Ultrasonic gas cyclone condensing and separating device

A condensation separation and supersonic technology, which is applied in the fields of natural gas dehydration and heavy hydrocarbon separation, can solve the problems of vortex dissipation of rotating gas, easy generation of shock waves, and reduced pressure recovery performance of devices, so as to reduce the impact of separation efficiency and reduce Radial velocity gradient, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structural features and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

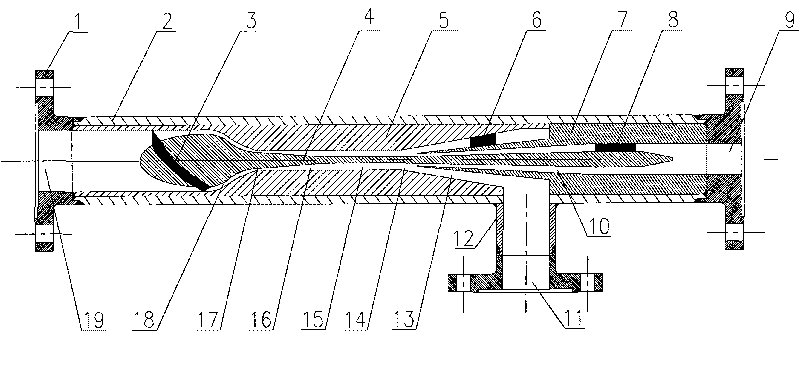

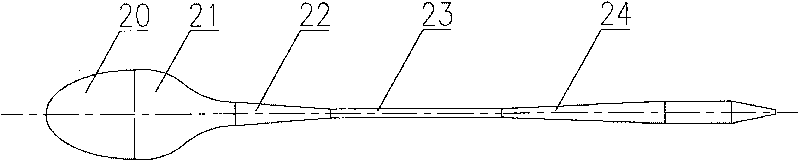

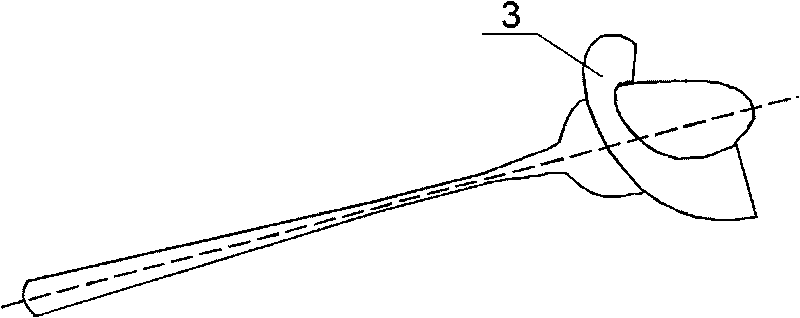

[0022] For the technical scheme of the present invention, see figure 1 , The supersonic gas cyclone condensation separation device is mainly composed of flange 1, shell 2, spiral swirl blade 3, inner core 4, shrink separation shell 5, liquid guide vane 6, diffuser casing 7, guide vane 8 , The drain pipe 12 is composed. Among them, the inner core 4 and the shrinking and separating shell 5 form an annular Laval nozzle, forming a subsonic shrinking flow channel 18, a throat 17, and a supersonic expansion flow channel 16; the inner core 4 and the diffuser shell 7 form an annular diffuser The tube forms a diffuser flow passage 10; the gap between the shrinkage separation shell 5 and the diffuser shell 7 forms a liquid separation port 14 and a liquid accumulation cavity 13.

[0023] See figure 1 , 2 , The inner core 4 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com