Exhaust gas pretreatment system for diesel engine

A pretreatment and diesel engine technology, which is applied in the direction of charging system, exhaust gas recirculation, mechanical equipment, etc., can solve the problems of increased complexity of the pretreatment system after exhaust gas, unfavorable application and promotion of marine diesel engine products, etc., and achieve the effect of cyclone separation Good, improve the effect of cyclone separation and realize the effect of timely discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

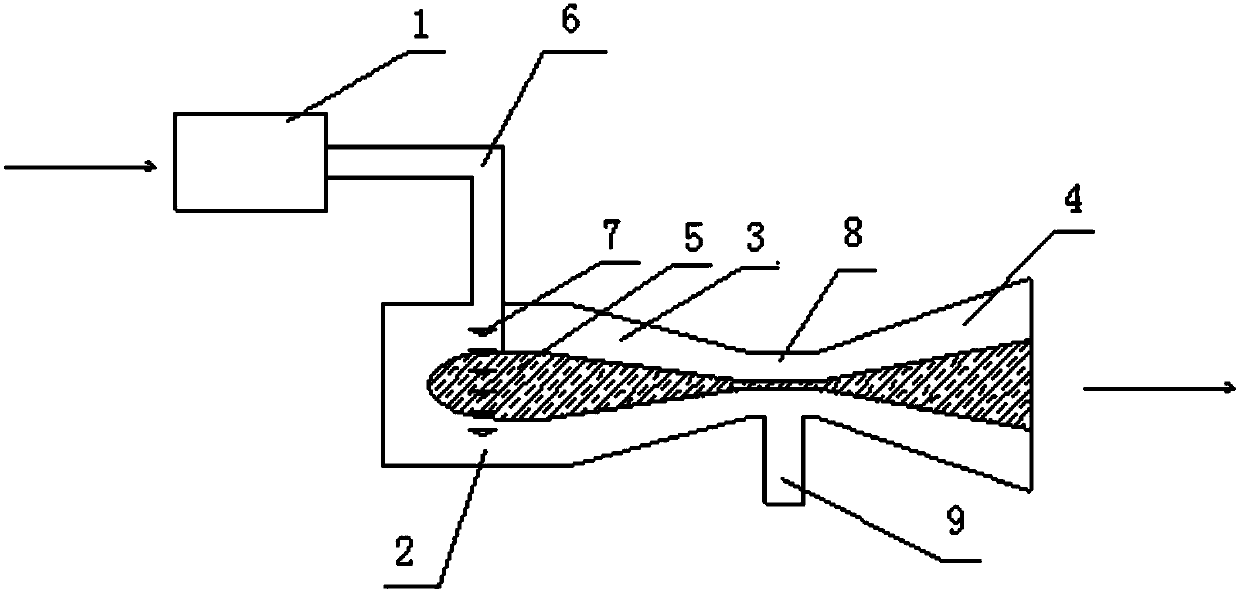

[0035] Such as figure 1 As shown, in one embodiment, an exhaust gas pretreatment system for a diesel engine is provided with a humidifier 1 , a cyclone separator 2 , a Laval nozzle 3 and a diffuser 4 in sequence along the exhaust gas flow. The cyclone separator 2, the Laval nozzle 3 and the diffuser 4 are coaxial; the cyclone 2, the Laval nozzle 3 and the diffuser 4 are provided with a center body 5 inside. The central body 5 sequentially includes a semi-ellipsoid section, a constricted section, a straight section, a first expanding section and a second expanding section along the flow direction of the exhaust gas.

[0036] Wherein, the direction of the arrow in the figure indicates the flow direction of exhaust gas in the exhaust gas pretreatment system for diesel engine of this embodiment.

[0037] The humidifying device 1 communicates with the cyclone separator 2 through a pipeline 6 . The humidifying device 1 adopts micro mist humidification or ultrasonic humidification....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com