Ultrasonic water meter coefficient processing method

A flow coefficient and processing method technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve the problems of processing result errors, inaccurate calculation of fluid flow, etc., to reduce circuit manufacturing costs, widely Apply, calculate precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

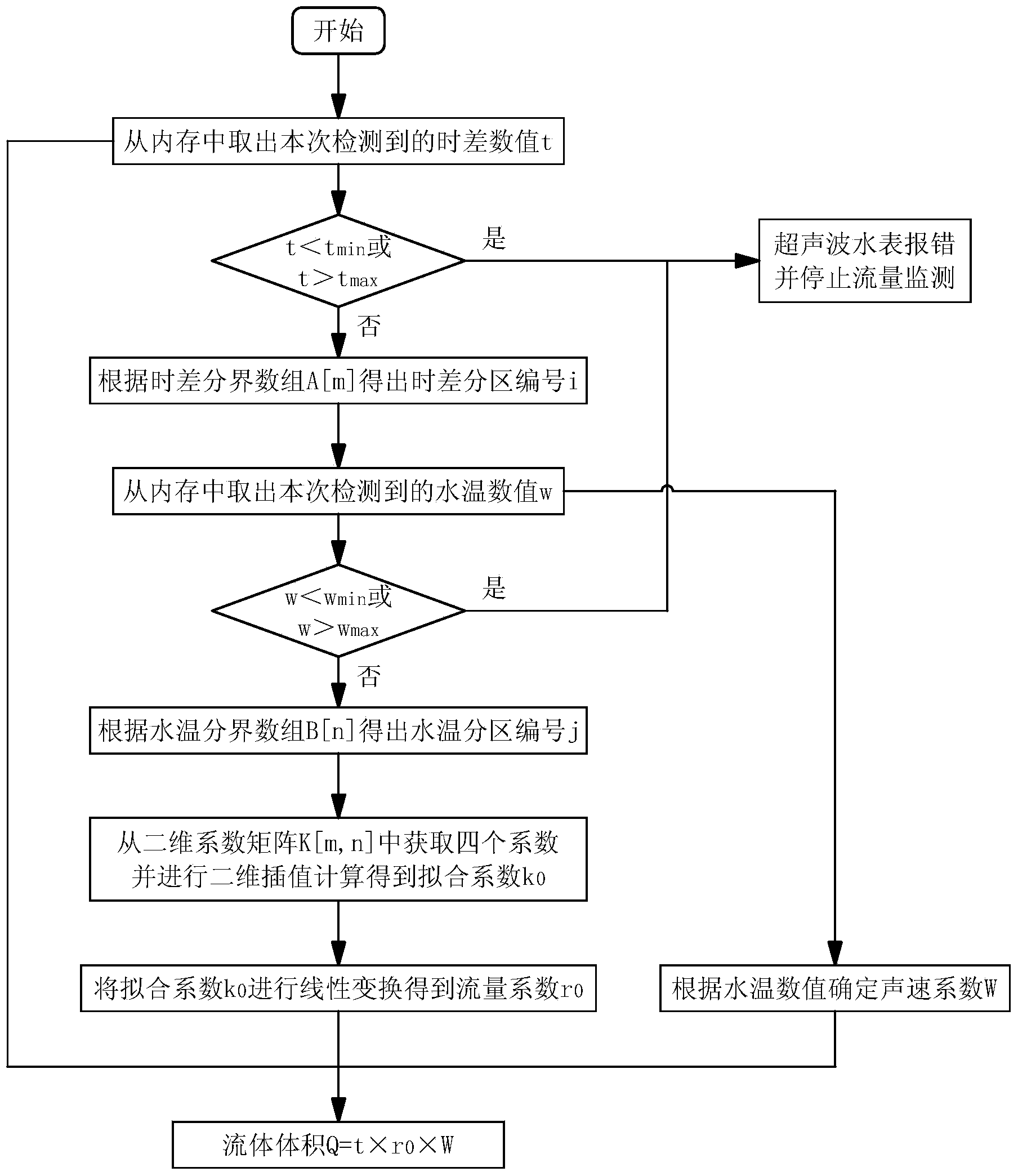

[0008] Combine below figure 1 , the present invention is described in further detail.

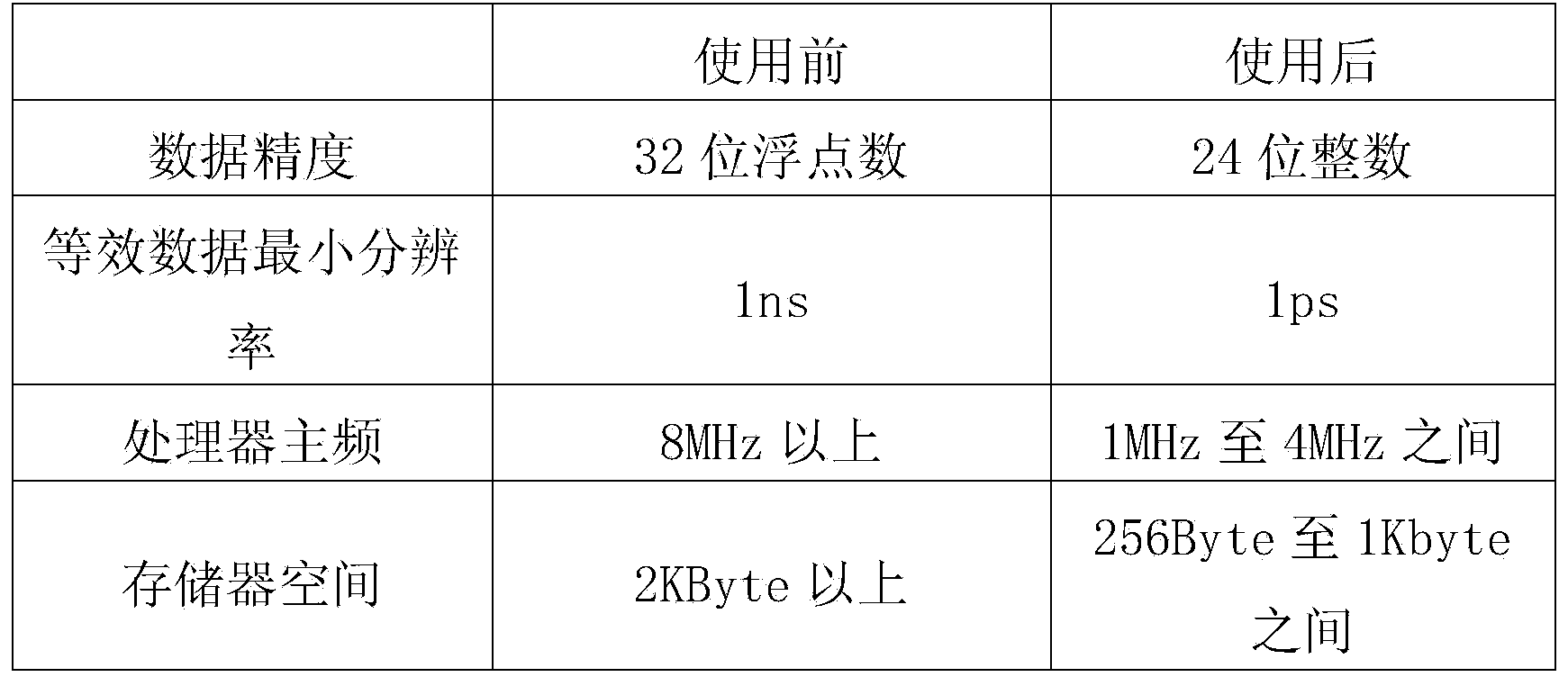

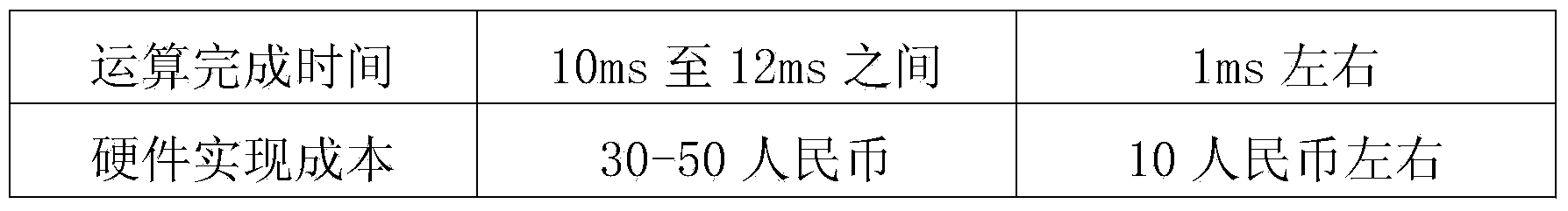

[0009] A method for processing the flow coefficient of an ultrasonic water meter, including the following steps: (A) Take out the time difference value obtained in this detection from the memory, and record it as t; (B) According to the built-in time difference boundary array A[m]={a 1 ,a 2 ,a 3 ,...,a m} to obtain the time difference partition number, where the time difference detection range of the ultrasonic water meter is [t min ,t max ] and a 1 min 2 m-1 max m , if tmin or t>t max , the ultrasonic water meter reports an error and stops flow detection, if a i ≤ti+1 , the time difference partition number is i; (C) Take out the water temperature value obtained from this test from the memory, which is w; (D) According to the built-in water temperature boundary array B[n]={b 1 ,b 2 ,b 3 ,...,b n} to obtain the water temperature partition number, where the temperature detection ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com