Patents

Literature

145 results about "Ultrasonic velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic interferometer is a simple device which yields accurate and consistent data, from which one can determine the velocity of ultrasonic sound in a liquid medium. Ultrasonic sound refers to sound pressure with a frequency greater than the human audible range (20Hz to 20 KHz).

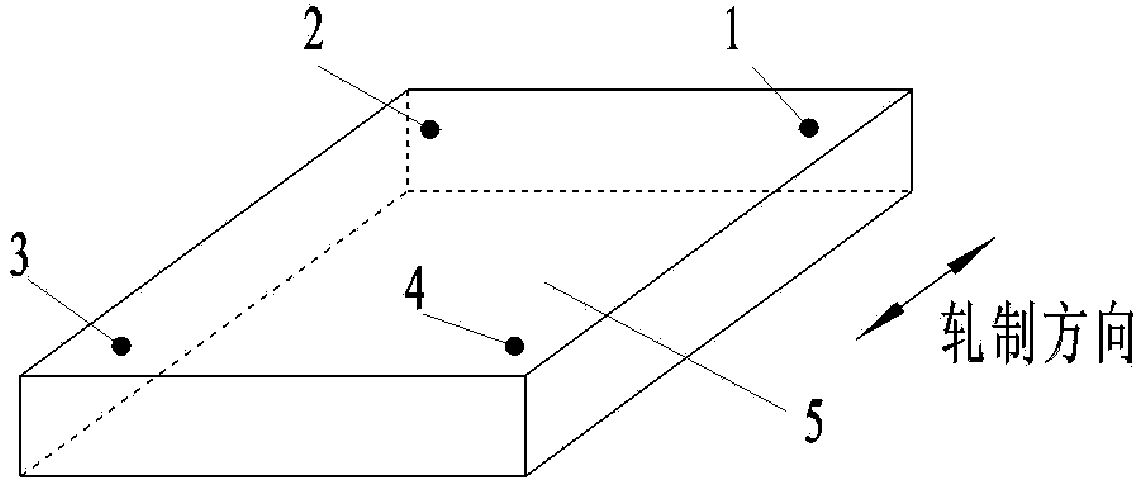

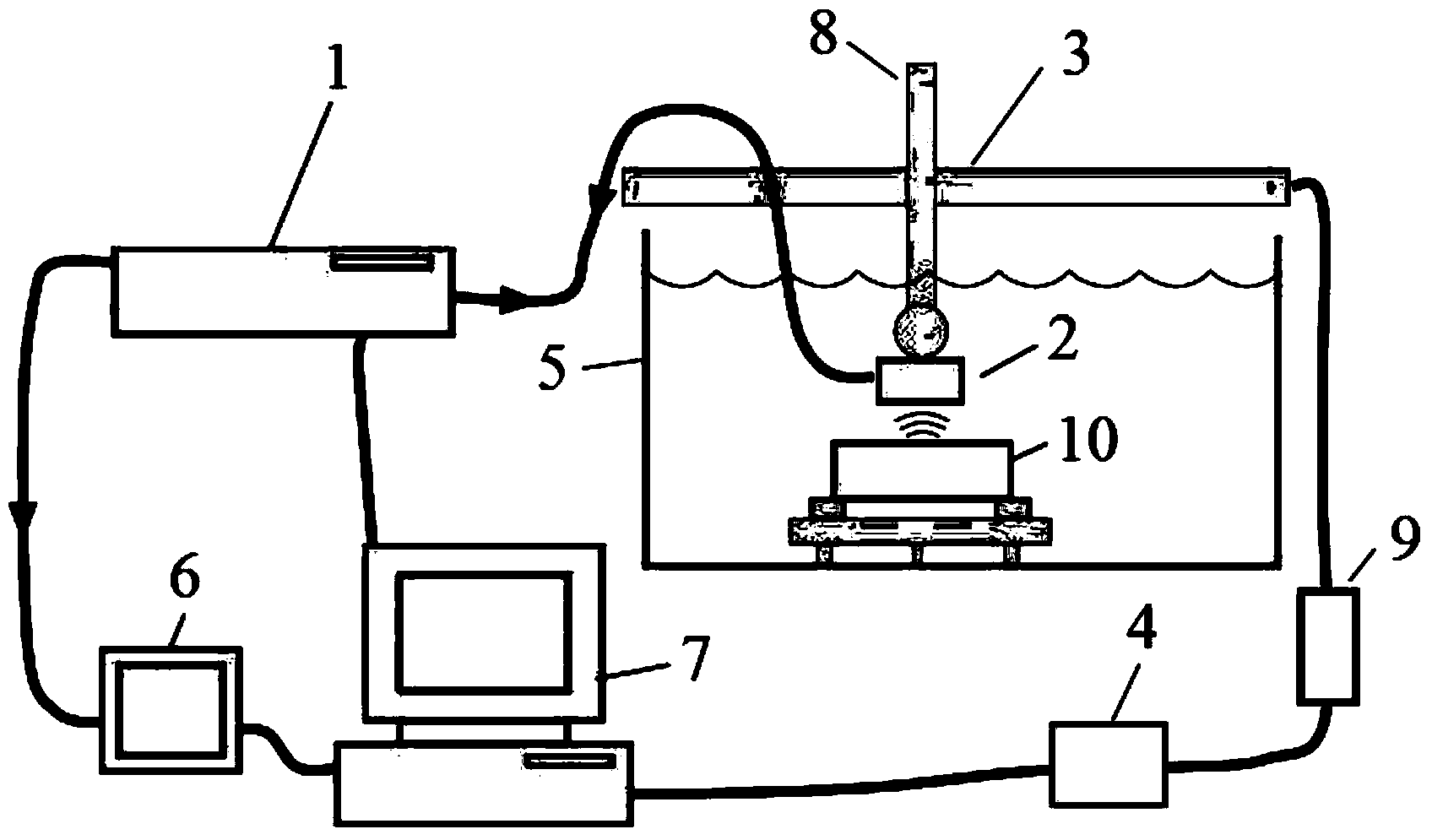

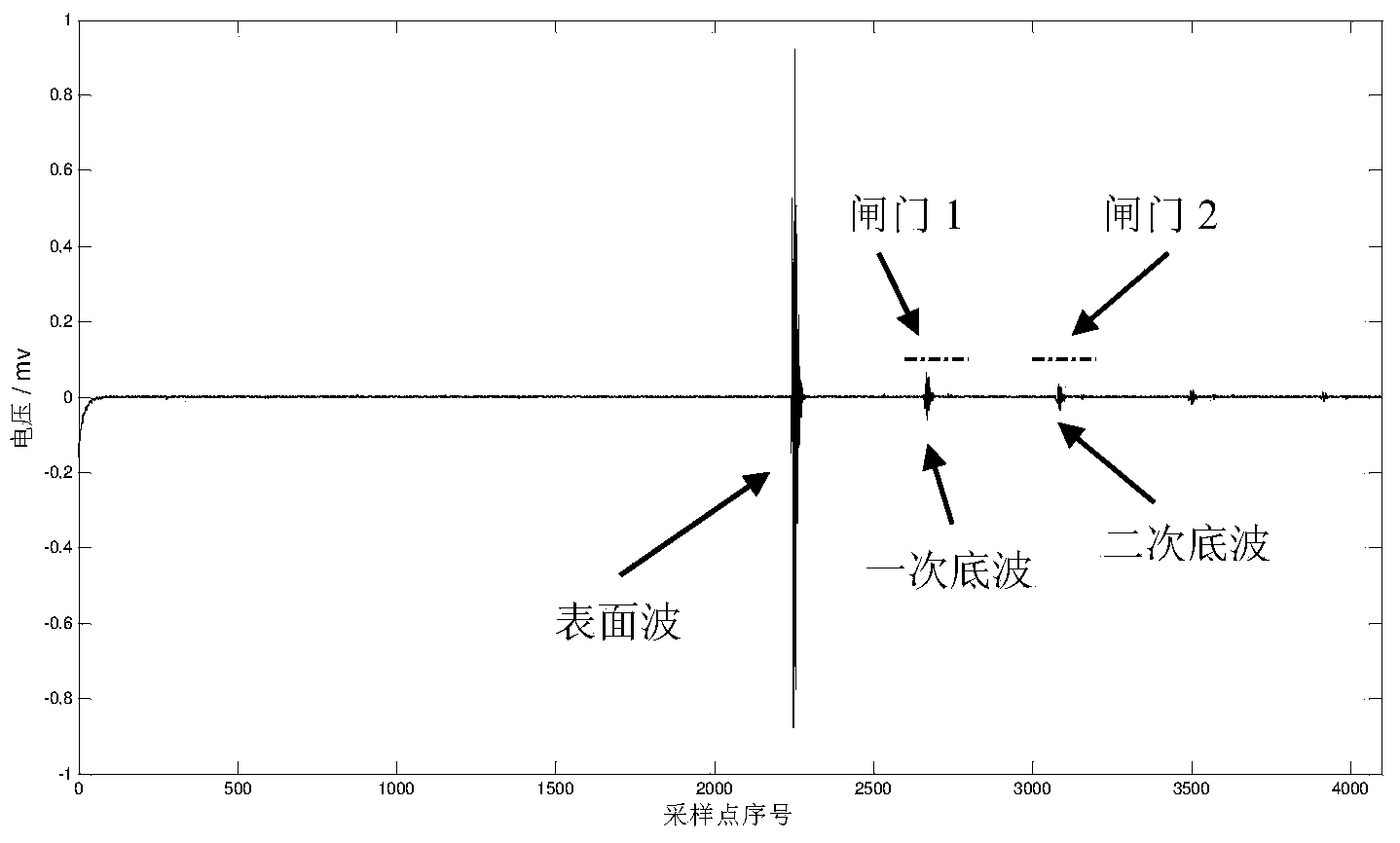

Method for carrying out ultrasonic inspection on residual stress of aluminium alloy pre-stretching board by water immersion

ActiveCN103543206AGood for non-destructive evaluationThe detection process is fastAnalysing solids using sonic/ultrasonic/infrasonic wavesStress measurementWater immersion

The invention provides a method for carrying out ultrasonic inspection on residual stress of an aluminium alloy pre-stretching board by water immersion, belonging to the field of non-destructive inspection. The method comprises the following steps of preparing a reference block; carrying out measurement and calibration; measuring the residual stress. In the method, the water immersion method is adopted, and the temperatures in stress calibration and stress measurement processes can be ensured to be consistent by controlling the water temperature not to be changed, thus eliminating the effects of temperature difference on the ultrasonic wave speed and eliminating temperature errors; besides, an automatic scanning frame is adopted instead of manual scanning, so that the distance between a probe and the surface of a material to be measured in the measurement process can be ensured not to be changed, thus eliminating the effects of coupling condition difference on sound propagation time and eliminating the coupling errors. The method is beneficial to non-destructive evaluation of the near surface residual stress of the aluminium alloy pre-stretching board.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

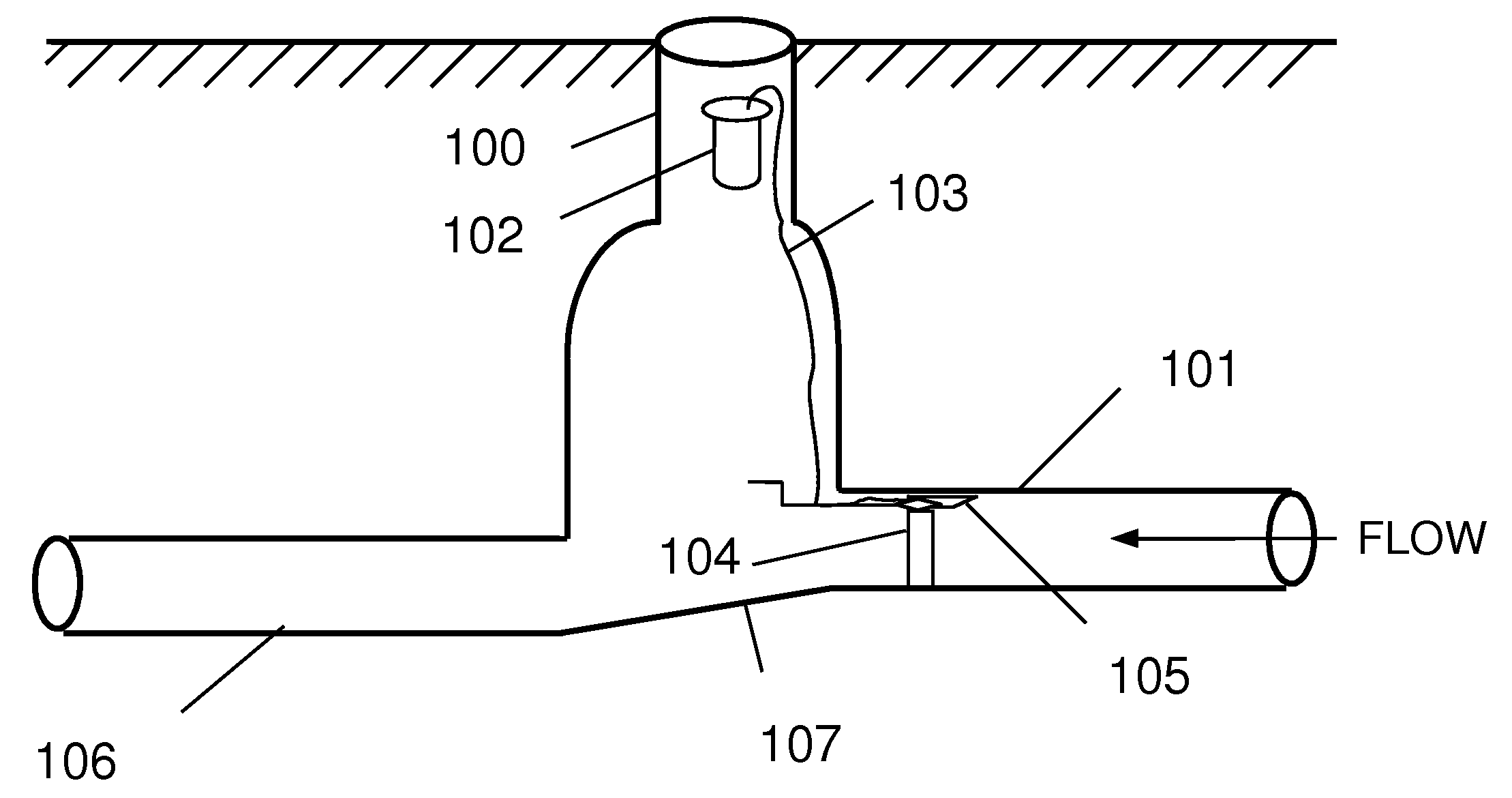

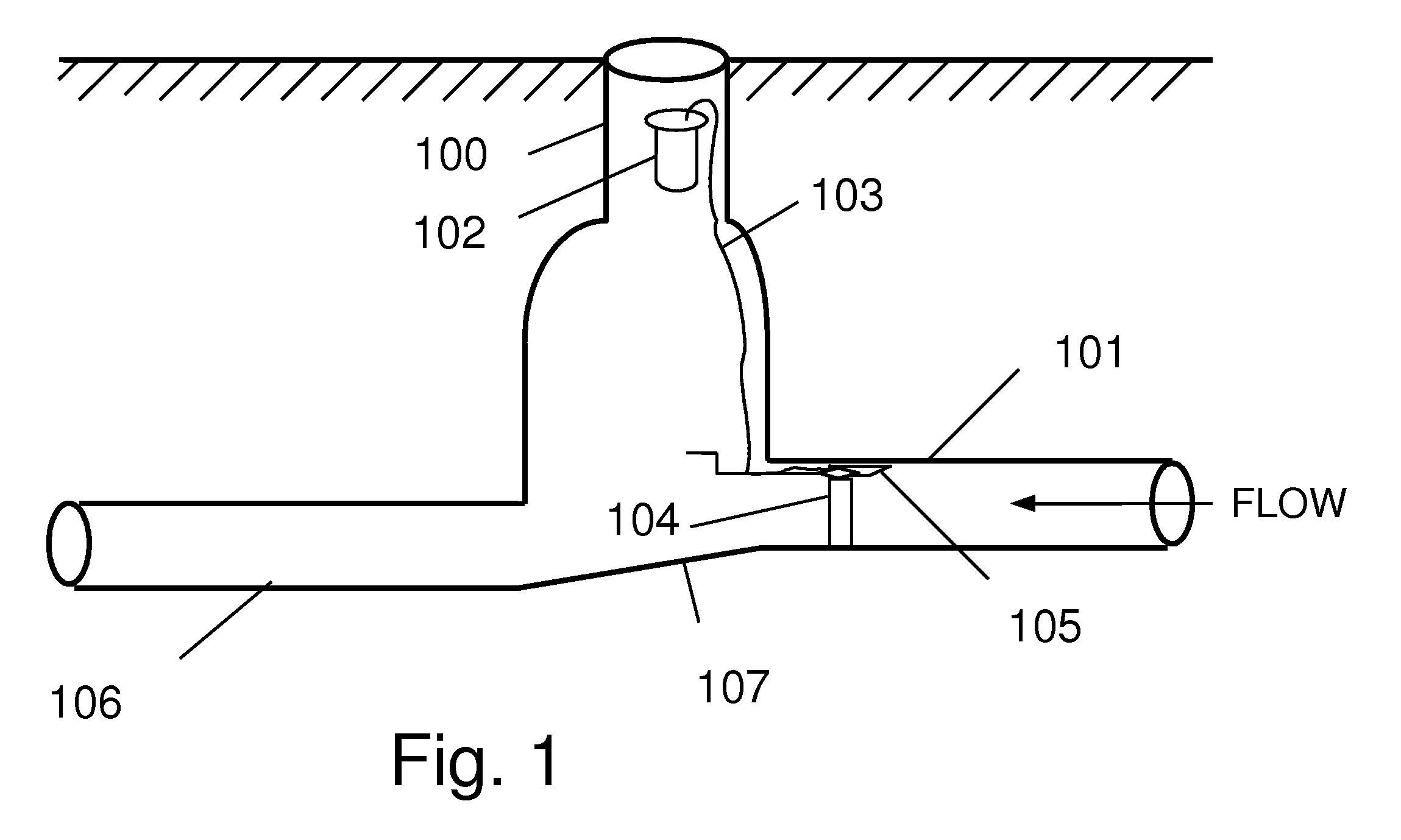

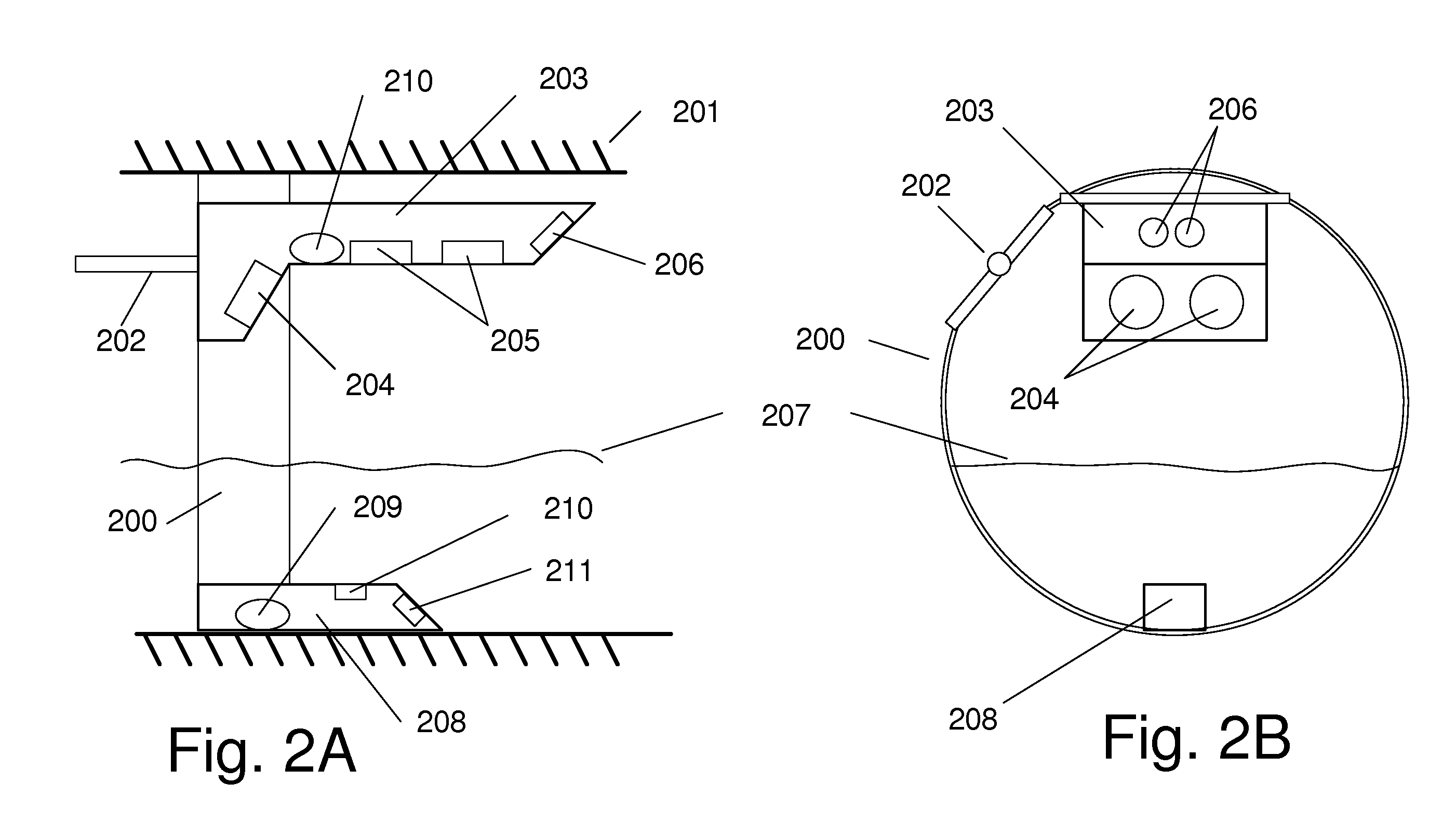

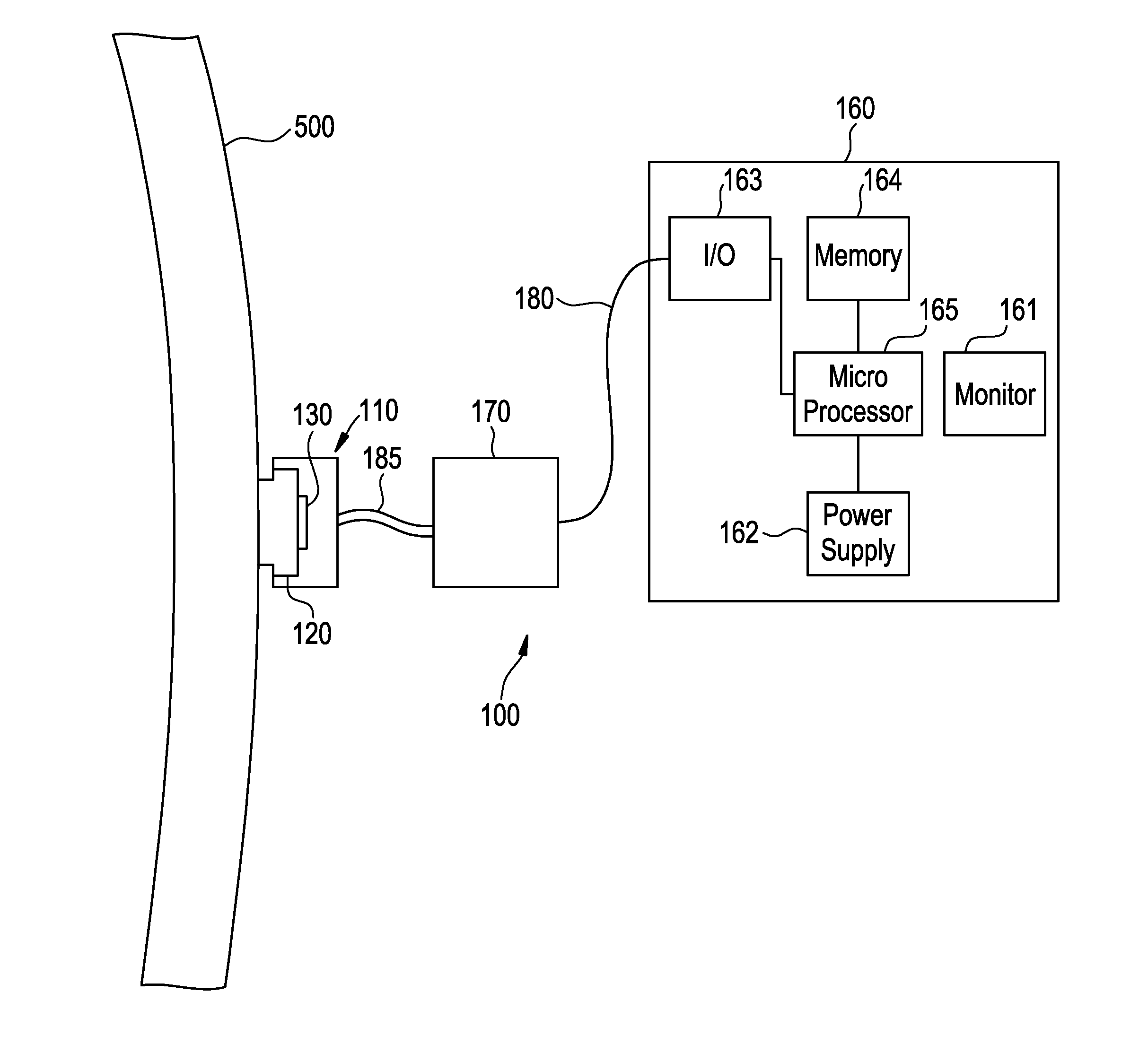

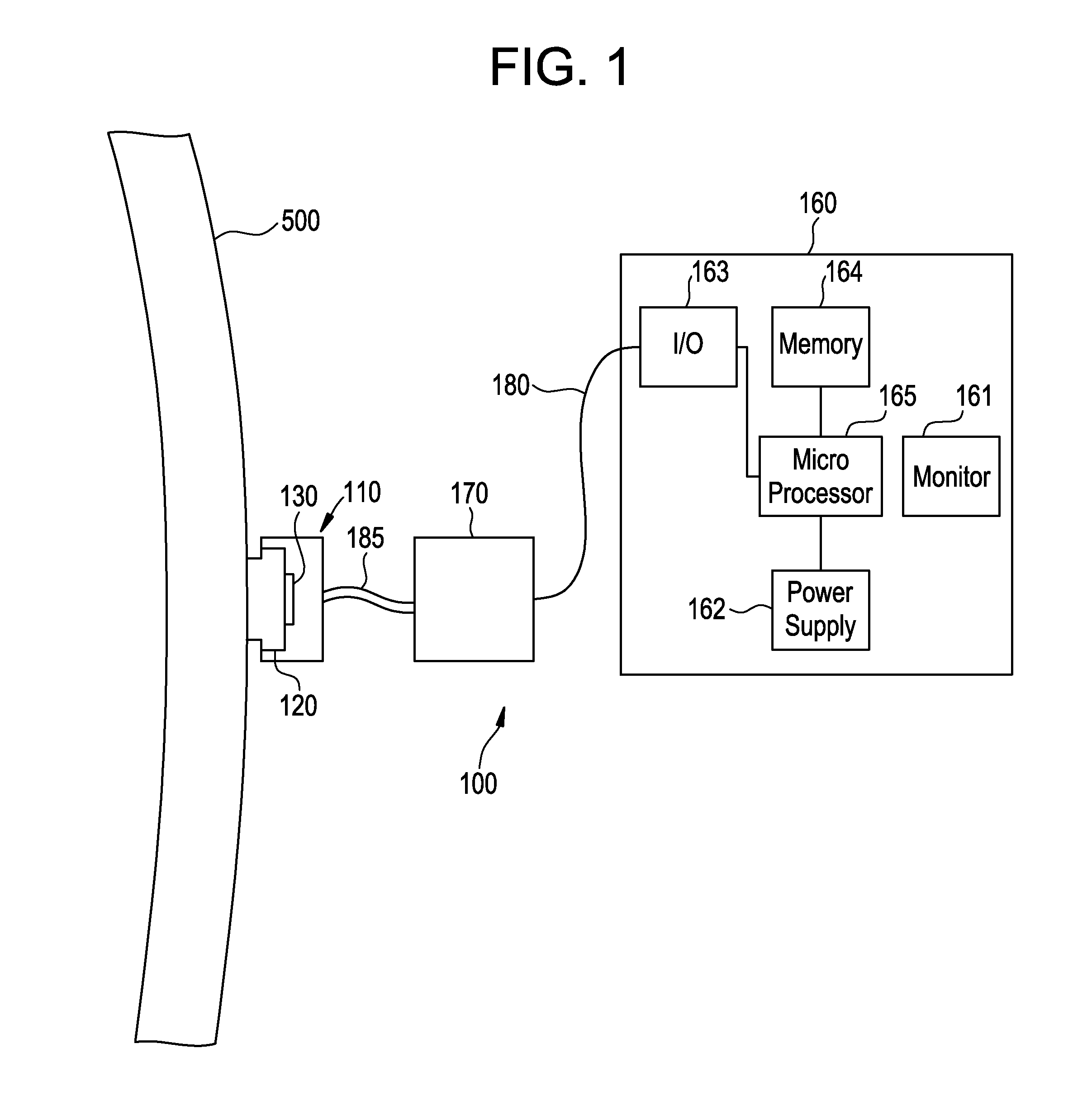

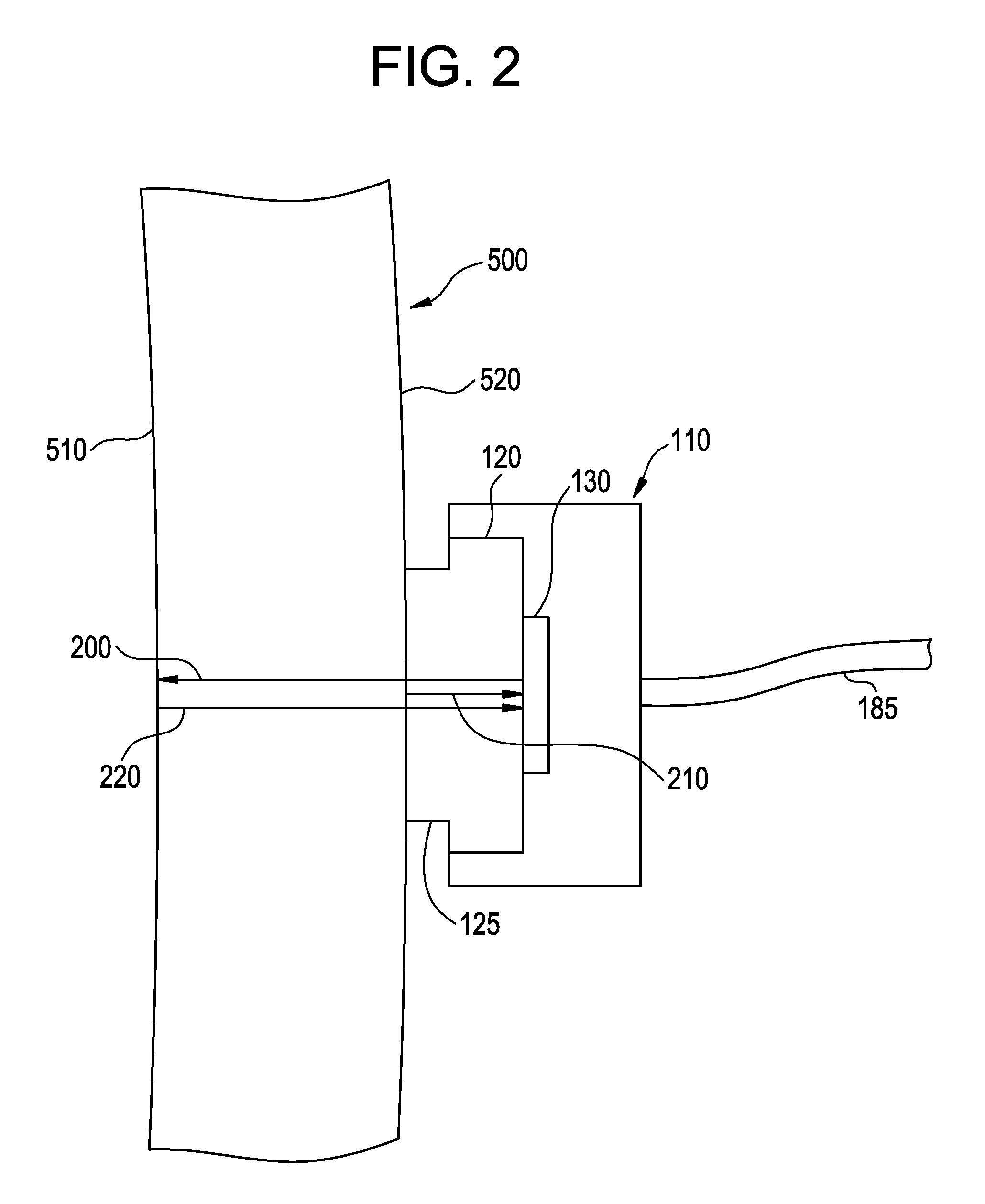

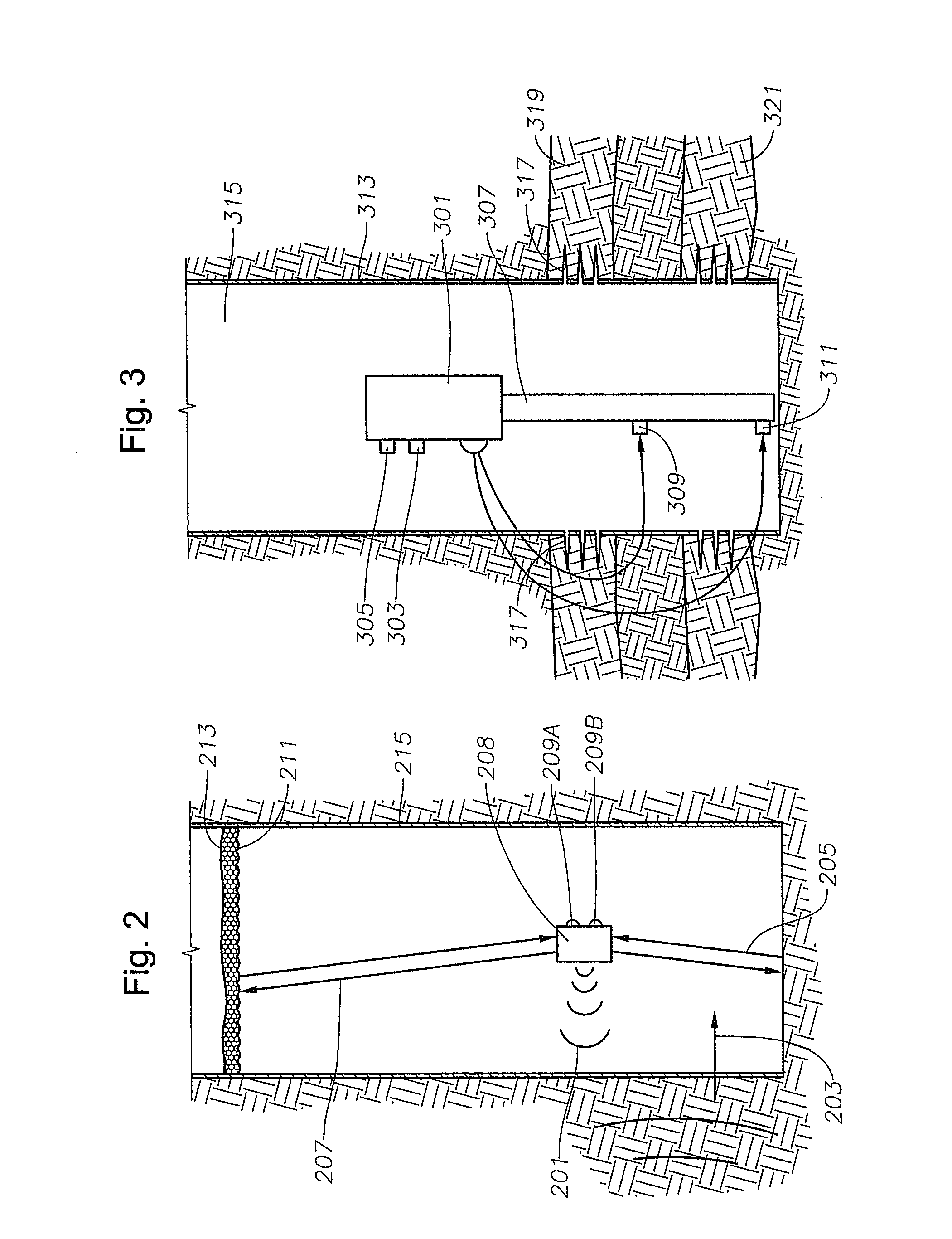

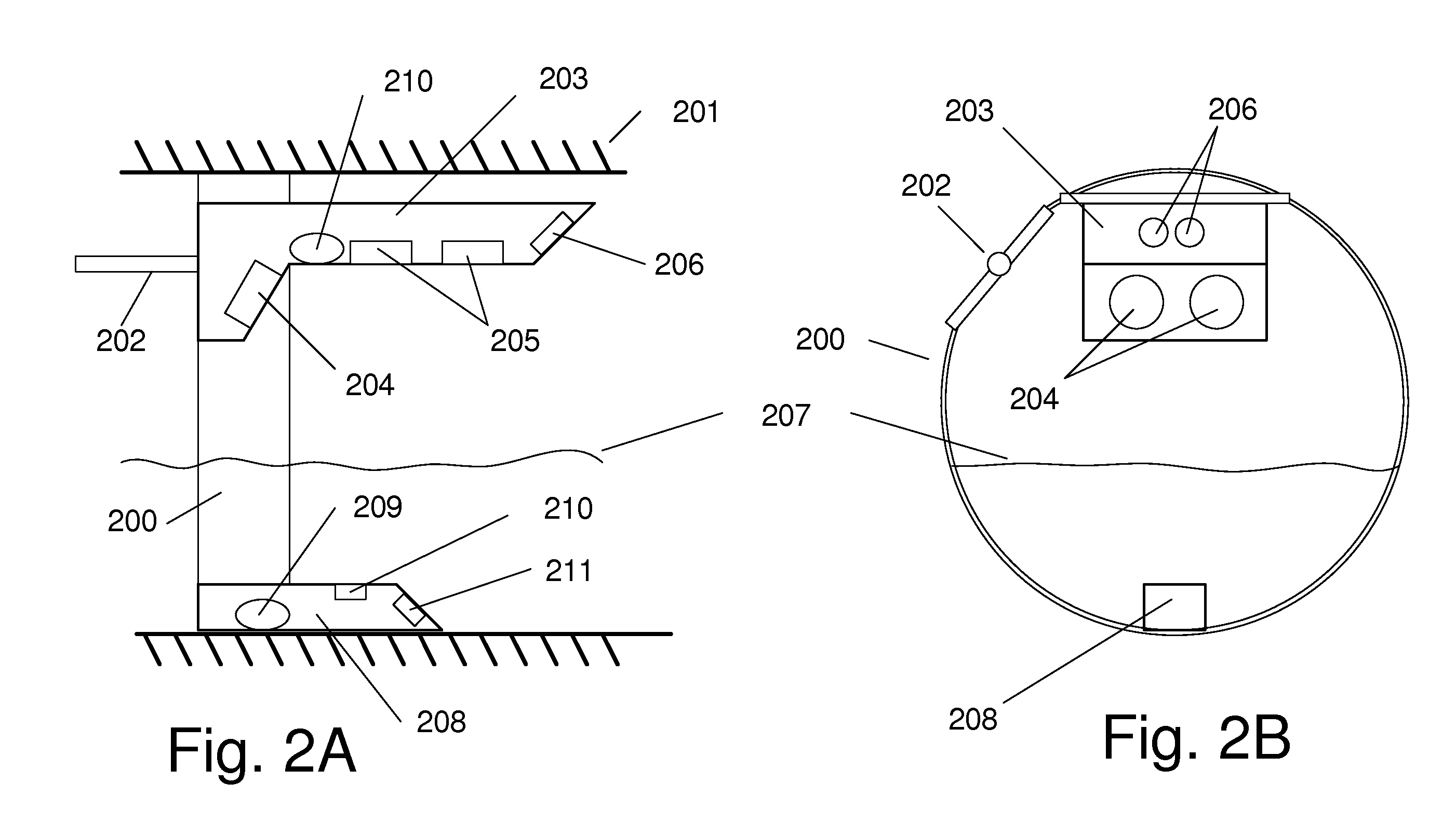

Augmented Surface Sensor for Measuring Flow Velocity

A system and method for measurement of flow parameters in a sewer pipe that may be partially or completely filled. Flow parameters may include flow velocity, flow volume, depth of flow and surcharge pressure. Measurements are taken from a sensor head installed on the inside of the pipe at the top of the pipe approximately the larger of at least 1 foot or 1 pipe diameter upstream of a pipe opening. Flow velocity may be measured by two different technologies. The technology employed depends on whether or not the pipe is full. If the pipe is not full then flow velocity may be measured, for example, using a wide beam, ultrasonic, diagonally downward looking Doppler signal that interacts with the surface of the flow. If the pipe is full, then flow velocity may be measured using, for example, an average velocity Doppler sensor, a peak velocity Doppler sensor or an ultrasonic velocity profiler.

Owner:ADS

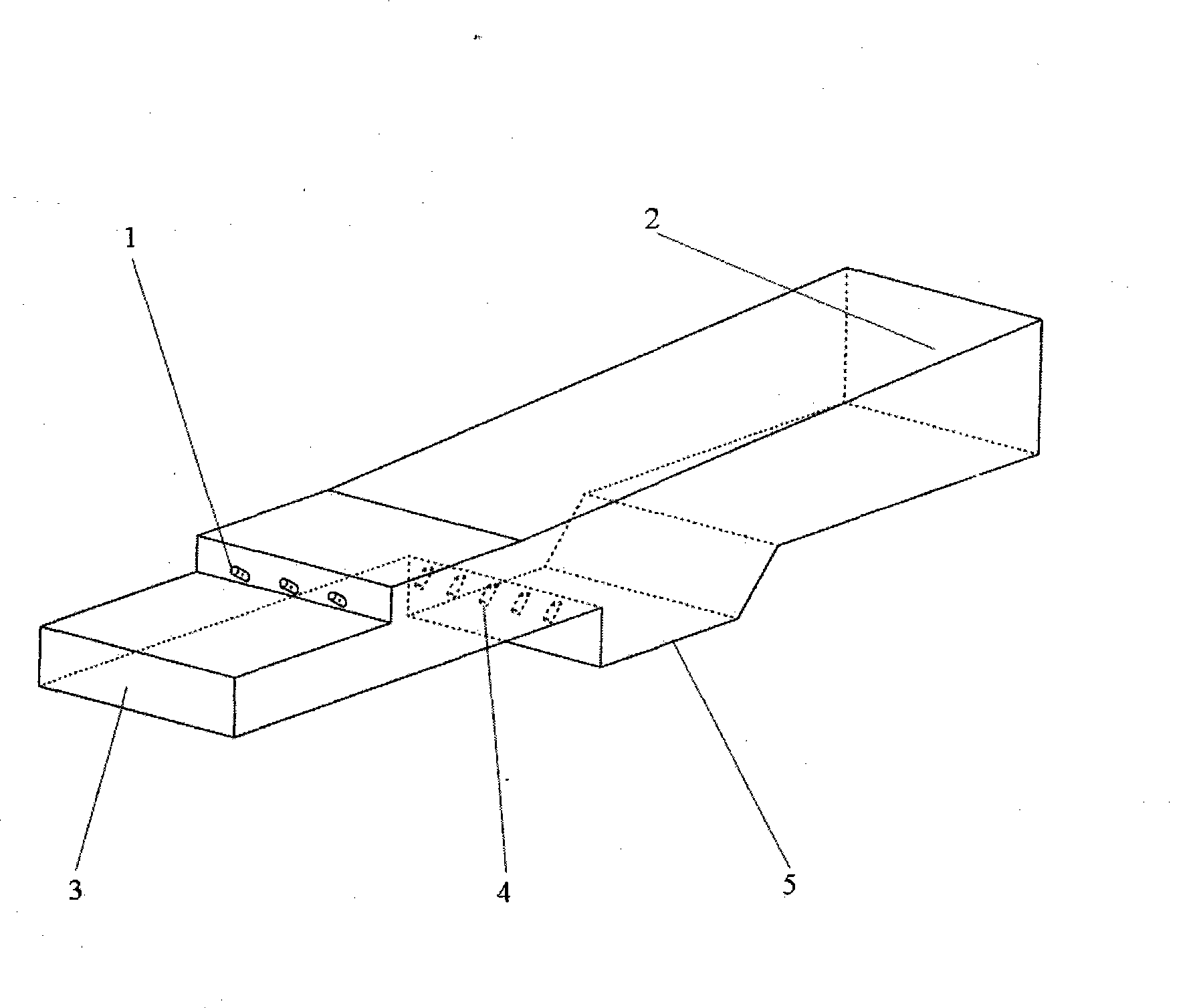

Asymmetric supersonic velocity spray pipe and design method thereof

ActiveCN102323961AHigh precisionImprove qualitySpecial data processing applicationsThroatMethod of characteristics

The invention provides an asymmetric supersonic velocity spray pipe and a design method thereof. The design method of the supersonic velocity spray pipe comprises the following steps: according to an inlet coordinate and a throat area, determining a subsonic velocity segment curve; according to the subsonic velocity segment curve and a throat radius of curvature, determining a characteristic line in a transonic velocity area; according to one end point of the characteristic line and a corresponding supersonic velocity area outlet end point, determining a first wall surface curve; and according to an initial characteristic line and the Mach number distribution of the first wall surface curve, determining a second wall surface curve by mass conservation with a characteristic line method. With the design method of the asymmetric supersonic velocity spray pipe, concentrated compression wave in the flow field of the asymmetric supersonic velocity spray pipe can be reduced or eliminated, the quality of the flow field of the spray pipe is greatly improved, equipment performance is improved, and research funds can be saved. According to the asymmetric supersonic velocity spray pipe disclosed by the invention, the design method of the asymmetric supersonic velocity spray pipe is adopted.

Owner:NAT UNIV OF DEFENSE TECH

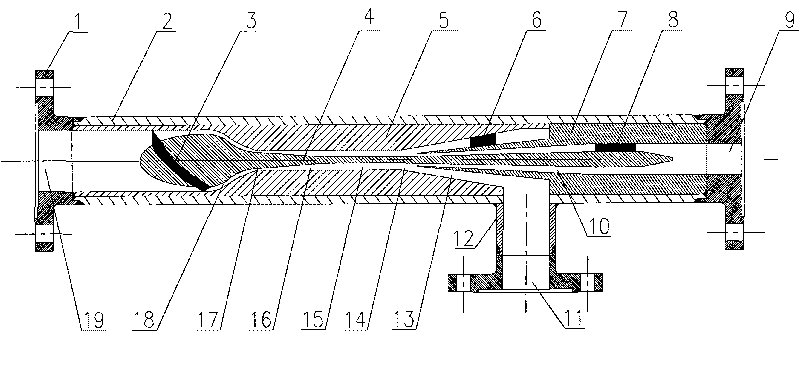

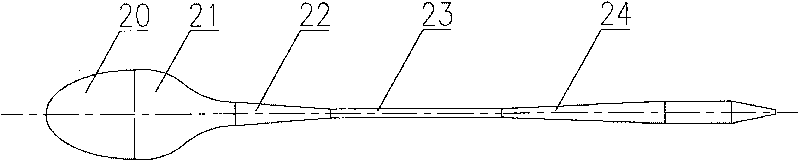

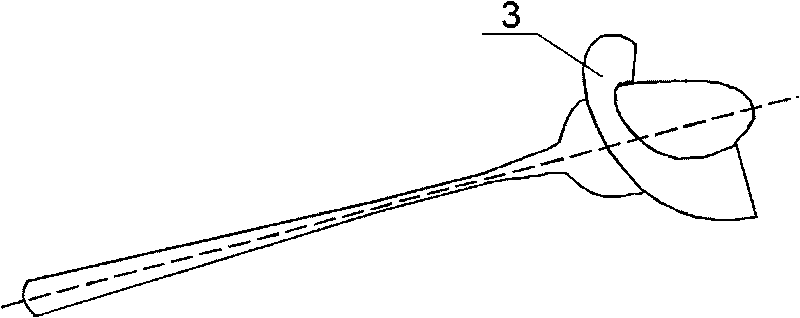

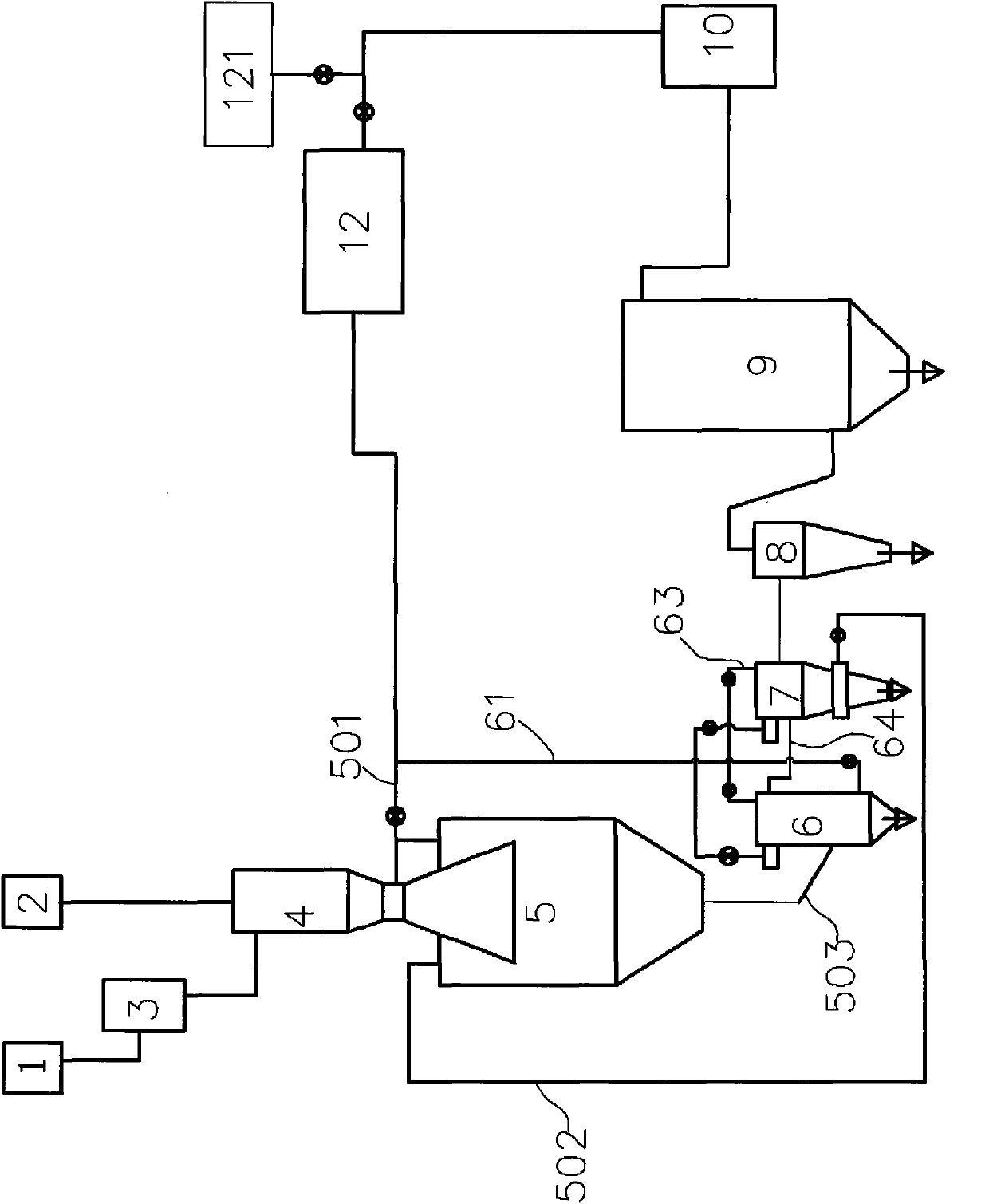

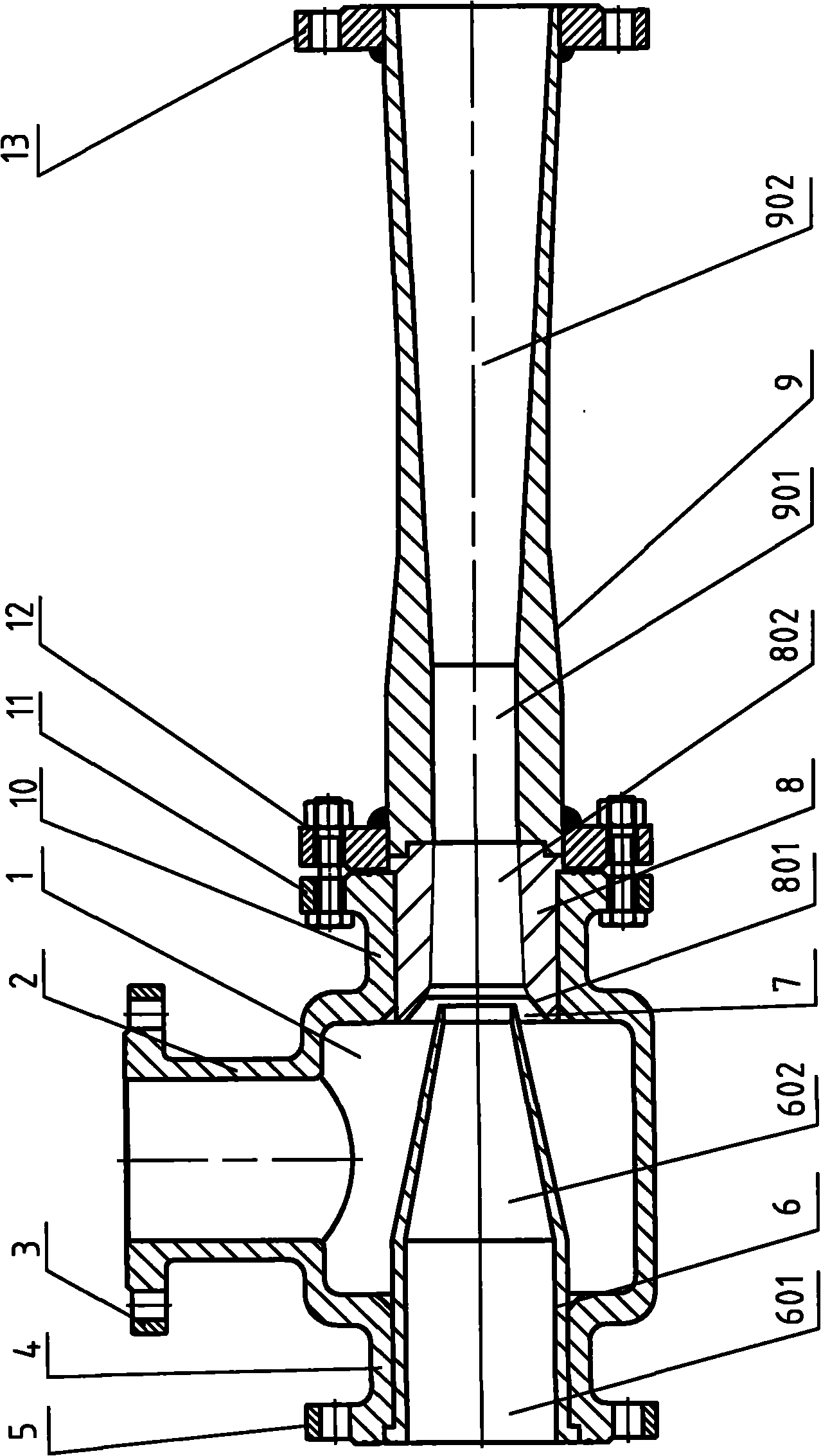

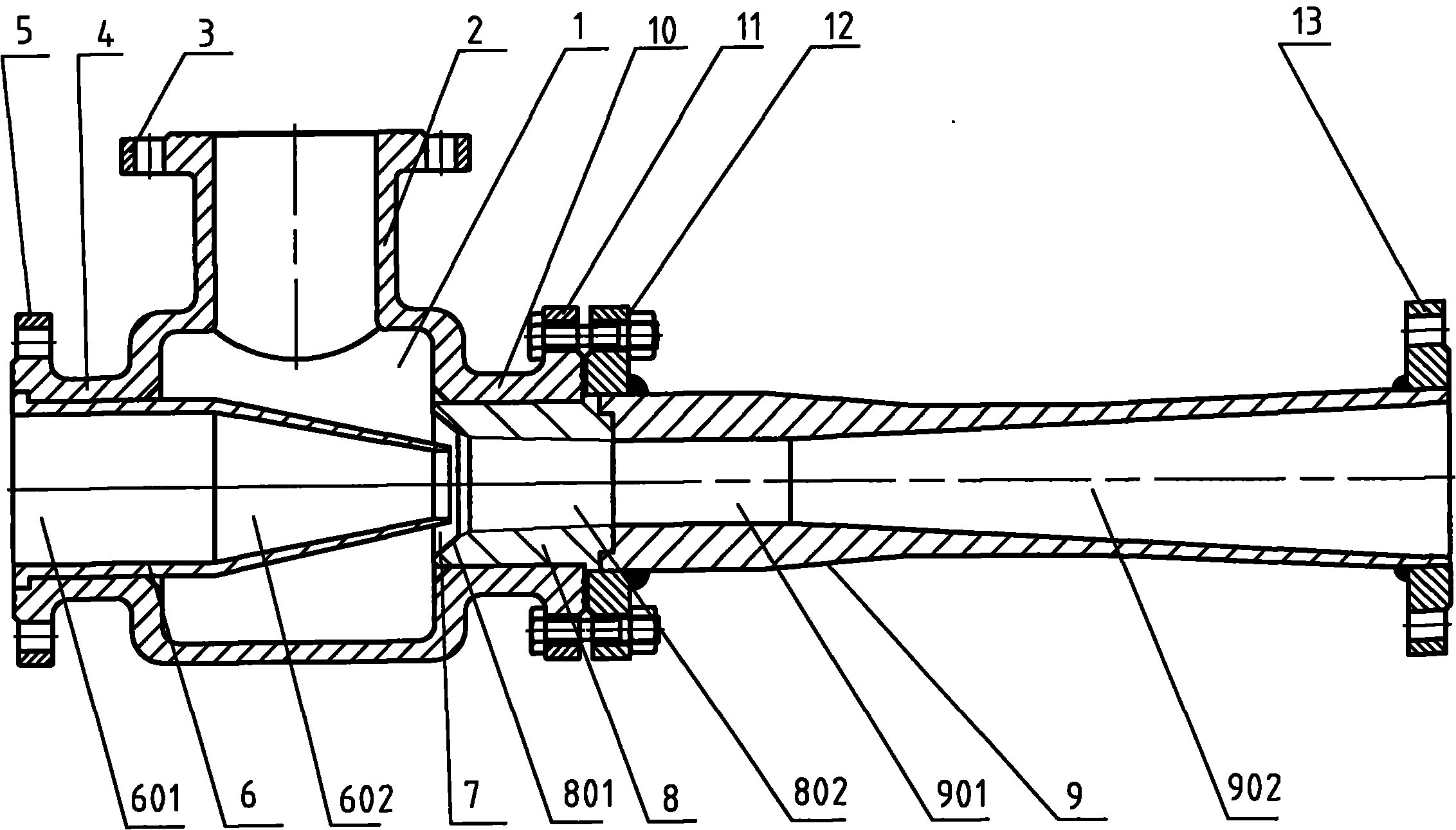

Ultrasonic gas cyclone condensing and separating device

InactiveCN101745246ASolving the Eddy Dissipation ProblemReduce radial velocity gradientDispersed particle separationVapor condensationCycloneNatural gas dehydration

The invention relates to an ultrasonic gas cyclone condensing and separating device applied to the field of gas purification, in particular to the field of natural gas dewatering and heavy hydrocarbon separation. Natural gas generates a cyclone by spiral cyclone blades, enters an Laval nozzle to adiabatically expand to an ultrasonic velocity and form low temperature and low pressure so that water and heavy hydrocarbon in the natural gas are condensed into liquid drops; meanwhile, a higher tangential velocity is generated to fling the water and the heavy hydrocarbon which are condensed to the wall surface under the action of a strong cyclone field; liquid flows into a liquid-collecting cavity from a liquid shunt hole and is discharged from a liquid outlet by a liquid-discharging pipe; and dry gas enters a circular diffuser pipe, is recovered by pressure and is discharged from a dry gas outlet. The shrinking section of the Laval nozzle of the device is designed by using a bicubic curve method to reduce flowing loss; the spiral cyclone blades can enhance the cyclone, generate greater tangential velocity and have good enhance effect. The device has simple structure, easy process and stable and reliable operation without movable parts.

Owner:文闯

Universal liquid concentration supersonic-detection method and universal liquid concentration supersonic-detection device

ActiveCN103278561AImprove general performanceImprove versatilityMaterial analysis using sonic/ultrasonic/infrasonic wavesSupersonic wavesEngineering

The invention discloses a universal liquid concentration supersonic-detection method and a universal liquid concentration supersonic-detection device. The universal liquid concentration supersonic-detection method is characterized in that because of different supersonic velocities of supersonic wave in different mediums, according to known sonic path distances, sonic travel time in the detected liquid is measured; and the measured value is corrected by real-time temperature values so that percentage contents of different solutes in different solvents are obtained. Through sampling of supersonic wave propagation velocities in different solvents and solutes at different temperatures, sampling results are obtained, and through the sampling results, a corresponding relationship formula of the supersonic velocities of supersonic wave in the solutions, and the temperatures and the concentrations is worked out so that liquid concentration measurement universality is realized. Through measurement of supersonic velocities in air and in purified water under laboratory conditions, the method and the device realize correction of system hardware errors and sonic path distance errors and improve a measurement precision.

Owner:无锡煤矿机械股份有限公司

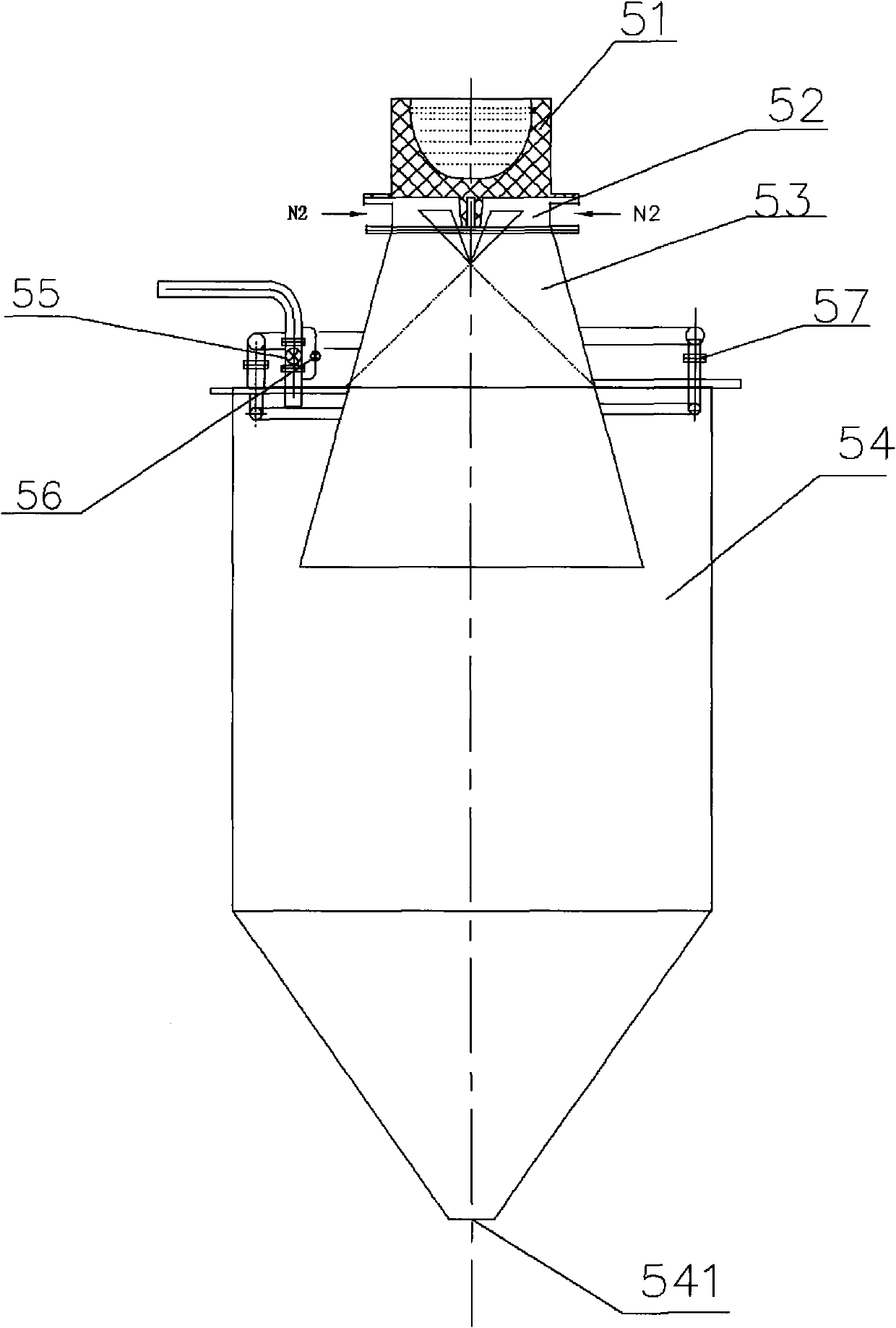

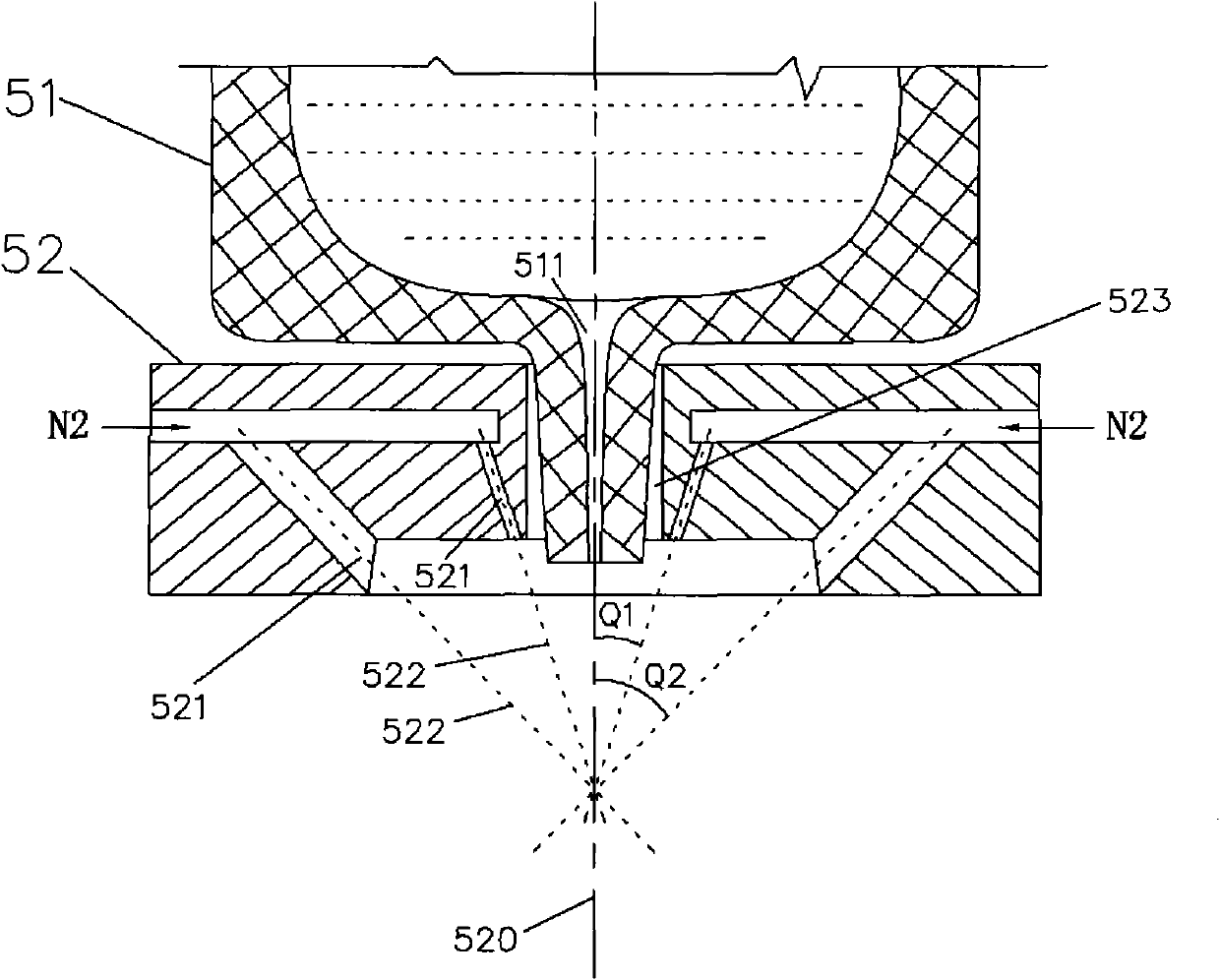

Metal ultrafine atomizing, crushing and grading system and metal atomizing device thereof

The invention provides a metal ultrafine atomizing, crushing and grading system, comprising a metal smelting furnace, a metal hydrogen-discharging and heating furnace, a metal atomizing device, a fluidized bed depolymerization grader, a second precise grader, at least one collector, a filter and a compressor. The invention also provides a metal atomizing device, comprising a crucible, a spray disc, a spray cover and a cylindrical spray cylinder, wherein a circle of evenly distributed inclined holes is respectively arranged on at least two circumferences with different diameters of the spray disc; each inclined hole is provided with a Laval nozzle; and the extension line of each Laval nozzle is intersected with the central axis of the spray disc at the same point. Through the airflow with ultrasonic velocity, ultralow temperature and large velocity pressure generated by the nozzle in the metal atomizing device, the liquid metal or alloy is directly crushed, or rapidly cooled into atomized powder and then depolymerized by a fluidized bed and precisely graded by the precise grader to obtain metal fine powder and ultrafine powder with finer granularity, more even granularity and better granularity sphericity.

Owner:宁波中物力拓超微材料有限公司

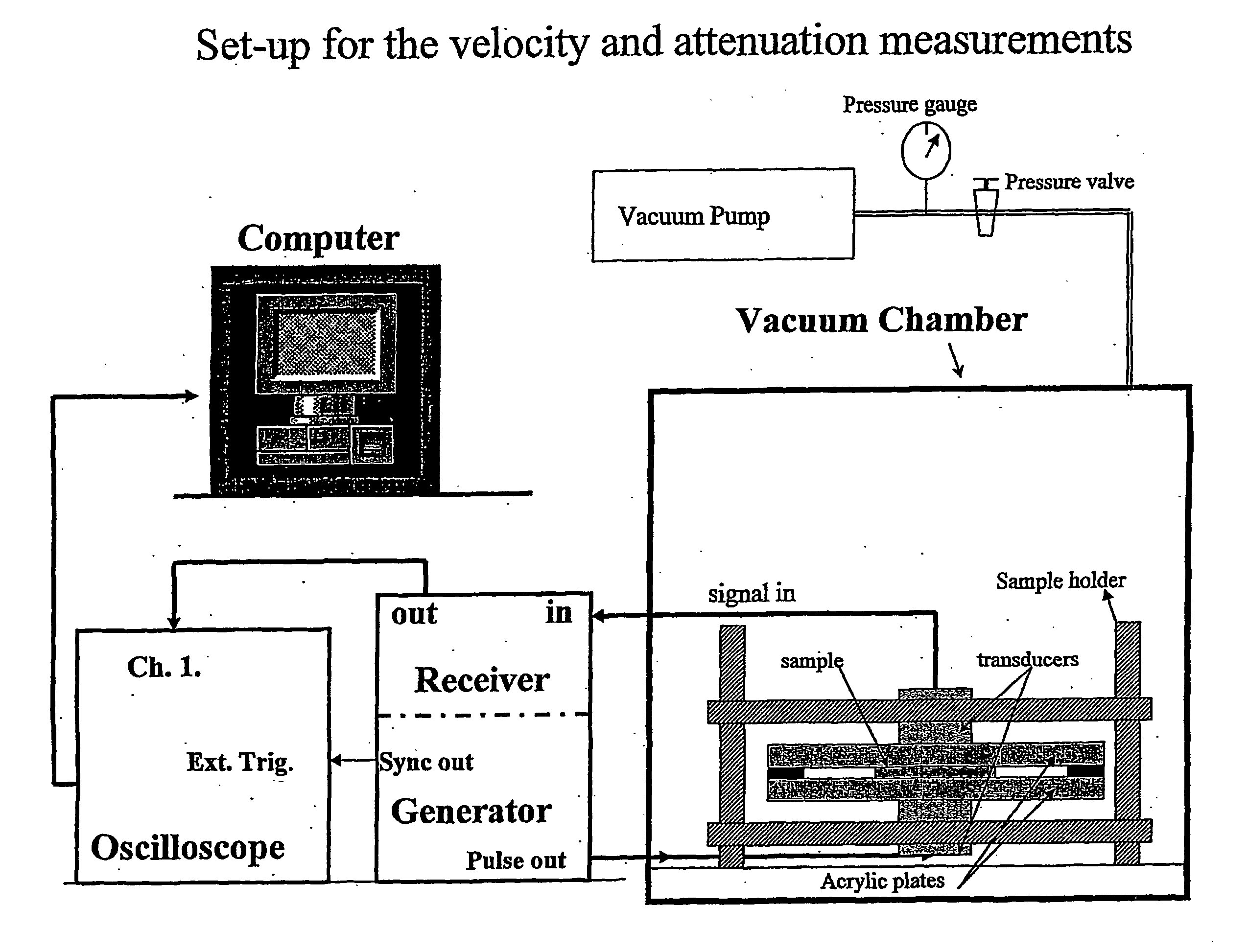

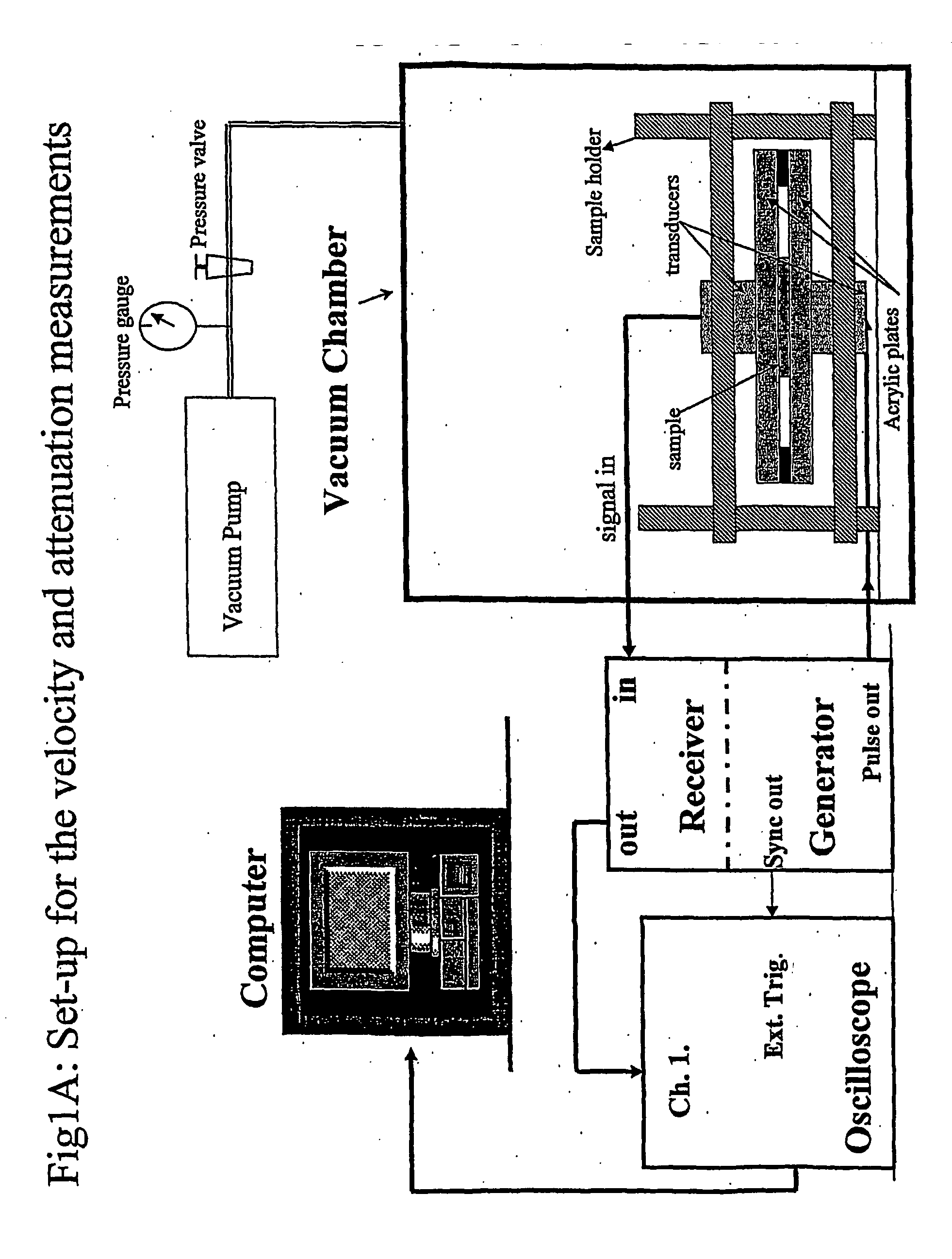

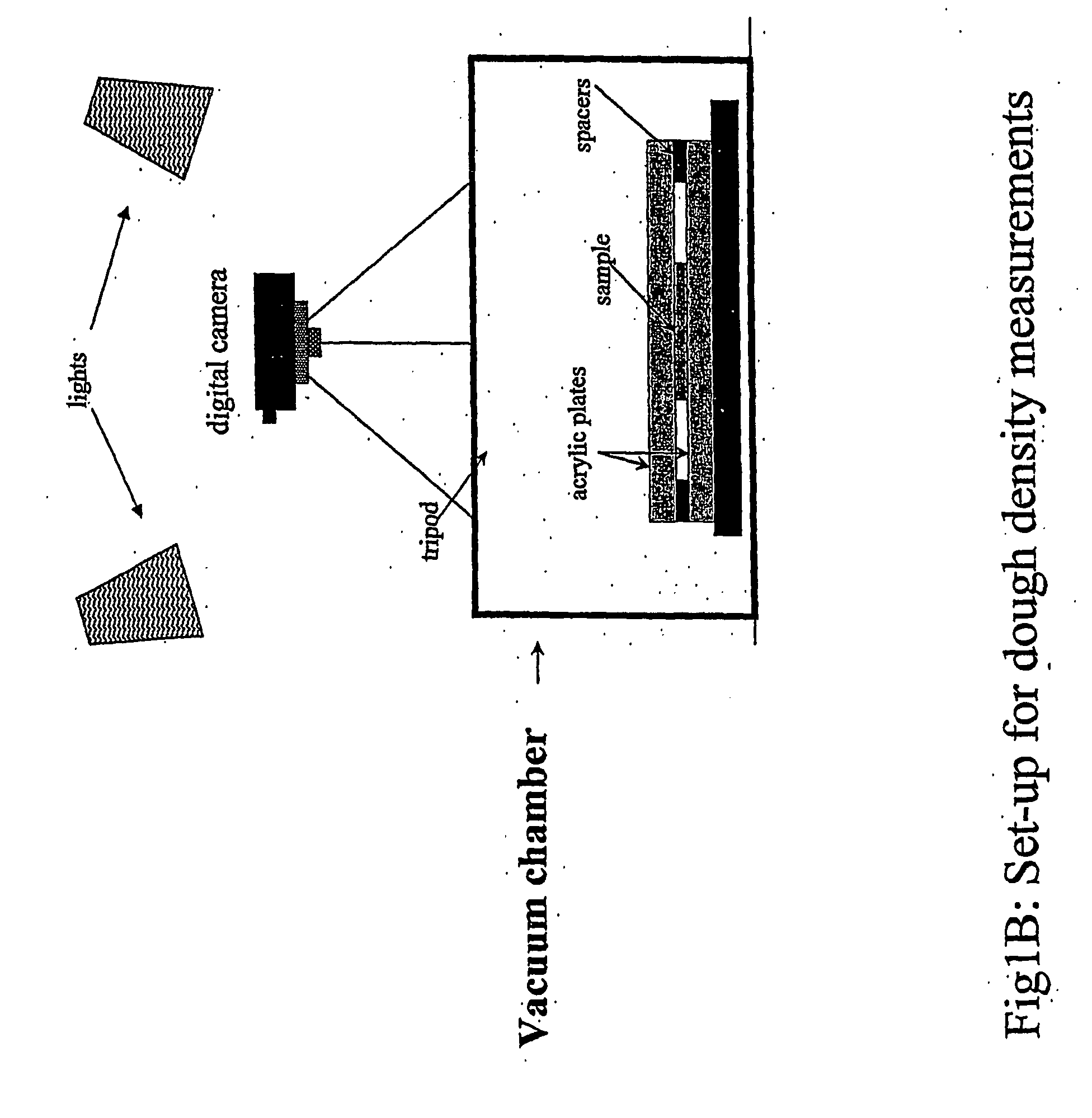

Ultrasonic evaluation of the strength of flour doughs

InactiveUS20060207329A1Testing starch susbtancesAnalysing fluids using sonic/ultrasonic/infrasonic wavesUltrasound attenuationUltrasonic velocity

Owner:MANITOBA THE UNIVERSIY OF

Method for performing ultrasonic testing

ActiveUS20110090935A1Thermometer detailsMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic attenuationThermal expansion

A method for performing ultrasonic testing comprising, in one embodiment, the steps of firing an ultrasonic transducer to generate an ultrasonic pulse that passes through a delay line, measuring a delay echo time of flight, and determining the temperature of the delay line using the delay echo time of flight, thereby eliminating the need for additional temperature measuring devices. Other embodiments further comprise the step of using the temperature of the delay line to determine the temperature of a test object, and using the temperature of the test object to determine a thickness of the test object that is compensated for thermal expansion and temperature dependent ultrasonic velocity.

Owner:GE INSPECTION TECH LP

Supersonic speed combustion chamber scheme of step / groove composite injection structure

InactiveCN101435586AAchieve ignitionStable ignitionContinuous combustion chamberCombustion chamberLow speed

The innovation of the invention is to provide a proposal for an ultrasonic velocity combustion chamber with a novel step / groove composite jet structure. The proposal is characterized in that fuel nozzles are additionally arranged in the front of a step and a groove of the combustion chamber and are jointly used for fuel jet and use in the combustion chamber. In the design proposal, design proposals of a jet structure of the step and a fuel nozzle structure in the front of the groove are applied in the ultrasonic velocity combustion chamber, and correspondingly improved types of the ultrasonic combustion chambers thereof. The proposal of the designed composite jet structure can ensure evenly jetting of fuel in the ultrasonic velocity combustion chamber, and achieve full mixing of the fuel and air in a low-speed flowing area in the combustion chamber, so as to ensure ignition and stable combustion of the fuel in ultrasonic velocity air flow. Compared with the proposal of a nozzle in the prior ultrasonic velocity combustion chamber, total pressure in the combustion chamber has little loss, thereby shortening structural size of the ultrasonic velocity combustion chamber, improving performance of the whole ultrasonic power system, and having considerable potential economic benefit and value. The proposal for the ultrasonic velocity combustion chamber mainly comprises designs of parts such as the step jet structure in the combustion chamber, the groove, the jet structure in the front of the groove.

Owner:周建兴 +1

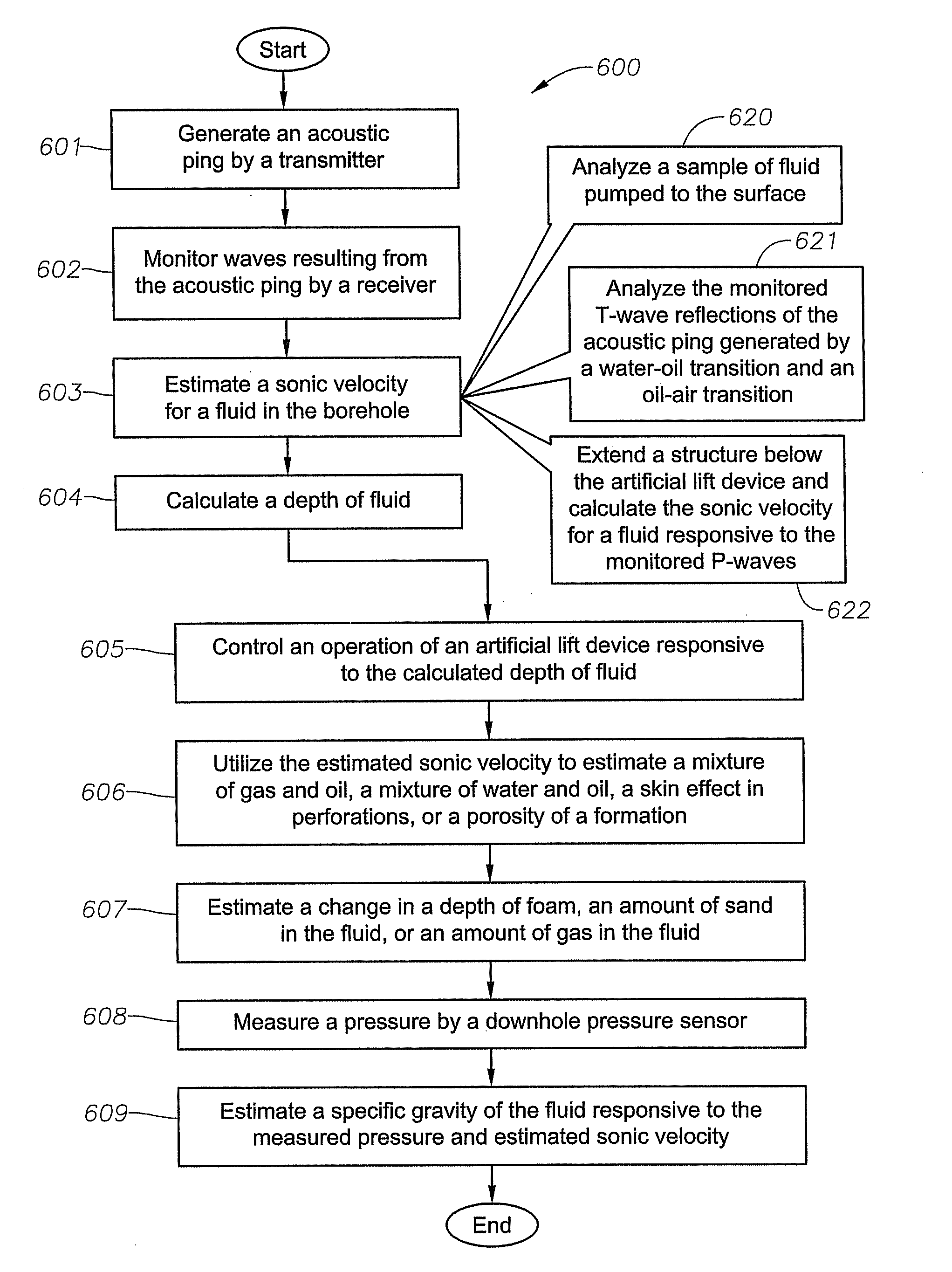

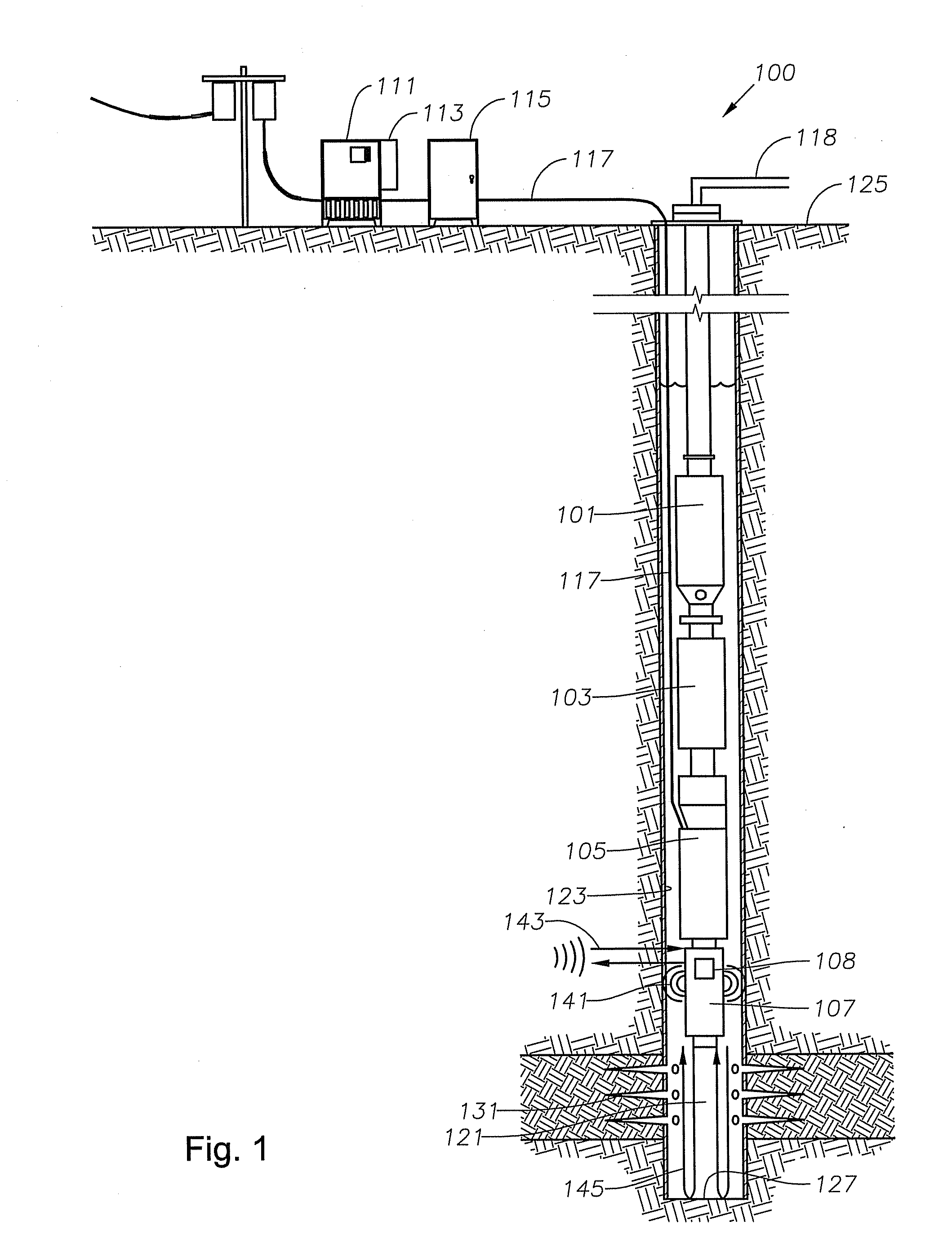

Using An Acoustic Ping and Sonic Velocity to Control an Artificial Lift Device

A transmitter generates an acoustic ping in a fluid in a borehole, and a receiver monitors waves resulting from the acoustic ping. Responsive to the monitored waves, an attribute of the fluid is estimated, including a sonic velocity, a mixture of gas and oil, a mixture of water and oil, an amount of sand, an amount of gas, an amount of skin effect, or a depth of fluid. An operation of the artificial lift device is then controlled responsive to the estimated attribute. Alternately, a sonic velocity is estimated for the fluid through an analysis of a sample pumped to the surface or through an analysis of monitored waves. A depth of the fluid is calculated responsive to the estimated sonic velocity for the fluid in the borehole and the monitored T-waves. The operation of the artificial lift device is then controlled responsive to the calculated depth of fluid.

Owner:BAKER HUGHES INC

Augmented surface sensor for measuring flow velocity

ActiveUS8215183B2Small sensor sizeFlow on effectVolume/mass flow measurementEngineeringUltrasonic velocity

Owner:ADS

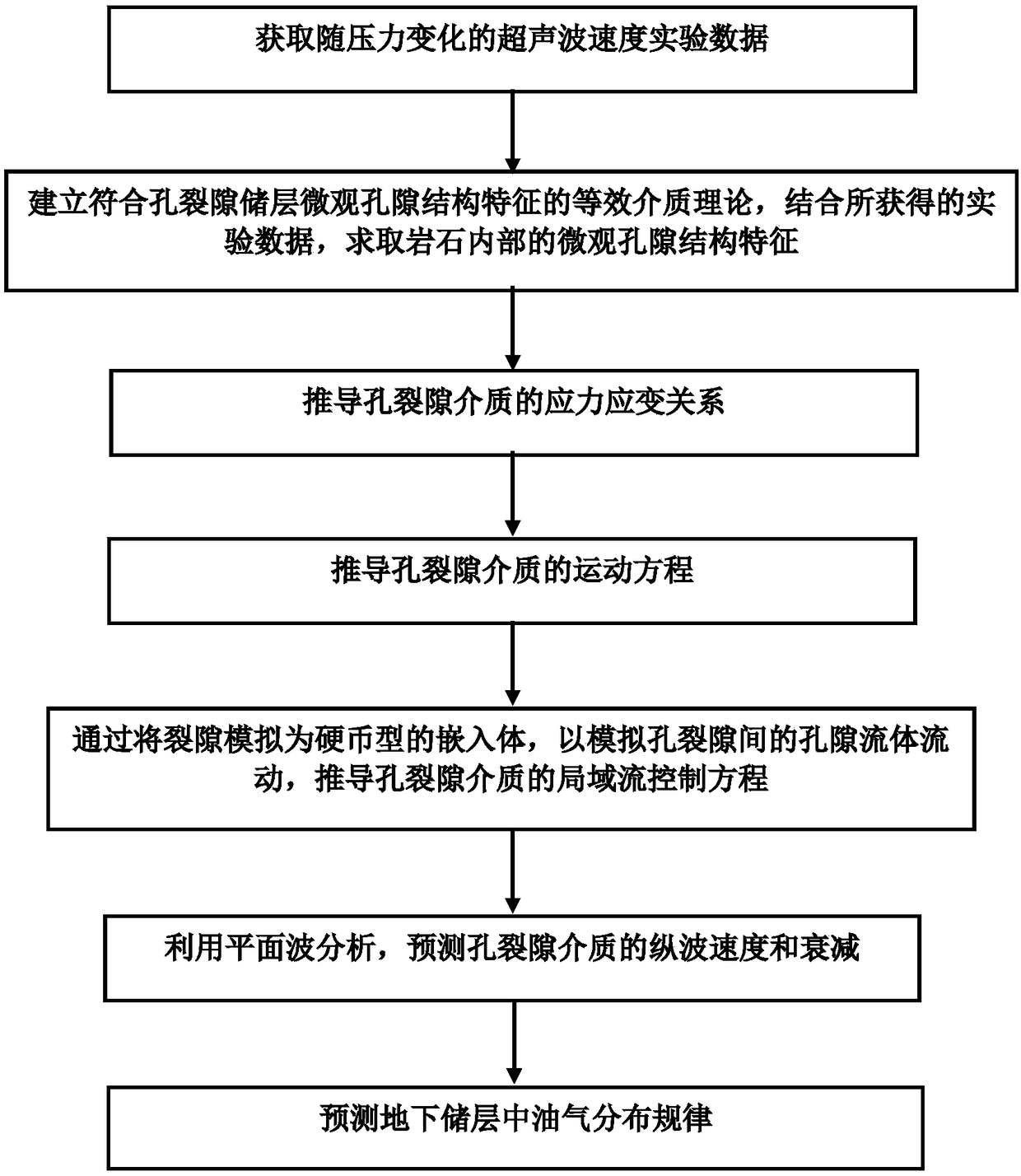

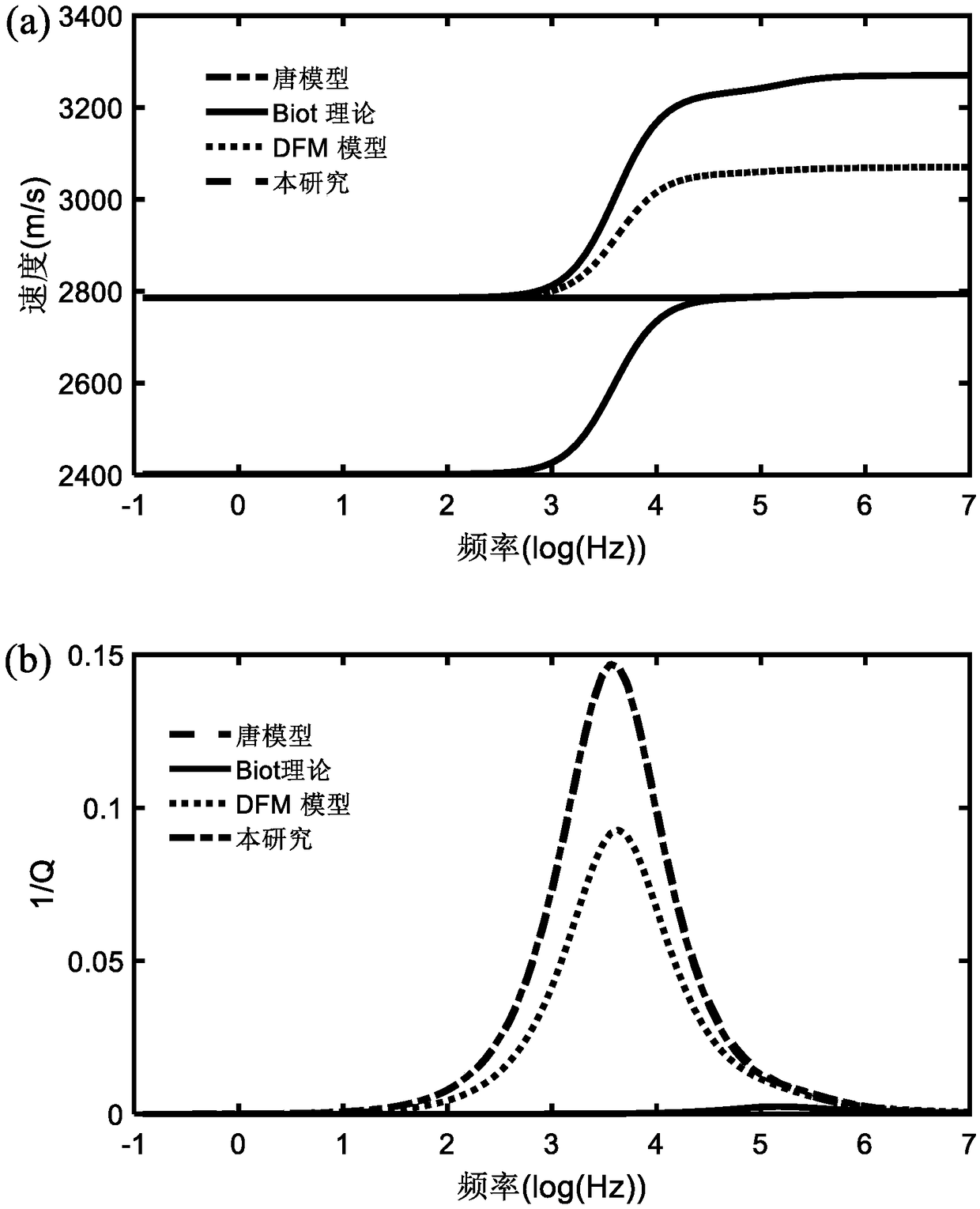

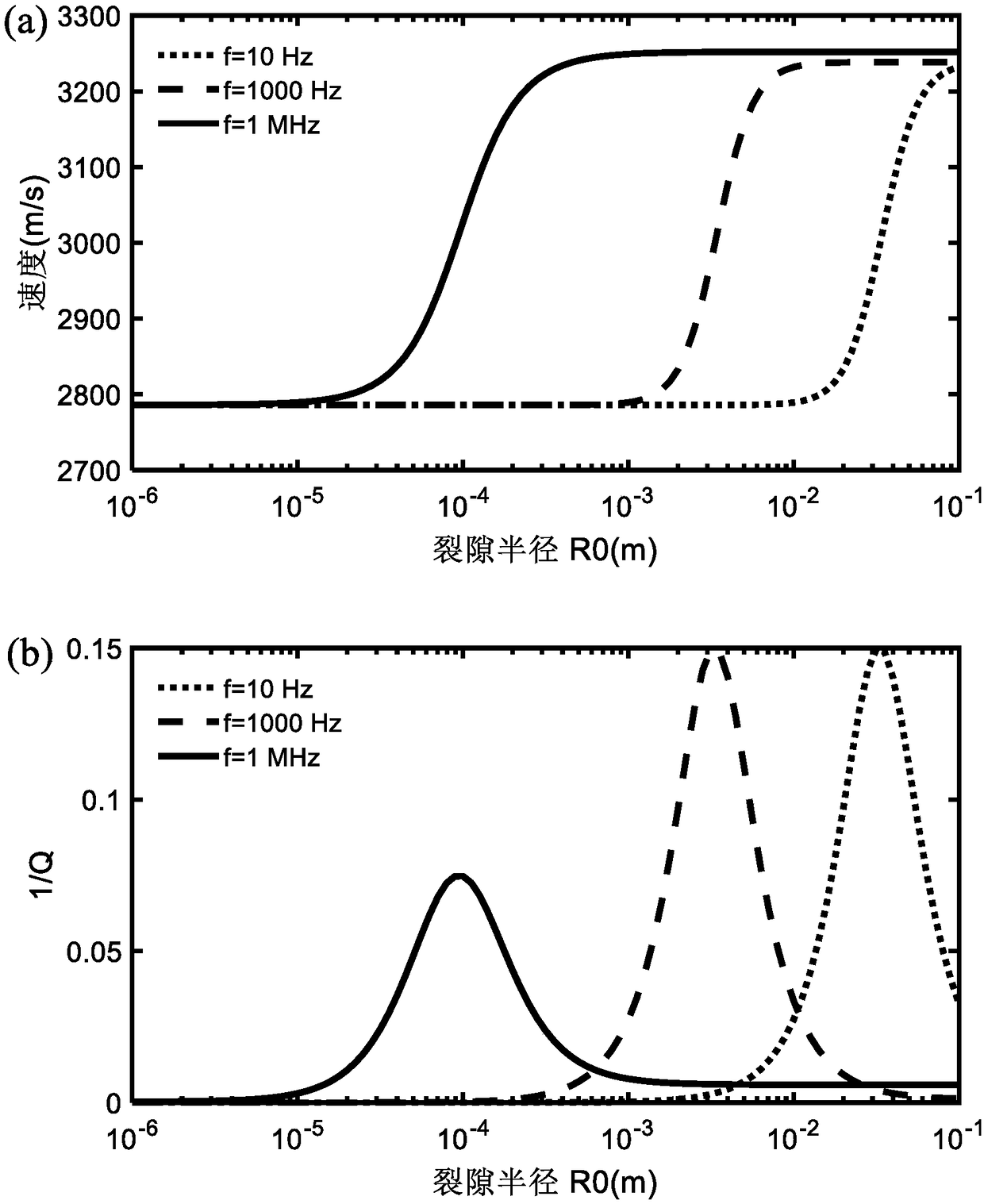

Predicting method for longitudinal wave speed and attenuation in pore fracture medium

The invention discloses a predicting method for longitudinal wave speed and attenuation in a pore fracture medium. The predicting method comprises the following steps of 1 obtaining ultrasonic speed experimental data of change along with pressure; 2, building an effective medium theory conforming to microcosmic pore structure characteristics of a pore fracture reservoir, and solving microcosmic pore structure characteristics inside rock in combination with the obtained experimental data; 3, deriving a stress strain relationship of the pore fracture medium; 4, deriving a motion equation of thepore fracture medium; 5, simulating the fractures as a coin-shaped embedding body to simulate flow of pore fluid among the pore fractures, and deriving a local area flow control equation of the pore fracture medium; 6, utilizing planar wave analysis for predicting longitudinal wave speed and attenuation of the pore fracture medium; 7, further guiding exploration and development of underground oiland gas reservoirs through the obtained longitudinal wave speed and attenuation of the pore fracture medium. According to the predicting method, the coin-shaped embedding body is utilized for simulating flow of the pore fluid among the pore fractures, and then transmission characteristics of seismic waves in the pore fracture medium are studied.

Owner:HOHAI UNIV

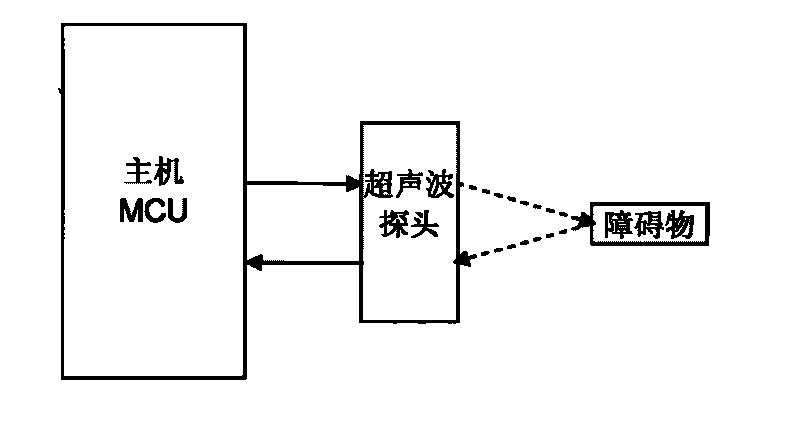

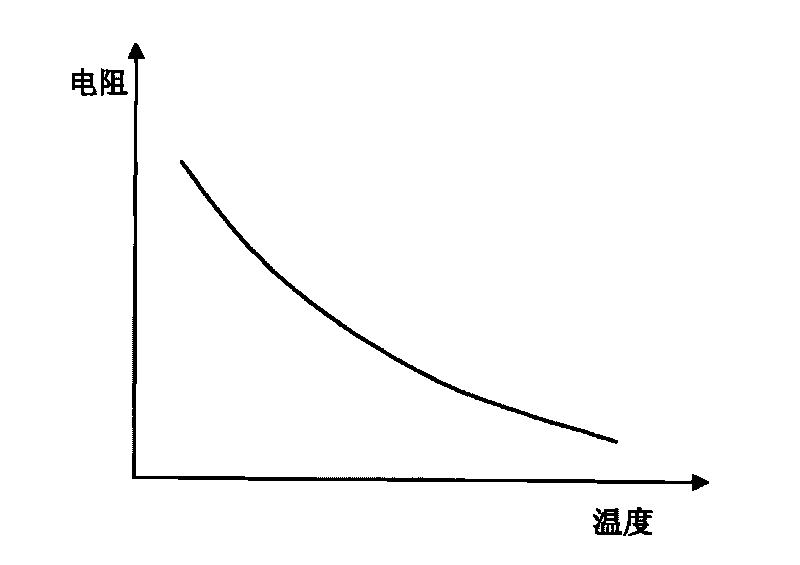

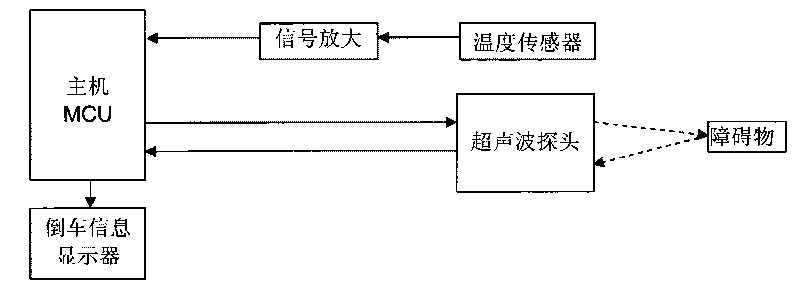

Reversing radar system

InactiveCN101750612AAccurate distanceEasy to installAcoustic wave reradiationMicrocontrollerRadar systems

The invention discloses a reversing radar system which comprises a microcontroller, an ultrasonic probe and a temperature sensor. The temperature sensor is used for monitoring exterior temperature and sending the exterior temperature to the microcontroller. The temperature sensor has the characteristics that the temperature sensor changes along with the change of temperature. The characteristic change of the temperature sensor at different temperatures and the calibration compensating values of the ultrasonic speed change are stored in a memory. According to the time difference of ultrasonic signal sending and ultrasonic return signal receiving, the exterior temperature sent from the temperature sensor, and the characteristic change of the temperature sensor at different temperatures and calibration compensating values of the ultrasonic speed change stored in the memory, the microcontroller computes the distance from the obstacle. The invention has high precision of detection distance.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

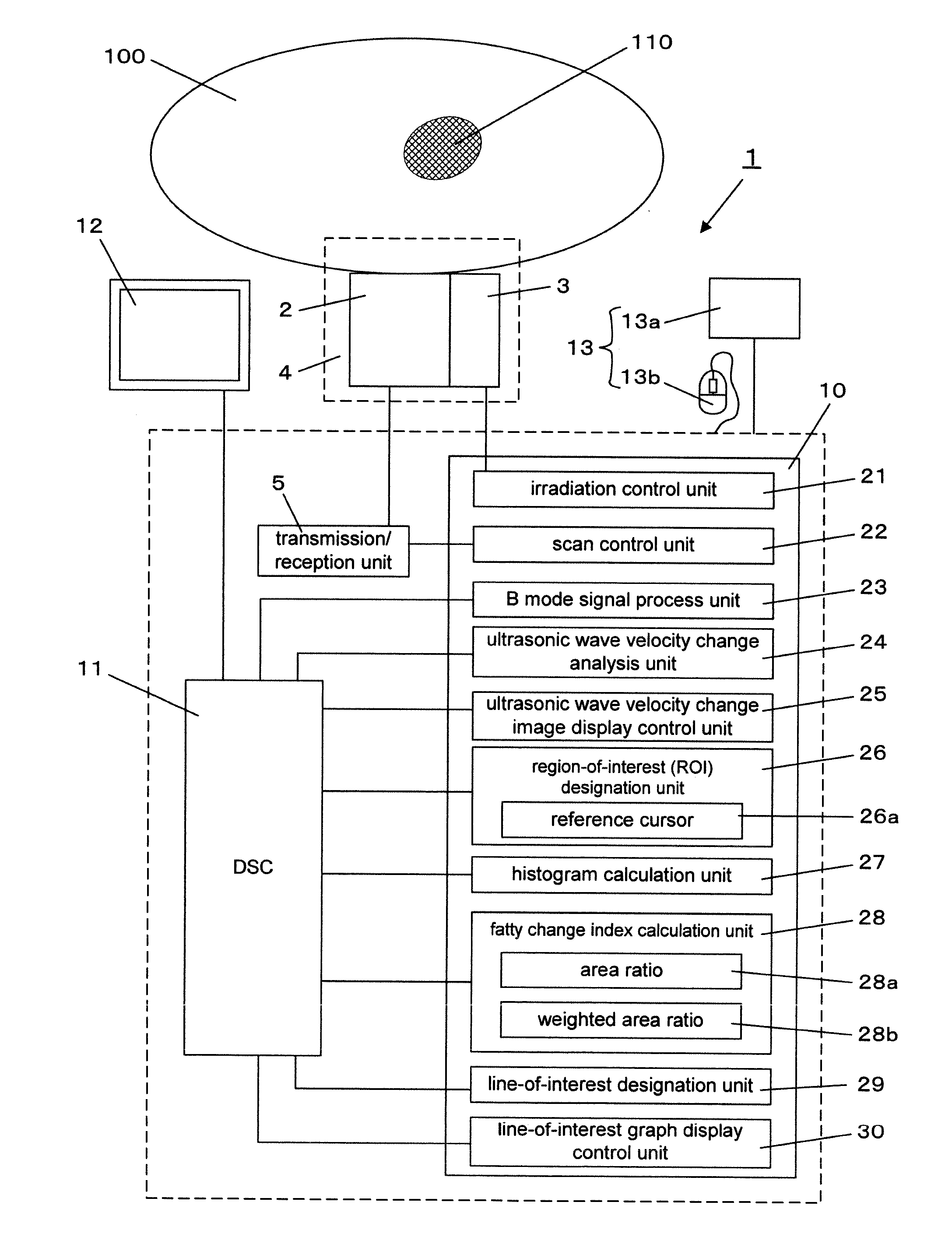

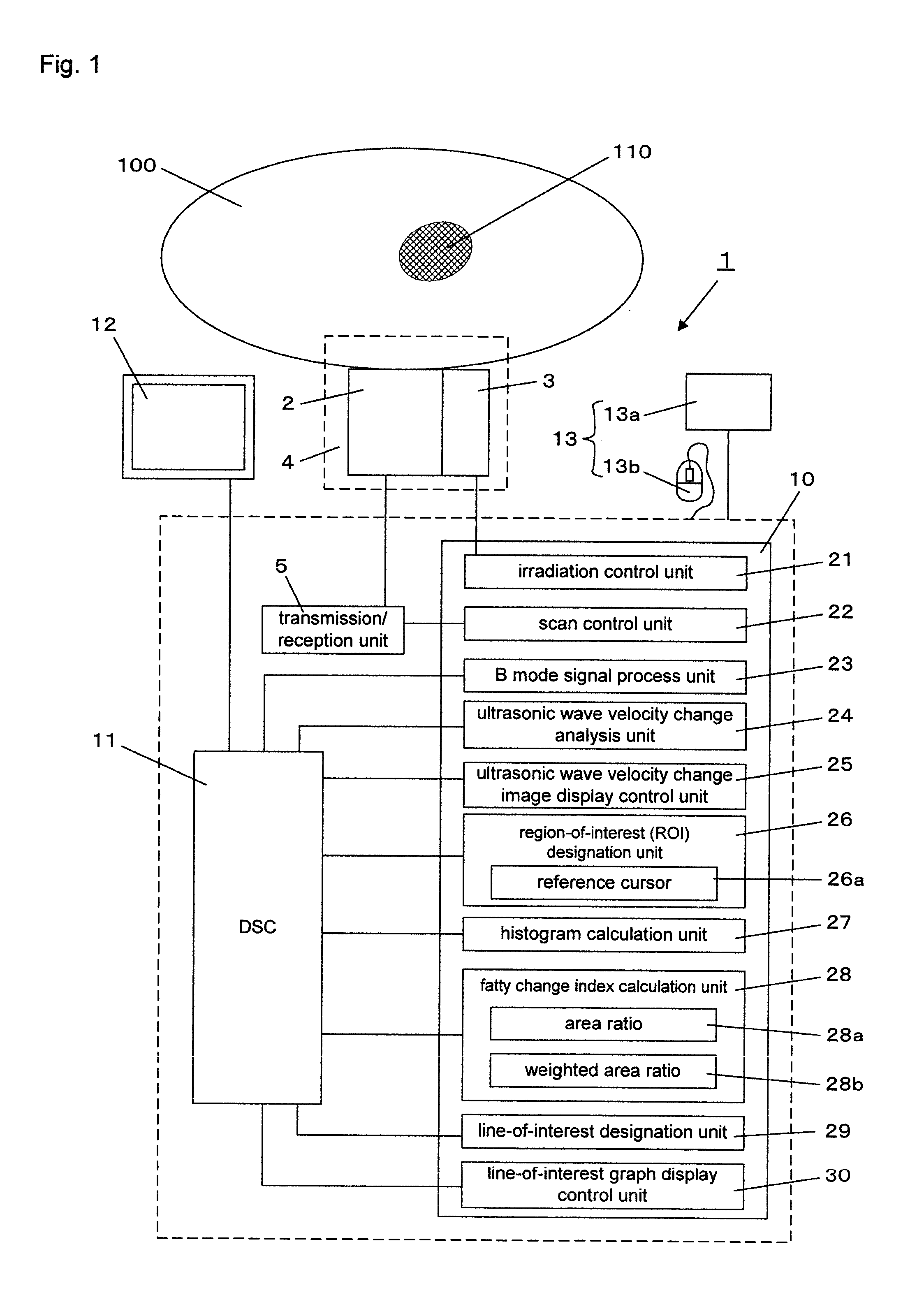

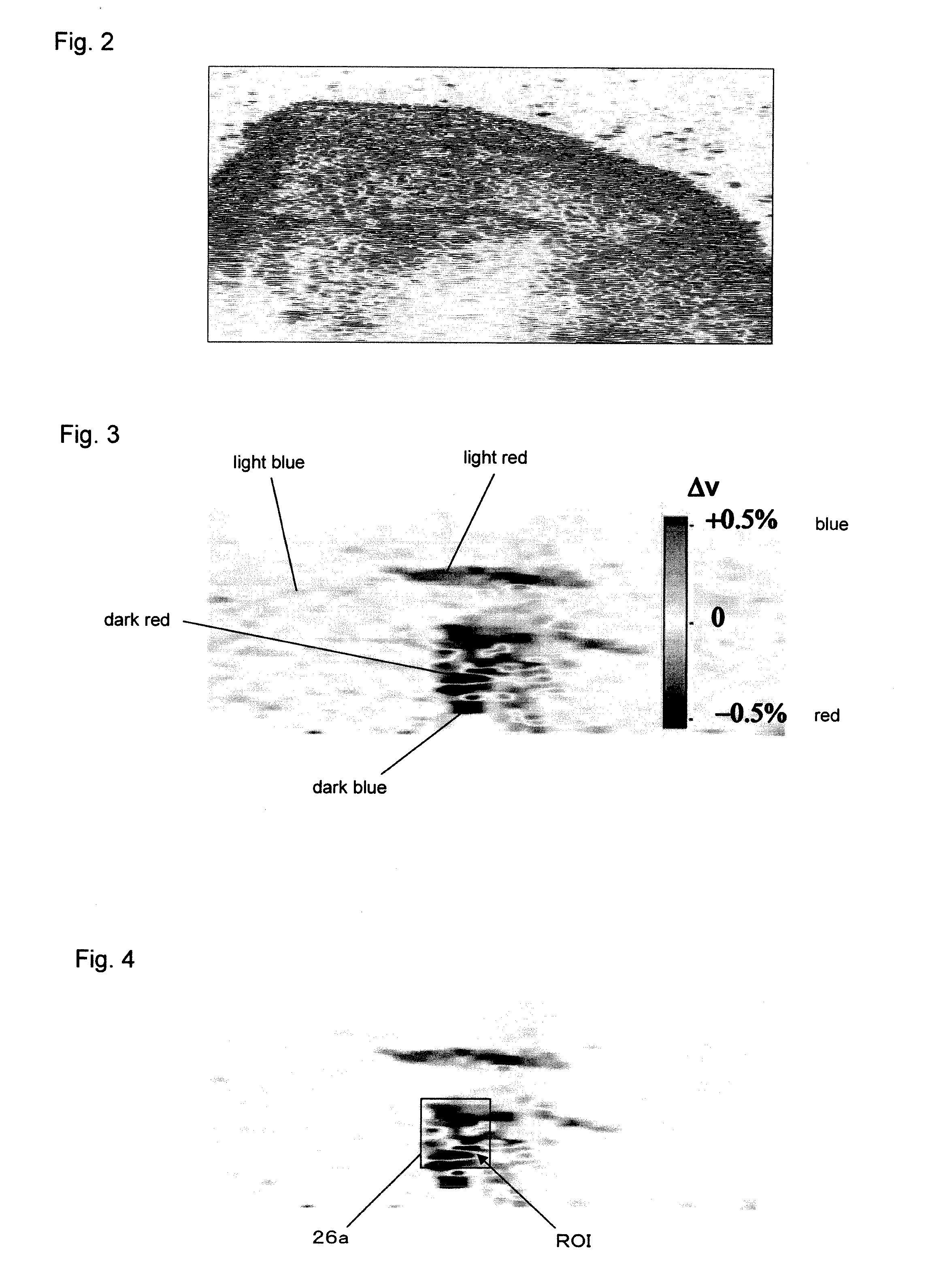

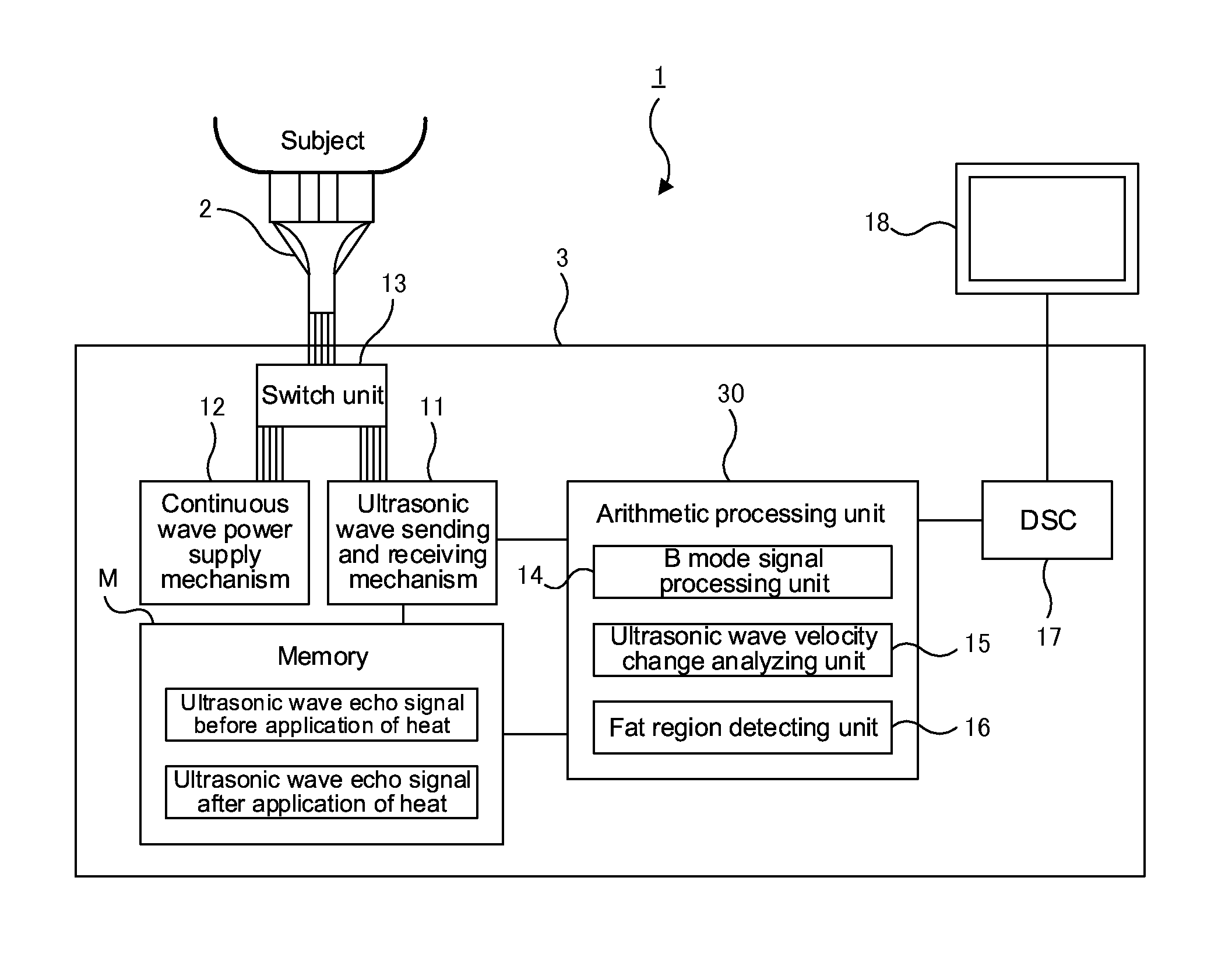

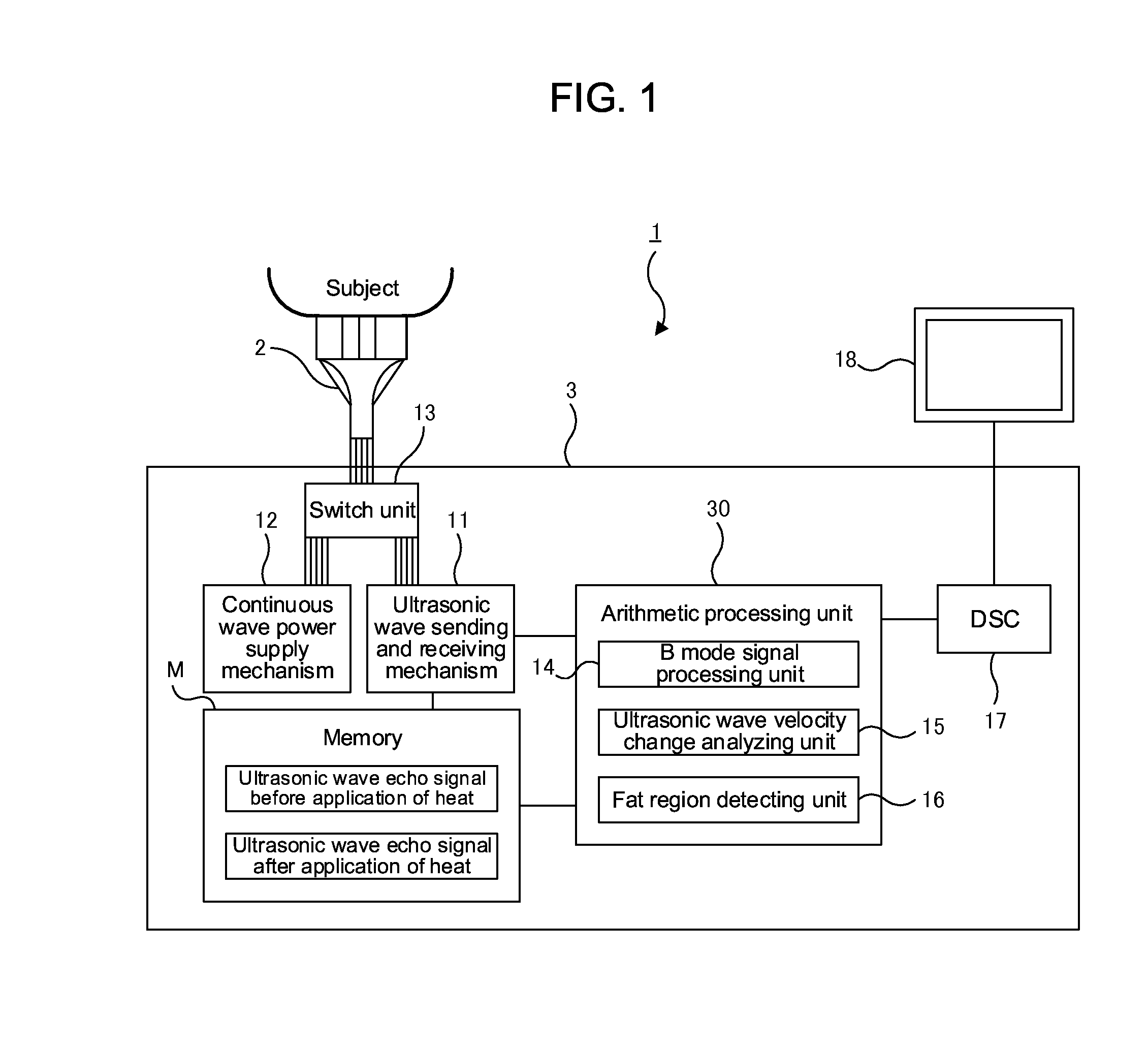

Fatty tissue image display device

InactiveUS20130018262A1Easy to seeDifficult to quantifyHealth-index calculationOrgan movement/changes detectionUltrasonic velocityTomographic image

Provided is a fatty tissue image display device capable of displaying an index indicating the degree of progress of fatty change. The fatty tissue image display device is provided with a light source (3), an ultrasonic wave transmission / reception mechanism (2, 5), an ultrasonic wave velocity change analysis unit (24) which calculates the change in the velocity of the ultrasonic waves after irradiation with a heating beam as compared to before irradiation with light, an ultrasonic wave velocity change image display control unit (25) which displays as a tomographic image the distribution of the calculated change in the velocity of the ultrasonic waves, a region-of-interest designation unit (26) which waits for the designation of a region of interest, a histogram calculation unit (27) which, on the basis of luminance information or color information within the designated region of interest, calculates the histograms of a fatty region showing a negative change in the velocity of the ultrasonic waves and a normal region showing a positive change in the velocity of the ultrasonic waves, and a fatty change index calculation unit (28) which, from the calculated histograms of the fatty region and the normal region, calculates a fatty change index that is the index of the proportion of fatty tissue.

Owner:ADVANTEST CORP +1

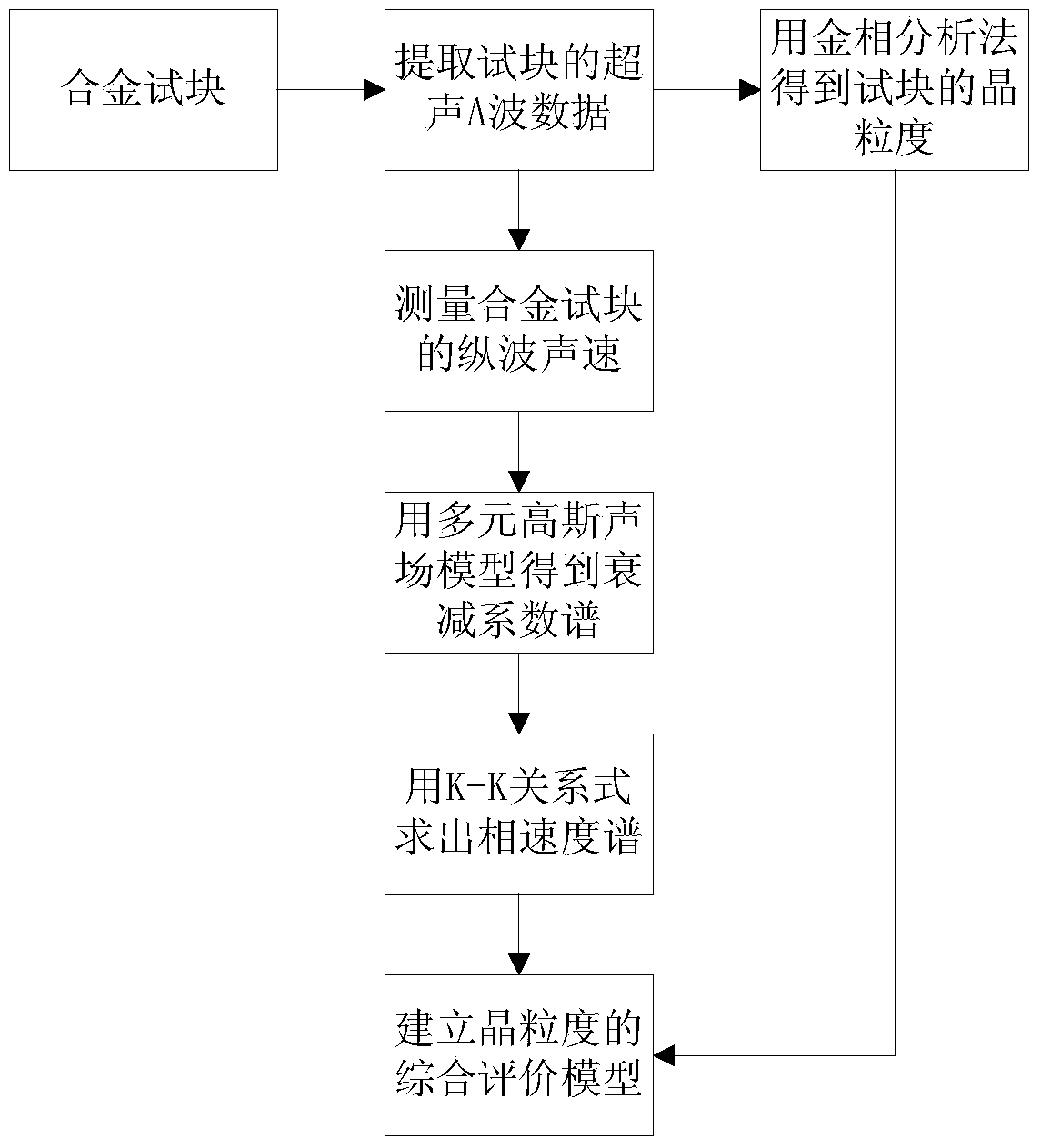

High-temperature alloy grain size evaluation method based on ultrasonic phase velocity

ActiveCN103645248AImprove stabilityHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesAttenuation coefficientPhase difference

The invention discloses a high-temperature alloy grain size evaluation method based on an ultrasonic phase velocity. The high-temperature alloy grain size evaluation method comprises the four steps of extracting original A wave information of a high-temperature alloy test block, calculating a longitudinal wave sound velocity of the test block, acquiring a phase velocity of the test block and constructing a comprehensive evaluation model. The high-temperature alloy grain size evaluation method has the technical effects that an attenuation coefficient spectrum is obtained through a two-medium multi-element Gaussian sound field model, and then a phase velocity spectrum is calculated according to the attenuation coefficient spectrum based on a K-K relational expression; compared with a phase difference algorithm for calculating the phase velocity, the algorithm disclosed by the invention is higher in stability, and the phase velocity of the curved-surface test block can be possibly extracted; moreover, in a process of using the K-K relational expression, the longitudinal wave sound velocity is used as a reference value, so that the high-temperature alloy grain size evaluation method actually integrates the advantages of a conventional ultrasonic longitudinal wave sound velocity method; meanwhile, the phase velocity and the dispersion degree of the phase velocity are considered, the multi-element sound velocity information is fully used, a comprehensive grain size evaluation model is constructed, and the precision of the sound velocity method for evaluating the grain size of high-temperature alloy is improved.

Owner:CENT SOUTH UNIV

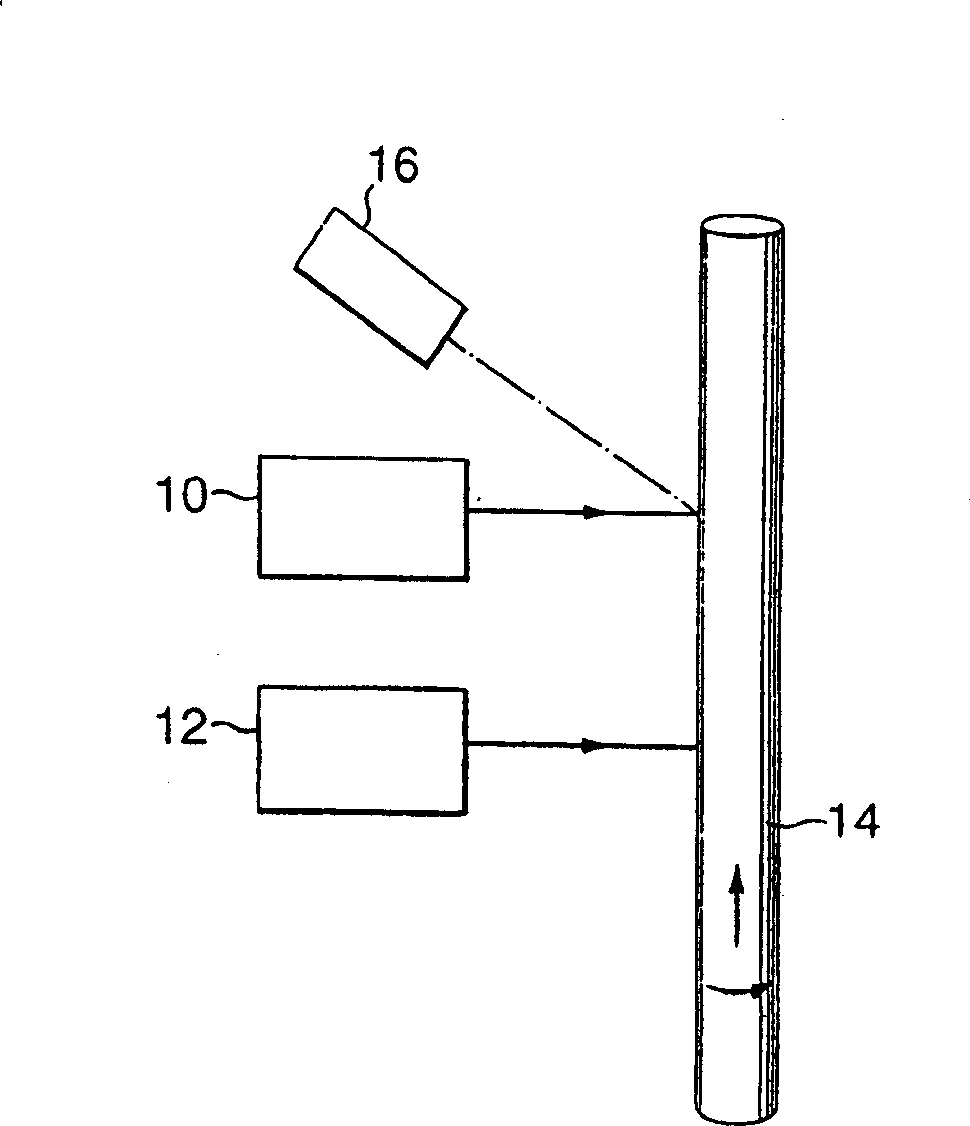

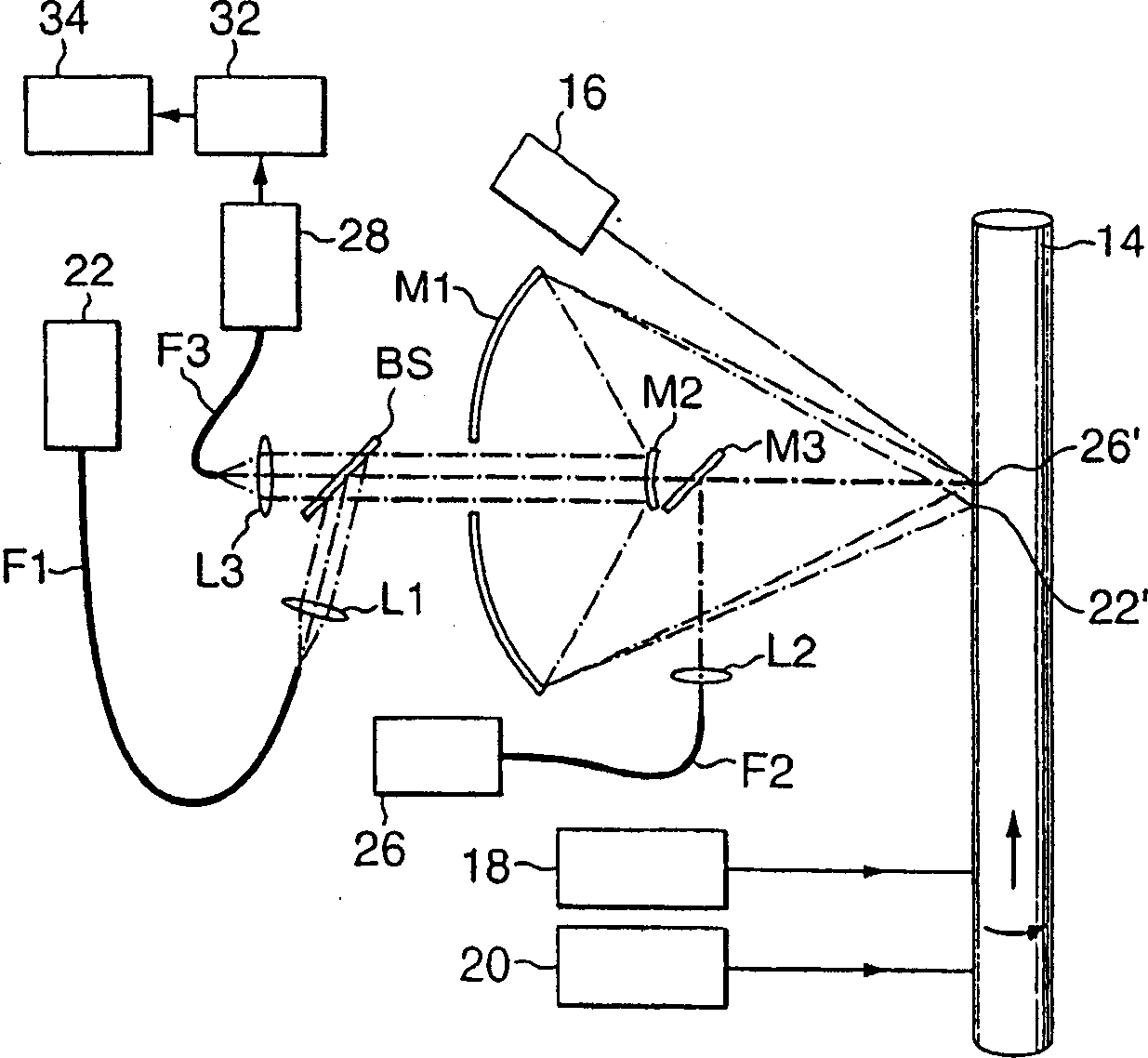

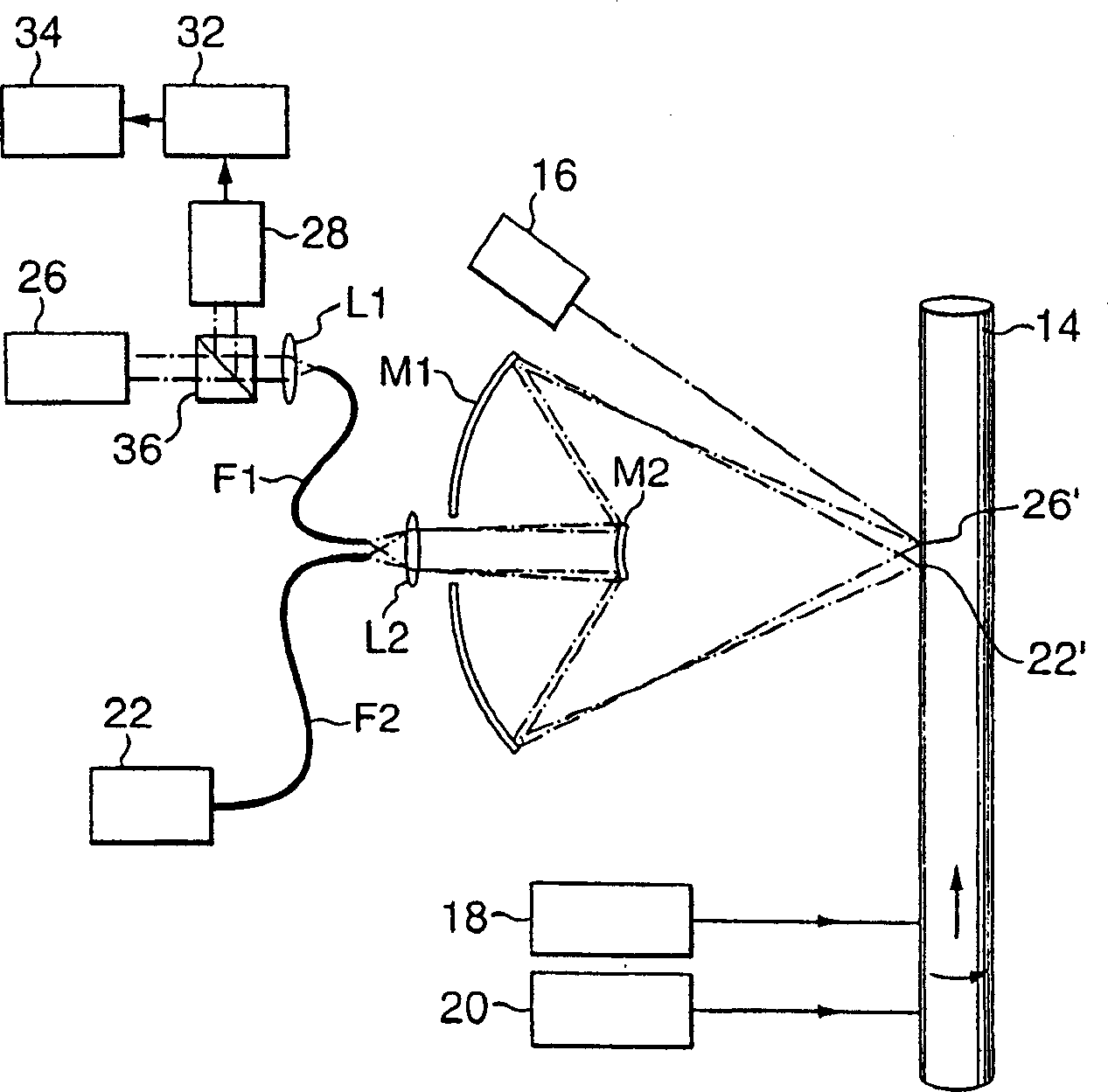

Laser-ultrasonic measurement of wall thickness

InactiveCN1357100AMaterial analysis using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic thickness measurementMeasurement device

An apparatus and method for mapping out wall thickness of a tube or other object having motion in two directions. The device includes a first laser for generating ultrasound propagating inside tube wall over a particular generation spot on a surface of the tube, a second laser coupled to an interferometer for detecting produced ultrasonic echoes over a detection spot on the surface. A processor is provided for operating on recorded ultrasonic echoes and using a given value of ultrasonic velocity and the distance between the generation spot and the detection spots for determining wall thickness at a mid-point between the generation and detection spot. An optical displacement measuring device determines a displacement in two dimensions between the generation spot and arbitrary starting spot and a display for displaying wall thickness values over the surface of the tube.

Owner:NAT RES COUNCIL OF CANADA

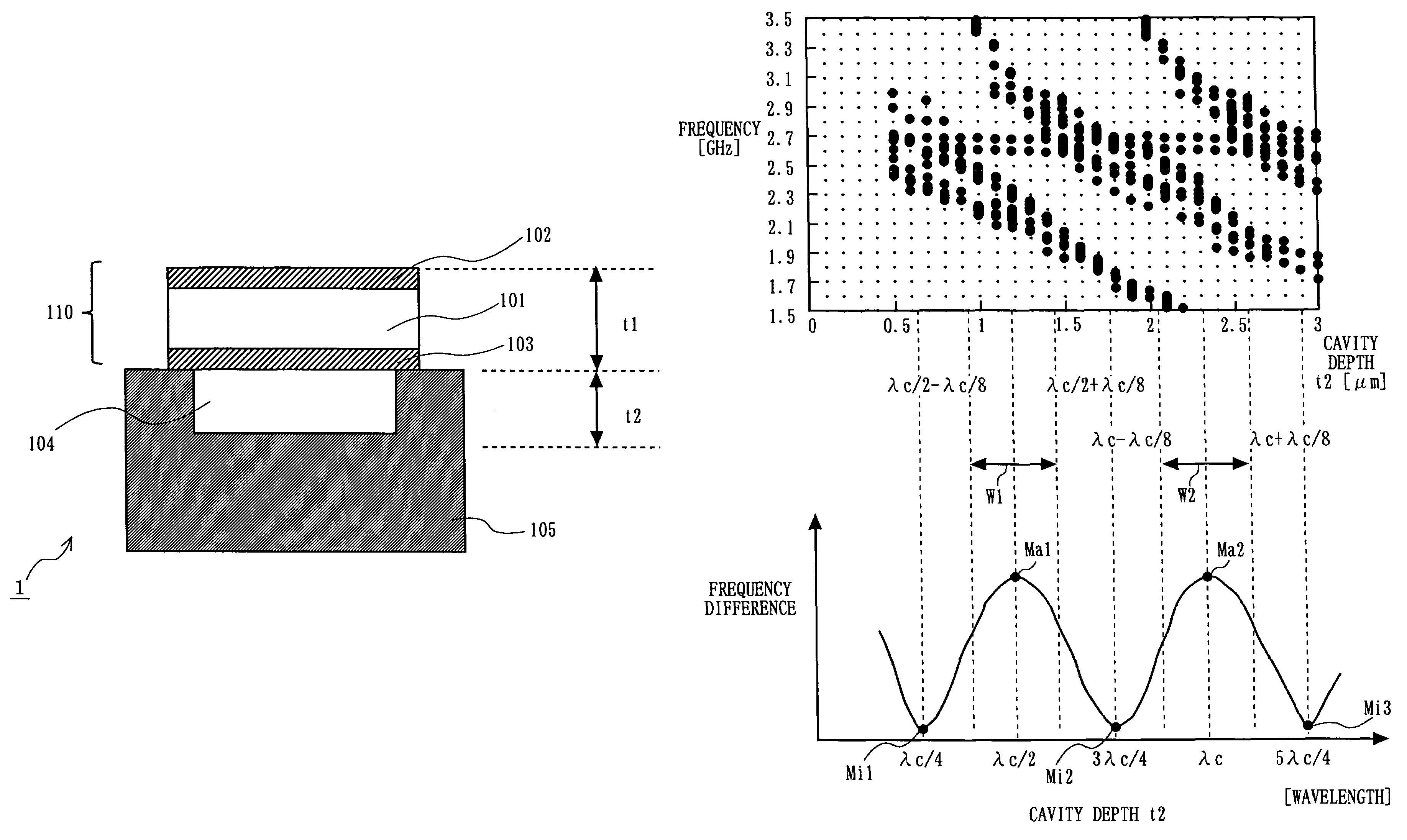

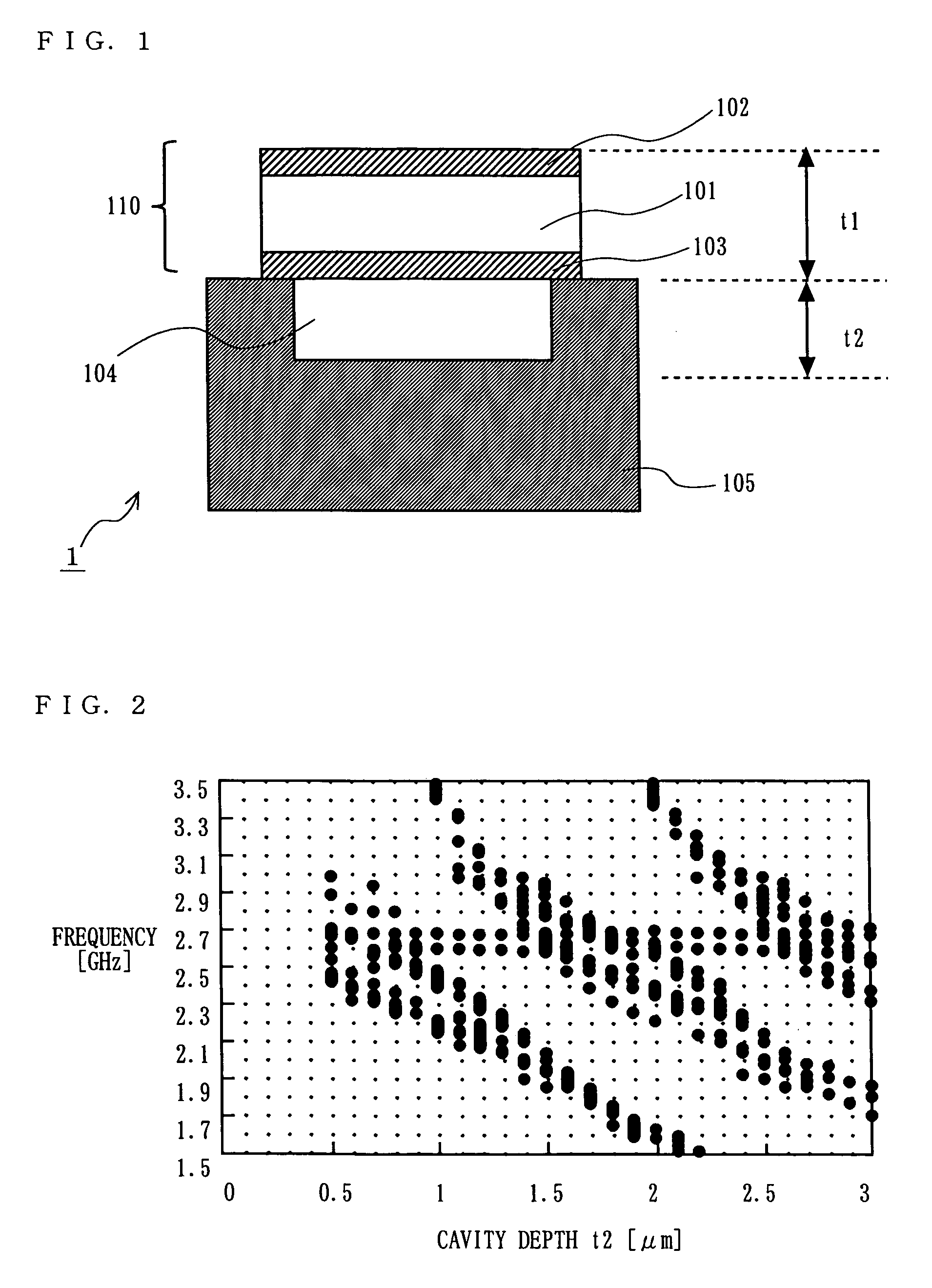

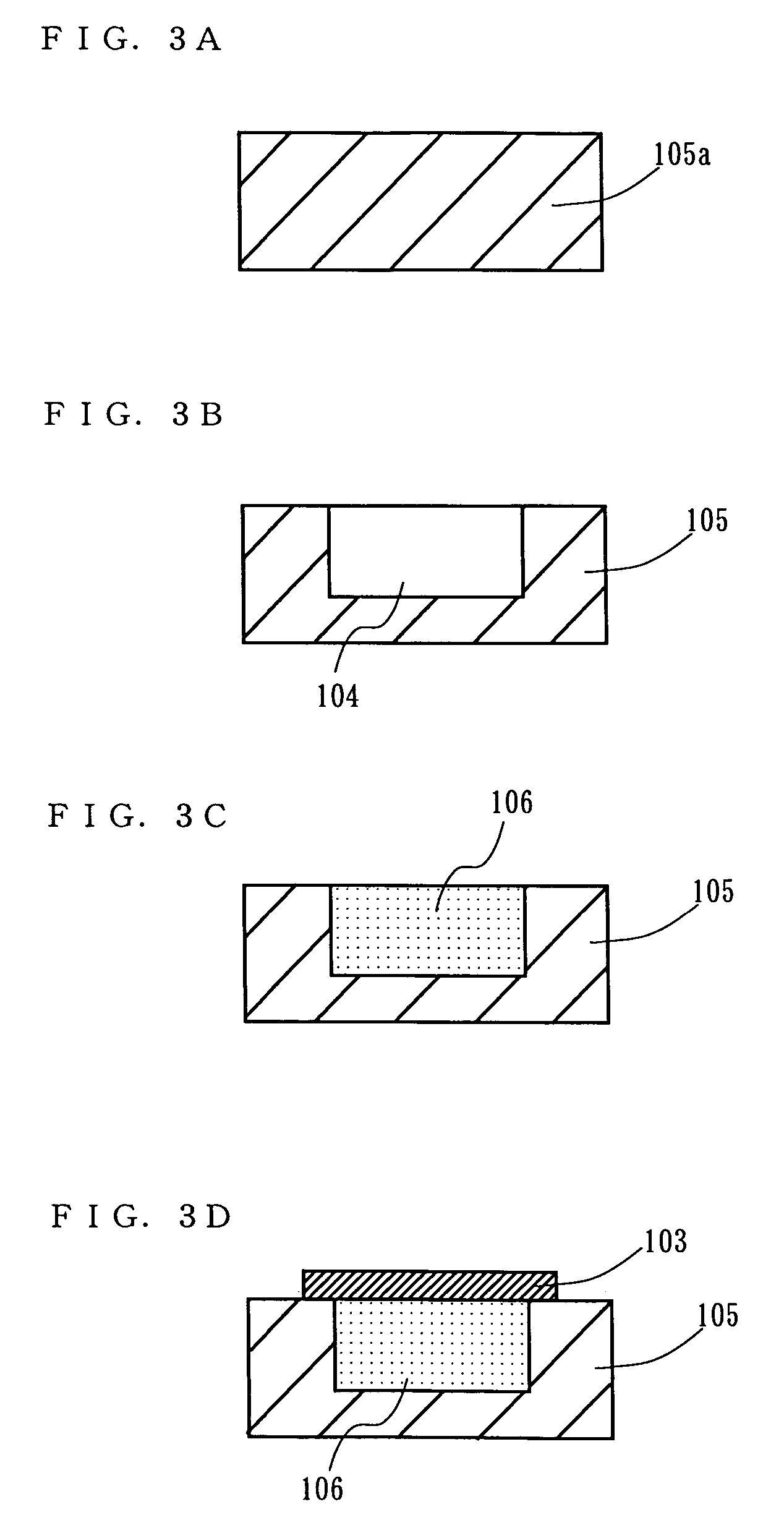

Piezoelectric resonator, method of manufacturing piezoelectric resonator, and filter, duplexer, and communication device using piezoelectric resonator

InactiveUS7113055B2Spurious resonanceSimple manufacturing processPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksUltrasonic velocityLength wave

A piezoeletric resonator includes: a substrate; a lower electrode formed on or above the substrate; a piezoeletric body formed on or above the lower electrode; an upper electrode formed on or above the piezoeletric body; and a cavity under a vibrating portion formed by the lower electrode, the piezoeletric body, and the upper electrode. Where a resonant frequency of vibration with a thickness of the vibrating portion being a half of a wavelength is taken as fr, an average of ultrasonic velocity in a material forming the cavity is taken as Vc, and a value determined based on the resonant frequency fr and the average of ultrasonic velocity Vc is taken as λc (=Vc / fr), a depth of the cavity is set so as to be equal to or larger than n×λc / 2−λc / 8 and equal to or smaller than n×λc / 2+λc / 8.

Owner:PANASONIC CORP

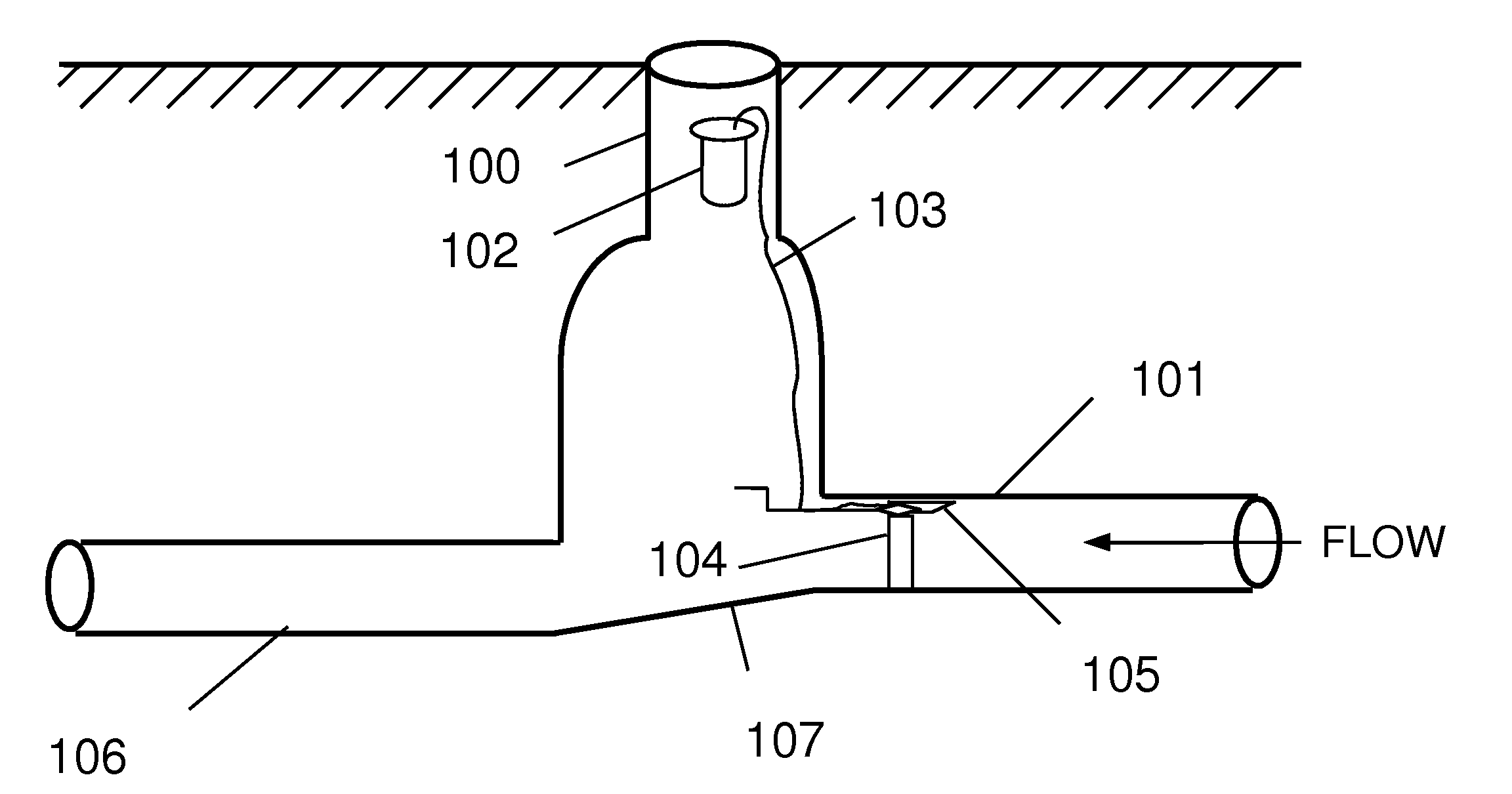

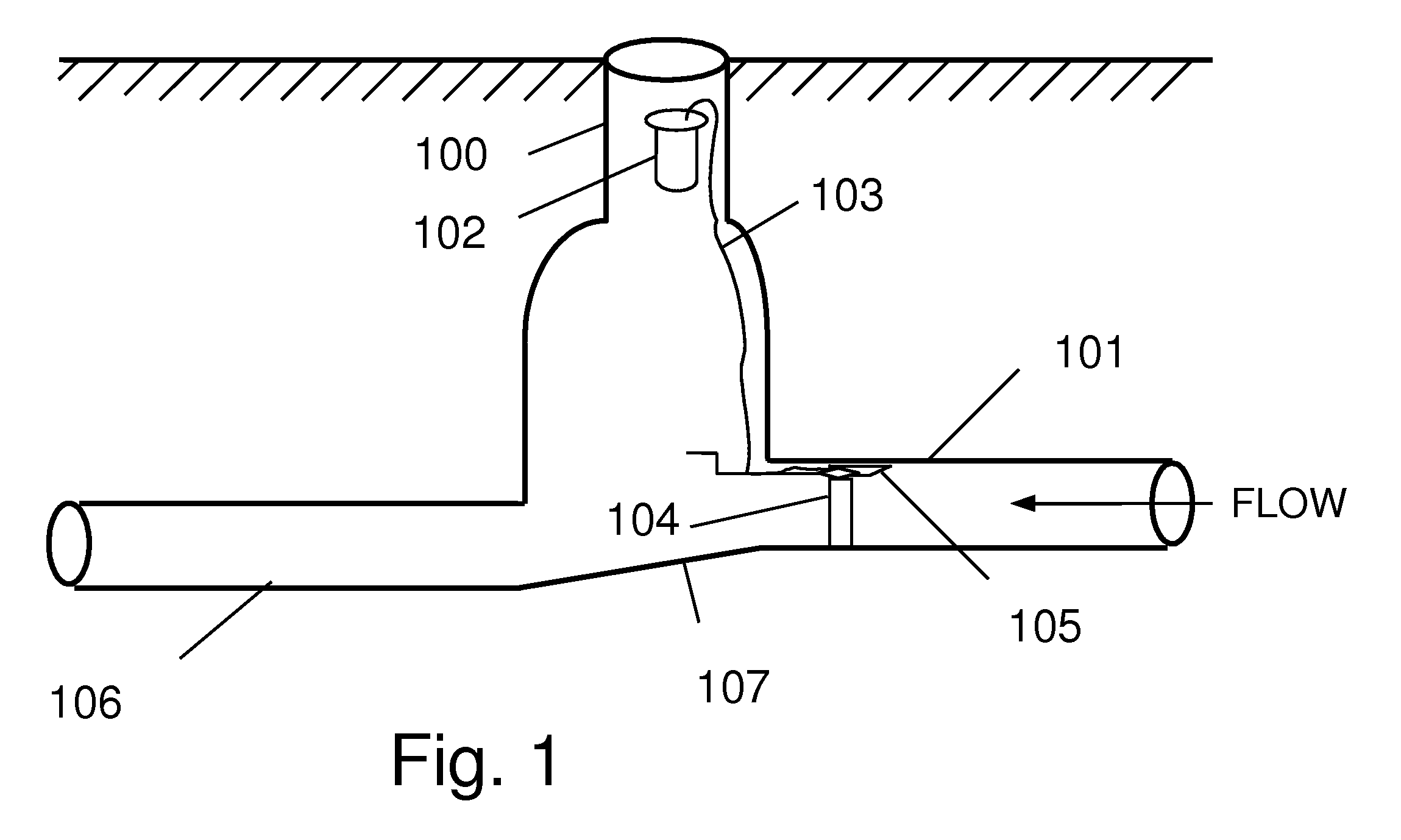

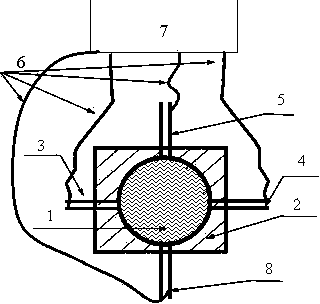

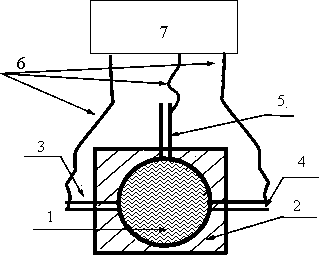

Vapor-water mixed heating device

InactiveCN102072676ALow mixing noiseGuaranteed uptimeDirect contact heat exchangersUltrasonic velocityEngineering

The invention relates to a vapor-water mixed heating device, which comprises a vapor-water heating chamber. The wall of the vapor-water heating chamber is provided with a water inlet pipe with a flange, a vapor inlet pipe and a water outlet pipe. The vapor-water mixed heating device is characterized in that: a convergent nozzle is arranged in the water inlet pipe; a mixing pipe is arranged in the water outlet pipe; a mixing cavity with a taper inlet is formed in the pipe body of the mixing pipe; the outlet of the convergent nozzle is positioned in the taper inlet of the mixing pipe; and the outer pipe wall at the outlet of the convergent nozzle and the inner pipe wall of the taper inlet of the mixing pipe form an annular Rafael convergent nozzle. Water to be heated is depressurized and accelerated by the convergent nozzle, and injected into the mixing pipe; vapor flows through the annular Rafael convergent nozzle, is adiabatically expanded, is injected into the mixing pipe in the ultrasonic velocity, and is rapidly mixed with the water to be heated, so that latent heat of vapor is released and the vapor is condensed into water, and the water to be heated absorbs the latent heat of vapor and is heated. The vapor-water mixed heating device is reasonable in design, simple in structure, low in vapor and water mixing noise, stable in operation, wide in regulating amplitude, high in thermal efficiency and wide in application range.

Owner:张夕斌

Method and device for online representing crystallization kinetic process through ultrasonic wave

InactiveCN103512956AConvenient variable temperature transient testOptimizing the cooling and solidification processAnalysing solids using sonic/ultrasonic/infrasonic wavesMolten stateThermal state

The invention discloses a testing method and device for online representing crystallization kinetic process through ultrasonic wave. Temperature and pressure sensors and an ultrasonic probe are mounted in the closed material cavity of a PVT testing device, the material is cooled to perform crystallization, synchronous detection is performed to obtain specific volume and ultrasonic wave sound velocity pair time curves at different pressure and temperature, the thermal state of the material can be classified into solid state, crystalline region and molten state from the inflection points of the curves, and the synchronous ultrasonic wave velocity pair specific volume is plotted and fitted to establish the quantitative relation. The mode that the crystallinity degree in a crystallization kinetic equation is expressed through adopting the specific volume, is changed into the mode that the crystallinity degree in a crystallization kinetic equation is expressed through adopting an ultrasonic wave velocity, the crystallization process is quantificationally analyzed, and the rule of influence of material composition, temperature, pressure and medium on the crystallization is researched. The temperature and pressure sensors and the ultrasonic probe are mounted on a production line or the material cavity of a die, the crystallization process can be online represented conveniently in the normal position and lossless way, feedback can be optimized, the cooling technology and the formula can be controlled, and the product quality can be evaluated. High-pressure online testing and rapid pressure and temperature change testing are performed easily through the method.

Owner:BEIJING UNIV OF CHEM TECH

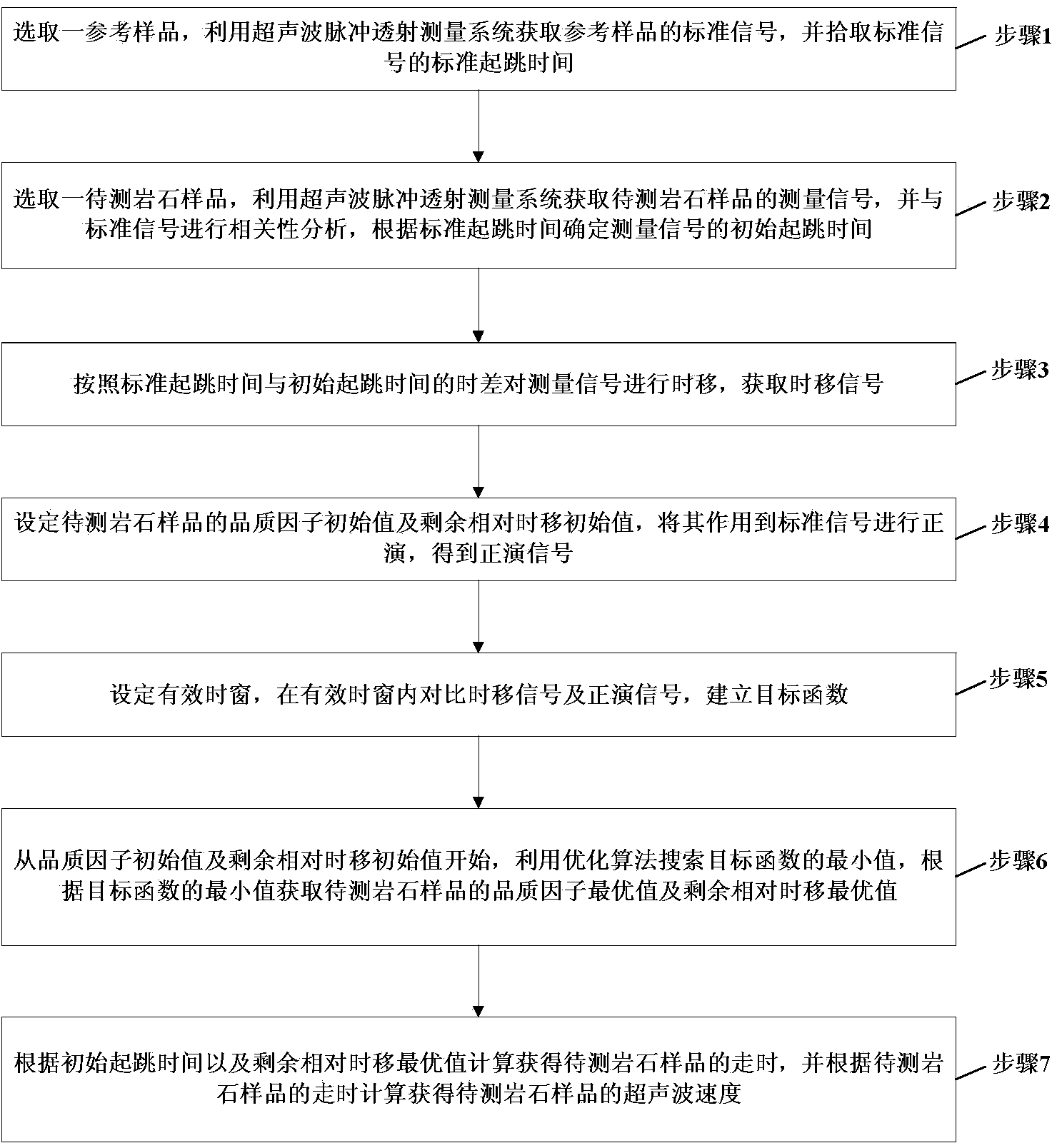

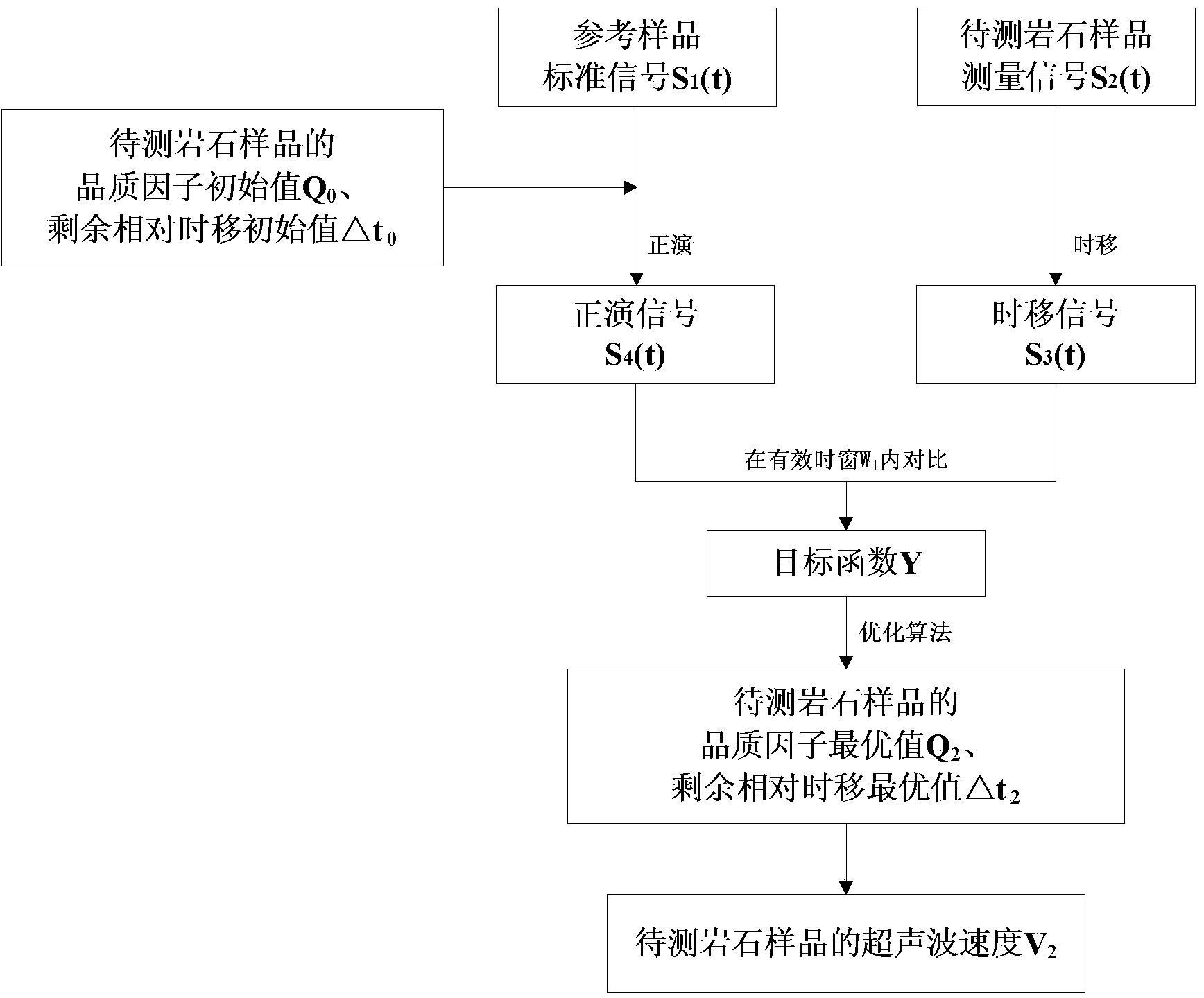

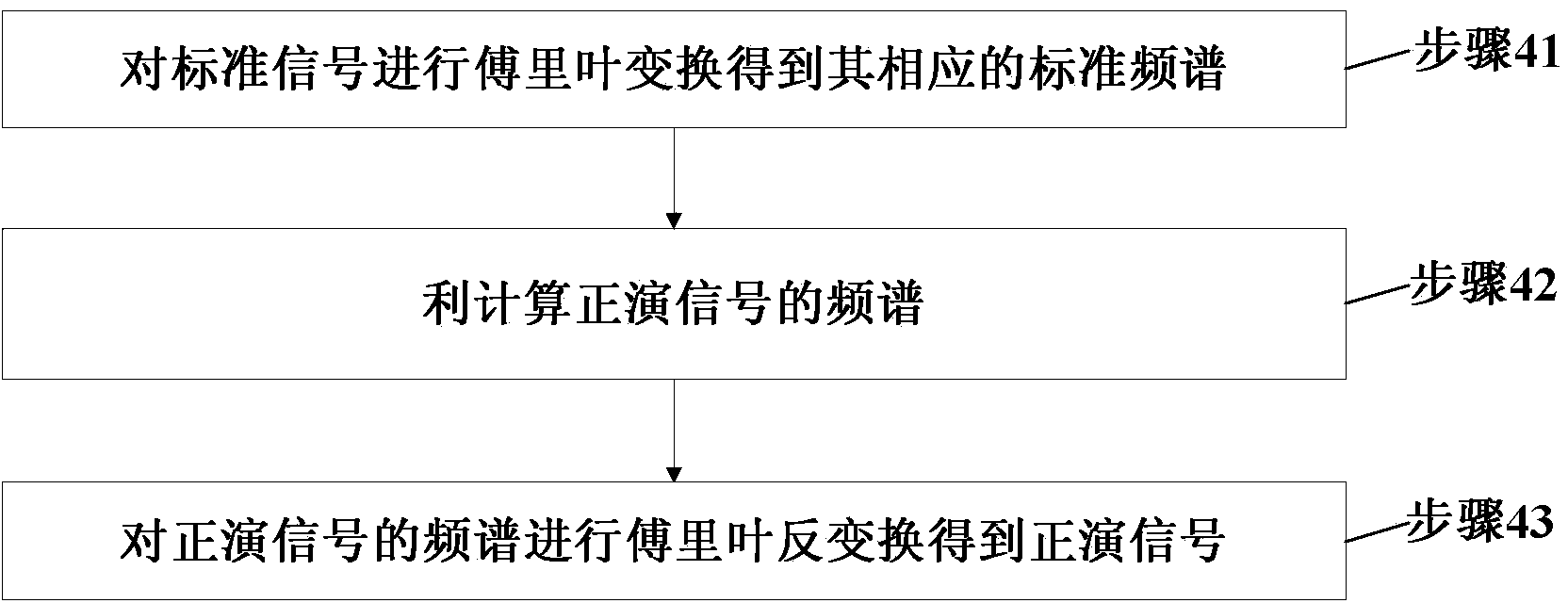

Method and system for simultaneously measuring ultrasonic wave speed and quality factor of rock

ActiveCN104237383AAvoid interactionEliminate the influence of subsequent interference wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalReference sampleUltrasonic velocity

The invention discloses a method and system for simultaneously measuring the ultrasonic wave speed and quality factor of a rock. The method comprises the following steps: selecting a reference sample, obtaining a standard signal of the reference sample by use of an ultrasonic save pulse transmitting measurement system and picking a standard take-off time; selecting a to-be-measured rock sample, obtaining a measuring signal of the to-be-measured rock sample and determining the initial take-off time of the measuring signal; time-shifting the measuring signal according to a time difference to obtain a time shift signal; setting an initial quality factor value and a remained relative time shift initial value of the to-be-measured rock sample and acting the initial quality factor value and the remained relative time shift initial value onto the standard signal to perform forward calculation, so as to obtain a forward calculating signal; comparing the time shift signal and the forward calculating signal within a valid time window to establish a target function; searching the minimum value of the target function by virtue of an optimized algorithm starting from the initial quality factor value and the remained relative time shift initial value, so as to obtain an optimal quality factor value and an optimal remained relative time shift value of the to-be-measured rock sample; calculating to obtain the elapsed time and the ultrasonic wave speed of the to-be-measured rock sample.

Owner:PETROCHINA CO LTD

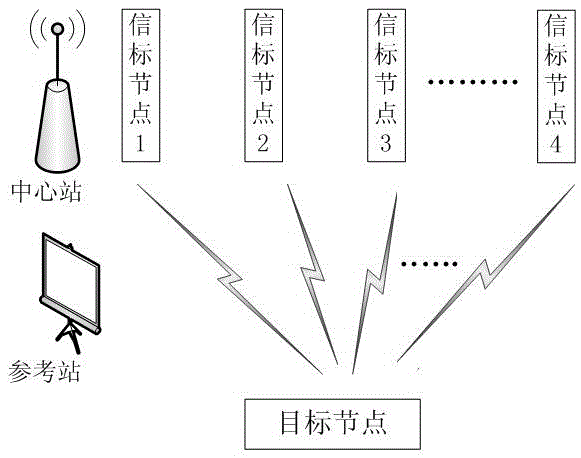

Indoor supersonic wave positioning position correction method

InactiveCN105629201AHigh precisionEliminate positioning errorsPosition fixationSupersonic wavesInformation accuracy

The invention discloses an indoor supersonic wave positioning position correction method. A positioning system consists of a center station, a beacon node, an object node and a reference station. The indoor supersonic wave positioning position correction method can eliminate the positioning errors caused by a supersonic wave speed error, a hardware delay error, an installation error and other errors. Compared with the prior art, the position information accuracy of the object node obtained through the indoor supersonic wave positioning position correction method is high.

Owner:NANCHANG UNIV

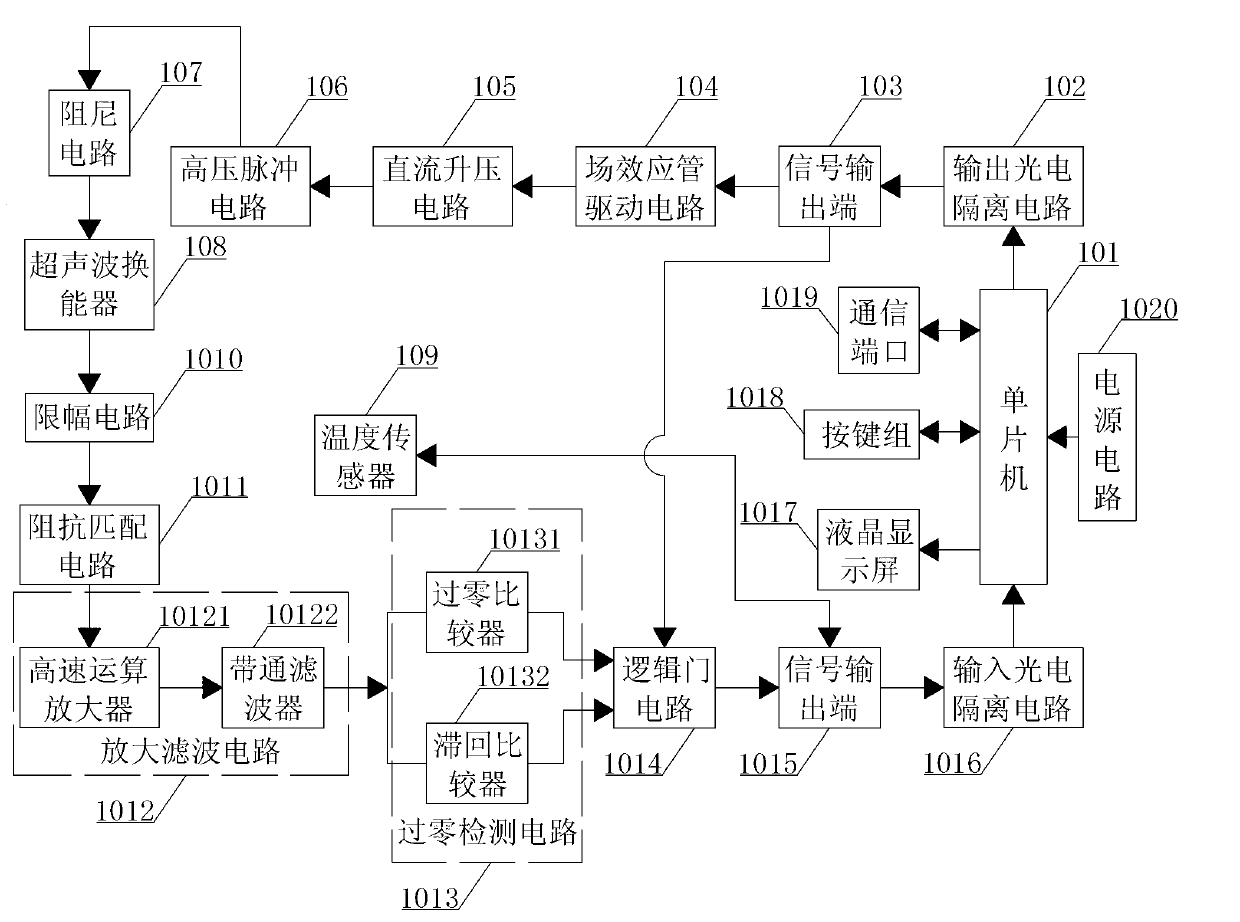

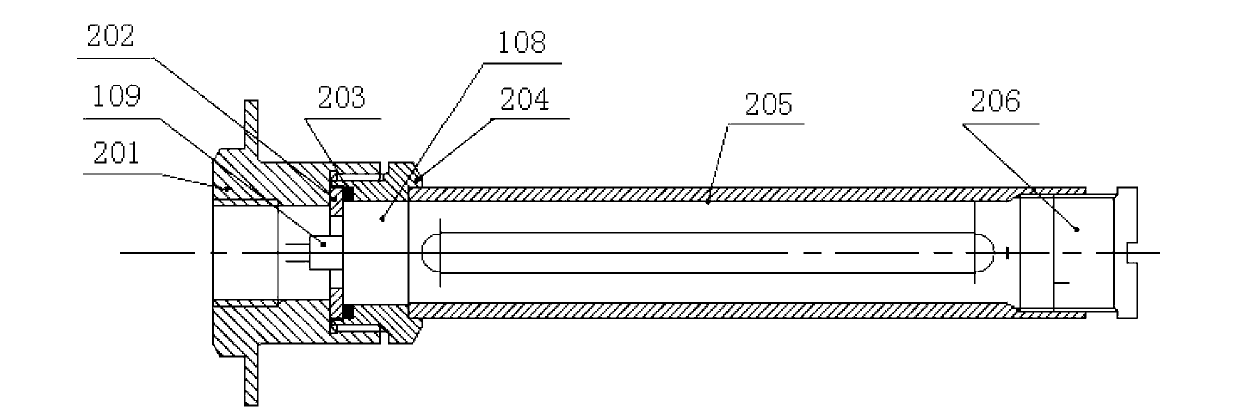

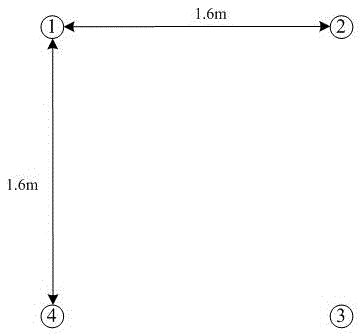

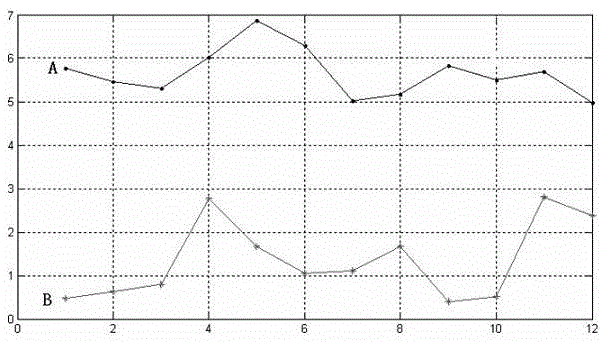

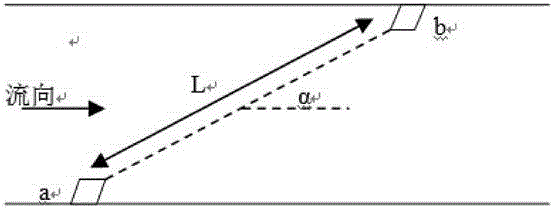

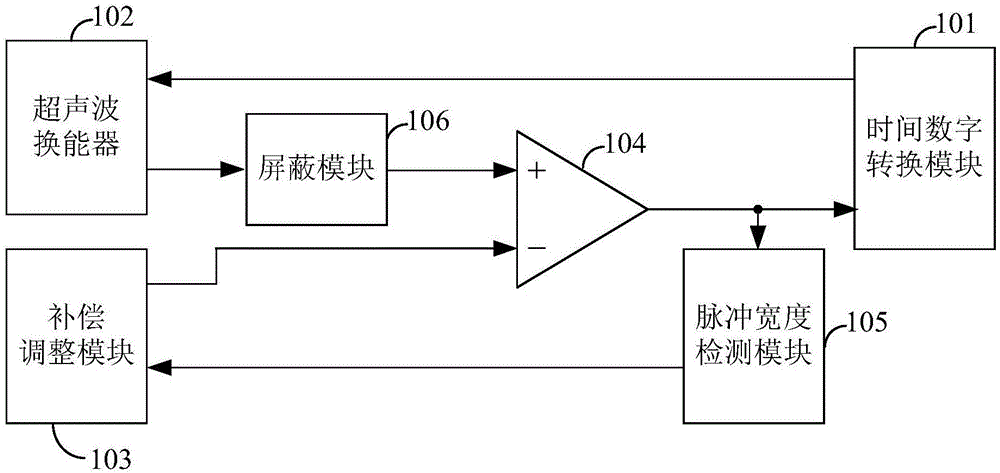

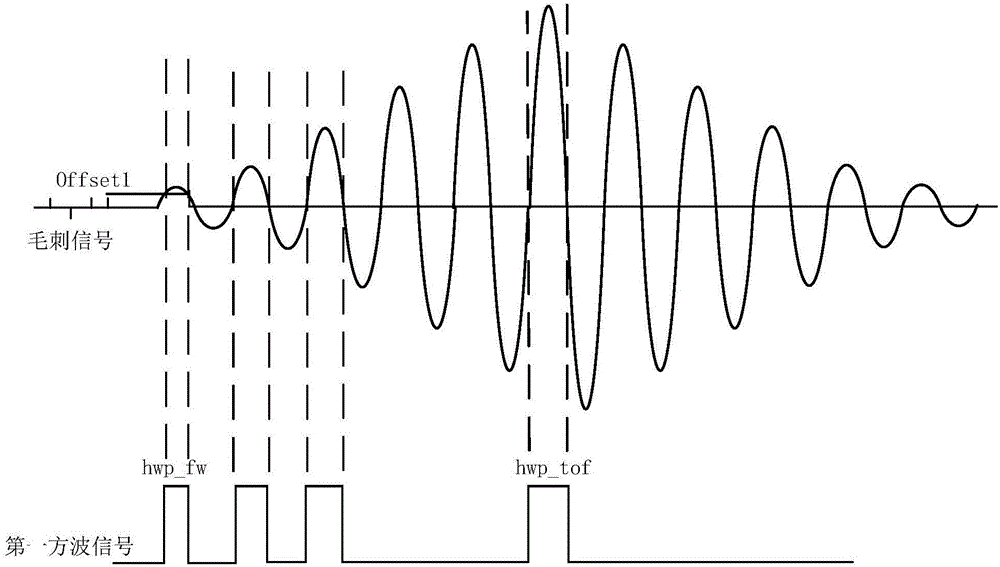

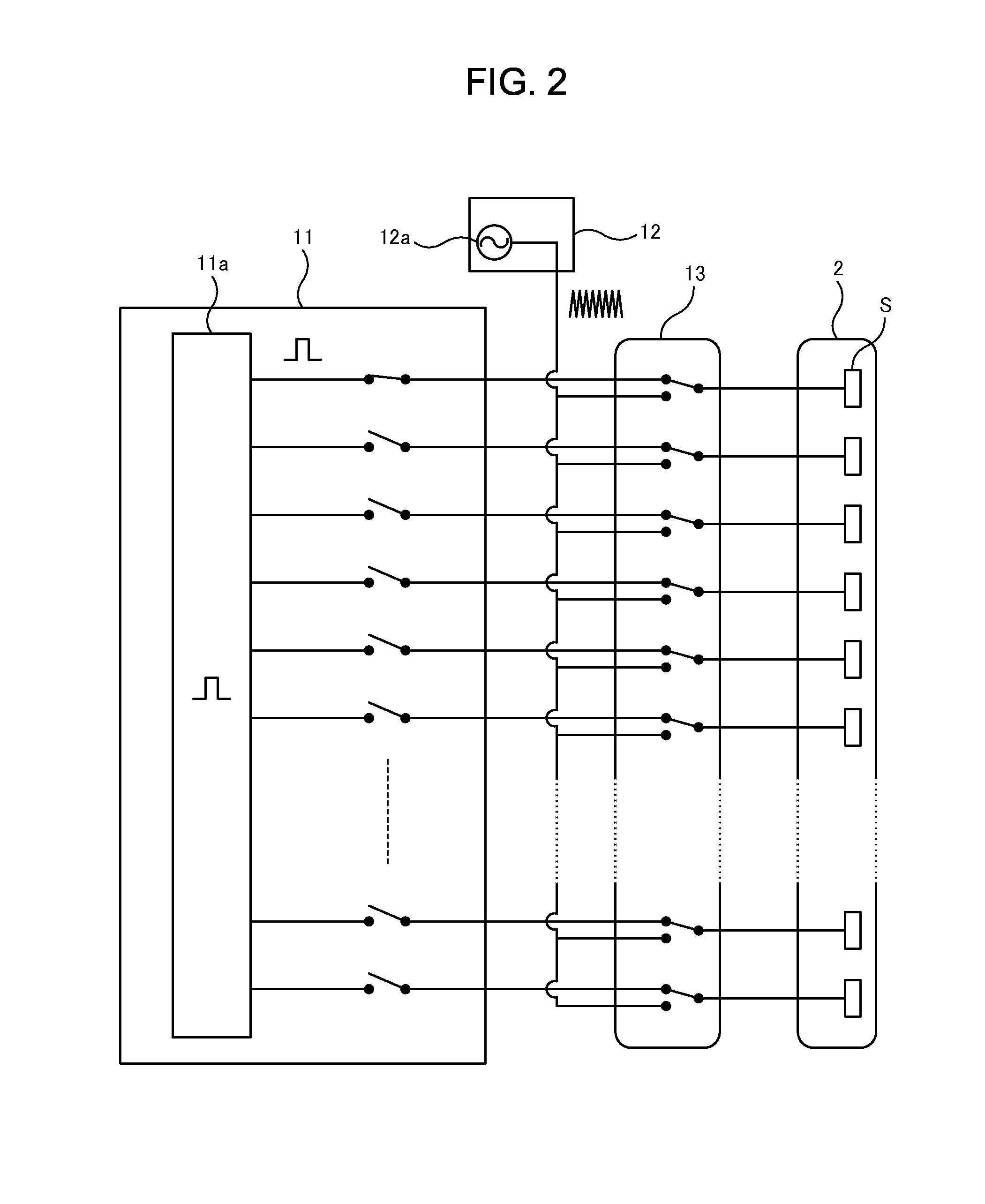

Ultrasonic velocity measurement device and velocity measurement method thereof

The invention belongs to the technical field of ultrasonic flowdetection and provides an ultrasonic velocity measurement device and a velocity measurement method thereof. The ultrasonic velocity measurement device comprises a time digital conversion module, an ultrasonic transducer, a compensation adjustment module, a comparator, a shielding module and a pulse width detection module, wherein a starting signal is outputted to the ultrasonic transducer by the time digital conversion module; an ultrasonicsine wave signal is outputted to the shielding module by the ultrasonic transducer; a shielding window is arranged on the shielding module and is used for shielding the ultrasonicsine wave signal; the comparator is used for acquiring a square signal according to a compensating signal and the shielded ultrasonicsine wave signal, filtering the square signal and acquiring a first wave signal and a sequence square wave; the time digital conversion module is used for acquiring an ultrasonic propagation time difference according to the starting signal and the sequence square wave. The shielding module is arranged for shielding an interference signal in the received ultrasonic wave, so that the problems of mistaken time calculation and flow velocity calculation caused by the operation of mistakenly considering the interference signal as an ultrasonic echo signal can be avoided.

Owner:SHENZHEN RENERGY TECH

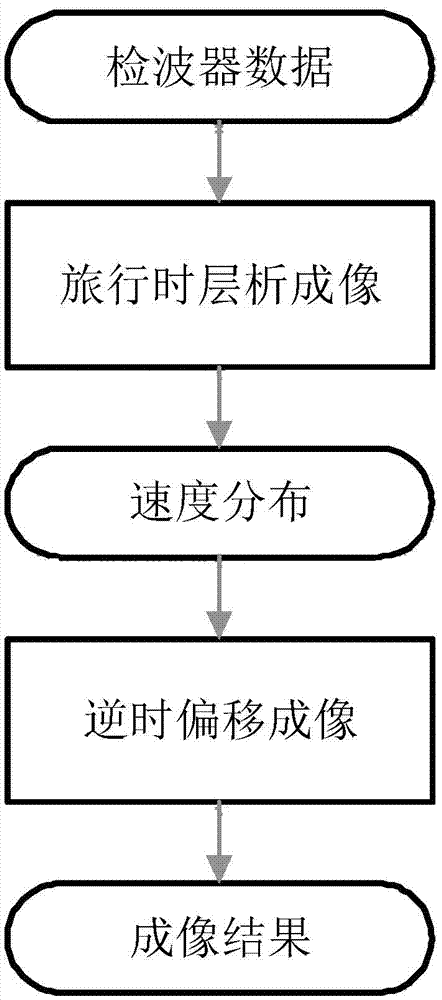

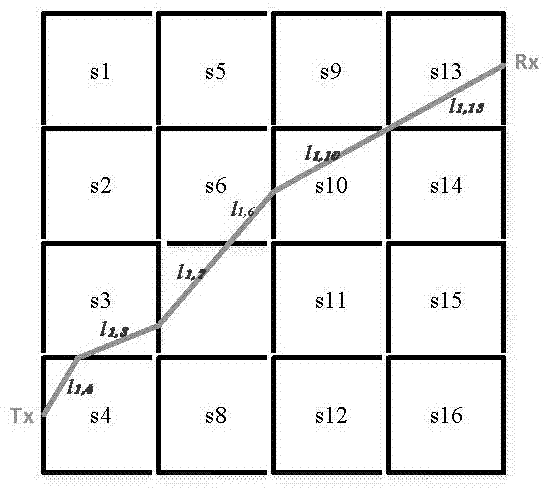

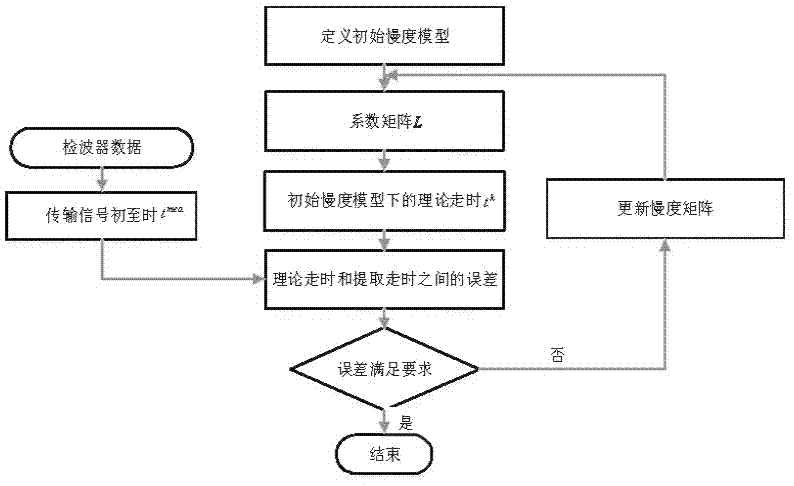

Ultrasonic nondestructive testing method based on travel time tomography and reverse time migration imaging

ActiveCN107356677AHigh precisionPracticalAnalysing solids using sonic/ultrasonic/infrasonic wavesReverse timeSonification

Owner:XIAMEN UNIV

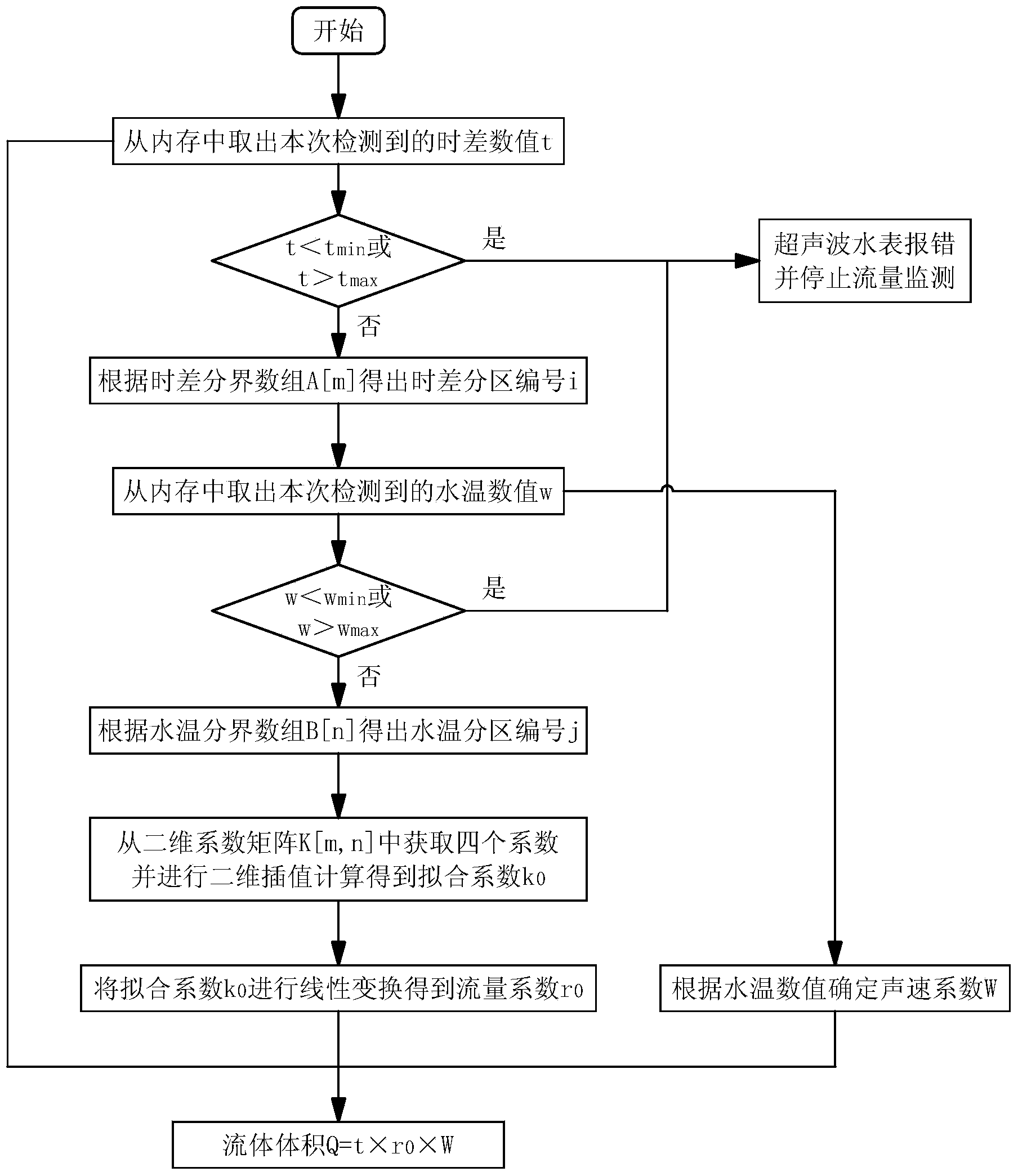

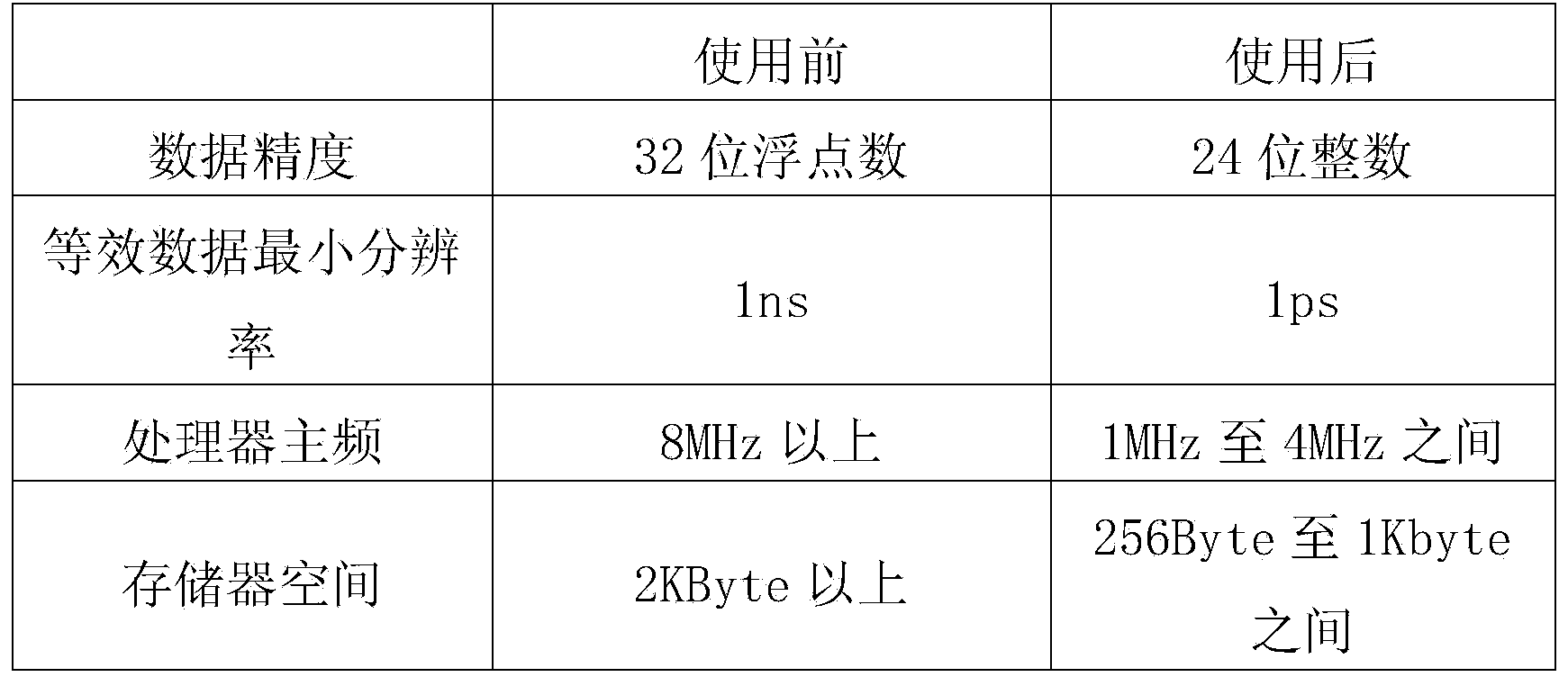

Ultrasonic water meter coefficient processing method

ActiveCN103913203AAccurate calculationReduce manufacturing costVolume/mass flow measurementVolume variation compensation/correction apparatusArray data structureUltrasonic velocity

The invention relates to the technical field of ultrasonic flow detection, in particular to an ultrasonic water meter coefficient processing method. The method includes extracting a time difference value acquired by the current detection in memory, and recording as t; acquiring a time difference area number i according to program built-in time difference boundary arrays A (m); acquiring a water temperature value w through the current detection in the memory; acquiring a water temperature area number j according to program built-in water temperature boundary arrays B (n); extracting and processing four elements ki, j and ki, j+1 and ki+1, j and ki+1, j+1 from a program built-in two-dimensional coefficient matrix (m, n) according to the time difference area number i and the water temperature area number j, and acquiring a fitting coefficient k0 through a formula k0 = S1+(S2-S1)*Delta B, an ultrasonic velocity coefficient W through a formula W=c4*w4+c3*w3+c2*w2+c1*w, and a fluid volume Q through a formula Q=t*k0*W. By the series of processing, the flow calculation of an ultrasonic water meter is more accurate, affects on the processing results by various factors are avoided, the processing process is simplified, and water meter manufacturing cost is reduced greatly.

Owner:姜跃炜

Recording paper

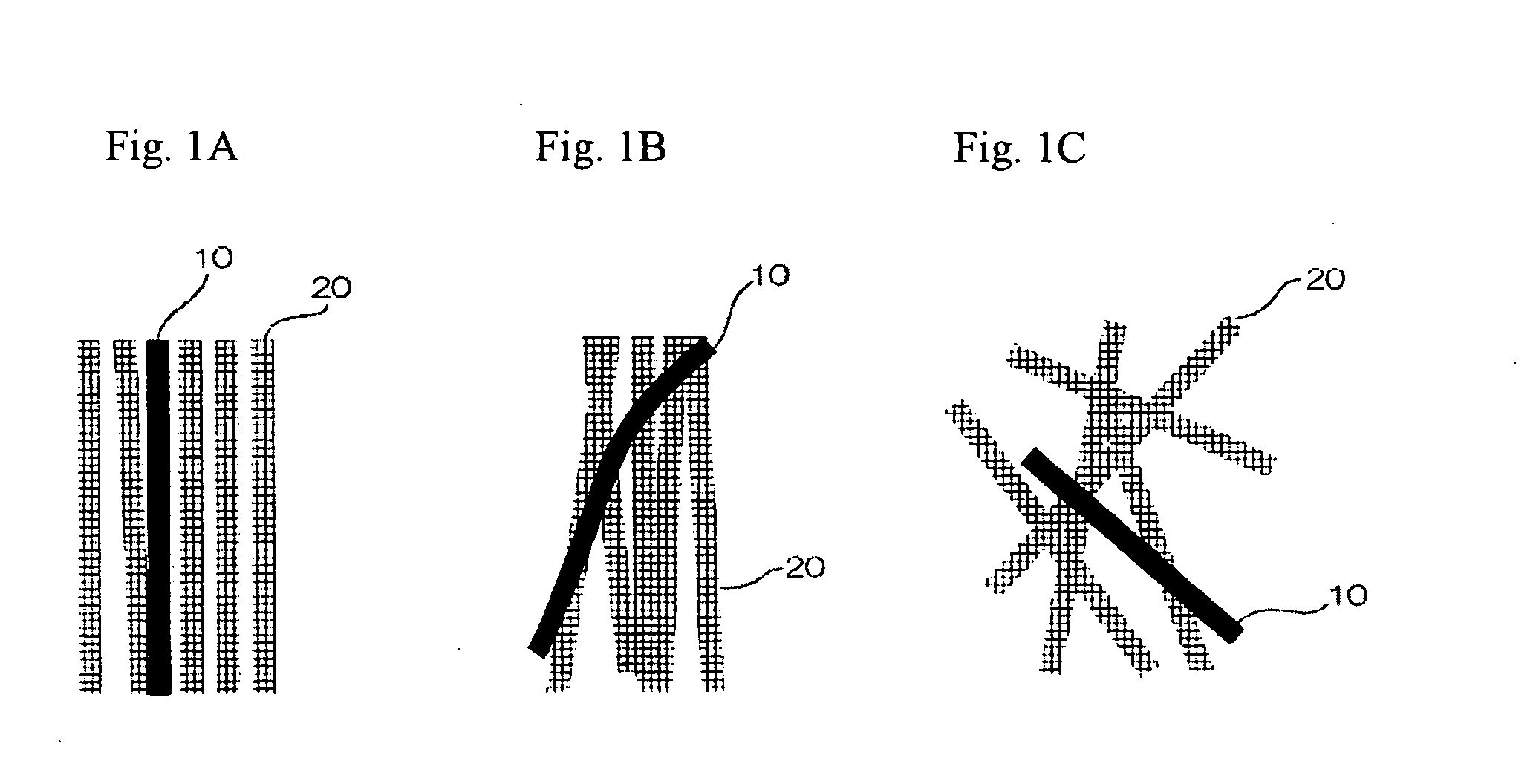

InactiveUS20070243403A1Control conditionReduce opacityDuplicating/marking methodsMaterials with cobaltUltrasonic velocityFiber orientation

Disclosed is a recording paper containing pulp fibers and magnetic fibers, in which the fiber orientation ratio is within a range selected from the range from 1.8 to 3.0 and the range from 1.0 to 1.3 as measured by an ultrasonic wave velocity method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

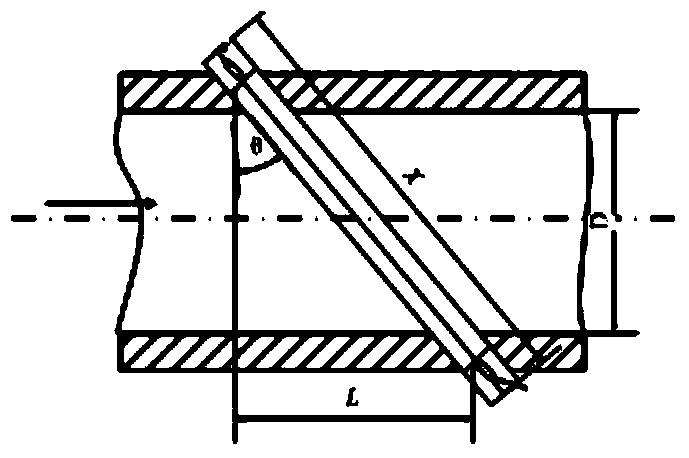

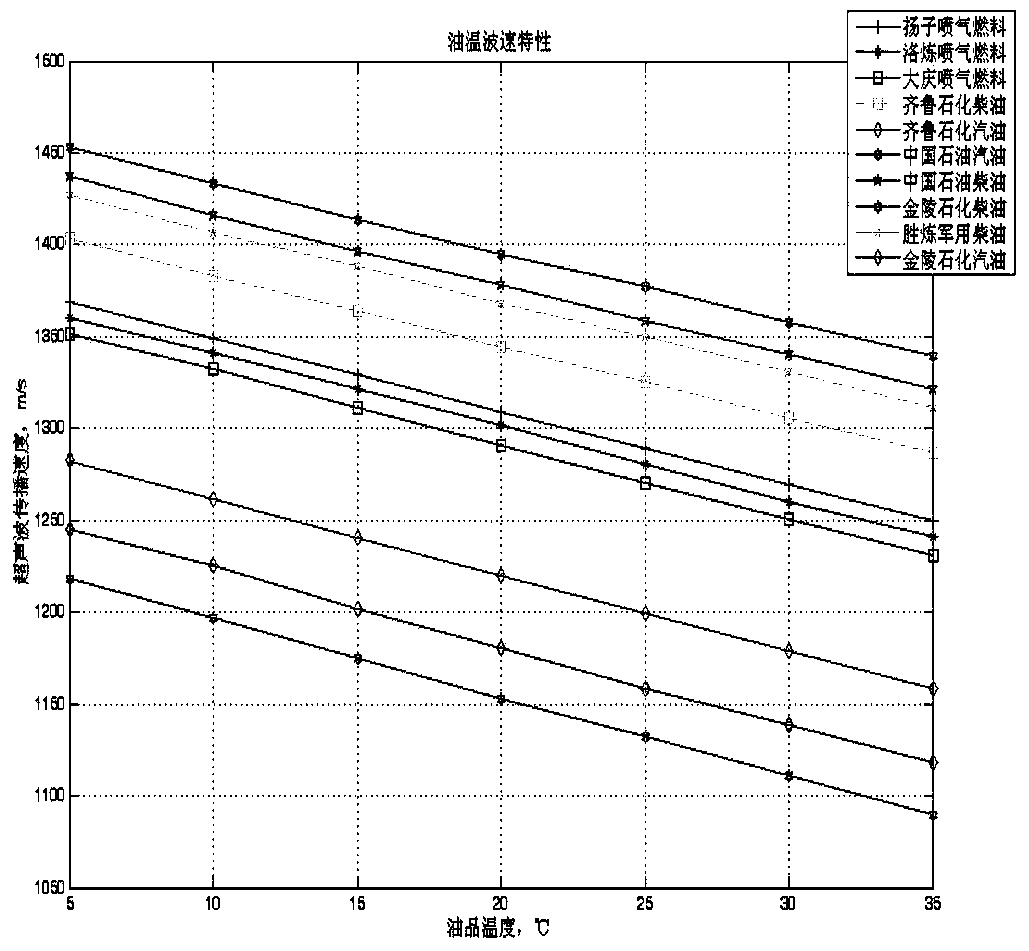

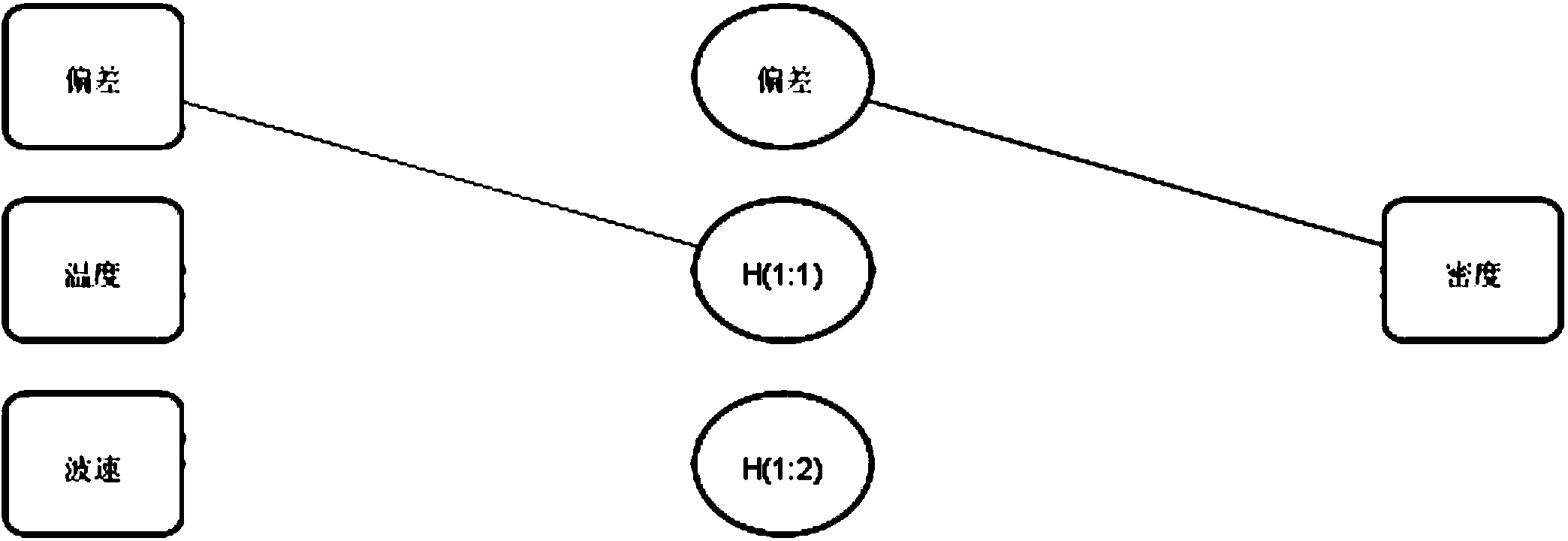

Method for measuring quality and flow of light oil product by using ultrasonic waves

InactiveCN104236653AHigh measurement accuracyIndirect mass flowmetersUltrasonic velocityTime difference

The invention discloses a method for measuring quality and flow of a light oil product by using ultrasonic waves and relates to the technical field of measuring on quality and flow of the light oil product. According to the invention, the relation among the density, sound velocity and temperature of the light oil product is generalized by using experiment data, and the density of the light oil product flowing in a pipeline can be directly obtained by measuring the speed and temperature with the ultrasonic waves. On the basis of the density measuring, volume and flow are measured by using a time-difference method, so the quality and flow of the light oil product are calculated. The method has the advantages that the measuring precision is improved and the maximal relative error is not greater than 0.24%.

Owner:中国人民解放军空军勤务学院

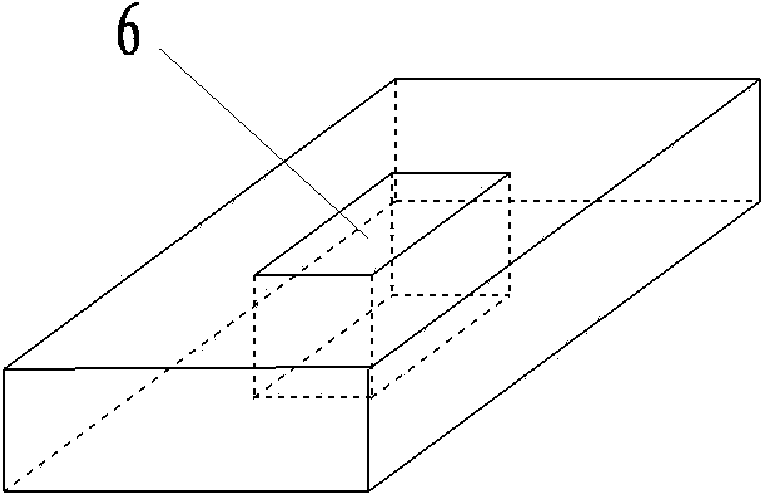

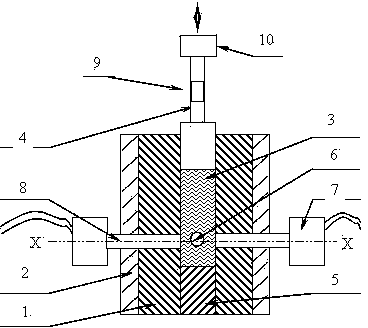

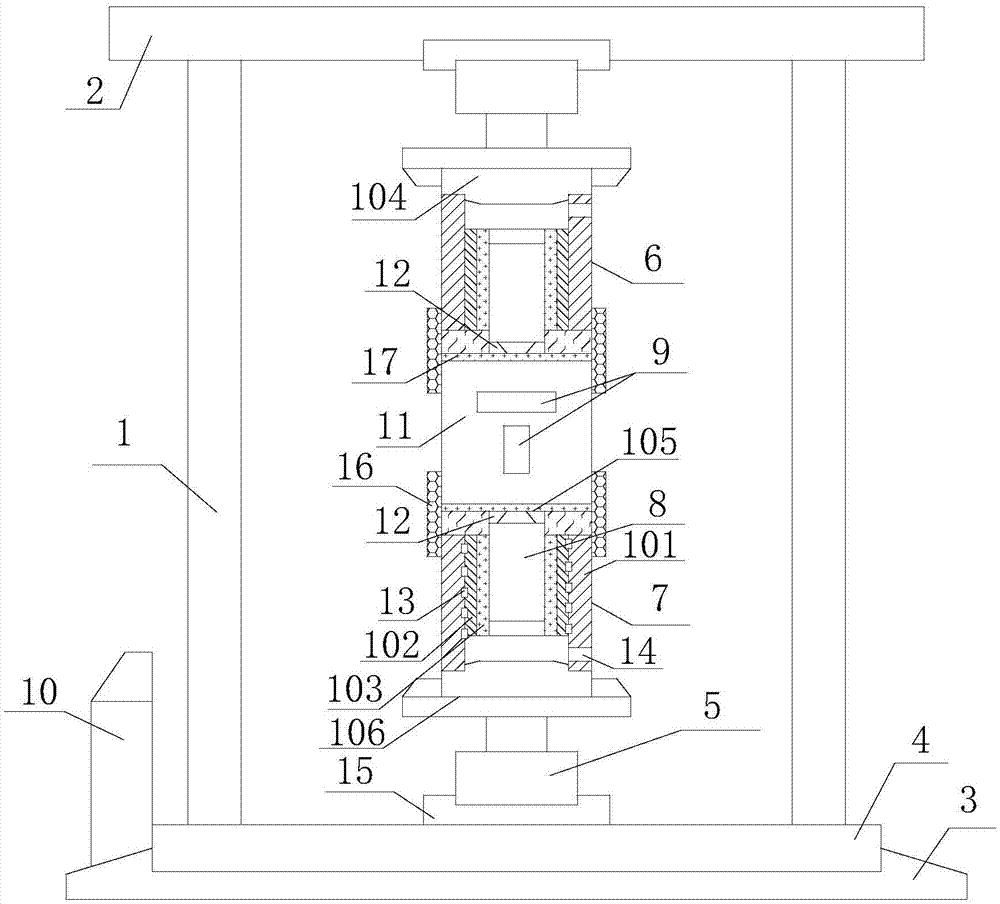

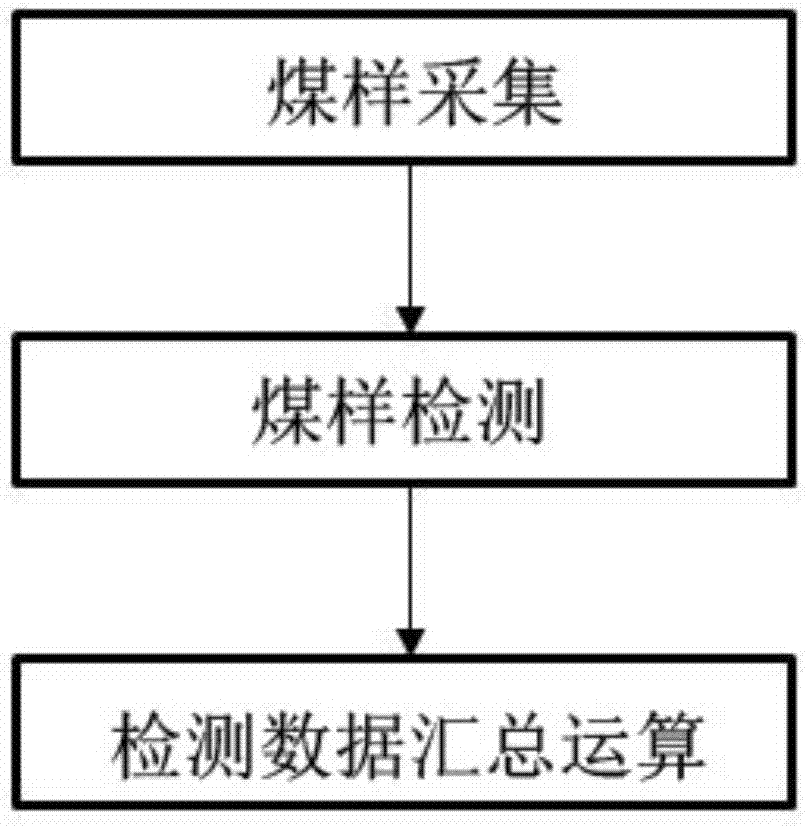

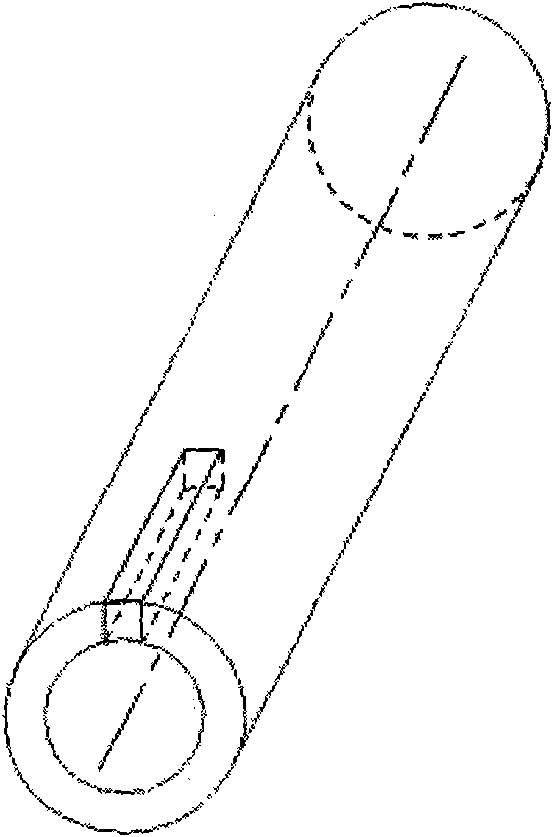

Uniaxial loaded coal ultrasonic velocity testing system device and experimental method thereof

ActiveCN107422039AImprove work efficiencyImprove working precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalTransducerEngineering

The invention relates to a uniaxial loaded coal ultrasonic velocity testing device. The device comprises a bearing stand column, a cross beam, a base, a workbench, a lifting driving mechanism, an upper detection body, a lower detection body, an acoustic transducer, a resistance strain gauge and a control circuit, wherein two ends of the bearing stand column are vertically connected with the cross beam and the base respectively to form a rectangular frame structure; the upper detection body and the lower detection body are respectively arranged on the base and the workbench on the cross beam, and respectively comprises a bearing column, a hard positioning casing, an elastic positioning sleeve and a pressure-bearing end; and the acoustic transducer is embedded in the elastic positioning sleeve. The experimental method of the device comprises three steps of collecting a coal sample, detecting the coal sample and summarizing and calculating detection data. According to the device and method, the work efficiency and accuracy of coal mechanical performance detection operation can be effectively improved on the one hand, and on the other hand, the universality of detection equipment can be effectively improved while the detecting operation efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

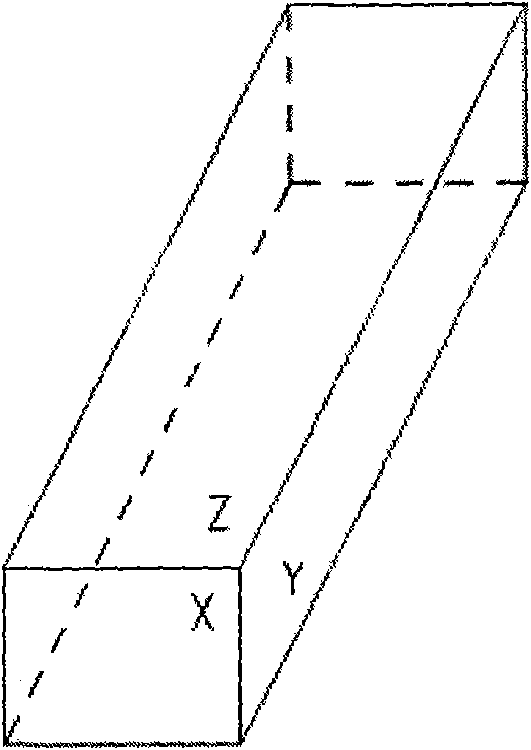

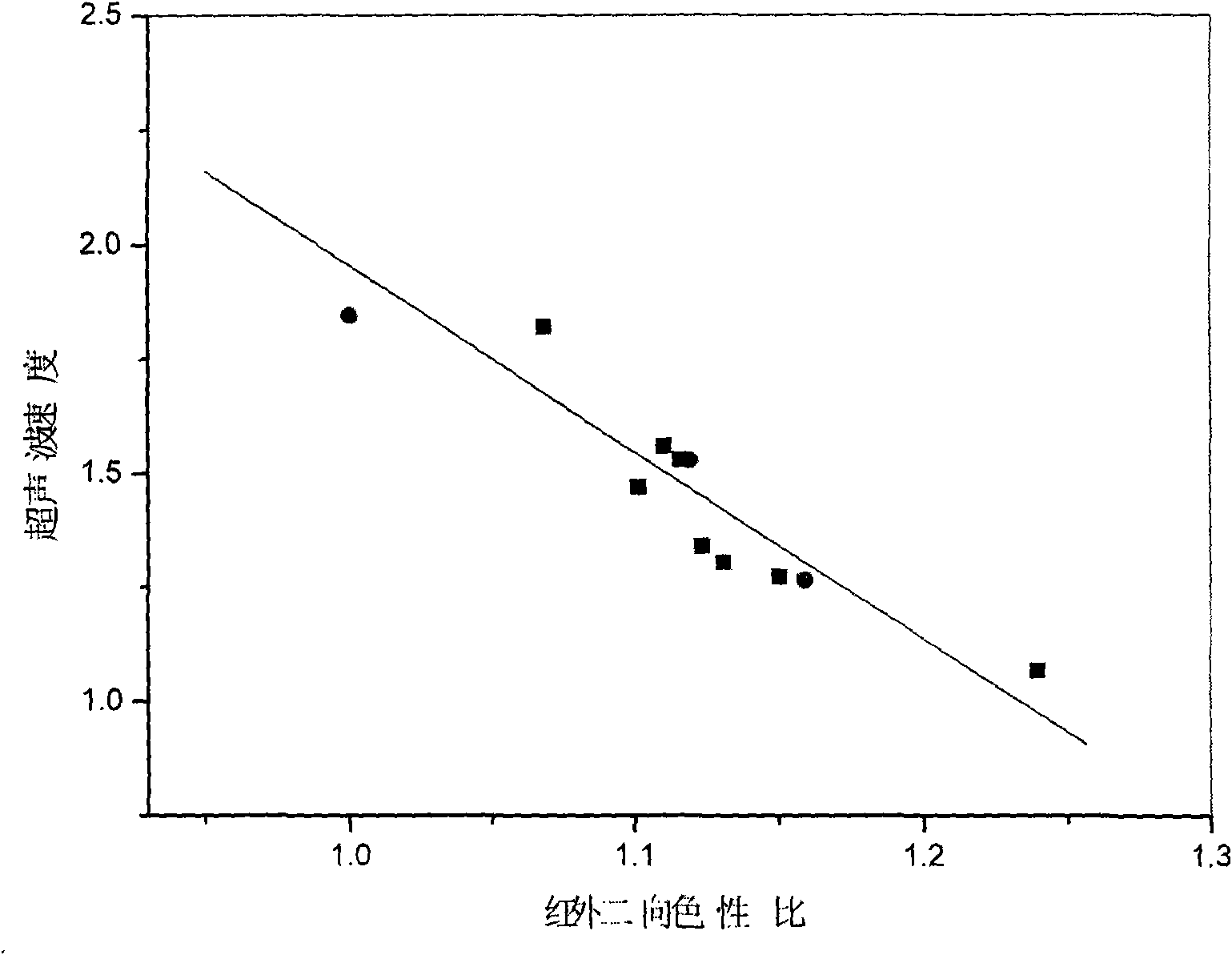

Method for ultrasonically detecting orientation degree of pipe on line

InactiveCN102012400AHigh precisionStrong penetrating powerMaterial analysis using sonic/ultrasonic/infrasonic wavesColor/spectral properties measurementsProduction lineClassical mechanics

The invention relates to a method for ultrasonically detecting the orientation degree of a pipe on line, which belongs to the field of the detection of the orientation degree. The method for detecting the orientation degree of the pipe on line during production is characterized by comprising the following steps of: preparing a plurality of samples with different orientation degrees from the same material, ultrasonically testing the sound velocities of directions, which are vertical to the orientation direction of the material, of the plurality of samples and accurately testing the orientation degrees of the plurality of samples by an infrared dichroism method; establishing a relation between an ultrasonic velocity of a direction which is vertical to the orientation direction and the orientation degree so as to obtain a corresponding working curve; and continuously testing the wave velocity of a pipe which is extruded during production on a pipe production line and testing the orientation degree of the pipe by using the working curve in real time. The defects of high requirement on the orientation degree of the sample, harsh requirement on sampling and offline sample measurement in the conventional test of the orientation degree are overcome. The method is convenient for realizing automatic and intellectualized online monitoring of the orientation degree, improves efficiency and can provide basis for product performance in time.

Owner:BEIJING UNIV OF CHEM TECH

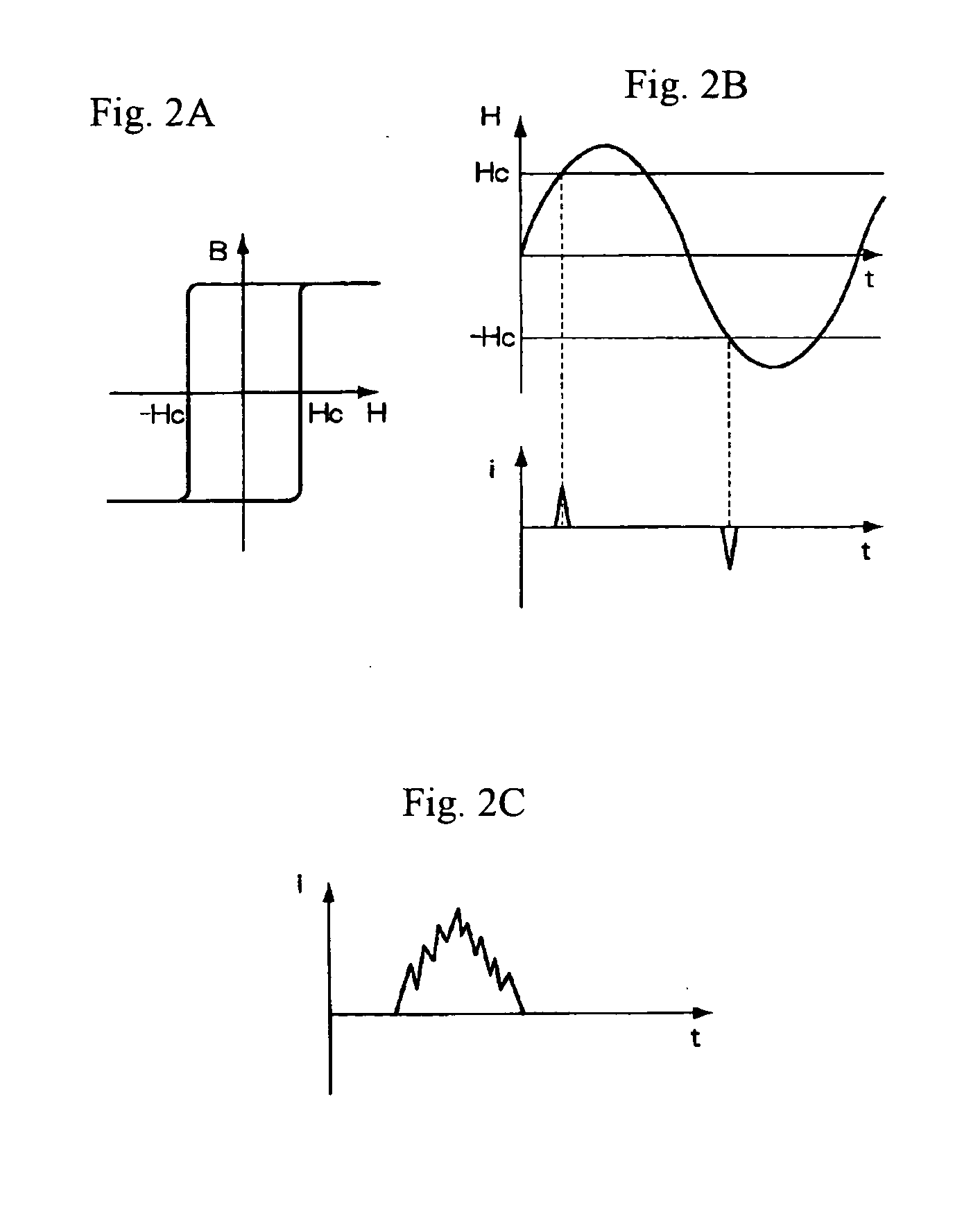

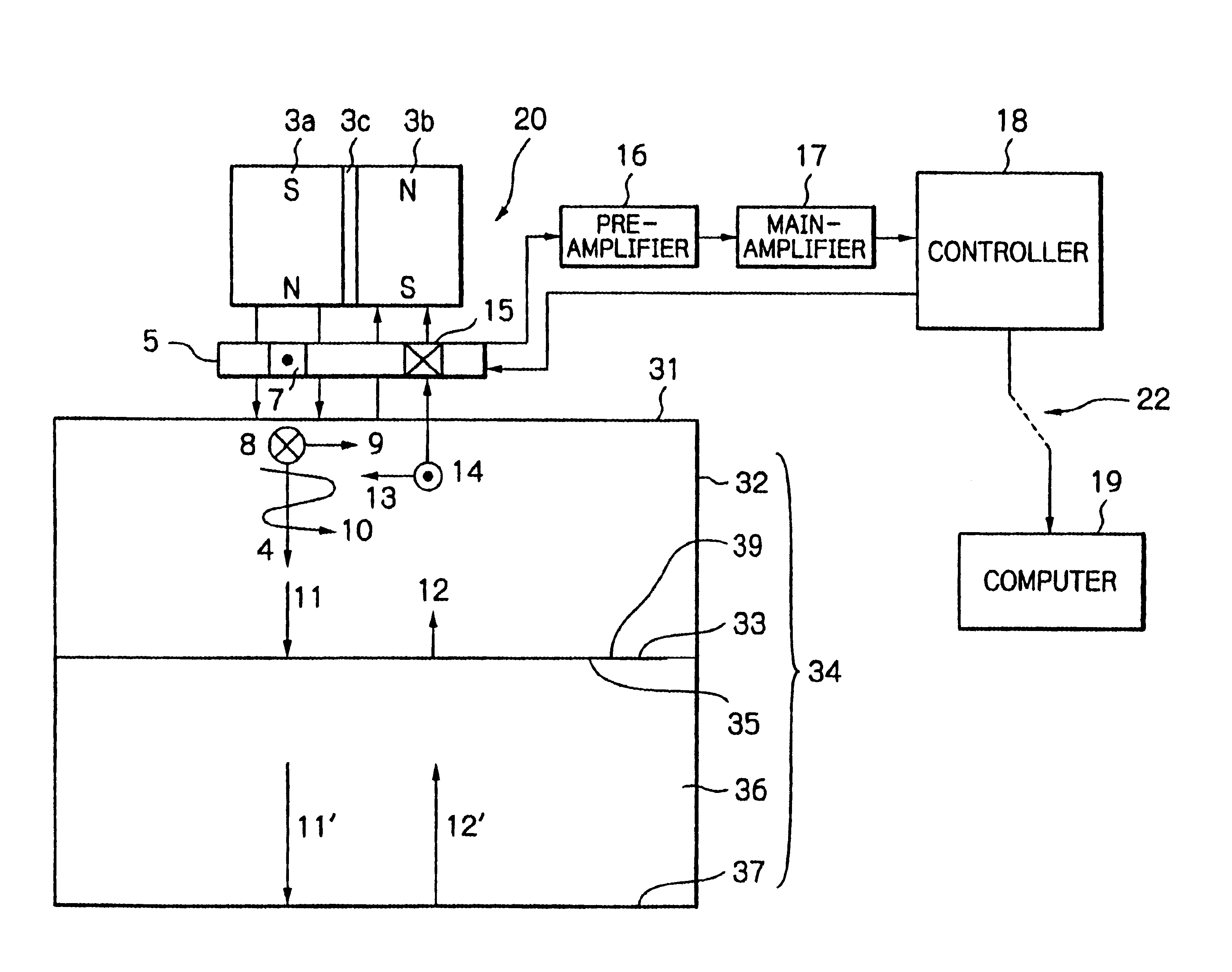

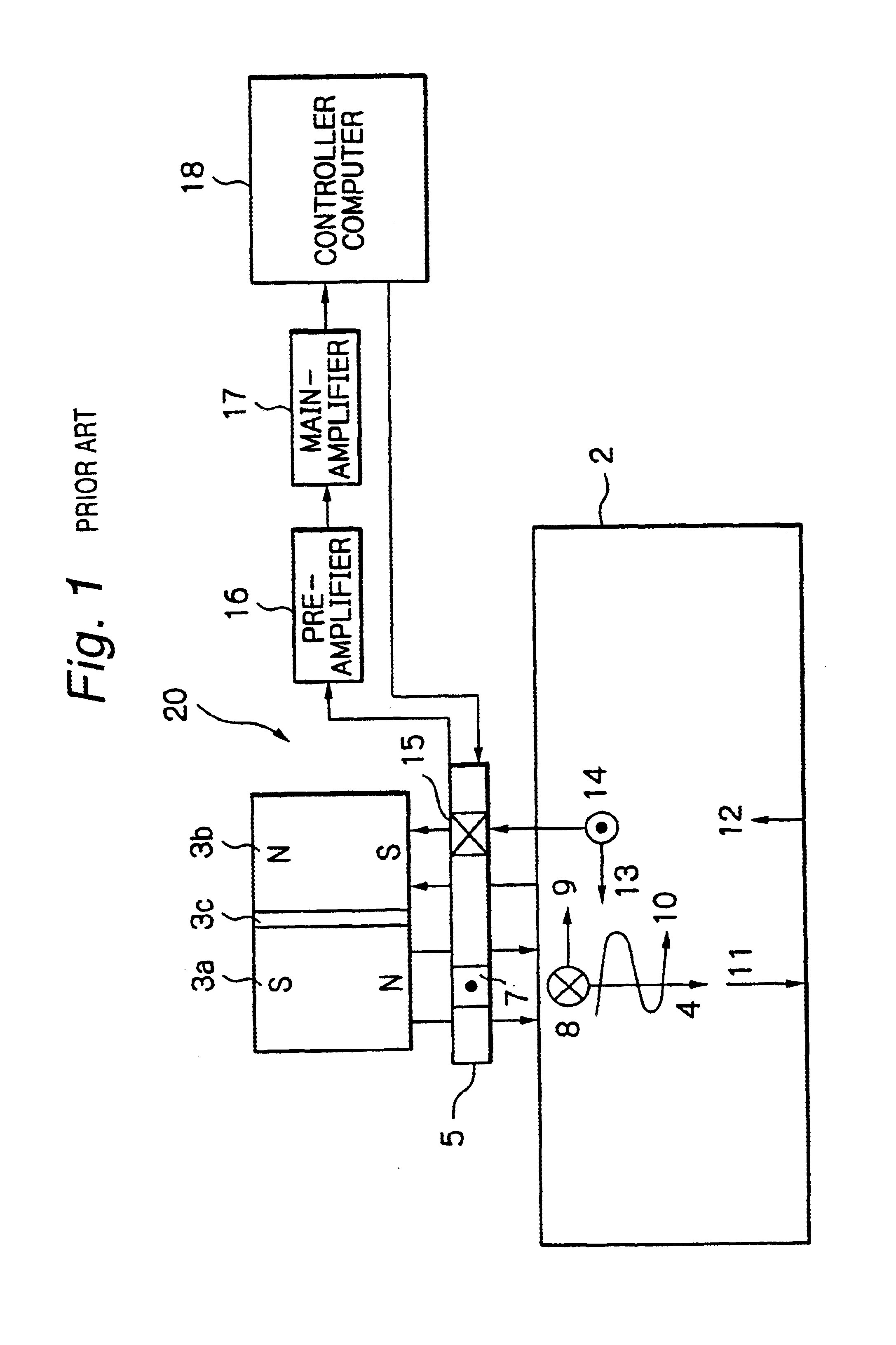

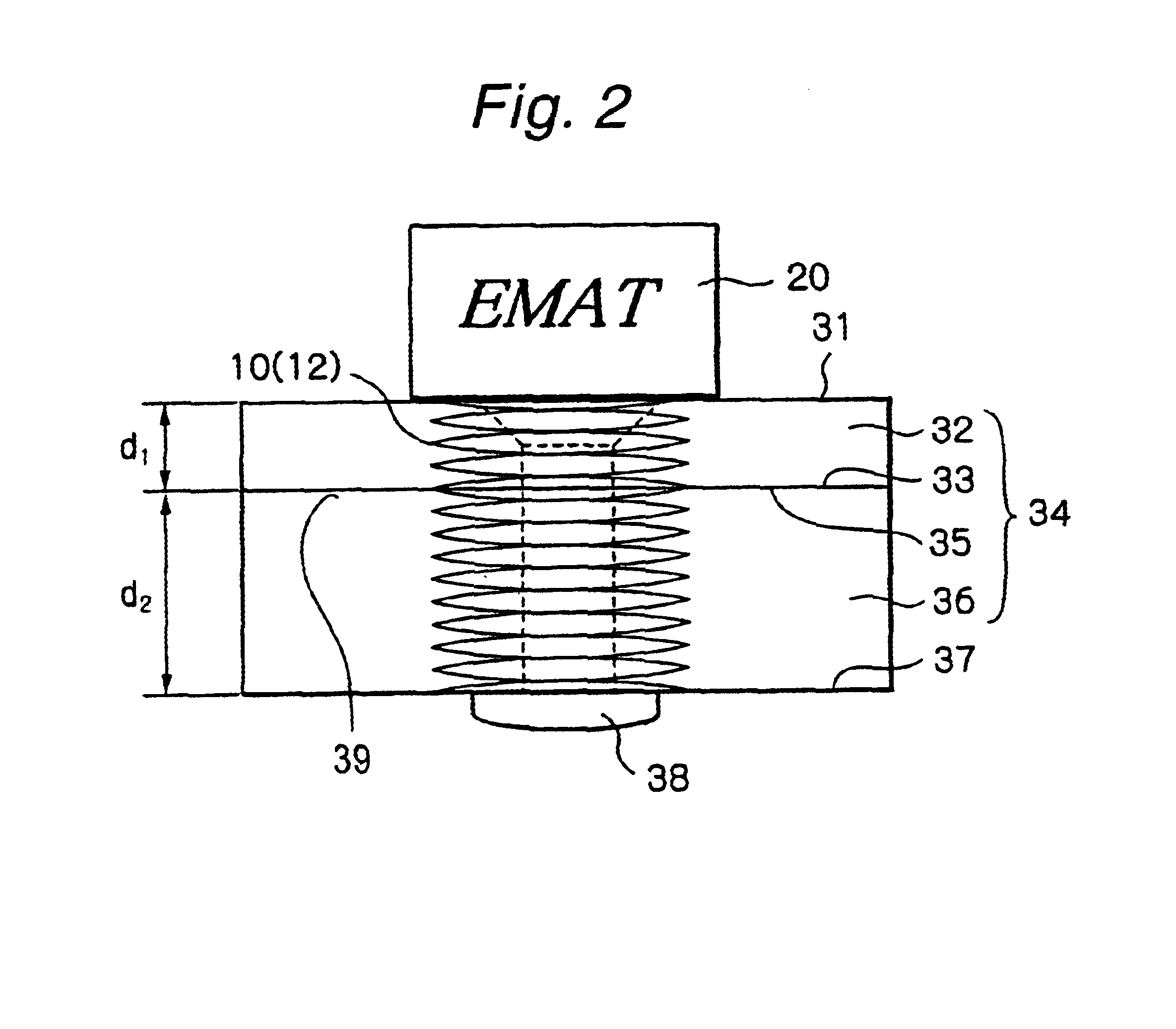

Method and apparatus for diagnosing damages of conductive materials

InactiveUS6839640B2Analysing solids using sonic/ultrasonic/infrasonic wavesSpecial data processing applicationsUltrasound attenuationTransducer

A diagnosing method and apparatus non-destructively performing damage evaluation of a piled up structure of conductive materials by using acoustic waves. The diagnosing method according to the present invention includes the steps of placing an electro-magnetic acoustic transducer 20 out of contact with a piled up structure 34 of conductive materials 32 and 34 piled up with a non-conductive interface 33 (35) interposed therebetween, transmitting ultrasonic waves from one side 31 of the piled up structure by the electro-magnetic acoustic transducer 20, receiving ultrasonic waves reflected from the other side of the piled up structure, and diagnosing a damaged condition of the piled up structure on the basis of the ultrasonic velocity and attenuation of the received ultrasonic waves.

Owner:EBARA CORP

Body fat diagnostic apparatus

InactiveUS20150257740A1Measure securityHealth-index calculationOrgan movement/changes detectionBone tissueUltrasonic velocity

A body fat diagnostic apparatus with which fat can be diagnosed safely is provided even in the case where a deep portion of the living body is diagnosed or there are bone tissues outside the measurement region. The body fat diagnostic apparatus is formed of: a probe 2 for emitting ultrasonic waves both for applying heat and for diagnosis; and an ultrasonic wave velocity change analyzing unit 15 for calculating the change in the velocity of ultrasonic waves in the measurement region on the basis of the ultrasonic wave echo signals acquired from the region before and after the application of heat using the probe 2, so that fat is diagnosed on the basis of the calculated change in the velocity of ultrasonic waves.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com