Device and method for ultrasonic testing of corrugated pipe duck grouting compactness

A technology of channel grouting and ultrasonic inspection, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve problems such as inability to achieve accurate measurement purposes, and achieve the effects of easy portability, accurate judgment, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

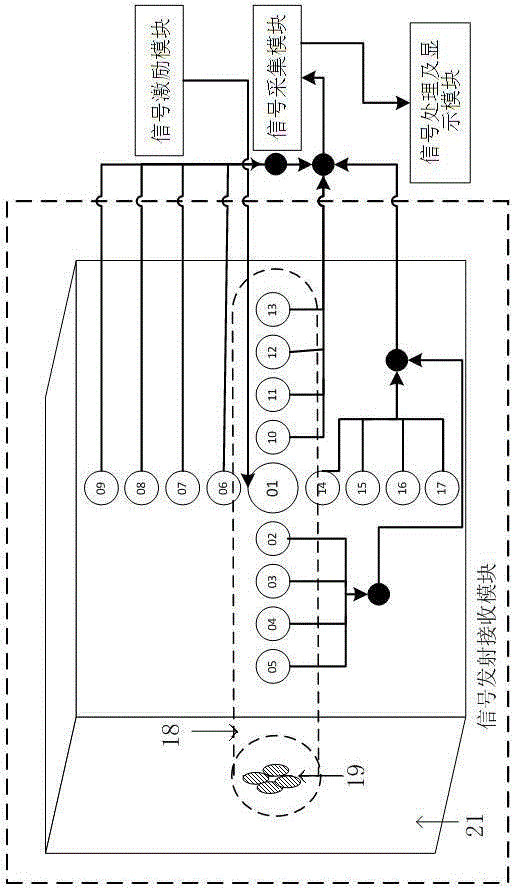

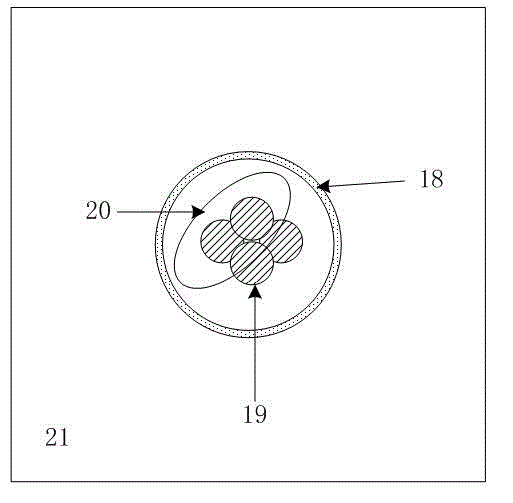

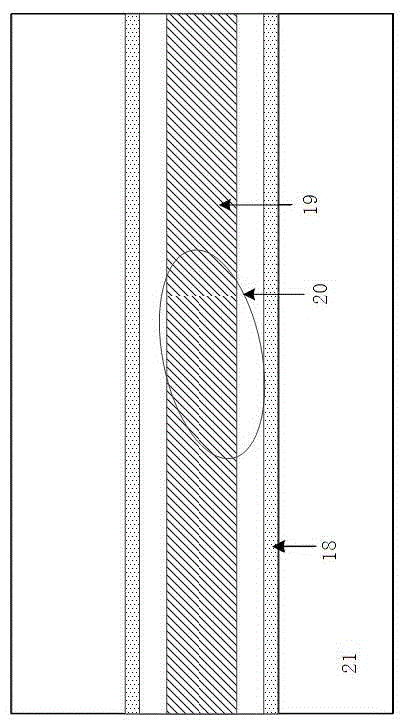

[0038] Such as figure 1 , figure 2 with image 3 As shown, the detection device of the present invention includes: a signal excitation module; a signal transmitting and receiving module; a signal acquisition module; a signal processing and display module for processing and displaying the received ultrasonic signal, and the signal processing and display module adopts the ultrasonic signal received by the signal processing and display module Correlation operations draw the image to determine the maximum value, thereby determining the position and relative size of the defect 20 .

[0039] The excitation signal module consists of a signal generation module with a square wave signal generator as the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com