High-yield-strength 600MPa-level ultra-thick hot-rolled H-shaped steel and production method thereof

A yield strength and production method technology, applied in the field of steel rolling production, can solve the problems of difficult performance stability control, thick hot-rolled H-shaped steel, and difficulty in obtaining flange thickness, etc., and achieve excellent economic benefits, excellent Z-direction performance, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

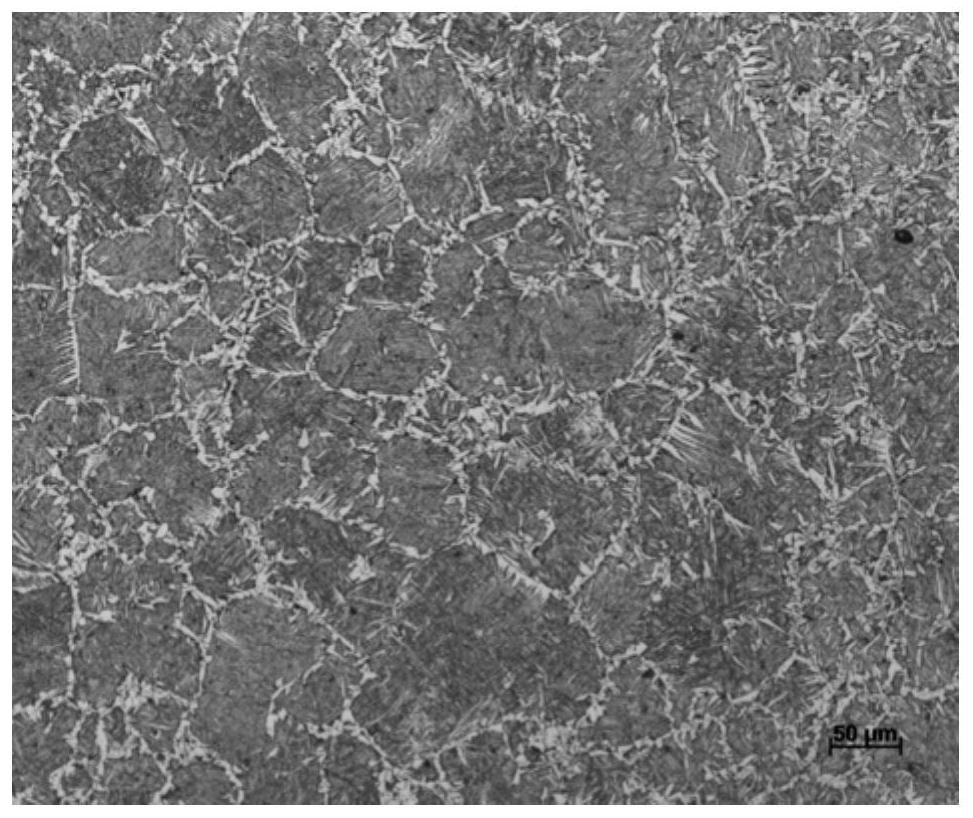

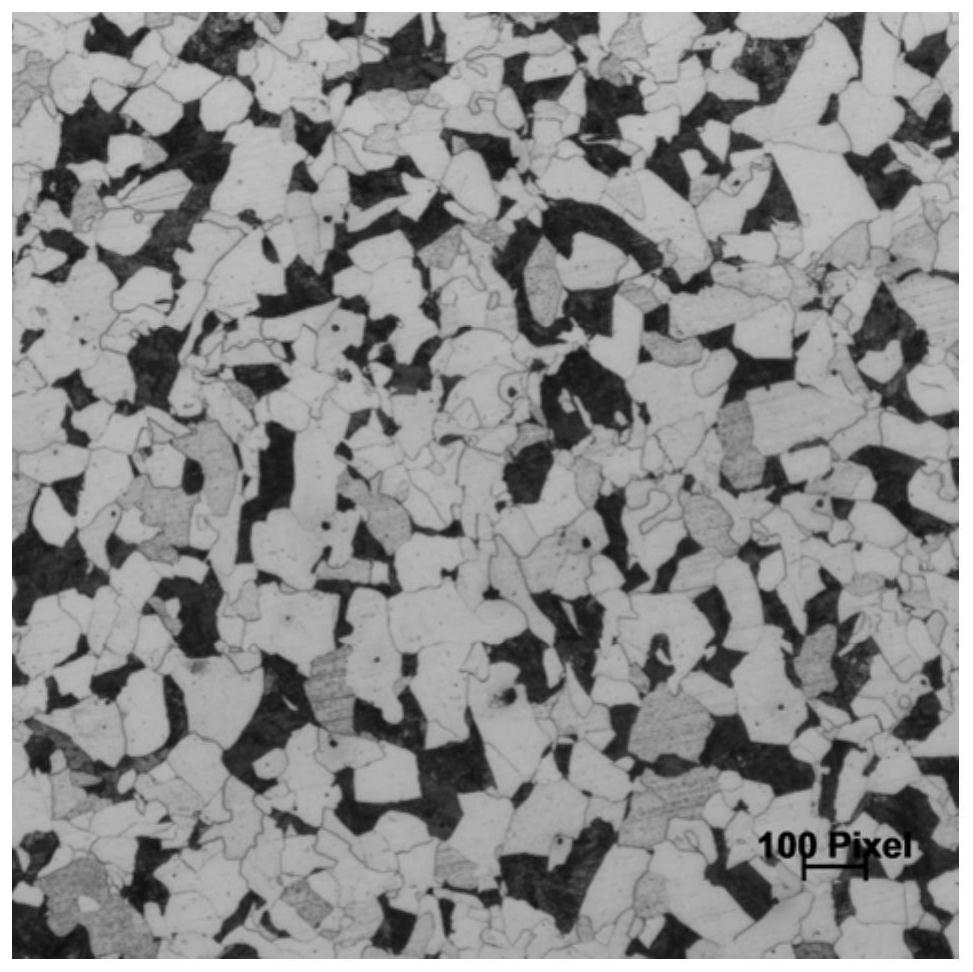

Image

Examples

Embodiment 1

[0053] An ultra-thick hot-rolled H-shaped steel with a yield strength of 600 MPa in this embodiment has the following weight percentage ranges of components: C: 0.6%, Si: 0.42%, Mn: 1.30%, P: 0.016%, S: 0.012% , V: 0.083%, Nb: 0.031%, N: 0.017%, and the rest are Fe and unavoidable impurities. The addition of vanadium elements is made of 60% V-N and 40% V-Fe alloy.

[0054] Its processing step adopts the technical process of the present invention, wherein, the main steps and process parameters of controlling H-beam rolling are as follows:

[0055] Step 1: Heating the billet; heating to 1232°C in a heating furnace, and holding time for 167 minutes.

[0056]Step 2: Control the start rolling temperature at 1164°C in the rough rolling stage, and control the finish rolling temperature at 1006°C. Specifically, in the temperature range of 1100-1150°C, the pass reduction rate is controlled at 17%; in the temperature range of 1050-1100°C , the pass reduction rate is controlled at 24%; ...

Embodiment 2

[0061] An ultra-thick hot-rolled H-shaped steel with a yield strength of 600 MPa in this embodiment has the following weight percentage ranges of components: C: 0.17%, Si: 0.45%, Mn: 1.32%, P: ≤0.020%, S: 0.018 %, V: 0.092%, Nb: 0.024%, N: 0.020%, and the rest are Fe and unavoidable impurities. The addition of vanadium elements is made of 60% V-N and 40% V-Fe alloys.

[0062] Its processing step adopts the technical process of the present invention, wherein, the main steps and process parameters of controlling H-beam rolling are as follows:

[0063] Step 1: Heating the billet; heating to 1228°C in a heating furnace, and holding time for 175 minutes.

[0064] Step 2: Control the start rolling temperature at 1158°C in the rough rolling stage, and control the finish rolling temperature at 1008°C. Specifically, in the temperature range of 1100-1150°C, the pass reduction rate is controlled at 17%; in the temperature range of 1050-1100°C , the pass reduction rate is controlled at 2...

Embodiment 3

[0069] An ultra-thick hot-rolled H-shaped steel with a yield strength of 600 MPa in this embodiment has the following weight percentage ranges of components: C: 0.16%, Si: 0.45%, Mn: 1.27%, P: 0.017%, S: 0.009% , V: 0.090%, Nb: 0.027%, N: 0.015%, and the rest is Fe and unavoidable impurities. The addition of vanadium element adopts 60% V-N and 40% V-Fe alloy.

[0070] Its processing step adopts the technical process of the present invention, wherein, the main steps and process parameters of controlling H-beam rolling are as follows:

[0071] Step 1: Heating the billet; heating to 1241°C in a heating furnace, and holding time for 158 minutes.

[0072] Step 2: Control the start rolling temperature at 1171°C in the rough rolling stage, and control the finish rolling temperature at 1013°C. Specifically, in the temperature range of 1100-1150°C, the pass reduction rate is controlled at 16%; in the temperature range of 1050-1100°C , the pass reduction rate is controlled at 23%; in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com