Zooming projection lens

A technology of projection lens and lens group, which is applied in the field of zoom projection lens, can solve problems such as inability to effectively correct aberrations, focal power allocation mismatch, and back focus not meeting requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

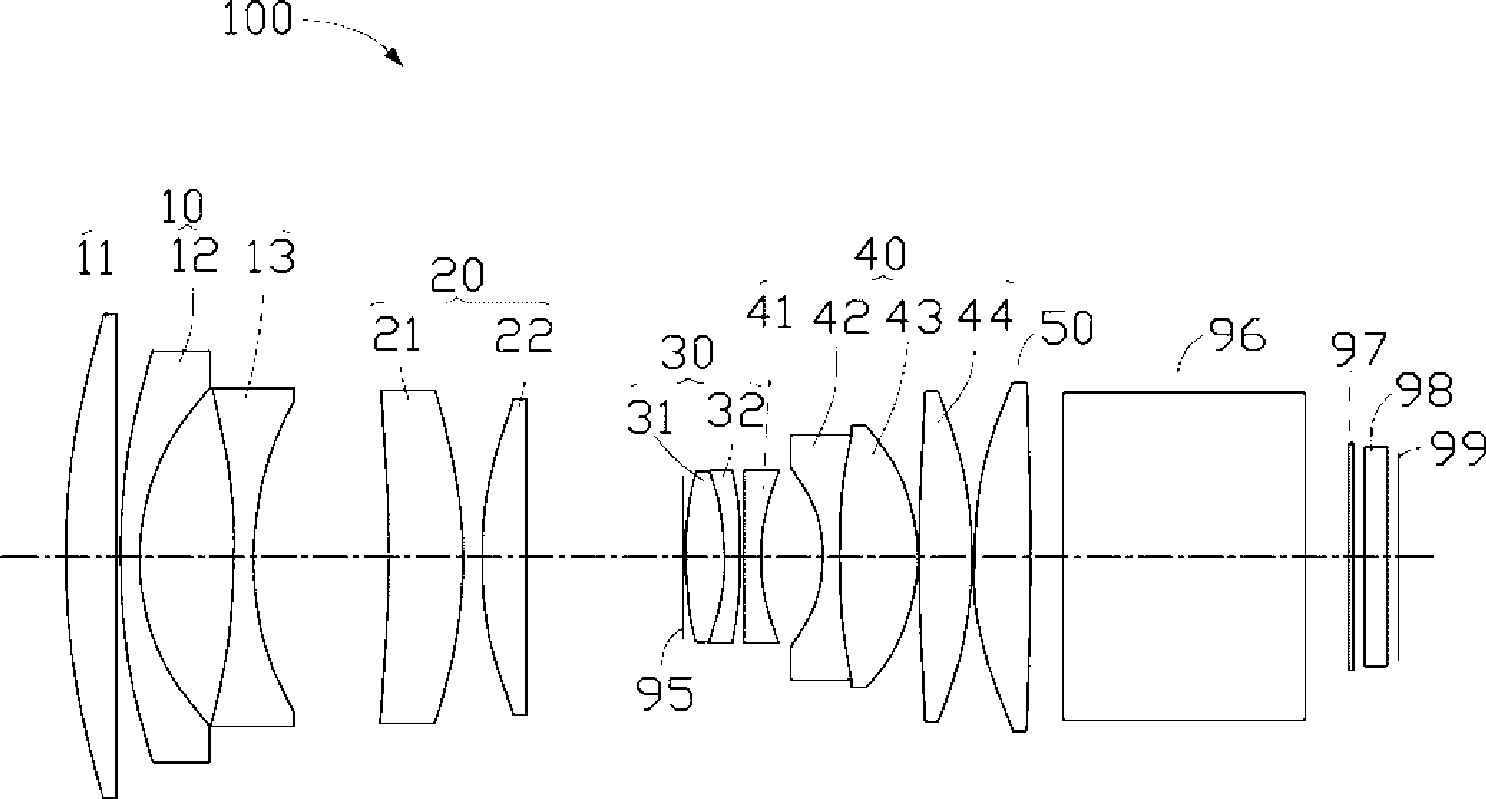

[0062] The zoom projection lens 100 of Embodiment 1 satisfies the conditions listed in Table 1 and Table 2, and F1=-28.8377 millimeters (Millimeter, mm), F2=33.0414mm, F3=40.8227mm, F4=-141.6108mm, F5=49.8472 mm.

[0063] Table 1

[0064] surface R(mm) D(mm) Nd vd The surface of the magnifying end of the first lens 79.971 5.035 1.6451 55.8878 first lens reducing end surface -998.751 0.15 - - Second lens magnifying end surface 67.492 1.8 1.5569 64.1644 Second lens reducing end surface 23.691 8.847 - - The surface of the magnifying end of the third lens -65.086 1.8 1.5994 54.9599 The surface of the third lens reducing end 31.281 D6 (refer to Table 2) - - The surface of the magnifying end of the fourth lens -161.501 6.962 1.744 44.8511 The surface of the fourth lens reducing end -51.457 1.83 - - The surface of the magnifying end of the fifth lens 40.839 4.456 1.7491 34.8735 Re...

Embodiment 2

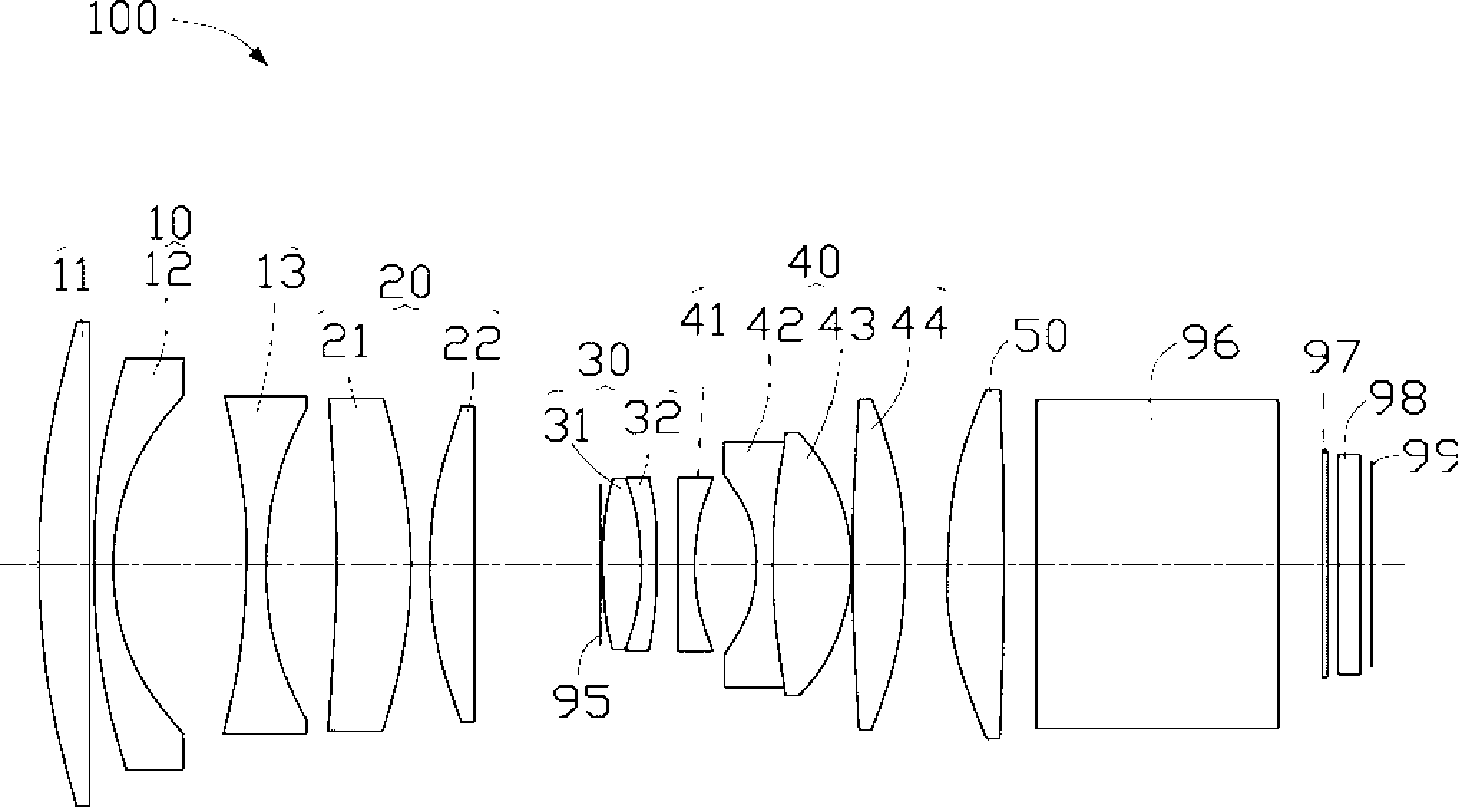

[0070] The zoom projection lens 100 of Embodiment 2 satisfies the conditions listed in Table 3 and Table 4, and F1=-29.3527mm, F2=33.8755mm, F3=40.6828mm, F4=-152.5071mm, F5=51.142mm.

[0071] table 3

[0072] surface R(mm) D(mm) Nd vd The surface of the magnifying end of the first lens 82.072 4.916 1.7023 48.5664 first lens reducing end surface -1344.621 0.17 - - Second lens magnifying end surface 63.239 1.8 1.5131 67.7652 Second lens reducing end surface 22.918 8.968 - - The surface of the magnifying end of the third lens -64.557 1.8 1.6315 50.4312 The surface of the third lens reducing end 32.077 D6 (refer to Table 4) - - The surface of the magnifying end of the fourth lens -153.501 7 1.6807 50.9542 The surface of the fourth lens reducing end -49.356 0.17 - - The surface of the magnifying end of the fifth lens 40.843 4.391 1.7306 31.8018 Reduced end surface of the fifth le...

Embodiment 3

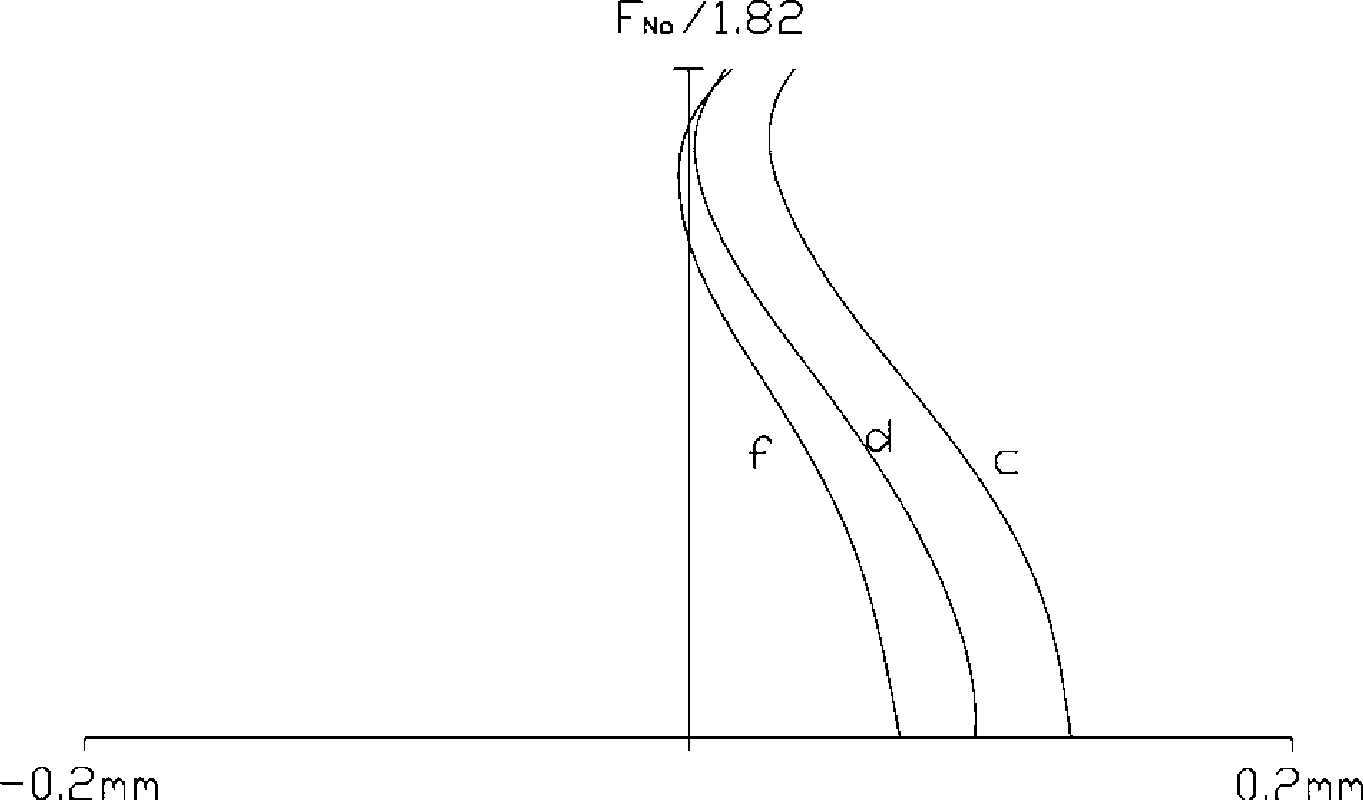

[0078] The zoom projection lens 100 of Embodiment 3 satisfies the conditions listed in Table 5 and Table 6, and F1=-28.0963mm,

[0079] F2=33.3390mm, F3=40.5215, F4=-182.3747mm, F5=53.1237mm.

[0080] table 5

[0081] surface R(mm) D(mm) Nd vd The surface of the magnifying end of the first lens 79.997 4.758 1.6879 50.1164 first lens reducing end surface -4583.001 0.353 - - Second lens magnifying end surface 60.664 1.8 1.5382 65.5839 Second lens reducing end surface 22.373 8.82 The surface of the magnifying end of the third lens -67.588 1.8 1.6376 56.2887 The surface of the third lens reducing end 31.666 D6 (refer to Table 6) - - The surface of the magnifying end of the fourth lens -144.43 7 1.6885 50.0393 The surface of the fourth lens reducing end -46.511 0.17 - - The surface of the magnifying end of the fifth lens 40.133 4.371 1.7346 34.607 Reduced end surface of the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com