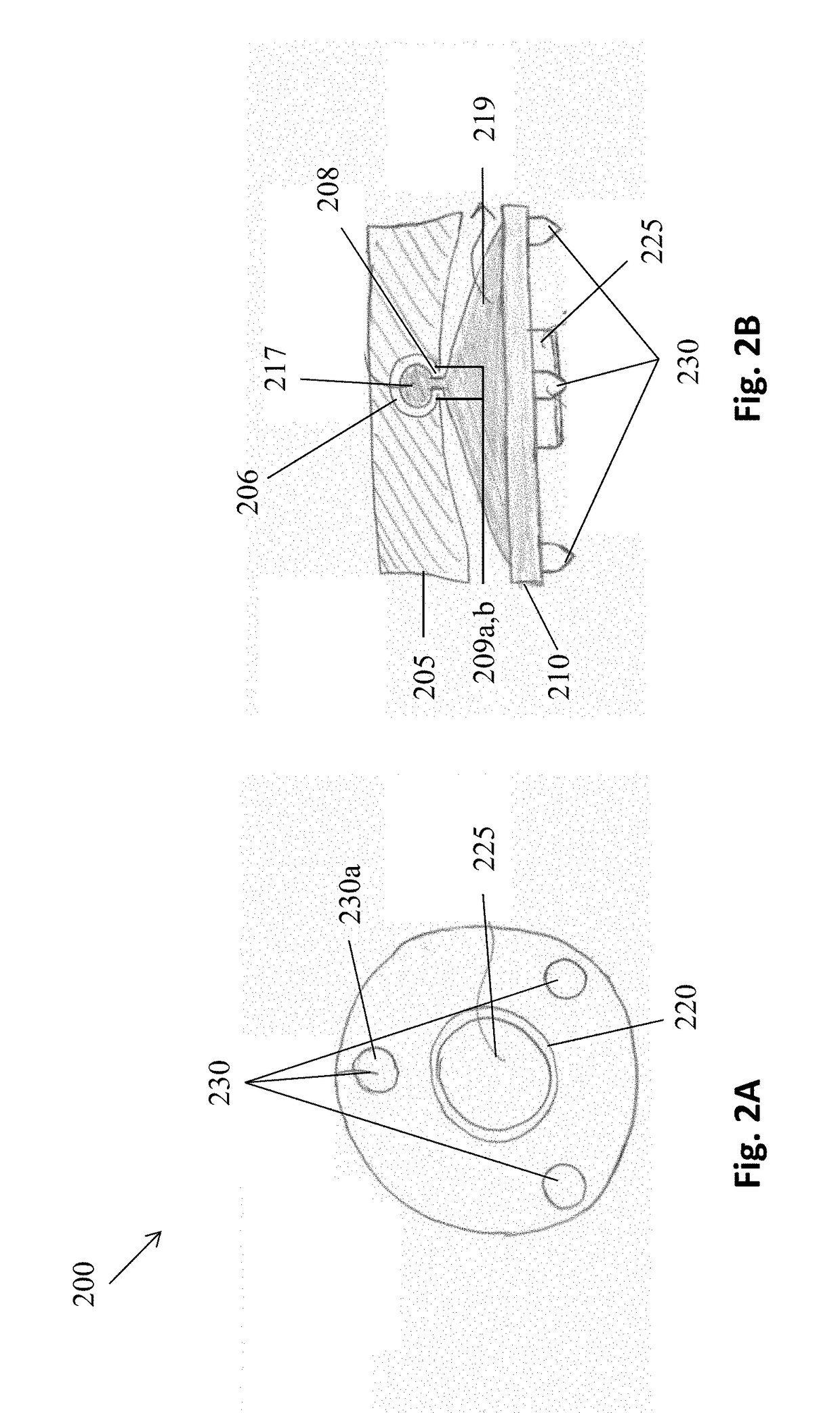

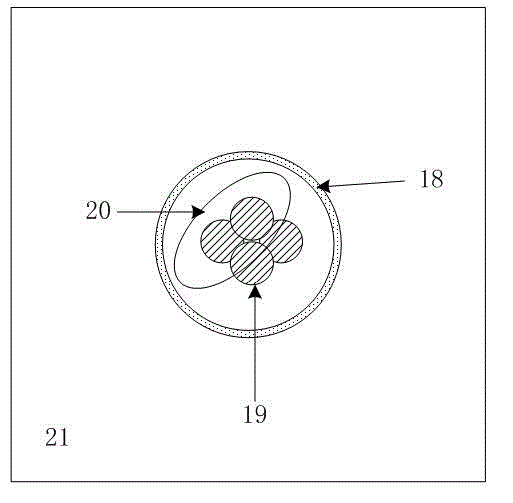

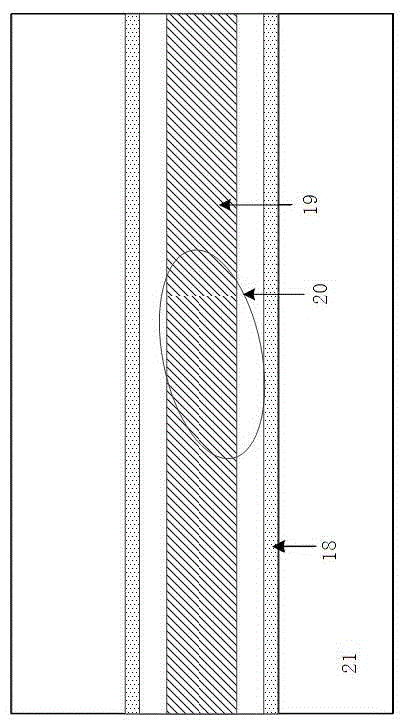

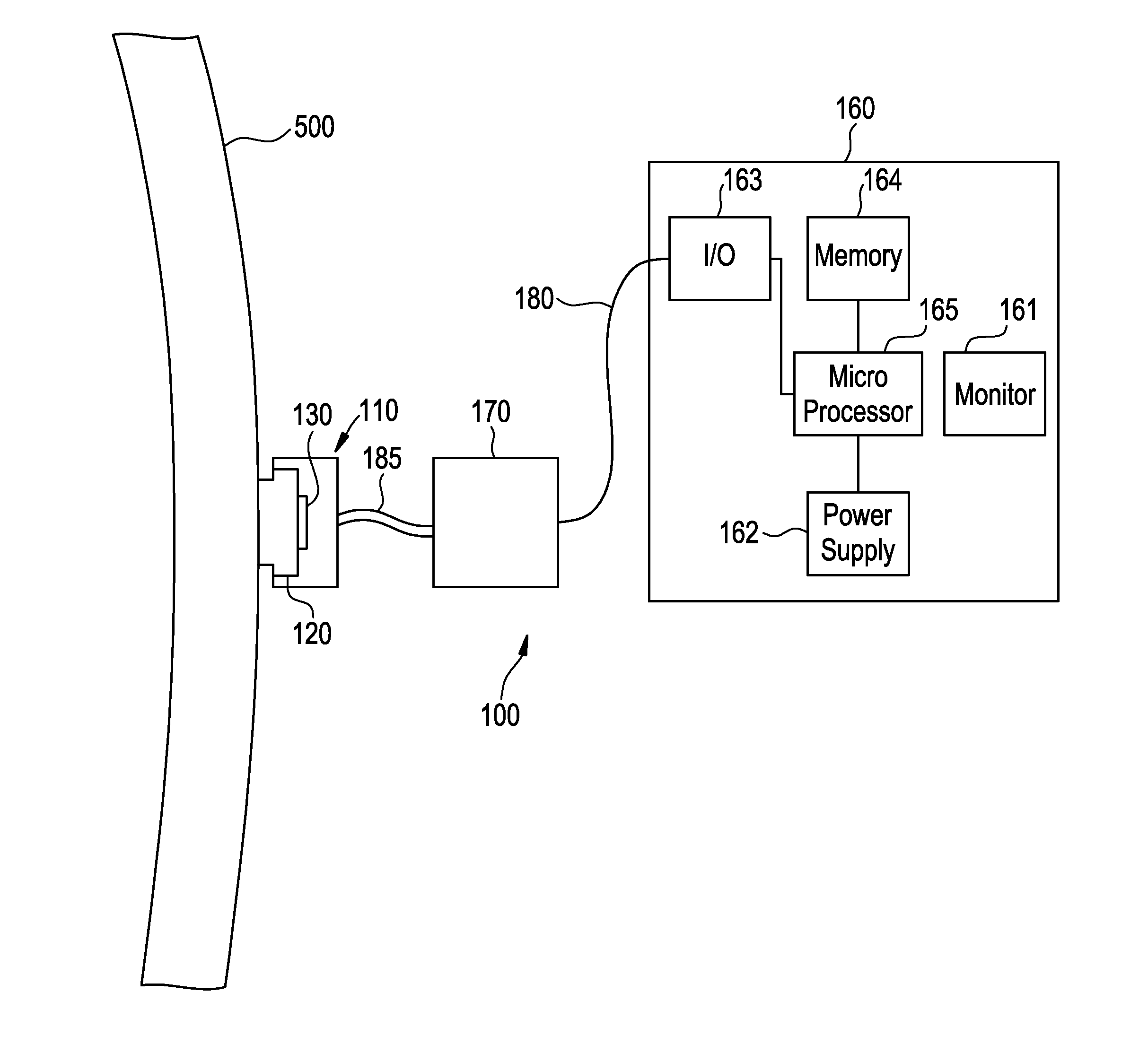

Integrated ultrasonic testing and cathodic protection measurement probe

ActiveUS20180073975A1Material analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceRobotic armUltrasonic attenuation

This application discloses integrated probes and probe systems, which can be attached to the robotic arms of a remotely operated vehicle to perform both cathodic protection (CP) voltage measurements and ultrasonic testing (UT) thickness measurements at an underwater surface. In some embodiments, the integrated probe system couples an inner and outer gimbal together such that one or more electrically conductive legs pass from the outer gimbal through the inner gimbal. These legs are arranged about an ultrasonic sensor which extends from the front surface of the inner gimbal. When the integrated probe contacts the underwater surface, both the ultrasonic sensor and at least one leg contact the surface, thereby providing substantially simultaneous CP and UT measurements.

Owner:SAUDI ARABIAN OIL CO

Time reversal and phase coherent music techniques for super-resolution ultrasound imaging

ActiveUS20140364733A1Accurate scatterer localizationHigher-resolution ultrasound imageOrgan movement/changes detectionInfrasonic diagnosticsPhase responseSonification

Systems and methods for super-resolution ultrasound imaging using a windowed and generalized TR-MUSIC algorithm that divides the imaging region into overlapping sub-regions and applies the TR-MUSIC algorithm to the windowed backscattered ultrasound signals corresponding to each sub-region. The algorithm is also structured to account for the ultrasound attenuation in the medium and the finite-size effects of ultrasound transducer elements. A modified TR-MUSIC imaging algorithm is used to account for ultrasound scattering from both density and compressibility contrasts. The phase response of ultrasound transducer elements is accounted for in a PC-MUSIC system.

Owner:TRIAD NAT SECURITY LLC

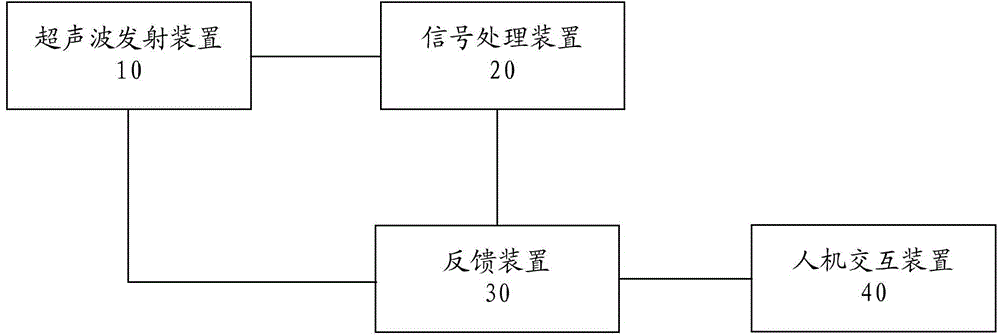

Phased array high-intensity focused ultrasonic detection and therapy system

InactiveCN104622504AAvoid therapeuticAvoid damageUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationUltrasonic attenuation

The invention provides a phased array high-intensity focused ultrasonic therapy system which comprises an ultrasonic transmitting device, a signal processing device, a feedback device and a human-computer interaction device. The ultrasonic transmitting device is respectively connected with the signal processing device and the feedback device, and the feedback device is respectively connected with the signal processing device and the human-computer interaction device. The feedback device of the phased array high-intensity focused ultrasonic therapy system can output intensity instructions and frequency instructions to the ultrasonic transmitting device according to a target tissue three-dimensional image, a non-target tissue three-dimensional image and a tissue variable quantity outputted by the signal processing device and a preset tissue variable quantity to control the intensity and the frequency of ultrasonic waves transmitted by the ultrasonic transmitting device to adapt to the intensity needed by therapy or detection, so that target tissues can be damaged, and non-target tissues cannot be damaged in the therapy process.

Owner:黄晶

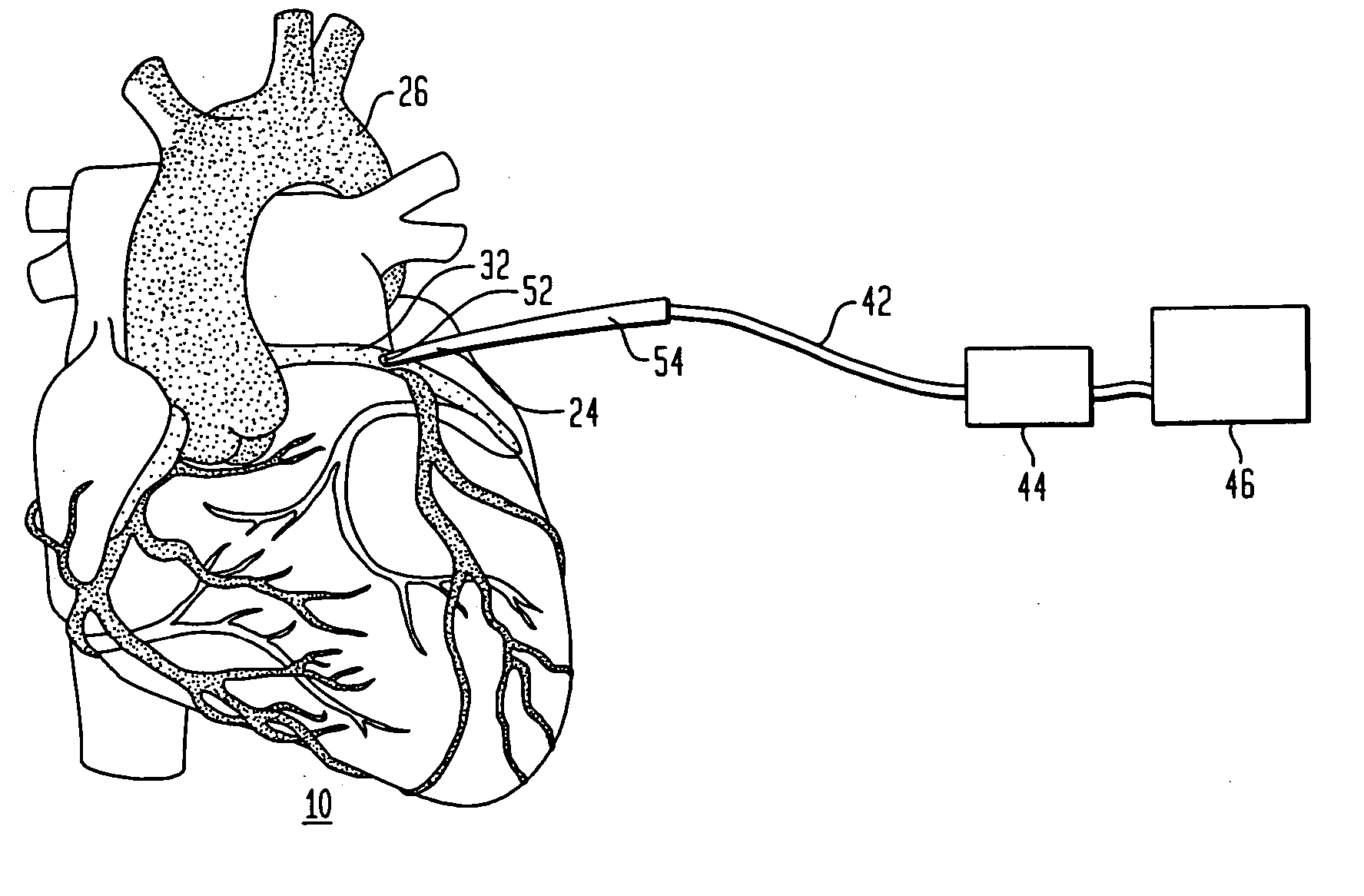

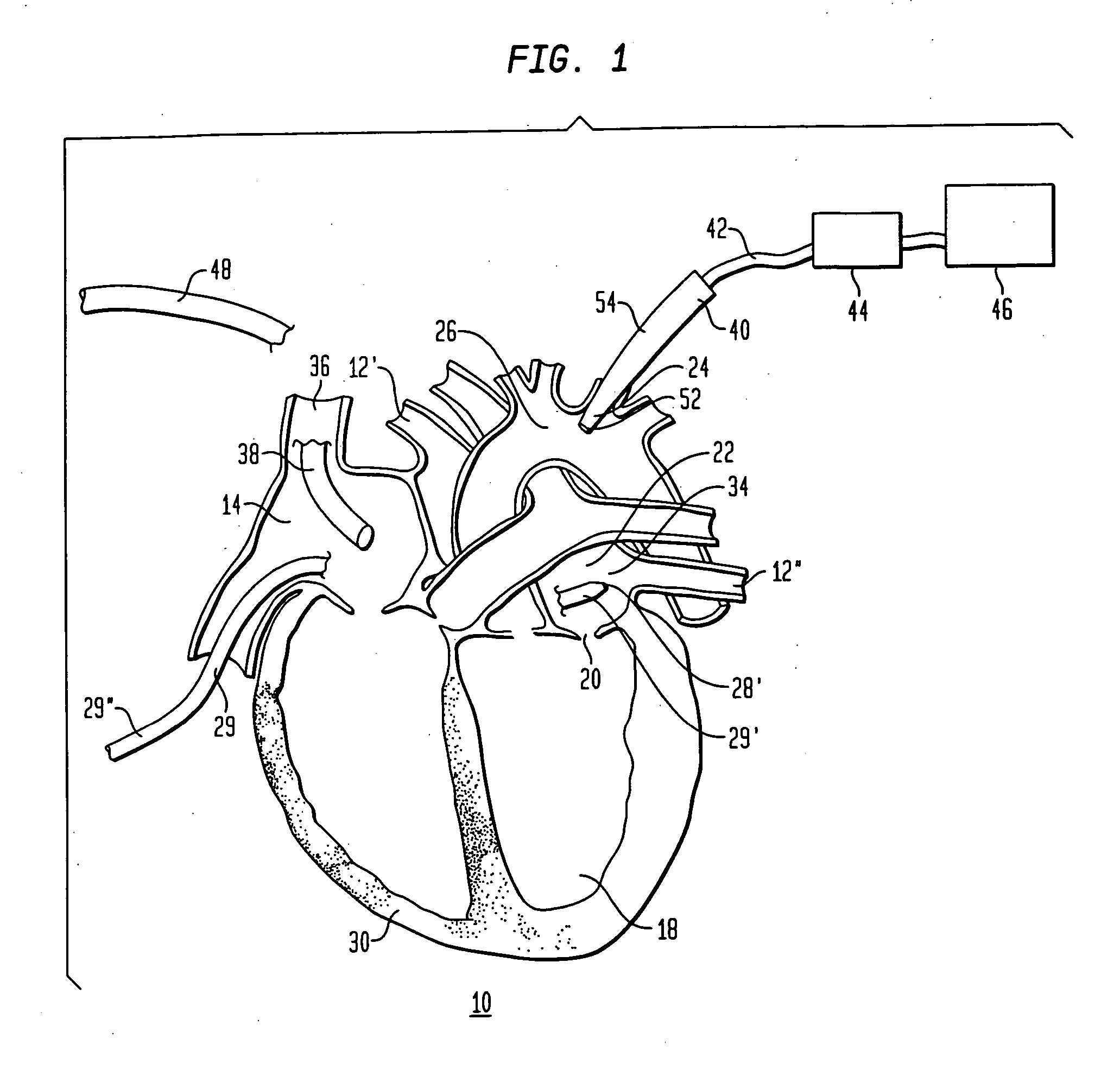

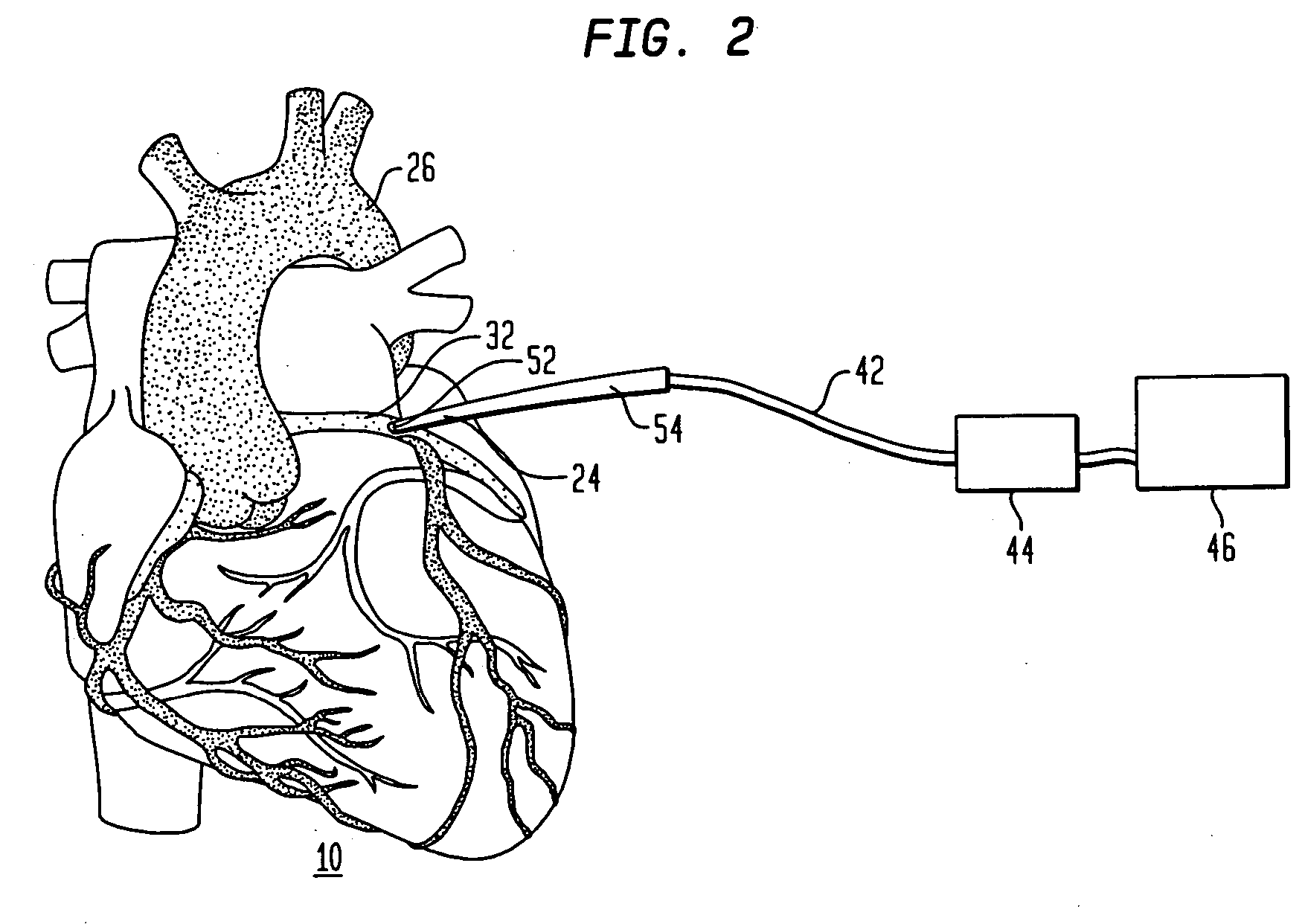

Cardiac ablation using microbubbles

InactiveUS20060100514A1Minimize dilutionReduce selection requirementsUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationBlood vessel

In a cardiac ablation procedure, ultrasonic energy is emitted from an ultrasonic ablation device (28) and is focused on myocardial tissue (30) within the wall of the heart or within the wall of a blood vessel connected to the heart (10). Ultrasound attenuation of the cardiac tissue is selectively increased by introducing microbubbles into the circulatory system of the subject so that the microbubbles enter the coronary arteries and pass into the myocardial tissue.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

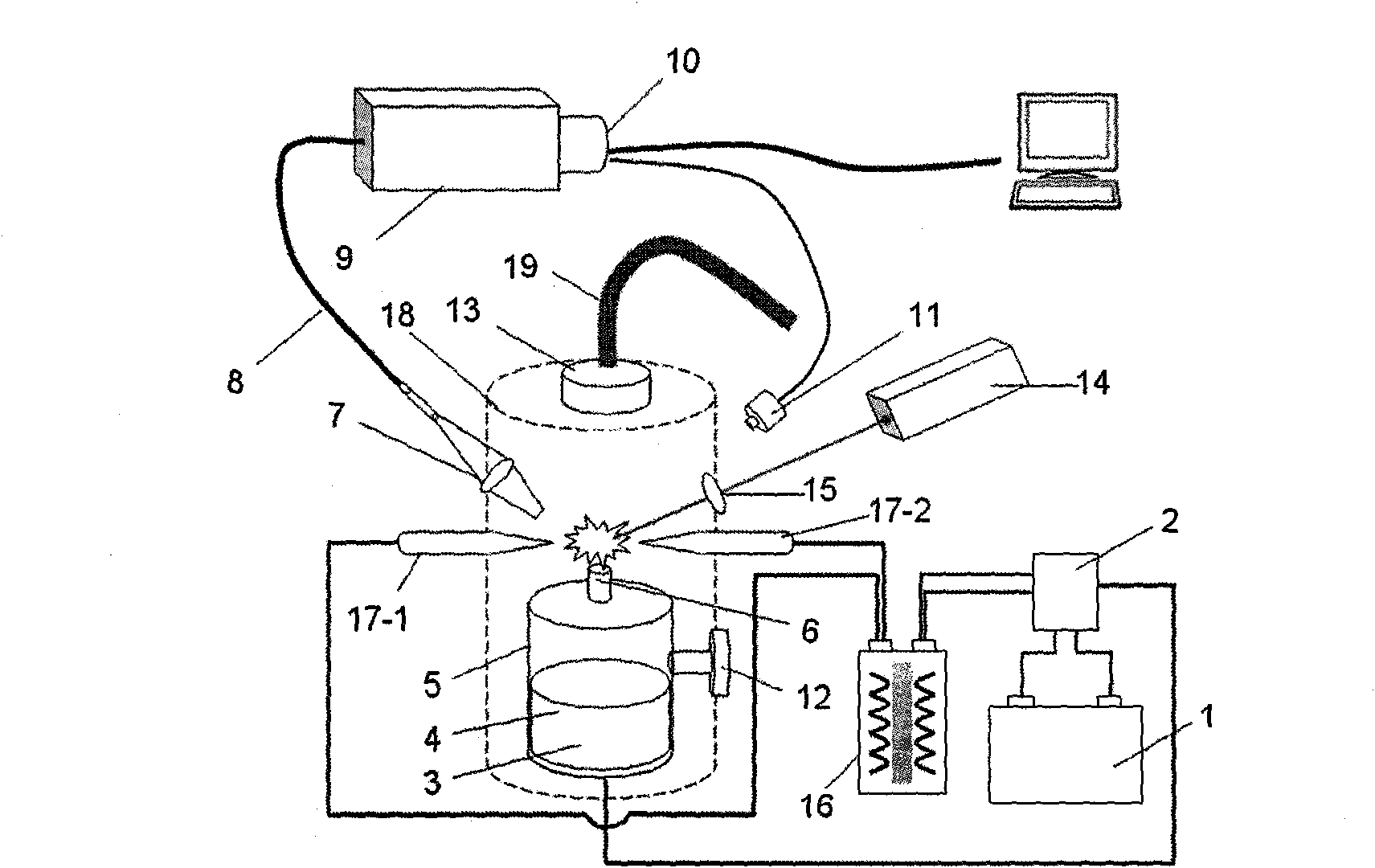

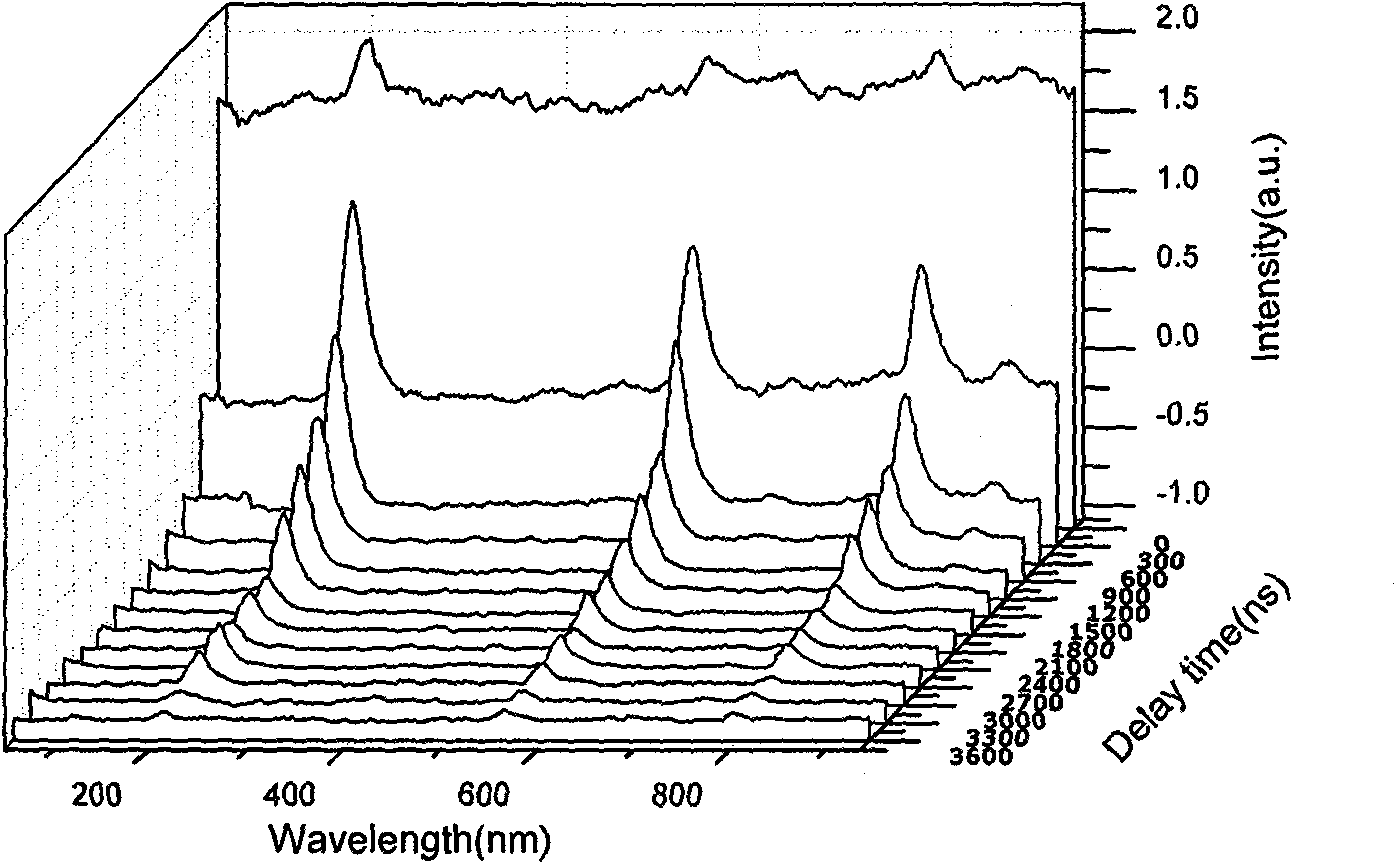

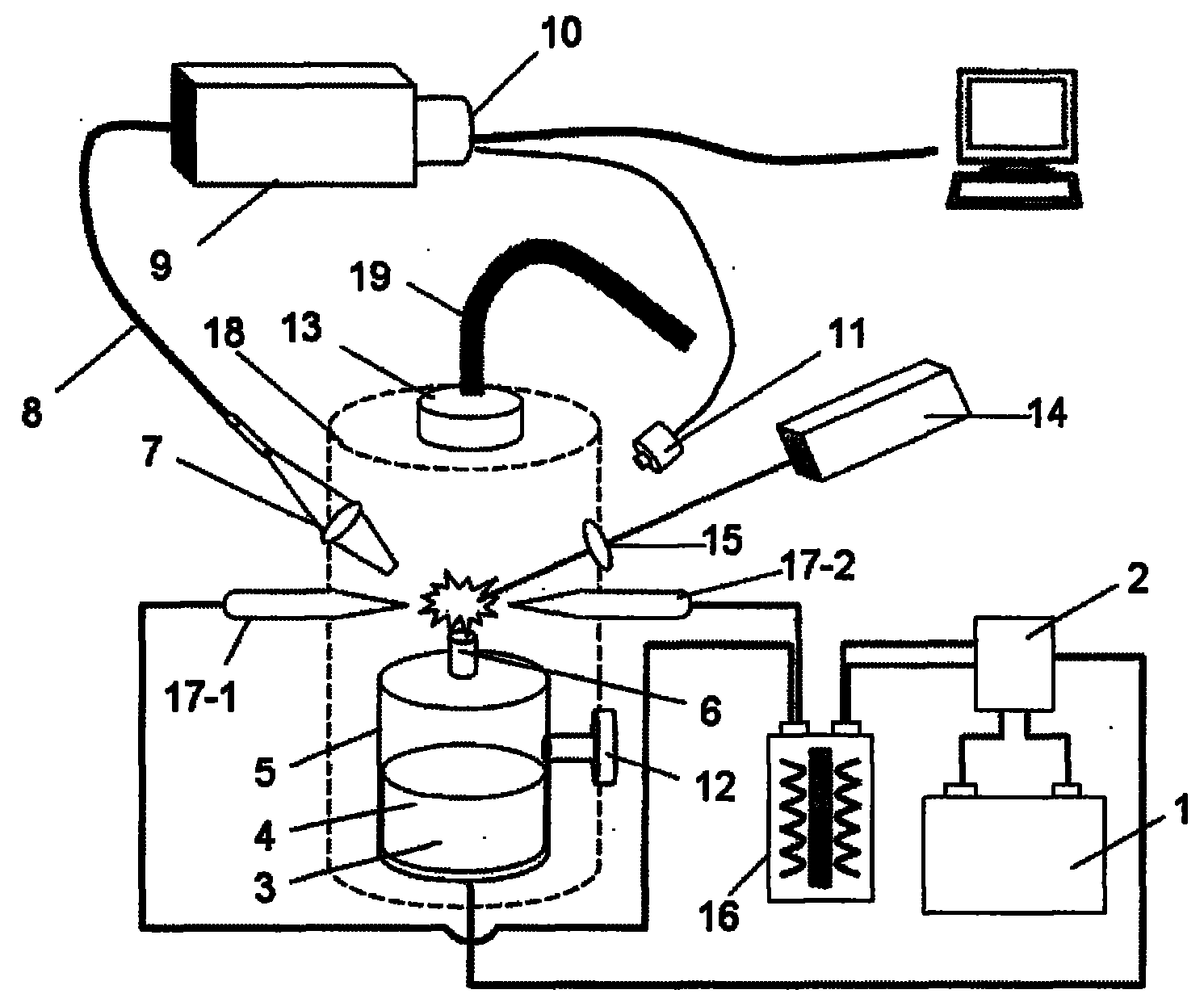

Method and device for detecting liquid sample by using ultrasonic atomization and breakdown spectroscopy

InactiveCN101788487AExtend your lifeHigh sensitivityAnalysis by thermal excitationSpectroscopySpectrograph

The invention relates to a method and device for detecting liquid samples by using breakdown spectroscopy. The device utilizes the ultrasonic atomization method to atomize the liquid samples to form massive and dense droplets in the air, breaks down and induces plasma and radiates an emission spectra signal. The method comprises the following steps: high-frequency oscillation is generated by the ultrasonic transducer (3) of the device of the invention to ensure that the liquid samples (4) in a sample cell (5) generate fog droplets, with the aid of a supply fan and an exhaust fan (13), columnar mist is generated above an air duct (6); plasma is generated at the edge of the columnar mist through breakdown, the plasma emission spectra signal is collected by a collection lens (7) and enters a spectrograph (9) through optical fiber (8) to split light; and finally a photoelectric sensor (11) fits with an ICCD detector (10) to collect spectral data. The method of the invention can reduce the breakdown threshold, increase the ablation efficiency and prolong the life of plasma. The detection device is applicable to the field component detection analysis field of the environment and mineral resources and the detection method has higher signal-to-background ratio and lower cost compared with the similar methods.

Owner:OCEAN UNIV OF CHINA

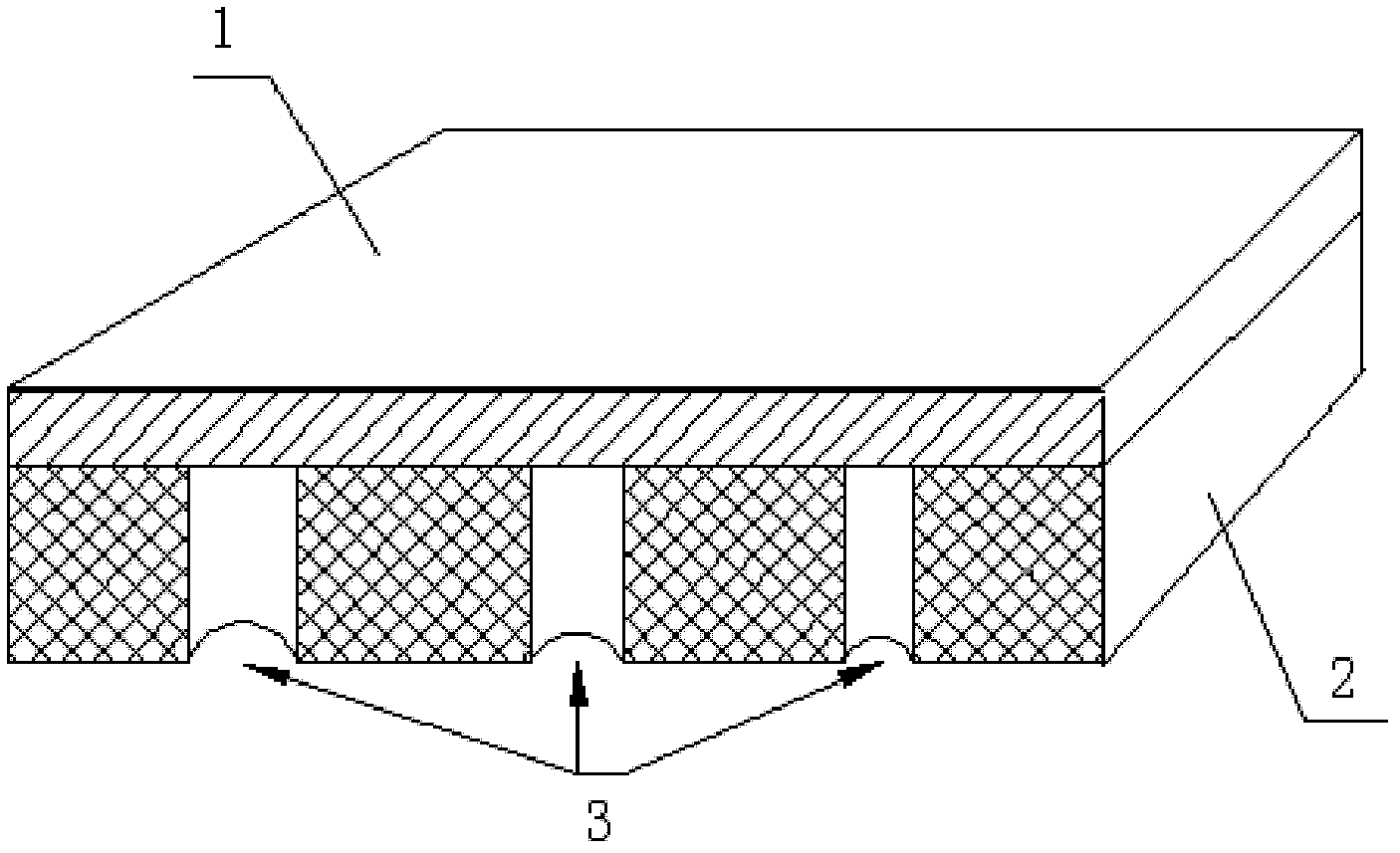

Method for ultrasonic detection of bonding quality of thin-walled metal and non-metal material

InactiveCN102608204AImprove quality reliabilityImprove the safety of useAnalysing solids using sonic/ultrasonic/infrasonic wavesOscillographyBond quality

The invention discloses a method for ultrasonic detection of the bonding quality of thin-walled metal and a non-metal material, wherein an ultrasonic instrument is adopted for detection. The method comprises the steps of: firstly, making a comparative sample, and calibrating the sensitivity of the ultrasonic instrument according to a debonding defect testing hole in the comparative sample; then performing defect position testing on a product: detecting the bonding quality of the thin-waled metal and the non-metal material by adopting the calibrated ultrasonic instrument, placing an output port of a longitudinal wave probe of the ultrasonic instrument on an outer metal surface of the material product, and performing 100% scanning on a bonding face by adopting a moving scanning manner; and if the height of multiple pulse echoes of longitudinal waves at cells 6 to 10 of a horizontal baseline on a oscillography screen of the instrument is found to reach or exceed initial sensitivity during moving scanning, judging that a part below the probe has a debonding defect position or an adverse bonding defect, and if a height envelope curve of the multiple pulse echoes of the longitudinal waves at cells 6 to 10 of the horizontal baseline on the oscillography screen is lower than 50% and gradually decreases to 20% or no reflected waves exist, judging that the bonding quality is intact.

Owner:湖北三江航天江北机械工程有限公司

Device and method for ultrasonic testing of corrugated pipe duck grouting compactness

InactiveCN102944608AAccurate judgmentJudgment is intuitive and reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationEngineering

The invention discloses a device and a method for ultrasonic testing of corrugated pipe duck grouting compactness. The device comprises a transmitting transducer, a plurality of receiving transducers, a signal acquisition module and a signal processing and display module, wherein the transmitting transducer is excited by a signal excitation module to generate ultrasonic signals, the plurality of the receiving transducers are arranged in a cross array, the signal acquisition module acquires signals, and the signal processing and display module performs processing and waveform display on acquired signals. The method includes determining an arrival time curve of waveforms received at different positions of a scattering sound field, extracting some waveforms through a window function from array measurement waveforms with the curve serving as a standard, calculating correlation coefficients and changing curves of the correlation coefficients along with medium sound velocities, corrugated pipe diameters and time, forming an image, and determining grouting defects of corrugated pipes through the image. The device and the method are simple and practical, applicable to rapid detection on the construction site, particularly applicable to construction quality on-site determination and bridge daily testing and maintenance in a bridge construction process, and accurate, visual and reliable in cavity position determination.

Owner:HOHAI UNIV CHANGZHOU

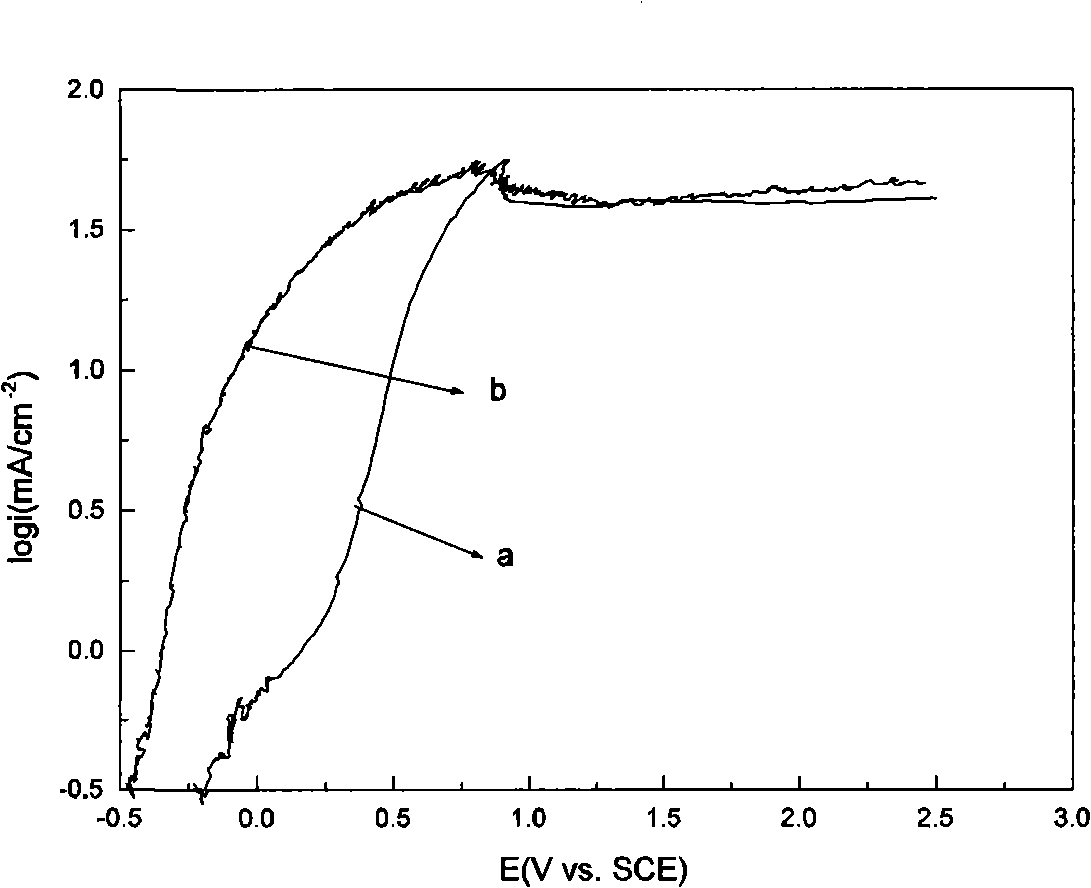

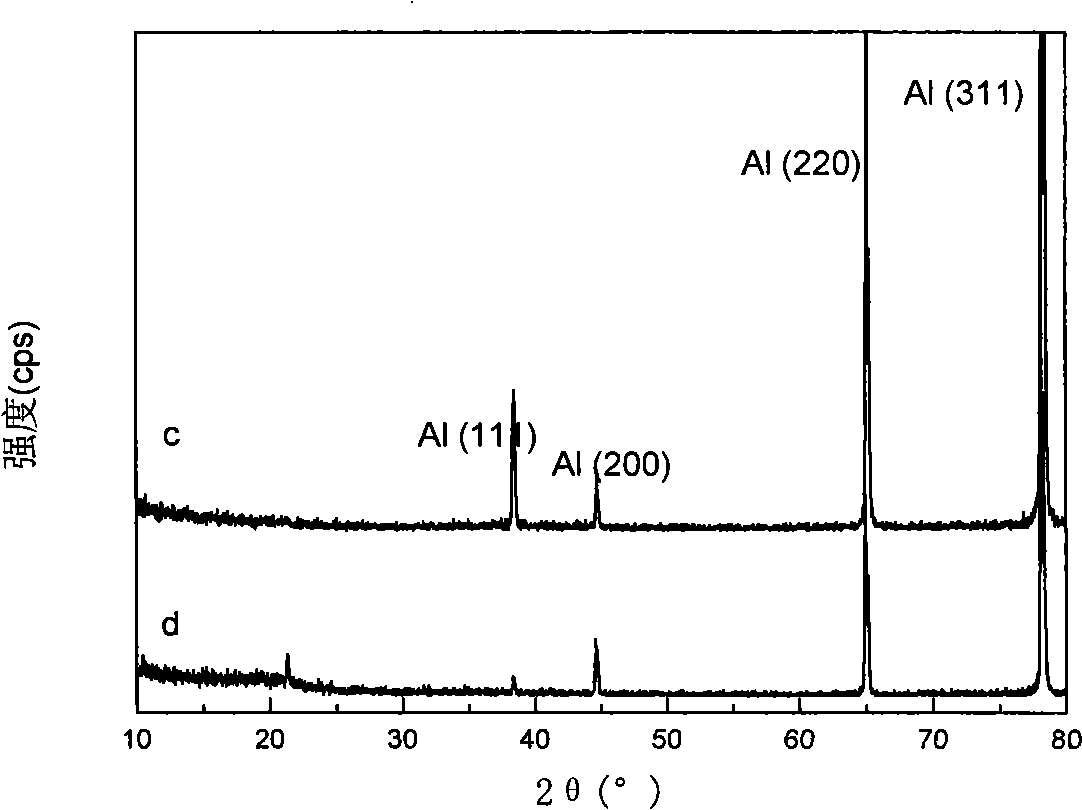

Electrochemical polishing method for high purity aluminum under ultrasonic agitation

The invention relates to an electrochemical polishing method for the high purity aluminium under ultrasonic agitation, which belongs to the fields of the material chemistry and the electrochemistry. The electrochemical polishing method under the ultrasonic agitation comprises the following steps: high purity aluminium foil is added in absolute ethyl alcohol, so as to be cleaned with deionized water and through ultrasonic oscillations, and the natural oxide film in sodium hydroxide is removed; the aluminium foil after being pretreated is used as an anode, the platinum sheet is used as the cathode, the reference electrode is saturated calomel electrode, and the electropolishing solution is the mixed liquor composed of absolute ethyl alcohol and perchloric acid; the electrolysis vessel is positioned in an ultrasonic wave cleaner, and electrochemical polishing is performed on a constant potential rectifier. The self-organizing structure with nanoscale stripe shape is formed on the aluminium surface, the structure is observed by adopting the atomic force microscopy, and the size of the stripe-shaped nanostructure changes under the ultrasonic agitation; the composition of the polishing surface is analyzed through the Raman spectrum and the X-ray diffraction, so as to indicate that the composition of the polishing surface is amorphous aluminum oxide.

Owner:DALIAN UNIV OF TECH

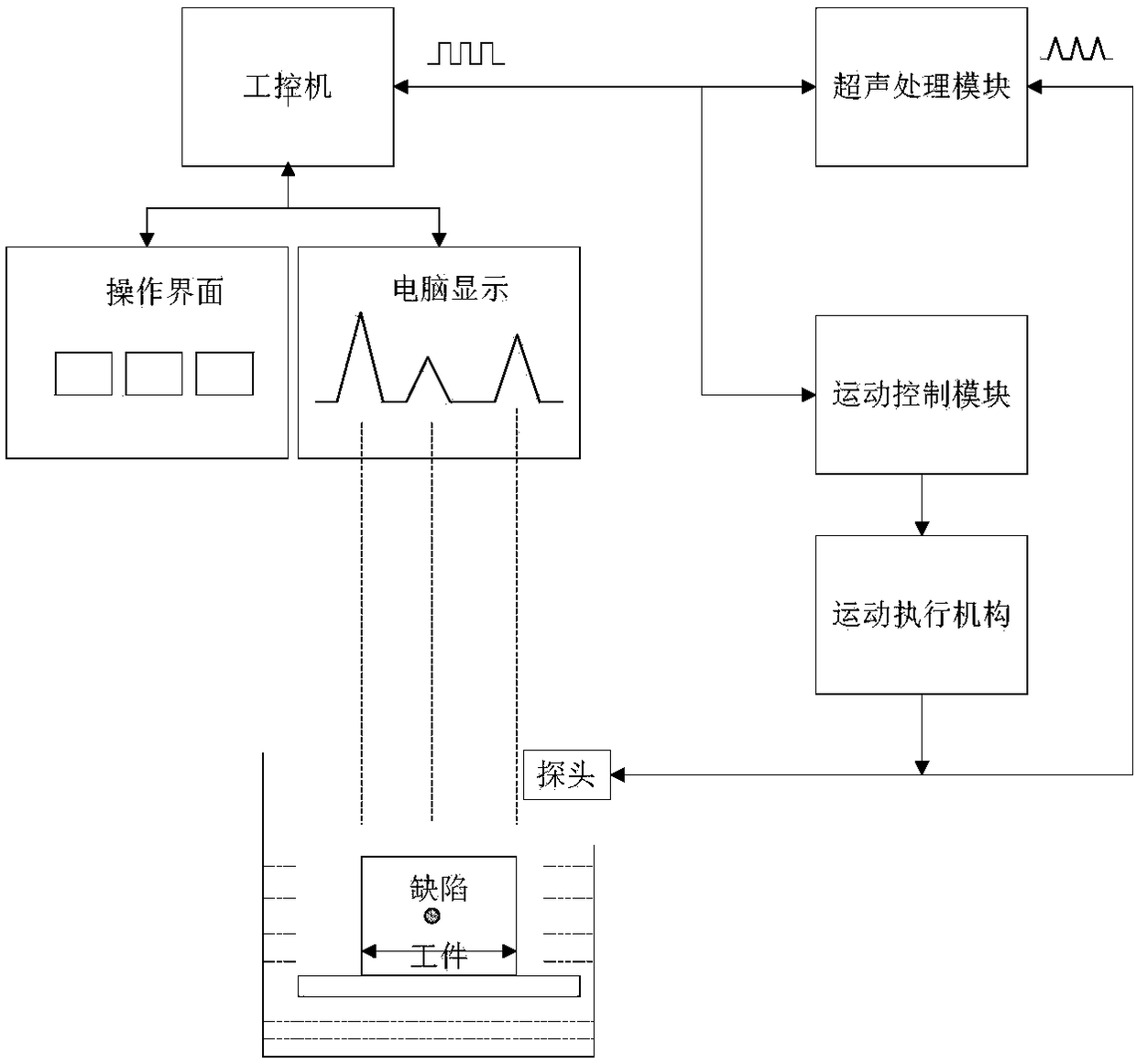

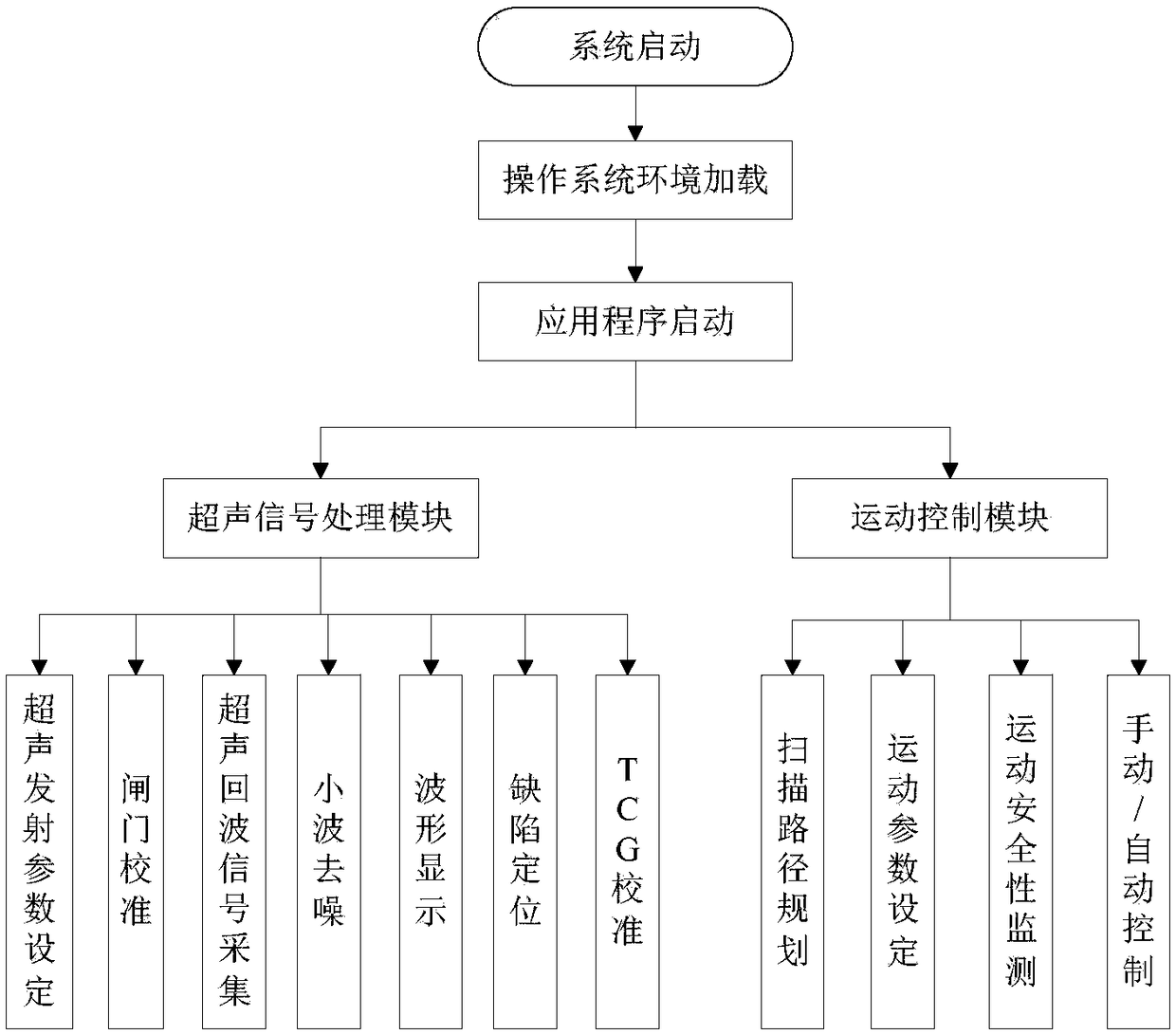

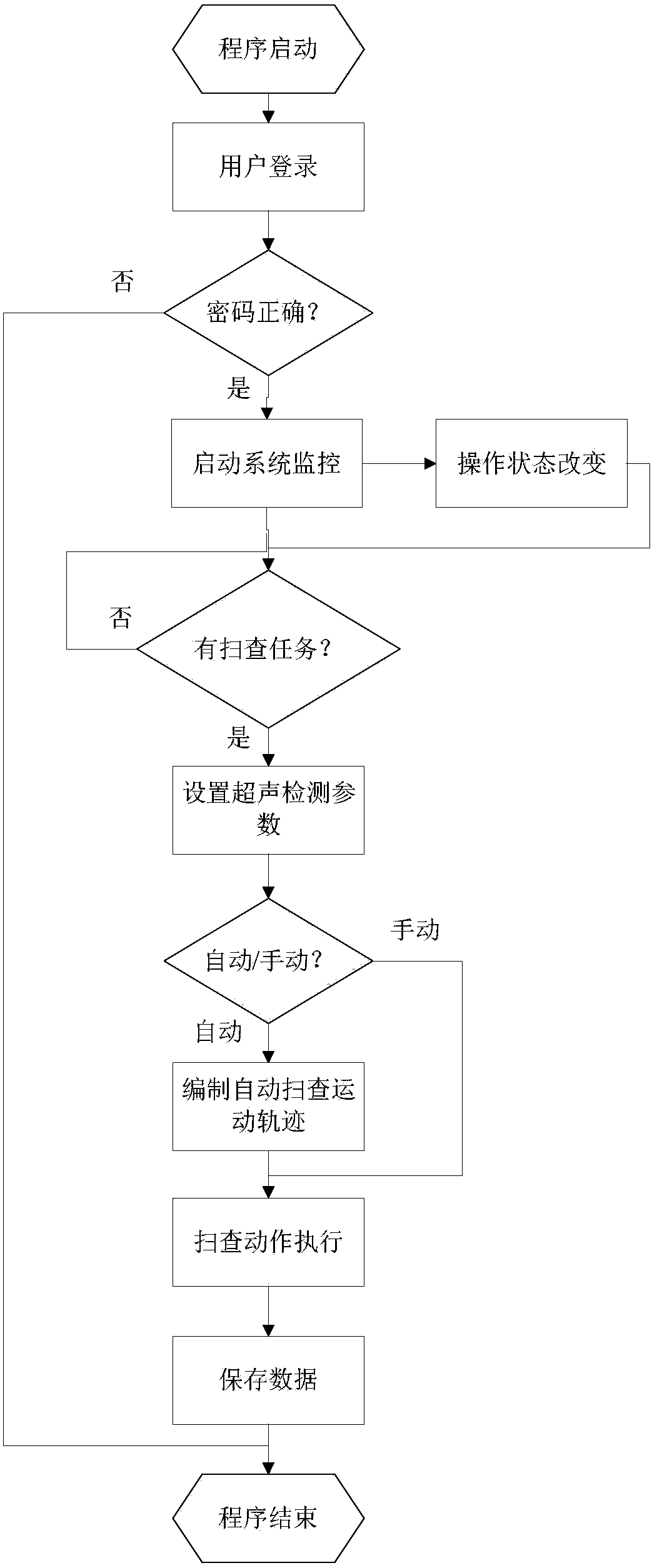

Water immersion ultrasonic flaw detection system and method

InactiveCN108072698AQuick responseChange the direction of the emitted ultrasound beamAnalysing solids using sonic/ultrasonic/infrasonic wavesAviationWater immersion

The invention relates to a water immersion ultrasonic flaw detection system and method. The system comprises an ultrasonic probe, an ultrasonic processing module, a motion control module, a motion execution mechanism, an industrial control computer and a water tank, wherein the ultrasonic probe is used for transmitting an ultrasonic emission signal to a to-be-detected workpiece and receiving an ultrasonic echo signal; the ultrasonic processing module is used for generating the ultrasonic emission signal under the control of the industrial control computer, processing the echo signal and outputting the detection echo signal to the industrial control computer; the motion control module is used for receiving a motion command of the industrial control computer and controlling the motion execution mechanism to complete automatic ultrasonic scanning of a motion track. The method comprises the following steps: ultrasonic detection setting parameters and the motion command are set in the industrial control computer, and output to the motion control module and the motion execution mechanism so as to realize automatic ultrasonic scanning of the motion track. The special ultrasonic processingmodule is manufactured to increase the ultrasonic signal processing speed, and a foundation for accuracy of ultrasonic flaw detection results is laid. The system and the method are successfully applied to nondestructive detection of aviation composite cake disc parts, and good application effect is achieved.

Owner:中国科学院沈阳计算技术研究所有限公司

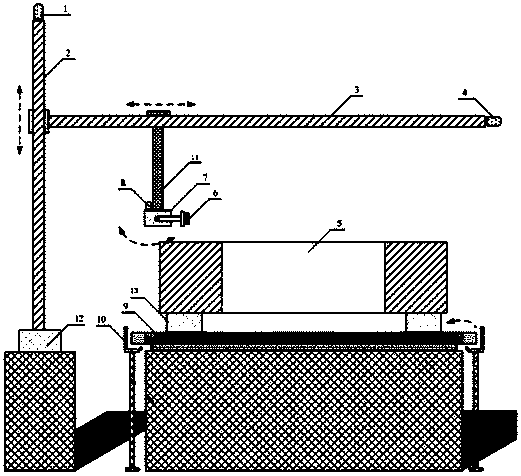

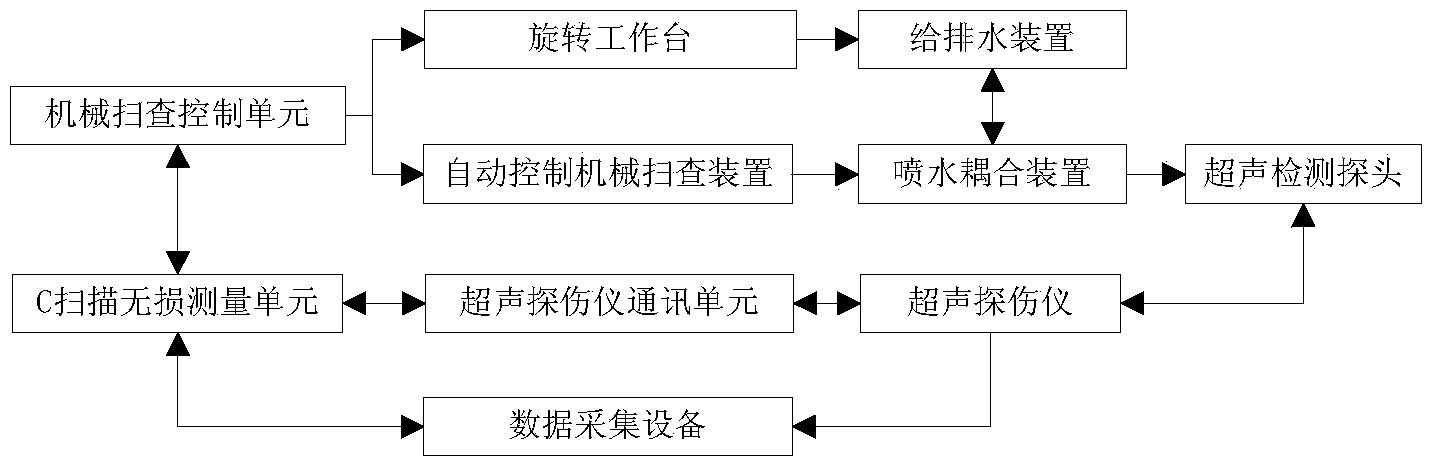

Automatic ultrasonic C scanning detection system for annular forging

ActiveCN104076089AImprove detection efficiencyReduced Alignment DifficultyAnalysing solids using sonic/ultrasonic/infrasonic wavesAutomatic controlData acquisition

The invention discloses an automatic ultrasonic C scanning detection system for an annular forging. The detection system comprises a mechanical scanning control unit, an automatic control mechanical scanning device, a rotary work platform, a water supply and drainage device, a water spray coupling device, an ultrasonic detection probe, an ultrasonic flaw detector and a communication unit thereof, data acquisition equipment and a C scanning nondestructive measurement unit, wherein the mechanical scanning control unit provides synchronous signals for the C scanning nondestructive measurement unit and controls the motions of the mechanical scanning device and the rotary work platform so as to drive the detection probe mounted in the water spray coupling device to scan; the water supply and drainage device is arranged on the edge of the rotary work platform so as to supply and drain water in real time; the ultrasonic flaw detector transmits and receives pulses through the detection probe and conveys detected echo information to the C scanning nondestructive measurement unit through the data acquisition equipment to perform imaging analysis. By adopting the system disclosed by the invention, the problems in ultrasonic detection of the annular forging with a complicated structure can be solved so that the imaging is accurate and visual.

Owner:NANJING CHENGUANG GRP

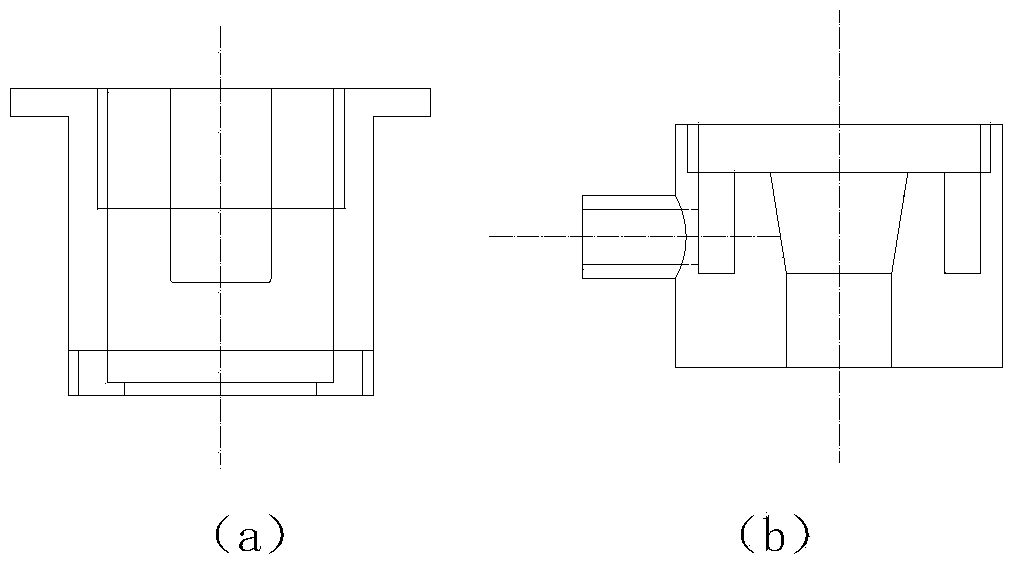

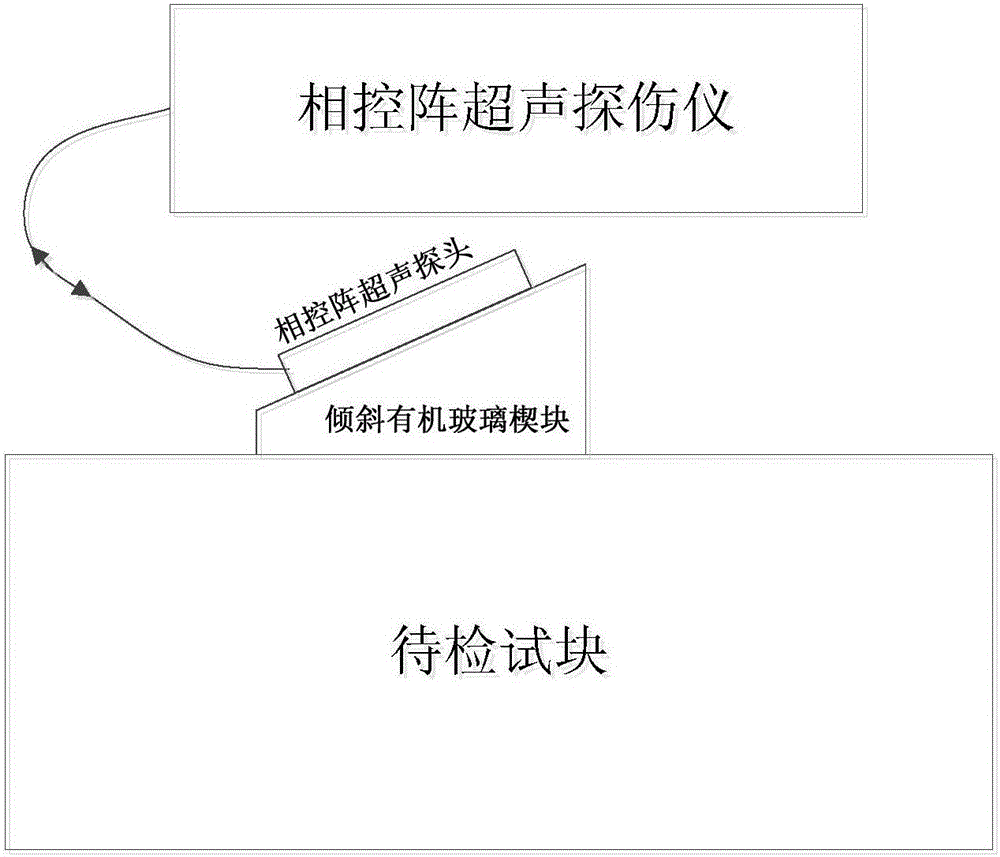

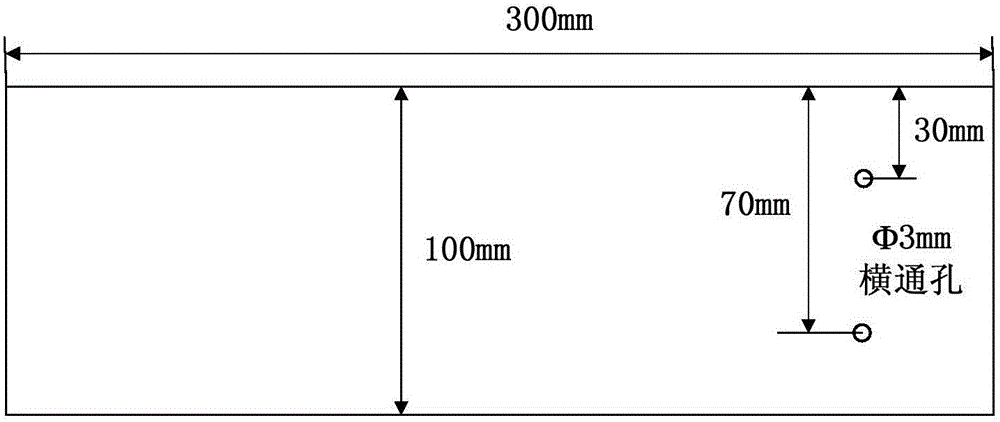

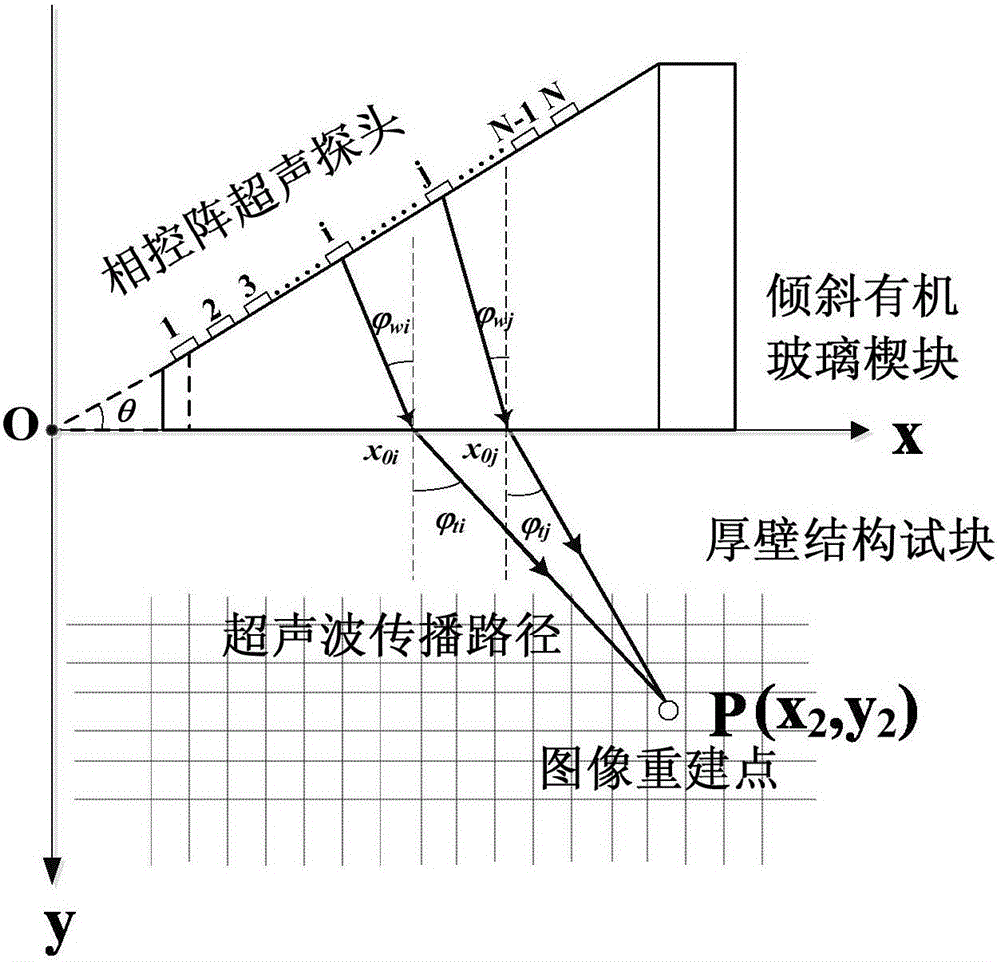

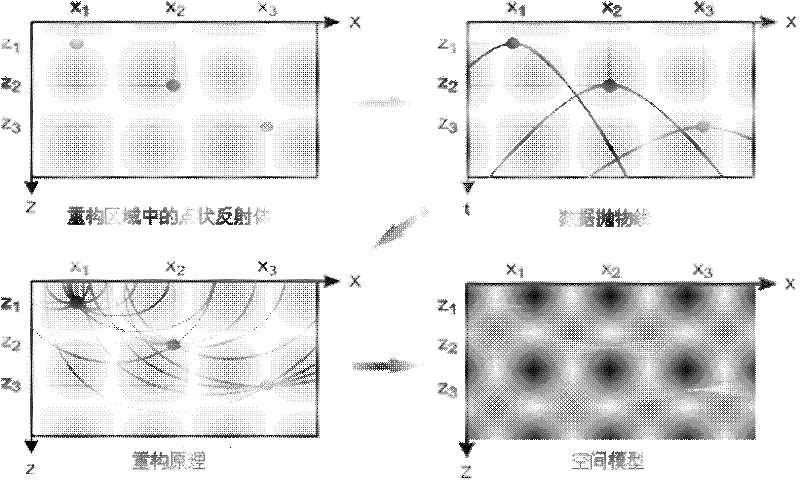

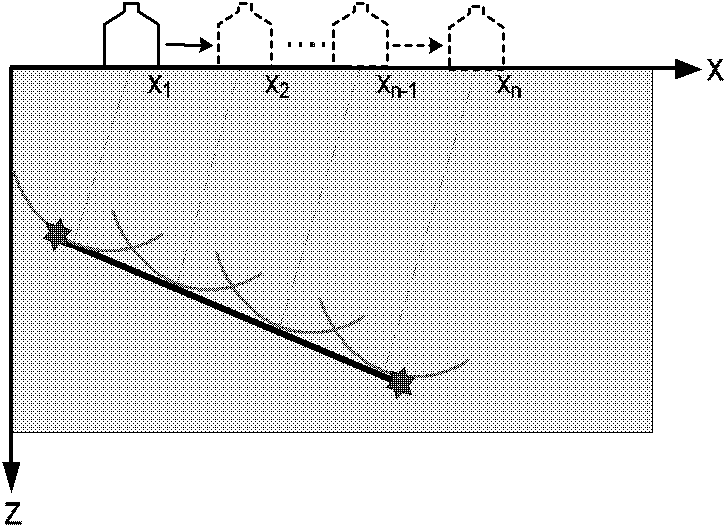

Oblique incident ultrasonic synthetic aperture focusing-based thick wall structure defect detection method

ActiveCN106093205ALarge energy coverageImprove defect detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic attenuationThick wall

The invention discloses an oblique incident ultrasonic synthetic aperture focusing-based thick wall structure defect detection method, and belongs to the technical field of nondestructive detection. The method comprises the following steps: a thick wall structure test block is detected through using a phased array electron scanning function by using an ultrasonic detection system comprising a phased array ultrasonic flaw detector, a phased array ultrasonic probe and an oblique organic glass wedge in order to obtain the A scanning signal set of all phased array elements; the Fermat's theorem is used to solve the emission point positions of all the phased array elements and image reconstruction points in the wedge / test block interface, and all A scanning signals undergo time delaying and amplitude superposing processing; and the processed A scanning signals undergo Hilbert transformation, and a difference function is used to obtain a reconstructed ultrasonic detection B scanning image. The method has the advantages of high defect detection resolution, large detection range, detection efficiency increase, and provision of an effective solving technology for the nondestructive detection problem of the defect of a thick wall structure. The method also can be embedded to the flaw detector to realize automatic real-time imaging, and has high engineering application values.

Owner:DALIAN UNIV OF TECH

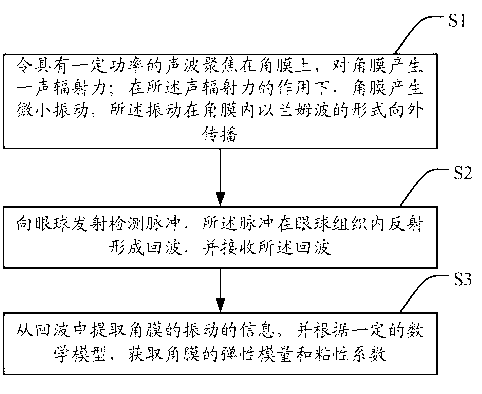

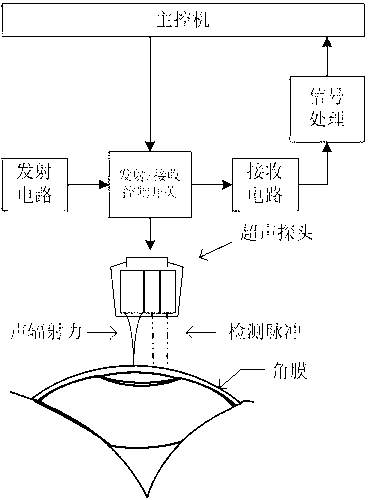

Method and system for ultrasonic detection of cornea viscoelasticity

InactiveCN103006274AComprehensive description of mechanical propertiesSimple structureEye diagnosticsEye inspectionMathematical modelViscoelasticity

The invention discloses a method and system for ultrasonic detection of cornea viscoelasticity. The method comprises the following steps of firstly, focusing sound waves with certain power onto a cornea to generate a sound radiant force on the cornea; under the action of the sound radiant force, the cornea generating slight vibration, and the vibration propagating outwards in the cornea in a Lamb wave way; then, transmitting a detection pulse to an eyeball, the pulse reflecting in the tissues of the eyeball to form echo, and receiving the echo; and finally, extracting the vibration information of the cornea from the echo, and according to a certain mathematical model, obtaining an elastic module and a viscosity coefficient of the cornea. The elastic module and the viscosity coefficient can be simultaneously and quantitatively measured, and mechanical properties of the cornea are fully described. Meanwhile, the system has the advantages that the structure is simple, easy implementation is realized, the cost is low, and the like. The system can be used as independent equipment, and also can be used as an additional function module to be loaded onto the existing color ultrasonic system for use, so the market population prospect is better.

Owner:SHENZHEN UNIV

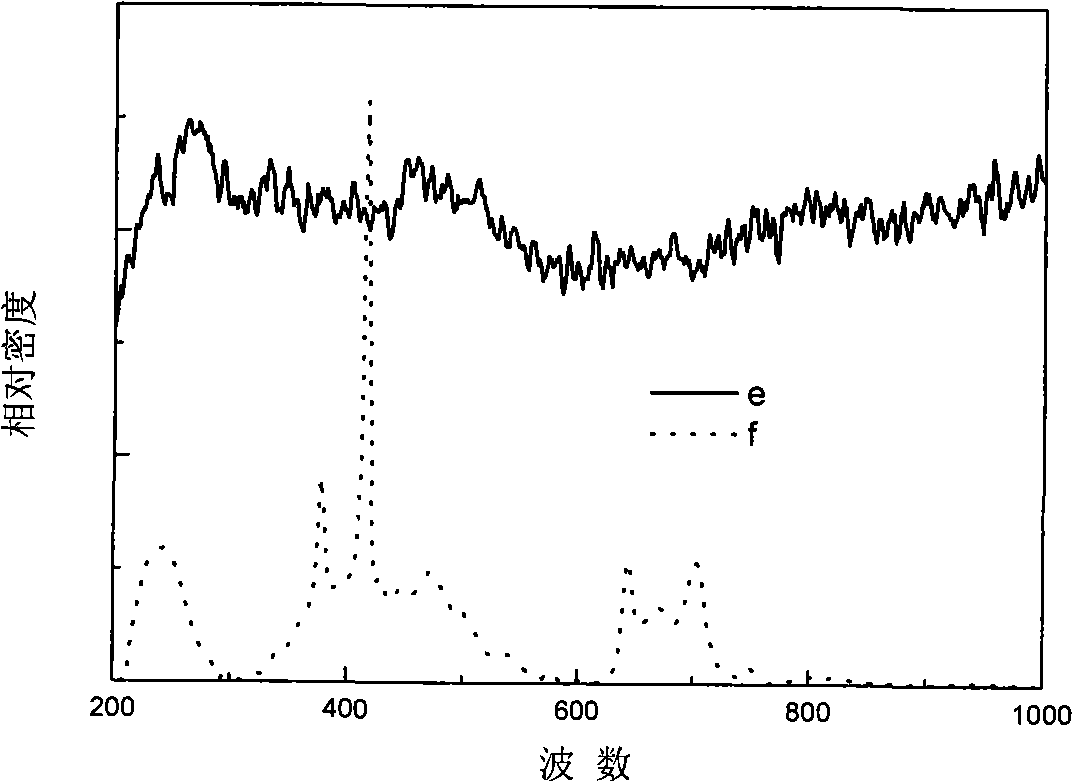

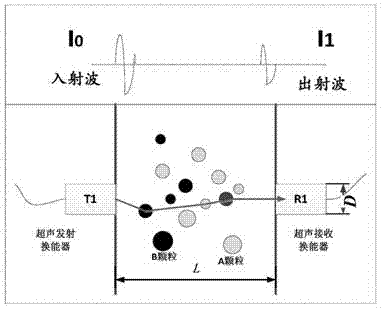

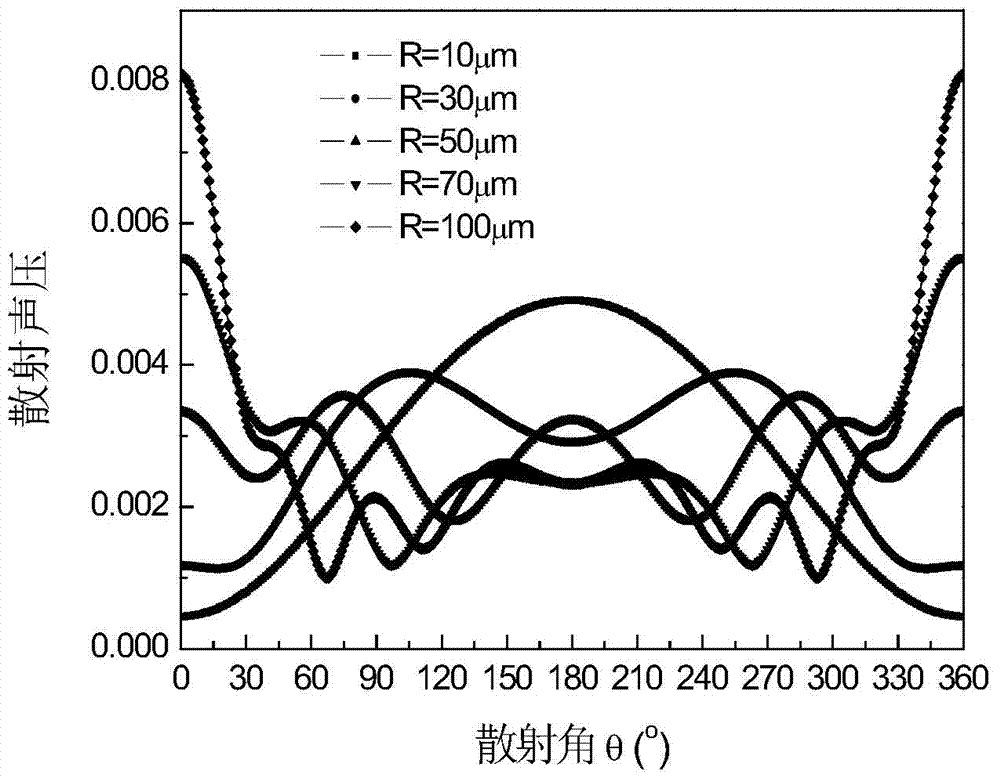

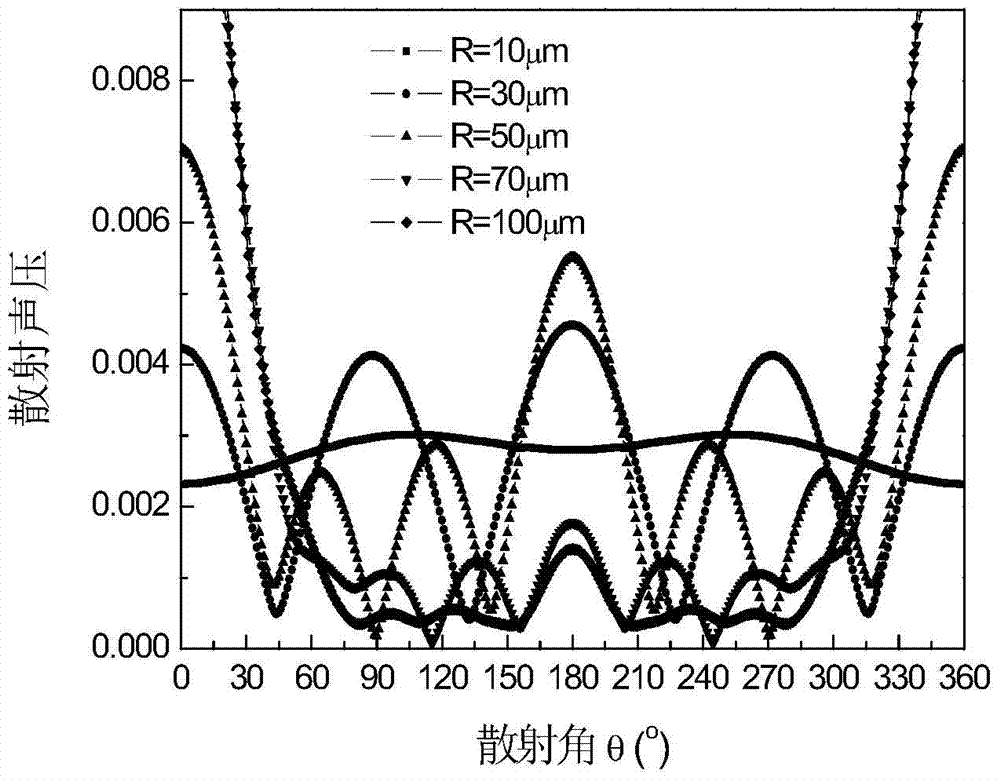

Ultrasonic attenuation spectrum based mixed solid particle size and concentration measurement method

InactiveCN104849183ASimple structureSmall structureParticle size analysisParticle suspension analysisSolid massUltrasonic attenuation

The invention relates to an ultrasonic attenuation spectrum principle based method for measuring the average particle size and concentration of two types of mixed solid particles in a liquid or gas medium. The ultrasonic attenuation spectrum principle based method comprises the following steps of step 1, measuring an experimental measurement ultrasonic attenuation spectrum alpha (f) under the condition that the two types of solid particles A and B are located in a measurement area, wherein f is the ultrasonic frequency; step 2, calculating an acoustic attenuation coefficient Kext of the particle and acoustic wave effect; step 3, determining whether the particles are A particles or B particles and determining whether phonons are absorbed or scattered through the acoustic attenuation coefficient; step 4, calculating a scattering emergence angle theta M1 of the scattered phonons; step 5, continuing to calculate a theoretical ultrasonic attenuation spectrum through a result of the step 4; step 6, establishing an objective function according to the theoretical ultrasonic attenuation spectrum and the experimental measurement ultrasonic attenuation spectrum to solve the particle size and volume concentration. The ultrasonic attenuation spectrum based mixed solid particle size and concentration measurement method can be applied to the two types of mixed solid particles and laboratory scientific research and the online measurement and the application of the industrial field can be implemented.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

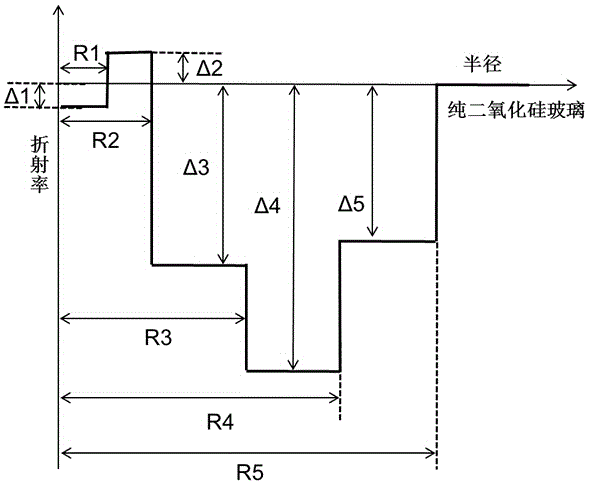

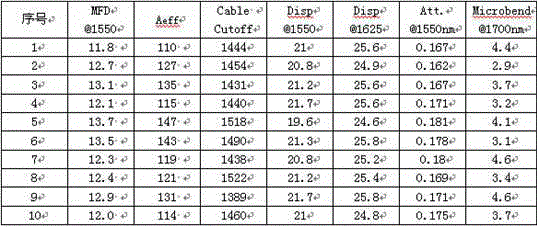

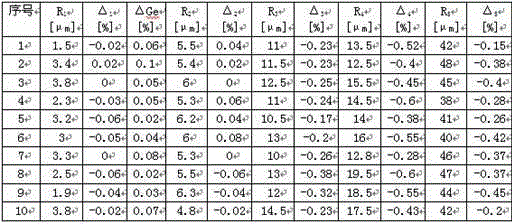

Single-mode optical fiber with ultralow attenuation and large effective area

ActiveCN104459876AReduce defectsReduce the attenuation factorOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

The invention relates to a single-mode optical fiber with ultralow attenuation and a large effective area. The single-mode optical fiber comprises a core layer and a wrapping layer and is characterized in that the core layer comprises a sinking core layer body and an outer core layer body from center to outside; the wrapping layer comprises an inner wrapping layer body, a sinking inner wrapping layer body, an auxiliary outer wrapping layer body and an outer wrapping layer body from inside to outside; the radius R1 of the sinking core layer body ranges from 1.5 Mum to 4 Mum, and the relative refractivity ranges from minus 0.10% to 0.02%; the radius R2 of the outer core layer body ranges from 4.5 Mum to 6.5 Mum, and the relative refractivity ranges from minus 0.08% to 0.10%; the radius R3 of the inner wrapping layer body ranges from 9 Mum to 15 Mum, and the relative refractivity ranges from minus 0.25% to minus 0.1%; the radius R4 of the sinking inner wrapping layer body ranges from 12 Mum to 20 Mum, and the relative refractivity ranges from minus 0.6% to minus 0.25%; the radius R5 of the auxiliary inner wrapping layer body ranges from 35 Mum to 50 Mum, and the relative refractivity ranges from minus 0.45% to minus 0.15%; the outer wrapping layer body is a pure silicon dioxide glass layer. The single-mode optical fiber has the large effective area and good bending loss and chromatic dispersion performance, the cabling cutoff wavelength is smaller than 1530 nm, and the production cost is low.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

Ultrasonic detection defect information acquisition method based on multi-wafer probe

ActiveCN102221579AHigh resolutionHigh sensitivityMaterial analysis using acoustic emission techniquesSonificationImage resolution

The invention relates to an ultrasonic detection defect information acquisition method based on a multi-wafer probe. The method comprises the following steps: a detected object is scanned by an ultrasonic probe with N wafers, the wafers are arranged uniformly, and each wafer has functions of transmission and reception; and a data matrix of probe sampling is obtained through controlling states of transmission and reception of each wafer in scanning, and defect characteristics can be reconstructed through the data matrix. In the invention, a mode of transmission by one wafer and reception by a plurality of wafers is formed in scanning by the array wafers, that is, any point on surfaces of a reflector corresponds to a plurality of measure informations for reconstructing the point, and reconstruction information of the whole reflector is finally obtained through synthesizing, so the resolution and the sensitivity are improved.

Owner:SUZHOU NUCLEAR POWER RES INST +2

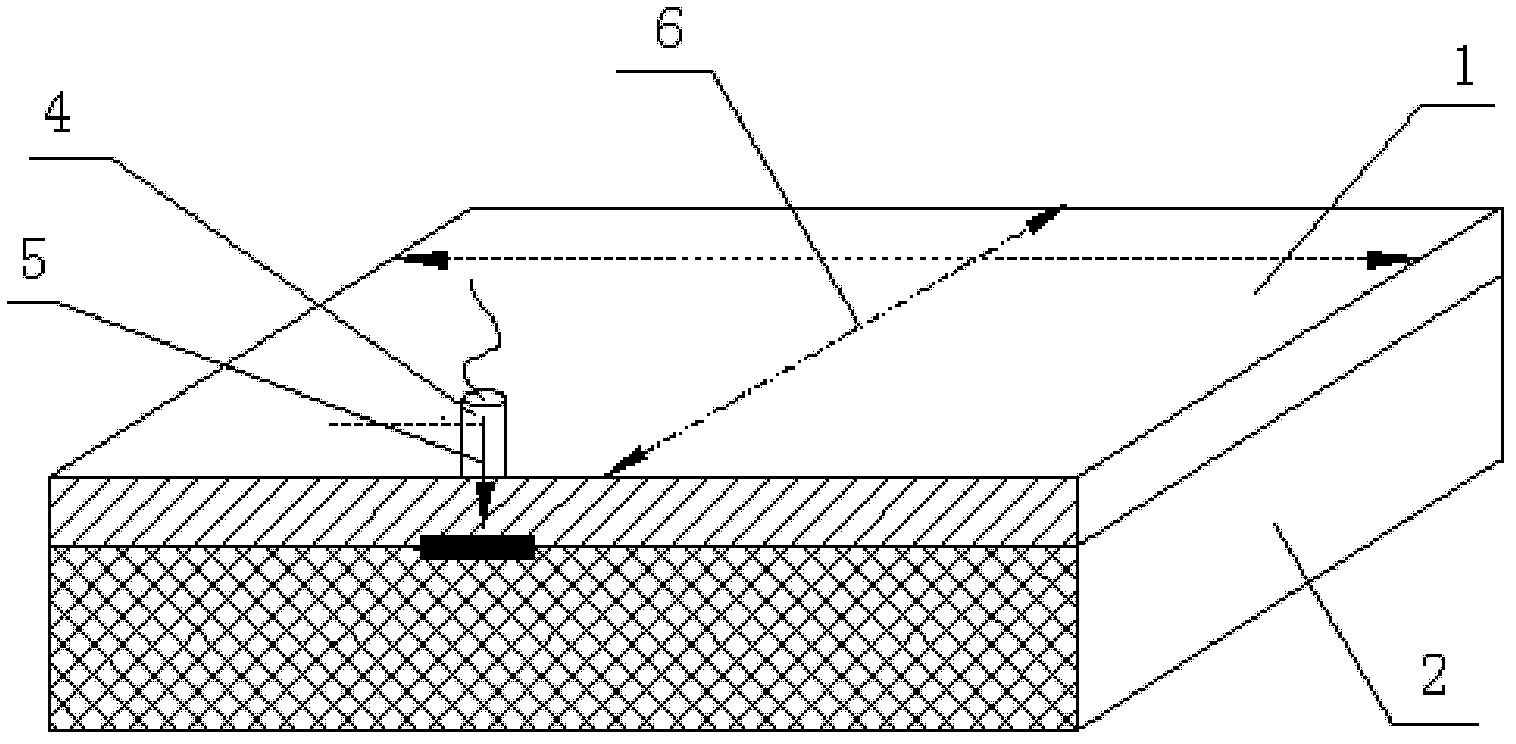

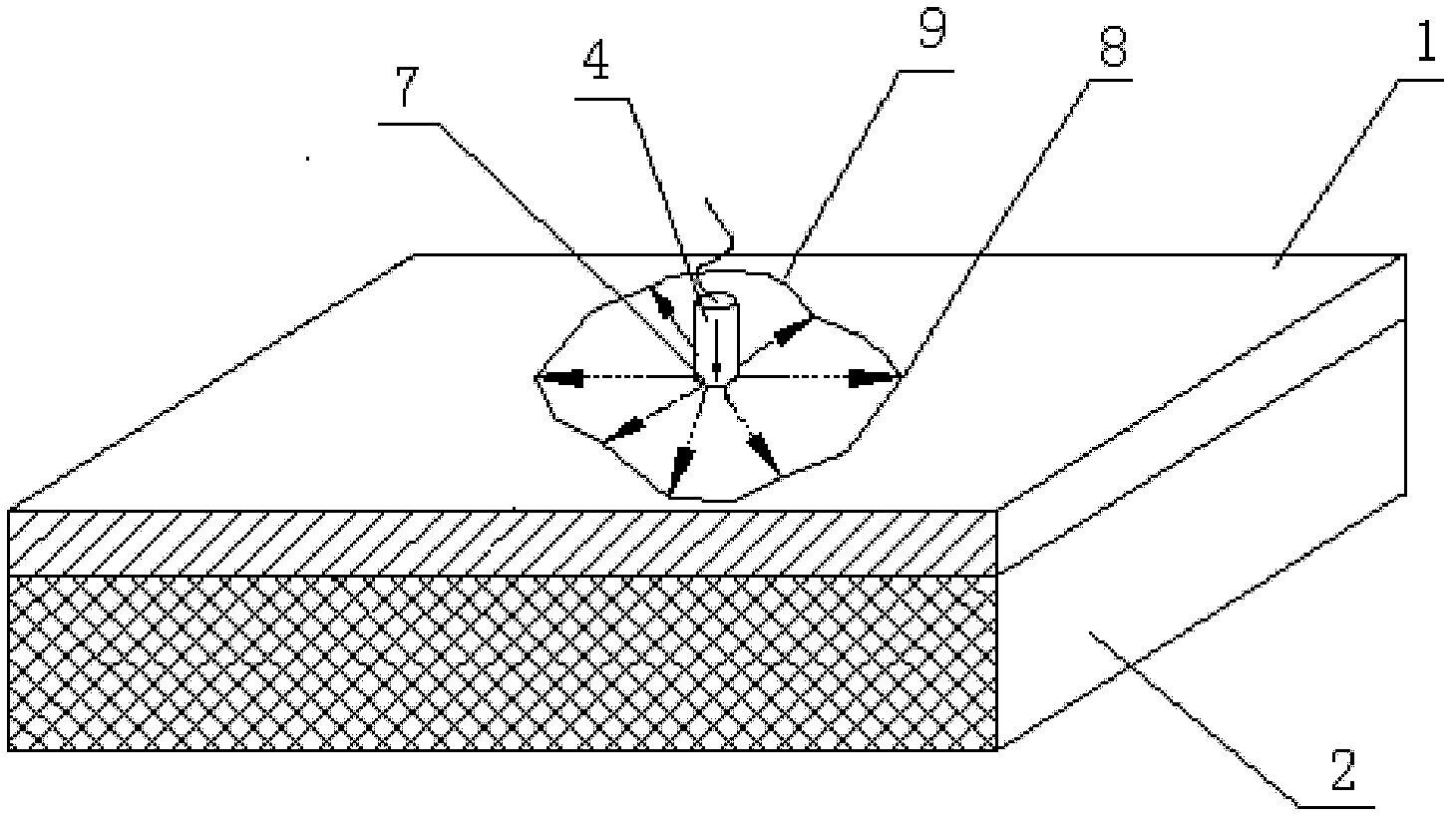

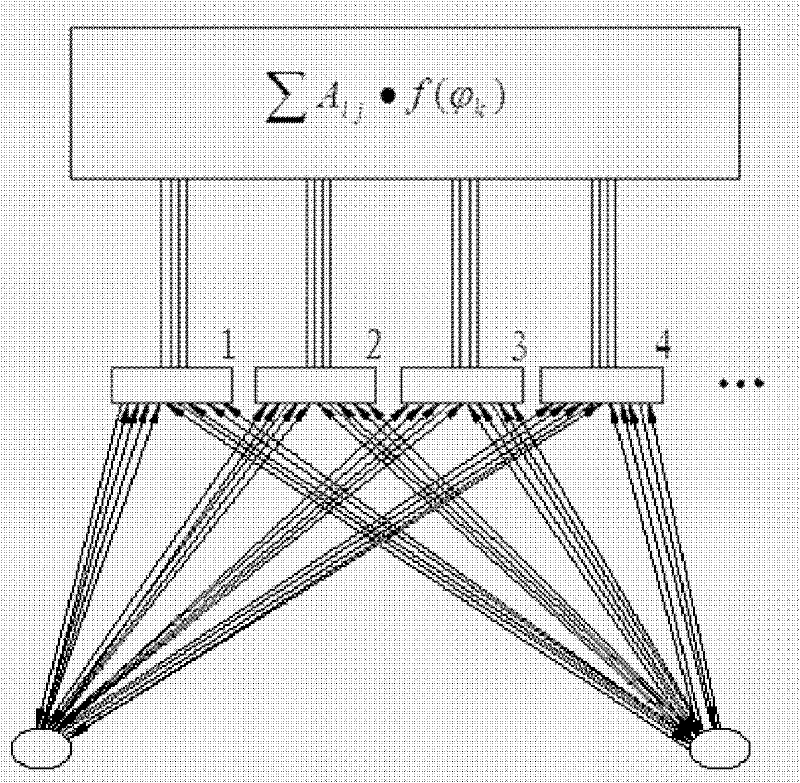

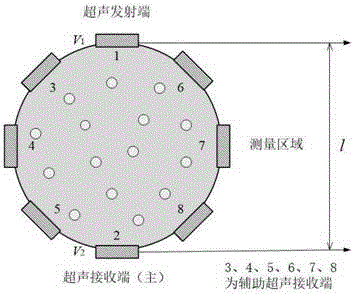

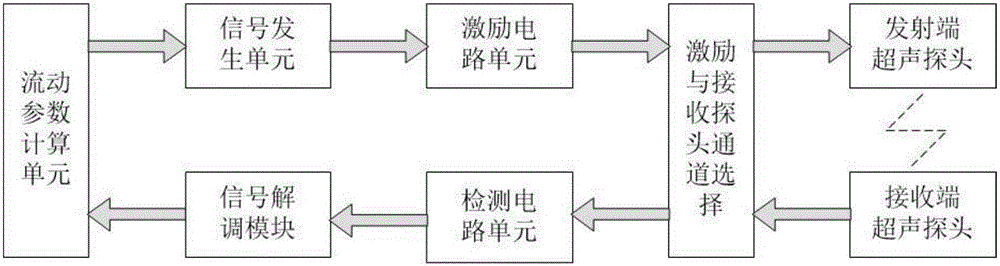

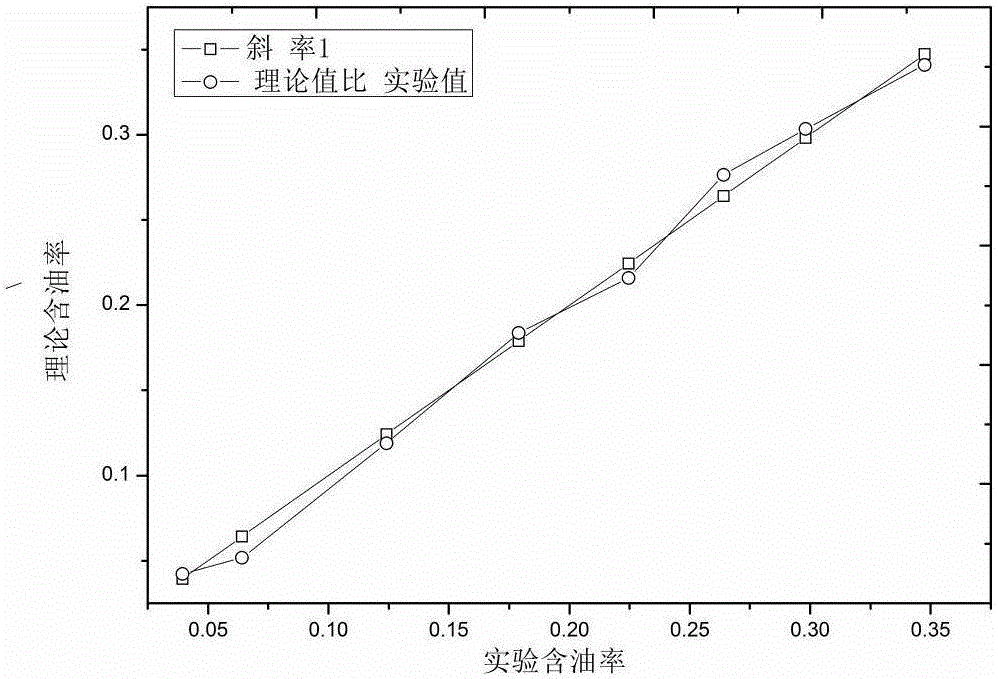

Method for measuring phase fractions of oil-water two-phase flows based on ultrasonic attenuation mechanism model

ActiveCN106226392AAvoid nonlinear responseNo corrosionMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasound attenuationDiffusion

The invention relates to a method for measuring the phase fractions of oil-water two-phase flows based on an ultrasonic attenuation mechanism model. According to the method, one main receiving sensor and six auxiliary ultrasonic receiving sensors are adopted. The method comprises the following steps: setting a detection signal of the main receiving sensor as V2, respectively setting detection signals of the six auxiliary ultrasonic receiving sensors as V3......V8, and calculating the ultrasonic intensity attenuation of the detection signals V2, V3......V8 and a drive signal V1; calculating the sum of a total ultrasonic attenuation coefficient of an oil-water two-phase-flow fluid and the ultrasonic diffusion attenuation amount of each auxiliary ultrasonic receiving sensor; detecting transit time from a time point when the drive signal is emitted by a signal emitting sensor to a time point when the signal is received by the main receiving sensor; calculating an oil-water two-phase scattering parameter; and calculating each phase fraction of the oil-water two-phase flows. By virtue of the method, the estimation precision of the moisture content can be increased.

Owner:TIANJIN UNIV

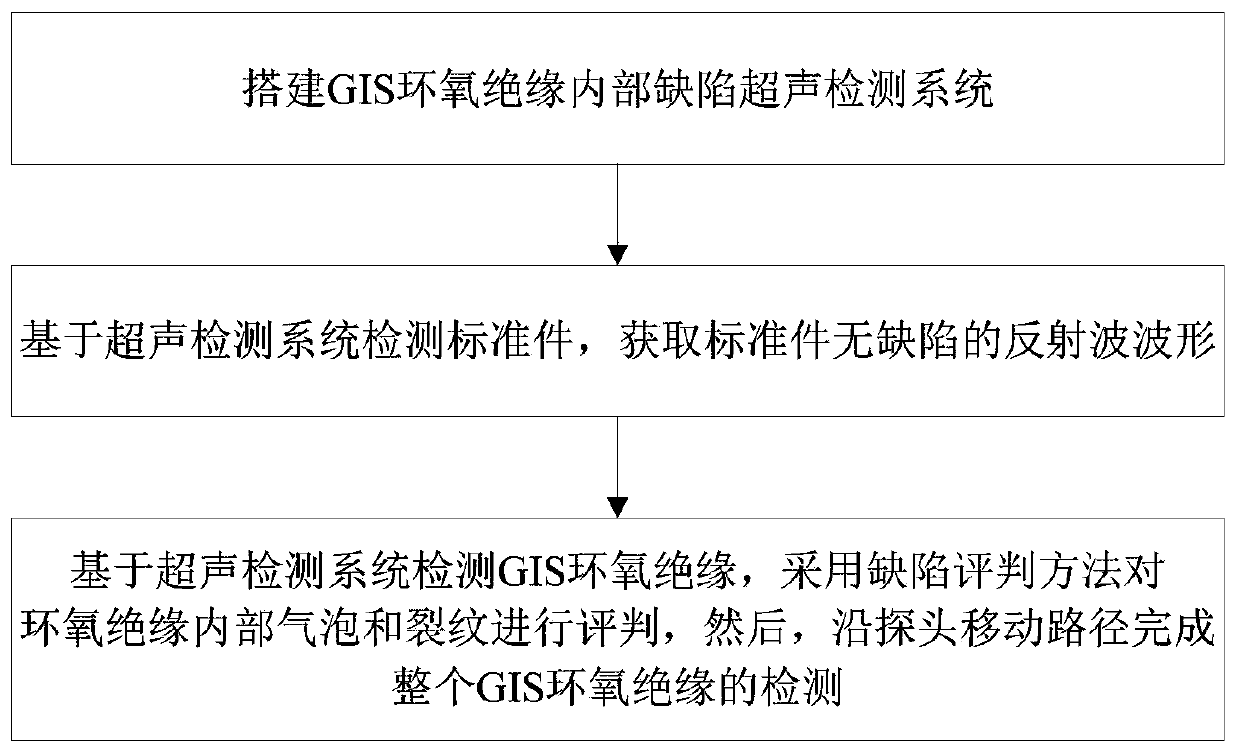

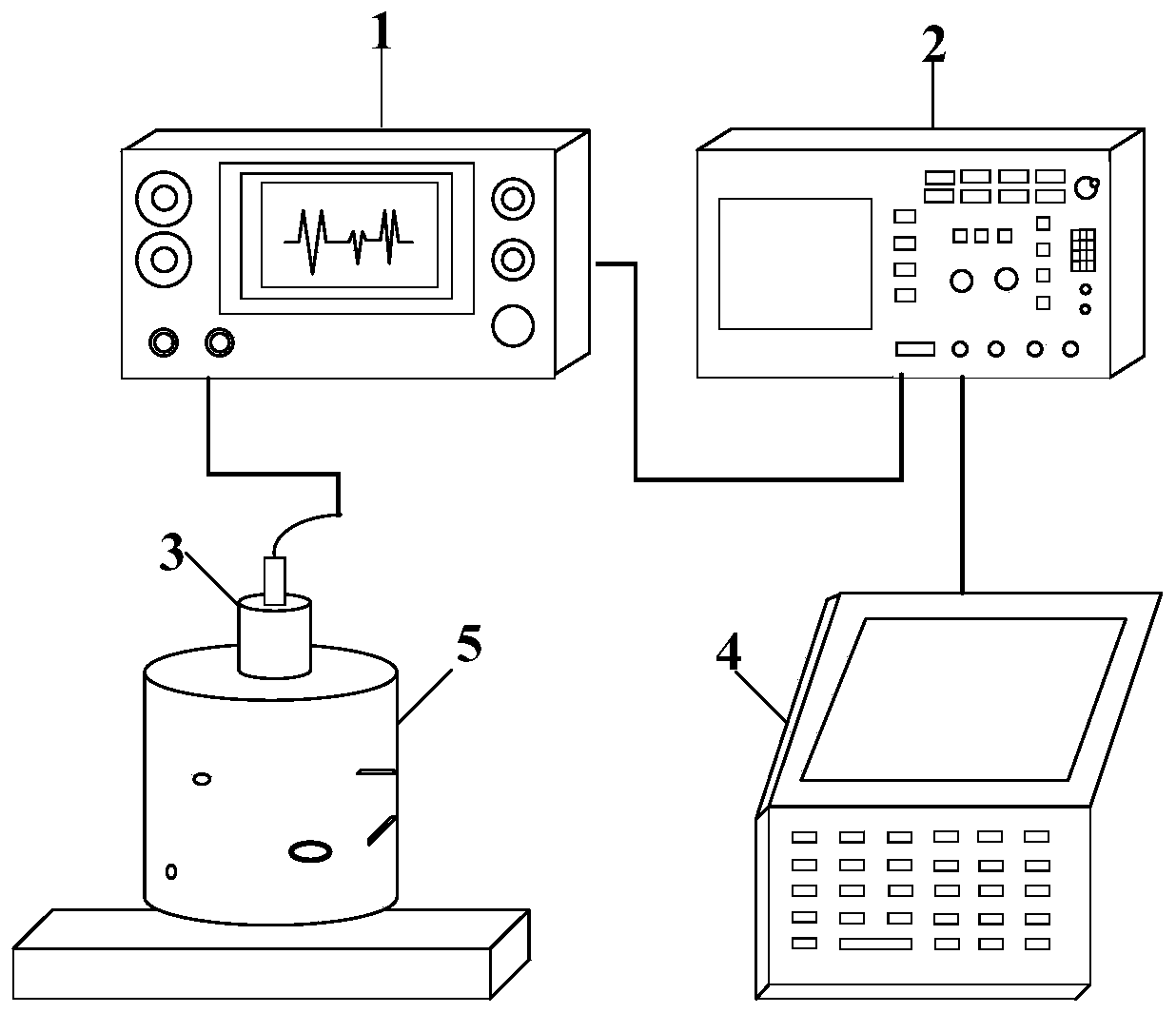

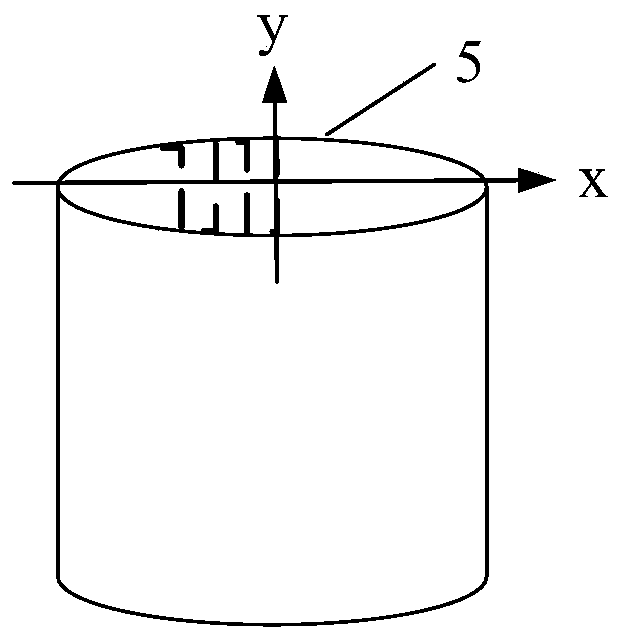

Ultrasonic testing method and ultrasonic testing system for internal defects of GIS epoxy insulator

InactiveCN110243935AImprove detection accuracyImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveUltrasonic attenuation

The invention belongs to the technical field of power transmission and transformation insulation equipment, and relates to an ultrasonic testing method and an ultrasonic testing system for internal defects of a GIS epoxy insulator. The ultrasonic testing method for internal defects of the GIS epoxy insulator comprises the following steps: constructing the ultrasonic testing system for internal defects of the GIS epoxy insulator; testing a testing standard component based on the ultrasonic testing system, and obtaining a non-defective reflected wave waveform of the standard component; testing the GIS epoxy insulator based on the ultrasonic testing system, judging interior bubbles and cracks of the epoxy insulator by using a defect judgment method, and then continuously testing the GIS epoxy insulator along the moving path of a probe. The method is high in testing precision and efficiency and accurate in defect positioning, small-sized bubbles and cracks can be tested, and the method can be used for pre-delivery inspection of insulators and also can be used for assembling field test of insulators. The ultrasonic testing system for internal defects of the GIS epoxy insulator comprises an ultrasonic instrument, an oscilloscope, an ultrasonic longitudinal wave normal probe, a computer and the GIS epoxy insulator. The system is low in cost, small in equipment volume, high in testing precision and efficiency and accurate in defect positioning.

Owner:SOUTH CHINA UNIV OF TECH

Method for performing ultrasonic testing

ActiveUS20110090935A1Thermometer detailsMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic attenuationThermal expansion

A method for performing ultrasonic testing comprising, in one embodiment, the steps of firing an ultrasonic transducer to generate an ultrasonic pulse that passes through a delay line, measuring a delay echo time of flight, and determining the temperature of the delay line using the delay echo time of flight, thereby eliminating the need for additional temperature measuring devices. Other embodiments further comprise the step of using the temperature of the delay line to determine the temperature of a test object, and using the temperature of the test object to determine a thickness of the test object that is compensated for thermal expansion and temperature dependent ultrasonic velocity.

Owner:GE INSPECTION TECH LP

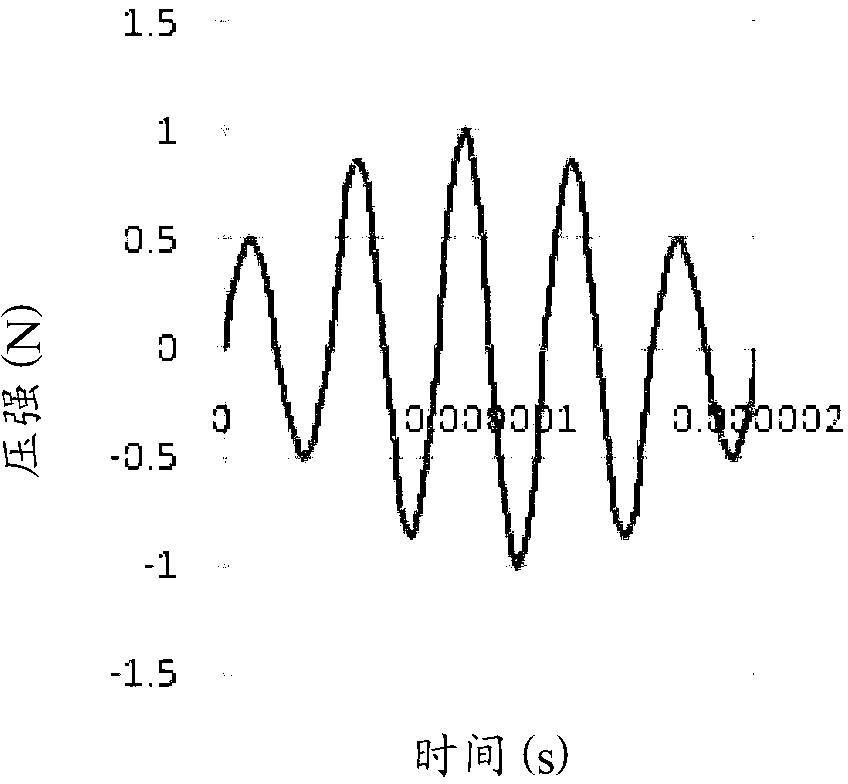

Microcosmic simulated analysis method for ultrasound attenuation coefficient of composite material with holes

ActiveCN103279609AAvoid regretsClear thinkingSpecial data processing applicationsUltrasound attenuationAttenuation coefficient

The invention provides a microcosmic simulated analysis method for an ultrasound attenuation coefficient of a composite material with holes. The method includes a first step of inputting modeling parameters to DIGIMAT software according to hole features of the composite material and building a microcosmic geometric model, a second step of introducing the microcosmic geometric model in the step a to ABAQUS software, conducting constraint on the composite material, dividing the composite material to form meshes and building a finite element model, a third step of exerting ultrasonic wave stimulation on the composite material in a simulated mode, a fourth step of storing model data and conducing ultrasound attenuation simulation calculation, and a fifth step of extracting a pressure intensity field distribution cloud picture, conducting result representation on the ultrasound attenuation of the corresponding model under the condition that the hole features exist and obtaining the ultrasound attenuation coefficient by conducting calculation on ultrasonic wave sound pressure distribution in different positions. The microcosmic simulated analysis method for the ultrasound attenuation coefficient of the composite material with holes can reflect a real microstructure and microcosmic material attributes of the composite material, can obtain a quantitative relation between the ultrasound attenuation coefficient and a pore rate, and provides an important theoretical basis and a technological base for nondestructive testing of the hole rate of the composite material.

Owner:SHANGHAI AIRCRAFT MFG +1

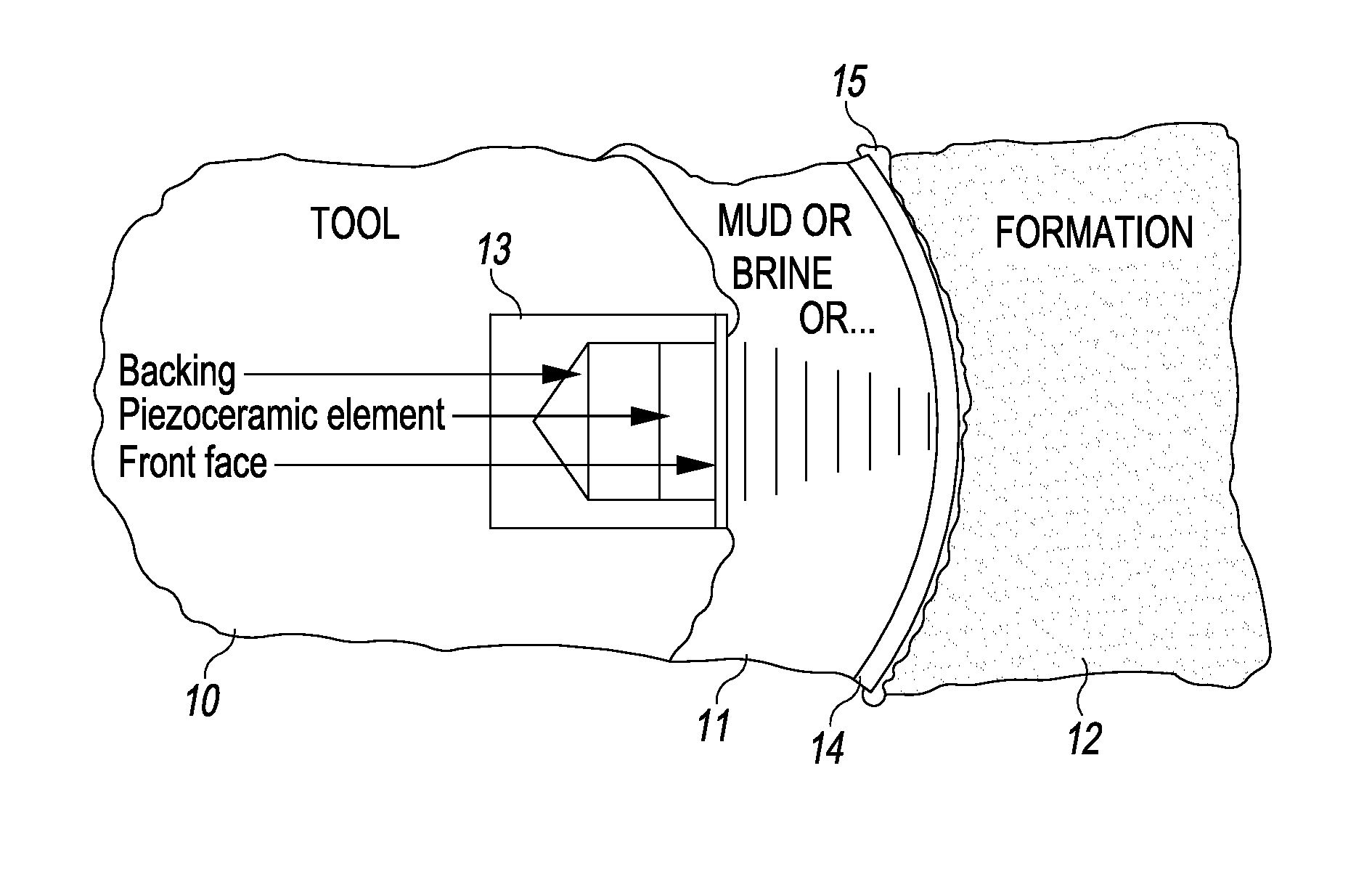

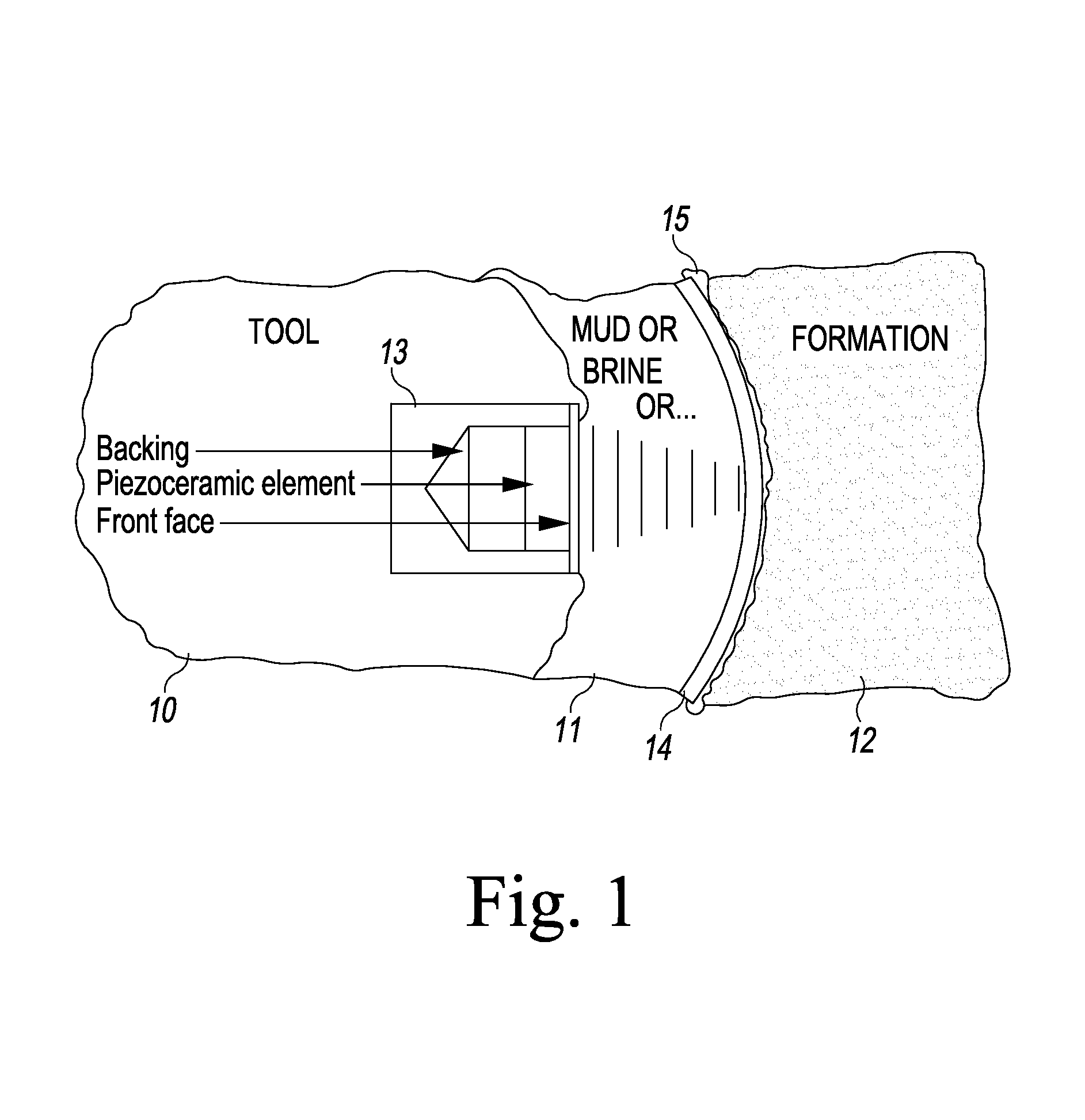

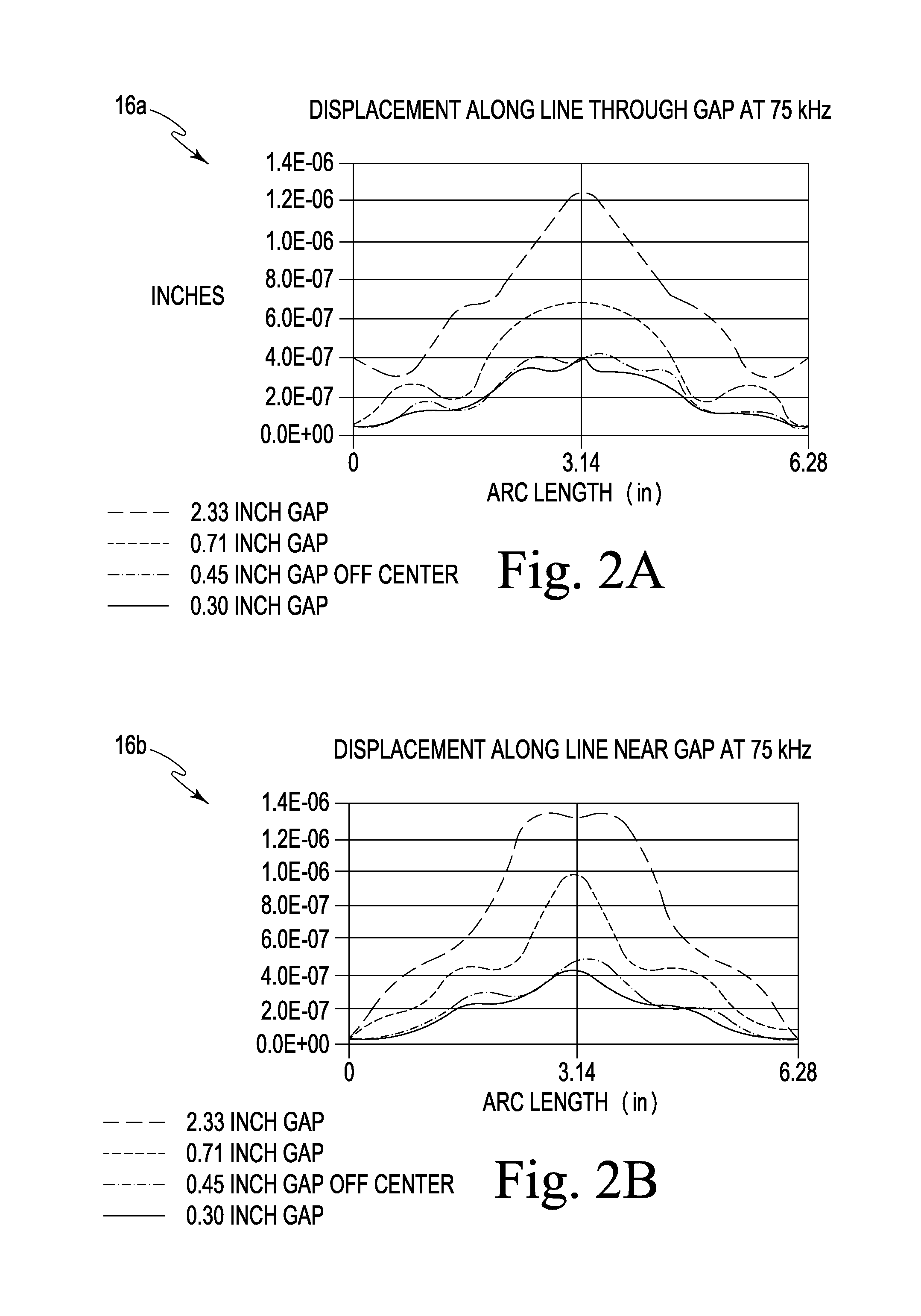

Low frequency broad band ultrasonic transducers

InactiveUS20130342077A1Wide frequency rangeWave based measurement systemsPiezoelectric/electrostriction/magnetostriction machinesTime delaysUltrasonic attenuation

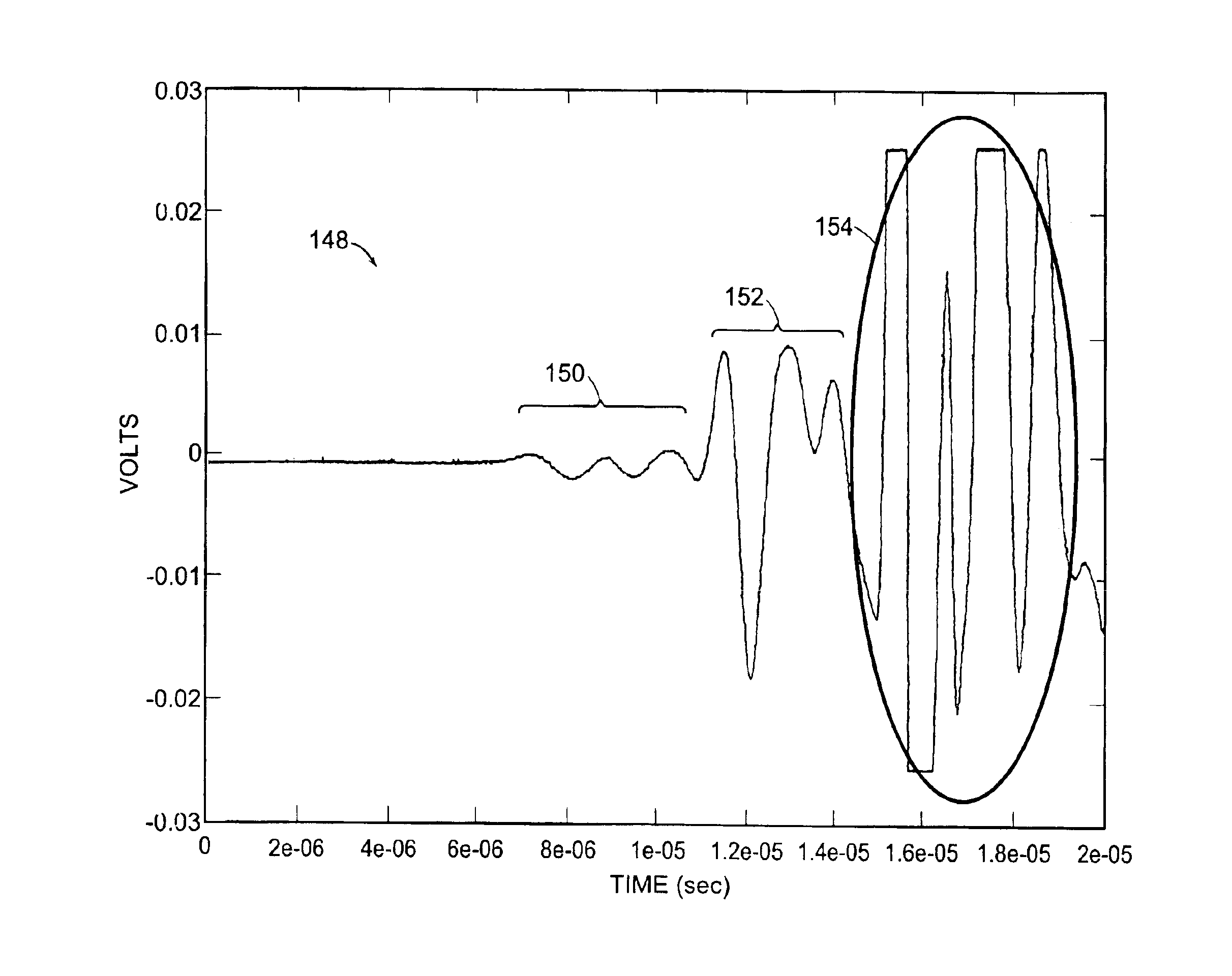

Low frequency pulse-echo ultrasonic transducers are provided especially suited for use in downhole cement bond evaluation, but usable for various applications. One frequency pulse-echo ultrasonic transducer comprises a transducer stack having alternating layers of a piezoceramic element and an ultrasonic attenuating element that is preferably acoustic impedance matched to the piezoceramic elements in order to reduce the Q of the transducer stack. Another low frequency pulse-echo ultrasonic transducer comprises an assembly having the present transducer stack disposed on an acoustic attenuating backing and a front face. Yet another low frequency pulse-echo ultrasonic transducer comprises a transducer composite made from a lead metaniobate. Still another frequency pulse-echo ultrasonic transducer comprises a composite stack. A further low frequency pulse-echo ultrasonic transducer comprises a composite stack, wherein multiple drive elements allow driving individual elements at different times. The transducers may be driven in a multiple-pulse time delayed manner.

Owner:PIEZO TECH

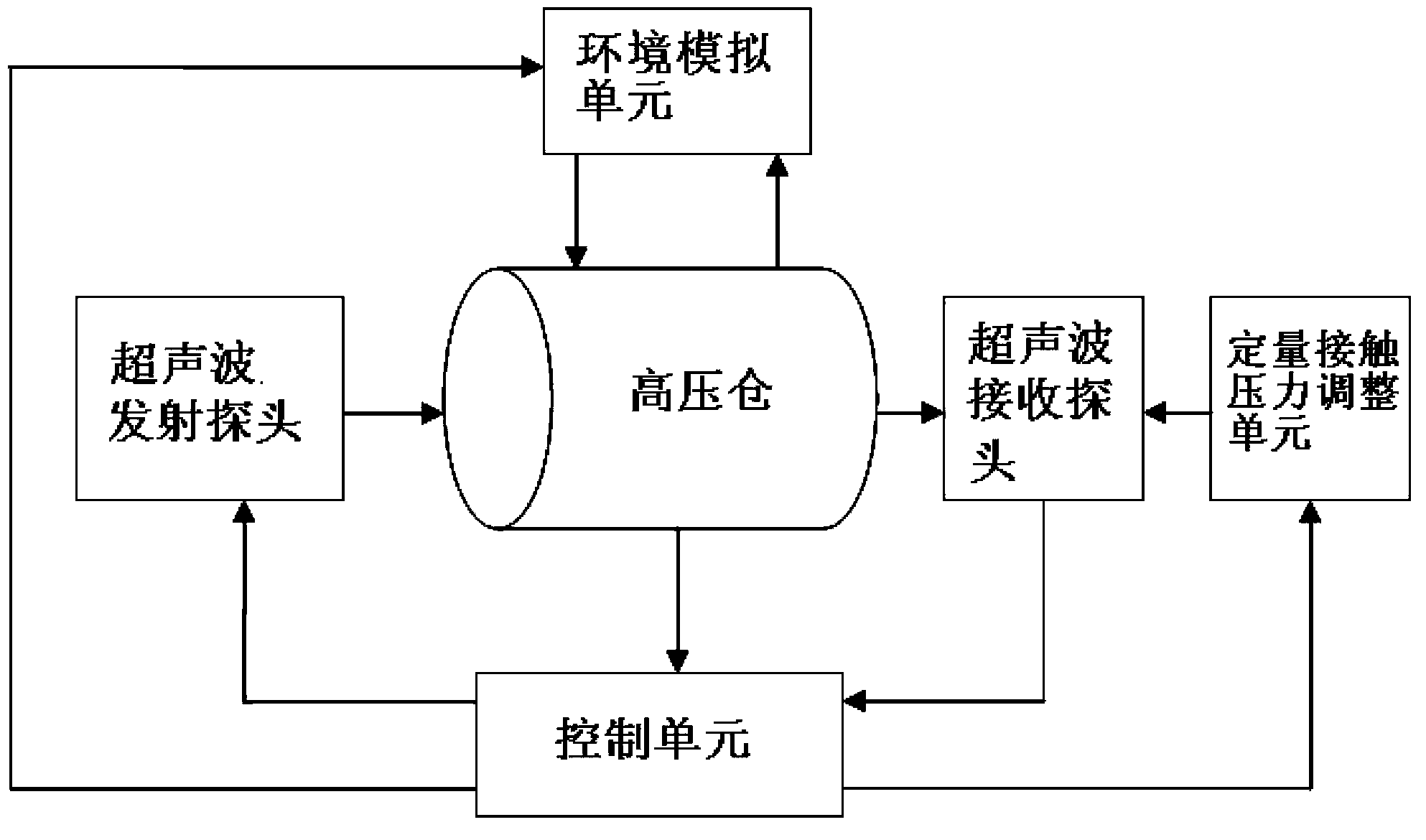

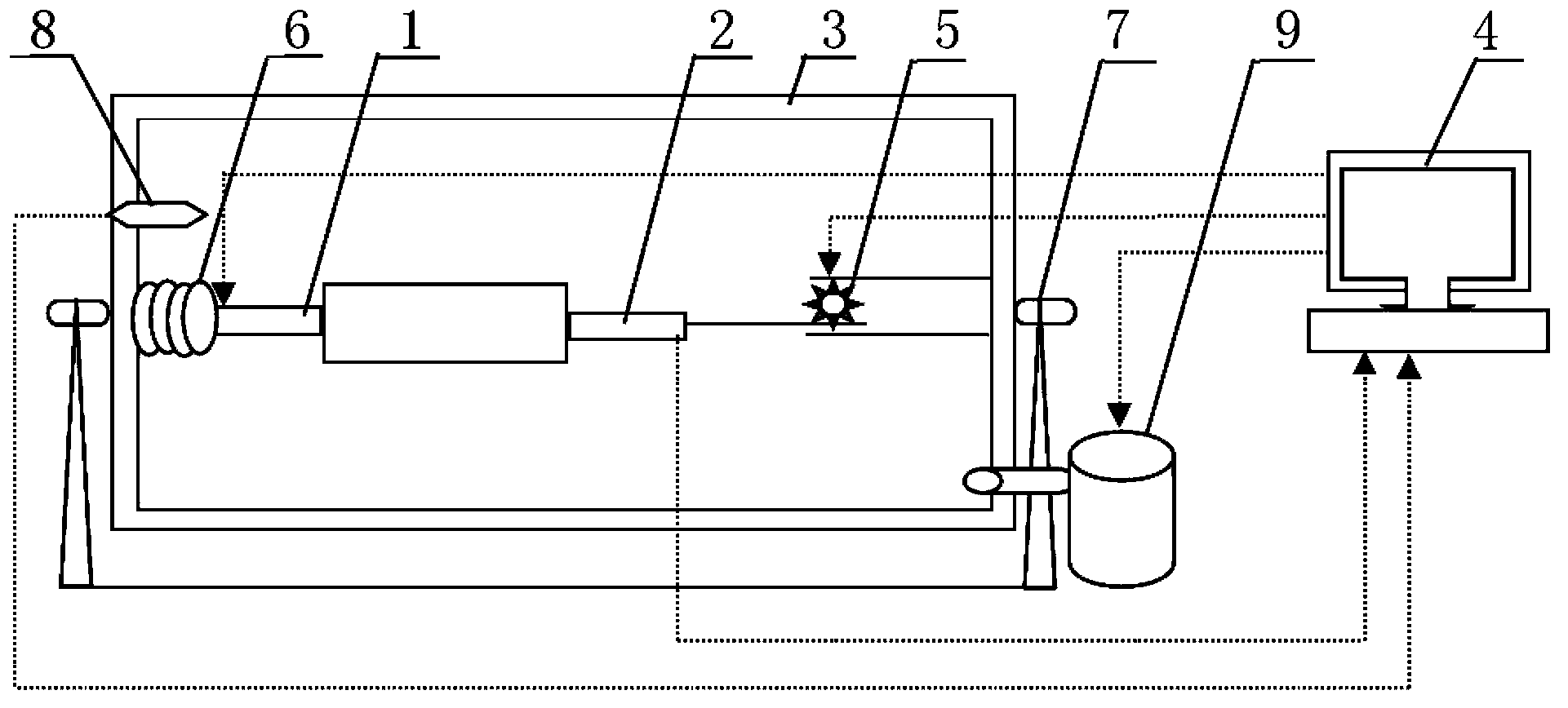

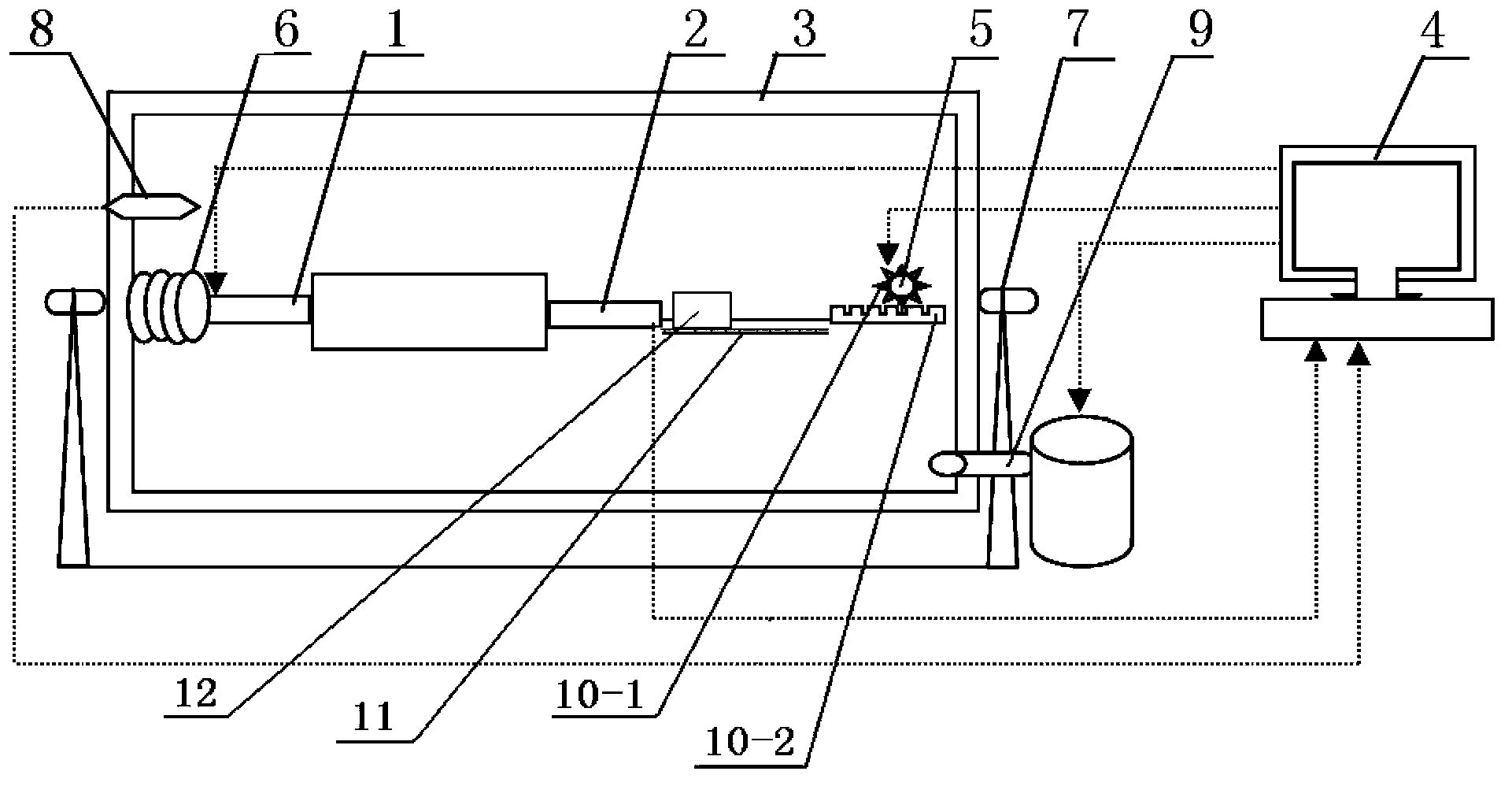

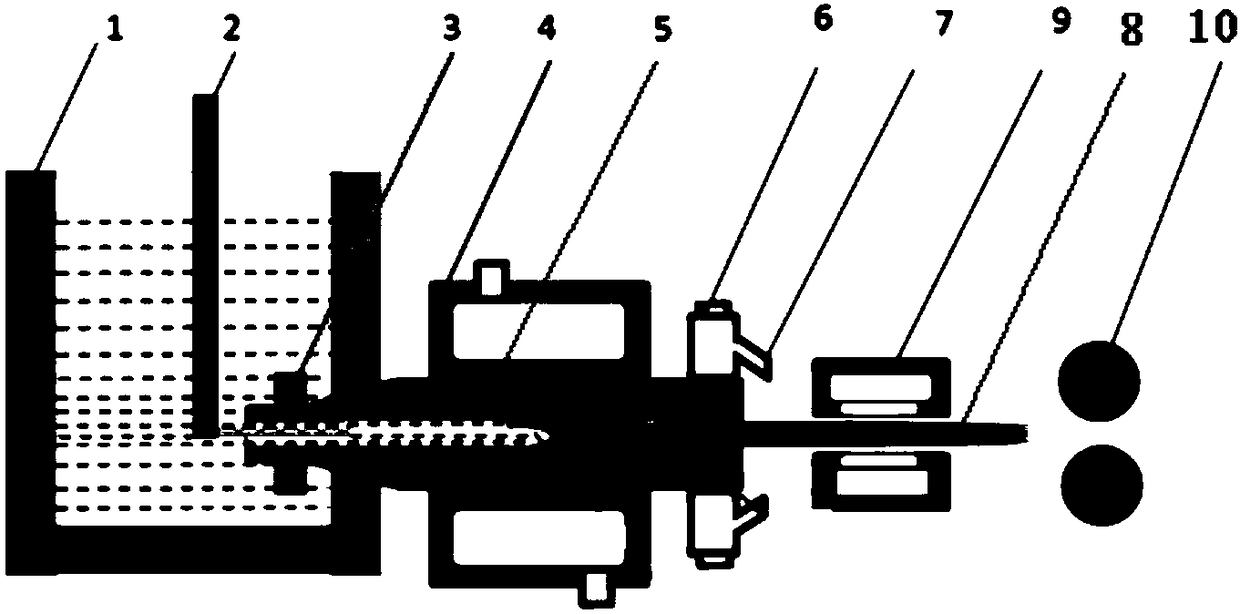

Ultrasonic detection system of quantitative contact pressure, and detection method thereof

ActiveCN103698397AReflect gradientReflect mutation processAnalysing solids using sonic/ultrasonic/infrasonic wavesContact pressureMotor drive

The invention relates to an ultrasonic detection system of a quantitative contact pressure, and a detection method thereof. The detection system comprises an ultrasonic probe, a high pressure cabin, a quantitative contact pressure adjusting unit, an environment simulation unit and a control unit; the quantitative contact pressure adjusting unit comprises a step motor and a transmission part; the motor drives the transmission part to be connected with the ultrasonic probe to realize tight coupling of a rock sample for detection and an ultrasonic receiving probe; the environment simulation unit comprises a heating module and a pressurizing module; and the heating module and the pressurizing module are connected with the high pressure cabin. The detection method is characterized in that the control unit controls the environment simulation unit and the quantitative contact pressure unit to complete the heating and pressurizing operation of the high pressure cabin and the ultrasonic detection; and a best contact point is obtained. In the invention, the nondestructive dynamic test of rocks having a high temperature and a high pressure can be carried out, a best ultrasonic detection signal can be obtained, and the gradual change and abrupt change processes of the internal structure of the sample can be finely reflected.

Owner:CHINA PETROLEUM & CHEM CORP +1

CuNiSn series alloy and strip billet composition external field horizontal continuous casting preparation method and device

The invention discloses a CuNiSn series alloy and strip billet composition external field horizontal continuous casting preparation method and device. A CuNiSn series alloy is in a Cu matrix, and meanwhile contains microalloying elements comprising B, Sr and V. The content sum of the microalloying elements comprising B, Sr and V is smaller than or equal to 0.3% of the mass of a CuNiSn series elastic copper alloy matrix. The preparation method comprises the steps of alloy melting and horizontal continuous casting. The technological process of horizontal continuous casting comprises stretching,primary standstill, reverse push, secondary standstill and stretching. The outlet end of a crystallizer of the horizontal continuous casting equipment is provided with a nitrogen nozzle which forms agas curtain on the periphery of a strip billet. An ultrasonic generator sealed by a boron nitride ceramic casing pipe with high heat resistance and low ultrasonic attenuation is further arranged in aheat insulation furnace. The inlet of the crystallizer is annularly sleeved with an electromagnetic induction coil. The prepared CuNiSn series elastic copper alloy has the characteristics of super strength, high stress relaxation resistance and the like, and is applicable to high-performance conductive elastic devices for spaceflight, aviation and microelectronics industry.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com