Preparation and stripping methods of mesoporous cobaltosic oxide nanosheet

A nano and mesoporous technology of cobalt tetroxide, applied in the directions of cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of less active sites, increase the interlayer spacing, agglomeration, etc., and achieve large lamellar structure and interlayer spacing. Enlarged, homogeneous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparation of layered precursor

[0029] Prepare 70mL cobalt ion concentration of 0.1mol / L cobalt nitrate hexahydrate, triton mixed solution, its molar ratio is 2:1, after stirring evenly, add urea again, make its molar ratio with cobalt nitrate hexahydrate be 2 : 1, then continue to stir; transfer the resulting mixed solution into a 100mL polytetrafluoroethylene liner, put the liner in a reactor, and place it in a 120°C oven for constant temperature reaction for 24h. After the reaction, cool, centrifuge, wash, and dry , after drying completely, the pink layered precursor nanosheets were obtained.

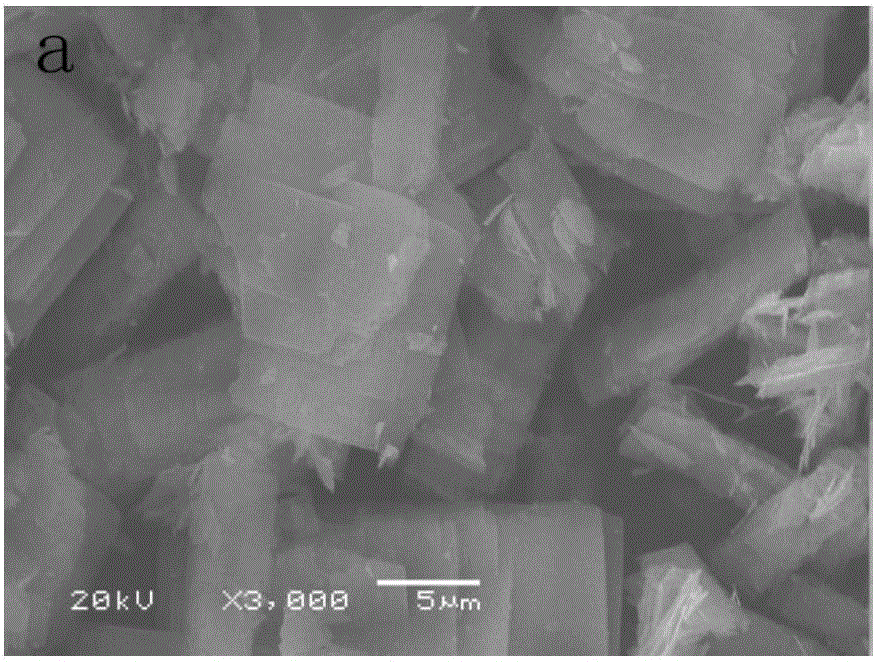

[0030] 2) Preparation of Mesoporous Layered Cobalt Tetroxide Nanosheets

[0031] Put the layered precursor obtained in step 1) into a crucible, put it into a muffle furnace, burn it at 300° C. for 3 hours, and cool it to room temperature to obtain mesoporous black cobalt tetraoxide nanosheets.

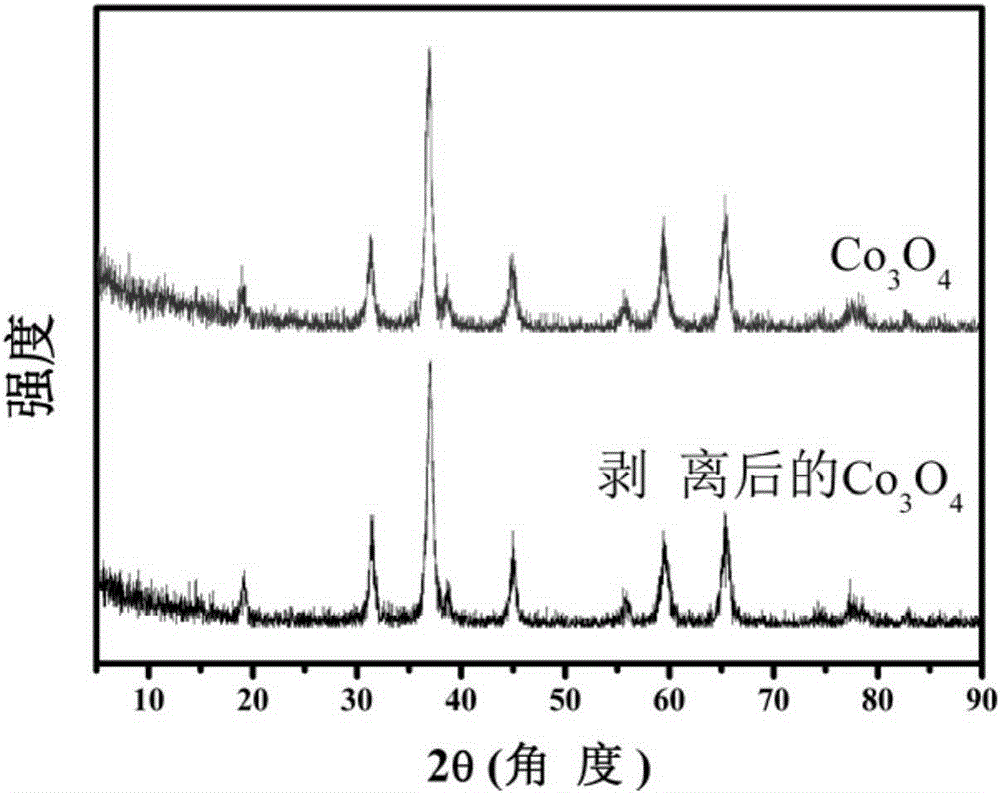

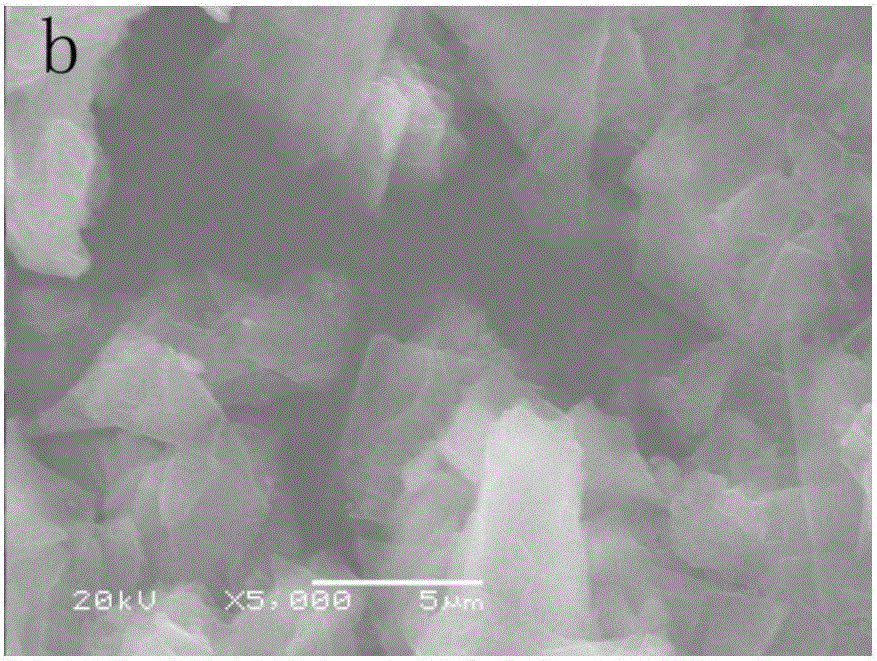

[0032] 3) Exfoliation of Mesoporous Co3O3 Nanosheets

[0033] The layered...

Embodiment 2

[0035] 1) Preparation of layered precursor

[0036] Prepare 70mL cobalt ion concentration of 0.2mol / L cobalt nitrate hexahydrate, triton mixed solution, its molar ratio is 2:1; after stirring evenly, add urea again, make it and cobalt nitrate hexahydrate molar ratio be 2 : 1, then continue to stir; The resulting mixed solution is transferred to a 100mL polytetrafluoroethylene liner, the liner is placed in a reaction kettle, and placed in a 120°C oven for constant temperature reaction for 24h. After the reaction is over, it is cooled, centrifuged, washed, After drying, after the drying is complete, a pink layered precursor nanosheet is obtained.

[0037] 2) Preparation of Mesoporous Layered Cobalt Tetroxide Nanosheets

[0038] Put the layered precursor obtained in step 1) into a crucible, put it into a muffle furnace, burn it at 300° C. for 3 hours, and cool it to room temperature to obtain mesoporous black cobalt tetraoxide nanosheets.

[0039] 3) Exfoliation of Mesoporous C...

Embodiment 3

[0042] 1) Preparation of layered precursor

[0043] Prepare 70mL cobalt ion concentration of 0.1mol / L cobalt nitrate hexahydrate, triton mixed solution, its molar ratio is 2:1; after stirring evenly, add urea again, make it and cobalt nitrate hexahydrate molar ratio be 2 : 1, then continue to stir; The resulting mixed solution is transferred to a 100mL polytetrafluoroethylene liner, the liner is placed in a reaction kettle, and placed in a 120°C oven for constant temperature reaction for 24h. After the reaction is over, it is cooled, centrifuged, washed, After drying, after the drying is complete, a pink layered precursor nanosheet is obtained.

[0044] 2) Preparation of Mesoporous Layered Cobalt Tetroxide Nanosheets

[0045] Put the layered precursor obtained in step 1) into a crucible, put it into a muffle furnace, burn it at 300° C. for 3 hours, and cool it to room temperature to obtain mesoporous black cobalt tetraoxide nanosheets.

[0046] 3) Exfoliation of Mesoporous C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com