Direct-blowing cement sampler

A sampler, direct blowing technology, applied in the field of direct blowing cement sampler, can solve the problems of high requirements, pipelines, gates, etc., and achieve the effect of small environmental pollution and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

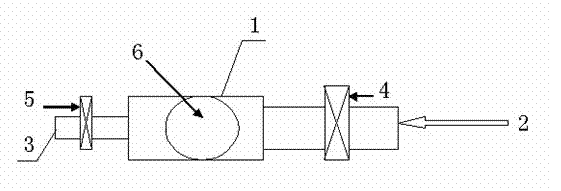

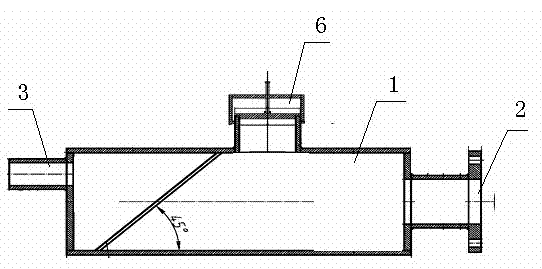

[0017] Such as figure 1 , figure 2 As shown, the direct blowing cement sampler includes a sample cylinder 1, one end of the sample cylinder 1 is the sample cylinder inlet 2, and the other end is the sample cylinder outlet 3, the sample cylinder inlet 2 is connected to the inlet valve 4 through a flange, and the sample cylinder outlet 3 The outlet valve 5 is connected by a flange, and a sample cylinder cover 6 is arranged in the middle of the sample cylinder 1 . When working, after the cement and additives are mixed evenly, they are all transferred into the tank at last, blow out the ash sample with compressed air pressure, open the inlet valve 4, the ash sample enters the sample cylinder 1, slowly open the outlet valve 5, and reduce the pressure in the sample cylinder , which is beneficial for the gray sample to enter the sample cylinder 1. After the sample cylinder is full of ash, close the inlet valve 4, slowly open the outlet valve 5, drain the pressure inside the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com