Patents

Literature

76results about How to "High resolution requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

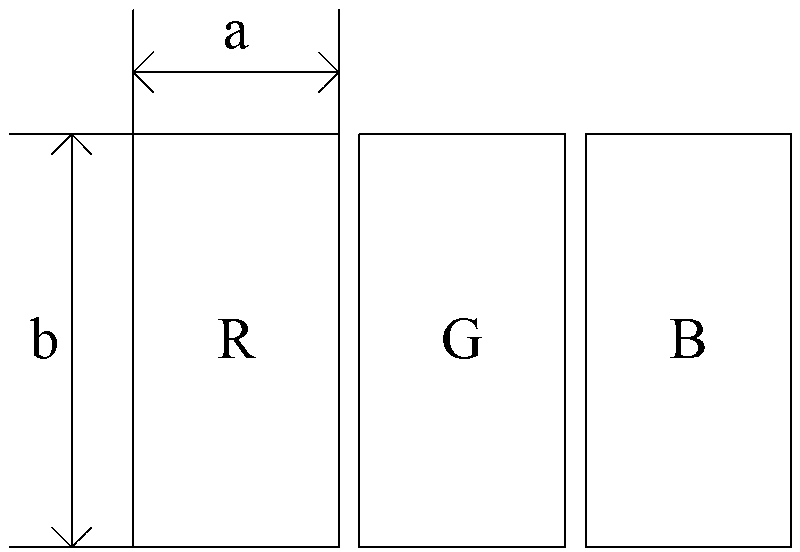

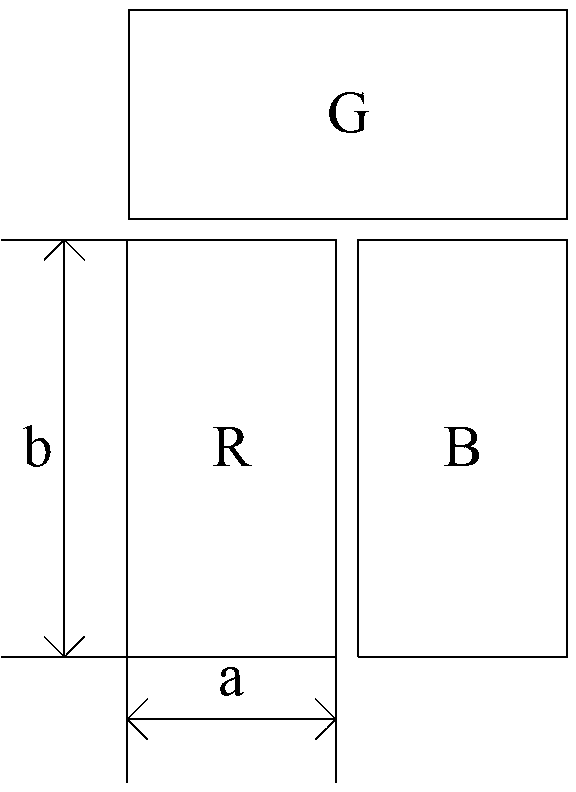

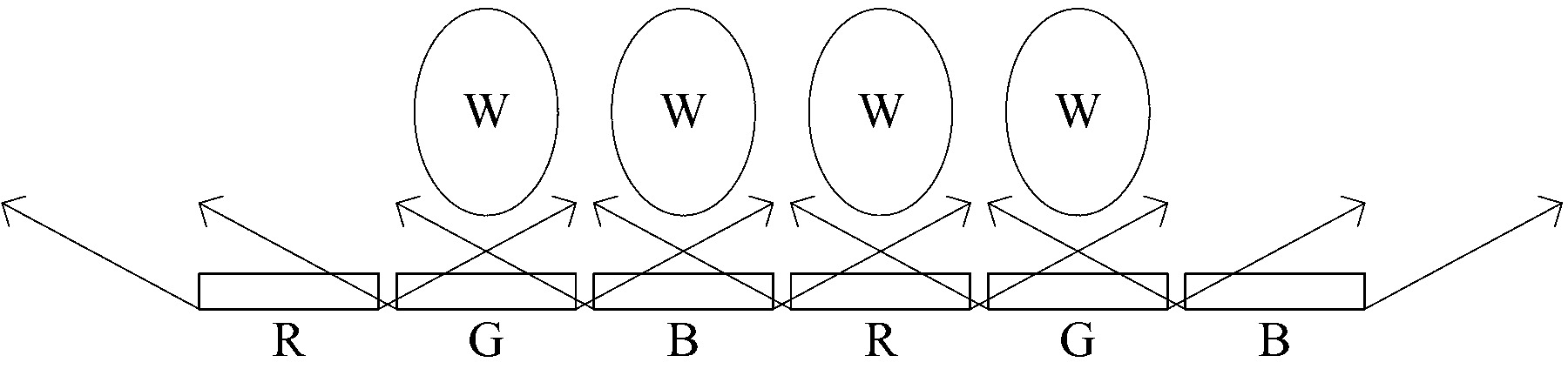

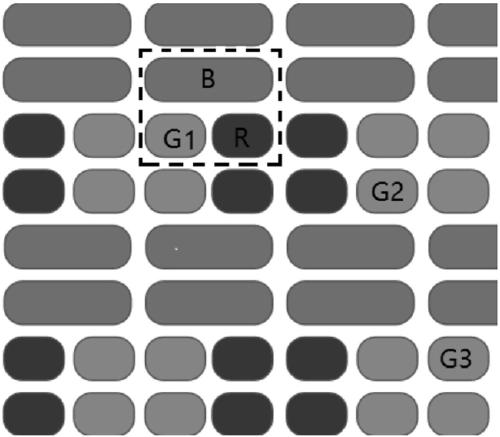

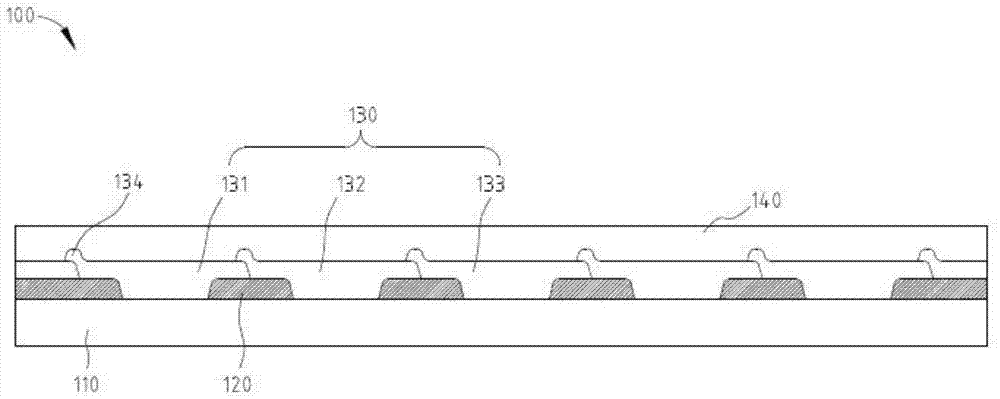

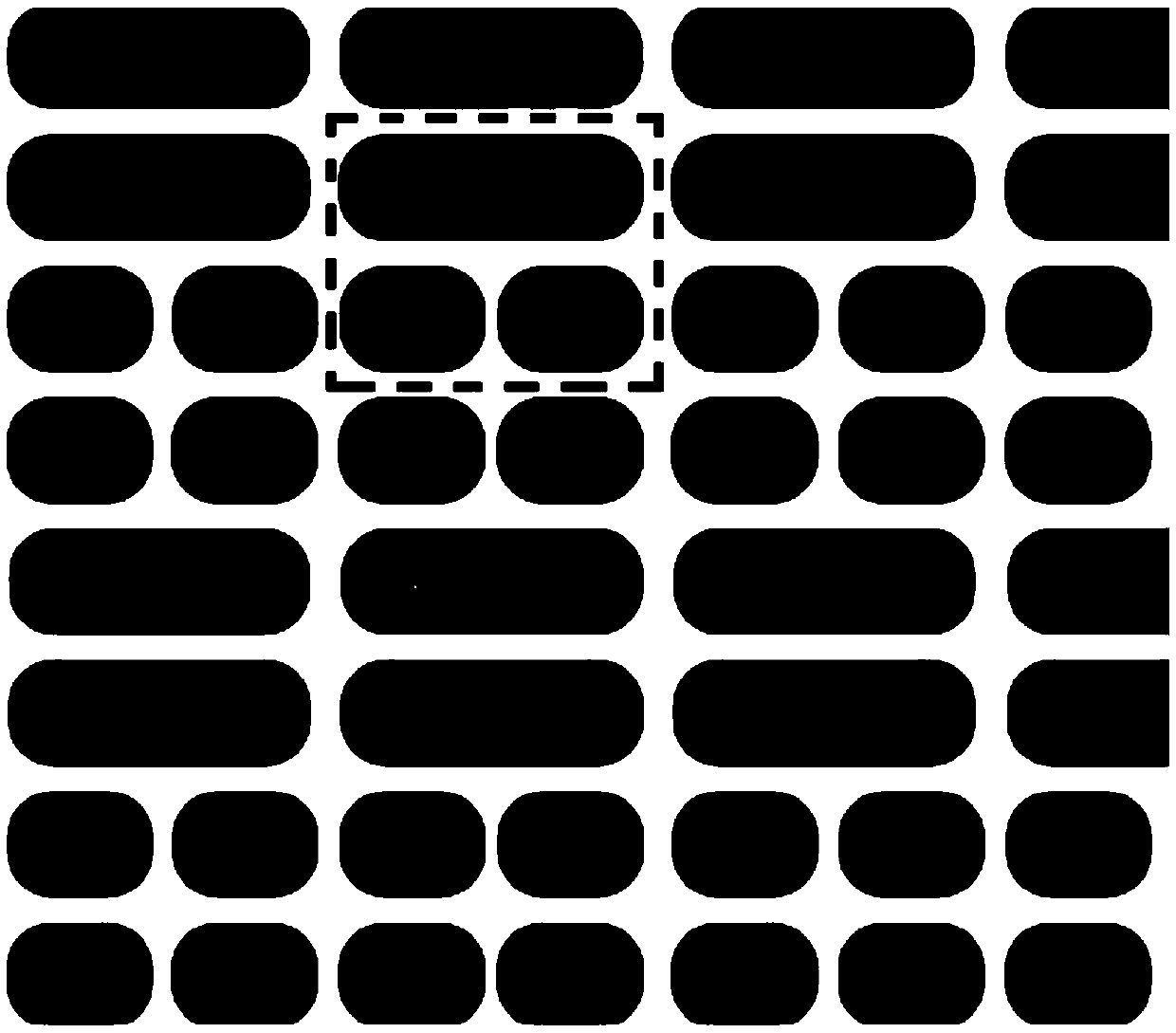

Display substrate and display device

ActiveCN103257494ASmall sizeBig sizeNon-linear opticsOptical elementsPixel densityLiquid-crystal display

The invention discloses a display substrate and a display device provided with the display substrate and belongs to the display technical field. The display substrate and the display device solve the technical problems that a display panel formed by an existing pixel unit neutron pixel arraying mode is low in pixel density and incapable of meeting requirements of products for high distinguishability. The display substrate comprises a plurality of pixel units distributed in an array mode. Each pixel unit comprises a first sub-pixel, a second sub-pixel and a third sub-pixel. The first sub-pixel, the second sub-pixel and the third sub-pixel are adjacent to each other and are all oblong. Each first sub-pixel is arranged in the transverse direction, and each second sub-pixel and each third sub-pixel are arranged in the longitudinal direction. The long edge of each second sub-pixel is adjacent to the long edge of each third sub-pixel. The long edge of each first sub-pixel is adjacent to the short edge of each second sub-pixel and the short edge of each third sub-pixel. The display substrate is used for display devices such as a liquid crystal display and an OLED.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

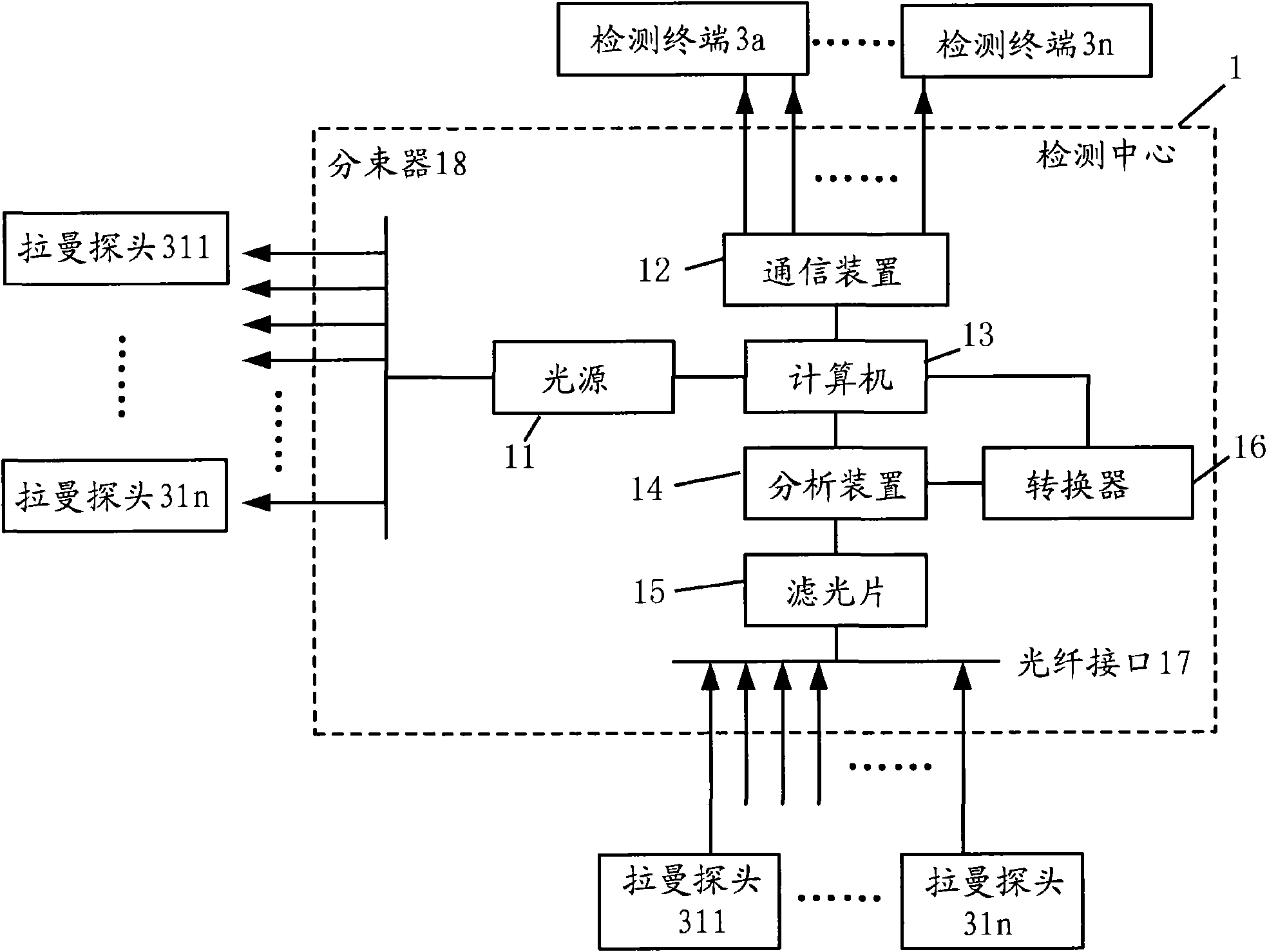

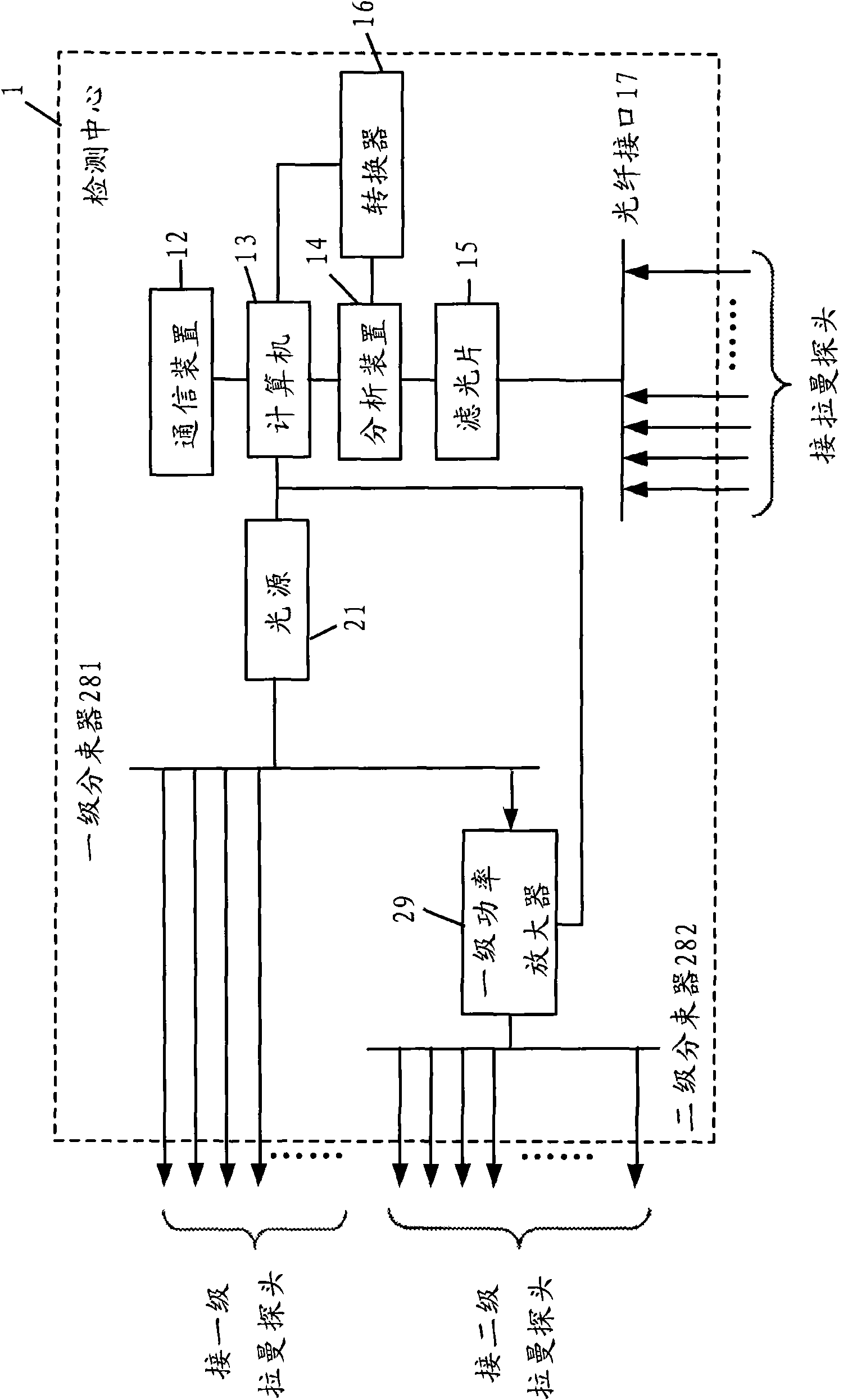

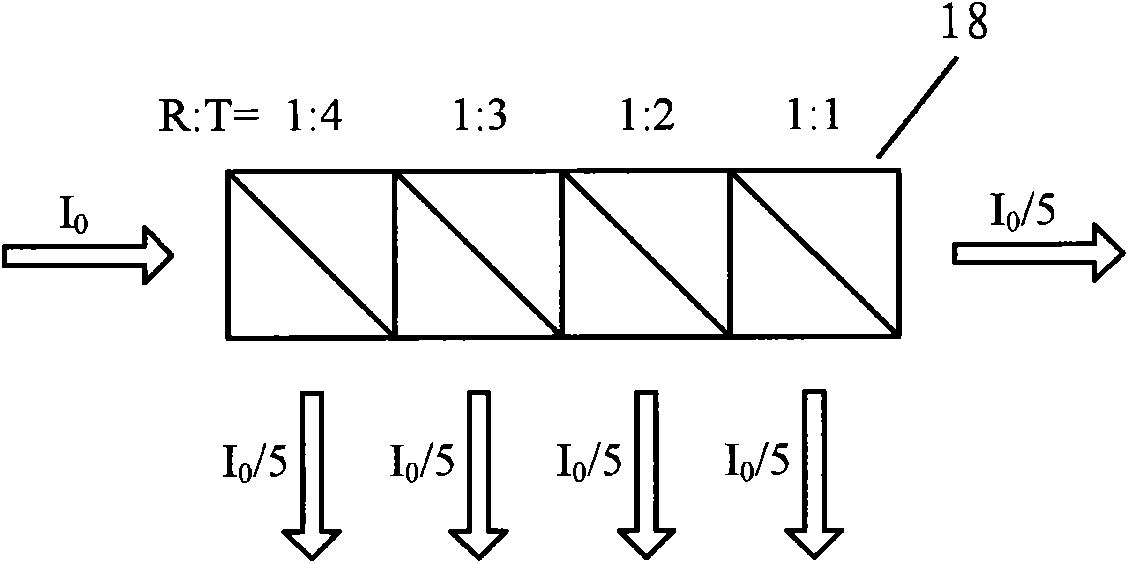

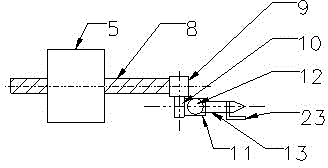

Raman spectrum system and method for measuring Raman spectrum

InactiveCN101614667ASolve portabilityEasy to moveData processing applicationsSpectrum investigationRaman scatteringLight source

The invention relates to a Raman spectrum system. The system comprises a detection center, an analysis device and at least one detection terminal, wherein the detection center comprises at least one light source for outputting exciting light which can excite a detected object to generate Raman scattered light; the analysis device is used for obtaining the Raman spectrum of the detected object; each detection terminal comprises at least one Raman probe; and each Raman probe guides the exciting light to the detected object and transmits the Raman scattered light generated by the detected object back to the detection center. The invention also relates to a method for measuring the Raman spectrum.

Owner:NUCTECH CO LTD +1

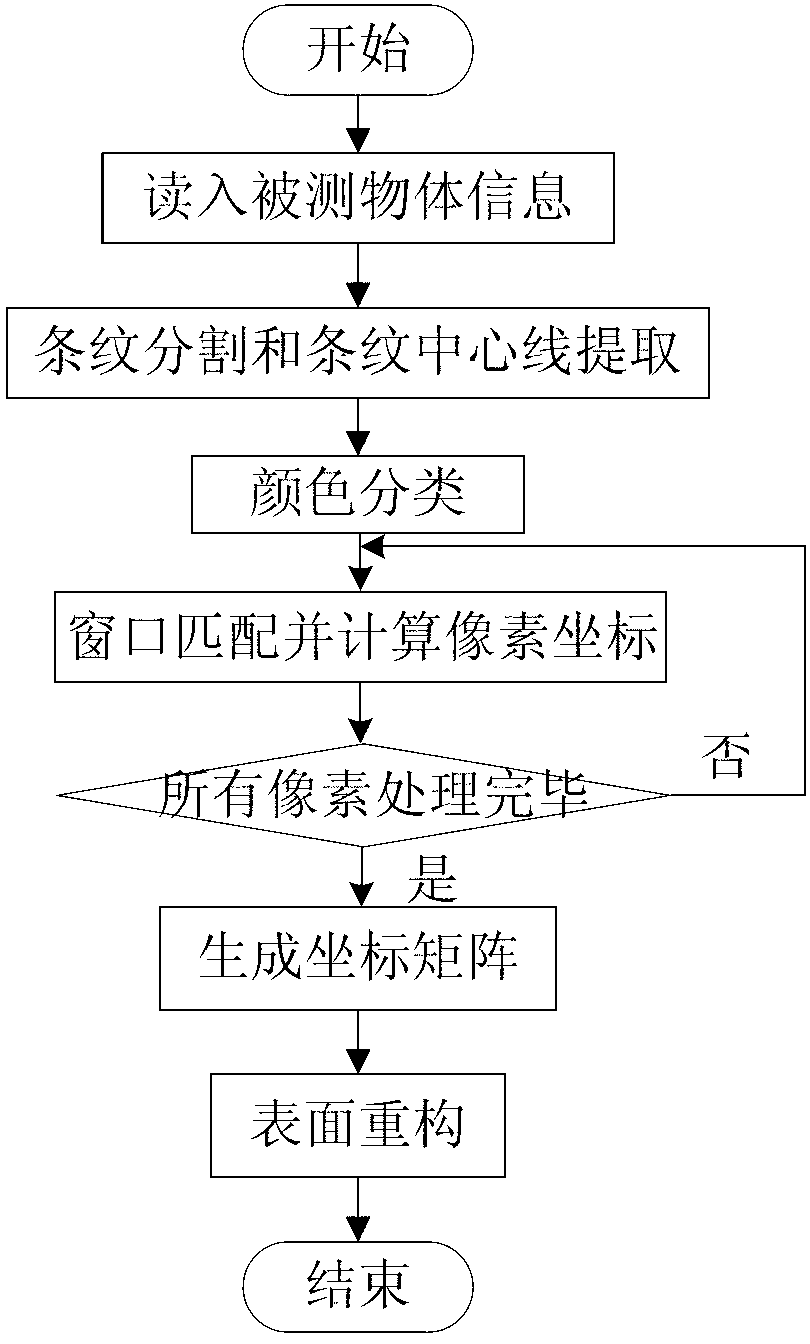

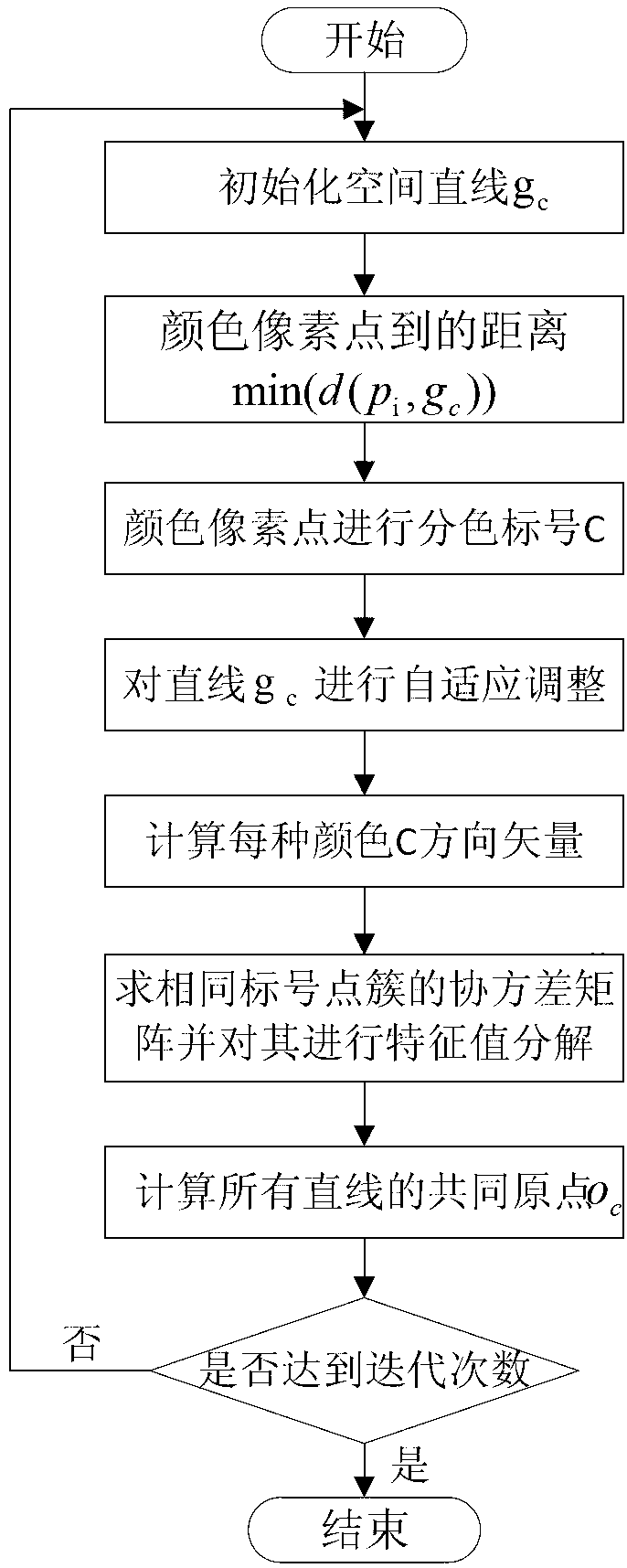

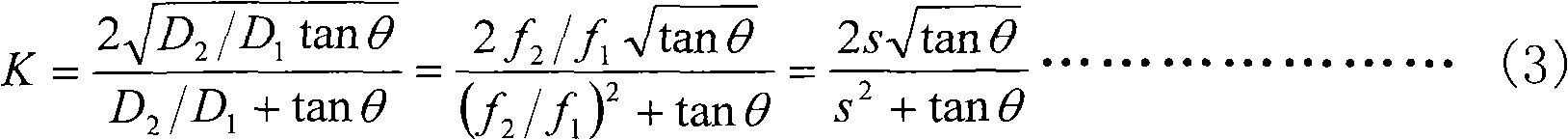

Structured light vision measurement method for 3D surface profiles of objects on the basis of K-means color clustering

InactiveCN103292741AHigh resolution requirementsImprove accuracyImage codingUsing optical means3d surfacesBinoculars

The invention aims to provide a structured light vision measurement method for 3D surface profiles of objects on the basis of K-means color clustering. The method includes: determining spatial lines in each color in the RGB space, calculating Euclidean distances of each pixel point to the spatial color lines, selecting the minimum distance, and ensuring that a corresponding color number is a most approximate color value of the current pixel point; adaptively regulating parameters by the pixel points with the same number, and fitting new spatial color lines; repeatedly iterating by the K-means clustering algorithm until the color value of each pixel point tends to be stable; sorting colors, acquiring a decoding sequence, determining the position of each matching point, and generating a matching point coordinate matrix; and acquiring depth information by triangulation so as to reconstruct the 3D surface of an object. The method has the advantages that accuracy in color sorting is improved, robustness and adaptive capability are high, and the problem of matching difficulty in binocular stereoscopic vision is solved.

Owner:HARBIN ENG UNIV

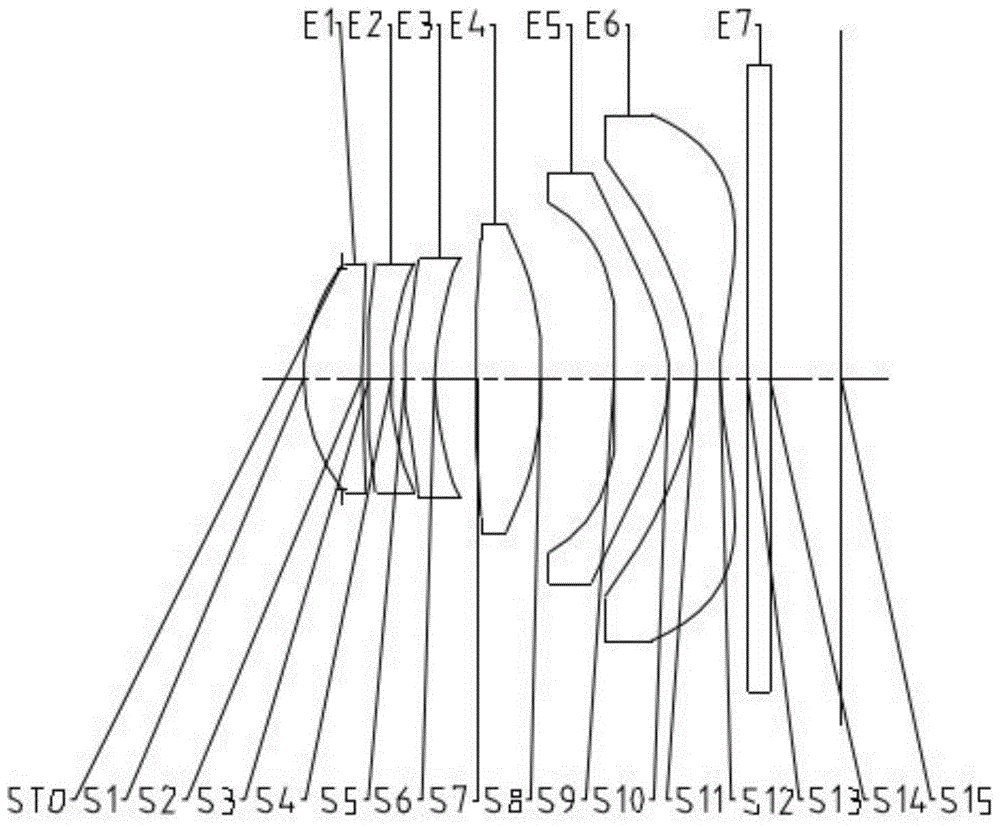

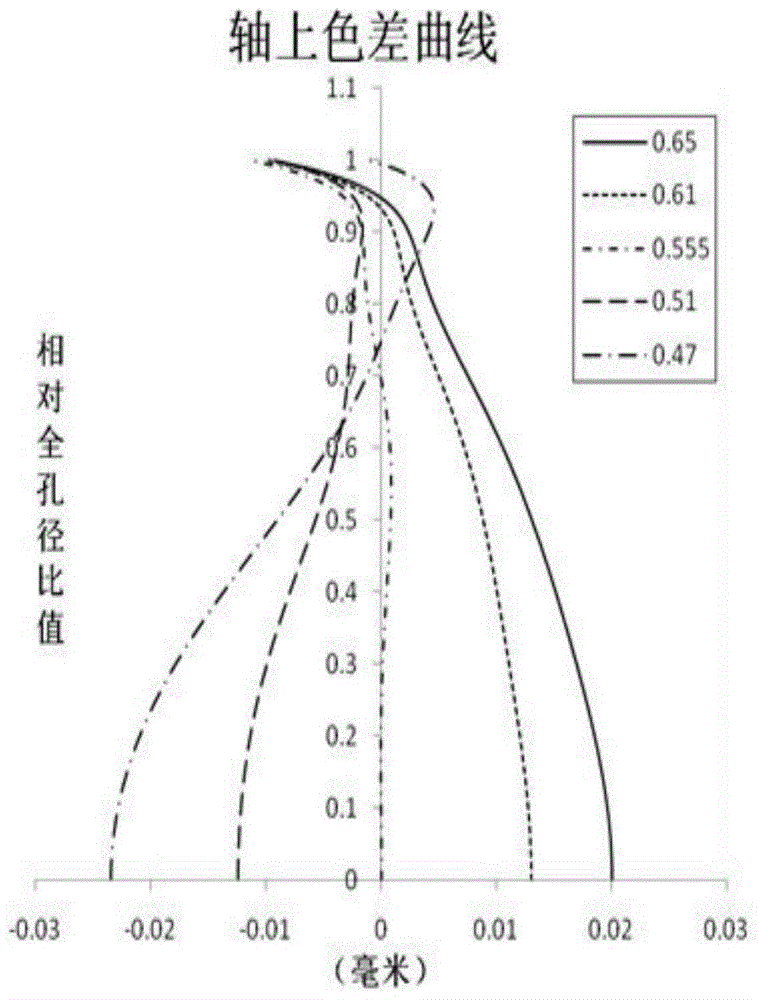

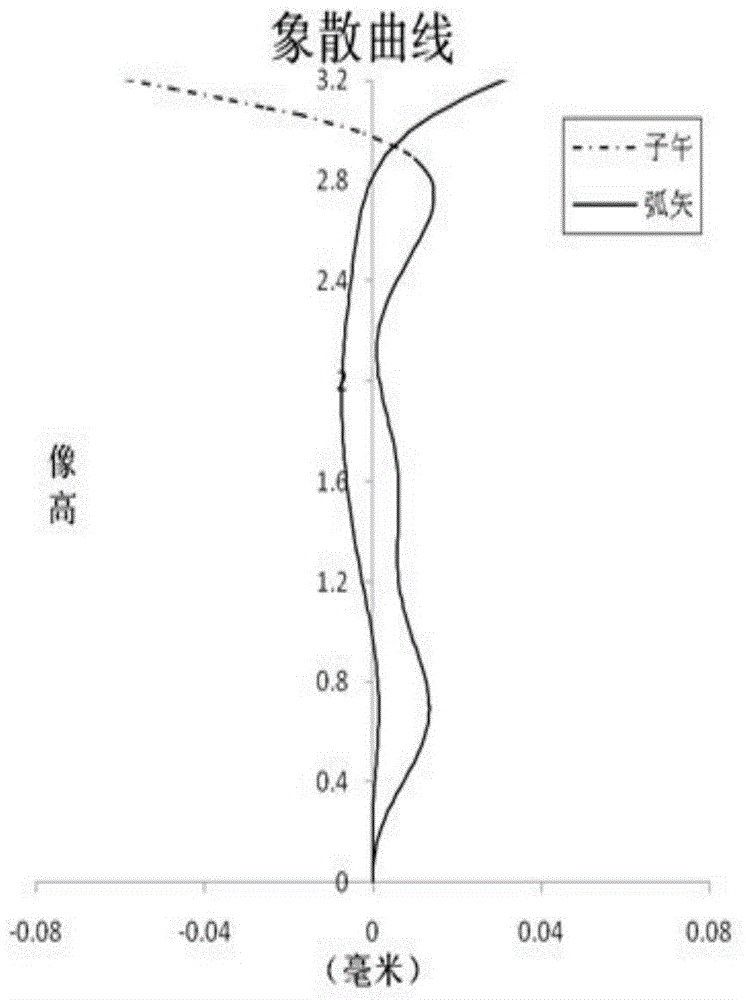

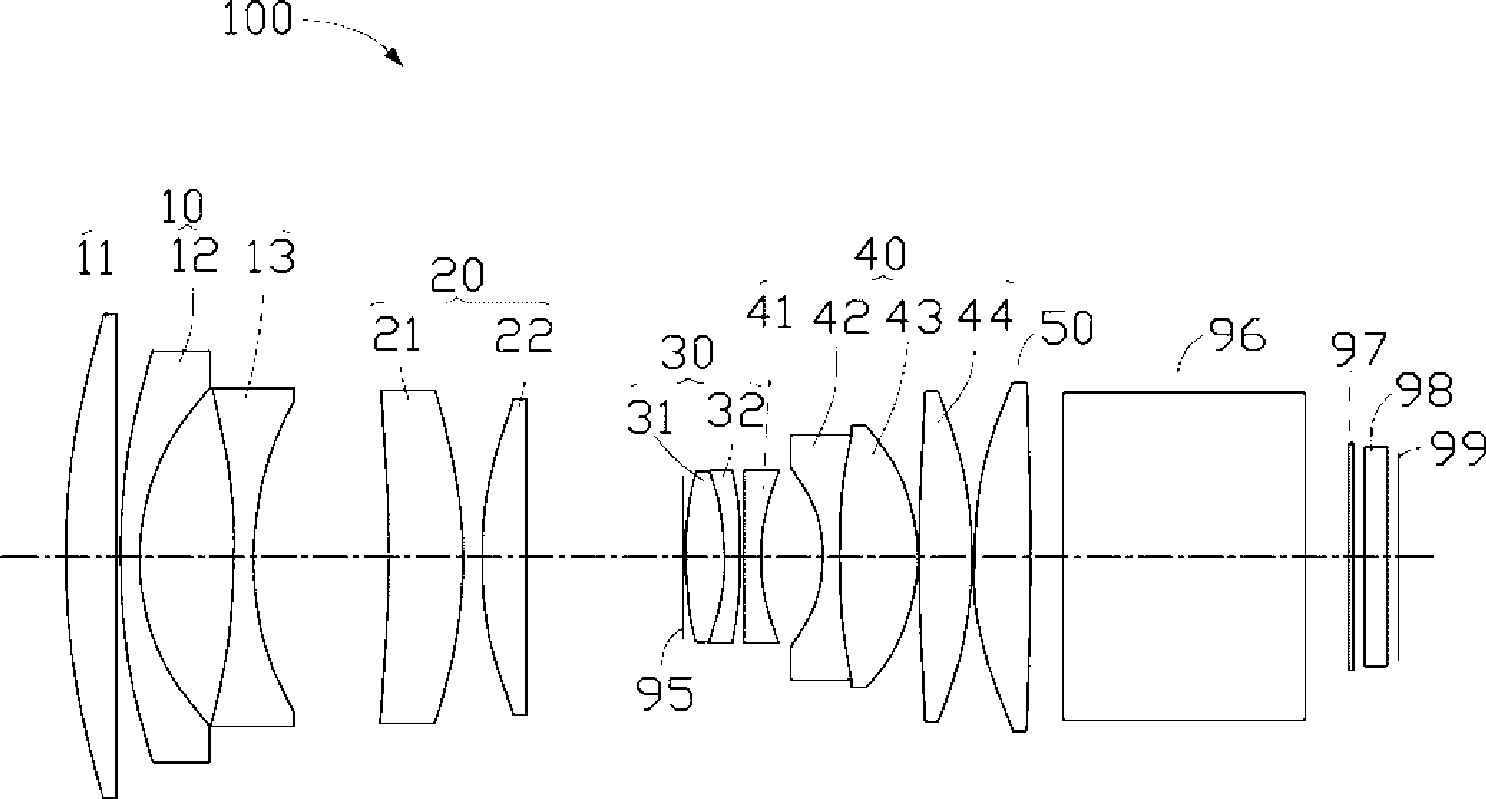

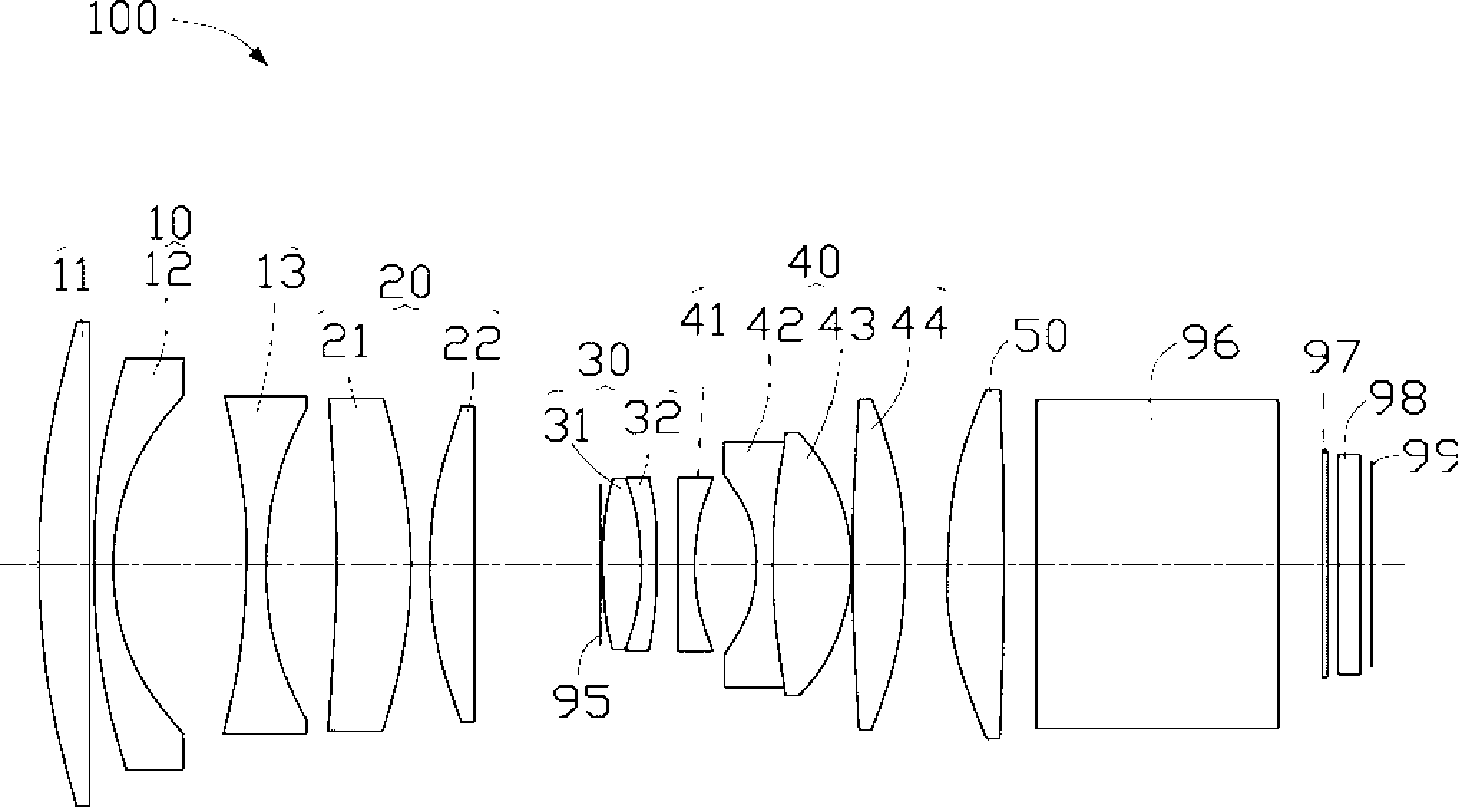

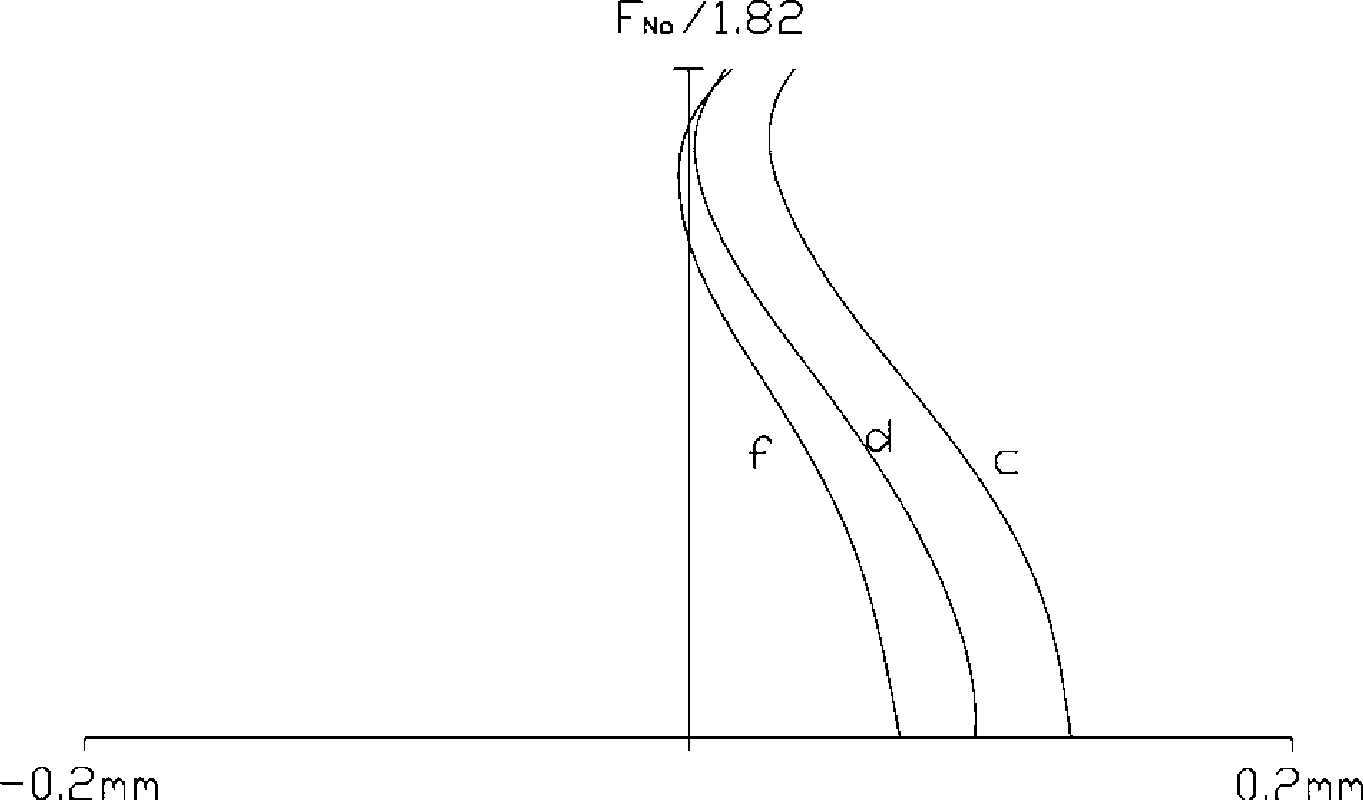

Shooting lens and module thereof, and terminal

ActiveCN103955047AShorten the lengthGuaranteed miniaturizationOptical elementsCamera lensImaging quality

The invention provides a shooting lens and a module thereof, and a terminal. The lens successively comprises from an object side to an image side: a first lens with positive focal power, a second lens with negative focal power, a third lens with negative focal power, a fourth lens with focal power, a fifth lens with positive focal power, a sixth lens with focal power, wherein object side surface of the second lens is a convex surface, the image side surface of the fifth lens is a convex surface, and the part, which is near to an axis, of the image side surface of the sixth lens is a recessed surface. The shooting lens satisfies the following: 5.5<f1.2.3 / Dr1r6<10, wherein the f1.2.3 is the combination focal length of the first lens, the second lens and the third lens, and the Dr1r6 is the interval from the objet side surface of the first lens to the image side surface of the third lens on an optical axis. According to the invention, six plastic aspheric eyeglasses are employed, through different focal power distribution, it is ensured that under large-caliber configuration, the volume of the lens is effectively shortened, the influences of image differences are reduced, and the imaging quality of the lens is improved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

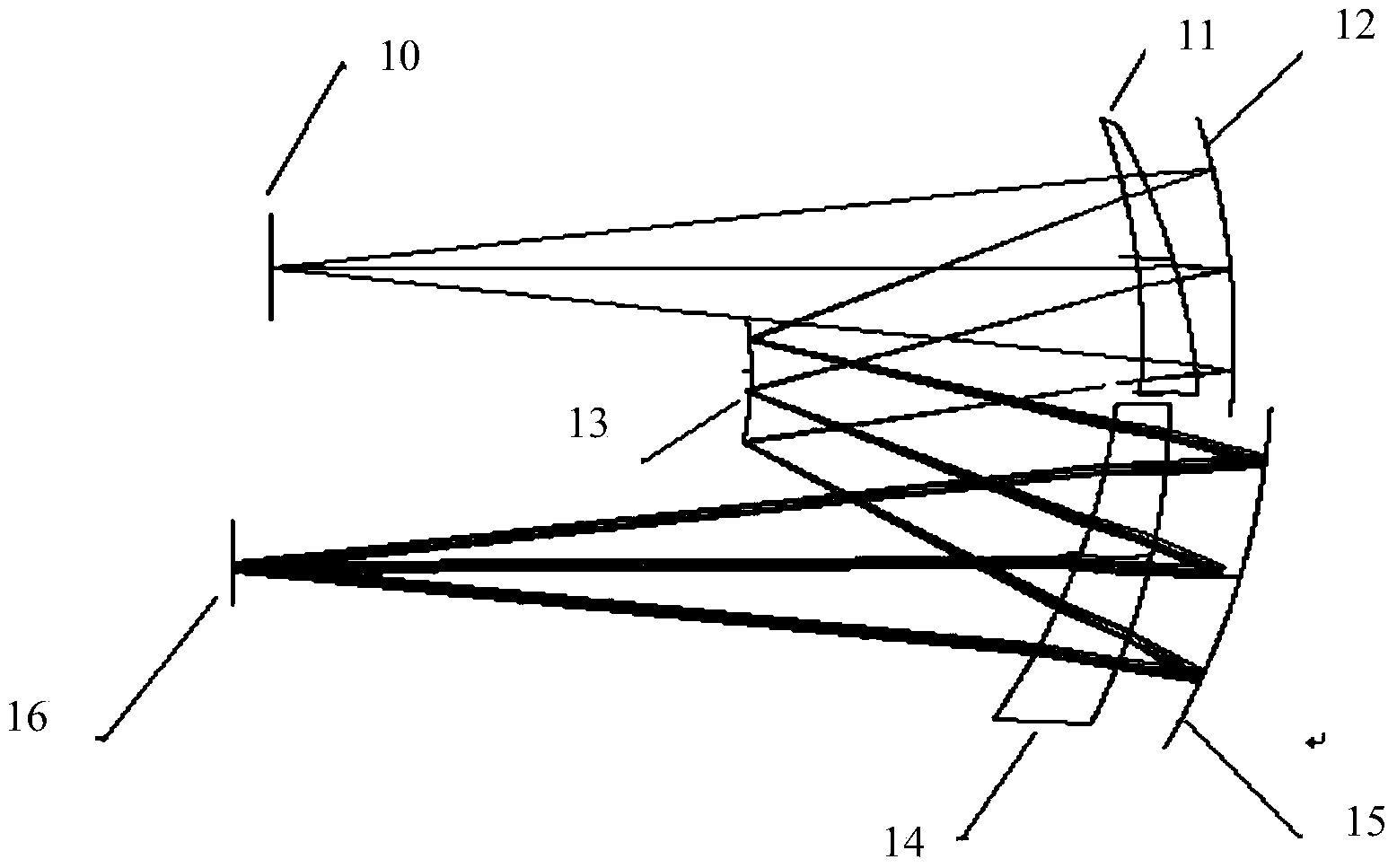

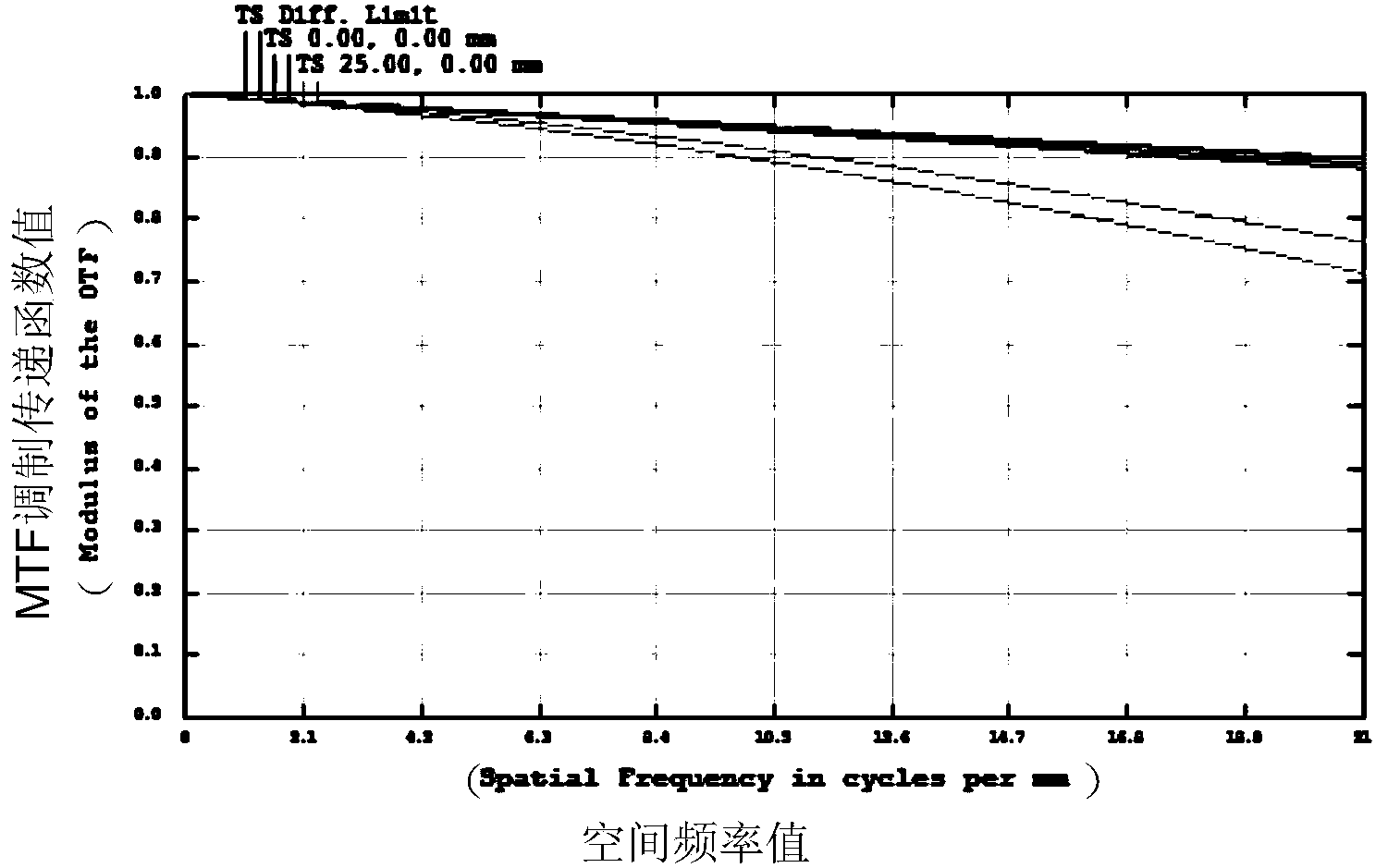

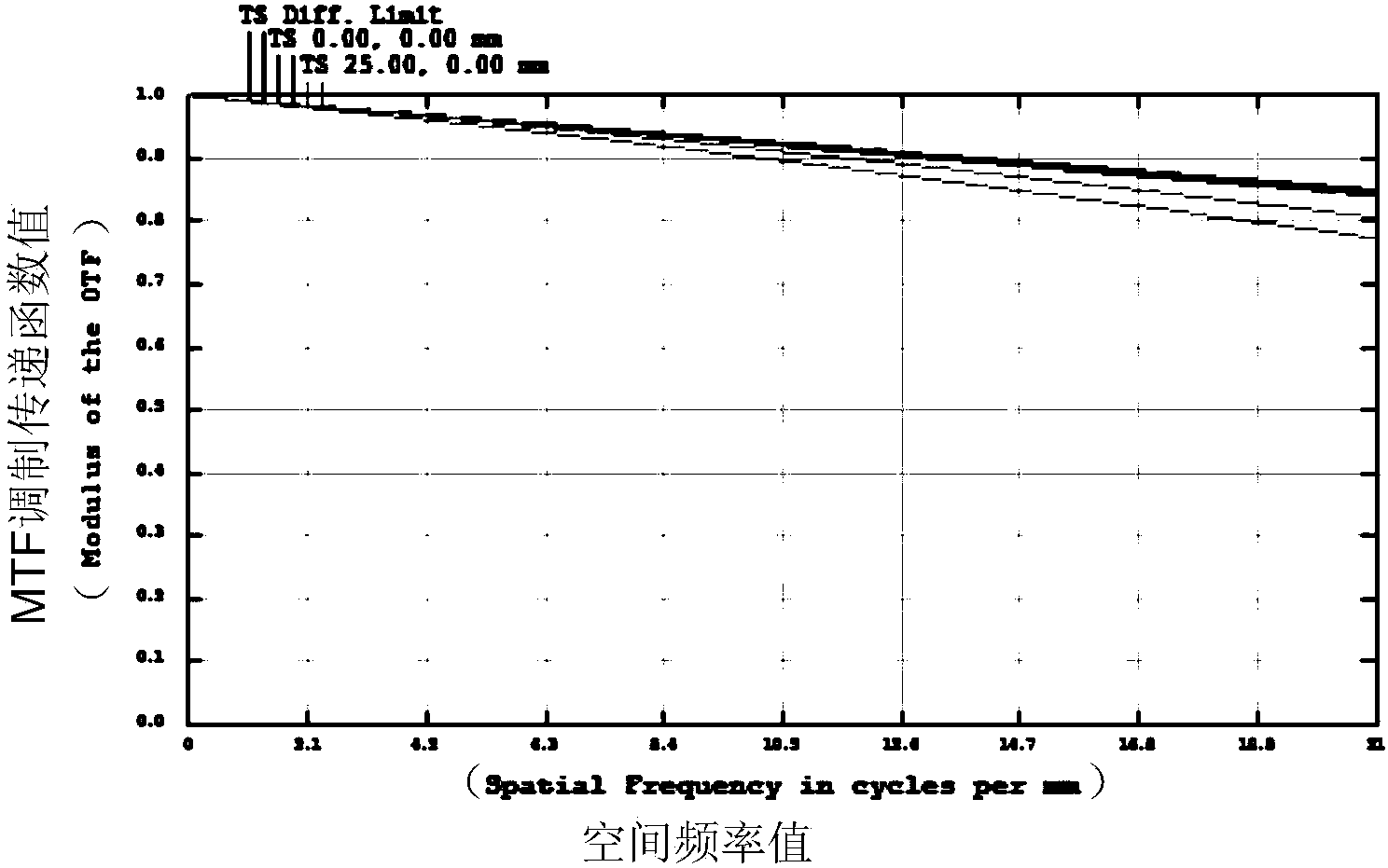

Imaging spectrometer

The invention discloses an imaging spectrometer. The imaging spectrometer comprises a first Fery prism, a first main reflector, a subsidiary reflector, a second Fery prism and a second main reflector. Light entering the imaging spectrometer through a slit arrives at the first main reflector after being transmitted by the first Fery prism, reaches the first Fery prism after being reflected by the first main reflector, reaches the subsidiary reflector after being transmitted by the first Fery prism, arrives at the second Fery prism after being reflected by the subsidiary reflector, reaches the second main reflector after being transmitted by the second Fery prism, arrives at the second Fery prism after being reflected by the second main reflector, and arrives at an imaging plane to realizing imaging after being transmitted by the second Fery prism. According to the imaging spectrometer, the light passes through the same Fery prism twice for chromatic dispersion, so that the size and weight of a system are reduced, a large view field is obtained, and a quite large chromatic dispersion width is obtained.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

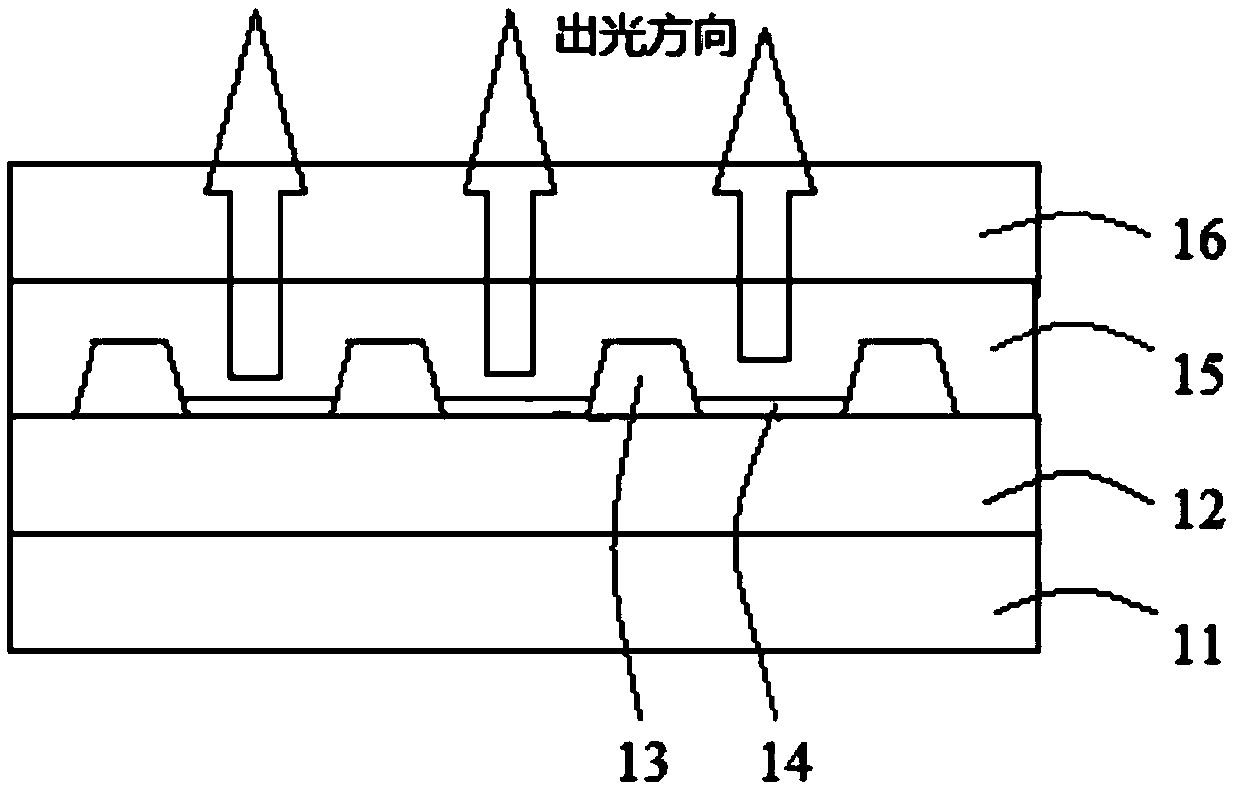

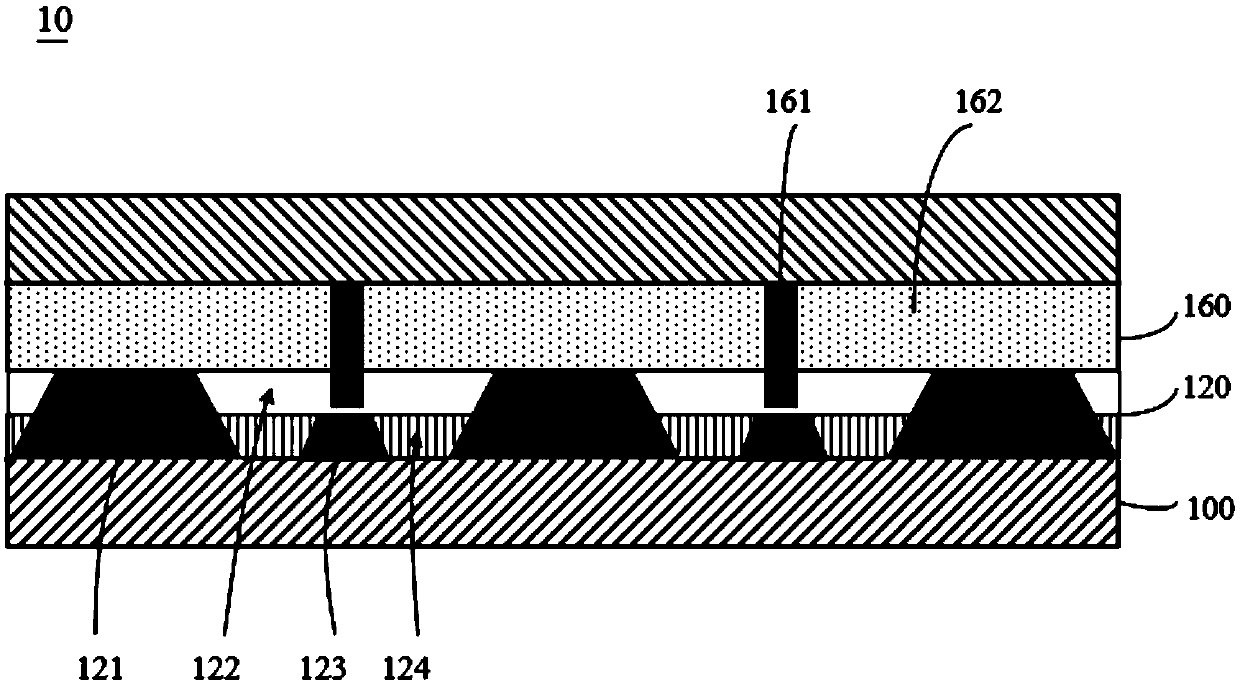

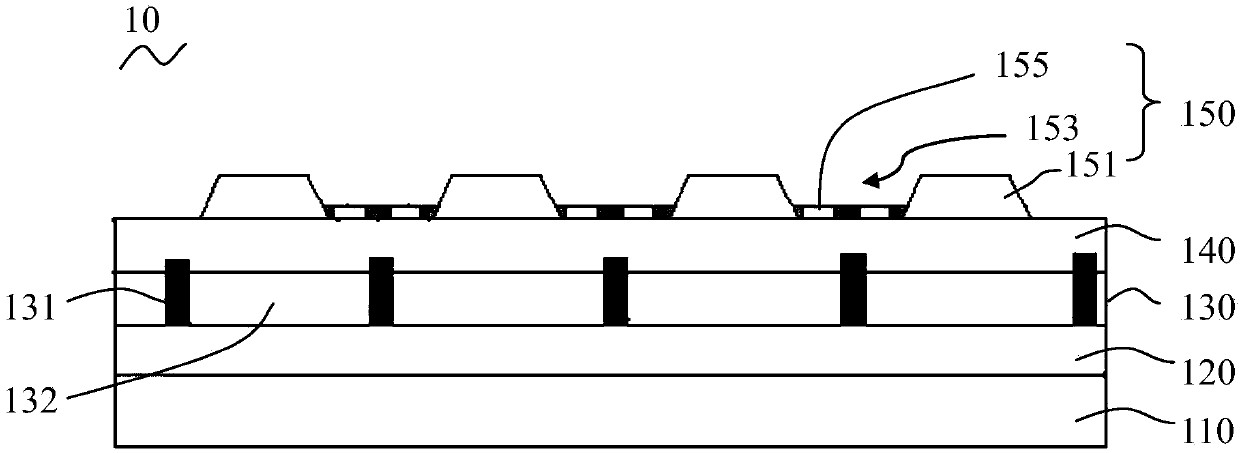

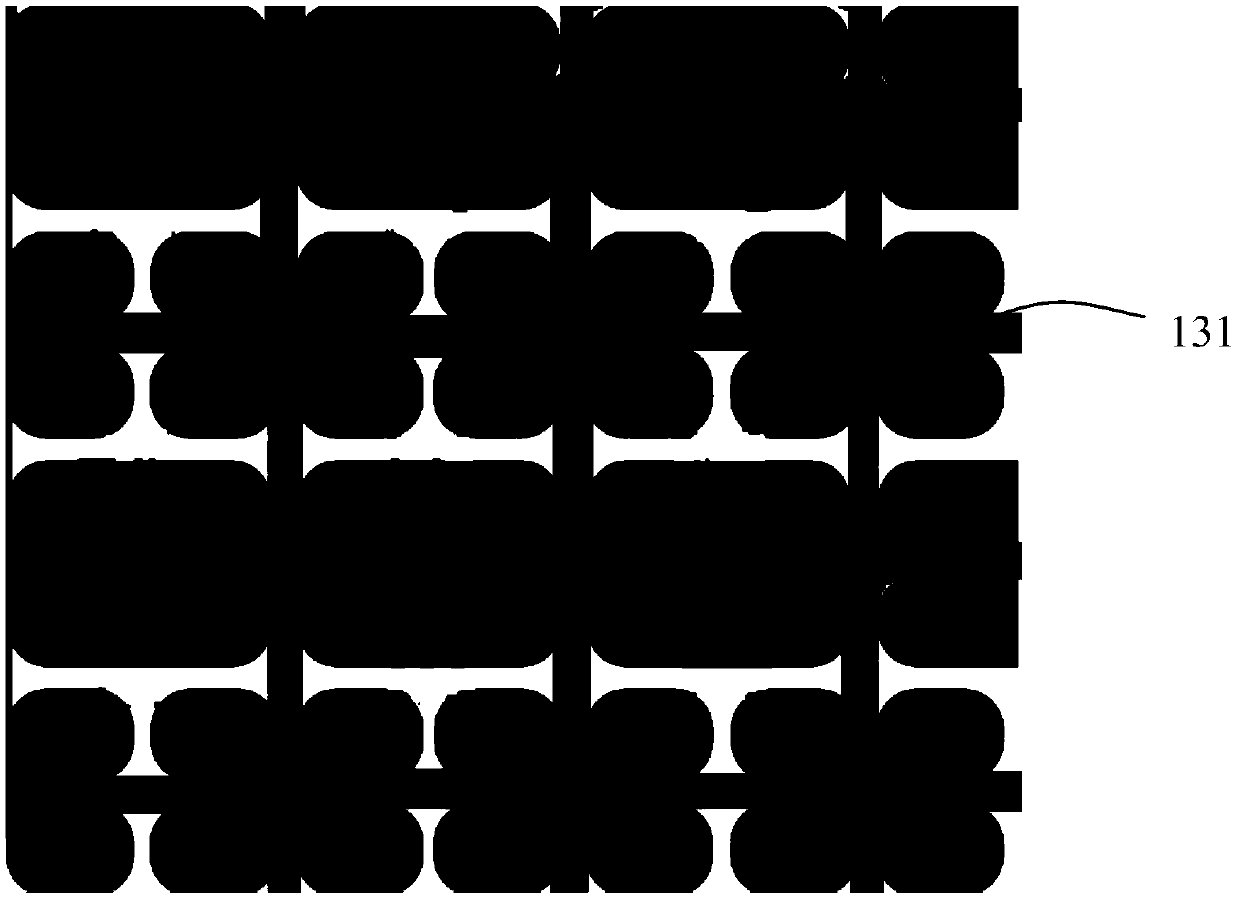

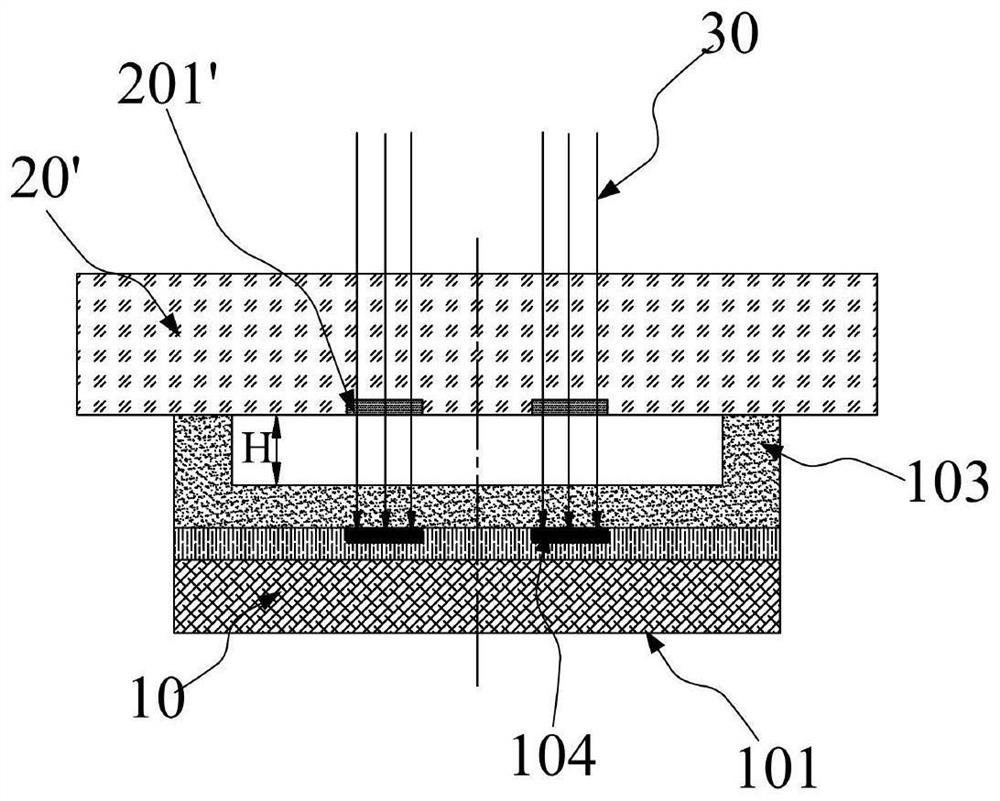

Display device, preparation method thereof and display device

PendingCN111341804AImprove Angular UniformityImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsOptics

The invention relates to a display device, a preparation method thereof and a display device. The display device comprises a TFT array substrate; a light-emitting structure which is arranged on the TFT array substrate and comprises a pixel bank, a pixel isolation column and a plurality of pixel units, wherein the height of the pixel bank is larger than that of the pixel isolation column, the pixelbank defines a plurality of pixel grooves in the TFT array substrate, the pixel isolation columns are located in the pixel grooves and divide the pixel grooves into at least two sub-pixel grooves, asub-pixel is formed in each sub-pixel groove, and the colors of the sub-pixels located in the same pixel groove are the same; a scattering layer which is arranged on the light-emitting side of the light-emitting structure and comprises a first black isolation wall and a plurality of scattering units separated by the first black isolation wall, wherein the scattering units and the pixel units are arranged in a one-to-one correspondence mode, and the first black isolation wall and the pixel isolation columns are arranged in a one-to-one correspondence mode. The display device can improve the light extraction efficiency and improve the display effect of a high-resolution display.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

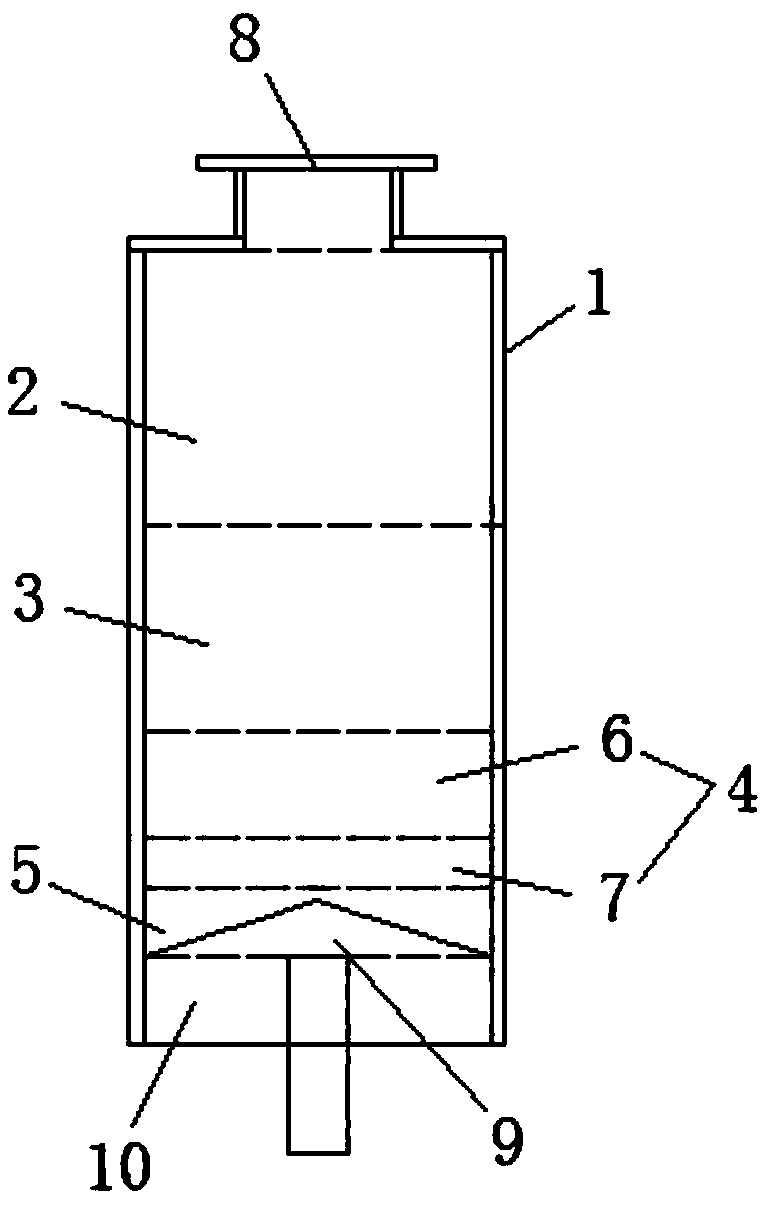

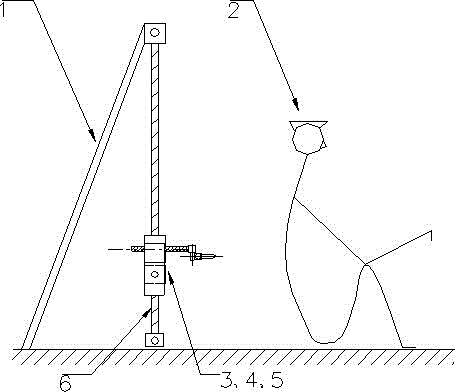

Rural small garbage pyrolysis gasification incineration process

InactiveCN109579017ASolve the problem of complex incineration processHigh resolution requirementsIncinerator apparatusCombustionLitter

The invention discloses a rural small garbage pyrolysis gasification incineration process. The rural small garbage pyrolysis gasification incineration process comprises a pyrolysis gasification incineration furnace body, and a drying layer, a pyrolysis gasification layer, a combustion layer and a burnout layer arranged in a furnace body in sequence from top to bottom, wherein the combustion layerconsists of a reducing area and an oxidizing area arranged up and down. The invention provides a rural small household garbage top-sucking low-temperature cracking incineration furnace for the first time to solve the problem of high requirement on high-temperature cracking furnace body materials; a process for drying garbage by garbage incineration afterheat is used for achieving an afterheat utilization effect; and three processes of drying, low-temperature cracking gasification and combustion are integrated to solve the problem of complication of a rural garbage incineration process.

Owner:朱海斌

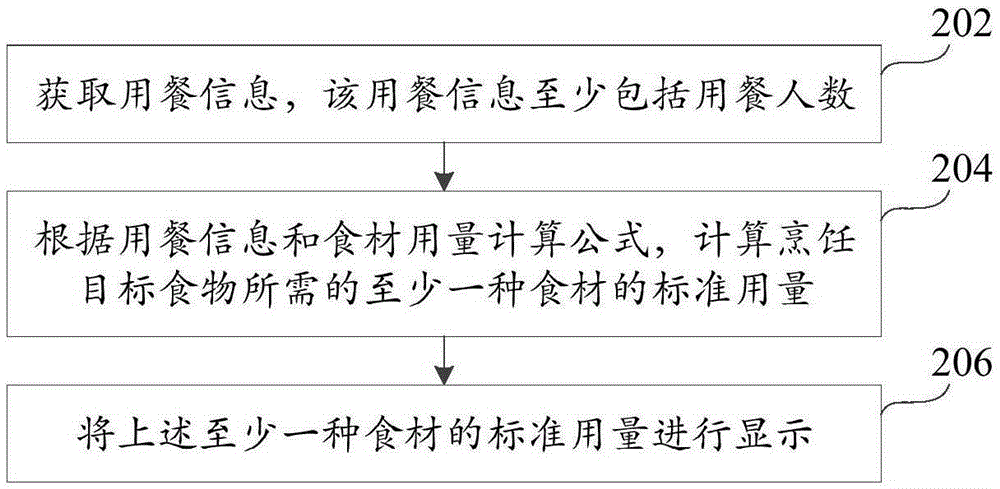

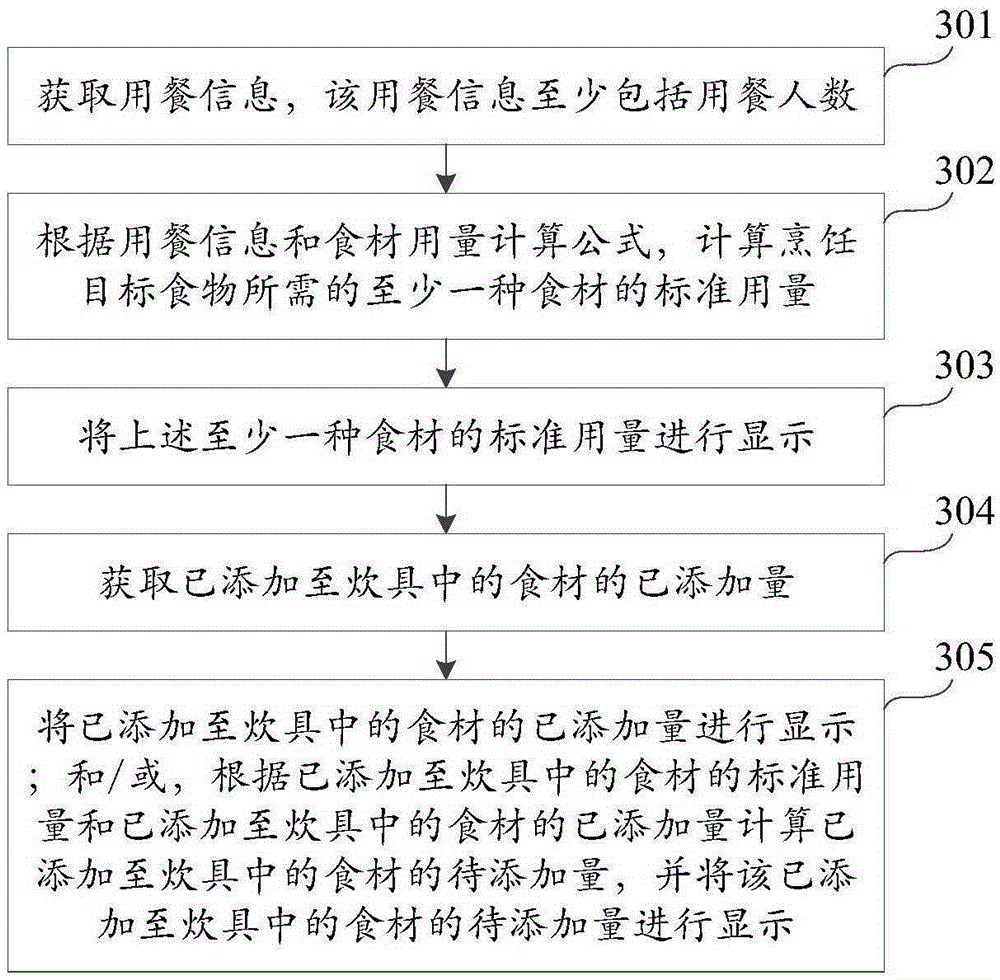

Information prompting method and device

ActiveCN105278378ASolve the problem of self-control of the amount of ingredients and high requirements for usersHigh resolution requirementsProgramme control in sequence/logic controllersAdditive ingredientComputer science

The invention discloses an information prompting method and device and belongs to the smart home technical field. The method comprises the following steps that: dining information is acquired, wherein the dining information at least comprises the number of people who have dinners; the standard dosage of at least one kind of ingredient required by cooking target food is calculated according to the dining information and an ingredient dosage calculation formula; and the standard dosage of at least one kind of ingredient is displayed. With the information prompting method and device of the invention adopted, the problem of high requirements for users, which is caused by a situation that the users themselves need to master the dosages of ingredients, can be solved; the users can be prompted with the dosages of the ingredients, and therefore, a cooking process becomes easier and intelligent, and requirements for the users can be reduced, and user experience can be improved.

Owner:XIAOMI INC

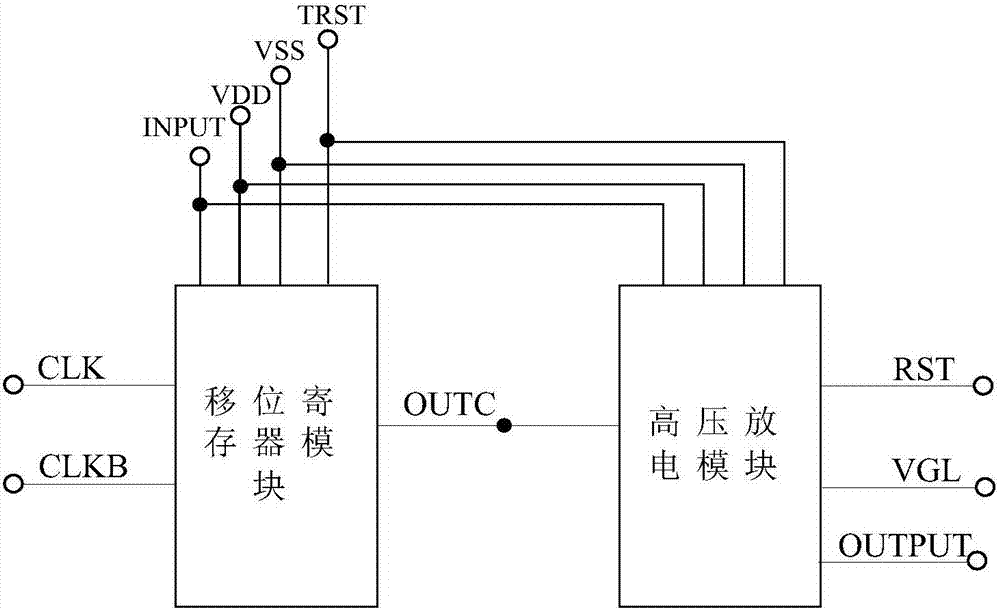

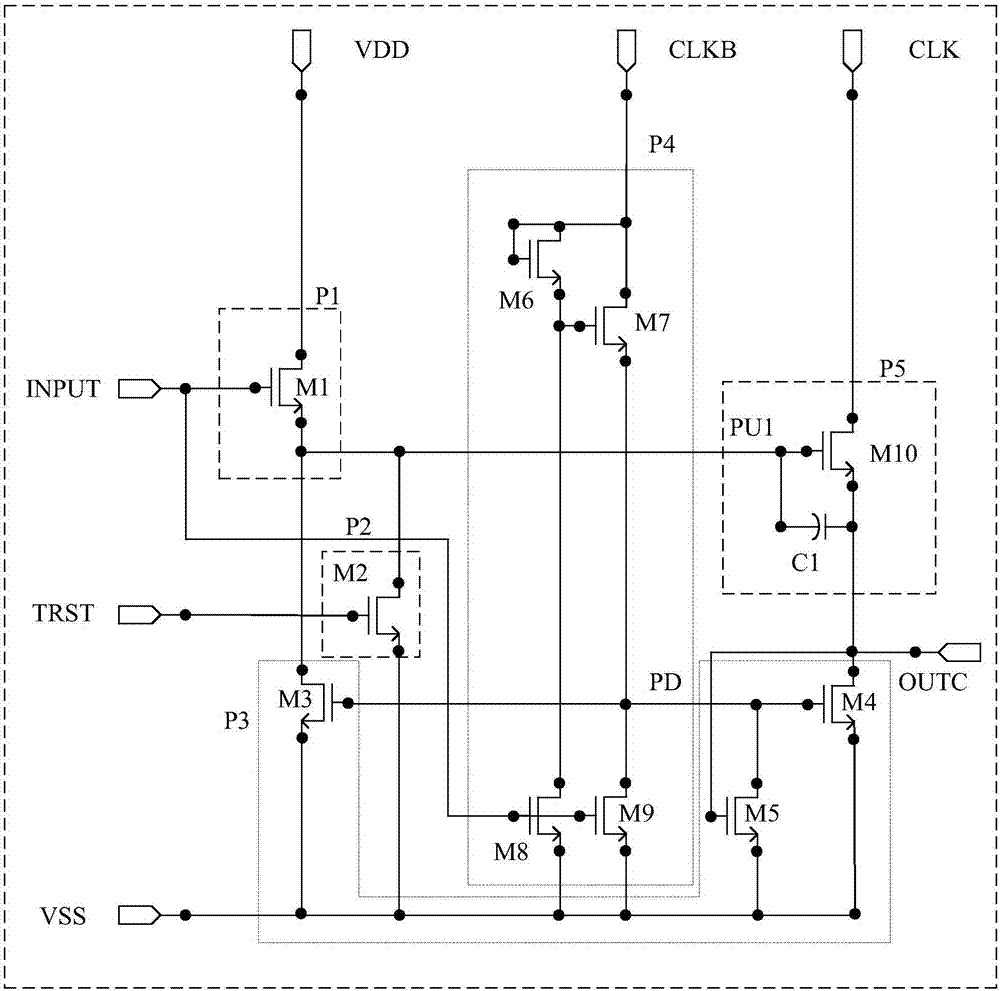

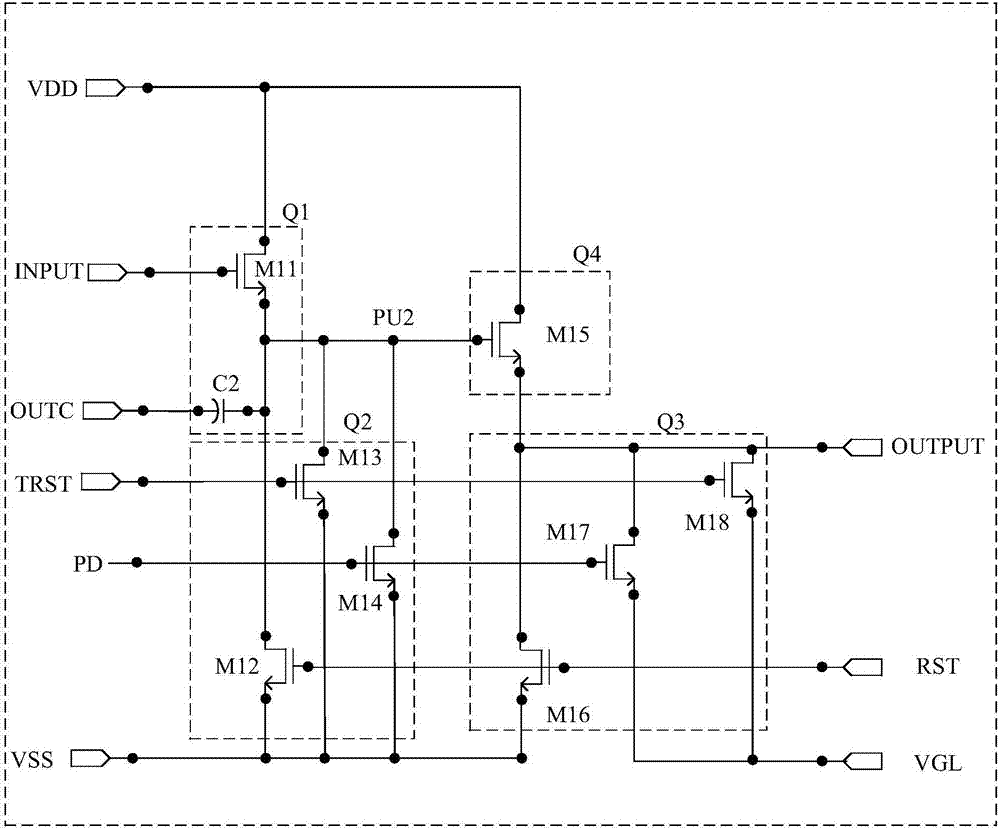

Shifting register unit and shifting register

ActiveCN106920519AShorten the timeHigh resolution requirementsStatic indicating devicesDigital storageShift registerProcessor register

The invention discloses a shifting register unit and a shifting register, and the shifting register unit comprises a shifting register module and a high-voltage discharge module; wherein the shifting register module is connected with a signal input end, a first reset signal end, a first low level end, a high level end, a first clock signal end and a second clock signal end; and the high-voltage discharge module is connected with an output end, a high level end, a signal input end, a first reset signal end, a second reset signal end, a first low level end and a second low level end of the shifting register module. According to the invention, the shifting register unit comprises the high-voltage discharge module which is connected with the shifting register module in series, the voltage difference of power supply for grid line is increased, the discharge speed is improved, the time of output voltage signal decrease is reduced, and the high-resolution requirement of an existing display device is met.

Owner:BOE TECH GRP CO LTD

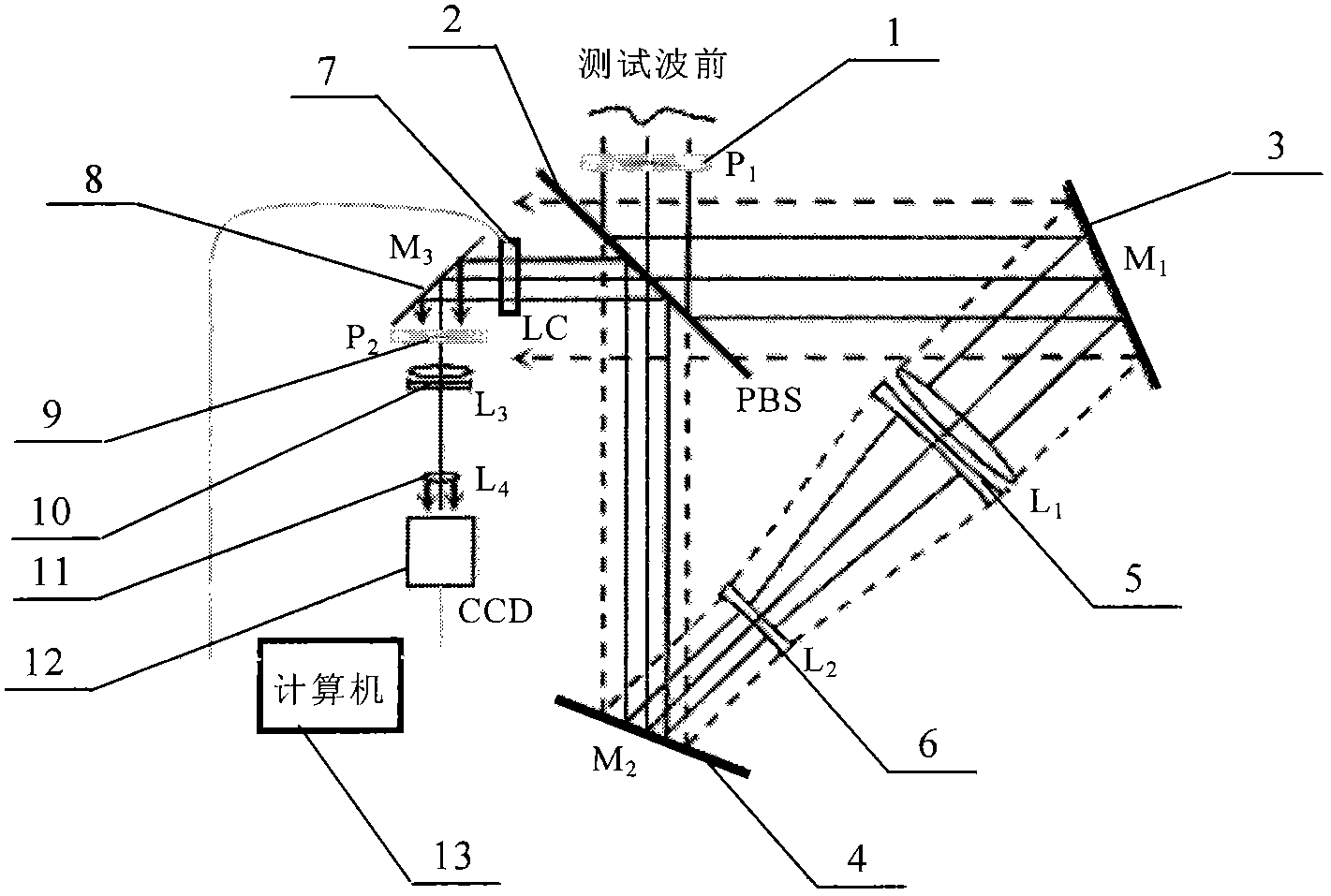

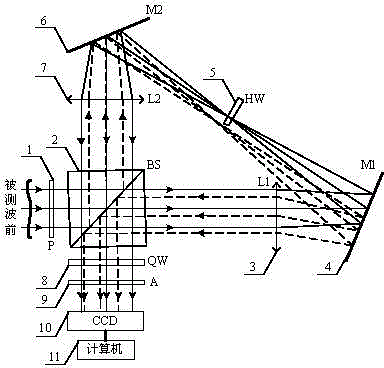

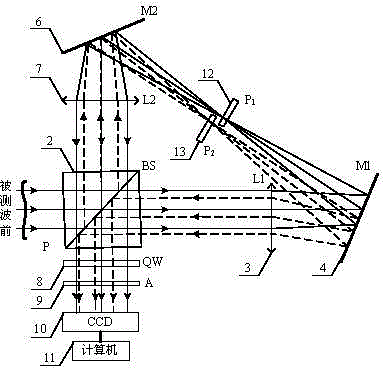

Common-path radial cutting liquid crystal phase shift interference wave-front sensor

InactiveCN102680117AImprove detection accuracyImprove spatial resolutionOptical measurementsVisibilityWavefront sensor

The invention discloses a common-path radial cutting liquid crystal phase shift interference wave-front sensor. The common-path radial cutting liquid crystal phase shift interference wave-front sensor is composed of a polarizer, a radial cutting system, an LC (Liquid Crystal Phase Modulator), a polarization analyzer, an imaging system and a computer. After a light beam to be detected enters into the wave-front sensor, the polarizer can be rotated, and the polarization direction of the incident light beam can be adjusted; then, two bundles of cutting light beams are formed after the incident light beam passes through the radial cutting system, the two bundles of the cutting light beams share the same light axis, the polarization directions of the two bundles of the cutting light beams are orthogonal, and the apertures of the two bundles of the cutting light beams are zoomed according to the same proportion; the two bundles of the cutting light beams can be directly irradiated to the LC, and the polarization directions of the LC and the enlarged light beams are kept the same; the computer drives the LC to introduce into N (N is larger than or equal to 3) different phase shifts between the cutting light beams, a polarized component, of which the polarization direction is consistent with that of the polarization analyzer, is obtained in the two bundles of the cutting light beams after passing through the polarization analyzer, and interference is generated; interference images are collected by the imaging system and are sequentially input into the computer in a time-division way, and the wave-front phase of the light beam to be detected can be reconstructed by analyzing and calculating. The common-path radial cutting liquid crystal phase shift interference wave-front sensor disclosed by the invention has the advantages that the structure of an optical system is simple, the impact of environmental vibration and non-common-path error can be restrained, the visibility of interference fringes is continuous and adjustable, and the wave-front detection accuracy is high.

Owner:INNER MONGOLIA UNIV OF TECH

Zooming projection lens

InactiveCN101398531AMeet basic requirementsMeet the requirements of telecentric imagingOptical elementsOphthalmologyMagnification

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

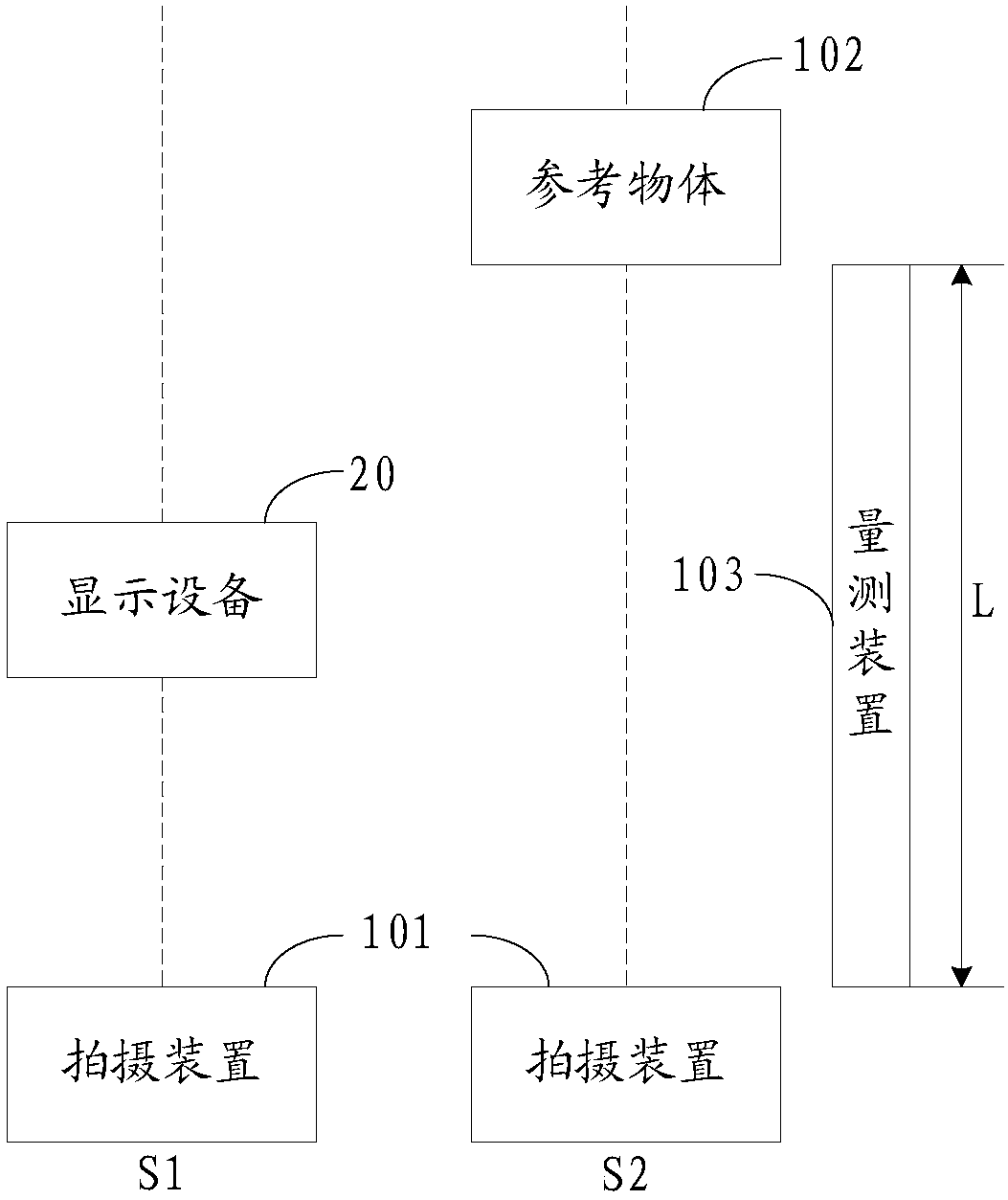

Virtual image distance measuring system and virtual image distance measuring determining method

ActiveCN108362479AMeet the detection and calibration needsThe method of determining the virtual image distance is simpleTesting optical propertiesOptical axisDisplay device

The invention provides a virtual image distance measuring system and a virtual image distance measuring determining method. The system includes a photographing device, a reference object, and a measuring device. The photographing device is configured to focus a virtual object in a preset mode when being at a first photographing position so that the virtual object is clearly imaged in the photographing device. The reference object is configured, when the photographing device is in a second photographing position and in a focusing state, to move along the optical axis until clearly imaged in thephotographing device. The measuring device is configured to calibrate the distance between the reference object and the photographing device when the reference object is clearly imaged in the photographing device, wherein the distance is the virtual image distance of the virtual object. The method for determining the virtual image distance is simple and easy to operate, and can meet the detectionand correction requirements of display devices such as a virtual reality device and an augmented reality device, and solves a problem that equipment is highly required for determining the virtual image distance in the prior art.

Owner:BOE TECH GRP CO LTD +1

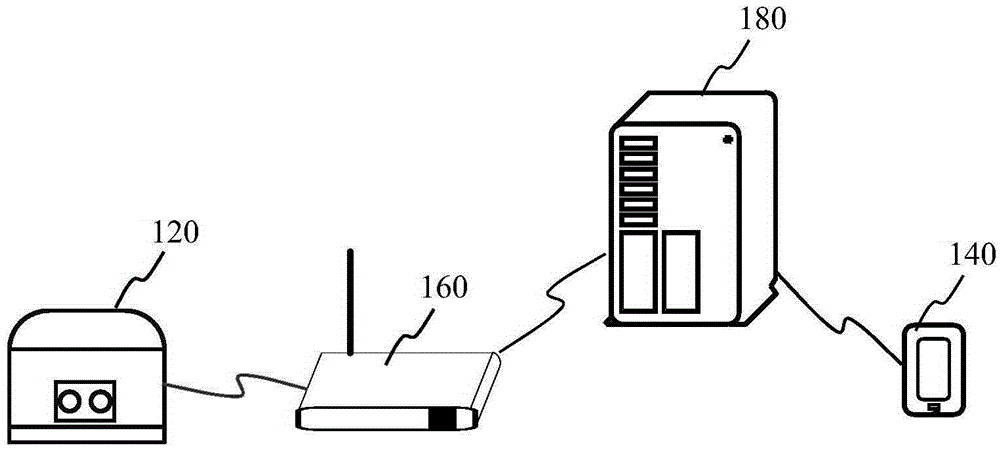

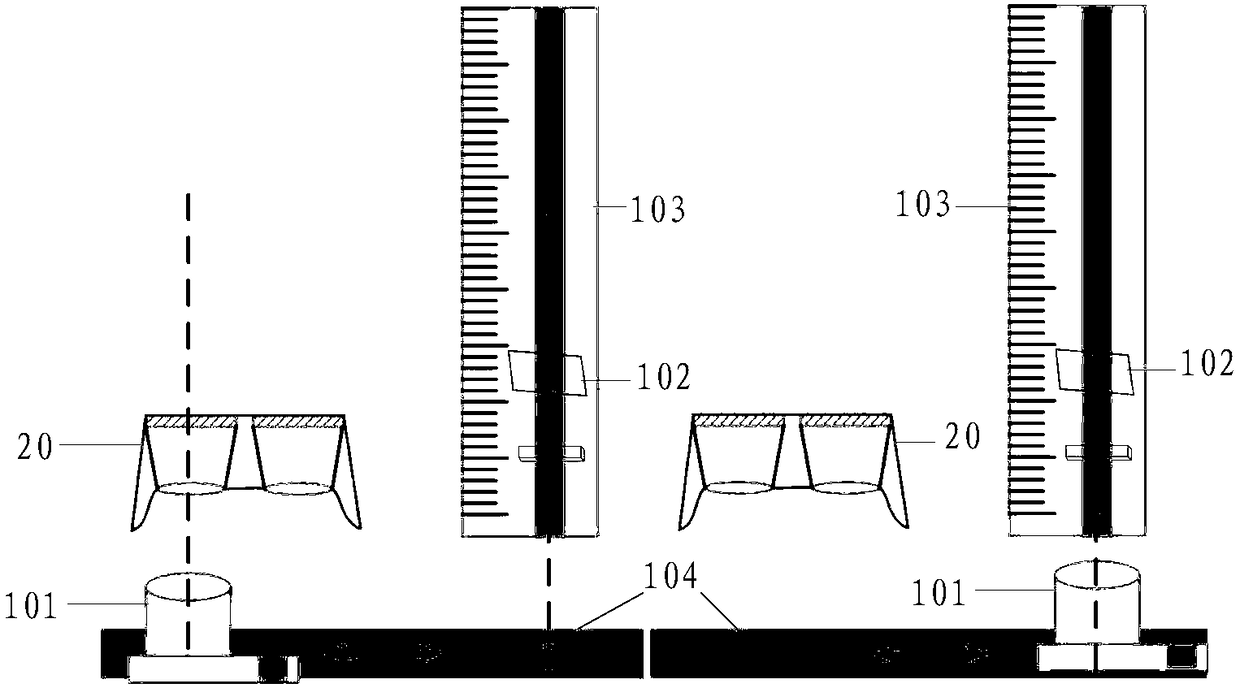

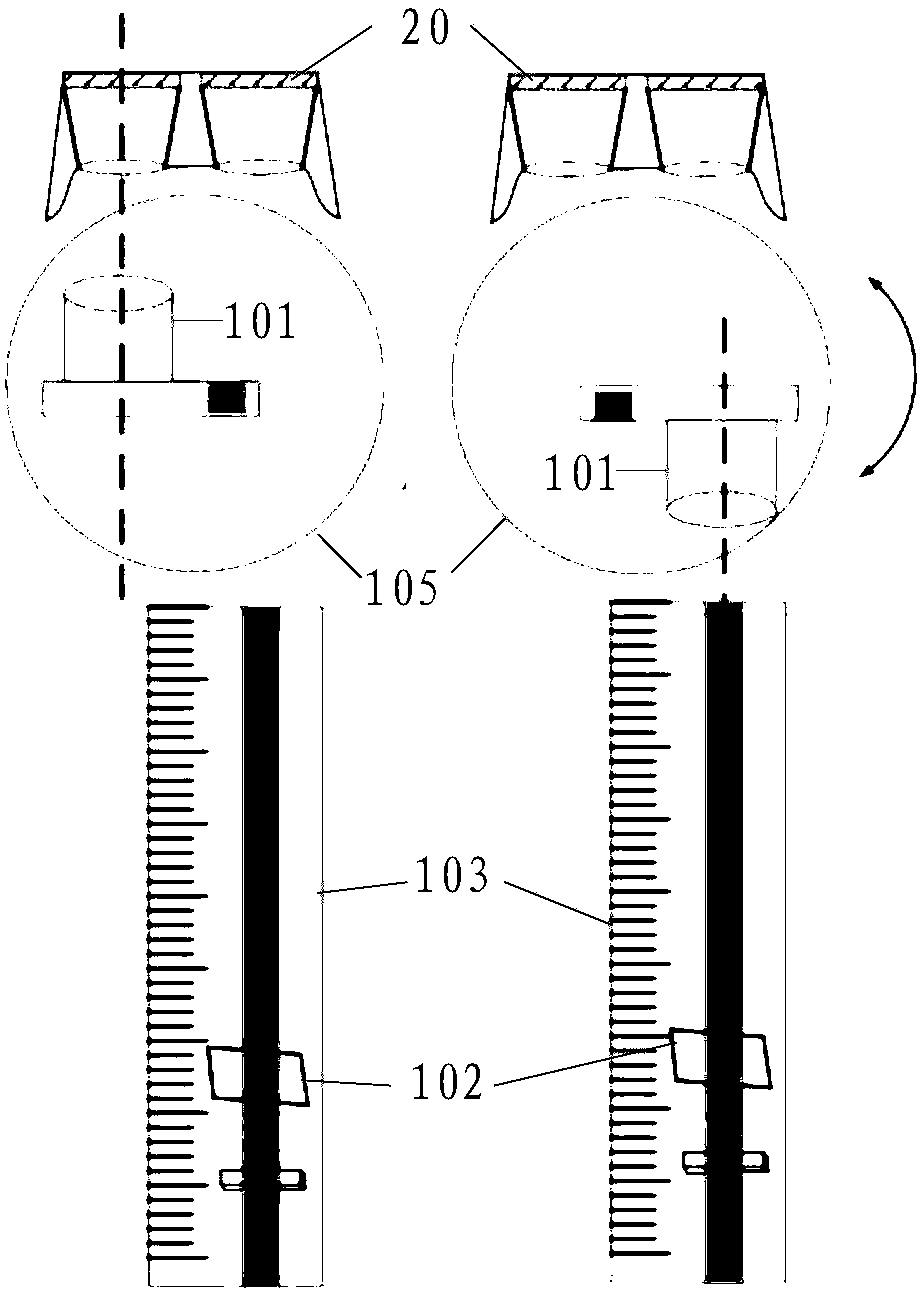

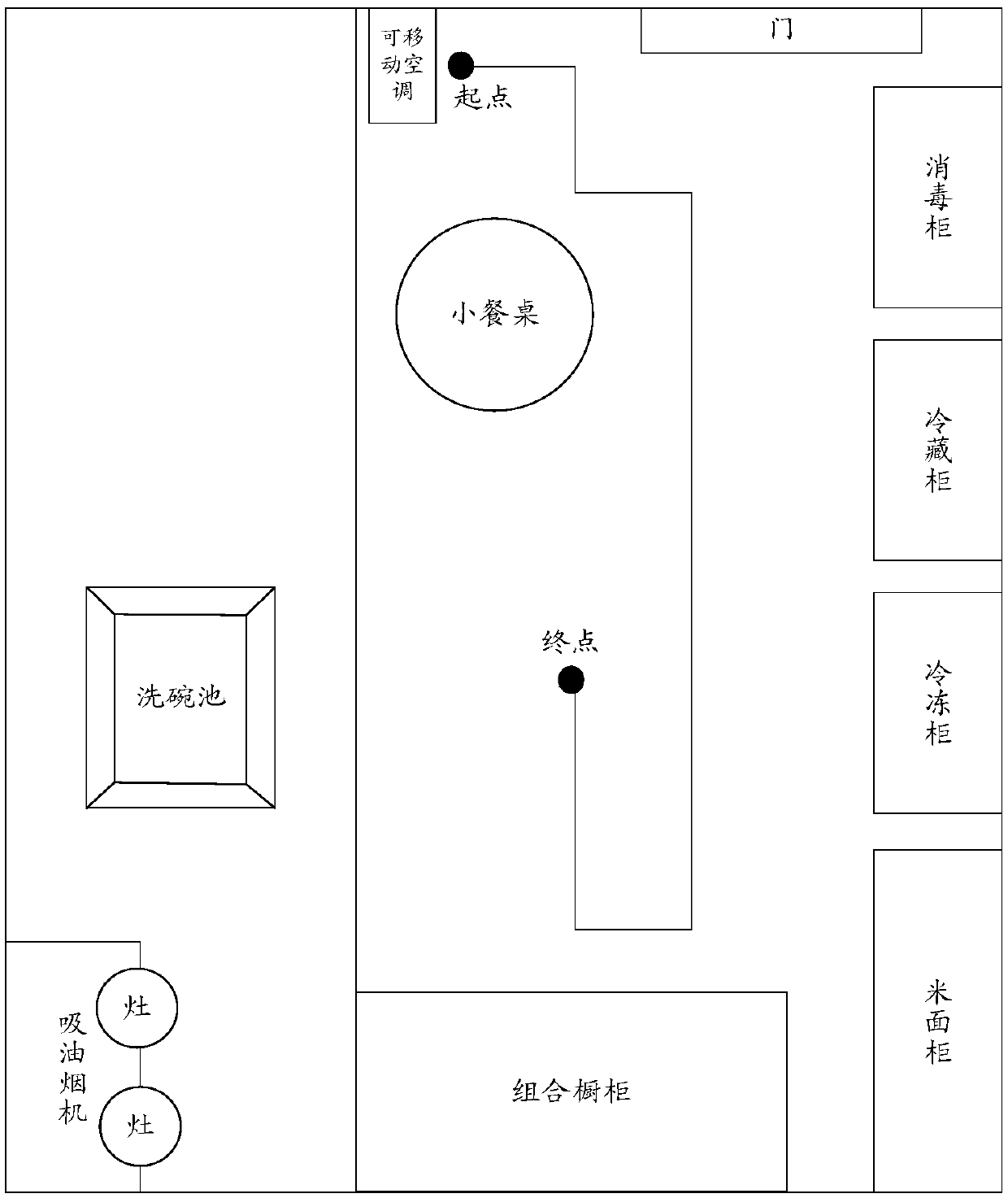

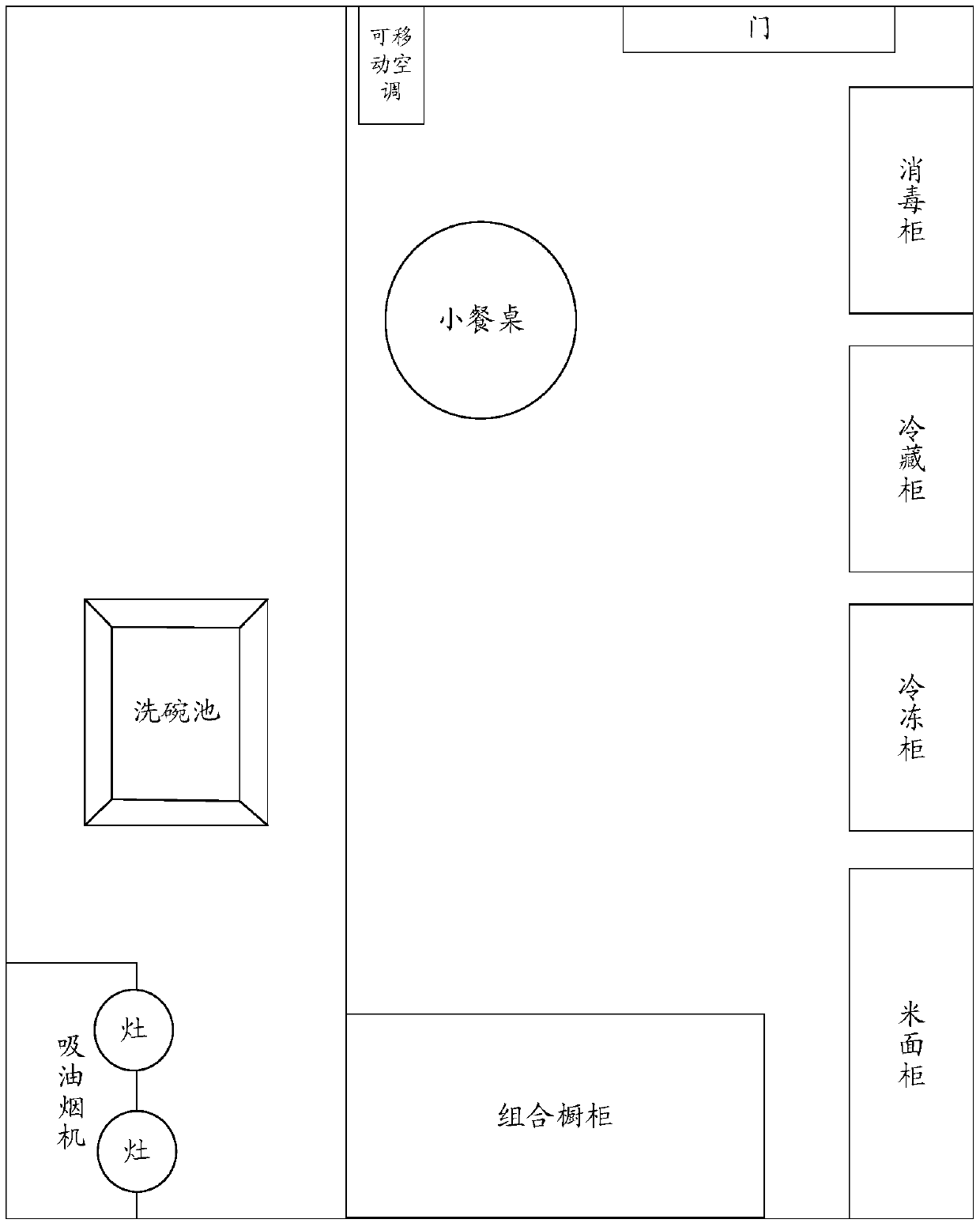

Moving method and equipment of movable temperature adjusting device

ActiveCN109442689AHigh resolution requirementsMechanical apparatusSpace heating and ventilation safety systemsComputer science

The invention discloses a moving method and equipment of a movable temperature adjusting device, and relates to the technical field of communication. The moving method and equipment solve the problemsthat the movable temperature adjusting device needs to support voice or image functions when moving, and therefore requirements for the movable temperature adjusting device are high. The method comprises the steps that a server plans a moving route of the movable temperature adjusting device according to room information of a room which the movable temperature adjusting device is located in and the current position of the movable temperature adjusting device, and the server sends the moving route to the movable temperature adjusting device, and therefore the movable temperature adjusting device can move according to the moving route. The server is adopted to send the moving route to the movable temperature adjusting device, and therefore the movable temperature adjusting device can move based on the moving route sent by the server. The movable temperature adjusting device does not need to support the voice or image functions, and therefore requirements for the movable temperature adjusting device are lowered.

Owner:GREE ELECTRIC APPLIANCES INC

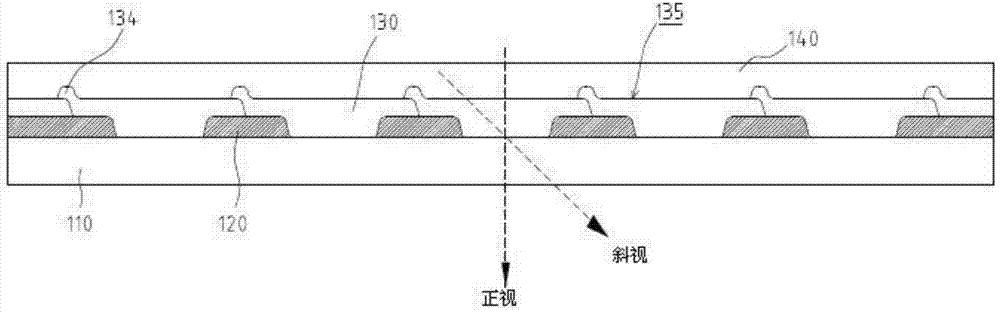

CF (Color Filter) substrate

ActiveCN102830457ADoes not directly affect flatnessImprove flatnessOptical filtersPhotomechanical apparatusPhysicsLight filter

The invention provides a CF (Color Filter) substrate, which can effectively reduce an oblique color cast phenomenon under the condition that the high resolution and the high color saturation are met. The CF substrate is provided with a plurality of color light resistors, wherein two adjacent color light resistors are in mutual contact, the color light resistors are all designed to be arc shapes, i.e. the upper surfaces of the color light resistors are of the arc shapes, a black matrix is positioned between two adjacent color light resistors, covers a part of the color light resistor and is positioned above edge parts of the color light resistors. When the CF substrate is manufactured, a plurality of the color light resistors can be formed on a substrate first, the black matrix can be then formed between the color light resistors and above the edge parts of the color light resistors, and then, a flat layer can be formed on the color light resistors and the black matrix.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

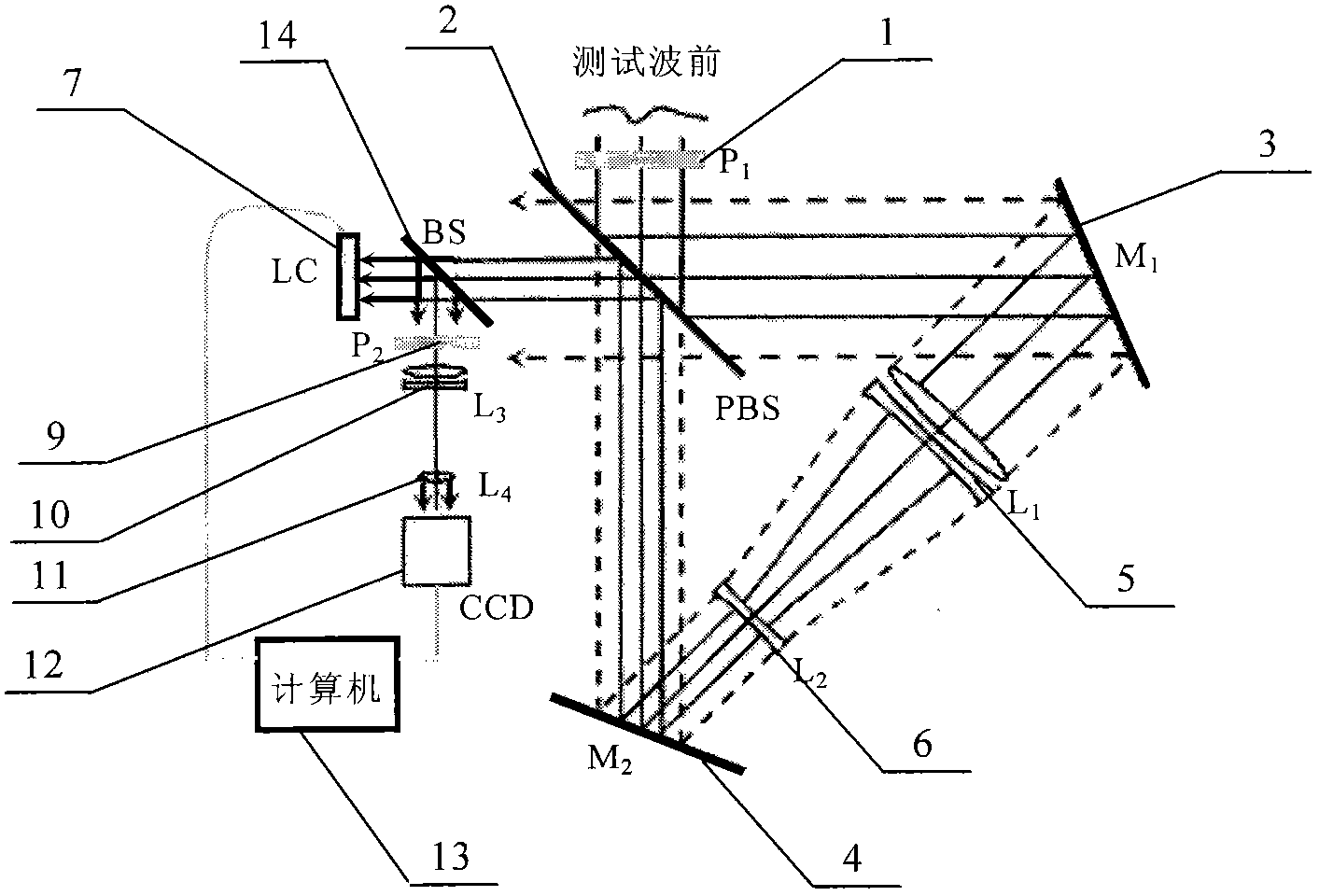

Non-common-optical-path loop radial shear polarization phase shift interferometer

InactiveCN104819780ALow resolutionHigh resolution requirementsOptical measurementsPhase shiftedInterference phenomenon

The invention provides a non-common-optical-path loop radial shear polarization phase shift interferometer which is formed by a polarization modulation system, a loop radial shearing system, an N-step phase shifting system and an imaging system. A detected wave moves forward to enter into the polarization modulation system to be linearly polarized light which goes through the loop radial shearing system to be two beams of widened and narrowed orthogonal polarized light, then the light is processed by the N-step phase shifting system to be two round polarized light with opposite rotation directions, an interference phenomenon is generated through the polarization analyzer, the imaging system collects N interference fringe patterns, a corresponding phase shift algorithm is used to reconstruct the phase distribution shearing wave-front, and an iterative method or Zernike polynomial fitting is used to separate detected wave-front from the shearing wave-front. According to the non-common-optical-path loop radial shear polarization phase shift interferometer, a special reference mirror is not needed, a non-common-optical-path structure is used to reduce the difficulty of alignment, thus the measurement is more simple and convenient, the N-step phase shift technology is used to recover the wave-front, and the data processing speed and arithmetic accuracy of phase extraction are improved.

Owner:SICHUAN UNIV

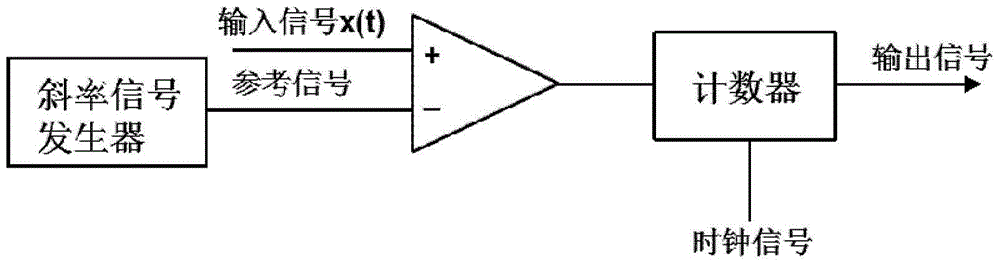

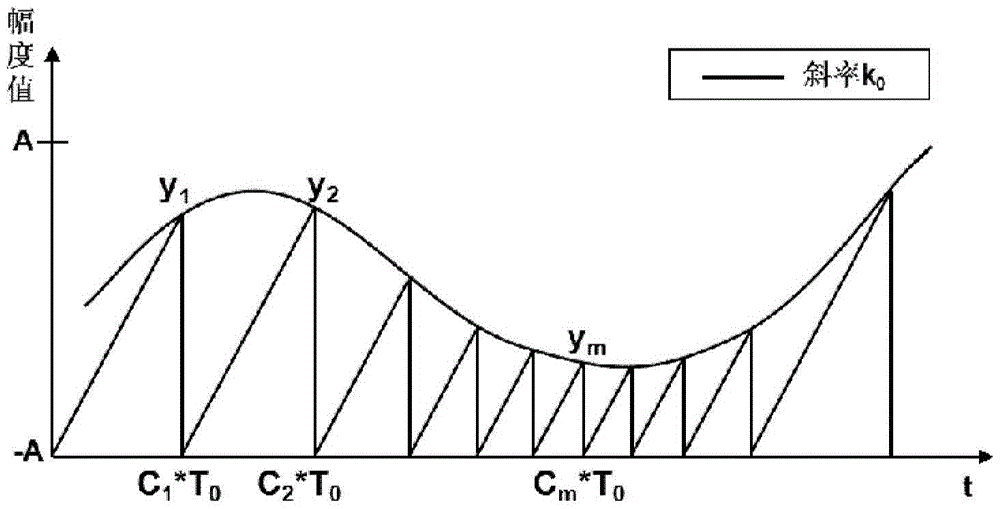

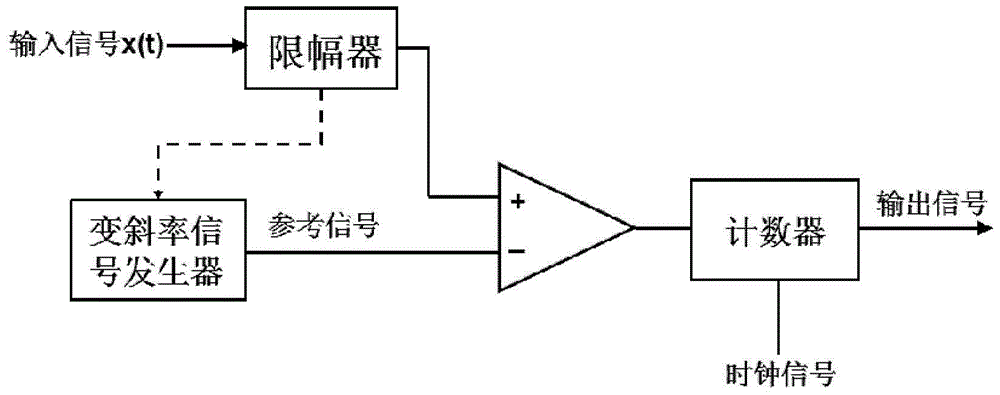

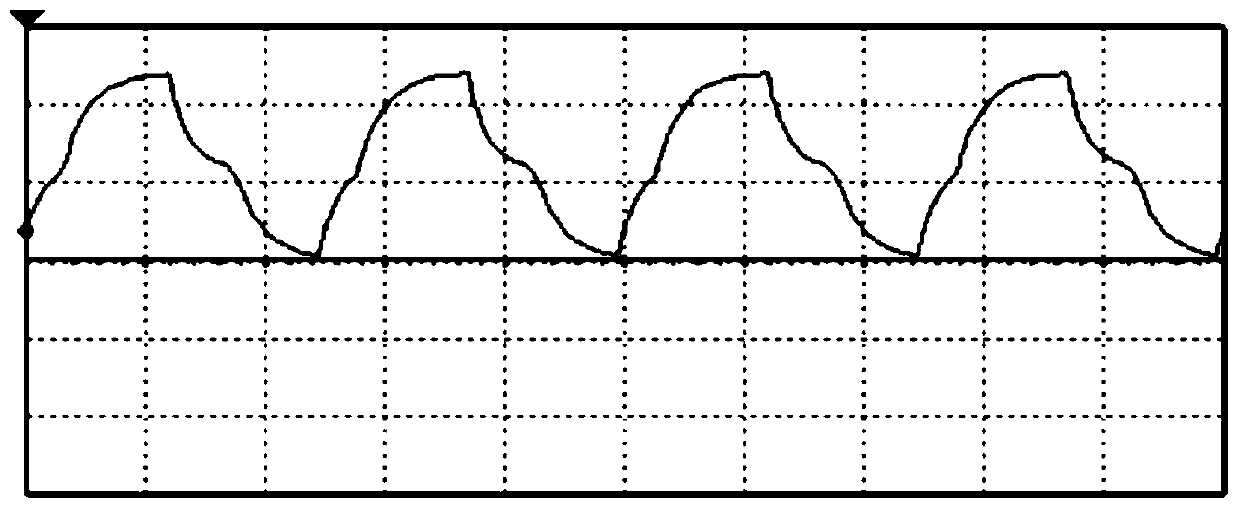

A Random Sampling Slope Analog-to-Digital Converter

ActiveCN103532552BHigh resolution requirementsReduce the sampling frequencyAnalogue-digital convertersDigital down converterControl signal

The invention discloses a random sampling slope analog-to-digital converter, which comprises a slope signal generator, a comparator and a counter connected in sequence, the reference signal generated by the slope signal generator and the input signal from the outside are respectively input to one end of the comparator for comparison The comparison is carried out in the comparator, and the counter starts counting at the same time. The random sampling slope analog-to-digital converter also includes: a limiter, the input signal from the outside is input to one end of the comparator through the limiter, and the limiter is based on The amplitude of the input signal controls the slope signal generator to generate reference signals with different slopes. The invention solves the problem that the existing random sampling slope analog-to-digital converter has a higher sampling frequency when the input signal amplitude is small and a higher requirement on the counter when the input signal amplitude is large.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

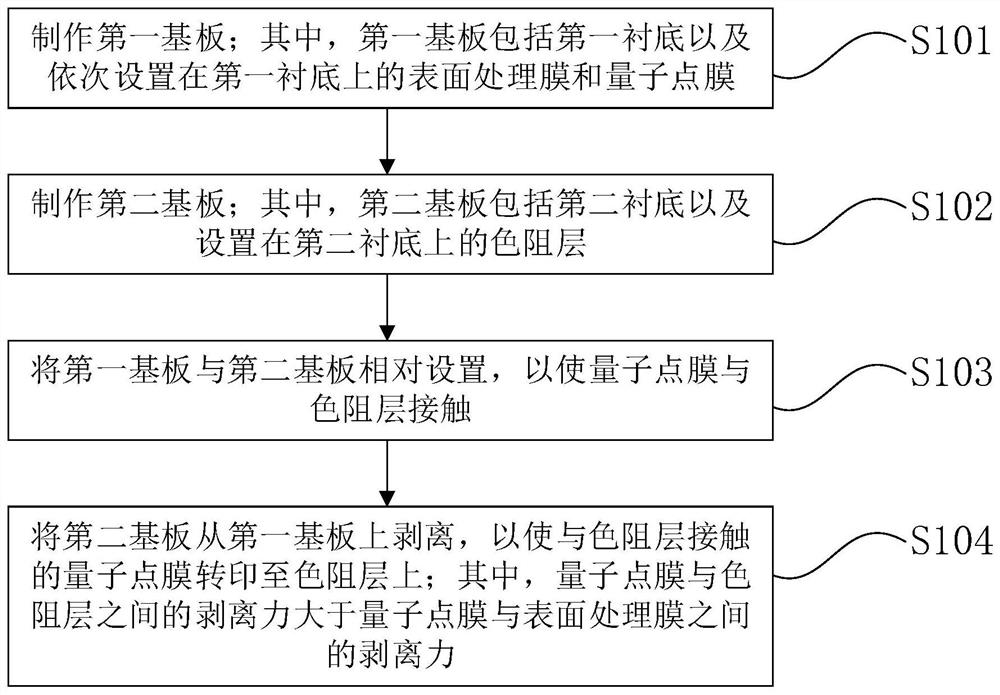

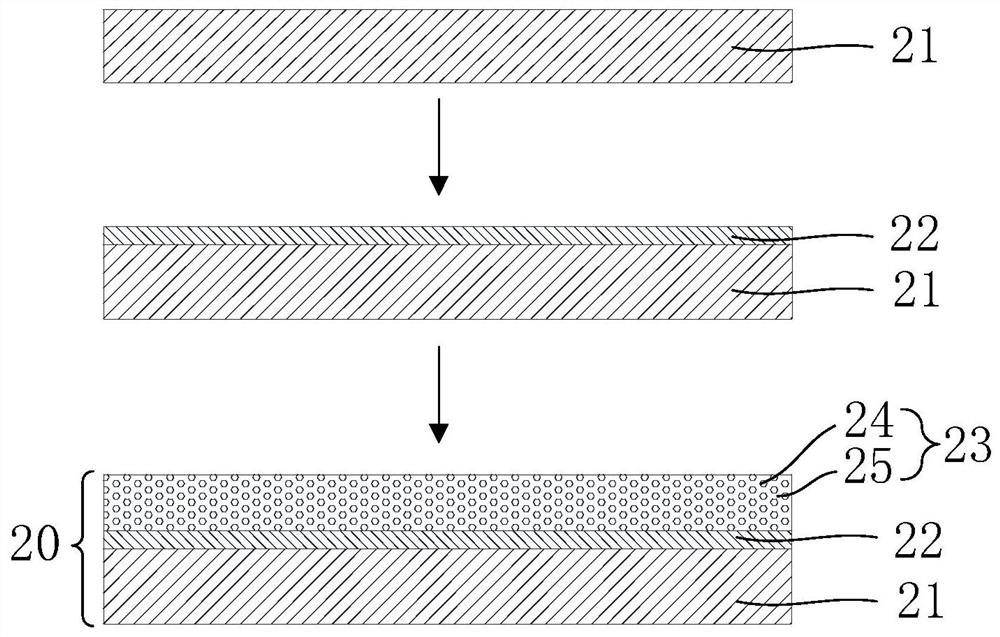

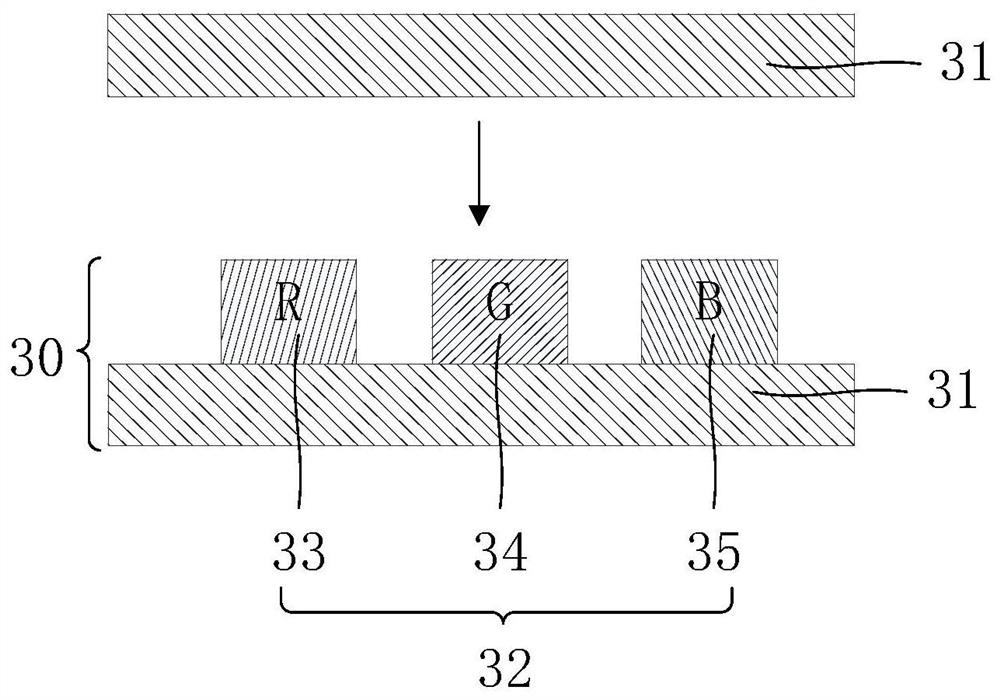

Manufacturing method of quantum dot color filter and display panel

ActiveCN112863377AImprove energy efficiencyAchieve mass productionOptical filtersSolid-state devicesColor gelHigh energy

The invention discloses a manufacturing method of a quantum dot color filter and a display panel. The manufacturing method of the quantum dot color filter comprises the following steps: manufacturing a first substrate, wherein the first substrate comprises a first substrate, and a surface treatment film and a quantum dot film which are sequentially arranged on the first substrate; manufacturing a second substrate, wherein the second substrate comprises a second substrate and a color resistance layer arranged on the second substrate; arranging the first substrate and the second substrate oppositely, and enabling the quantum dot film to be in contact with the color resistance layer; and stripping the second substrate from the first substrate, and enabling the quantum dot film in contact with the color resistance layer to be transferred to the color resistance layer, wherein the stripping force between the quantum dot film and the color resistance layer is greater than the stripping force between the quantum dot film and the surface treatment film. The quantum dot color filter with high energy efficiency, high resolution and high contrast can be obtained, and mass production of the display panel containing the quantum dot color filter can be realized.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

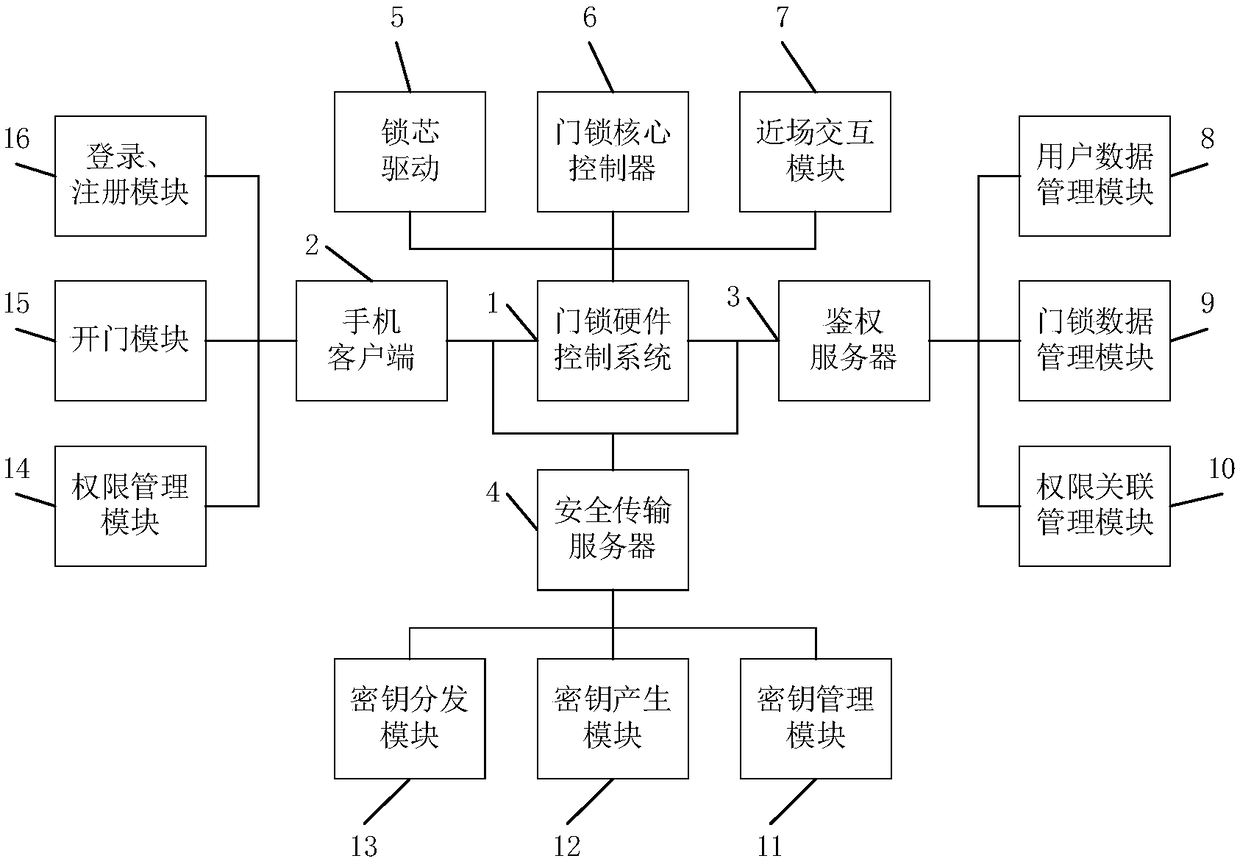

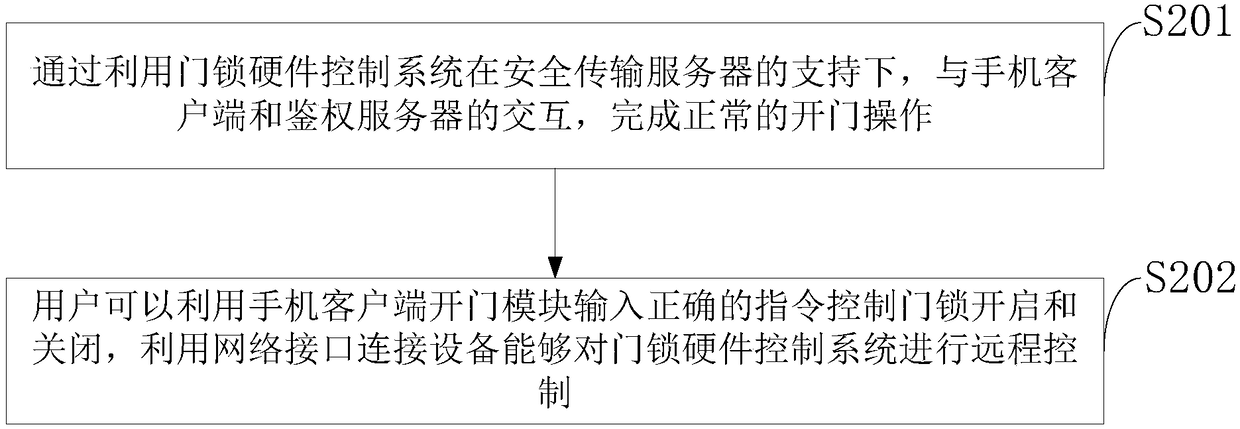

NFC based safe intelligent hotel access control system and method

ActiveCN109493493ASolve the short board that is easy to be lost and copiedHigh resolution requirementsIndividual entry/exit registersSecure transmissionControl system

The invention belongs to the technical field of hotel access, and discloses an NFC based safe intelligent hotel access control system and method. One end of a door lock hardware control system is connected with an authentication server through network, and the other end of the door lock hardware control system is connected with a mobile phone client through NFC; the authentication server is provided with a user data management module, a door lock data management module and a permission association management module; the mobile phone client is provided with a logon module, a registration module, a door-open module and an authentication module. According to the system, the door lock hardware control system is interacted with the mobile phone client and the authentication server under supportof a safe transmission server to complete normal door opening operation, a user can input a command by utilizing the door-open module of the mobile phone client to control open and close of a door lock, and the door lock hardware control system can be controlled remotely by utilizing network interface connection equipment. The system has a reasonable structure, and the safety of a hotel can be effectively improved.

Owner:XIDIAN UNIV

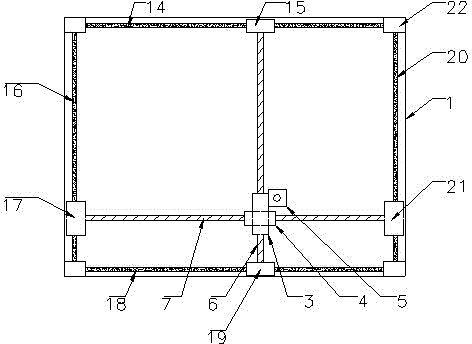

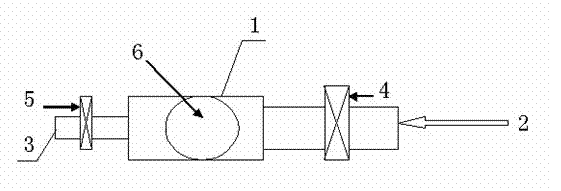

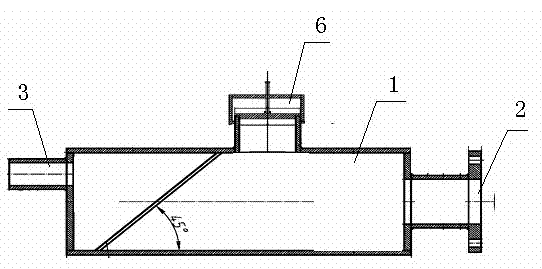

Direct-blowing cement sampler

InactiveCN103033396AReduce pollutionEasy to operateWithdrawing sample devicesInlet valveMaterials science

The invention relates to a direct-blowing cement sampler which is characterized in that the direct-blowing cement sampler comprises a sample cylinder (1), wherein a sample cylinder inlet (2) is formed at one end of the sample cylinder (1); a sample cylinder outlet (3) is formed at the other end of the sample cylinder (1); the sample cylinder inlet (2) is connected with an inlet valve (4) by a flange; the sample cylinder outlet (3) is connected with an outlet valve (5) by a flange; and a sample cylinder cover (6) is arranged in the middle of the sample cylinder (1). The sampler solves the problems that pipelines and gates are more, and requirements on operators are high. The sampler can ensure correct cement mixing procedures and correct operation.

Owner:CHANGQING GUJING OF CNPC CHUANQING DRILLING ENG

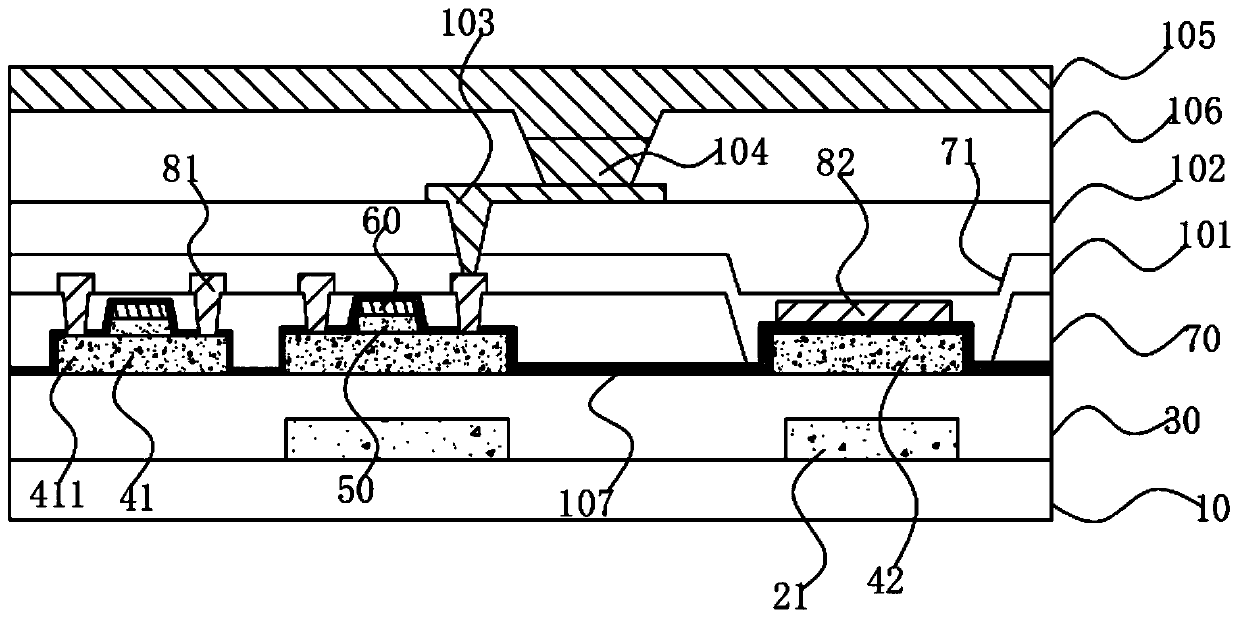

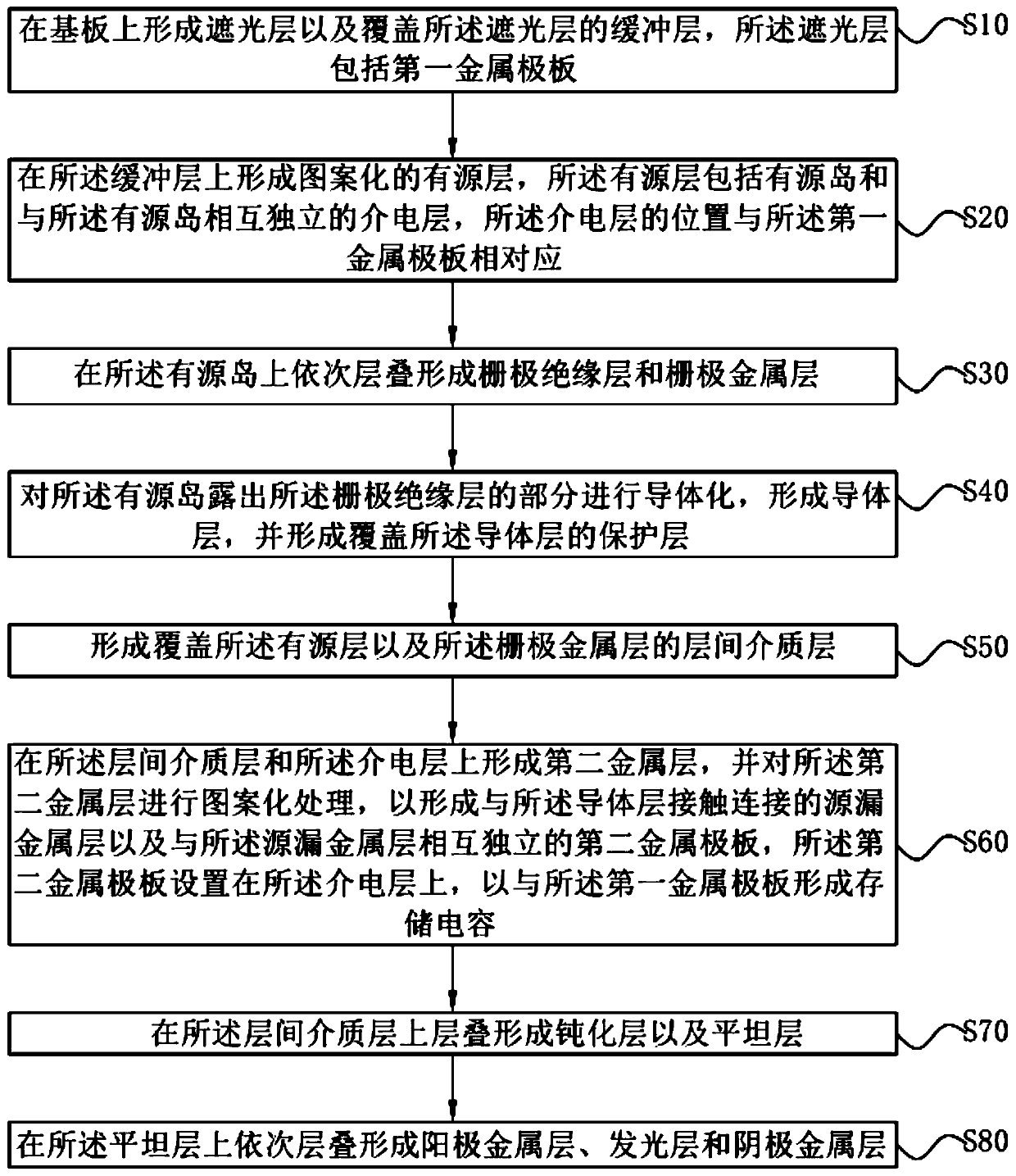

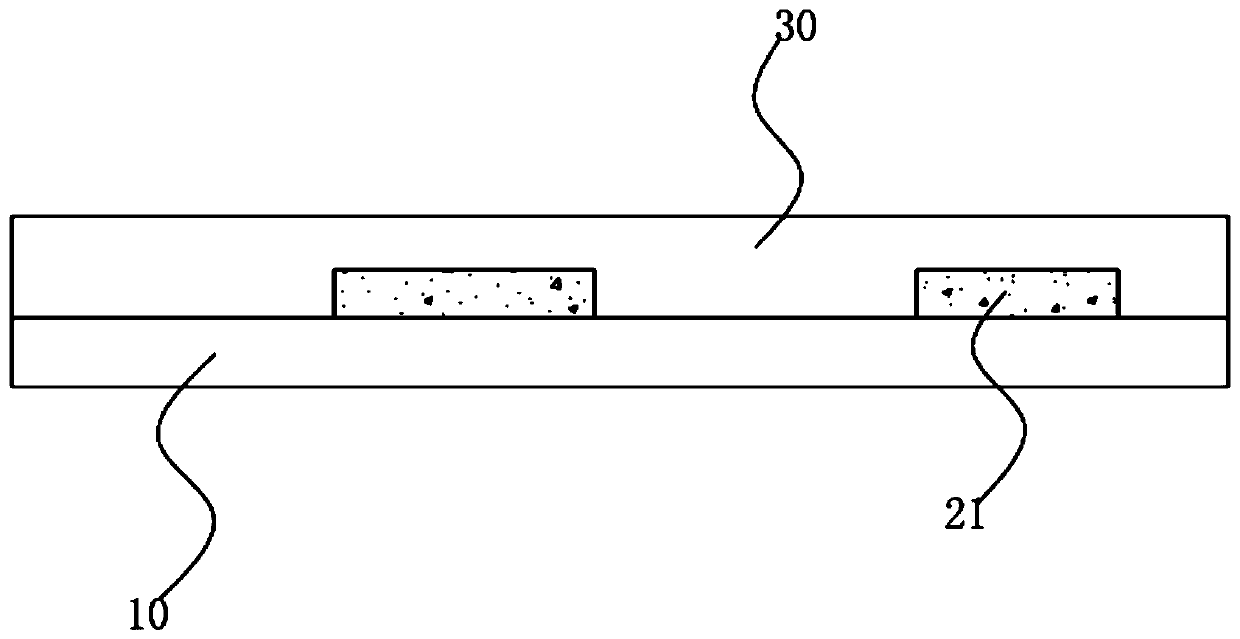

Display panel and preparation method thereof

ActiveCN110571226AIncrease resistanceIncrease capacitance per unit areaSolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceCapacitance

The invention provides a display panel and a preparation method thereof. The display panel comprises a substrate, a shading layer arranged on the substrate, a buffer layer covering the shading layer,an active layer arranged on the buffer layer, a gate insulating layer, a gate metal layer, an interlayer dielectric layer and a second metal layer arranged on the interlayer dielectric layer, whereinthe gate insulating layer and the gate metal layer are stacked on the active layer, the interlayer dielectric layer is arranged on the buffer layer and covers the gate metal layer; the active layer comprises an active island, the active island comprises a conductor layer and a semiconductor layer which corresponds to and is in contact with the gate insulating layer, and the conductor layer is provided with a protective layer. The aluminum oxide protective layer with a compact structure is generated on the surface of the conductor layer by utilizing a mutual diffusion effect of aluminum atoms and oxygen atoms in the indium gallium zinc oxide, so that the conductor layer after conductor formation is protected, and the conductor layer is prevented from being influenced by the subsequent manufacturing process; and meanwhile, the aluminum oxide has the characteristic of high resistance, so that the capacitance per unit area of the storage capacitor can be effectively improved, and the requirement of high resolution is met.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

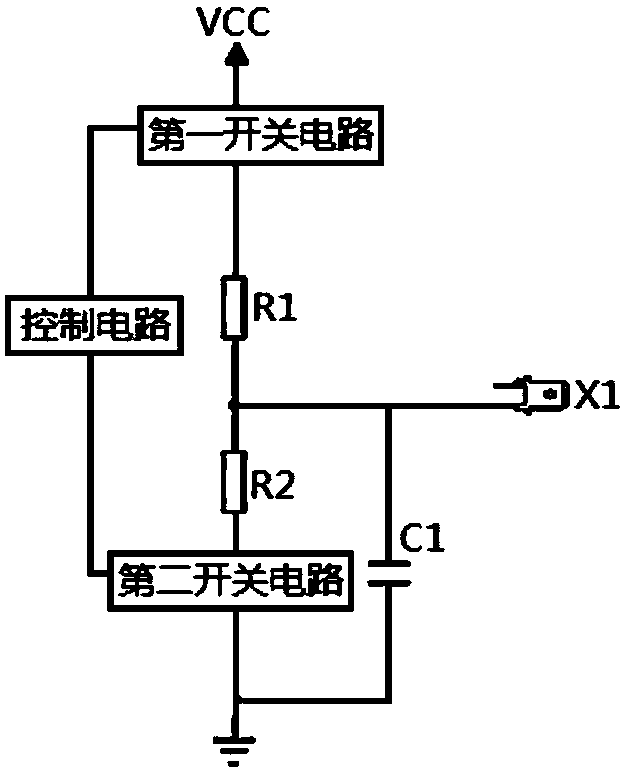

Frequency signal generating circuit and liquid level detecting circuit

PendingCN110617866ASolve detection inaccuracyThe water level and voltage are stableLevel indicators by physical variable measurementElectric variable regulationCapacitanceEngineering

The invention discloses a frequency signal generating circuit and a liquid level detecting circuit, and the frequency signal generating circuit comprises the following parts of a DC power source VCC,a first switch circuit, a first resistor R1, a second resistor R2 and a second switch circuit that are connected in series, wherein the other end of the second switch is grounded; the first switch circuit and the second switch circuit are respectively connected to a control circuit for controlling the on / off thereof; and a first capacitor C1 connected in parallel with the second resistor R2 and the second switch circuit, wherein a first joint X1 is connected between the first resistor R1 and the second resistor R2. The invention controls the opening and closing cycles of the first switch circuit and the second switch circuit to control the charging and discharging of the first capacitor C1, thereby generating a high-frequency AC signal. High-frequency AC signals can be generated by using only a DC power source, thereby simplifying requirements on the power source.

Owner:GREE ELECTRIC APPLIANCES INC

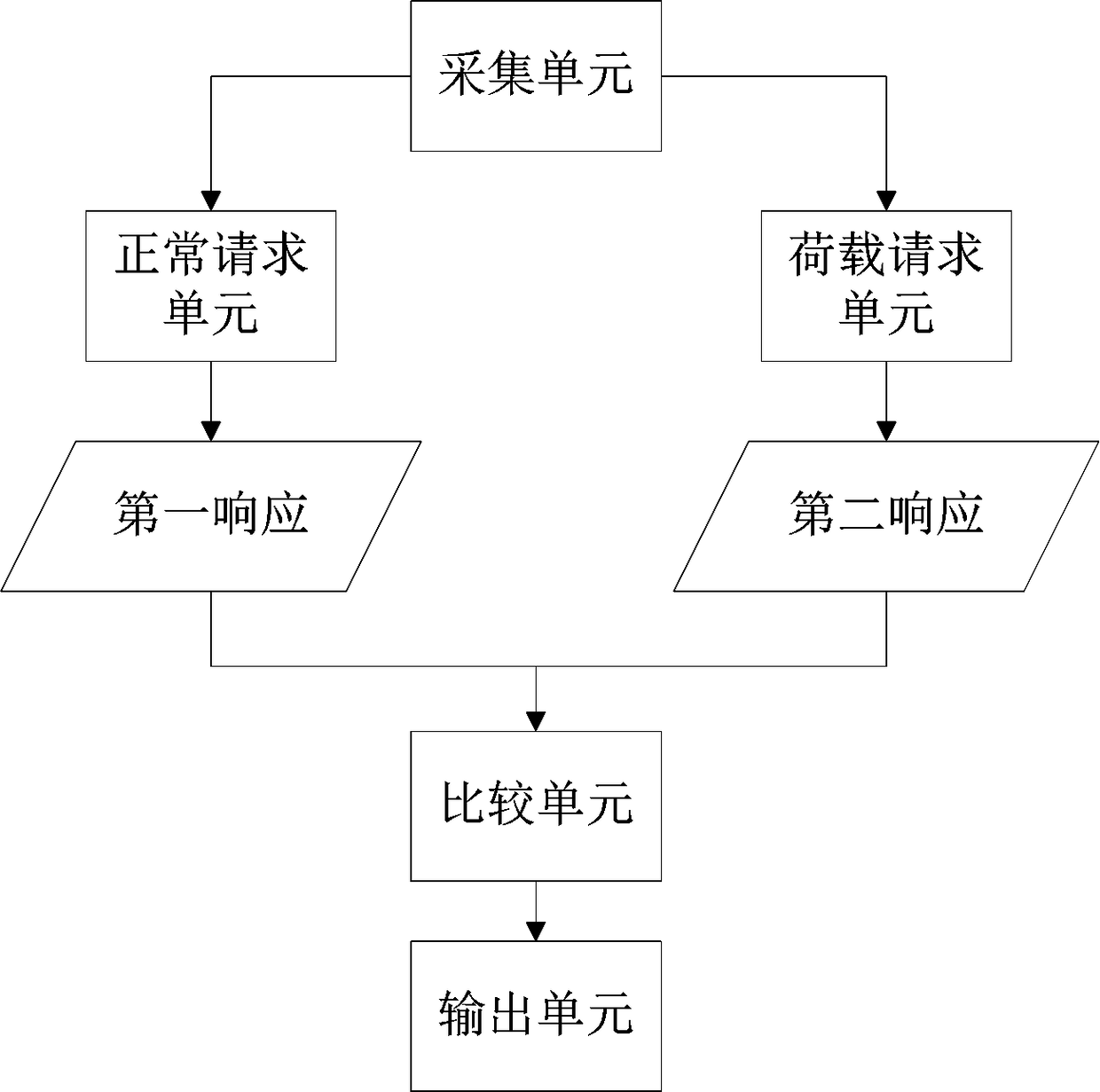

EL expression injection vulnerability batch detection device and method

InactiveCN109450846AEasy to operateHigh resolution requirementsTransmissionWeb data retrieval using information identifiersTime costUniform resource locator

The invention relates to an EL expression injection vulnerability batch detection device and method. A collection unit collects a URL file; a first response of a server is obtained based on a normal HTTP request; an HTTP request is sent based on an EL expression injection detection statement; a second response of the server is obtained; difference between the first response and the second responseis compared; and if the first response does not has an execution result of the detection statement and the second response exists, vulnerabilities exist, and a detection result is output and stored.According to the detection device and method, the requirement of batch vulnerability detection is met; the collection of a URL containing a keyword or the manual importing of files of URLs needing tobe detected is supported; the problems of low efficiency, time waste and high security tester requirements in testing the EL expression injection vulnerabilities are solved; the detection coverage rate is improved; the labor time cost is greatly reduced; the operation of a security tester is simplified; and the detection result is automatically generated for reference.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

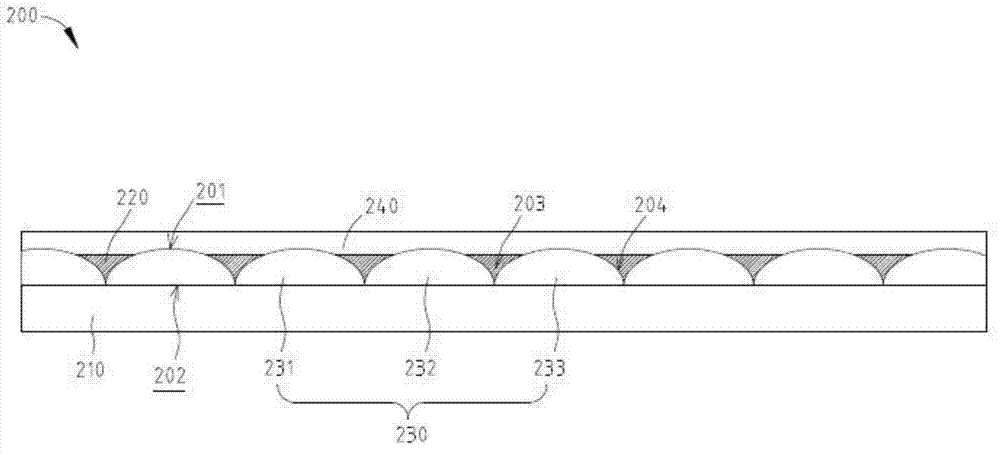

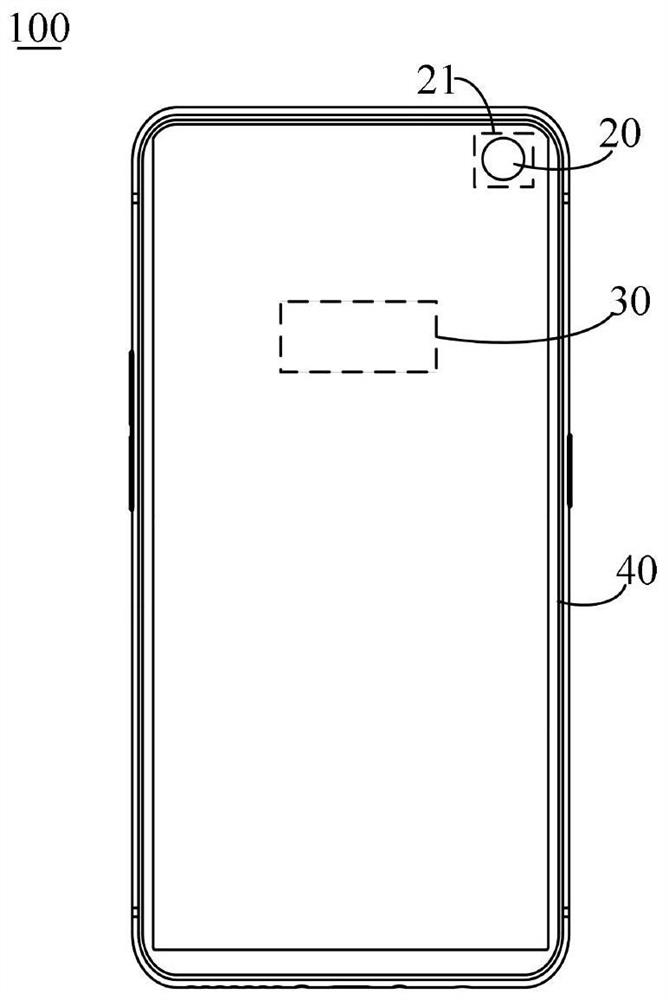

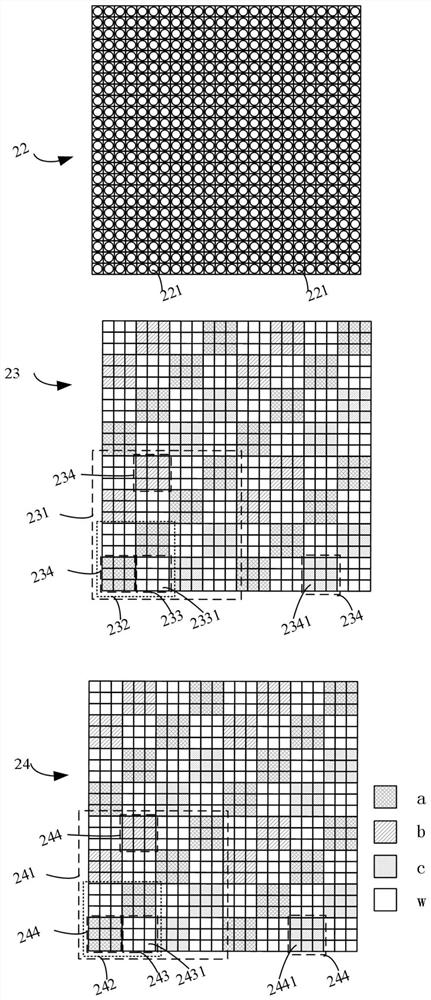

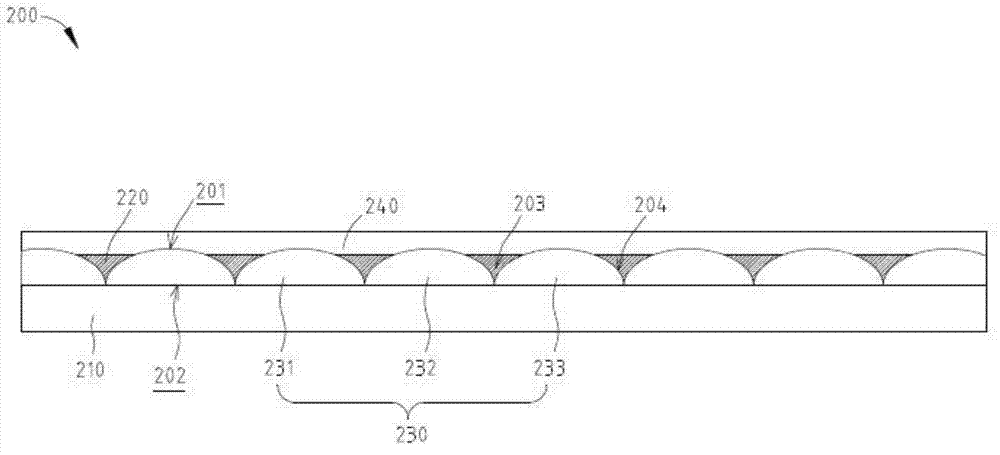

Image sensor, image generation method and device and electronic equipment

PendingCN113840067AImprove quality requirementsNarrow spectral responseTelevision system detailsColor television detailsColor gelImage resolution

The invention relates to an image sensor, an image generation method and device, electronic equipment and a storage medium. The image sensor 21 comprises a filter array 23 and a pixel array 24, the filter array 23 comprises a minimum repeating unit 231, the minimum repeating unit 231 comprises a plurality of filter groups 232, the filter groups 232 comprise a panchromatic filter 233 and a color filter 234, the color filter 234 has a narrower spectral response than the panchromatic filter 233, each of the color optical filter 234 and the panchromatic optical filter 233 comprises nine sub optical filters; the pixel array 24 comprises a plurality of pixels, the pixels of the pixel array 24 and the sub-filters of the optical filter array 23 are correspondingly arranged, and the pixel array 24 is configured to be used for receiving light rays penetrating through the optical filter array 23 to generate electric signals. By adopting the image sensor, images with various resolutions can be output so as to adapt to different application scenes.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

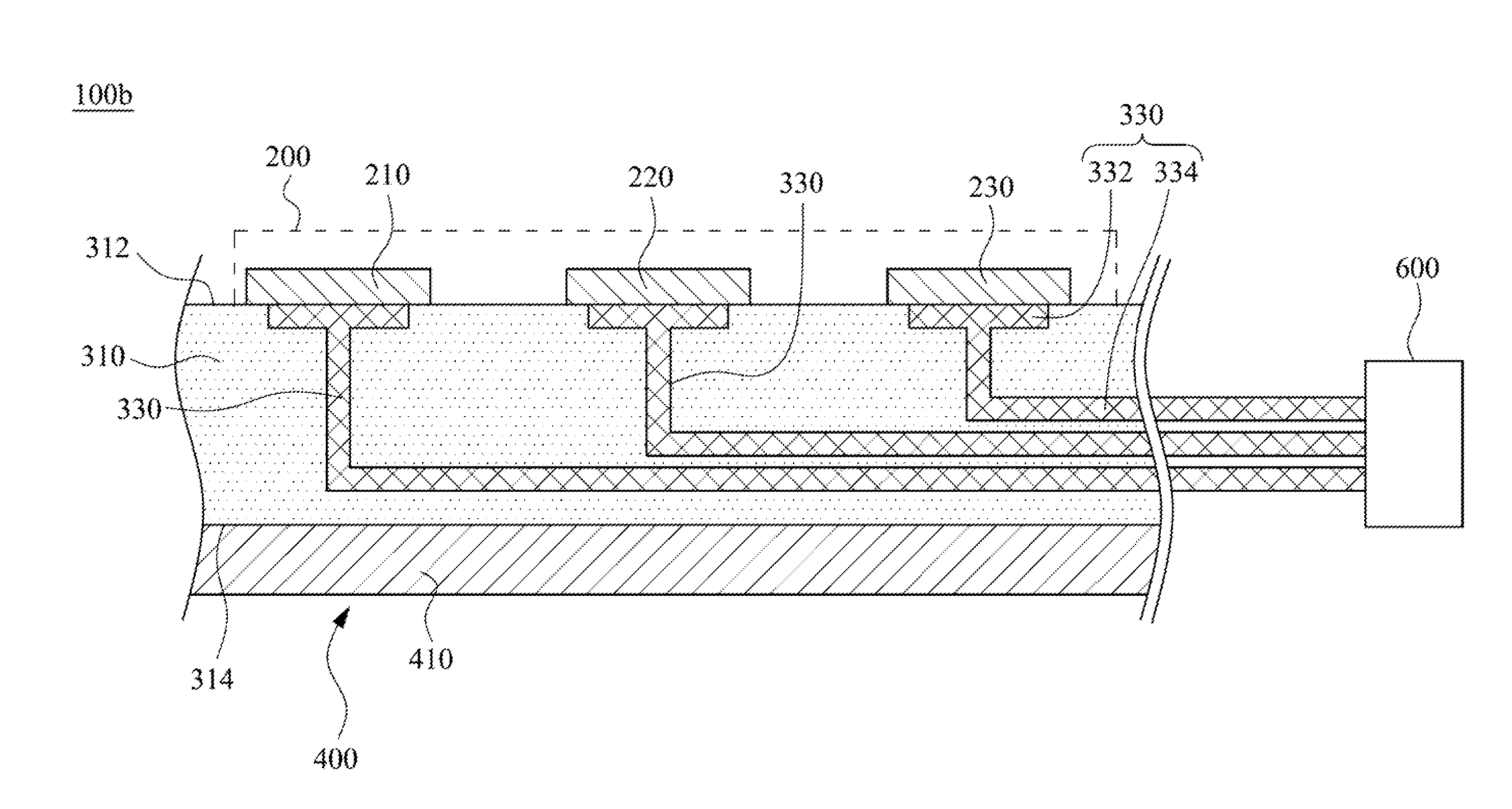

Display apparatus, display module and pixel structure thereof

ActiveUS20150371976A1High resolution requirementsReduce intervalStatic indicating devicesSemiconductor/solid-state device detailsFlexible circuitsComputer module

Owner:E INK HLDG INC

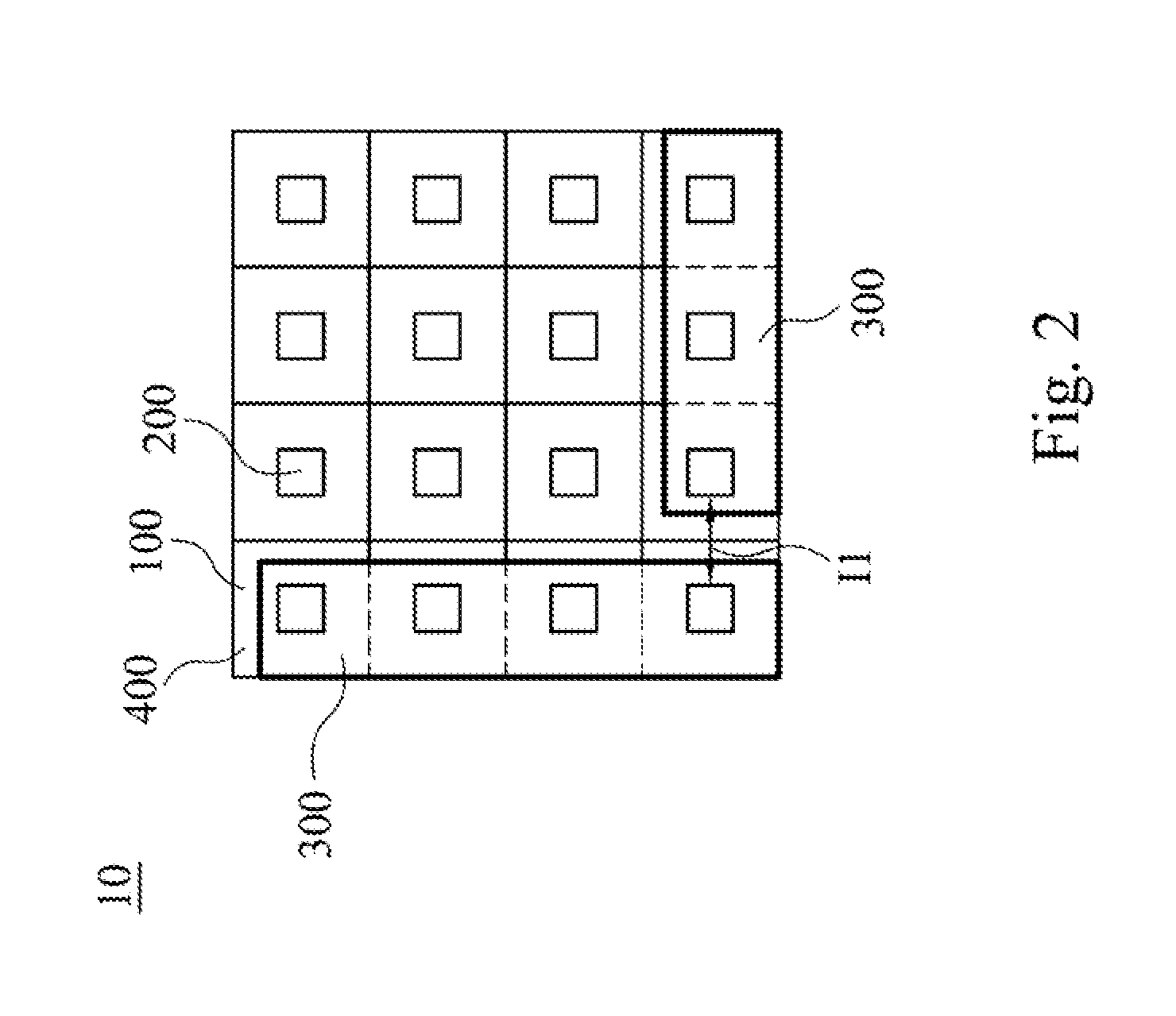

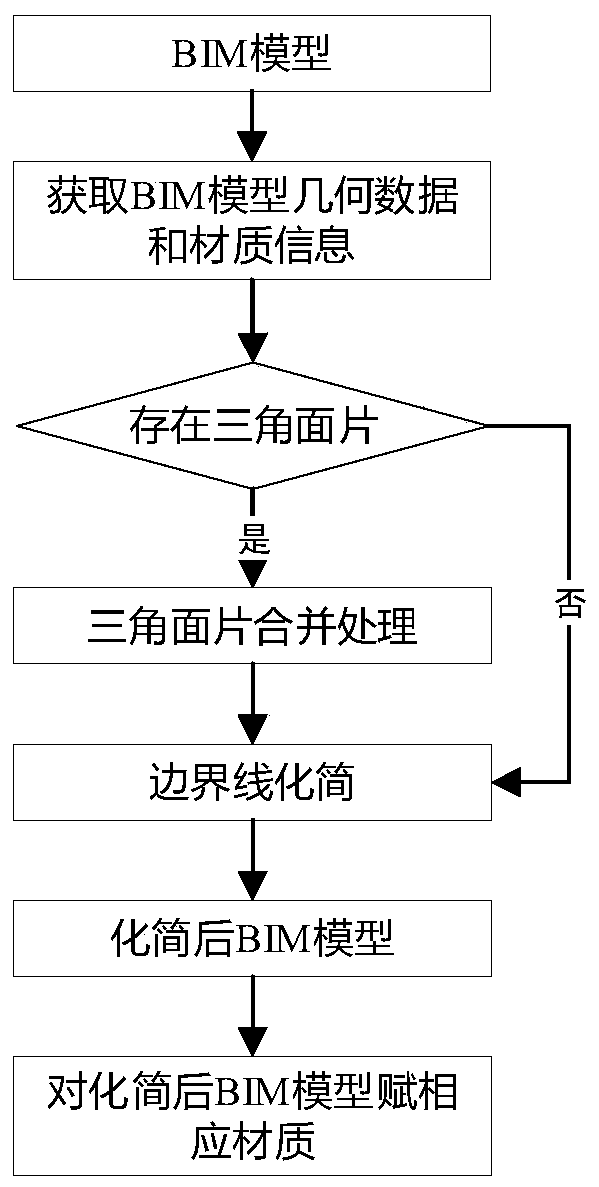

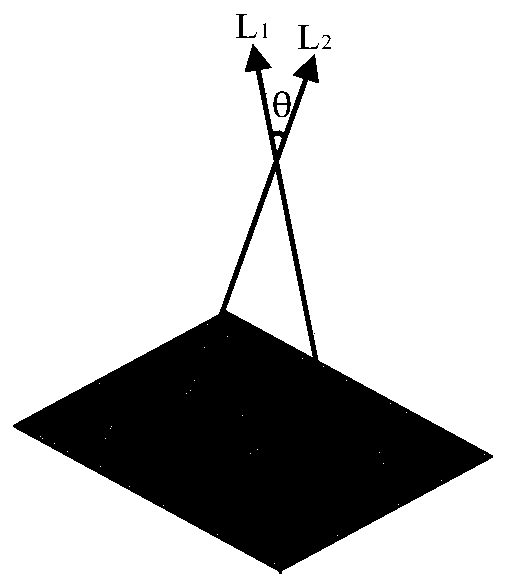

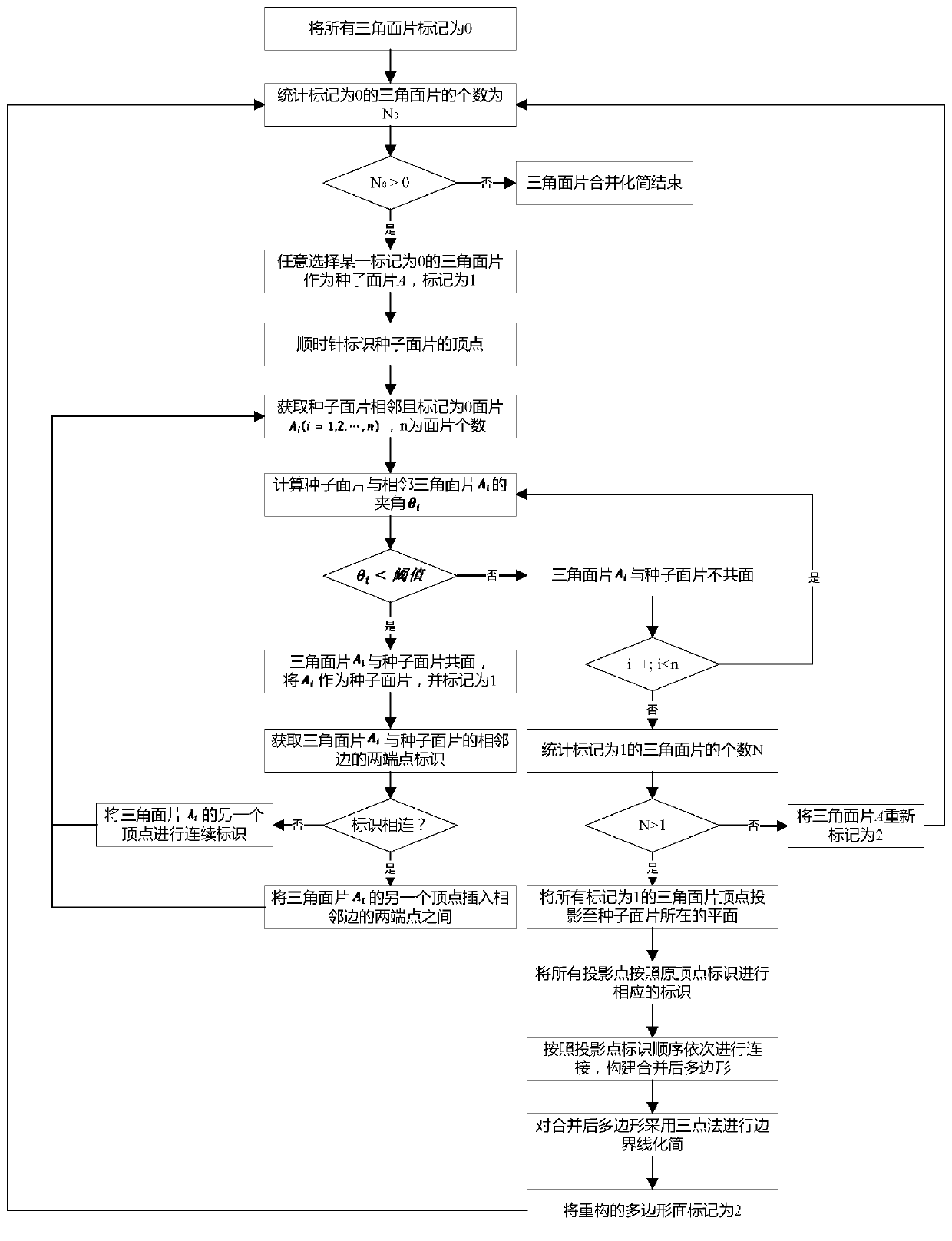

Geometric figure simplification method for BIM model

PendingCN110675508ASmooth browsing and managementHigh resolution requirementsImage data processingTriacontagonEngineering

The invention discloses a geometric figure simplification method for a BIM model. The geometric figure simplification method comprises the following steps: 1, acquiring surface geometric data of a BIMmodel body; 2, judging whether a certain grid surface of the BIM model is a triangular surface or not; judging whether the grid is a triangular patch or not according to the number of vertexes of a certain grid of the BIM model; when the polygon is a triangular surface, carrying out triangular patch merging simplification on the polygon, and then carrying out boundary line simplification on the merged polygon by adopting a three-point method; 3, according to a short edge principle, moving a point deleted after simplifying the boundary line of the polygon to the other vertex of the short edgein the adjacent edges; and 4, according to the obtained material information, endowing the simplified model with corresponding material attributes according to grid division. According to the geometric figure simplification method, simplification of triangular patches and boundaries of geometric data of the BIM model can be quickly realized; and by judging the shapes after combination, the advantages of the original geometric figure characteristics of the BIM model can be reserved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +1

A color filter substrate

ActiveCN102830457BDoes not directly affect flatnessImprove flatnessOptical filtersPhotomechanical apparatusOptoelectronicsHigh color

The invention provides a CF (Color Filter) substrate, which can effectively reduce an oblique color cast phenomenon under the condition that the high resolution and the high color saturation are met. The CF substrate is provided with a plurality of color light resistors, wherein two adjacent color light resistors are in mutual contact, the color light resistors are all designed to be arc shapes, i.e. the upper surfaces of the color light resistors are of the arc shapes, a black matrix is positioned between two adjacent color light resistors, covers a part of the color light resistor and is positioned above edge parts of the color light resistors. When the CF substrate is manufactured, a plurality of the color light resistors can be formed on a substrate first, the black matrix can be then formed between the color light resistors and above the edge parts of the color light resistors, and then, a flat layer can be formed on the color light resistors and the black matrix.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

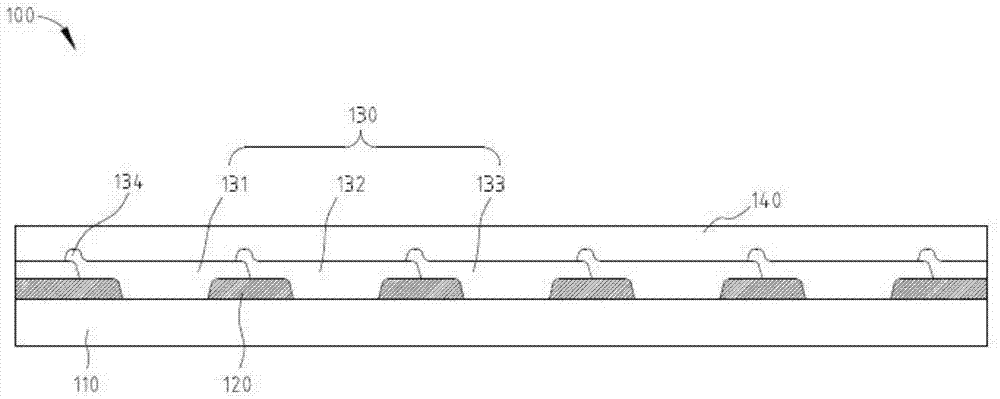

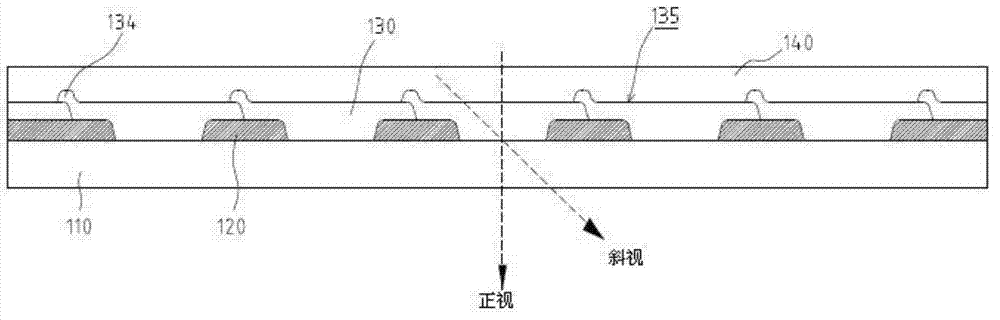

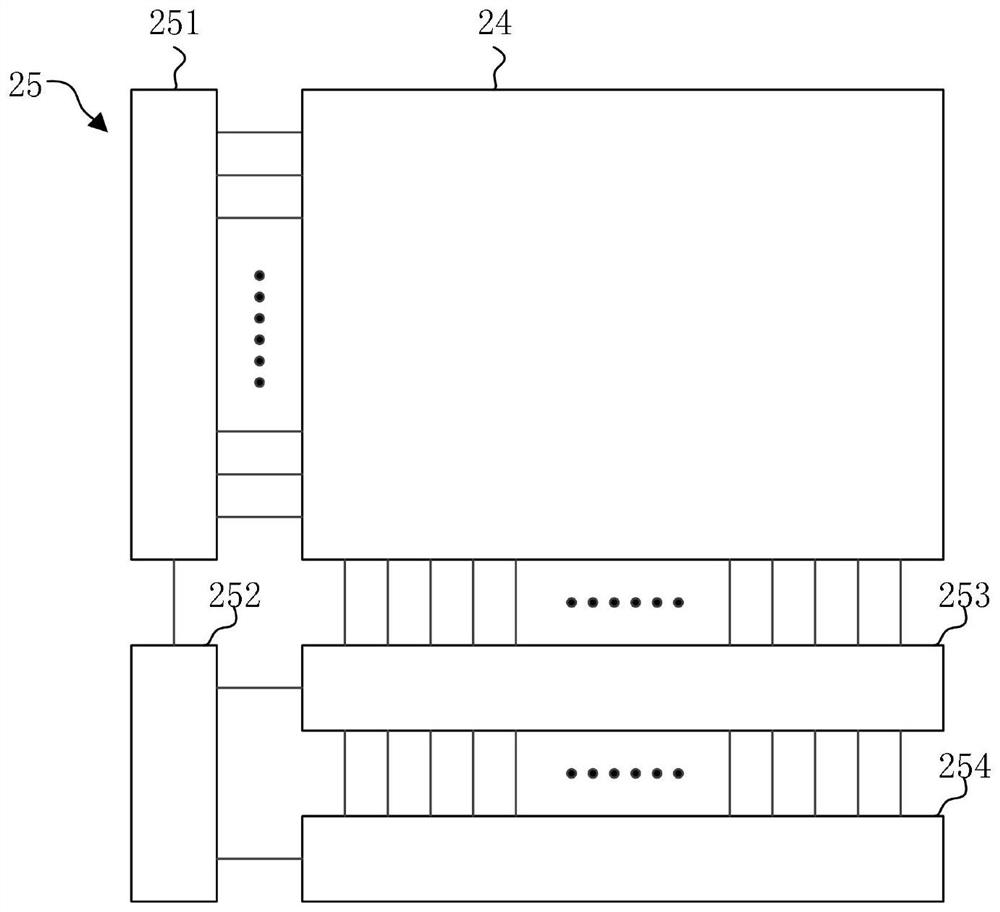

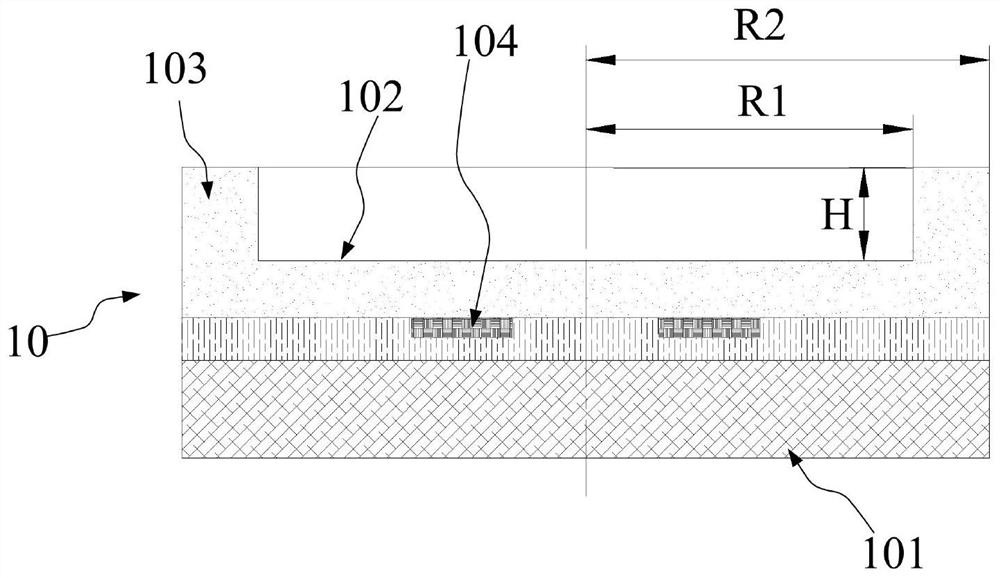

Display device, method for manufacturing display device, and display unit

ActiveCN110429196AAvoid light lossAvoid crosstalkSolid-state devicesSemiconductor/solid-state device manufacturingImaging qualityDisplay device

The present invention relates to a display device, a method for manufacturing the display device, and a display unit. The display device includes: a TFT array substrate; a light-emitting layer disposed on the TFT array substrate and including a plurality of pixel units; and a scattering layer disposed between the TFT array substrate and the light-emitting layer and including a light-blocking separating wall and a plurality of scattering units separated by the light-blocking separating wall, wherein the scattering units and the pixel units correspond to each other one to one. The display device, by means of the scattering layer arranged between the substrate and the light-emitting layer and having scattering units corresponding to the pixel units of the light-emitting layer one to one, canprevent a light loss in a waveguide mode and improve light-emitting efficiency. In addition, the light-blocking separating wall can prevent crosstalk caused by the scattered light between adjacent pixel units and avoid a fuzzy phenomenon. The scattering layer can also improve an image quality loss caused by the uneven arrangement of factor pixels, and achieves the display effect of a high-resolution display, thereby satisfying a requirement for high resolution.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

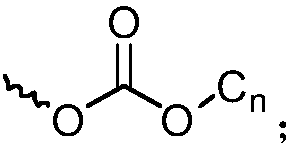

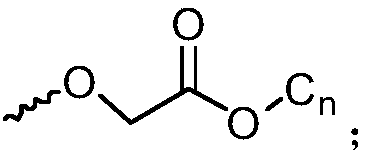

Octaphenyl substituted polyhedral oligomeric silsesquioxane derivative molecular glass and application thereof

ActiveCN108314785AThe synthesis process is simpleHigh yieldPhotomechanical apparatusPhenyl groupPhotoresist

The invention discloses octaphenyl substituted polyhedral oligomeric silsesquioxane derivative molecular glass, which has the following molecular structure: the molecular structure is shown in the description, wherein substituent groups R1 to R24 are respectively hydrogen atom, hydroxyl group or acid-sensitive substituent group; the substituent groups R1 to R24 may be the same or different, but the three substituent groups on a same benzene ring cannot be hydrogen atom simultaneously. The invention further discloses application of the octaphenyl substituted polyhedral oligomeric silsesquioxanederivative molecular glass. The molecular glass can be used as a main material of a photoresist to be prepared into a thin film, and can be used for photoetching.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Mask plate and method for exposing wafer with protrusions

PendingCN111722468AHigh resolution requirementsLow costOriginals for photomechanical treatmentGraphicsWafer

The invention provides a mask plate and method for exposing a wafer with protrusions. At least one protrusion is arranged on the side, facing the mask plate, of the wafer, a graphic layer and alignment marks are arranged on the mask plate, and notches capable of allowing the protrusions to be inserted therein are further formed in the side, facing the wafer, of the mask plate. Before the method isused for exposure, all the protrusions of the wafer are inserted into the notches corresponding to the mask plate, and the depth of the protrusions inserted into the notches is adjusted according tothe required resolution so as to keep the positions of the mask plate and the wafer unchanged after a preset exposure gap requirement is met between the mask plate and the exposure surface of the wafer, and exposing is carried out on the wafer by using an exposure light source. By utilizing the mask plate and the exposure method, a preset gap can be formed between the mask plate and the wafer exposure surface without improving a stepping photoetching machine, so that the alignment precision and the resolution ratio are improved, and the cost is saved.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com