Patents

Literature

84results about How to "Big size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

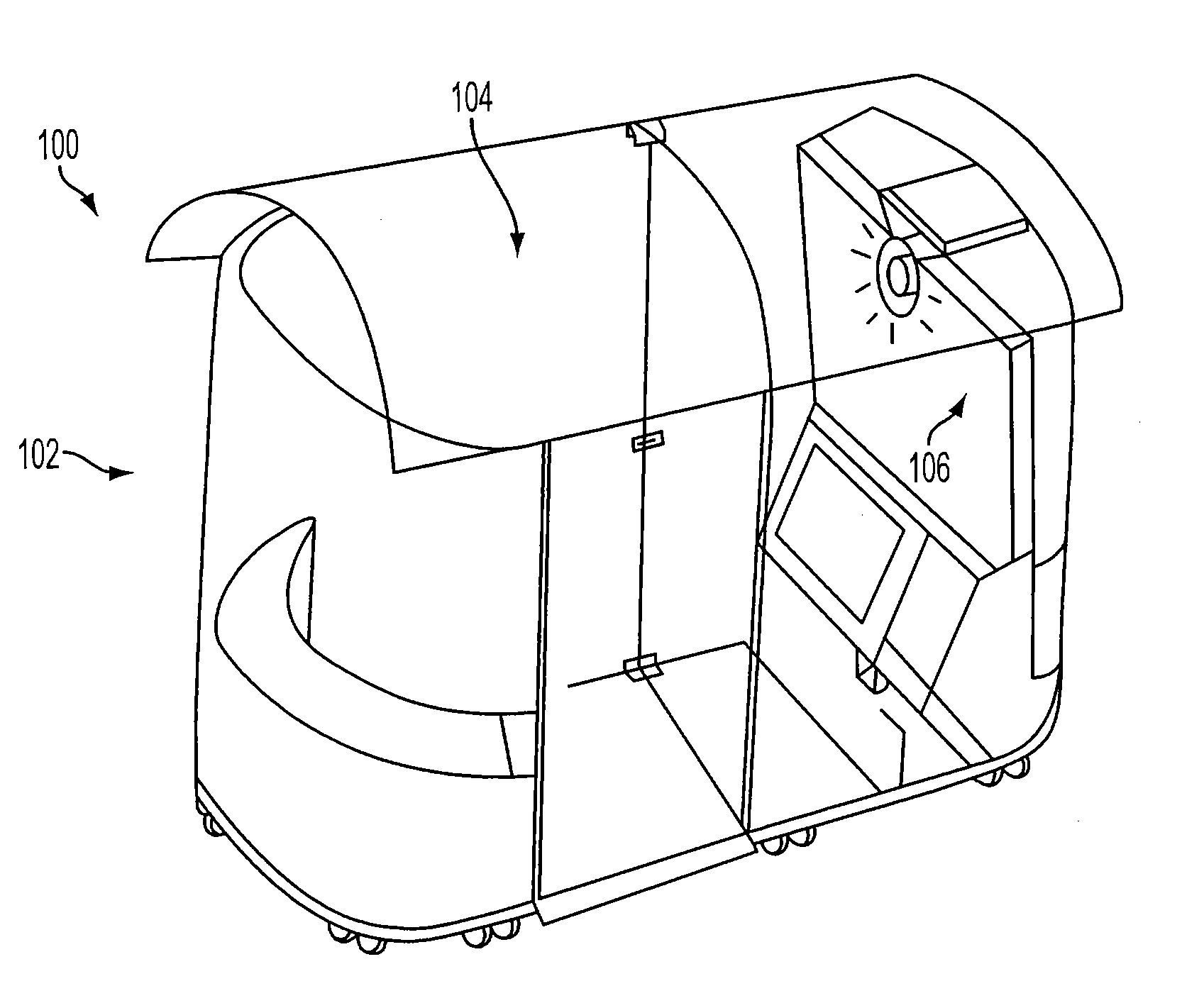

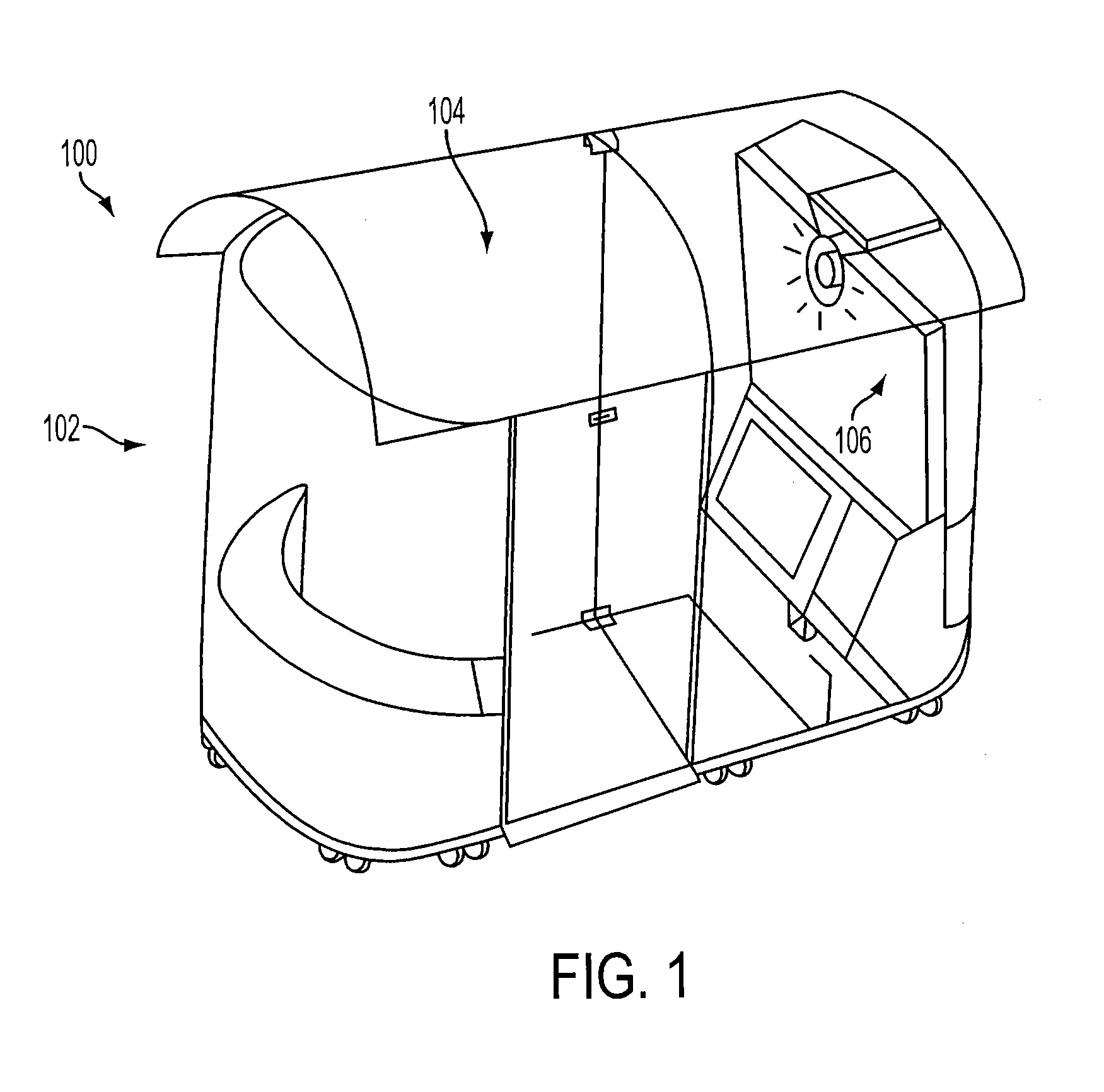

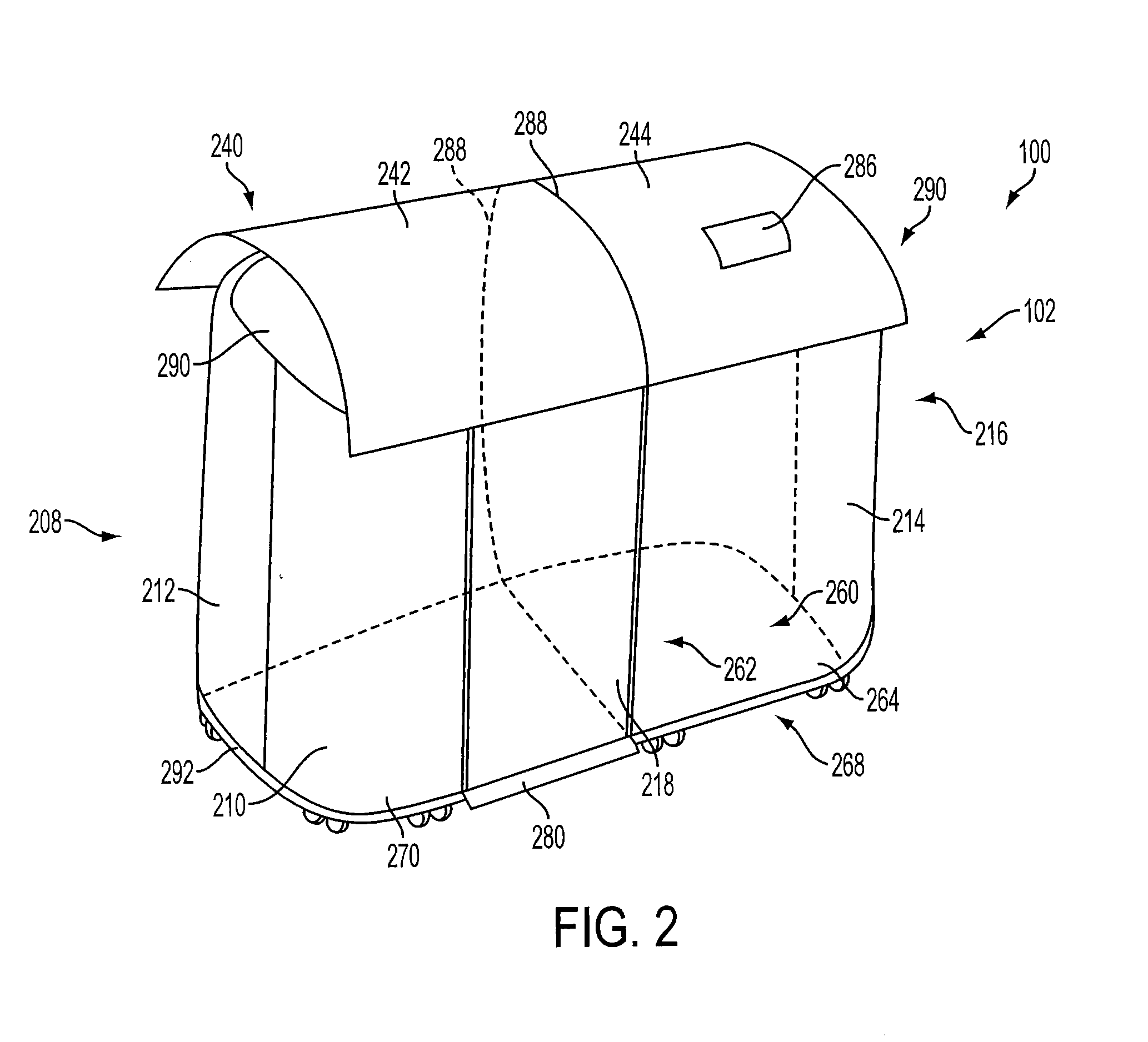

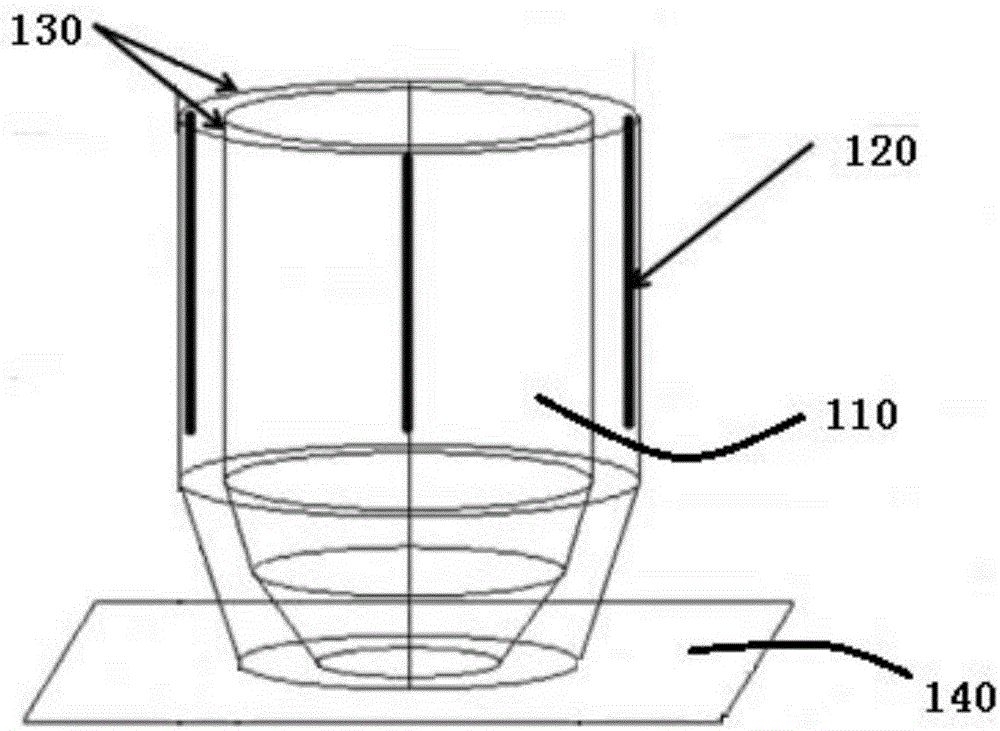

Portable studio

The present disclosure is directed to portable studio comprising a module with an interior and an exterior. The module includes a floor comprised of at least one panel; side walls detachably connectable to the floor, wherein the side walls are comprised of at least one panel; and a top detachably connectable to the side walls, wherein the top is comprised of at least one panel. The module includes side walls and a top that are comprised of a semi-translucent material that allows ambient light into the interior of the module. The module is configured to create studio-quality photos, videos, and sound recordings.

Owner:DIYPHOTOSHOOT

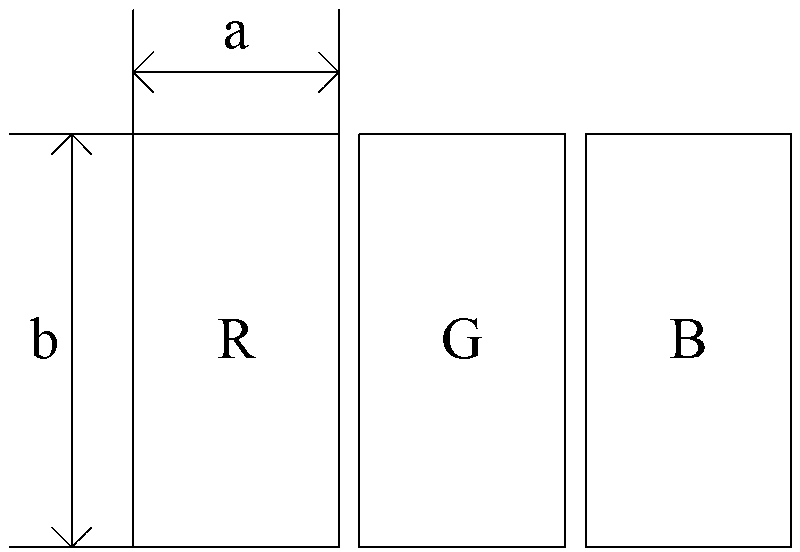

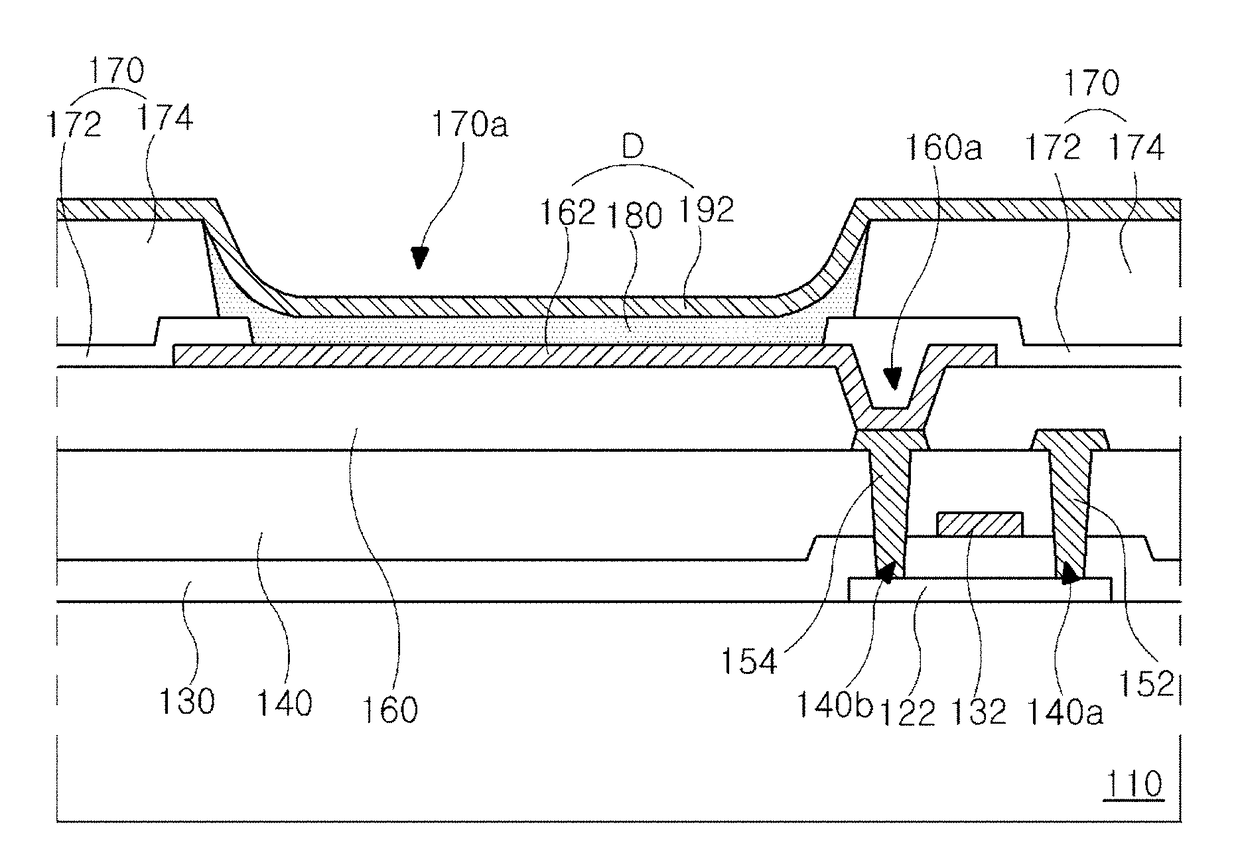

Display substrate and display device

ActiveCN103257494ASmall sizeBig sizeNon-linear opticsOptical elementsPixel densityLiquid-crystal display

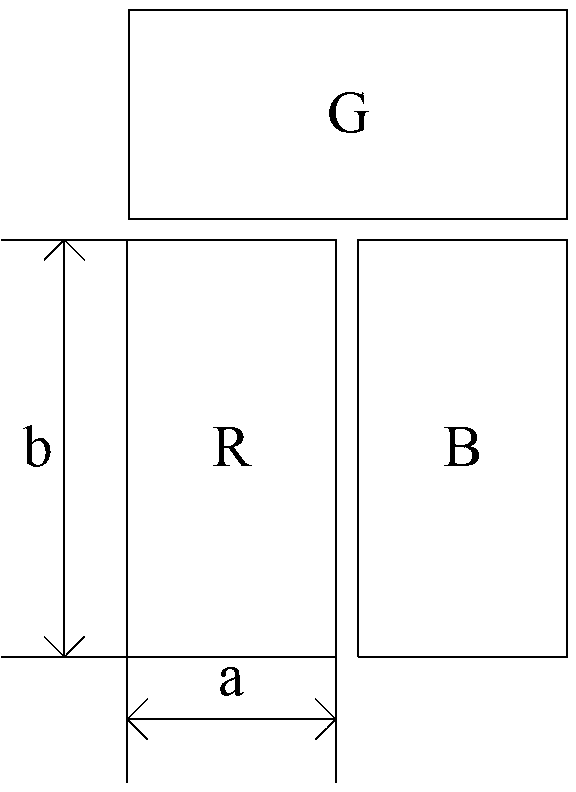

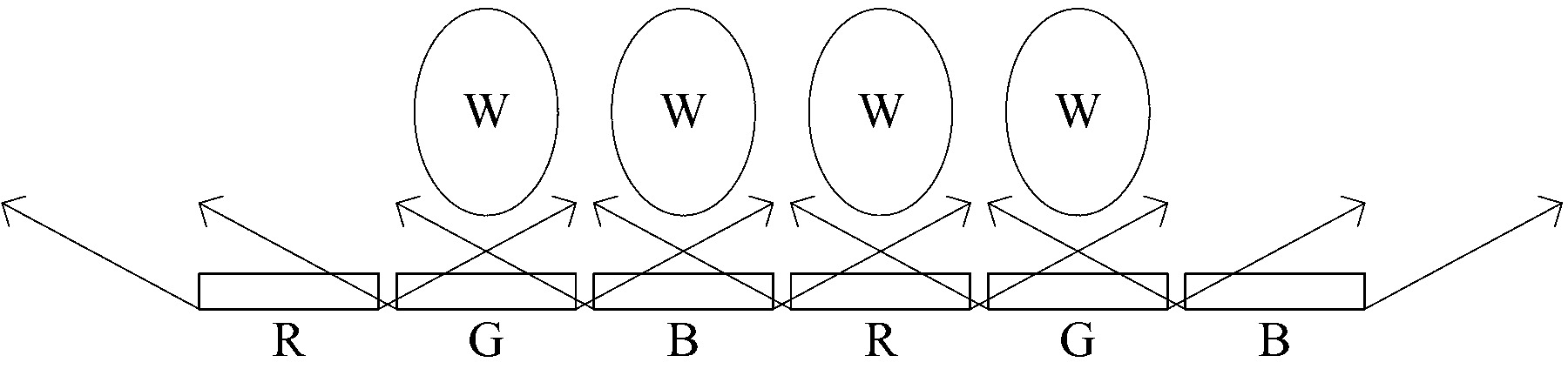

The invention discloses a display substrate and a display device provided with the display substrate and belongs to the display technical field. The display substrate and the display device solve the technical problems that a display panel formed by an existing pixel unit neutron pixel arraying mode is low in pixel density and incapable of meeting requirements of products for high distinguishability. The display substrate comprises a plurality of pixel units distributed in an array mode. Each pixel unit comprises a first sub-pixel, a second sub-pixel and a third sub-pixel. The first sub-pixel, the second sub-pixel and the third sub-pixel are adjacent to each other and are all oblong. Each first sub-pixel is arranged in the transverse direction, and each second sub-pixel and each third sub-pixel are arranged in the longitudinal direction. The long edge of each second sub-pixel is adjacent to the long edge of each third sub-pixel. The long edge of each first sub-pixel is adjacent to the short edge of each second sub-pixel and the short edge of each third sub-pixel. The display substrate is used for display devices such as a liquid crystal display and an OLED.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Anisotropic conductive adhesive for fine pitch and COG packaged LCD module

InactiveUS20060035036A1Big sizeReliable connectionLiquid crystal compositionsNon-macromolecular adhesive additivesAverage diameterAnisotropic conductive adhesive

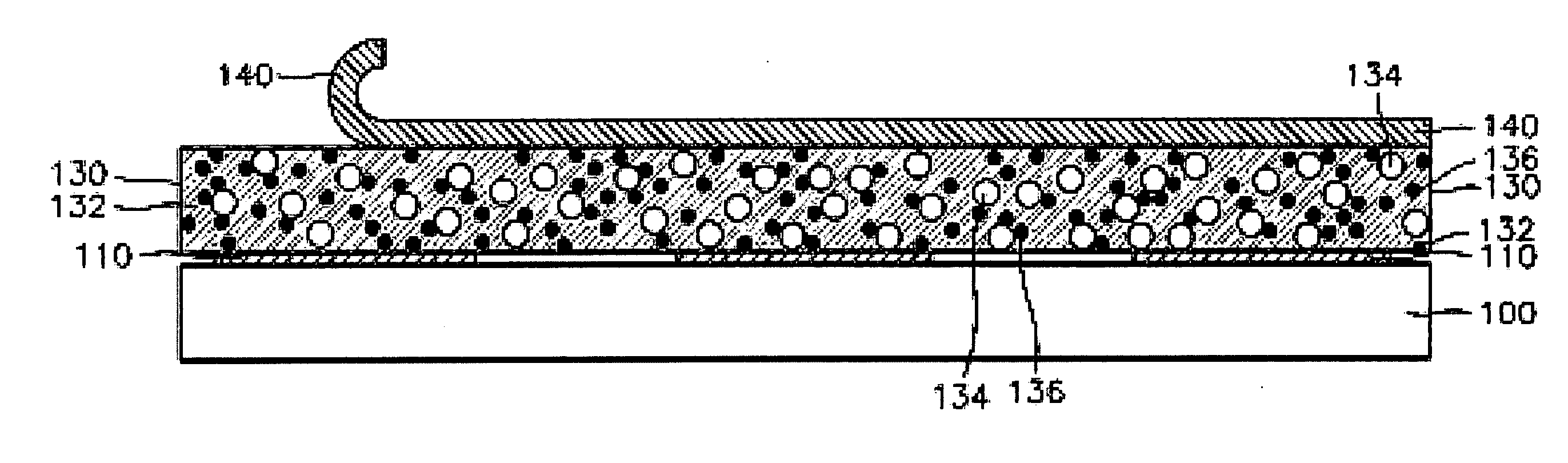

Provided are an anisotropic conductive adhesive (ACA) for a fine pitch including conductive particles and non-conductive particles, and a chip-on-glass (COG) packaged liquid crystal display (LCD) module including the ACA. The sizes of the conductive particles and non-conductive particles in the ACA are adjusted according to a gap between electrodes of fine pitch arranged on a glass substrate of the LCD module. The provided ACA for a fine pitch is used for connecting the IC onto the glass substrate such as to electrically connect the IC to the electrodes. The provided ACA includes a thermosetting resin, a curing agent for curing the thermosetting resin, a plurality of conductive particles having an average diameter of less than half of a gap between the electrodes, the plurality of conductive particles being included at a first dispersion density, and a plurality of non-conductive particles having an average diameter of less than half of the average diameter of the conductive particles, the plurality of conductive particles being included at a second dispersion density that is larger than the first dispersion density.

Owner:TELEPHUS

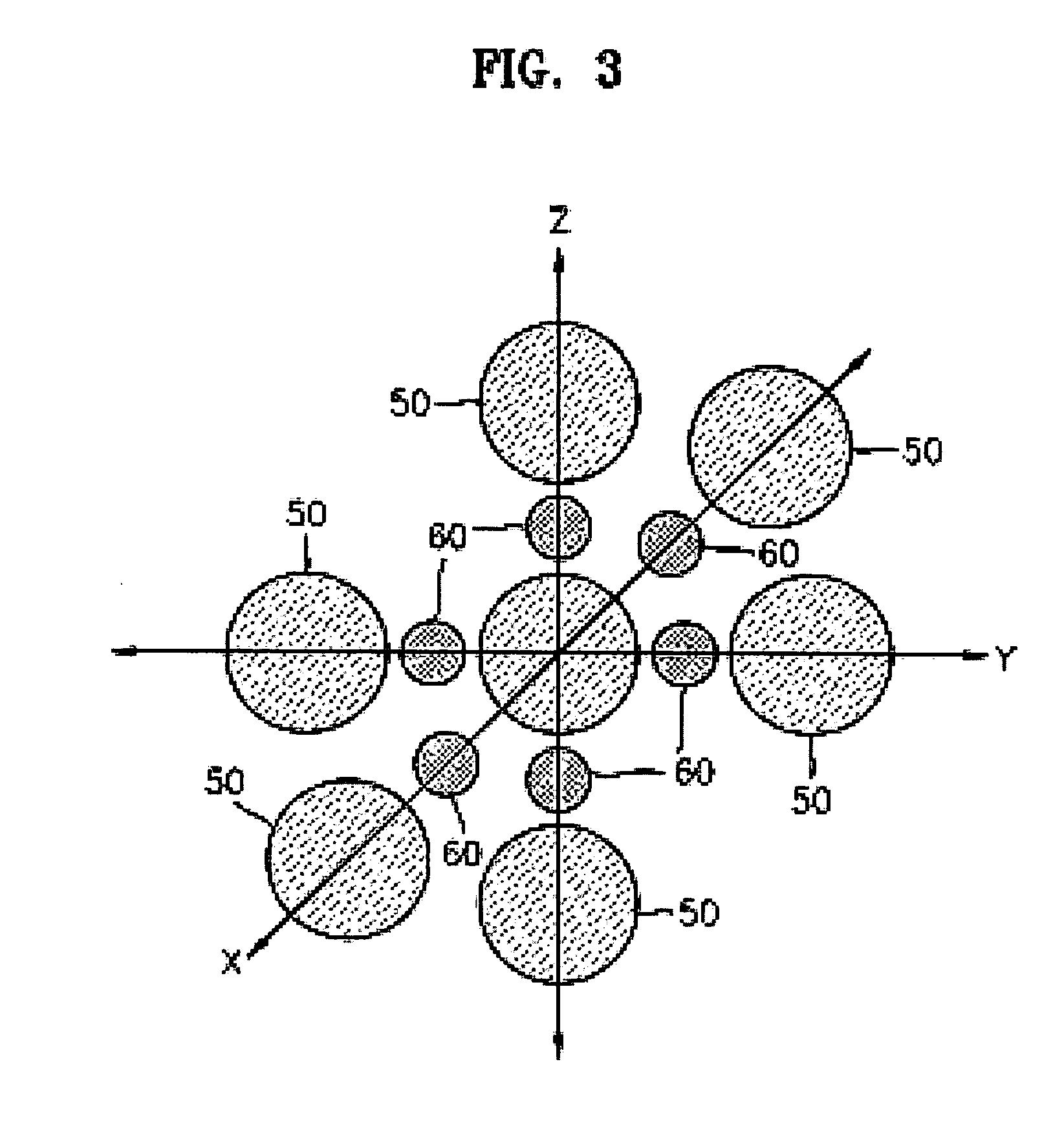

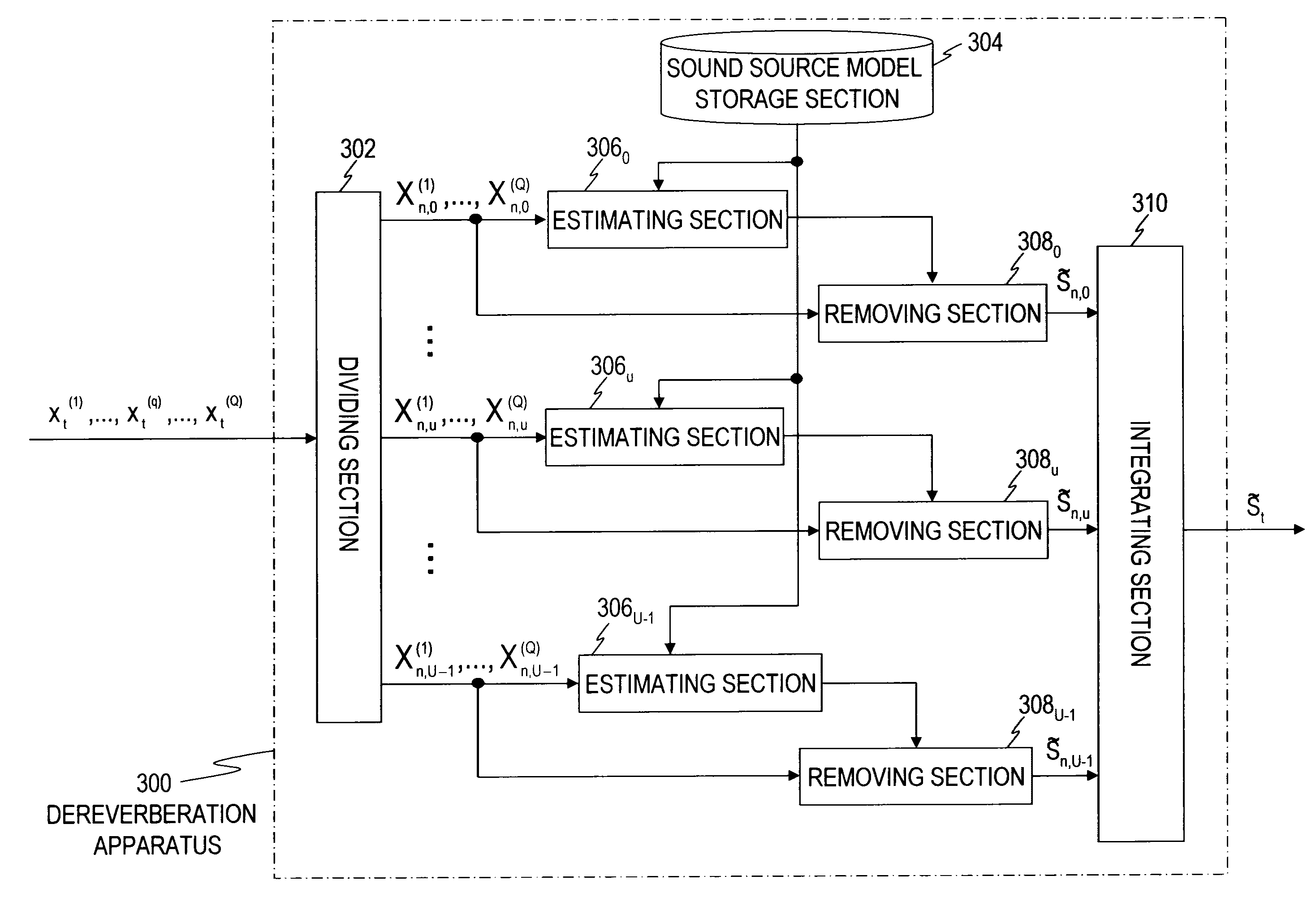

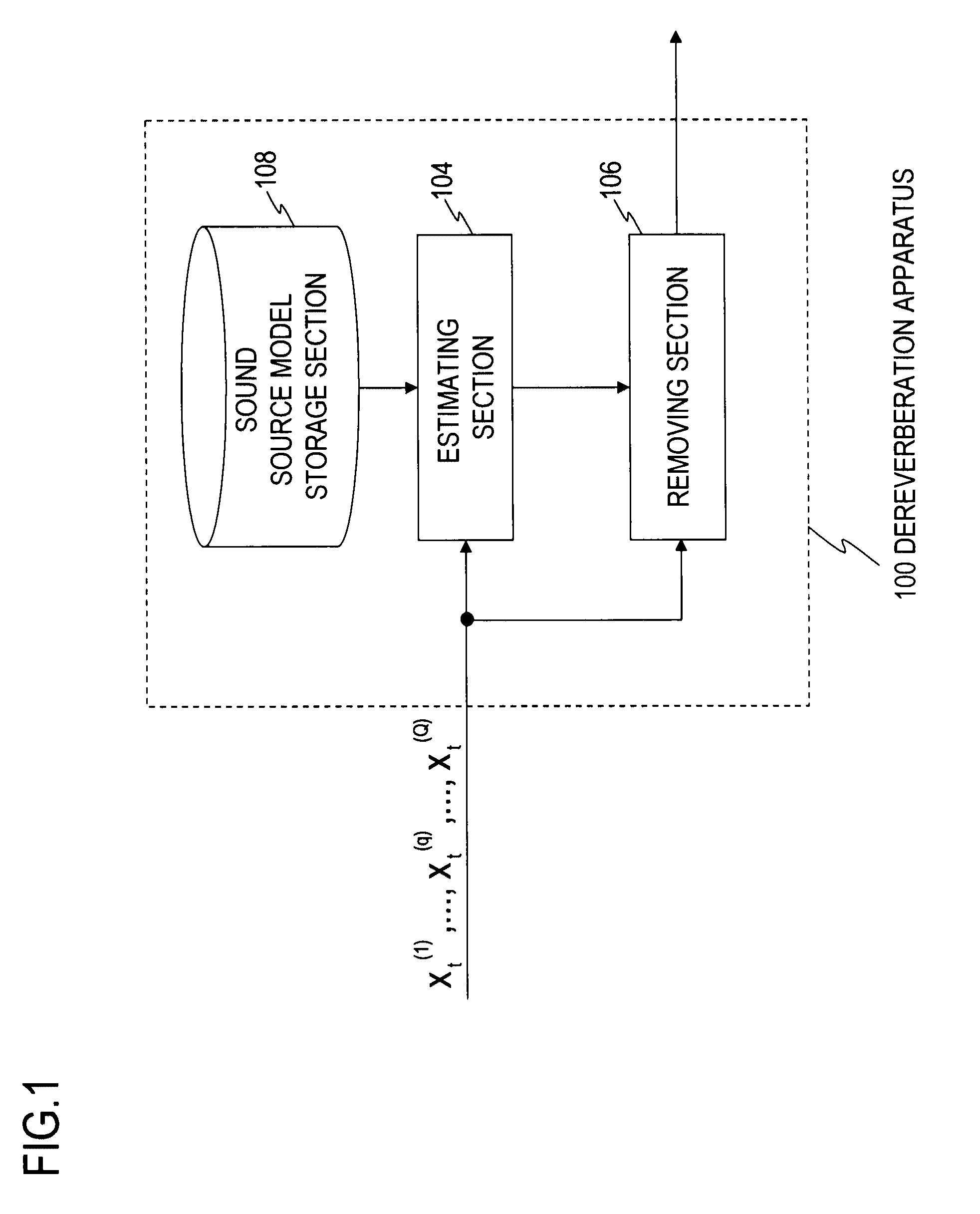

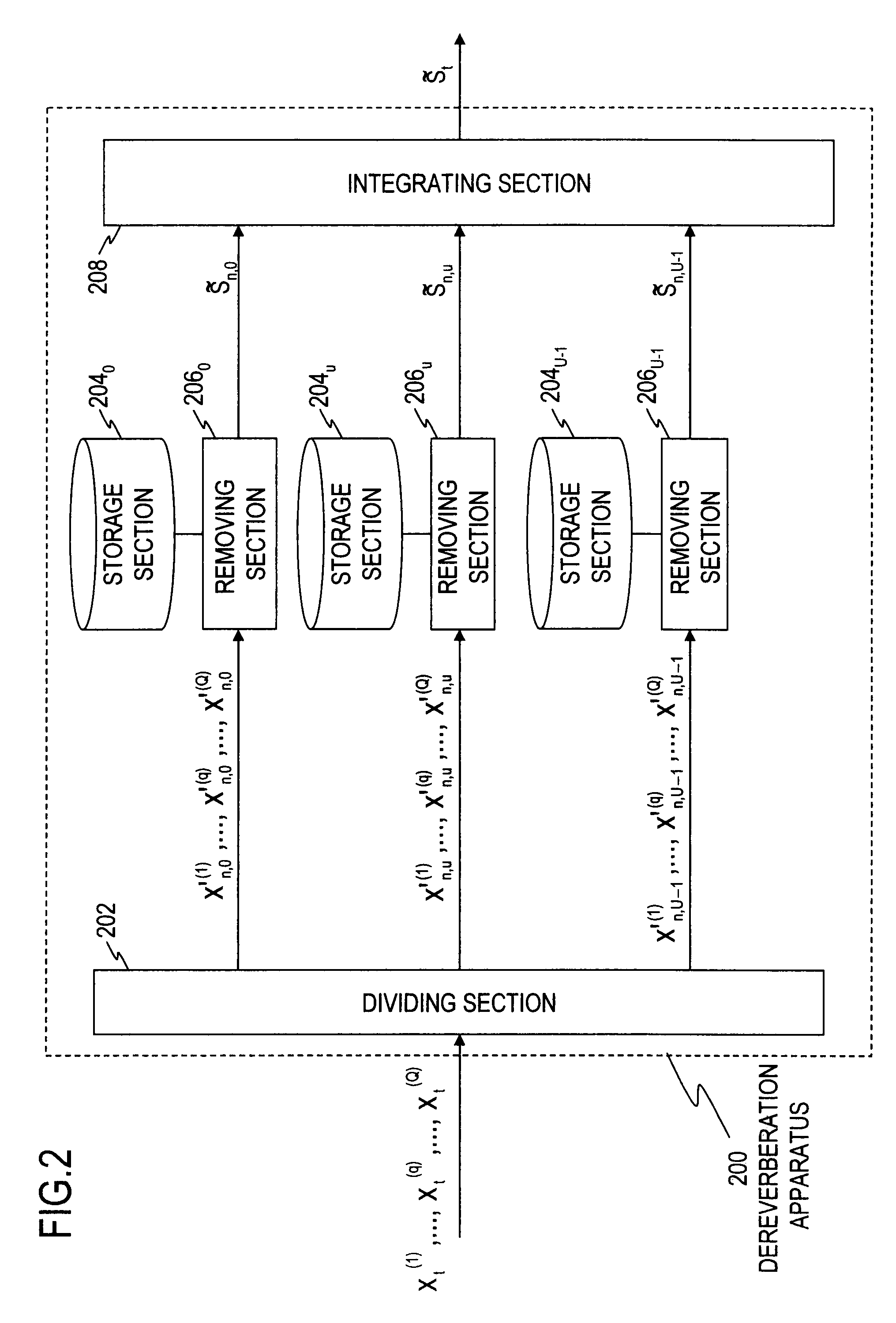

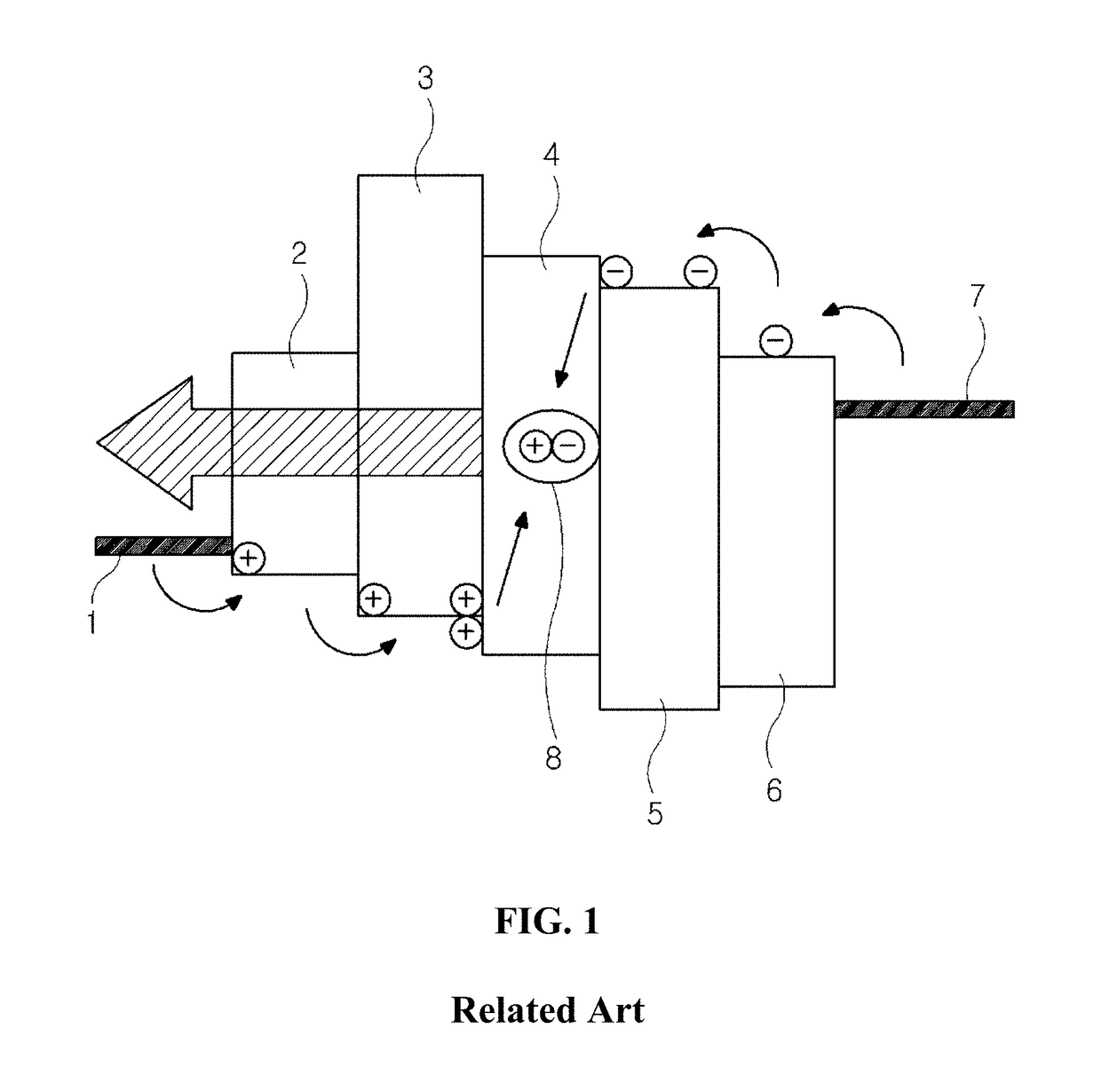

Dereverberation apparatus, dereverberation method, dereverberation program, and recording medium

ActiveUS20110002473A1Big sizeCalculation method is fastSpeech analysisLine-transmissionFrequency bandAudio signal

A sound source model storage section stores a sound source model that represents an audio signal emitted from a sound source in the form of a probability density function. An observation signal, which is obtained by collecting the audio signal, is converted into a plurality of frequency-specific observation signals each corresponding to one of a plurality of frequency bands. Then, a dereverberation filter corresponding to each frequency band is estimated by using the frequency-specific observation signal for the frequency band on the basis of the sound source model and a reverberation model that represents a relationship for each frequency band among the audio signal, the observation signal and the dereverberation filter. A frequency-specific target signal corresponding to each frequency band is determined by applying the dereverberation filter for the frequency band to the frequency-specific observation signal for the frequency band, and the resulting frequency-specific target signals are integrated.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

System and process for manufacturing application specific printable circuits (ASPC'S) and other custom electronic devices

InactiveUS20060190917A1Big sizeLow costPrinted circuit assemblingPrinted electric component incorporationAsic technologyIntegrated circuit

A system and process for manufacturing custom printed circuit boards on pre-provided substrates, wherein the substrate can be pre-provided with electronic devices. The electronic devices can be pre-provided on the substrate by direct printing, or in a more conventional manner, such as by standard integrated circuit technologies, in many different packing technologies. The user designs the custom printed circuit board using a design tool to perform one or more specific electronic functions, based on the pre-provided electronic devices, and / or custom designed and direct printed electronic devices. The electronic devices includes transistors, resistors, capacitors, among other types of devices. Examples of the electronic functions that can realized using the system and process described herein include, but are not limited to, include an RFID device, and a PROM.

Owner:CABOT CORP

Preparation method of multicomponent large-size rare earth boride LaxCe1-xB6 monocrystalline block cathode material

InactiveCN102433587ABig sizeHigh purityPolycrystalline material growthBy zone-melting liquidsBorideQuartz

The invention discloses a preparation method of a multicomponent large-size rare earth boride La*Ce1-xB6 monocrystalline block cathode material, belonging to the technical field of rare earth boride thermionic cathode and cold cathode materials. At present, little research has been done into multicomponent rare earth boride monocrystals, the preparation technology in the prior art is complicated, and the prepared monocrystals in the prior art has bad quality and small size and is difficult for practical application. The cathode material disclosed herein is represented as LaxCe1-xB6, wherein, x ranges from 0.2-0.6. The method disclosed herein is characterized in that: a discharge plasma sintering method is adopted, a LaxCe1-xB6 polycrystalline rod is prepared in a high vacuum environment, and then the prepared polycrystalline rod is smelted in a smelting furnace of an optic zone. In the process of crystal growth, for effectively inhibiting the volatilization and oxidation of La and Ce, high-purity flow argon is introduced to a quartz tube, wherein, the gas flow velocity is 1-2 L / min, and the gas pressure is 0.5-0.7 MPa. For making a melting zone more uniform, a seed crystal and a charge bar are reversely rotated, wherein, the rotating speed is 30-40 rpm, and the growth speed is 7-10 mm / h. The prepared monocrystal has the advantages of large size, high purity, and good quality.

Owner:BEIJING UNIV OF TECH

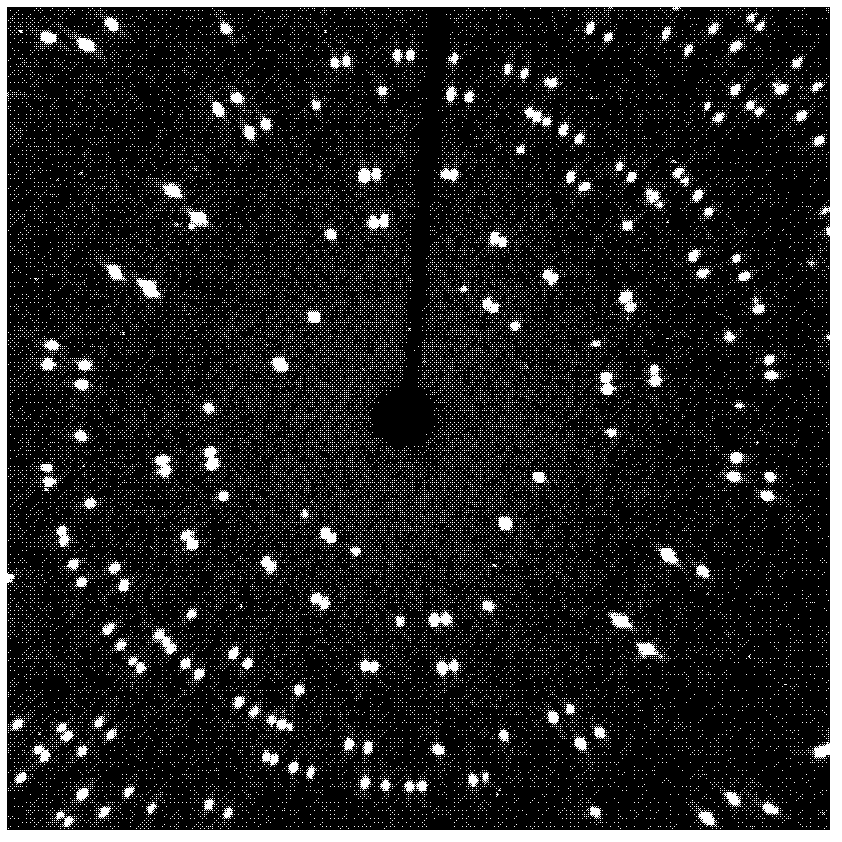

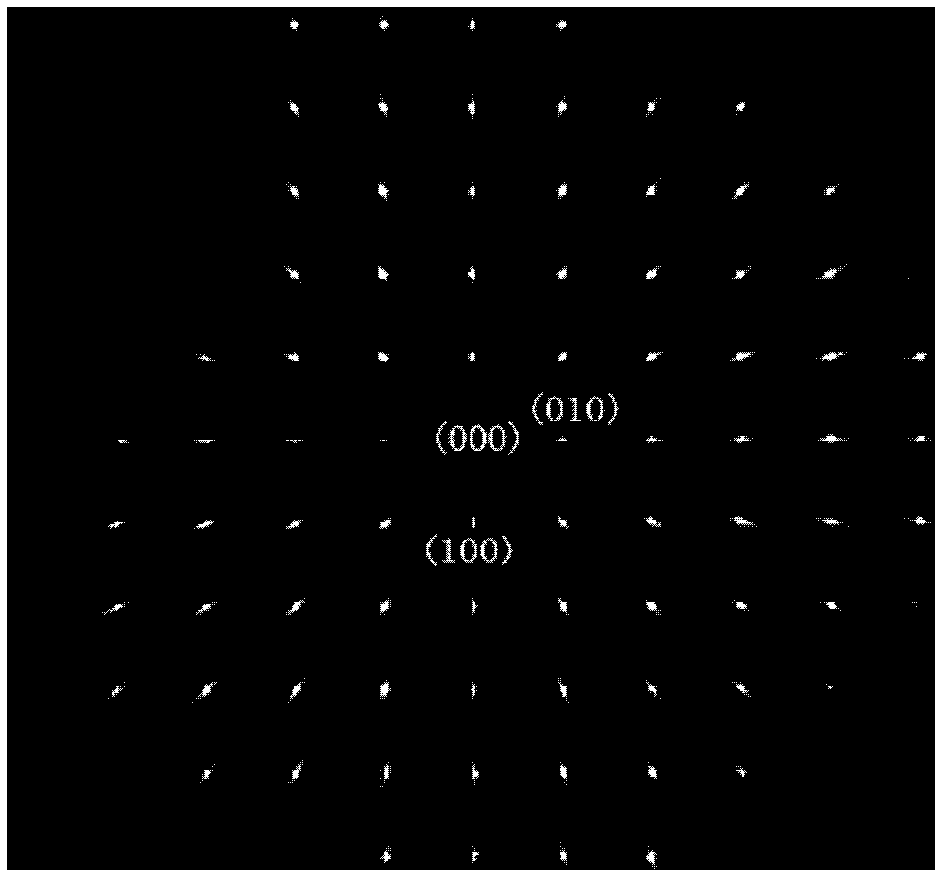

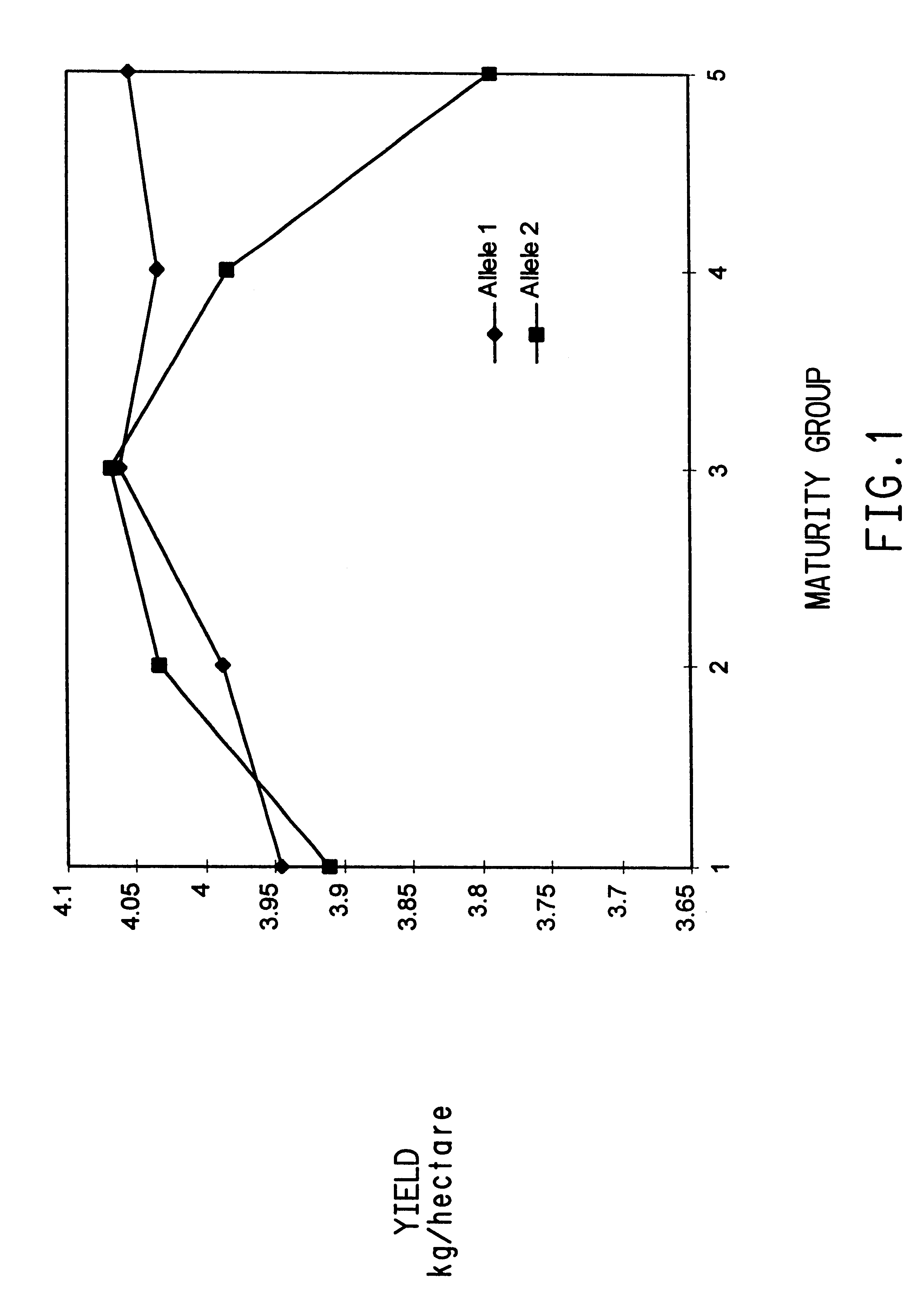

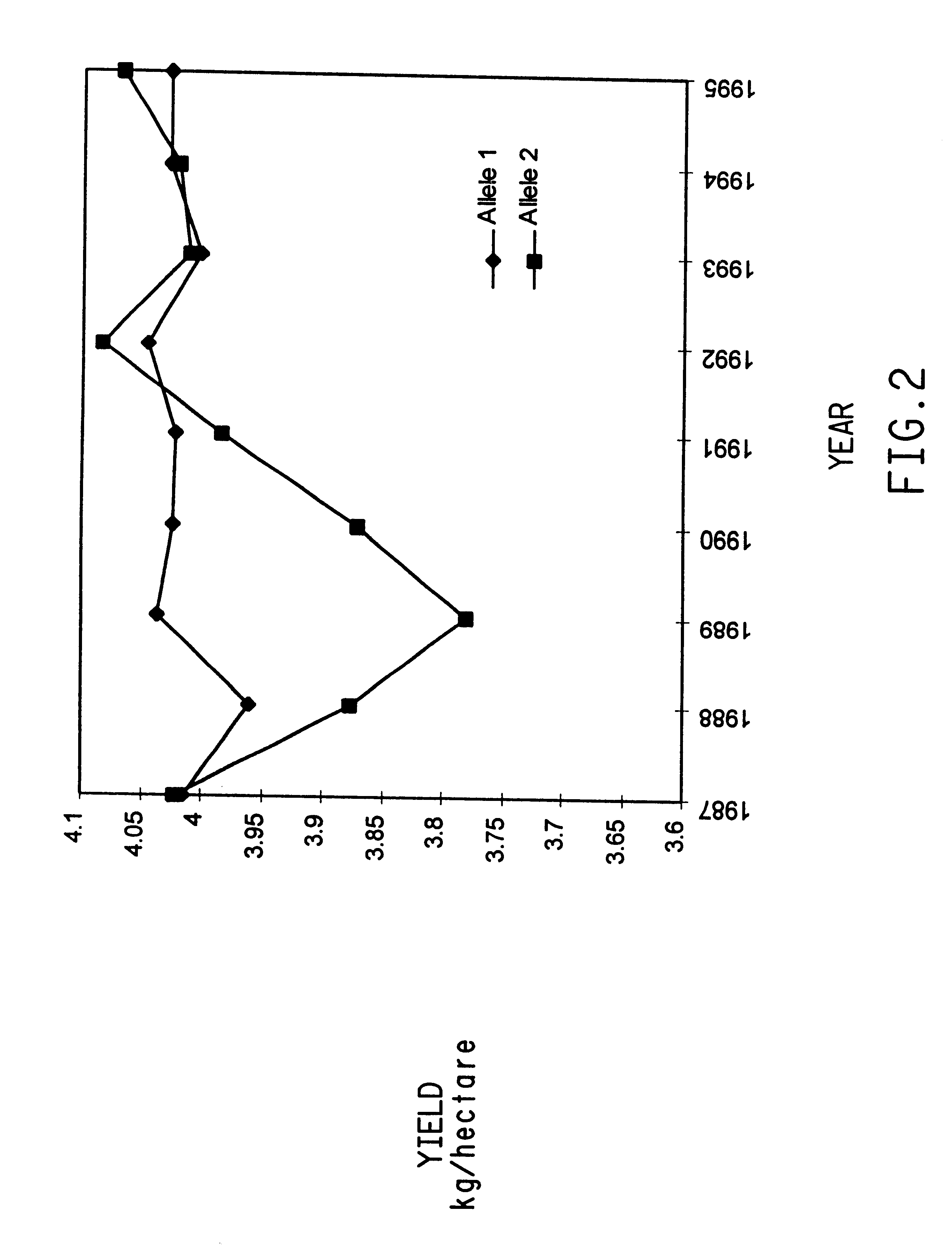

Method for identifying genetic marker loci associated with trait loci

InactiveUS6219964B1Big sizeAccurate and more valuable phenotypic valueSeed and root treatmentMicrobiological testing/measurementGenetic markerGenotyping by sequencing

A method for identification of trait loci using genetic marker loci and the use of genetic marker loci as a selection method in a plant breeding program is disclosed. The method comprises comparing genotypic survey data to phenotypic data collected from the same entries used to create the genotypic survey and identifying genetic marker loci that are associated with traits. The method allows new and superior plants to be identified and selected for in a plant breeding program by genotyping with identified genetic marker loci.

Owner:ASGROW SEED +1

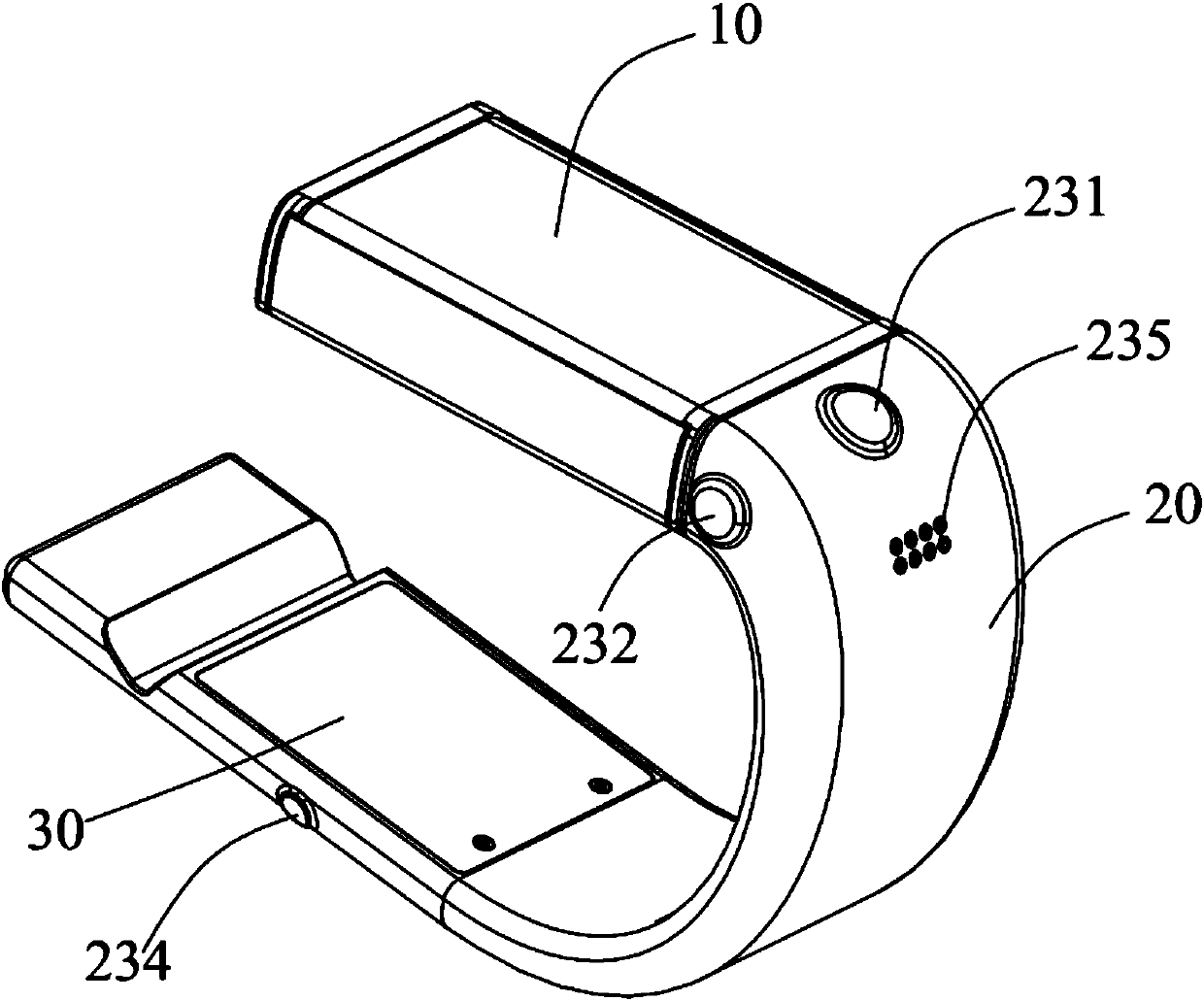

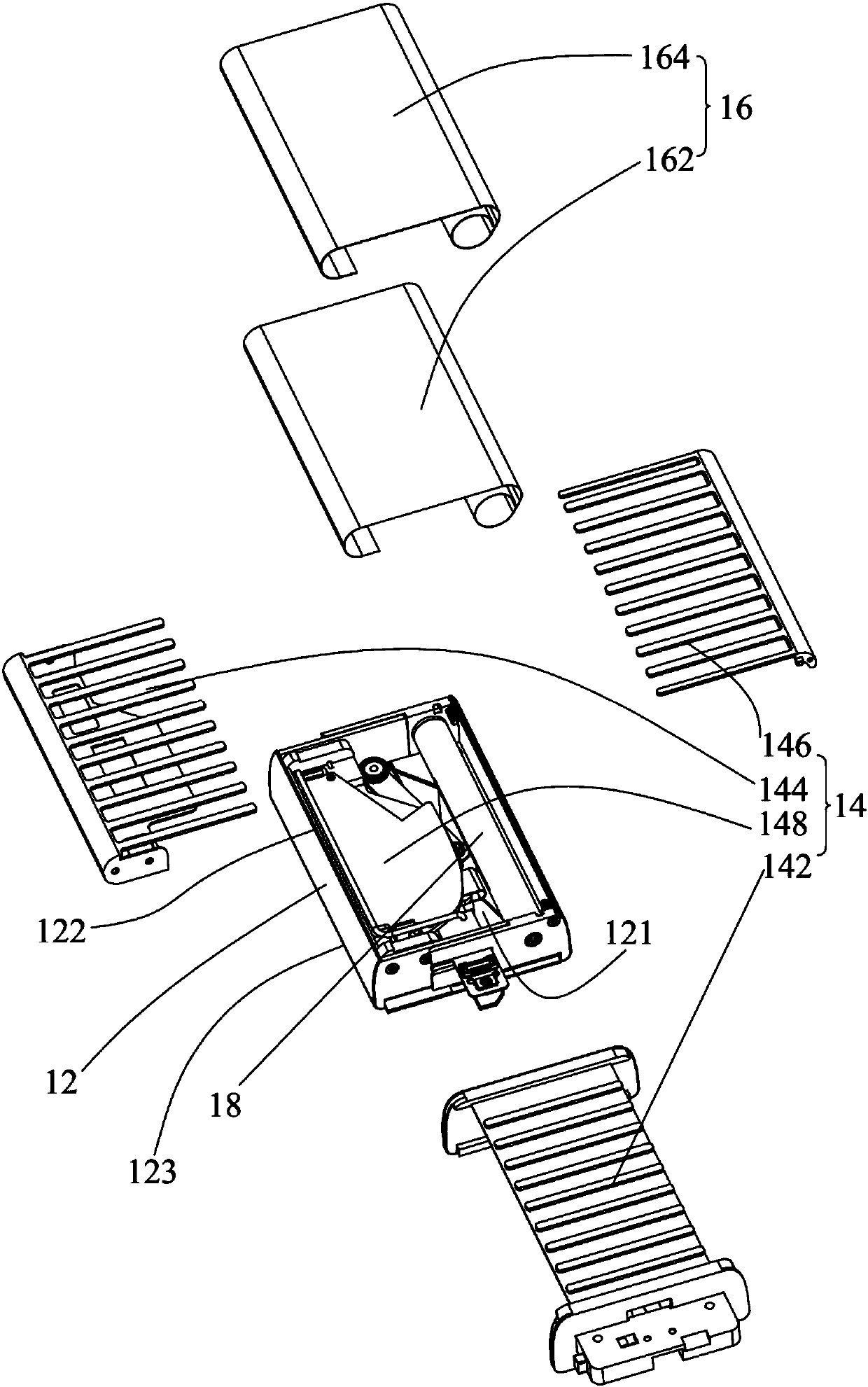

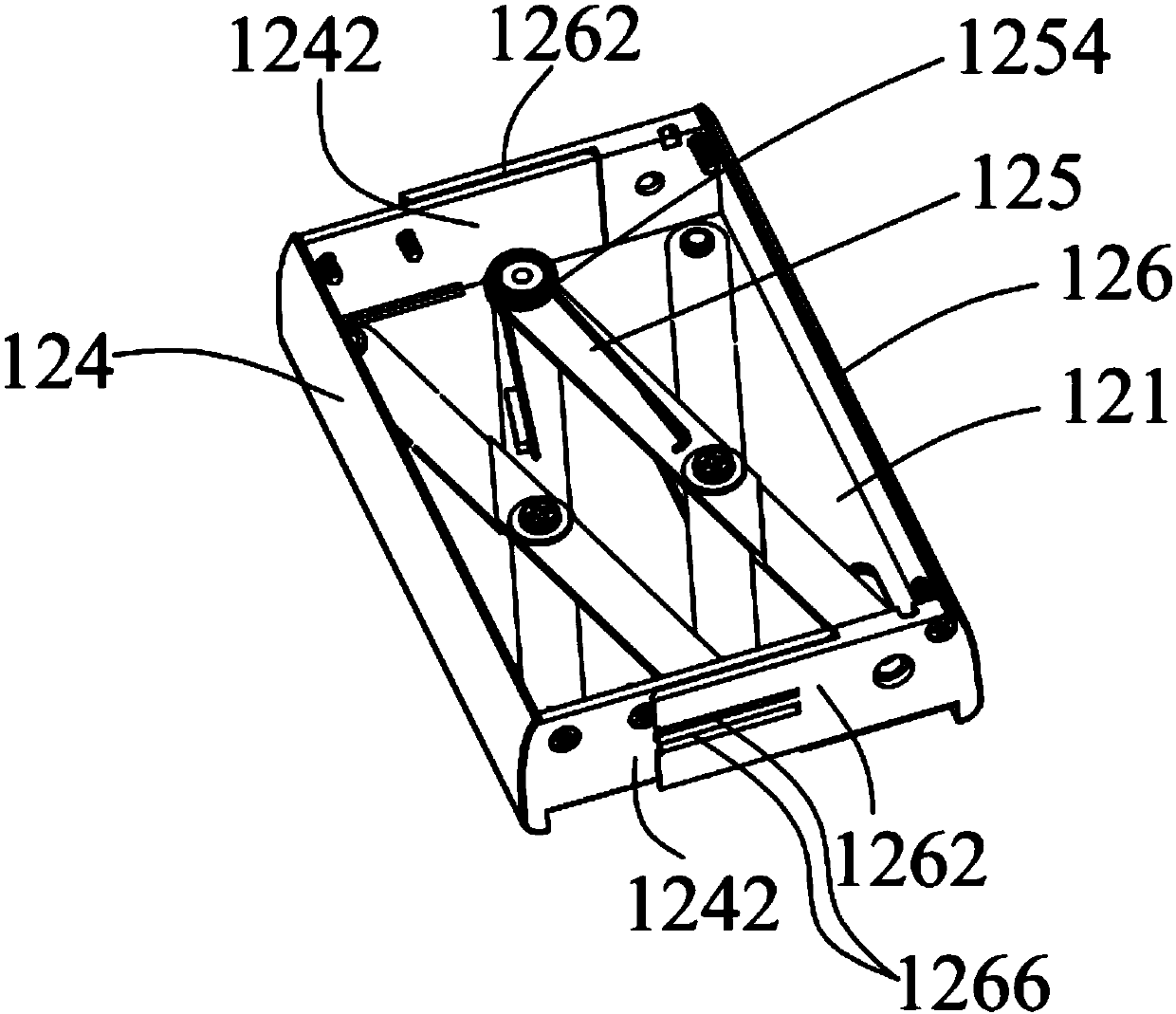

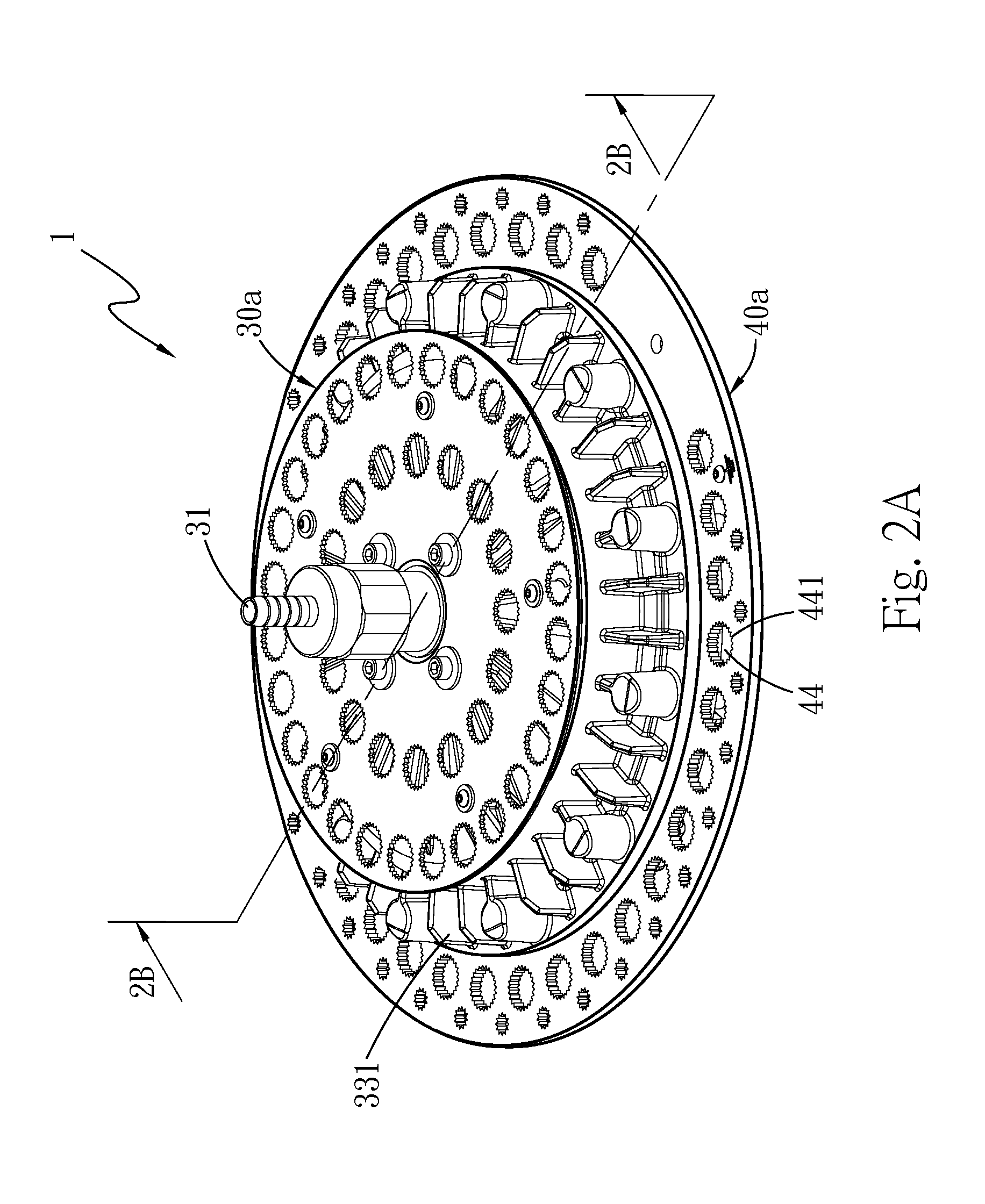

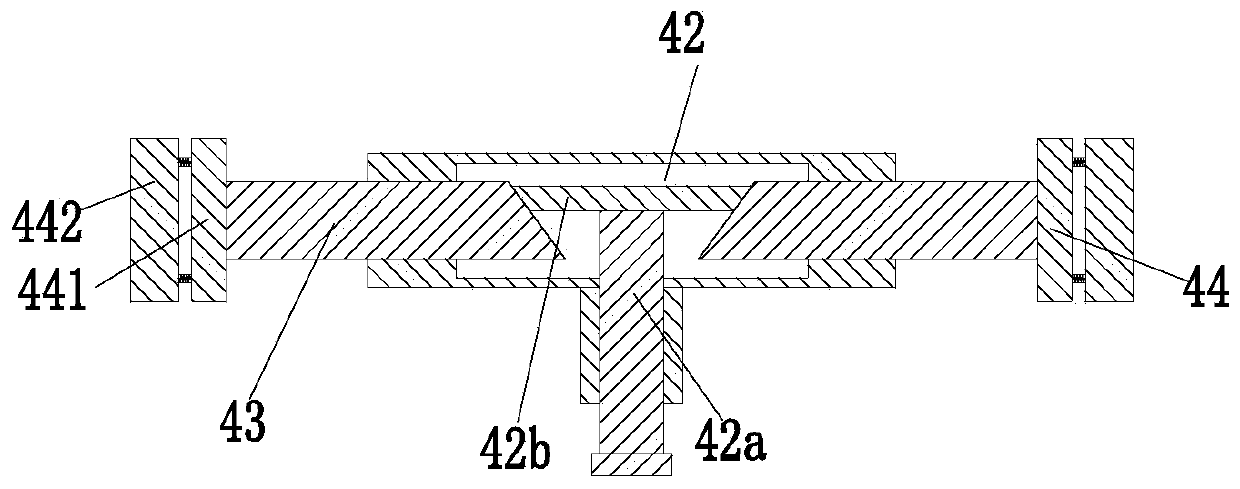

Supporting assembly, dial plate and intelligent bracelet

ActiveCN107820399AMeet miniaturizationBig sizeElectronic time-piece structural detailsVisual indicationsEngineeringTooth part

A supporting assembly (14) comprises a left supporting frame (144), a right supporting frame (146) and a support (142), wherein the left supporting frame (144) and the right supporting frame (146) arein slide connection to the support (142); multiple storage grooves are formed in the surface of the support (142); the left supporting frame (144) comprises a first tooth part (1444); the right supporting frame (146) comprises a second tooth part (1464); and both the first tooth part (1444) and the second tooth part (1464) comprise multiple racks (1445, 1465). When the supporting assembly (14) isshrunk, the rack (1445) of the first tooth part (1444) and the rack (1465) of the second tooth part (1464) can be stored in a storage groove to support a shrunk screen assembly (16). When the supporting assembly (14) is extended, the rack (1445) of the first tooth part (1444) and the rack (1465) of the second tooth part (1464) can be stretched out from the storage groove to support the extended screen assembly (16). The invention also provides a dial plate (10) and an intelligent bracelet. The supporting assembly (14) can be extended and support the screen assembly (16), so the demand for a small size of the dial plate (10) can be satisfied, and a screen size can be expanded.

Owner:SHENZHEN ROYOLE TECH CO LTD

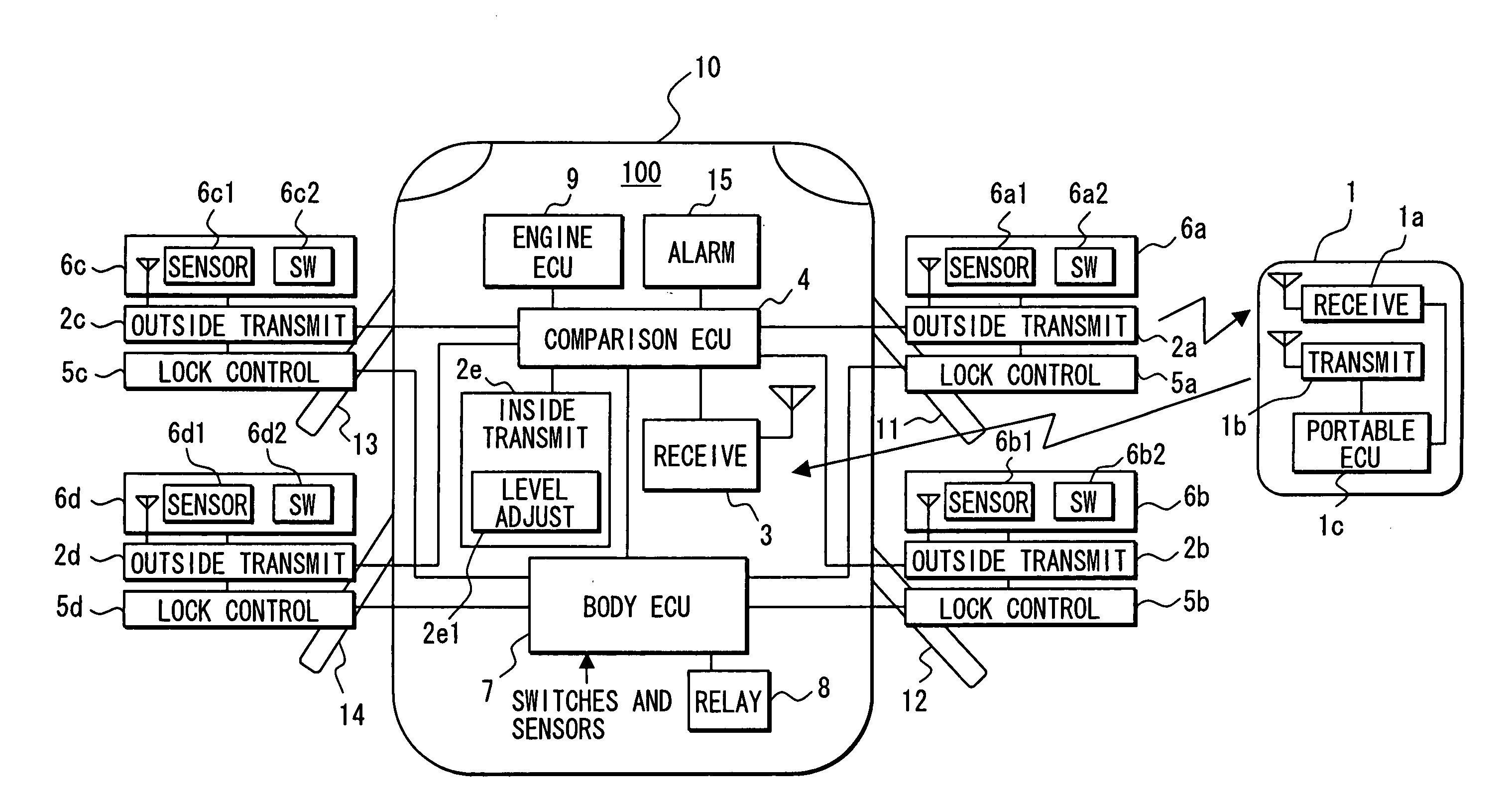

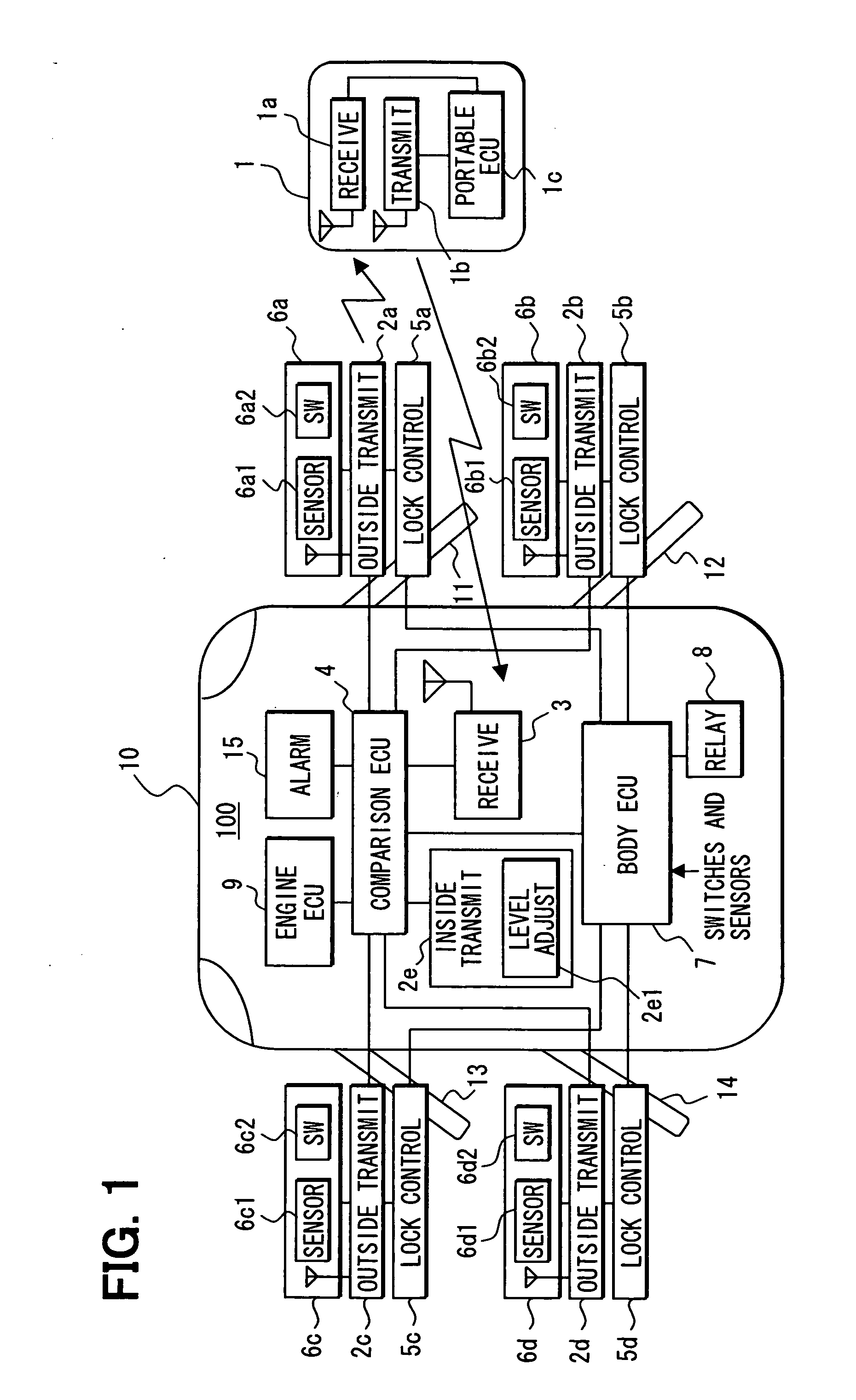

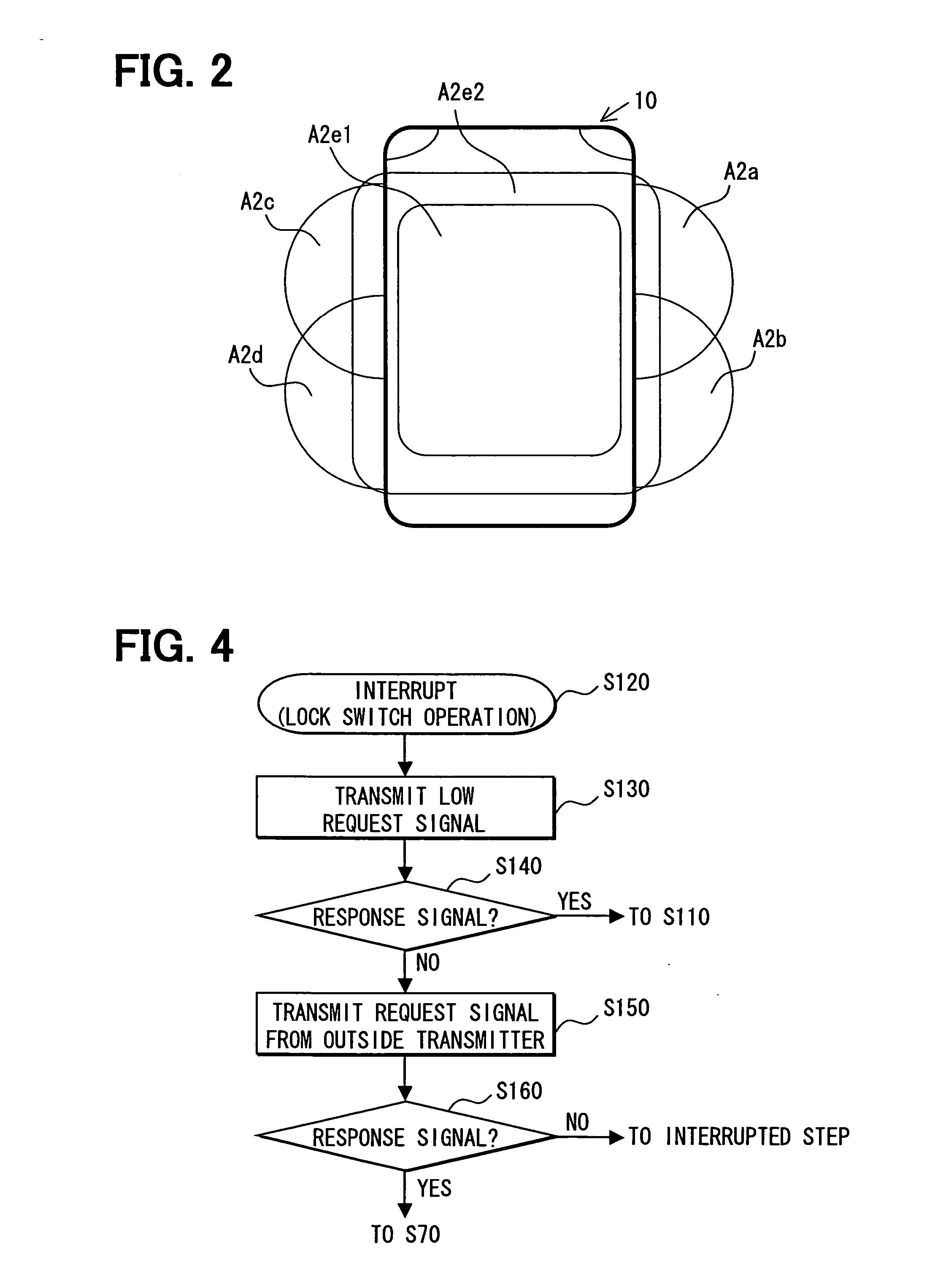

Vehicle equipment control system and method

InactiveUS20070024121A1Big sizeSmall sizeLock applicationsDigital data processing detailsCar doorEngineering

A vehicle equipment control system locks vehicle doors by any one of auto-lock and trigger lock systems. In the auto-lock system, a wide communication area is set that covers an entire vehicle compartment is set. In the trigger lock system, a narrow communication area is set that disables the communication with a portable unit carried by a user near a vehicle. When no response signal is received from the portable unit in the respective communication areas, the respective vehicle doors are locked. Accordingly, even when any one of the auto-lock and trigger lock systems is used, the portable unit is prevented from being left in the compartment, and the respective vehicle doors can be locked.

Owner:DENSO CORP

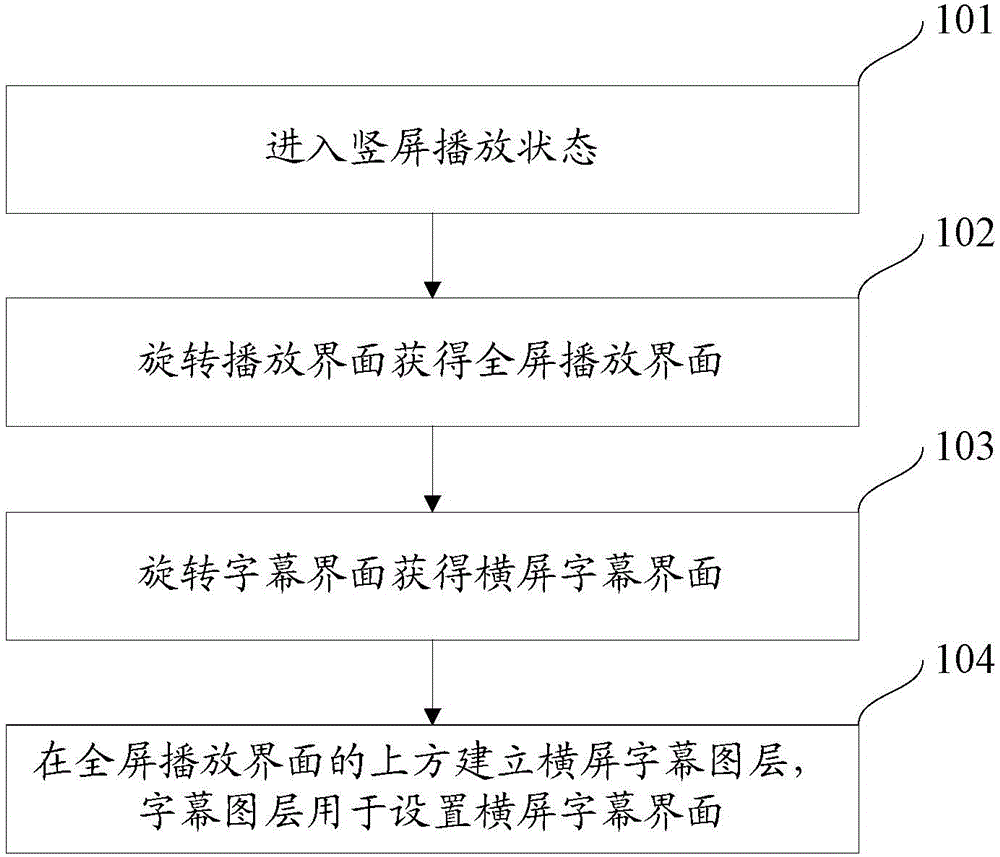

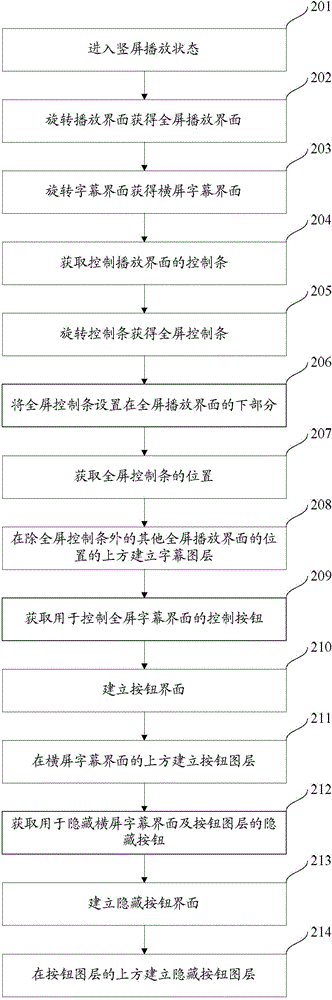

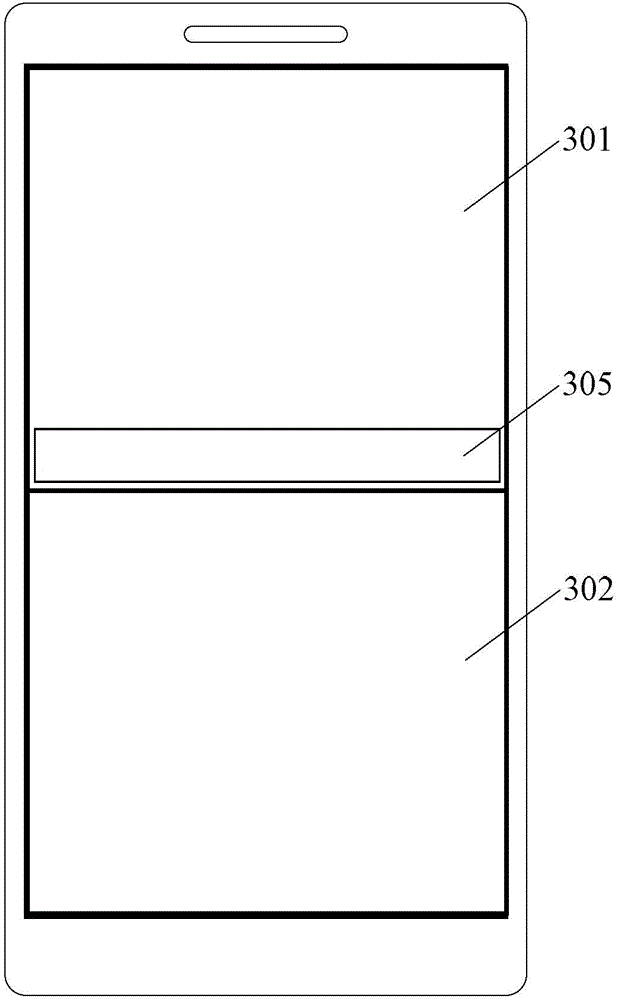

Method and device for displaying playing interface

InactiveCN104363505AIncrease the size of the full-screen playback interfaceBig sizeSelective content distributionImage layerMultimedia

The invention discloses a method and device for displaying a playing interface. The method comprises the steps that when a vertical-screen playing state is carried out, a displaying interface is divided into an upper part and a lower part, the playing interface for playing video information is displayed on the upper part of the displaying interface, and a subtitle interface for displaying subtitle information corresponding to the video information is displayed on the lower part of the displaying interface; when preset screen-rotating operation that the vertical-screen playing state is converted into a horizontal-screen playing state is received, the playing interface is rotated, a full-screen playing interface is obtained, and the full-screen playing interface is filled with the displaying interface; the subtitle interface is rotated, and a horizontal-screen subtitle interface is obtained; and a horizontal-screen subtitle image layer is established above the full-screen playing interface, and the subtitle image layer is used for setting the horizontal-screen subtitle interface. When a vertical-screen playing mode is converted into a horizontal-screen playing mode, the size of the full-screen playing interface is increased, and the problem that subtitles occupies a large part of the video playing interface, and user video watching is affected is solved.

Owner:TVMINING BEIJING MEDIA TECH

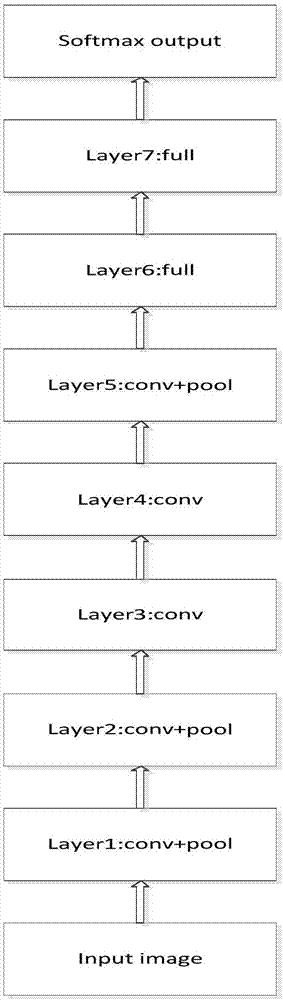

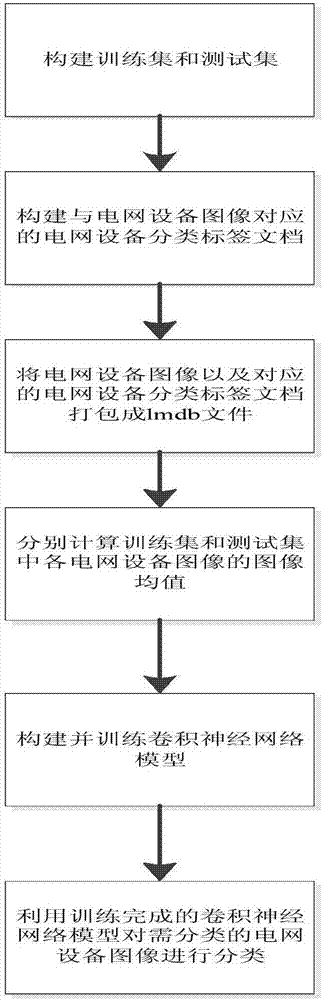

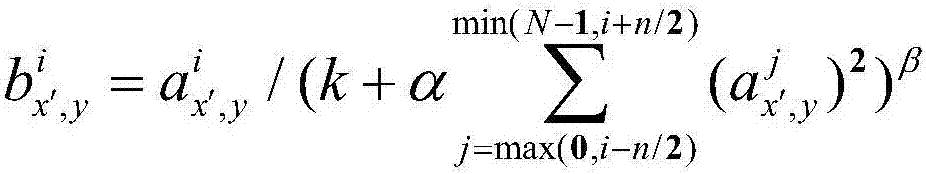

Method for classifying grid equipment based on convolution neural network

ActiveCN106897739ABig amount of dataBig sizeBiological neural network modelsCharacter and pattern recognitionEnhancement TechnologiesNetwork model

The present invention discloses a method for classifying grid equipment based on the convolution neural network. The method comprises that Step 1, a convolution neural network model is trained according to the existing training set and test set of the grid equipment image, and the input layer preprocesses the input image data, so as to increase the amount of data, wherein the number of convolution layers is not greater than N, and N+1 is the number of convolution layers of the common convolution neural network; and Step 2, the trained convolution neural network model is used to carry out classification on grid equipment images that need to be classified. According to the method disclosed by the present invention, the data enhancement technology is used to preprocess the input image data to increase the amount of data, so that the problems that the network is over-fitted and the precision is decreased due to that the amount of data is insufficient are solved; and considering that the amount of the trained data is relatively small, the number of the convolution layers and the number of convolution kernels are reduced while the size of the convolution kernel is increased and the size of the feature map extracted by each layer of the convolution layers is reduced, so that the number of features extracted by the convolution layers is reduced, the effect of preventing the over-fitted phenomenon is reached, and accuracy is improved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +2

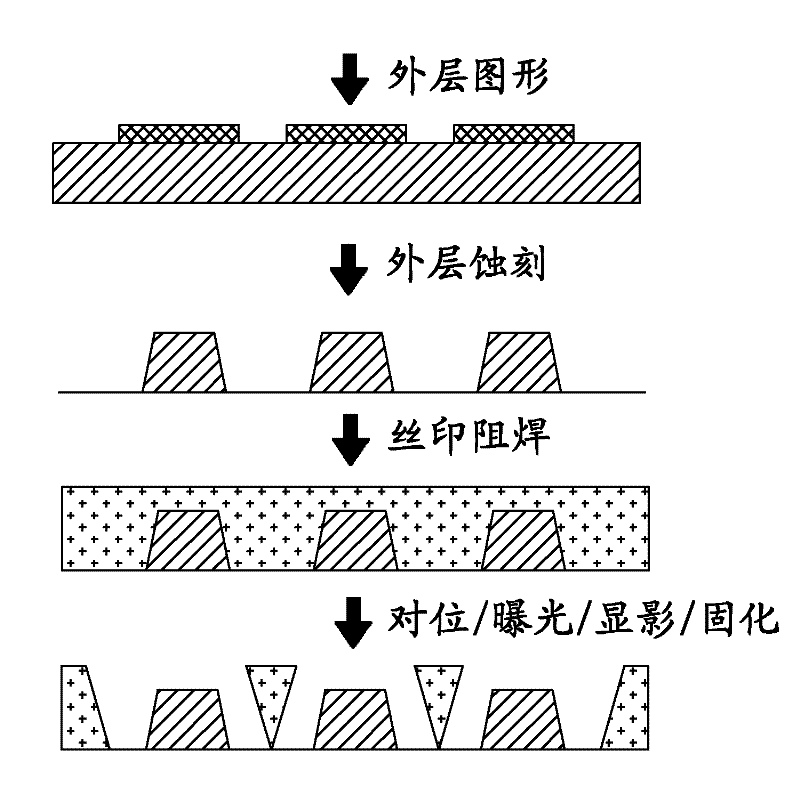

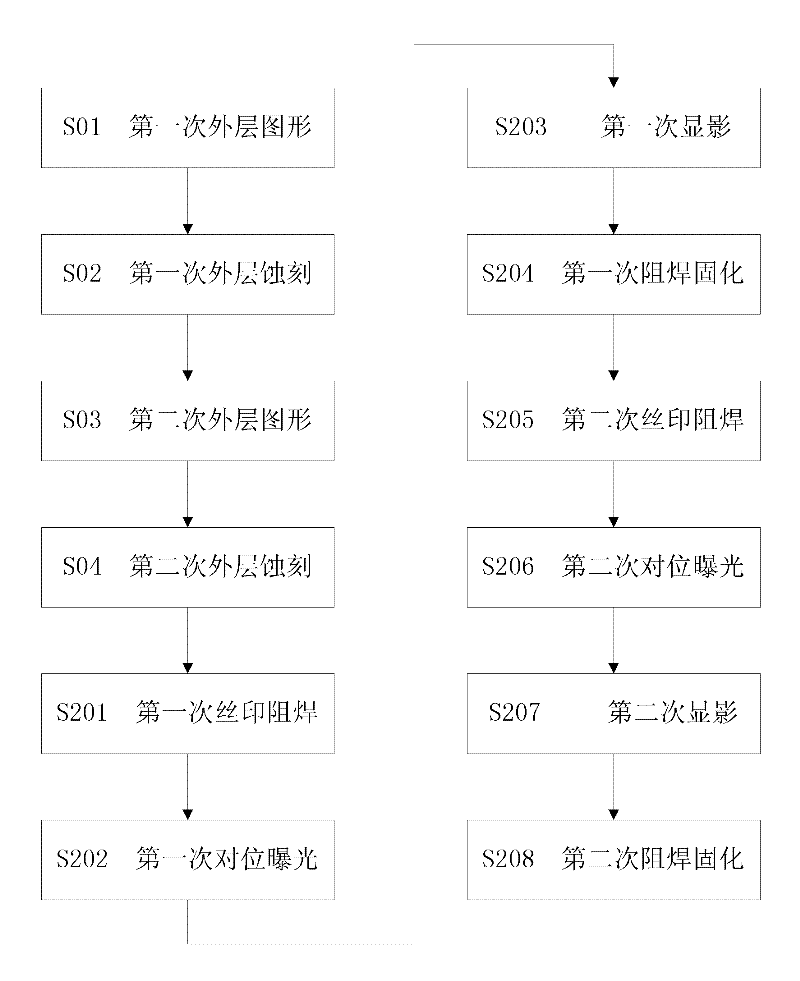

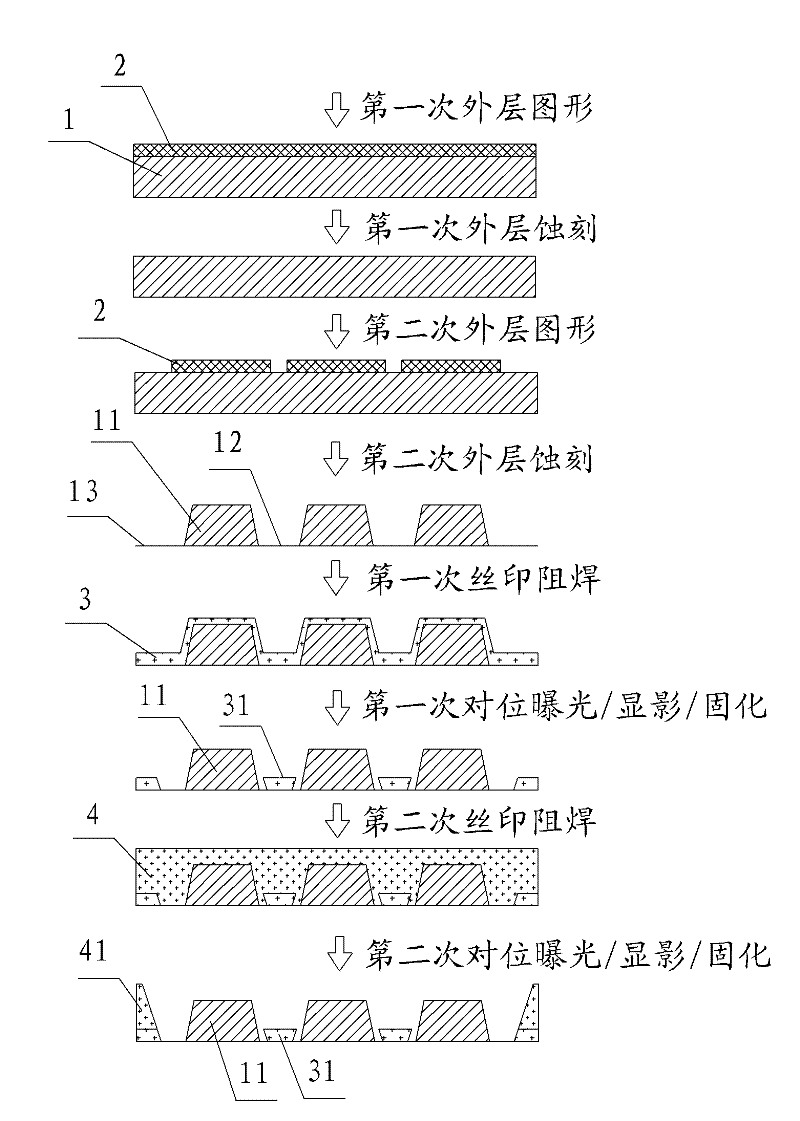

Processing method of surface-mounted pads on thick copper circuit board

ActiveCN102244985ABig sizeMeet the design size requirementsConductive material chemical/electrolytical removalSolder maskCopper

The invention discloses a processing method of surface-mounted pads on a thick copper circuit board. The processing method comprises the following steps: S01. patterning an external layer for the first time; 2. etching the external layer for the first time; 3. patterning the external layer for the second time; 4. etching the external layer for the second time; and 5. manufacturing a solder mask bridge among the surface-mounted pads by a fractional solder resisting method. The processing method has the beneficial effects that the surface-mounted pads are manufactured by a partitioned etching method, which strengthens size control of the surface-mounted pads and meets the design requirements; and the solder mask bridge among the surface-mounted pads are manufactured by utilizing the fractional solder resisting method so that the solder mask bridge and the circuit board are firmly connected together and are not easily separated from each other.

Owner:WUXI SHENNAN CIRCUITS CO LTD

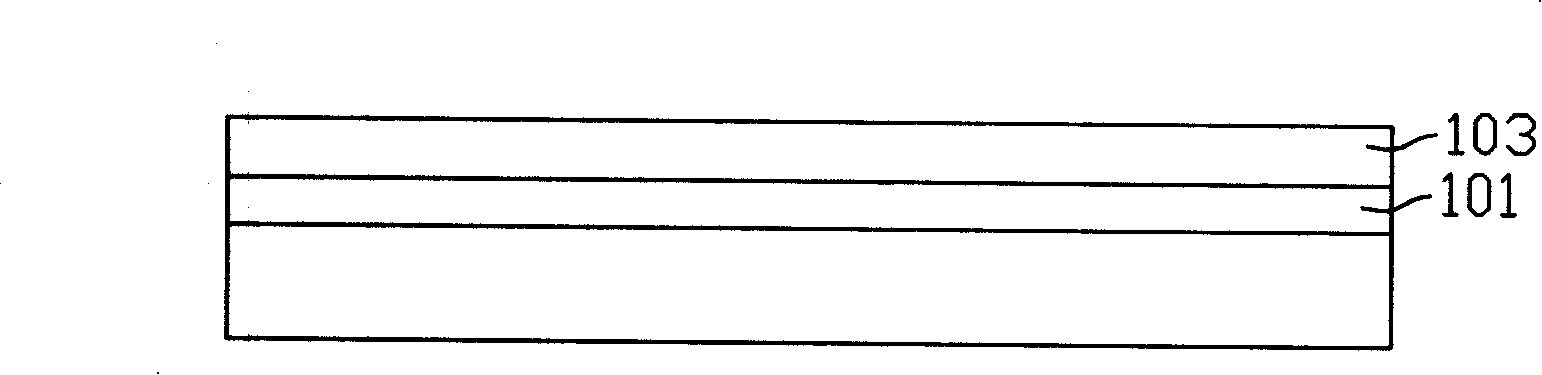

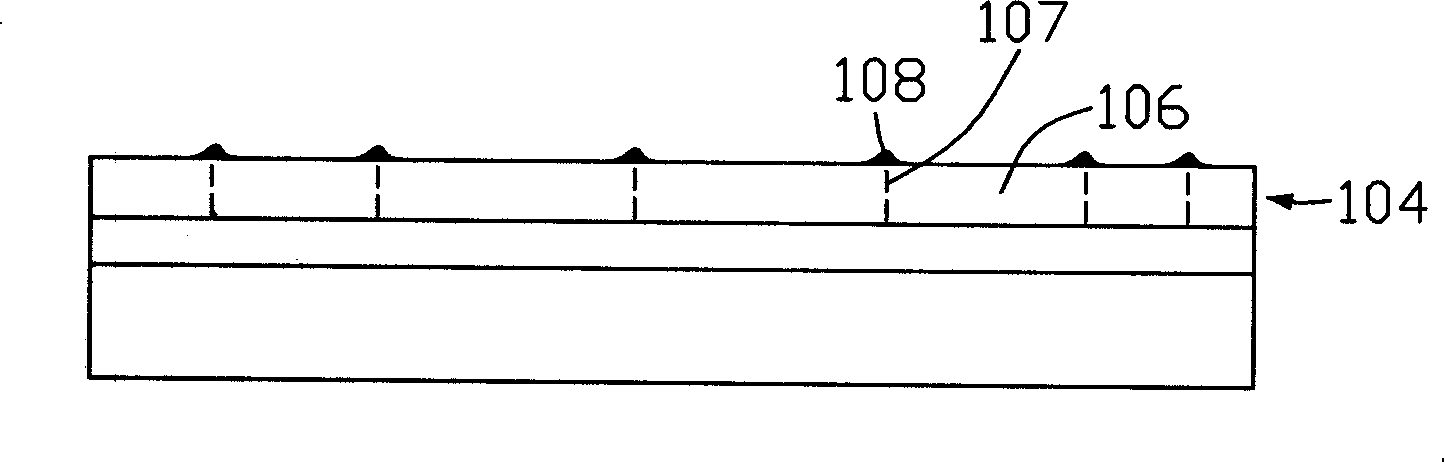

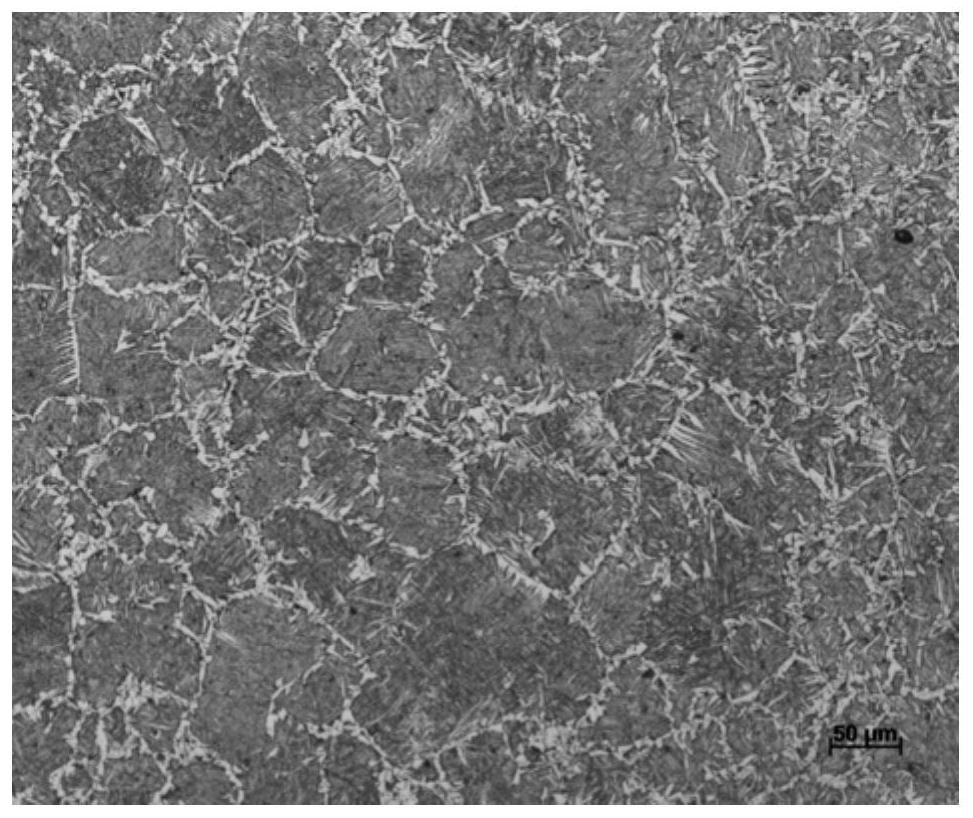

Making method for low-temperature multi-crystal silicon film

InactiveCN101236898ABig sizeUniform performanceSemiconductor/solid-state device manufacturingSeed crystalLow-temperature polycrystalline silicon

The invention provides a manufacturing method for a low temperature polycrystalline silicon thin film, which includes the following steps that: a substrate is provided, and a buffer layer is formed on the substrate; a first amorphous silicon thin film is deposited on the buffer layer; the first amorphous silicon thin film is etched by the lithography / etching process, and a plurality of scattered amorphous silicon particles are kept on the buffer layer; a second amorphous silicon thin film which covers the amorphous silicon particles is deposited on the buffer layer; a recrystallization process is applied to the second amorphous silicon thin film, which makes the second amorphous silicon thin film recrystallized by taking the plurality of amorphous silicon particles as crystal seeds after the second amorphous silicon thin film is melted, forming the polycrystalline silicon thin film.

Owner:INNOCOM TECH SHENZHEN +1

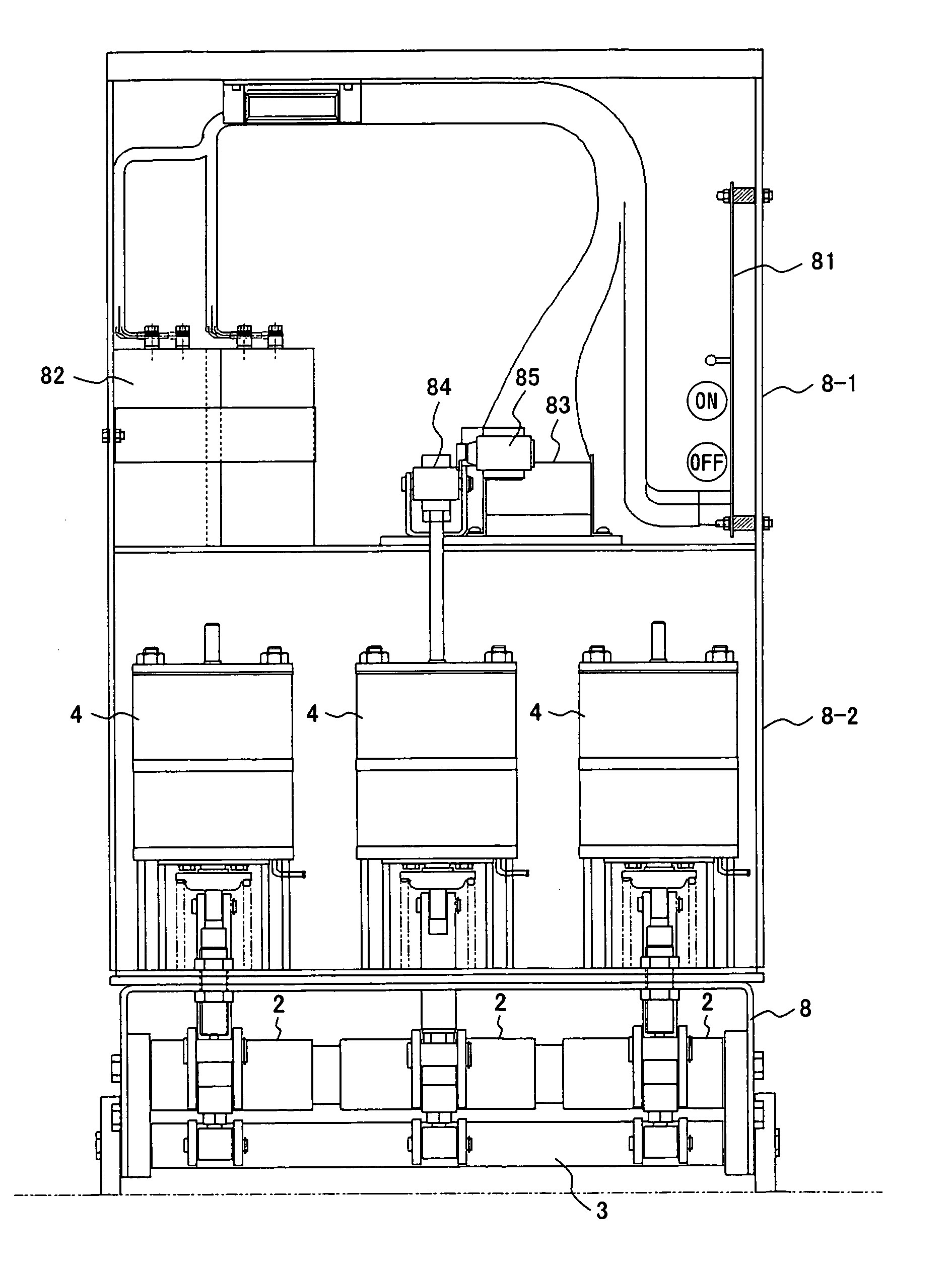

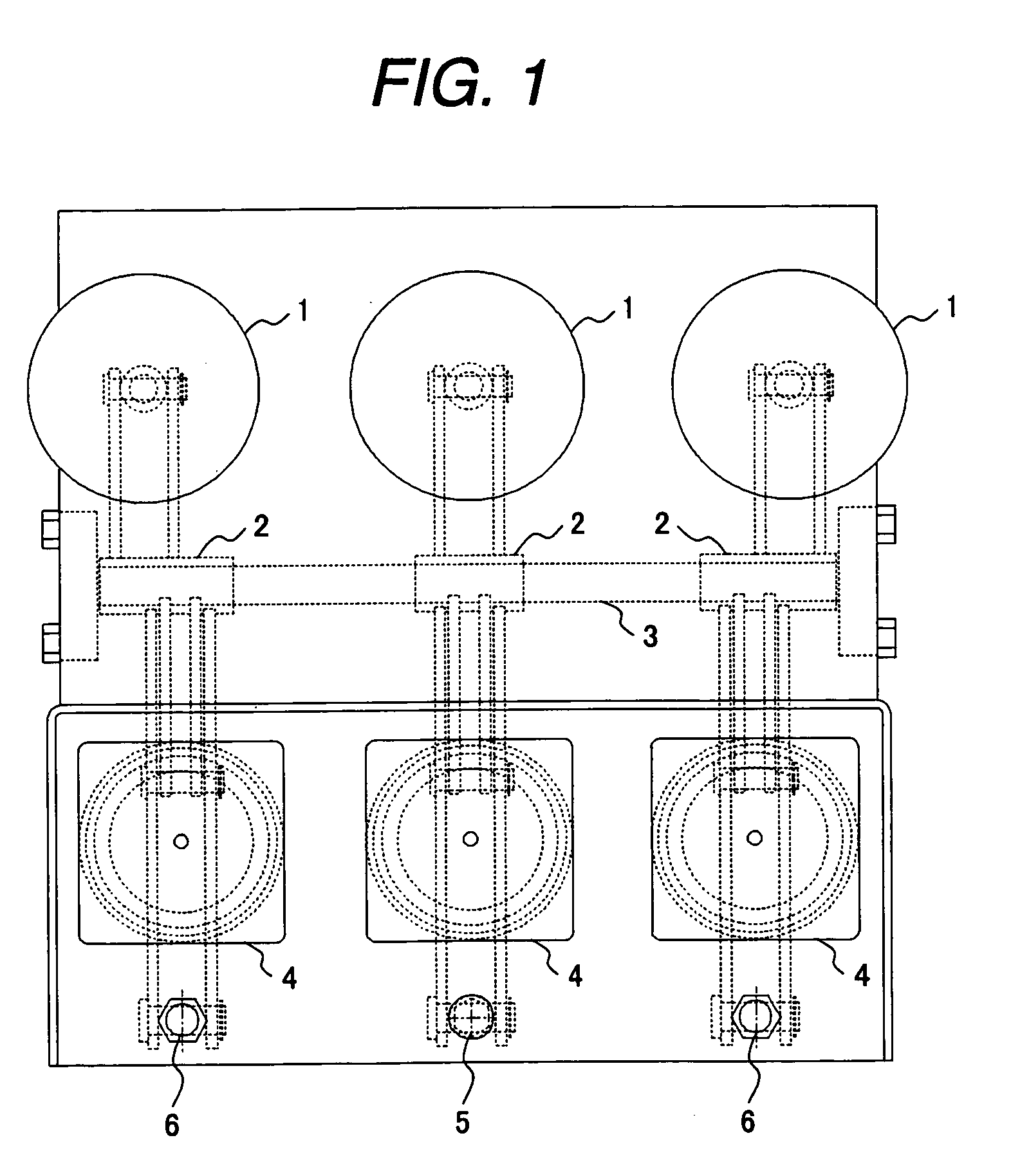

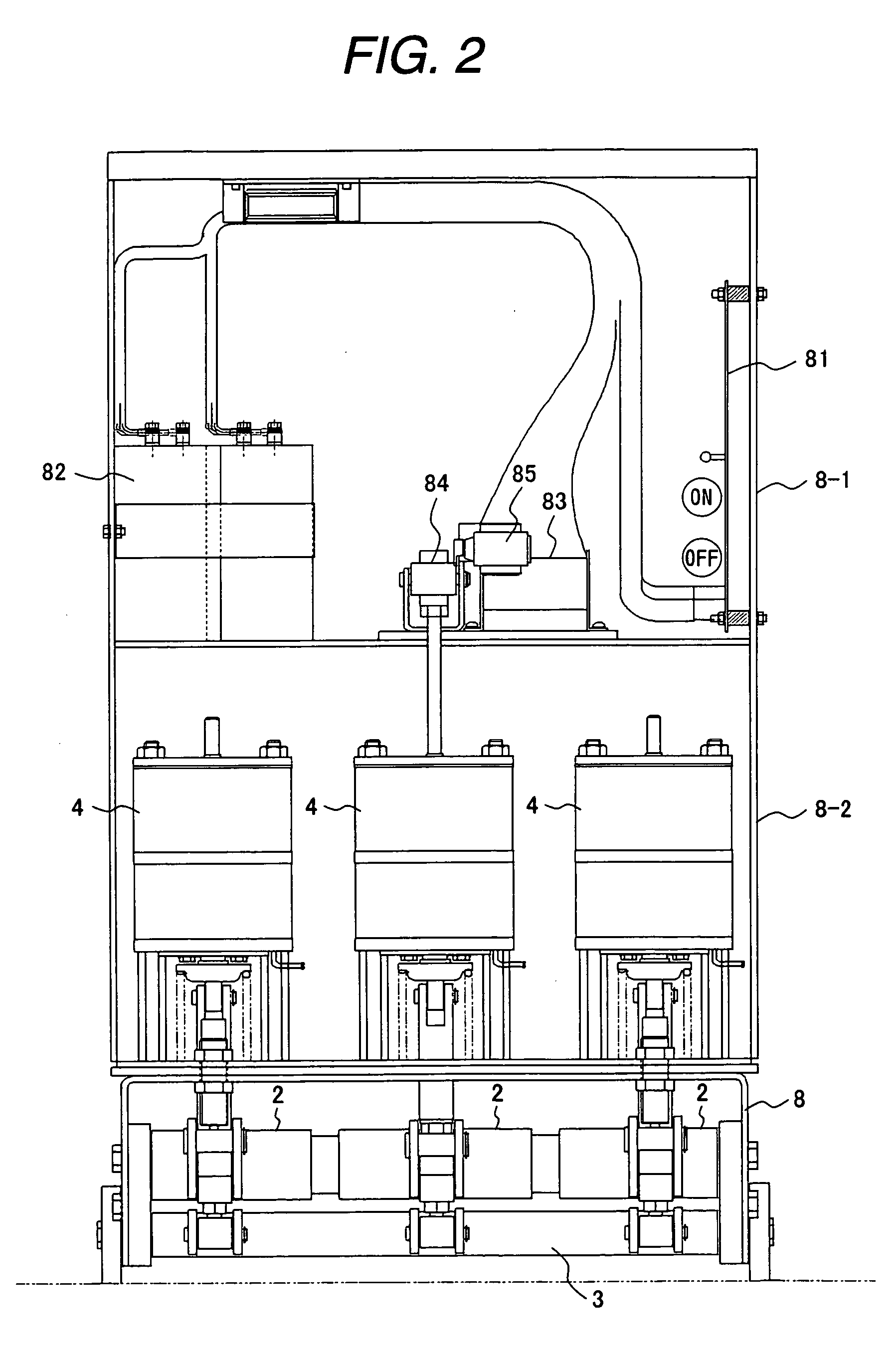

Electromagnetic operation device

InactiveUS20060028073A1Disables space savingBig sizeHigh-tension/heavy-dress switchesPropulsion systemsThree-phaseLinkage concept

Owner:HITACHI LTD

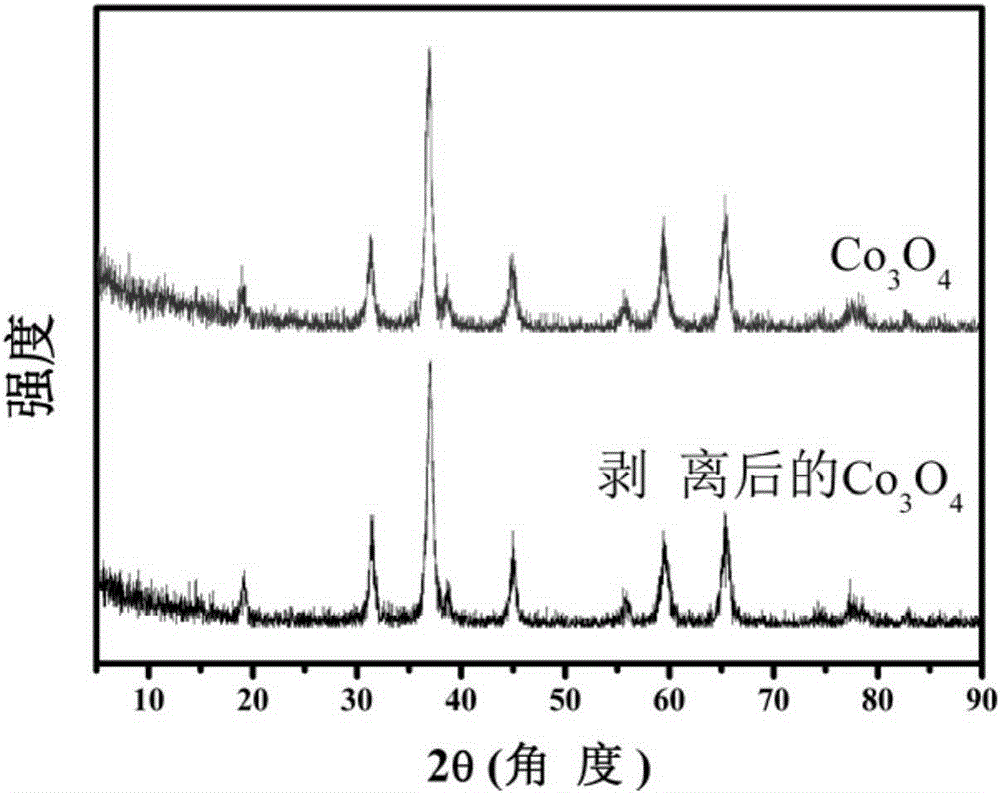

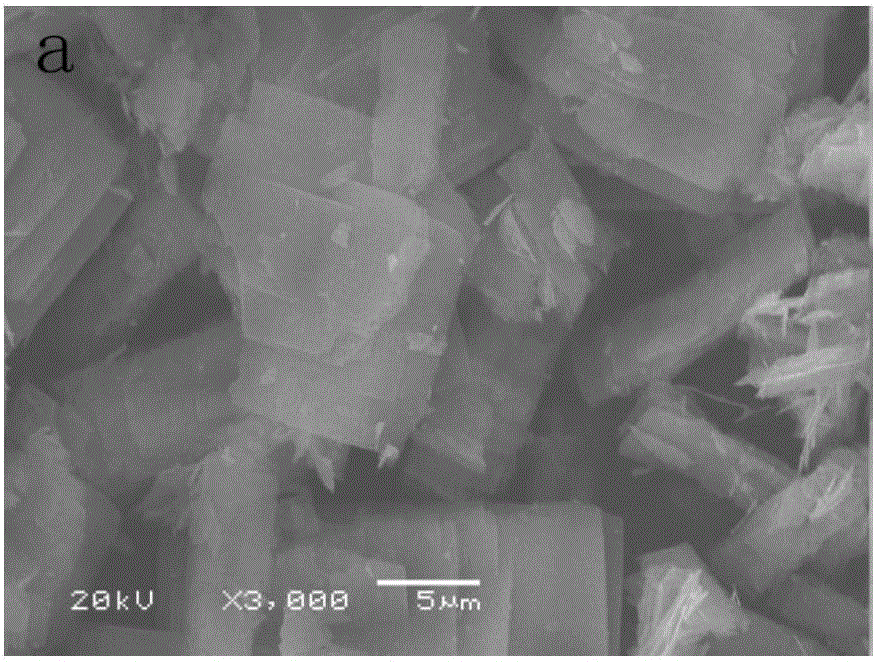

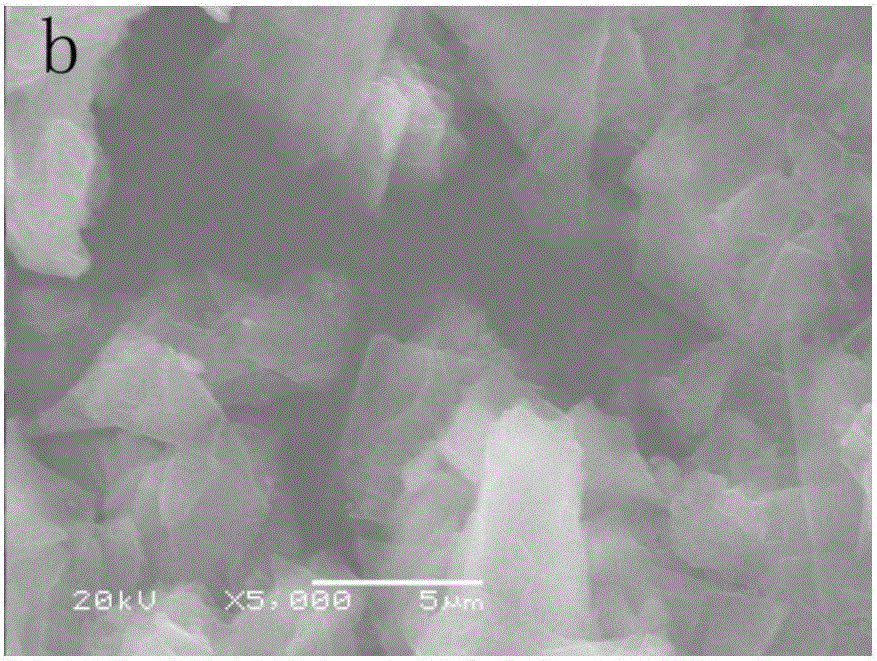

Preparation and stripping methods of mesoporous cobaltosic oxide nanosheet

ActiveCN105198007ABig sizeUniform shapeMaterial nanotechnologyCobalt oxides/hydroxidesUreaFormamides

The invention provides preparation and stripping methods of a mesoporous cobaltosic oxide nanosheet. According to the method, urea is added into a solution with the Co<2+> concentration being 0.01 to 0.5 mol / L; constant-temperature reaction is performed for 24h at 120 DEG C; cooling, centrifugation, washing and drying are performed; after the drying is completed, a pink lamellar precursor nanosheet is obtained; the lamellar precursor nanosheet is calcined at the temperature being 200 to 400 DEG C to obtain a mesoporous black cobaltosic oxide nanosheet. The mesoporous black cobaltosic oxide nanosheet is dissolved in an ammonium nitrate solution for pretreatment; after centrifugation, supernatant liquid is dissolved in formamide; mixed liquid is subjected to water bath ultraphonic treatment for 1 to 2h at 100 to 200W at the room temperature; constant-temperature oscillation is performed for 3d in a constant-temperature oscillator at a rotating speed being 100 to 300r / min; supernatant obtained after centrifugation is a striped single lamellar cobaltosic oxide nanosheet. Obtained cobaltosic oxide inherits excellent properties of matrixes; the crystallinity is high; a larger lamellar structure is used; meanwhile, the surface also has the obvious mesoporous features.

Owner:HARBIN ENG UNIV

Manufacturing process of graphene transparent conductive film

The invention relates to a manufacturing process of a graphene transparent conductive film. The manufacturing method includes the steps of 1), uncoiling a copper foil in a vacuum chamber, heating a copper-clad chemical deposition reaction zone by using a resistor, feeding in methane gas and hydrogen, subjecting a copper-clad surface to chemical sedimentation to generate a graphene layer, and then adopting plasma to perform etching processing on the graphene layer; 2), adopting a gravure printing process to obtain an oxidize graphene layer; 3), obtaining an oxide graphene film; 4), coating a copper chloride etching solution which is 200g / L in concentration on a copper-clad face of the oxidize graphene film; 5), subjecting the oxidize graphene film to thermal annealing and reduction; 6), coating resin adhesive, sticking the film for packaging, and finally obtaining the patterned graphene transparent conductive film. The manufacturing process is short in film forming time, and low-cost and large-scale mass manufacturing can be realized; the graphene transparent conduction film is high in electric conductivity, good in flexibility, high in pattern definition, higher in acid and alkali resistance of the transparent conductive film and lower in cost.

Owner:苏州瑞邦塑胶有限公司

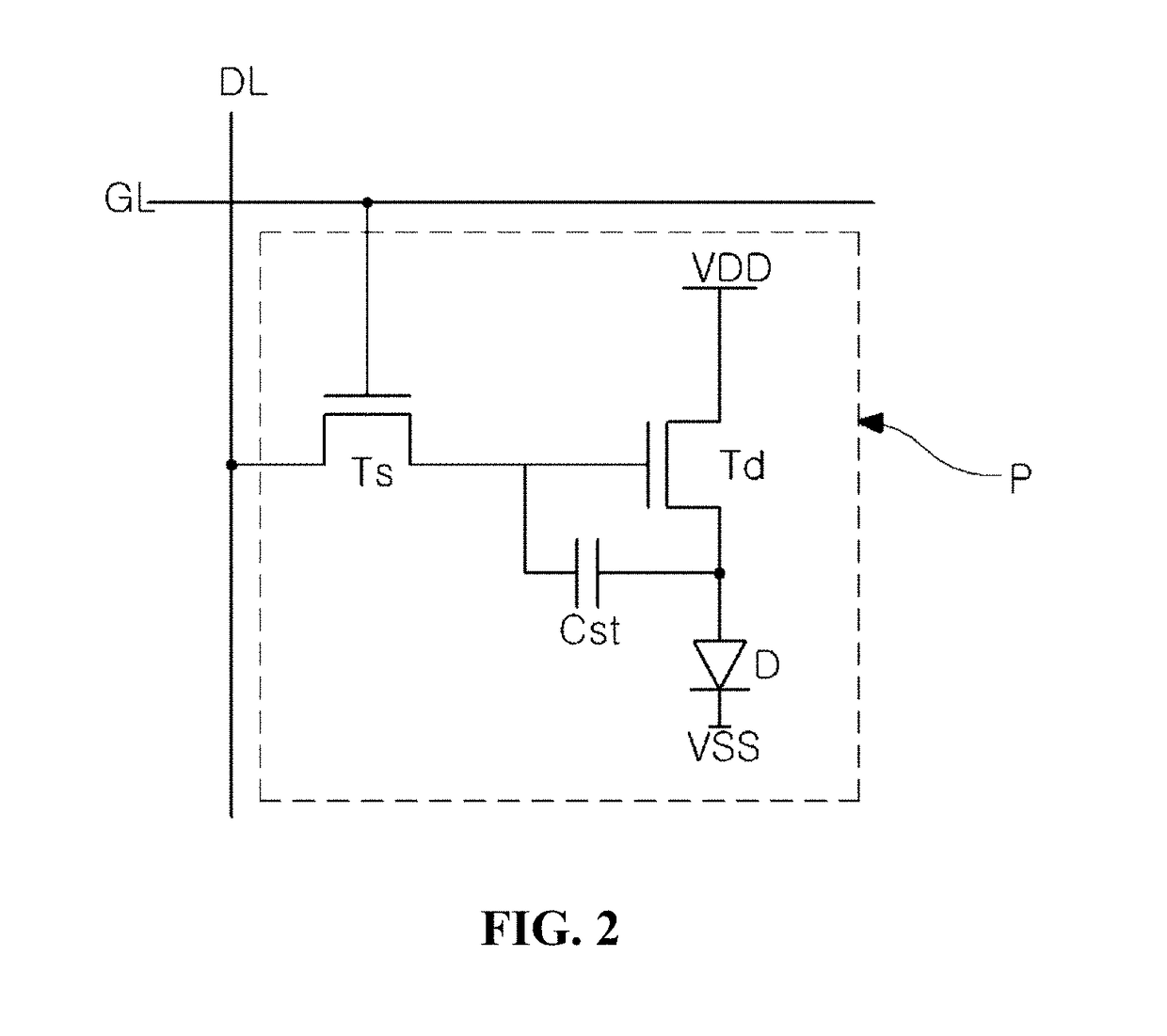

Organic light emitting diode and organic light emitting diode display device including the same

ActiveUS20180138435A1Big sizeReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingWhite lightDisplay device

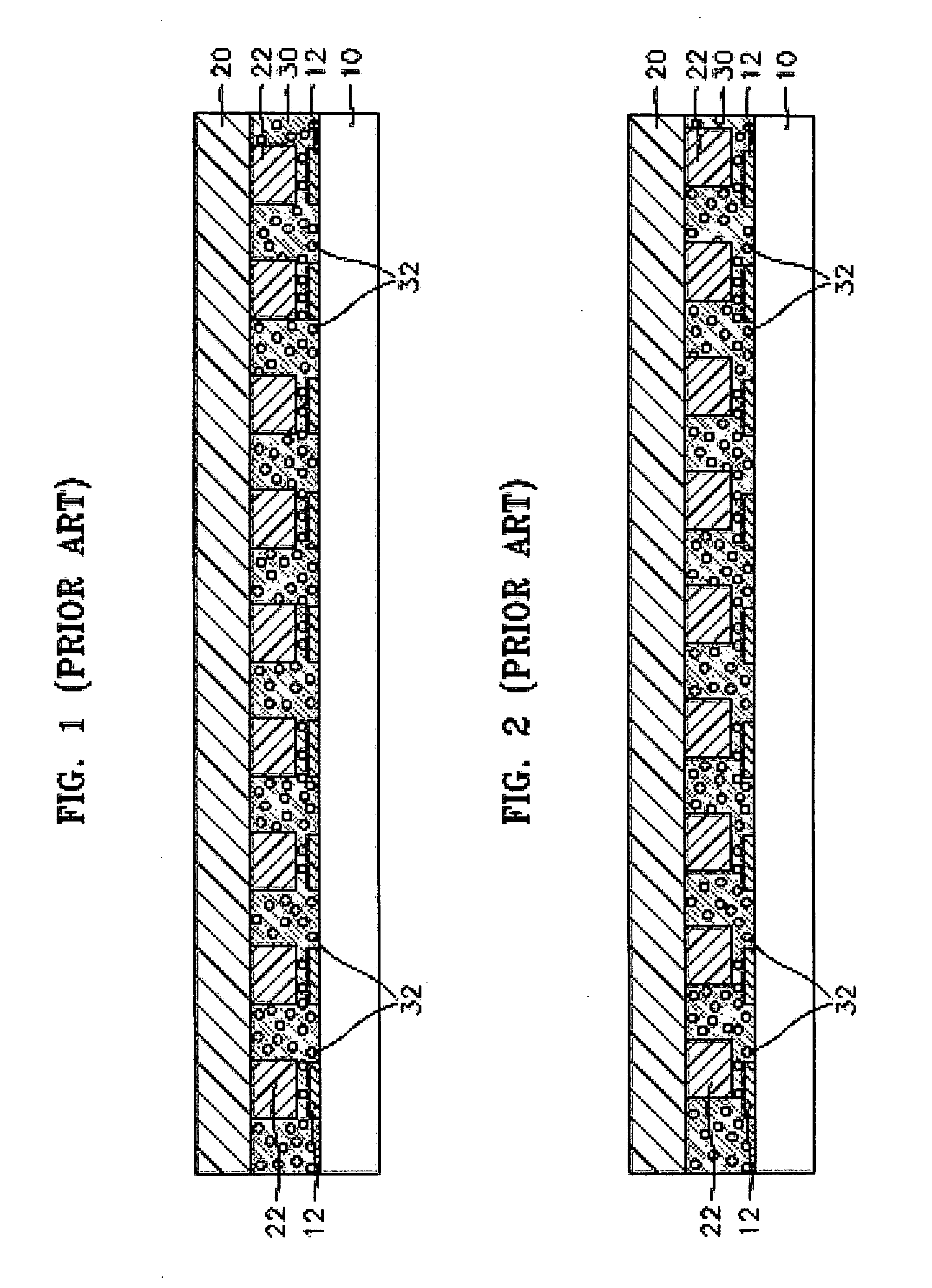

An organic light emitting diode includes a first electrode; a hole auxiliary layer on the first electrode; a light emitting material layer on the hole auxiliary layer and emitting white light; an electron auxiliary layer on the light emitting material layer; and a second electrode on the electron auxiliary layer, wherein the light emitting material layer includes a first light emitting material layer, a second light emitting material layer and a third light emitting material layer sequentially layered, and wherein the first light emitting material layer includes an electron blocking material.

Owner:LG DISPLAY CO LTD

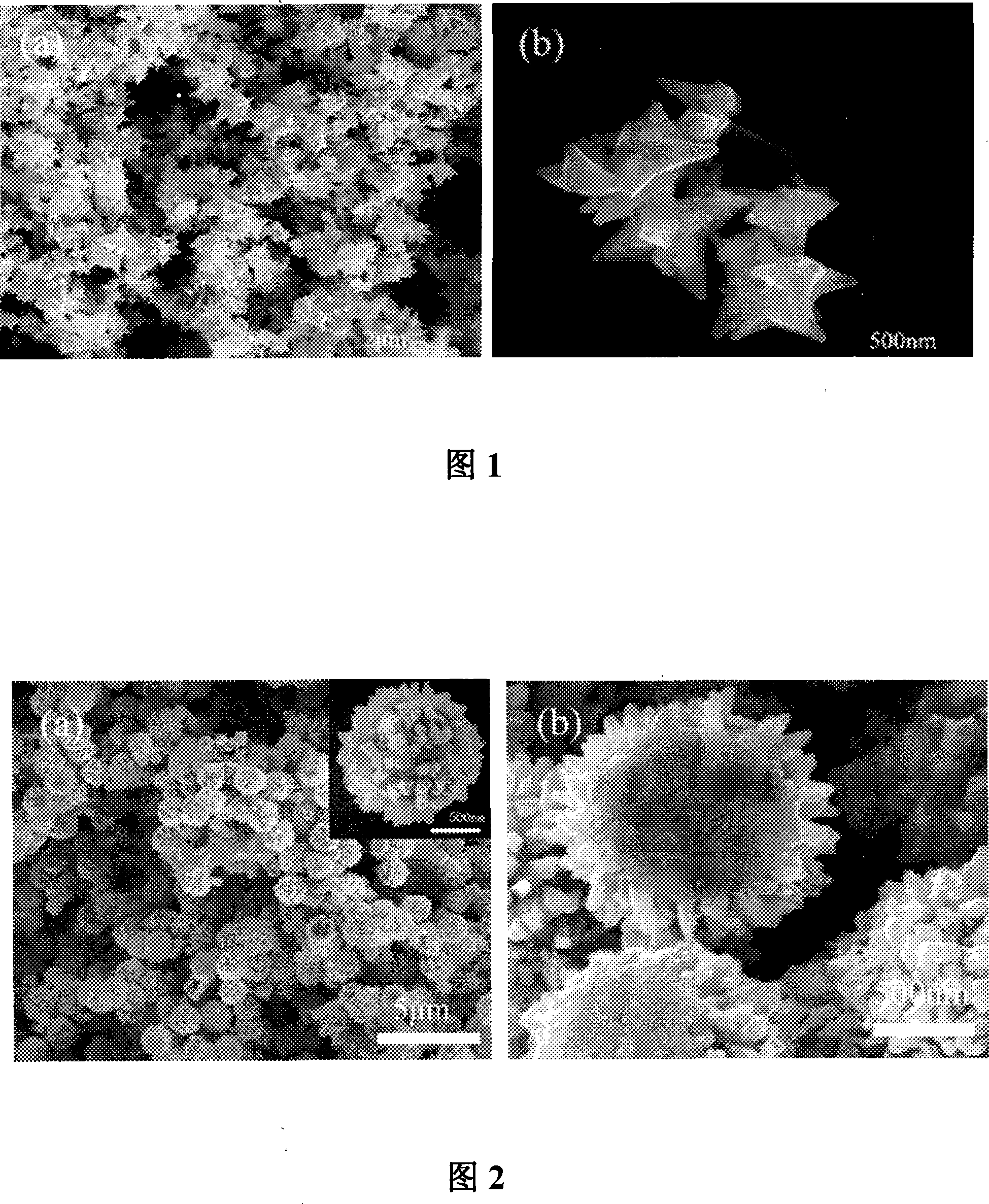

Method for preparing gold micron crystal with surface enhanced Raman active branched surface

InactiveCN101144183ANovel surface topographyBig sizePolycrystalline material growthFrom normal temperature solutionsRaman scatteringChlorauric acid

The present invention relates to a preparation method for golden micro-crystal with a branchy surface with enhanced Raman scattering activities. The present invention uses disodiumedetate (Na2EDTA) as reductant and appearance controlling reagent for the first time, three kinds of gold micro-crystal are prepared through the mixing of the disodiumedetate and hydrochloroauric acid (HAuCl4) at different temperatures, and the three kinds of gold micro-crystal have a novel branchy surface and a micron sized measurement. The operation of the method is simple, and the prepared gold micro-crystal has high surface-enhanced Raman scattering activitiesand application value in the analysis field.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

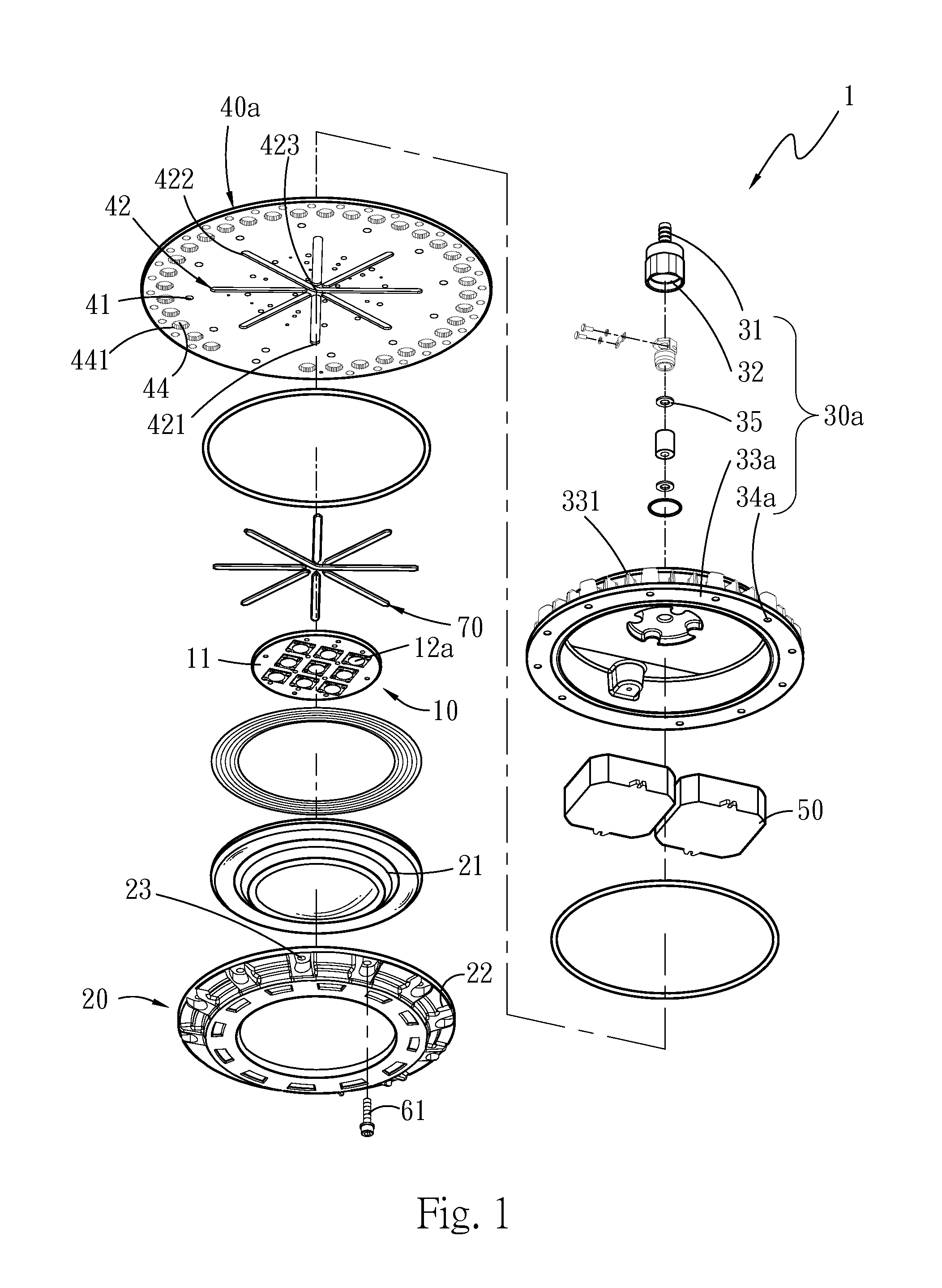

Heat dissipation structure for LED explosion-proof lamp

InactiveUS20160018096A1Big sizeSmall sizePoint-like light sourceElectric circuit arrangementsEngineeringComputer module

A heat dissipation structure for an LED explosion-proof lamp includes an illumination module, a heat conduction disk, a window frame shell and a lamp set shell. The illumination module includes a base and at least one light-emitting diode. The heat conduction disk includes a plurality of installation holes. The window frame shell includes a light permeable portion, a window frame and a plurality of window frame connection holes. The lamp set shell includes a casing portion and a plurality of lamp set connection holes. Each compact member presses and holds the window frame shell and the lamp set shell. The heat conduction disk has a heat conduction zone formed on a projection location of the window frame shell and the lamp set shell, and a cooling zone encircled the heat conduction zone at an outer side to perform heat exchange with external air.

Owner:LI HONG SCI & TECH

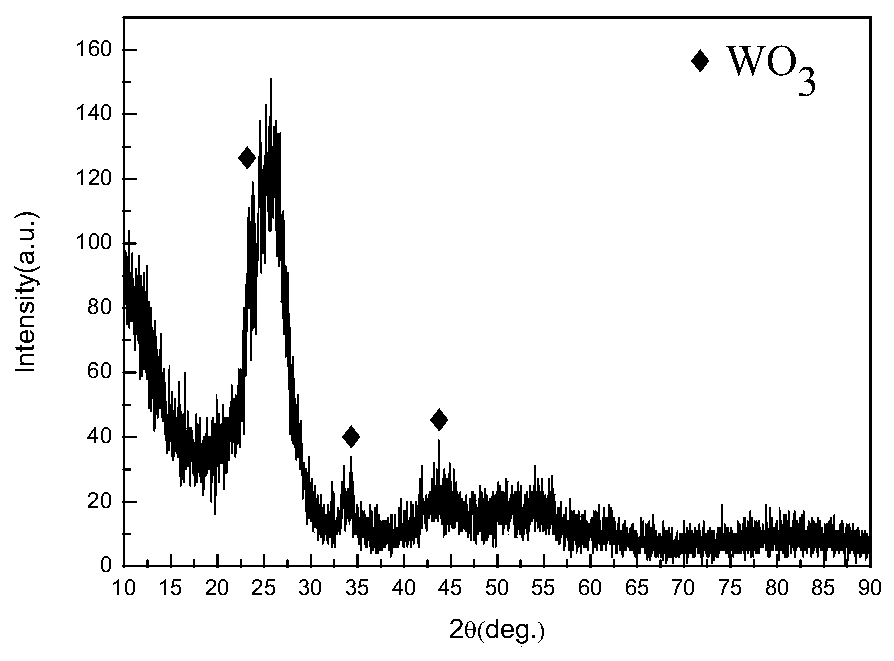

Preparation method of tungsten disulfide nanosheet for electrocatalytic hydrogen evolution

InactiveCN110563040AEvenly distributedBig sizeTungsten compoundsElectrodesTube furnaceTungsten disulfide

The invention relates to a preparation method of a tungsten disulfide nanosheet for electrocatalytic hydrogen evolution. The preparation method comprises the following steps: preparation of tungsten trioxide / carbon cloth (WO3 / CC); and preparation of tungsten disulfide / carbon cloth (WS2 / CC): under the protection of an argon atmosphere, calcining the tungsten trioxide / carbon cloth in a high-temperature area of a double-temperature-area tubular furnace, carrying out heating to 600 DEG C at a speed of 20 DEG C / min, putting 1 g of sulfur powder into a low-temperature area of the double-temperature-area tubular furnace, carrying out heating to 200 DEG C at a speed of 7 DEG C / min, preserving heat for 1 to 3 h, naturally cooling the tubular furnace to room temperature, and then taking out the tungsten disulfide / carbon cloth (WS2 / CC).

Owner:TIANJIN UNIV

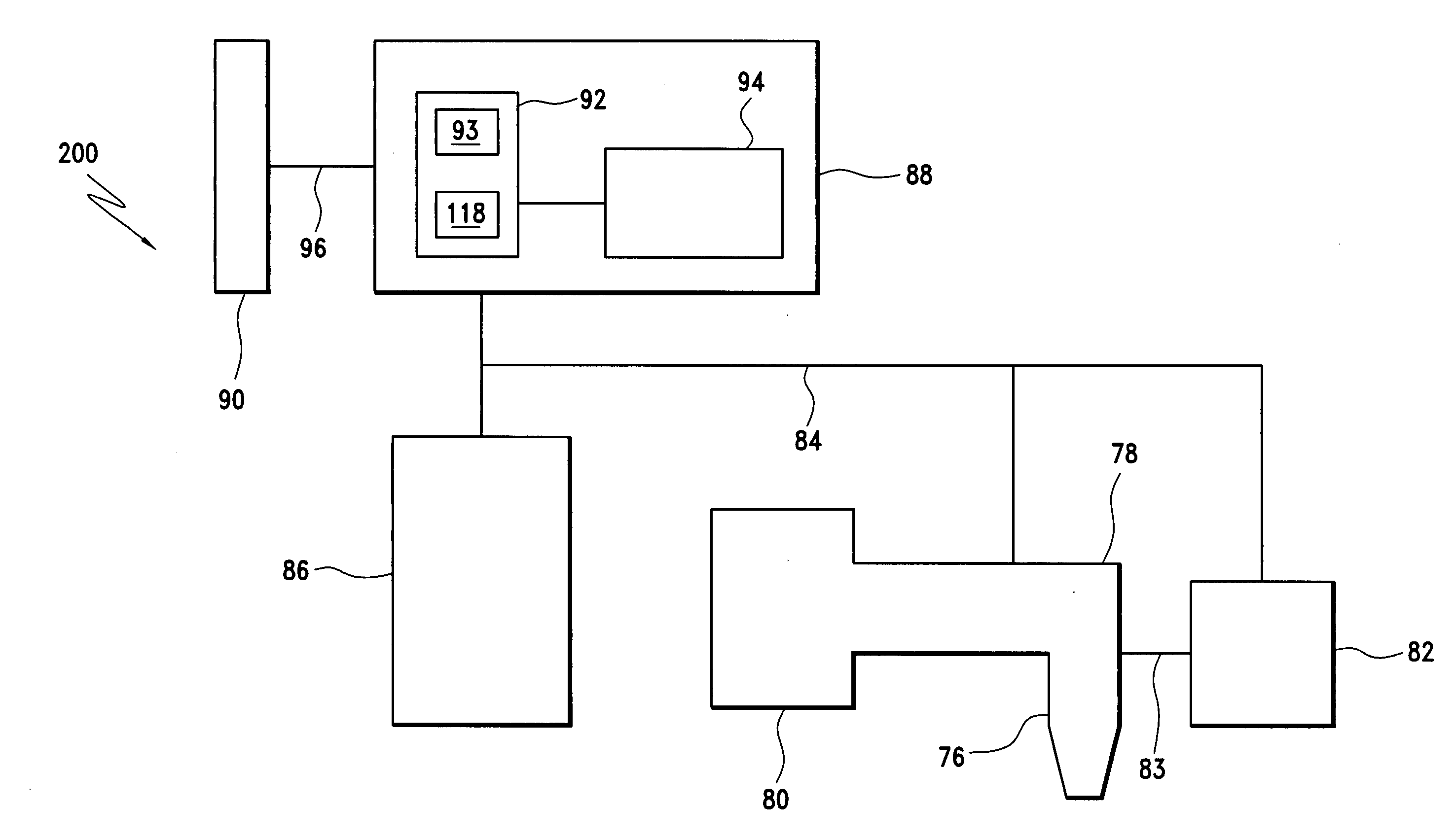

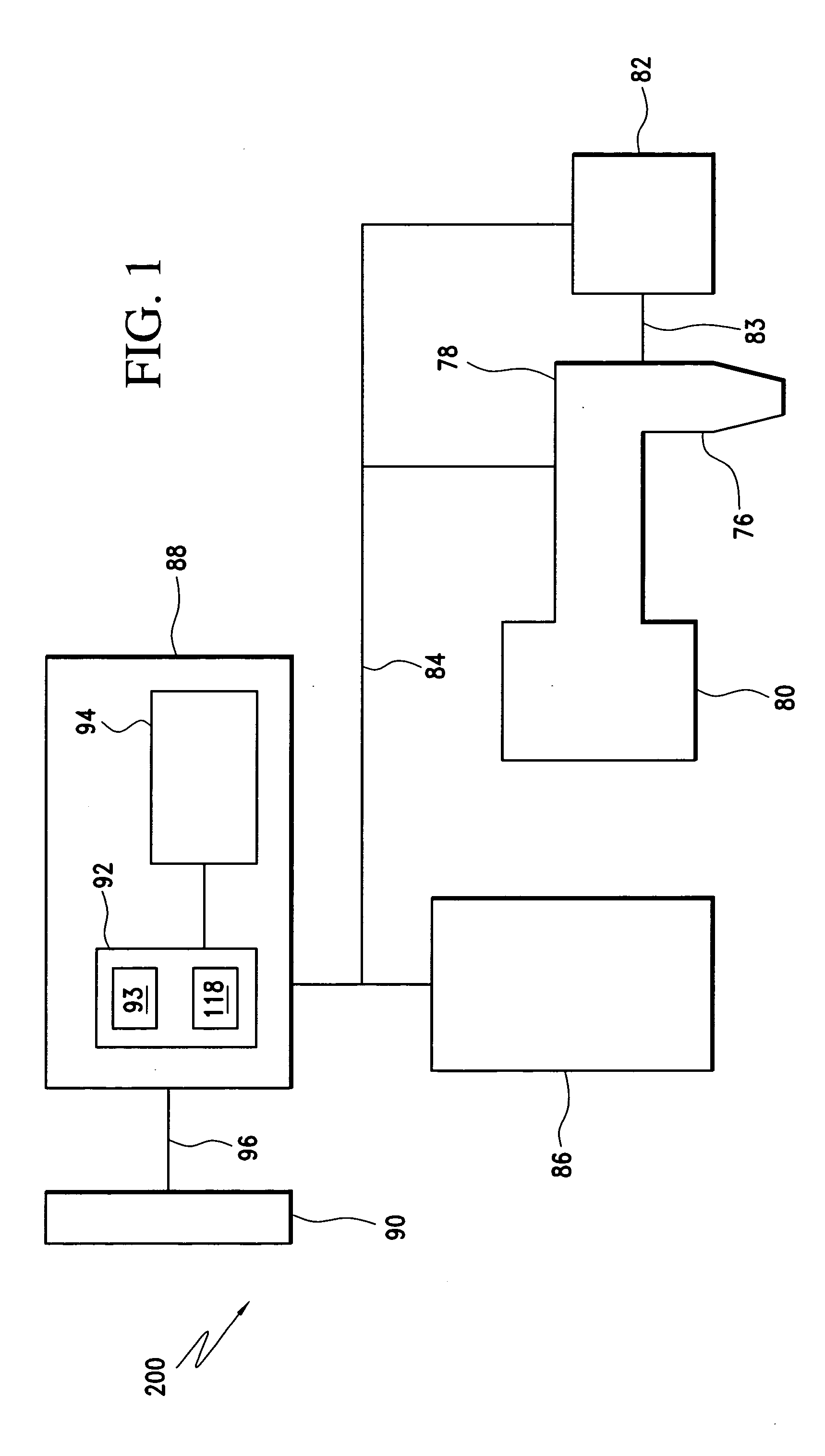

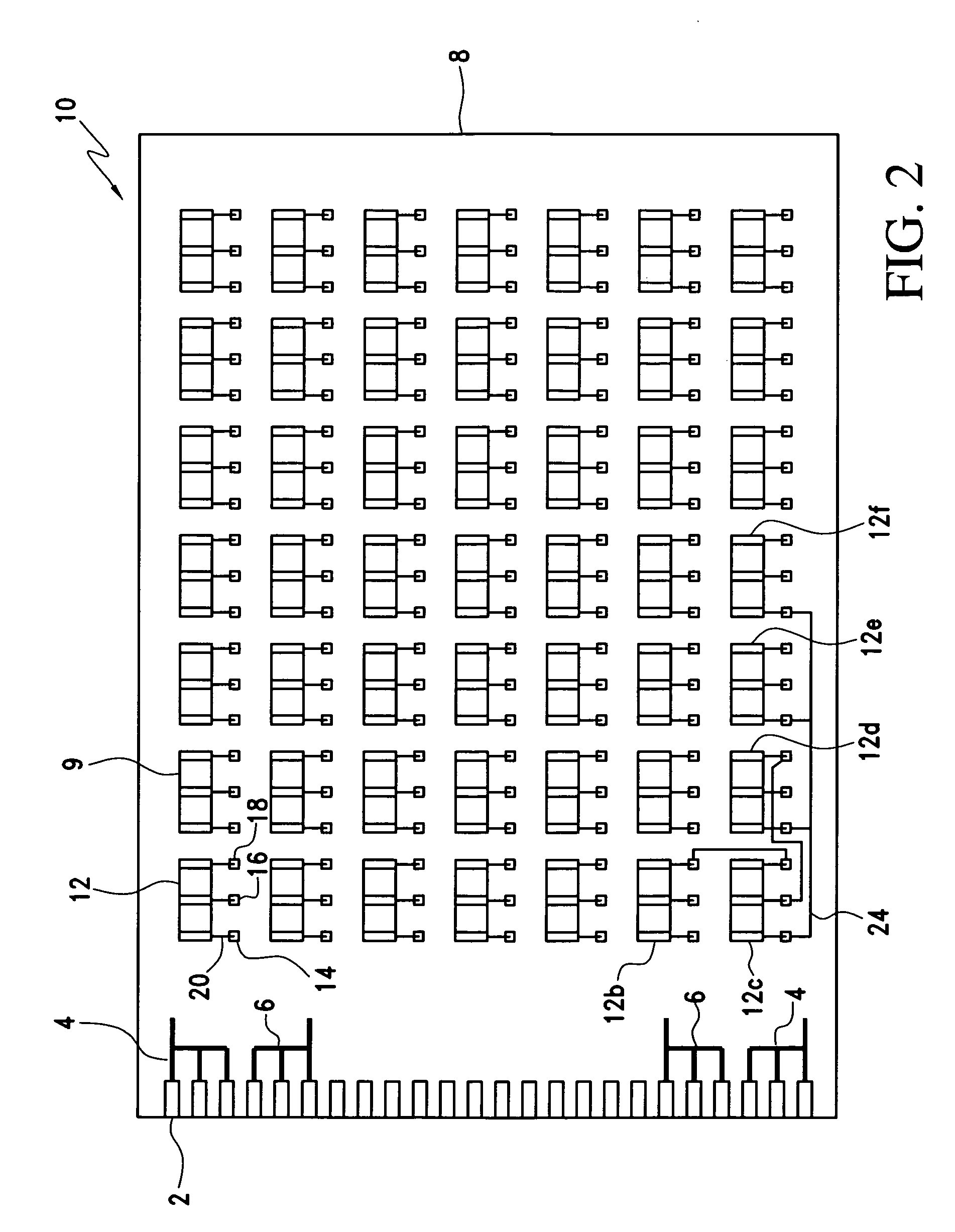

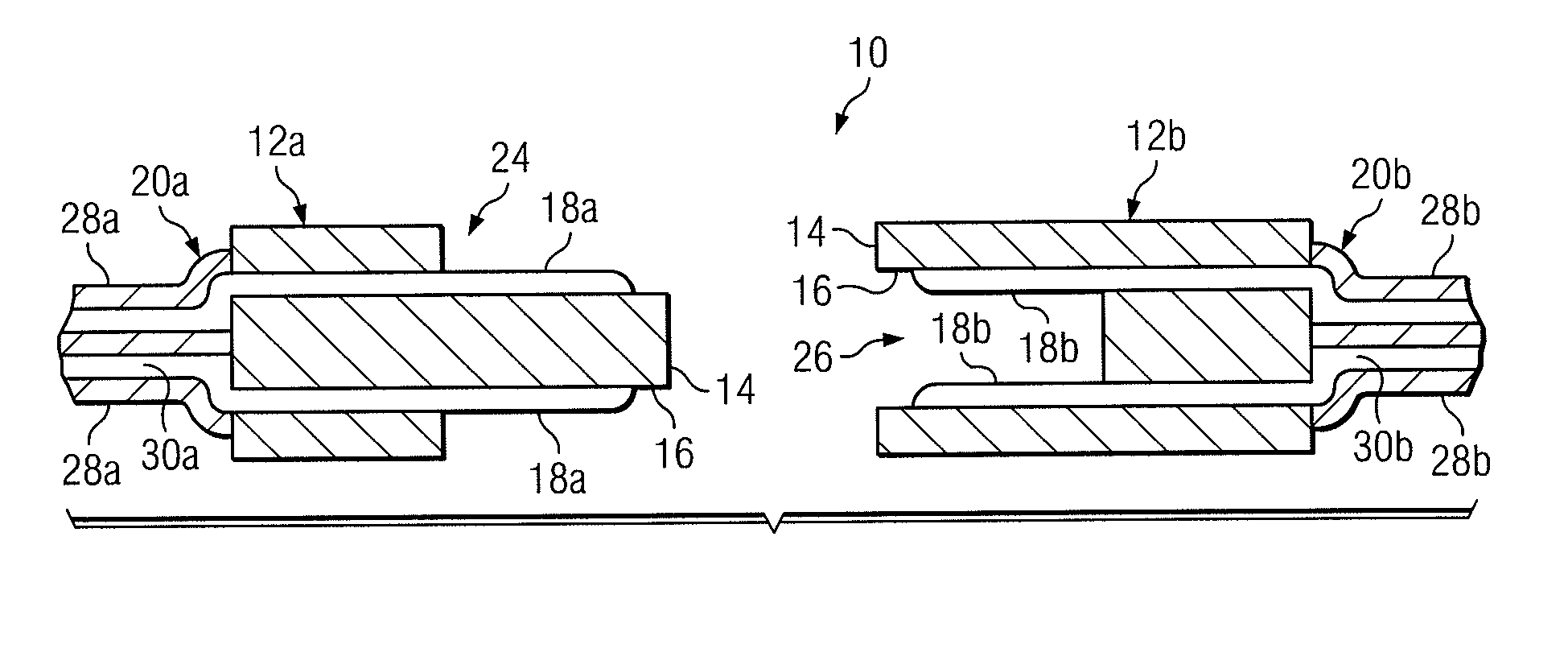

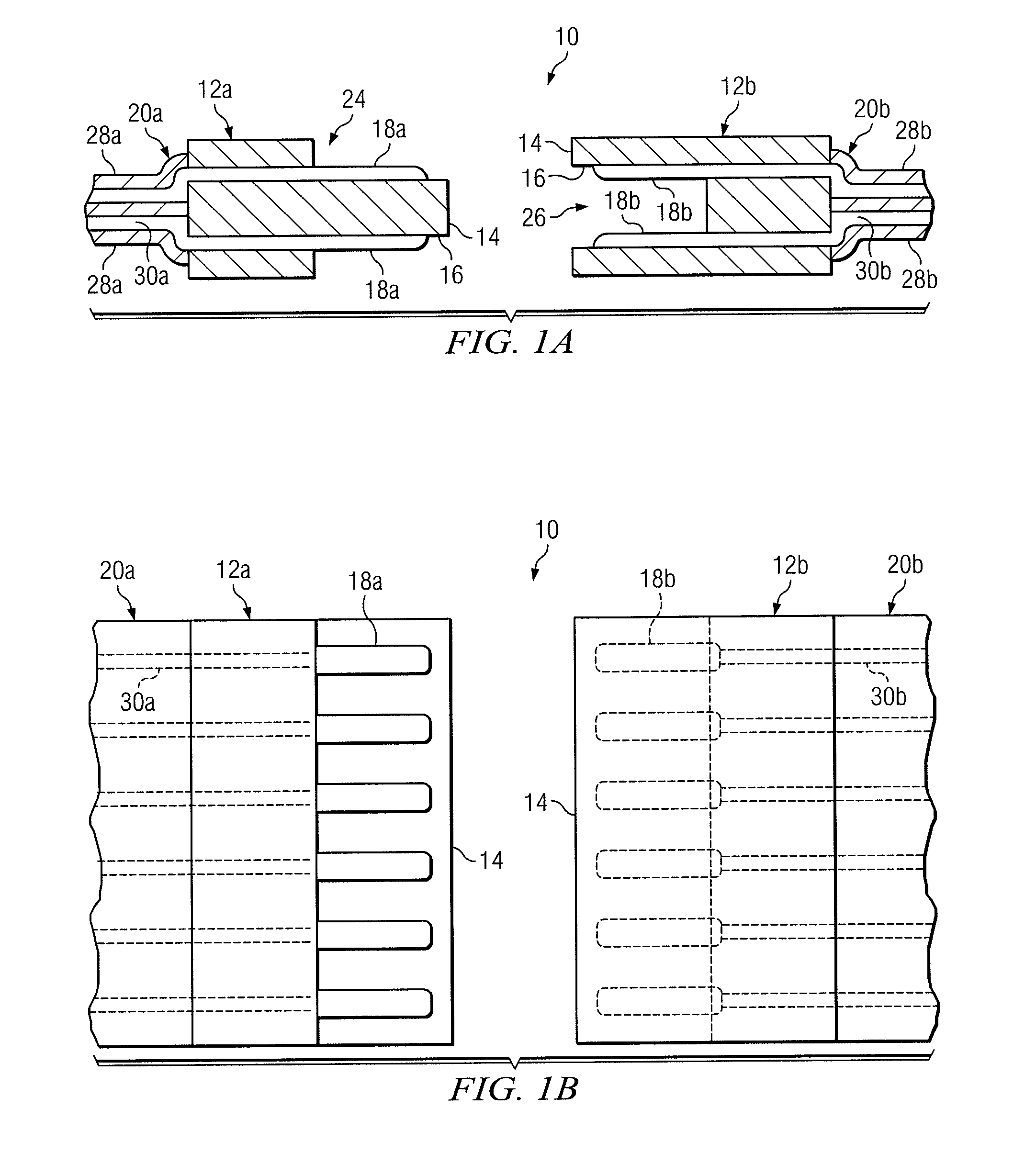

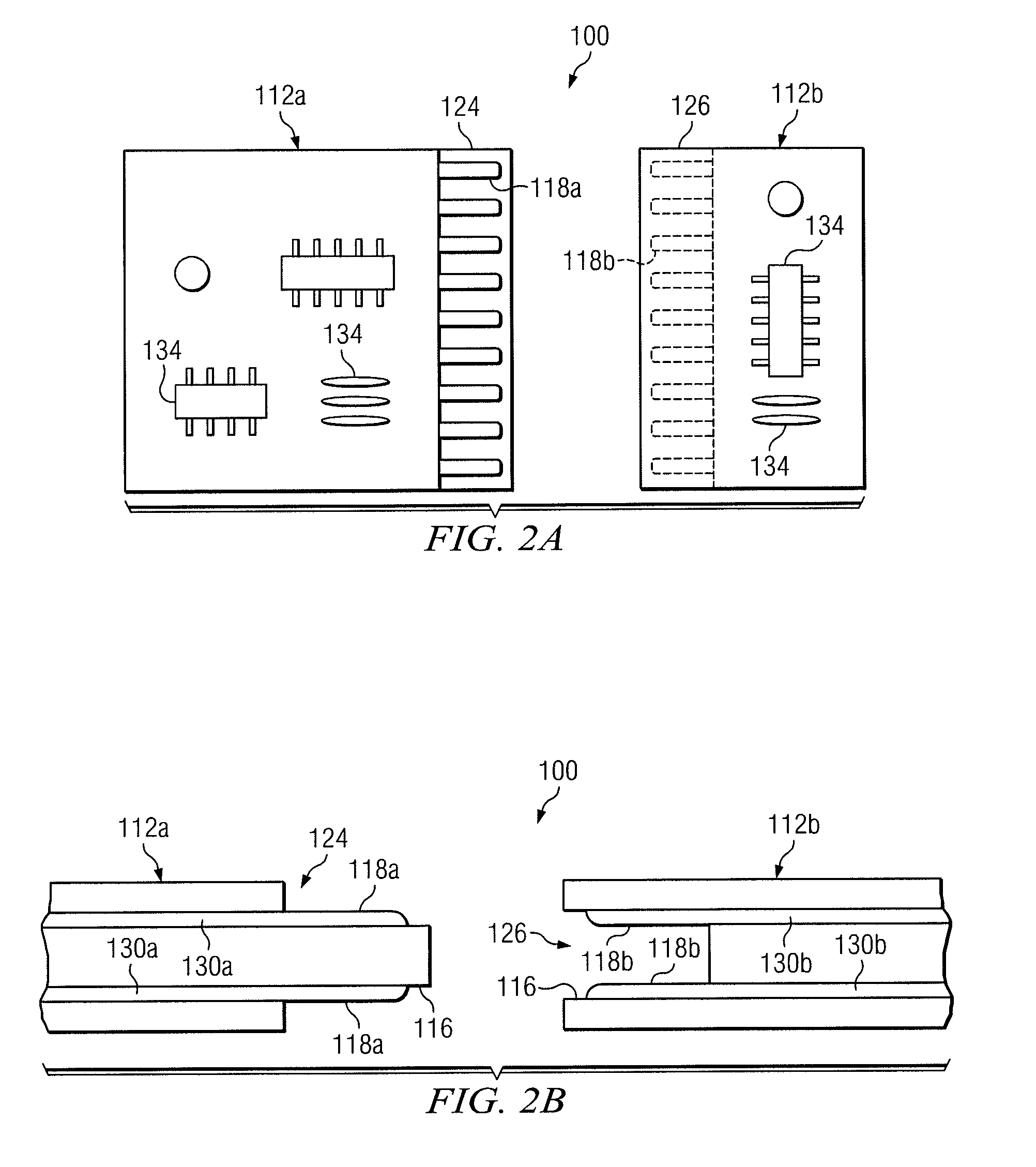

Electrical Interconnection System

InactiveUS20100134995A1Big sizeCumbersome workCoupling device detailsPrinted circuit aspectsElectrical and Electronics engineeringElectrical interconnect

According to one embodiment, an electrical interconnection system includes a pair of printed wiring boards formed of a printed wiring board material. Each printed wiring board has multiple surface pads formed on a surface of the printed wiring board adjacent its outer edge. The surface of each printed wiring board is operable to be placed adjacent to one another such that an electrical circuit coupled to one printed wiring board is electrically coupled to another electrical circuit of the other printed wiring board by contact of the surface pads of each printed wiring board with one another.

Owner:RAYTHEON CO

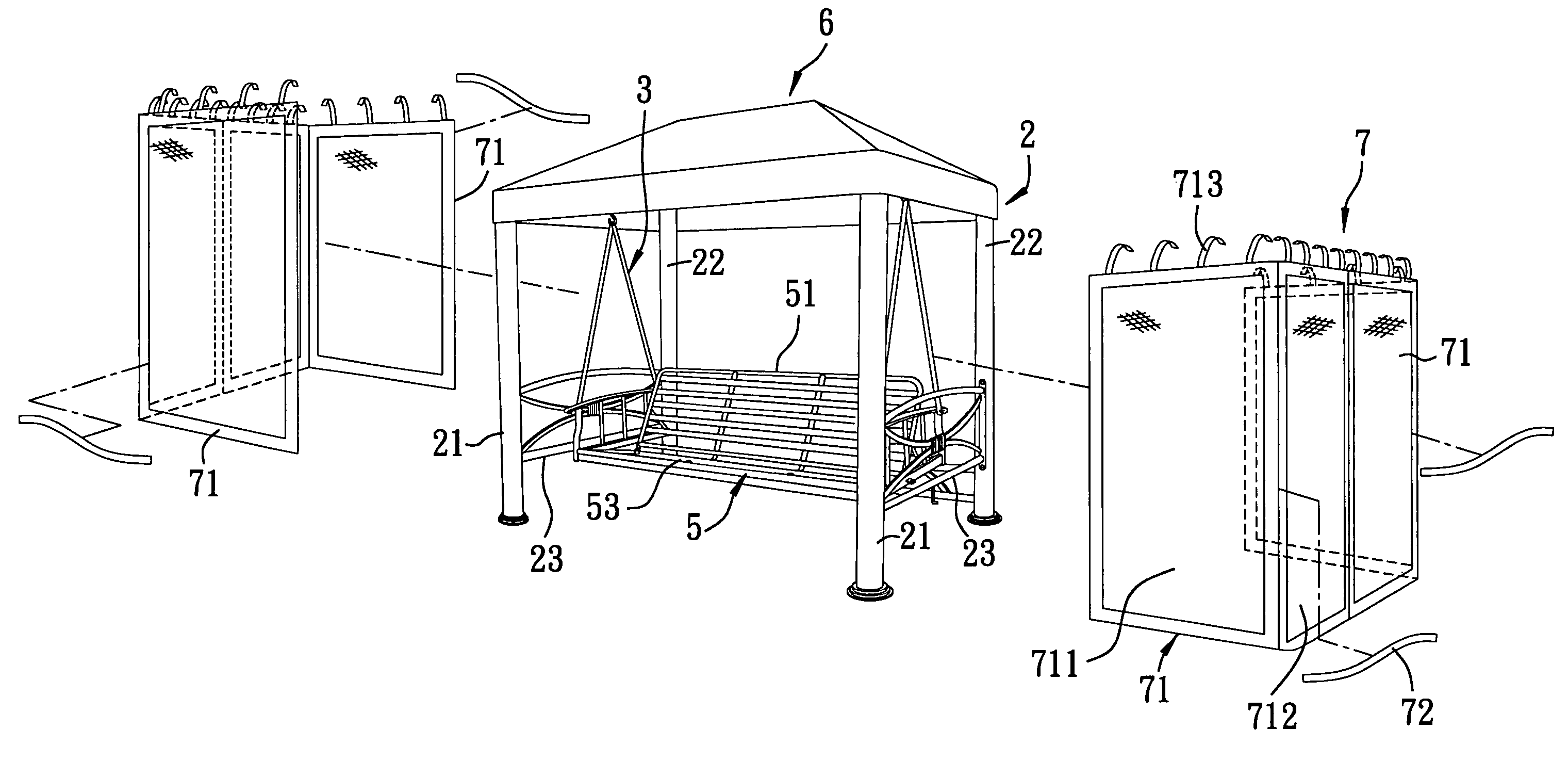

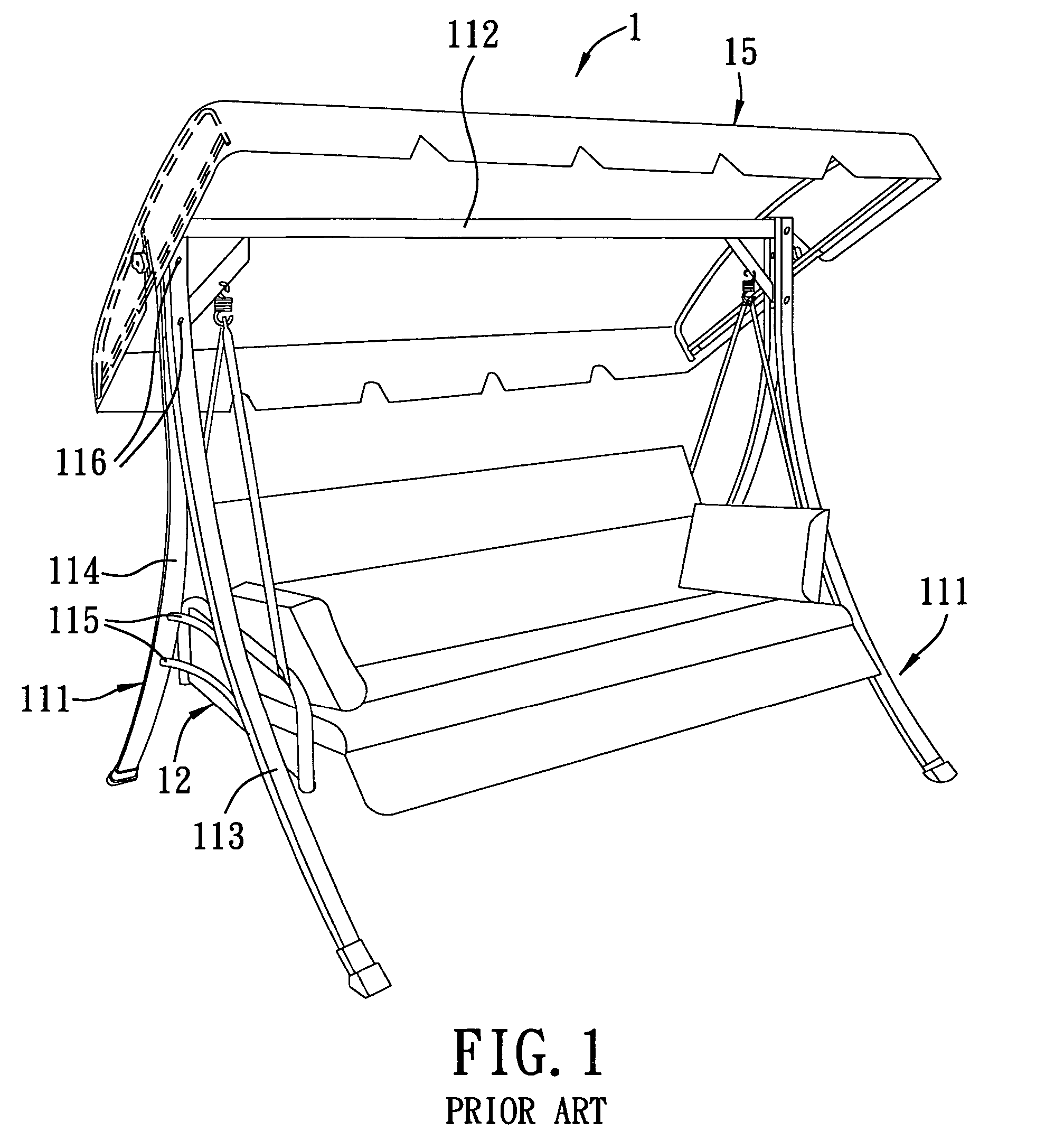

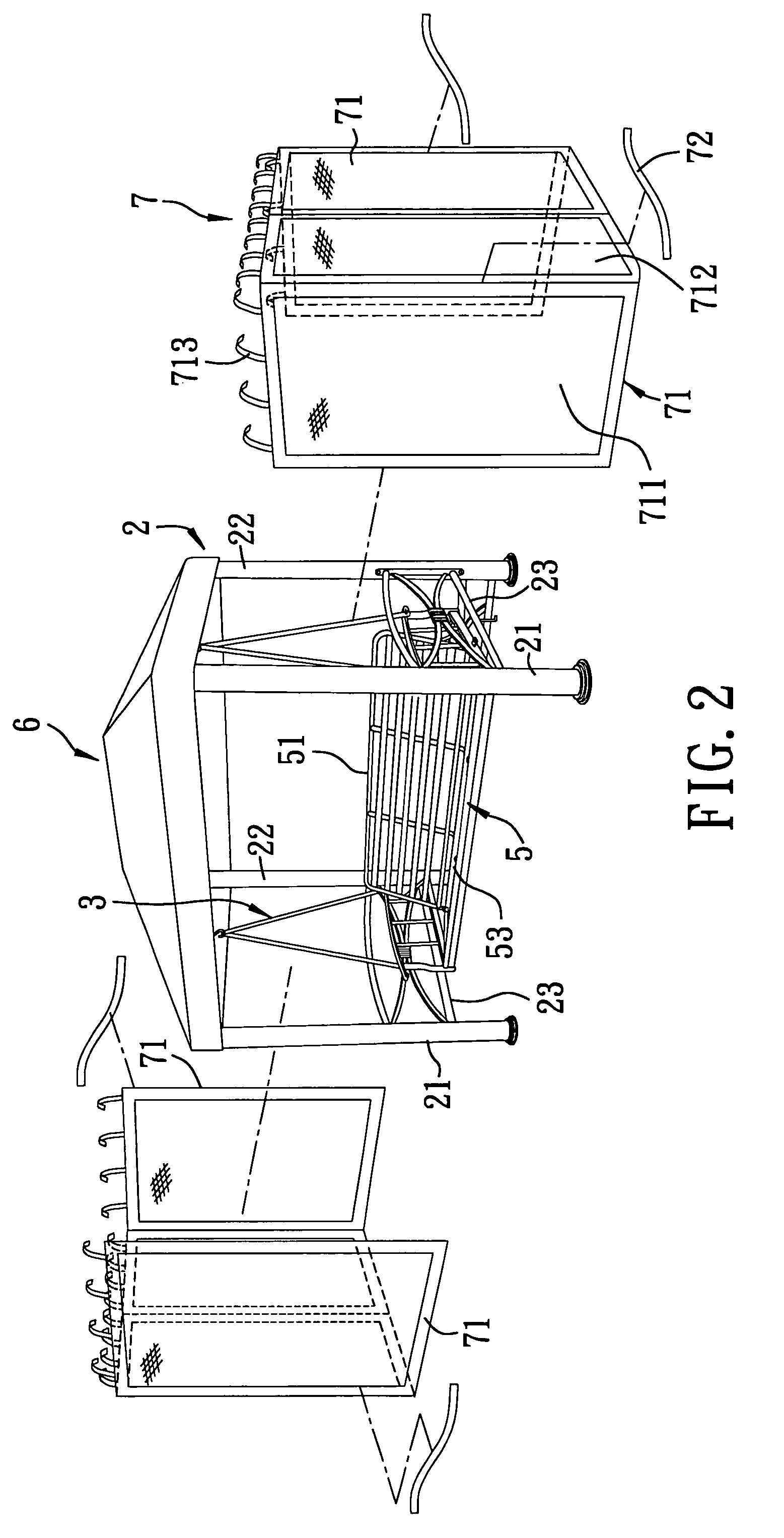

Swing assembly with drapes

A swing assembly includes a main support frame and a swing chair unit. The main support frame includes four spaced-apart upright posts, and a top frame connected to the upright posts. The swing chair unit includes a suspending frame hung movably on the top frame, and a seat frame held by the suspending frame. The swing assembly further includes a roof assembly mounted on the top frame, and a drape assembly hung on the top frame and extending downwardly along and between the upright posts.

Owner:SHIN YEH ENTERPRISE

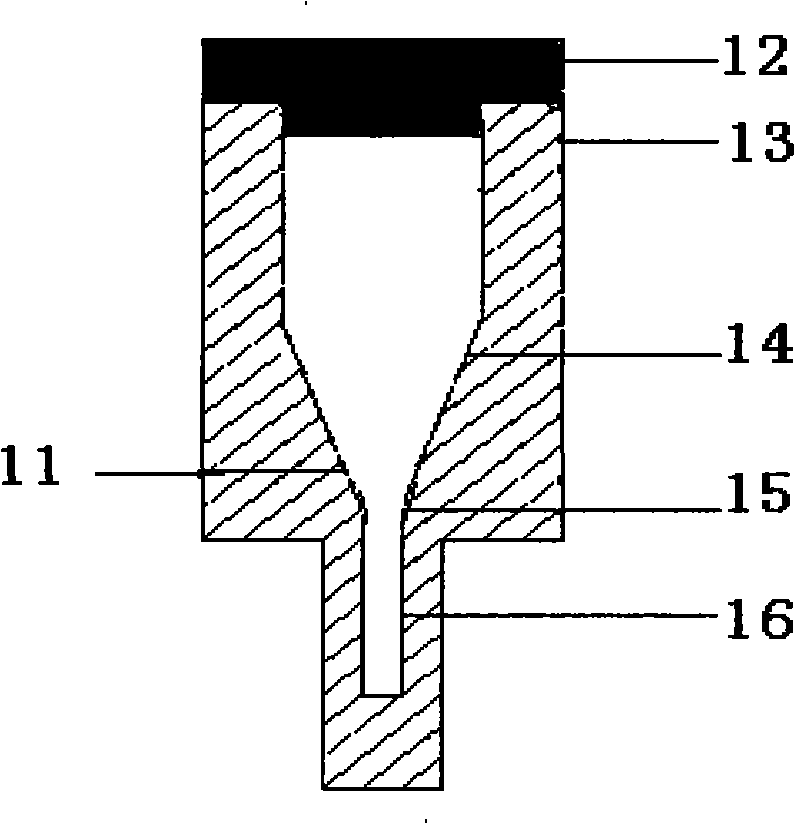

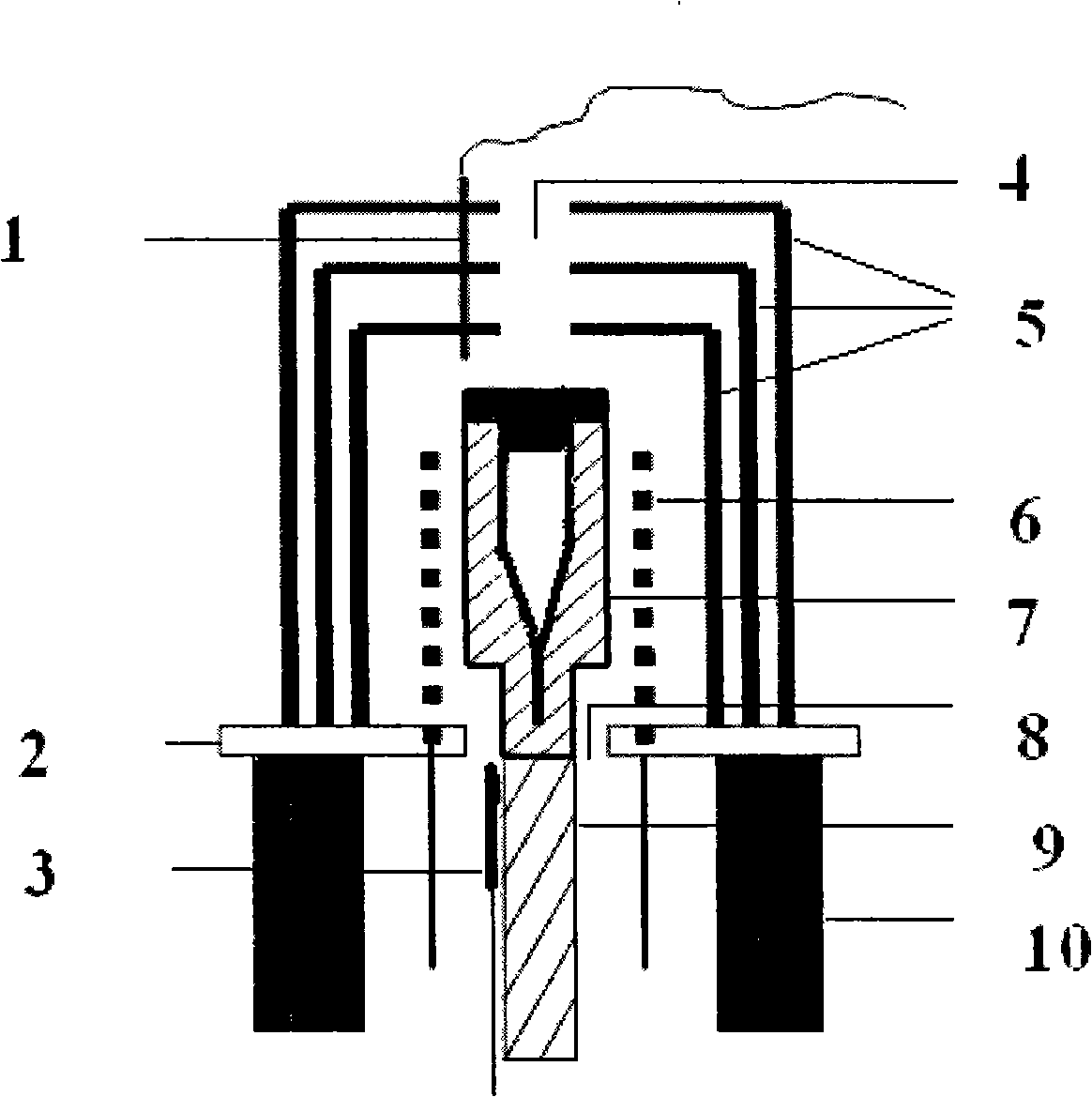

Improved temperature gradient method for BaY2F8 monocrystal growing and device therefor

InactiveCN101275272AGood crystal qualityBig sizePolycrystalline material growthFrom frozen solutionsChemistryAlumina ceramic

An improved temperature gradient method suitable for BaY2F8 monocrystal generation and a small cone angle pot used by the method and improvement of related monocrystal generation are provided. The small cone angle pot provided by the invention is made of highly pure graphite. A shoulder part in the middle of the pot is in conversed cone-shape. A vertex angle of the cone is 25 degrees to 35 degrees. The monocrystal generation device comprises a small cone angle said and other improved related devices. Other related devices are mainly improved in that a gap that is no less than 2cm is left between a top opening of the molybdenum layer heat preservation cylinder, an alumina ceramic plate and a molybdenum-made pot. The keys of the improved temperature gradient method that generates BaY2F8 monocrystal lie in that under axial temperature gradientno less than 6 deg C / mm, reducing temperature and generating the crystal at temperature reduction speed that enables the generation speed not higher than 1.8mm / h. The method of the invention is also suitable for generation of doped BaY2F8 of various types.

Owner:TIANJIN UNIV

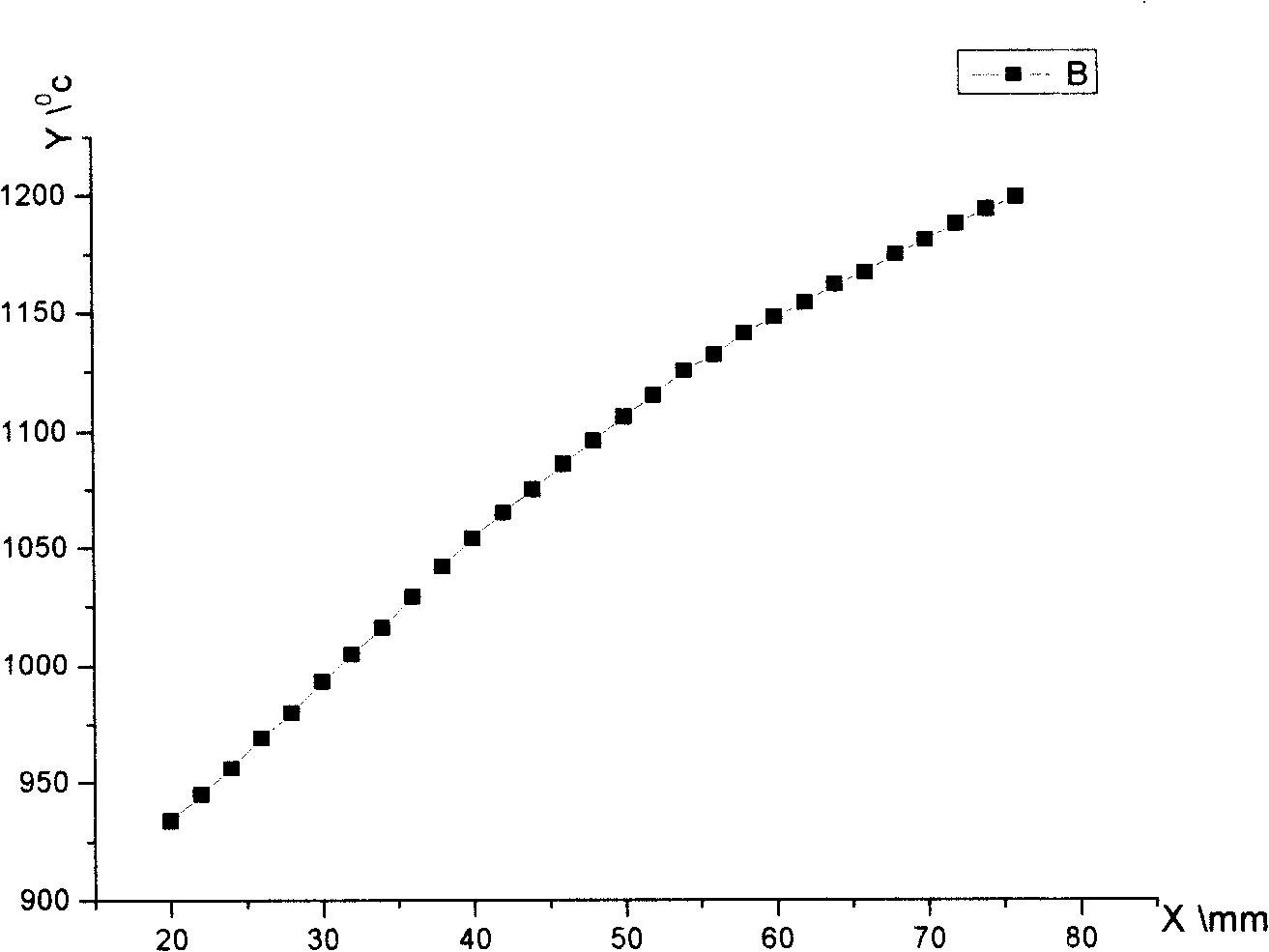

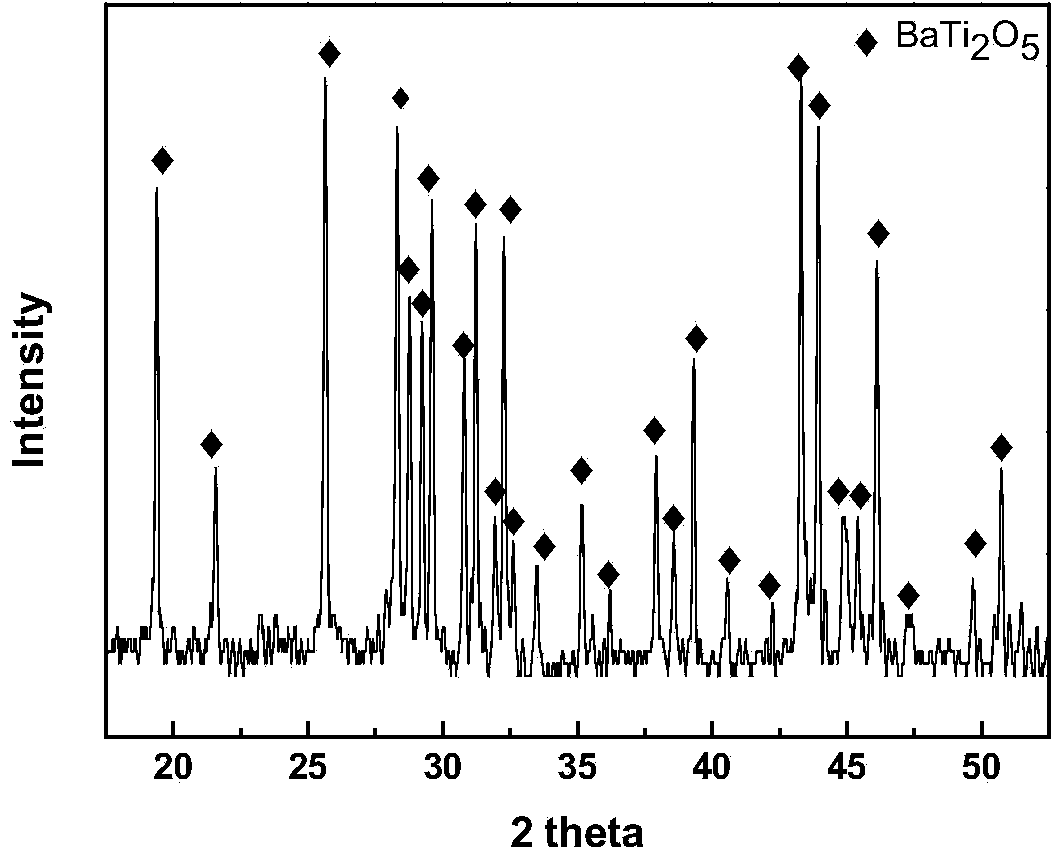

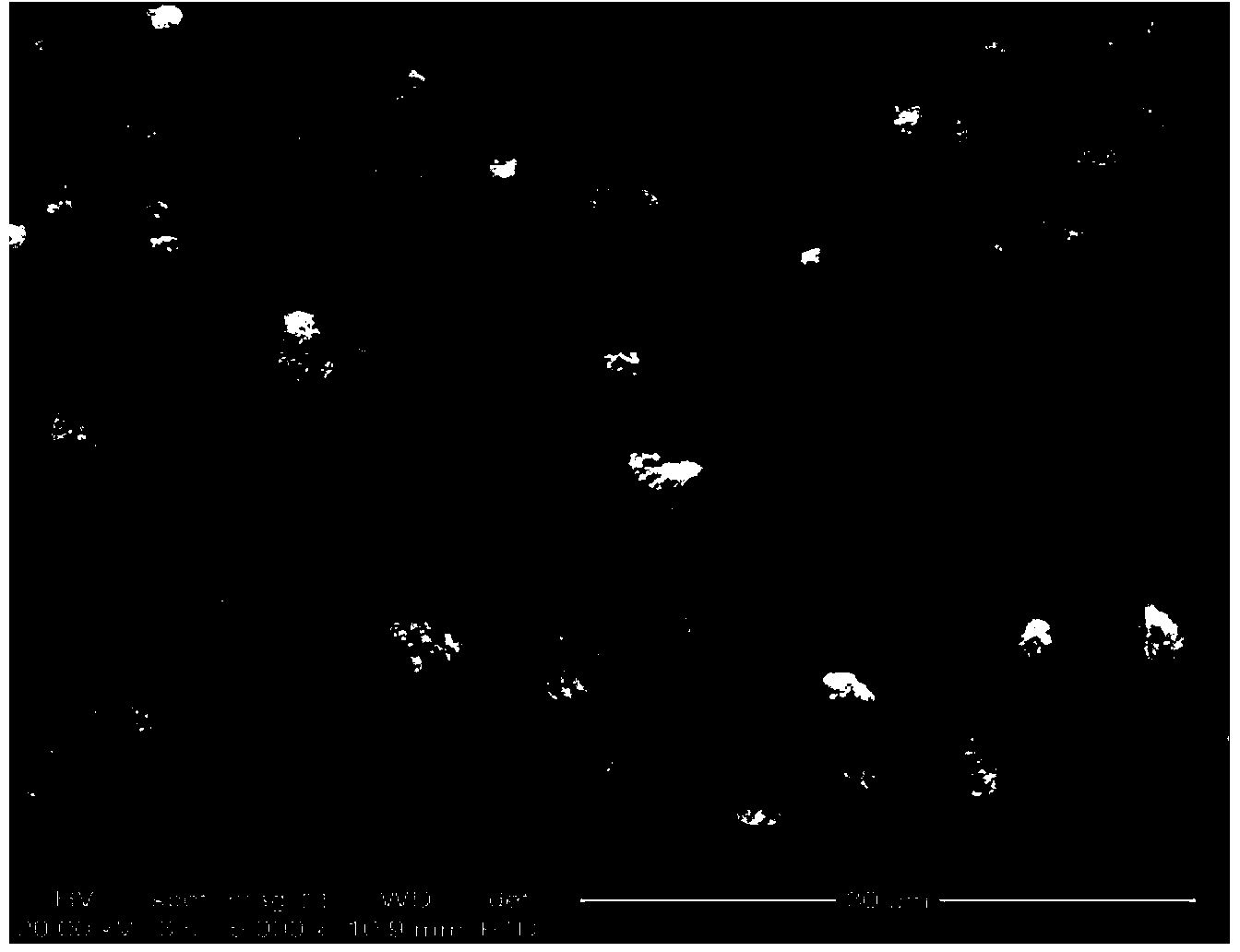

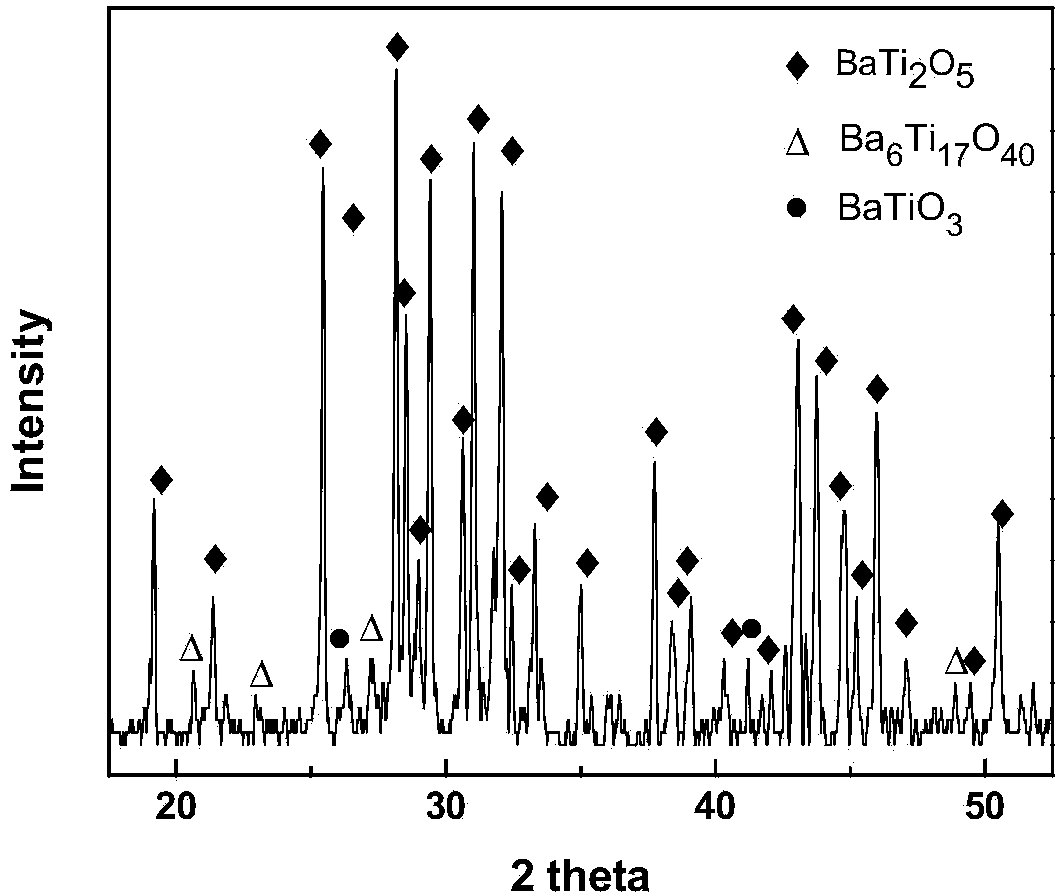

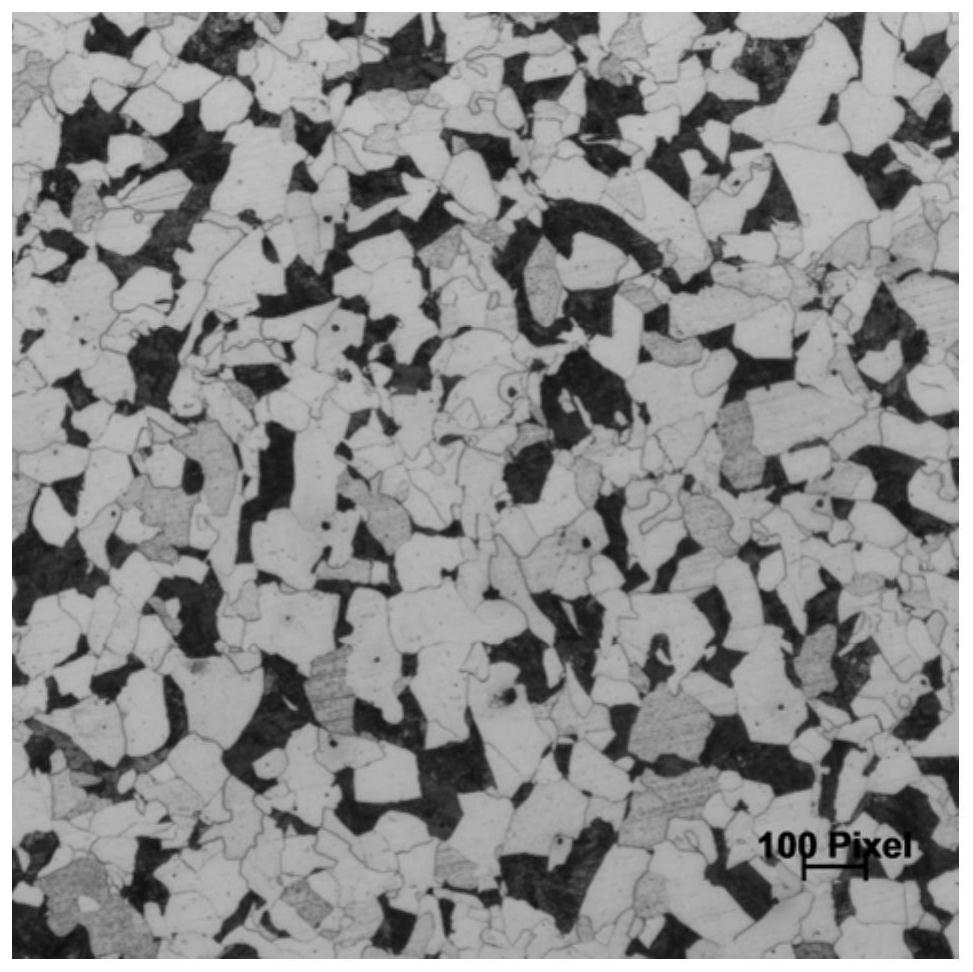

Preparation method for large-size dense barium titanate ceramic target material

The invention discloses a preparation method for a large-size dense barium titanate ceramic target material. The preparation method comprises the following steps: mixing and drying BaTiO3 powder and TiO2 powder in the molar ratio of 1:1, and tableting the dried mixture by using a tableting machine; placing tablets into electric arc melting equipment for melting to obtain a block; crushing the block to obtain barium titanate powder with the particle size of below 10 microns; placing the powder into a graphite mold and then moving the graphite mold into an FCT electric field activated sintering furnace, applying an axial pressure of 40 to 60 MPa, heating to 1,100 DEG C at the heating rate of 95 to 105 DEG C / min, heating to 1,150 DEG C at the heating rate of 8 to 12 DEG C / min, keeping the temperature for 20 to 30 minutes, cooling, depressurizing, cooling the graphite mold along with the furnace, and finally obtaining the barium titanate ceramic target material with the material phase of BaTi2O5 and the density of 90 to 95 percent. Compared with the conventional preparation method for the BaTi2O5 target material, the method provided by the invention has the advantages that the sintering time is short, the size is large and the density is high.

Owner:WUHAN UNIV OF TECH

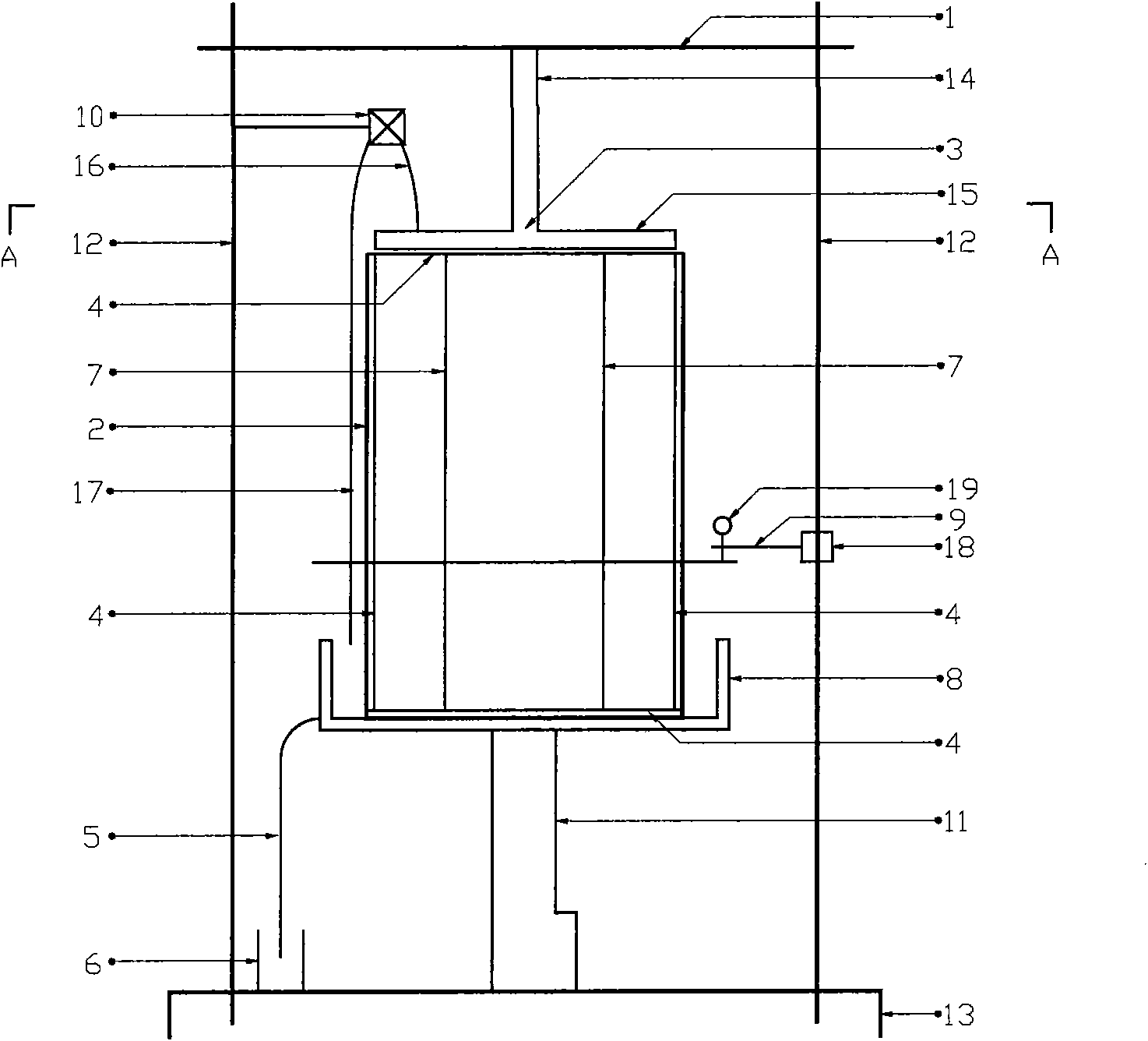

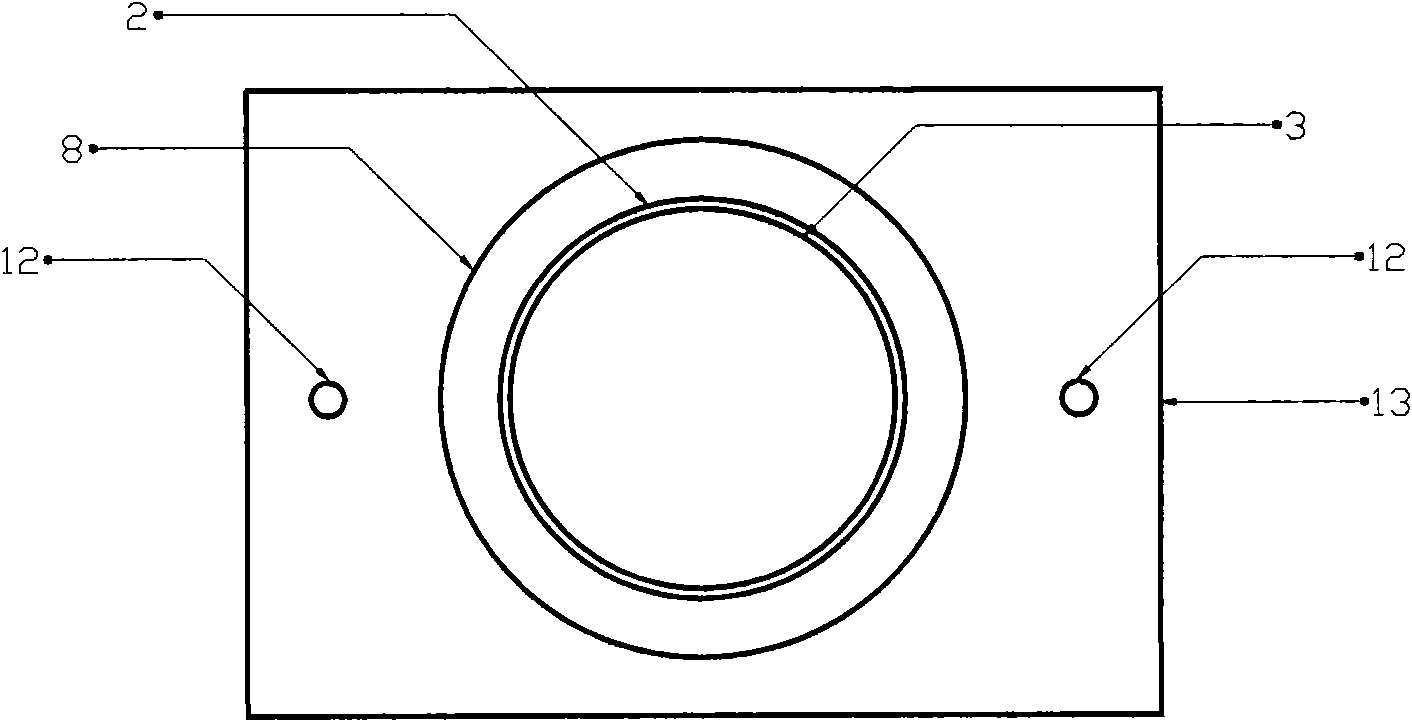

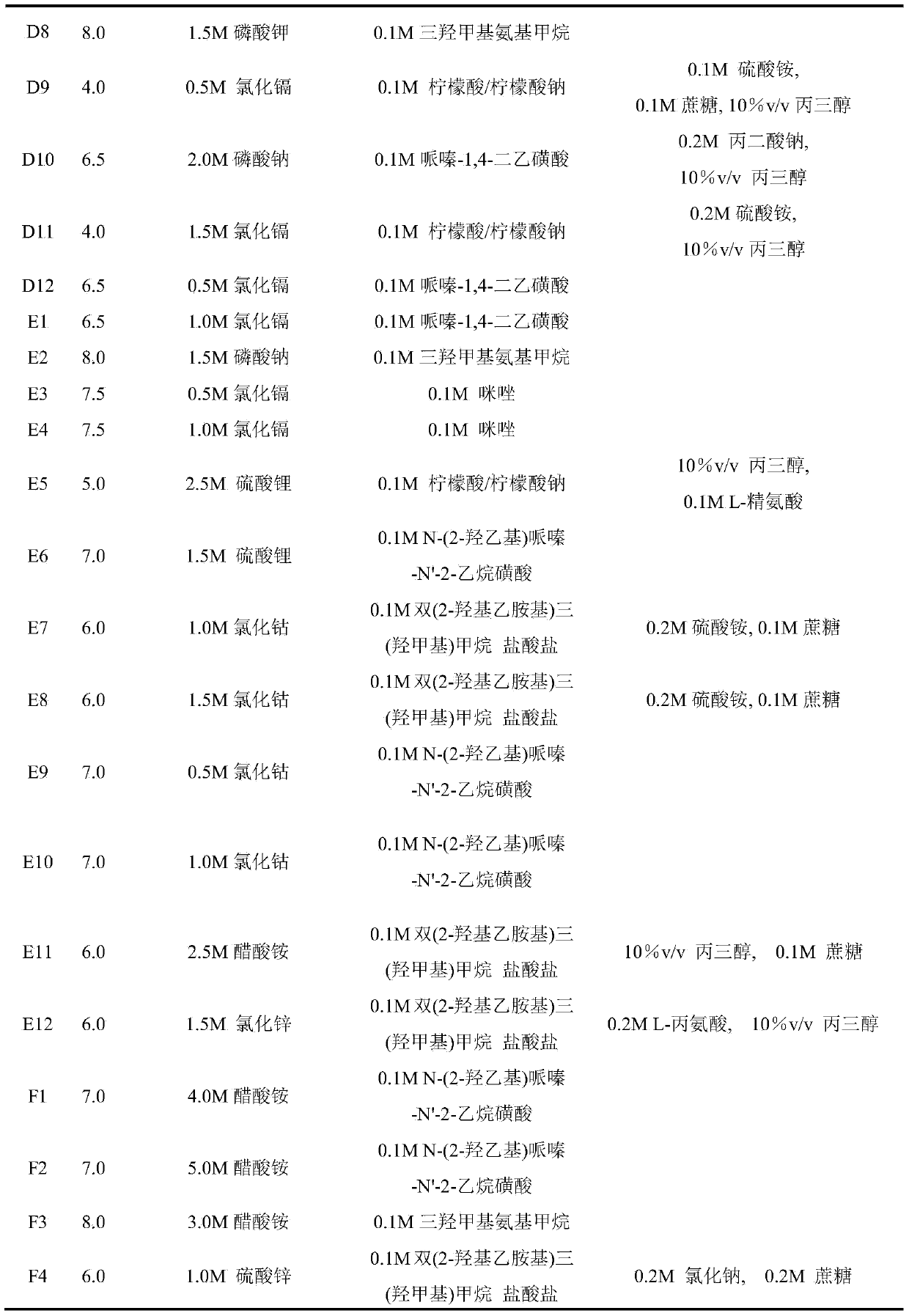

Anti-force type large-size sludge solidifying and compressing tester

InactiveCN101587048AMany drainage pathsBig sizeMaterial strength using tensile/compressive forcesGeotextilePiston

The invention relates to an anti-force type large-size sludge solidifying and compressing tester, belonging to the technical field of environmental geotechnical engineering and composed of a top plate, a compressing container, a pressure piston, a geotextile, a connecting pipe, a percolate collector, a plastic drain bar, a tray, a displacement meter, a peristaltic pump, a jack, an upright post and a pedestal. The pressure piston is disposed above the compressing container which is disposed above the tray and in which the geotextile is paved; the geotextile at the top is disposed below a compressing disk; the plastic drain bar is inserted into the compressing container; the side wall of the tray is provided with drain holes; the jack is disposed between the tray and the pedestal; the displacement meter is composed of a magnetic support and a test instrument; the peristaltic pump is arranged on the upright post; a drinking-water pipe is disposed above the compressing disk; a drain pipe is disposed above the tray; one end of the connecting pipe is connected with drain holes on the side wall of the tray, and the other end is connected with the percolate collector. The cross action tester for solidifying and compressing characteristics of large-size sludge has many drain routes and large size; parts of elements are done with preservative treatment; the invention solves problems of using existing instrument to test solidifying and compressing characteristics of sludge, and can reasonably evaluate solidifying and compressing characteristics of sludge.

Owner:TONGJI UNIV

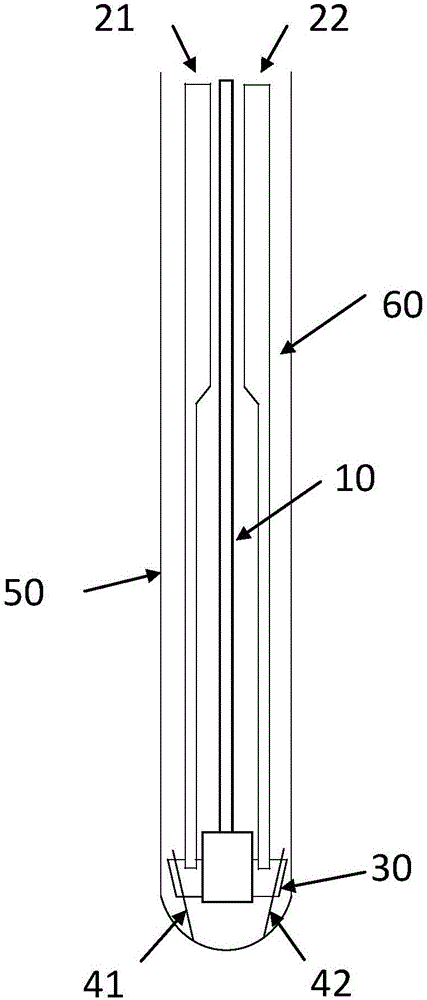

Photoacoustic probe and photoacoustic imaging system

ActiveCN106691390AGood imaging effectBig sizeUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringPhotoacoustic imaging in biomedicineOptical fiber cable

The invention discloses a photoacoustic probe. The photoacoustic probe comprises an ultrasonic probe; an optical fiber bundle comprising a first optical fiber bundle and a second optical fiber bundle, wherein two optical fiber bundles are respectively positioned at two relative outer sides of the ultrasonic probe; a reflecting device positioned at the extension line of the tail end of the first optical fiber bundle and the tail end of the second optical fiber bundle, wherein the reflecting device is slantwise installed, and the distance from one end of the central shaft of the reflecting device adjacent to the optical fiber bundle to the central shaft of the ultrasonic probe is greater than the distance from one end of the central shaft of the reflecting device away from the optical fiber bundle to the central shaft of the ultrasonic probe, the reflecting device is used for reflecting the laser emitted by the first optical fiber bundle and the second optical fiber bundle to a sample, and the reflecting device is used for enabling the overlapping area of the illuminated area on the sample surface by the laser emitted by the first optical fiber bundle and the second optical fiber bundle and the detection area of the ultrasonic probe to be greater than 30% of the detection area. The invention further discloses a photoacoustic imaging system. The photoacoustic probe has the advantage of better imaging effect.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

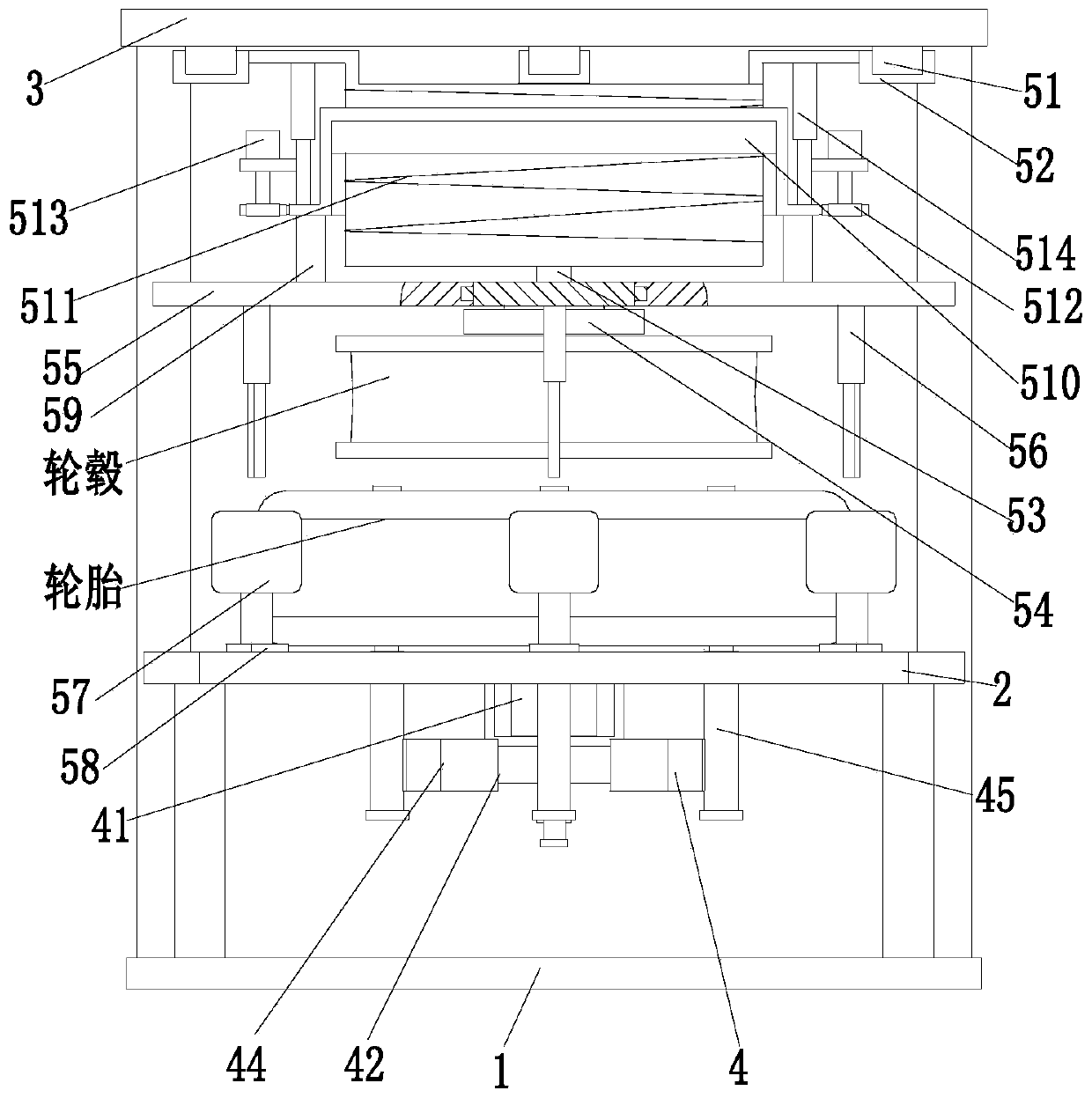

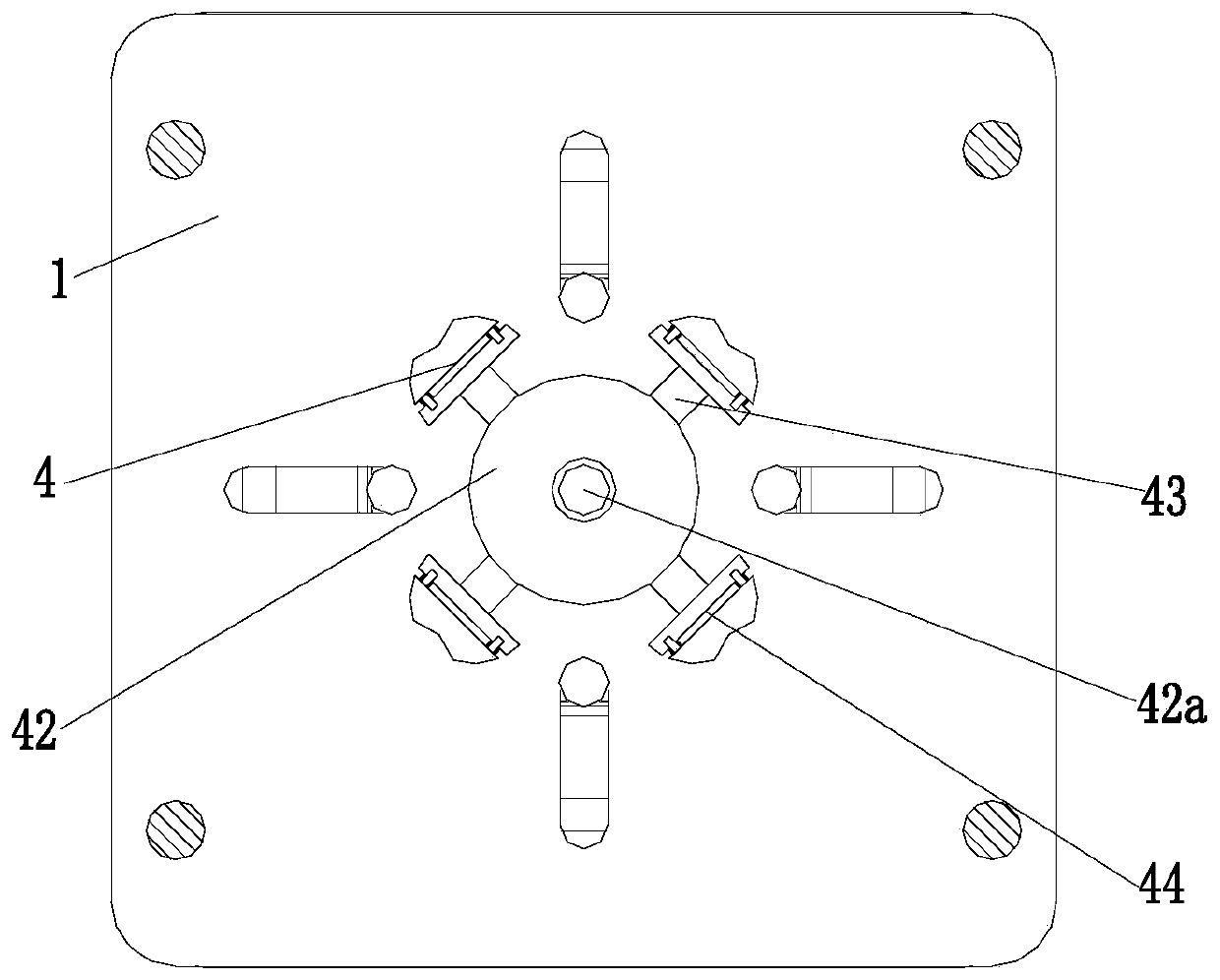

Automatic tire and hub assembling machine and assembling method

InactiveCN111361366AImprove assembly efficiencyBig sizeTyre repairingElectric machineryStructural engineering

The invention relates to an automatic tire and hub assembling machine and assembling method. The assembling machine comprises a bottom plate, a workbench, a mounting frame, an outer supporting mechanism and a pressing mechanism, the workbench is installed at the upper end of the bottom plate, the outer supporting mechanism is installed on the workbench, the pressing mechanism is arranged at the upper end of the outer supporting mechanism, the pressing mechanism is installed on the mounting frame, the mounting frame is installed on the bottom plate, moving grooves are evenly formed in the upperend of the workbench, and the outer supporting mechanism comprises a rotating motor, a rotating block, a connecting rod, an extrusion block and an outer supporting rod. The assembling method comprises the following steps: equipment adjusting, tire placing, hub grabbing, assembling and discharging. The outer supporting mechanism and the pressing mechanism are matched to complete assembly work of the tire and the hub, the outer supporting mechanism can support the tire outwards in the assembly process, then the difficulty that the pressing mechanism presses the hub into the tire is reduced, andthe tire and the hub can be assembled at a time, so the assembly efficiency is improved.

Owner:缪心怡

High-yield-strength 600MPa-level ultra-thick hot-rolled H-shaped steel and production method thereof

ActiveCN113234995ABig sizeIncreasing the thicknessMechanical properties of carbon nanotubesMaterials science

The invention discloses high-yield-strength 600MPa-level ultra-thick hot-rolled H-shaped steel and a production method thereof, and belongs to the technical field of production of rolled steel. The hot-rolled H-shaped steel disclosed by the invention comprises the following elements in percentage by mass: 0.14 percent to 0.18 percent of C, 0.35 percent to 0.55 percent of Si, 1.10 percent to 1.40 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.080 percent to 0.12 percent of V, 0.020 percent to 0.040 percent of Nb, less than or equal to 0.025 percent of N, and the balance of Fe and inevitable impurities. The production process of the ultra-thick hot-rolled H-shaped steel comprises a step of pre-treatment of molten iron, a step of converter smelting, a step of argon blowing and refining, a step of LF refining, a step of full-protection and casting of shaped blank, a step of heating of blanks, a step of rolling the blanks, and performing QST (Quantitative Sensory Testing) cooling after rolling. According to the method disclosed by the invention, through reasonable proportioning of the ingredients and rolling process, particularly distribution of controlled reduction quantity and controlled-temperature rolling, the hot-rolled H-shaped steel with excellent comprehensive mechanical performance, the thickness 70mm to 100mm of flanges, the yield strength being more than or equal to 600MPa, the tensile strength being more than or equal to 750MPa, the elongation rate being more than or equal to 15 percent, 0-DEG C longitudinal V-shaped impact power KV2 mean value being more than or equal to 60J and Z-directional performance being more than or equal to 20 percent for high-rise buildings can be obtained.

Owner:MAANSHAN IRON & STEEL CO LTD

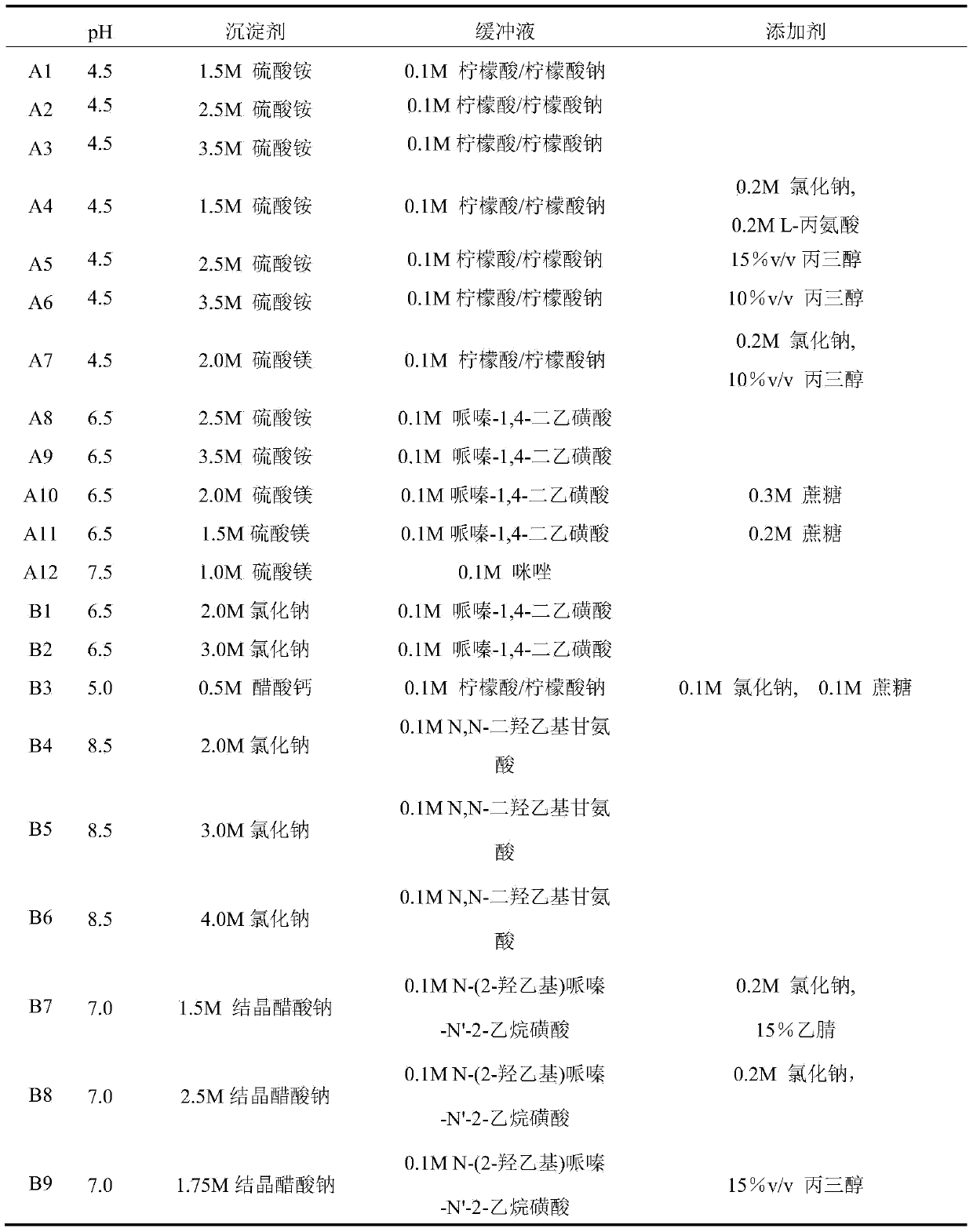

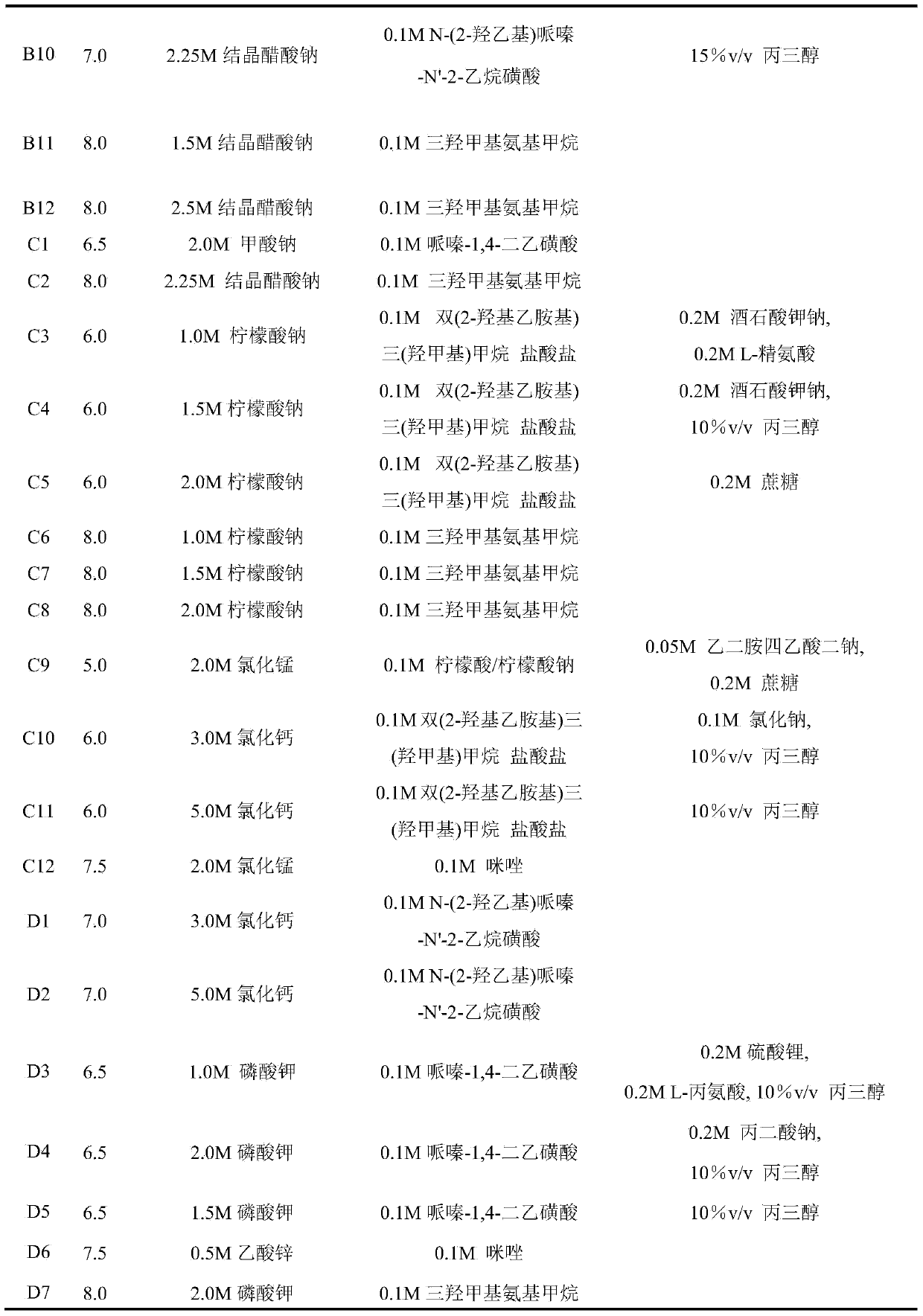

Kit for screening protein crystals by taking salt as precipitator

InactiveCN103436591ABig sizeGood lookingMicrobiological testing/measurementBiological testingProtein proteinProtein crystallization

The invention provides a kit for screening protein crystals by taking salt as a precipitator. The kit comprises a buffer solution, a precipitator and an additive, wherein the salt with relatively high crystallization efficiency is selected as the precipitator in the crystal kit; and meanwhile, a few of additive molecules are added to improve the solubility and stability of the protein, so as to obtain relatively high screening efficiency. By adopting the kit, the success rate of screening of protein crystallization conditions can be effectively improved.

Owner:ZHONGSHAN HYGENE BIOPHARM

Grinding machine with spraying function

InactiveCN106965079ABig sizeImprove processing efficiencyGrinding machine componentsSpraying apparatusDrive motorCost savings

The invention discloses a grinding machine with spraying function, which comprises a grinding machine body, a grinding machine control center, a grinding machine base and a grinding machine top cover. There is a fixed block, a baking pan is arranged under the fixed block, a supporting column is arranged under the baking tray, a hydraulic cylinder is arranged in the base of the grinder, the hydraulic cylinder is connected with the supporting column, and a connecting rod is arranged under the top cover of the grinding machine , a rotating disk is arranged below the connecting rod, a grinding head and a nozzle are arranged on the rotating disk, a drive motor is arranged above the top cover of the grinder, a liquid storage tank is arranged on the grinder body, and a compressed gas interface is arranged on the liquid storage tank. The invention provides a grinding machine with a spraying function, which realizes the spraying function, improves the processing efficiency of products, and saves costs.

Owner:CHANGSHU SHUANGYUE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com