Common-path radial cutting liquid crystal phase shift interference wave-front sensor

A technology of wavefront sensor and phase-shifting interference, which is applied in the direction of instruments, scientific instruments, and measuring optics. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

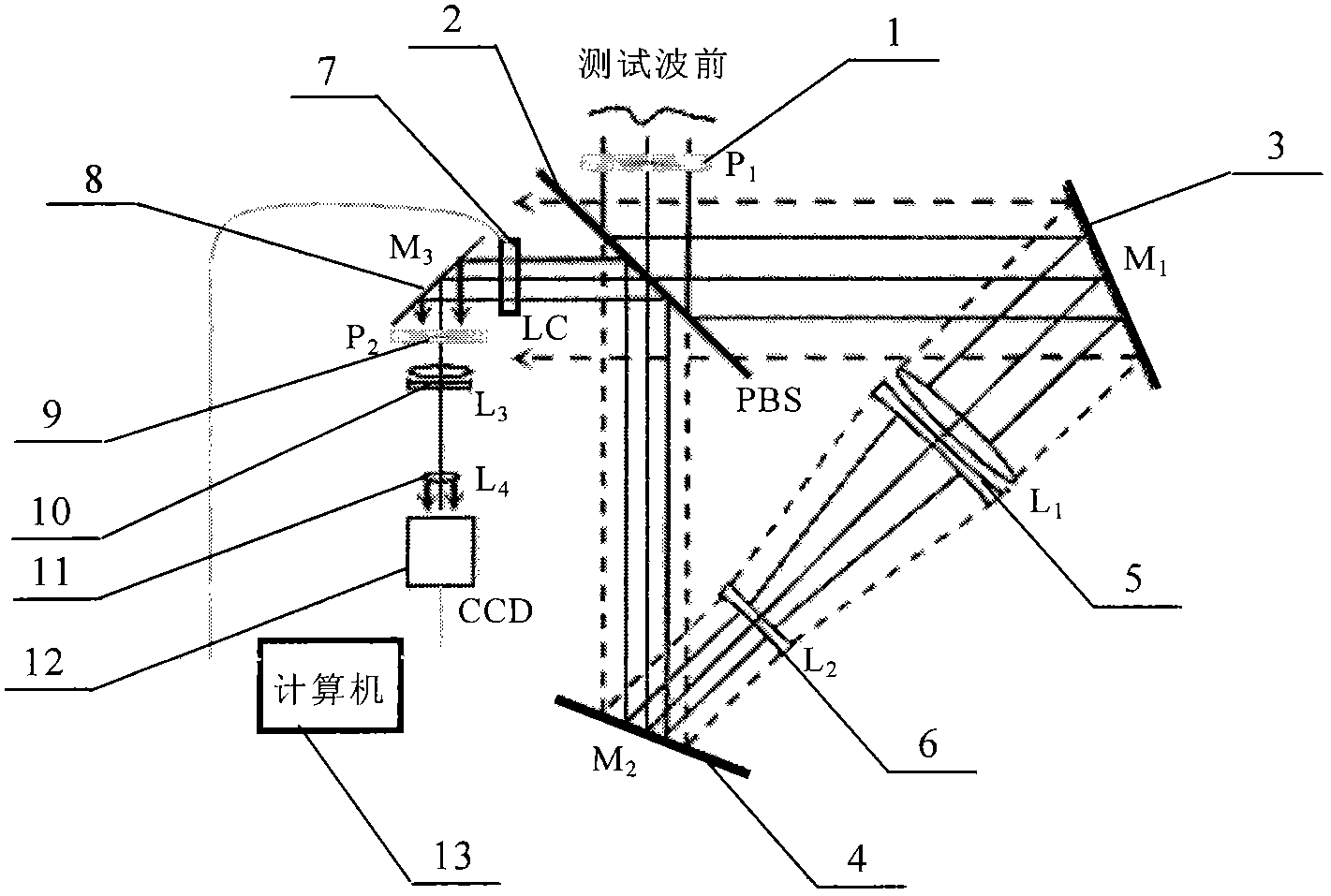

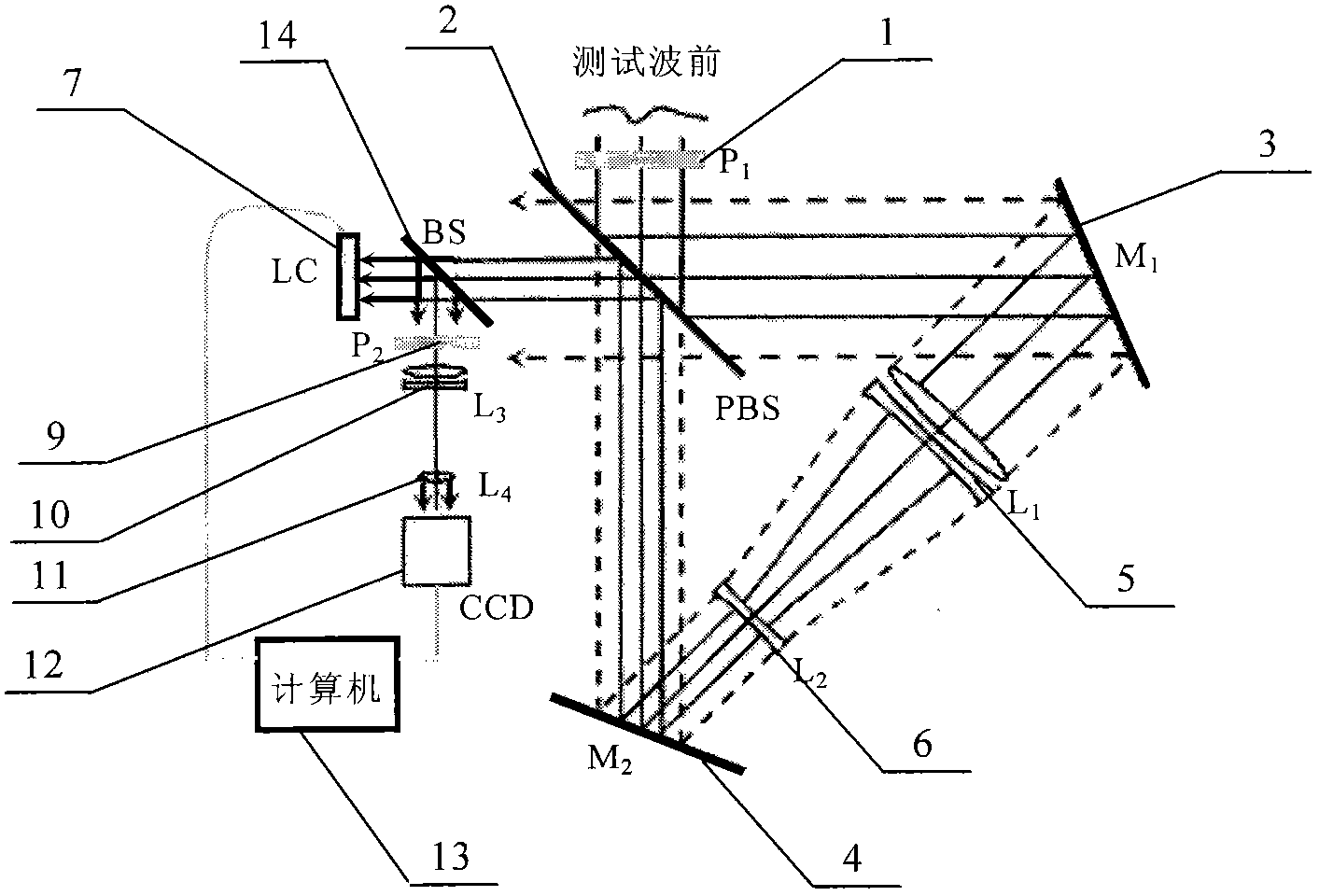

[0024] Such as figure 1 As shown, the sensor consists of a polarizer P 1 1. Polarizing beam splitter PBS2, mirror M 1 3 and M 2 4. Lens L 1 5 and L 2 6. Liquid crystal phase modulator LC7, mirror M 3 8. Analyzer P 2 9. Lens L 3 10 and L 4 11. A photodetector CCD12 and a computer 13 are formed, wherein the polarizing beam splitter PBS2 and the mirror M 1 3 and M 2 4. Lens L 1 5 and L 2 6 composed of radial shear system; liquid crystal phase modulator LC7, mirror M 3 8 and analyzer P 2 9 forms a phase-shifting interference system; lens L 3 10 and L 4 11 and the photodetector CCD12 form an imaging system. Polarizer P 1 1 placed before the radial shearing system, the polarizing beam splitter PBS2, the mirror M 1 3 and M 2 The optical axis of 4 forms a plane right triangle, lens L 1 5 and L 2 6 is placed between the right triangle, and the optical axis of the two lenses is collinear with the optical axis formed by the right triangle, lens L 1 5 close to the mir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com