Piezoresistance type microwave power sensor and microwave power sensing method thereof

A technology of microwave power and sensing methods, which is applied in the direction of instruments, measuring devices, measuring electronics, etc., can solve the problems of incompatibility of mainstream processes, high production costs, poor repeatability and reliability, etc., achieve good application value, improve performance, Effects of improved repeatability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

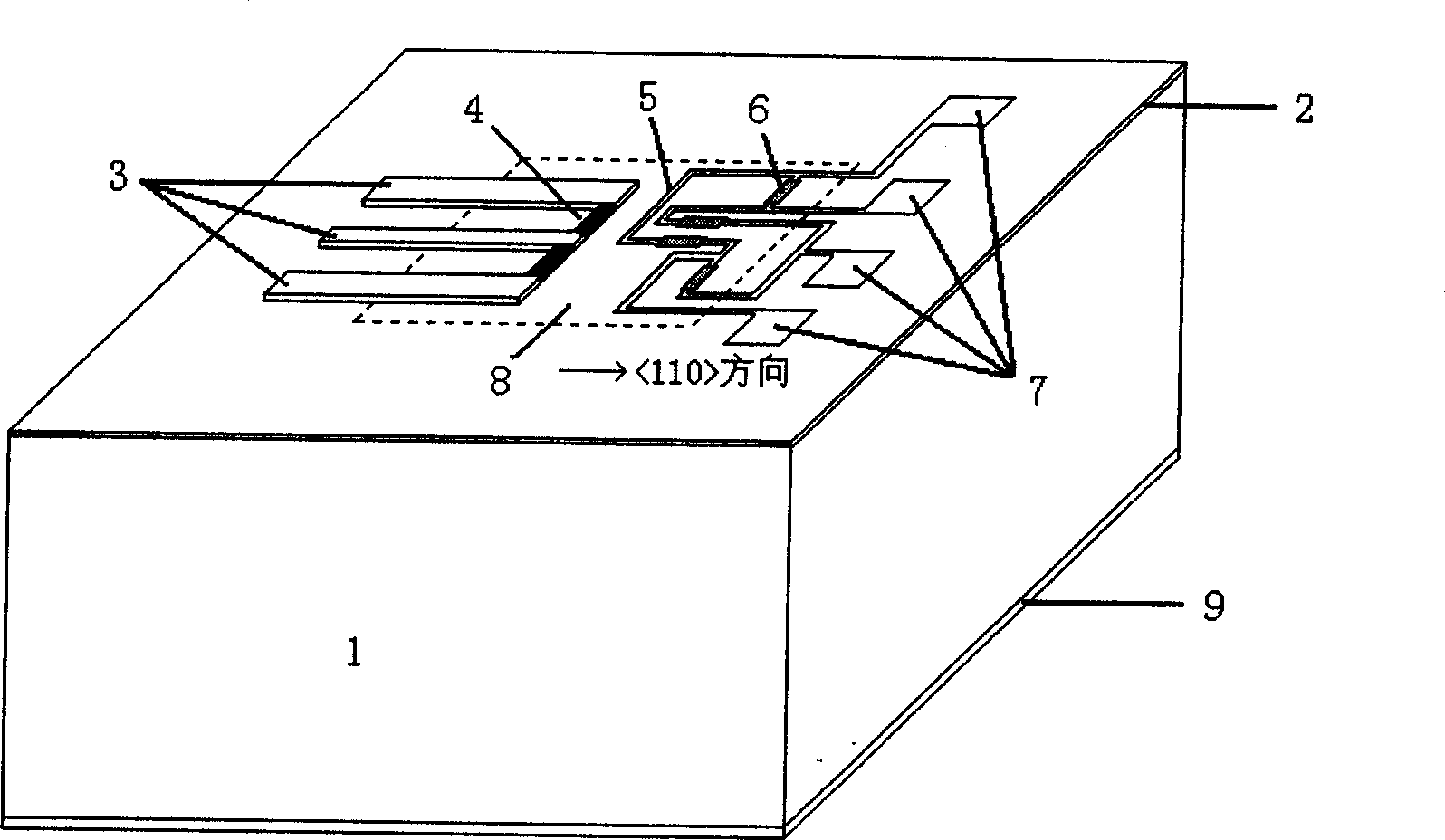

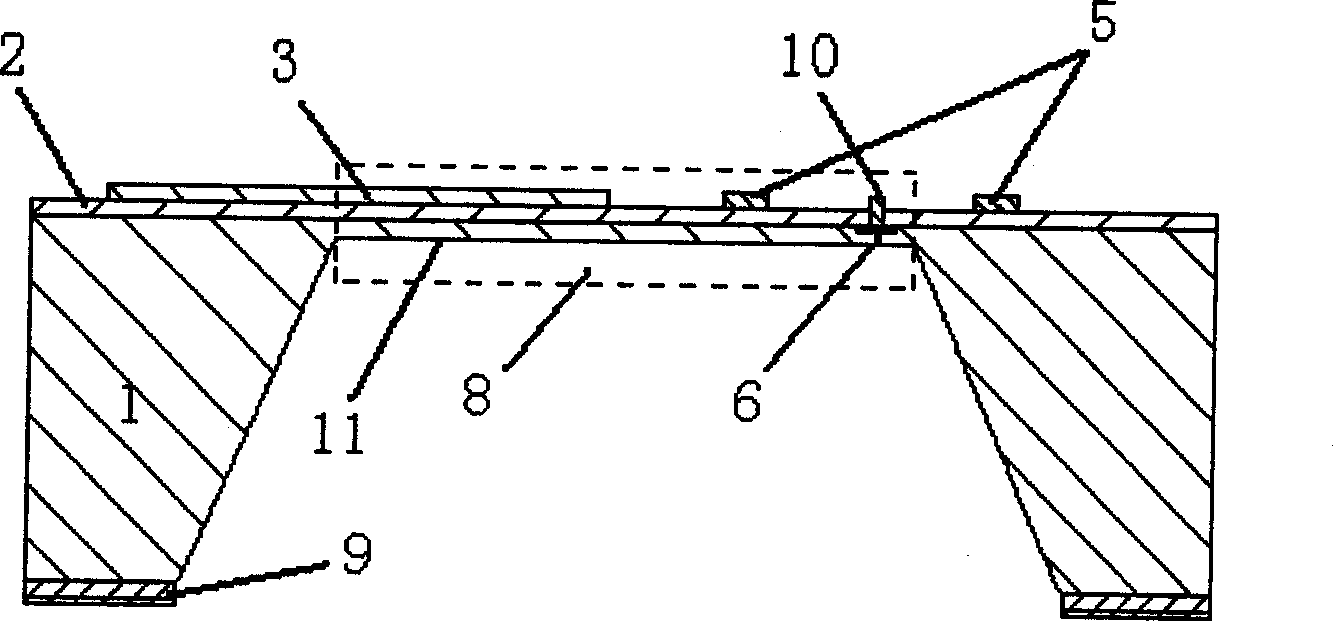

[0013] The piezoresistive microwave power sensor of the present invention adopts Si substrate, and obtains the silicon film of certain thickness through substrate backside corrosion process, is provided with SiO on Si substrate 2 insulating layer, made of silicon film and SiO 2 The insulating layer constitutes a double-layer film structure, and a coplanar waveguide is arranged on the double-layer film structure. The terminal of the coplanar waveguide is a matching resistor, and four piezoresistors along the direction are arranged on the edge of the double-layer film structure. , The varistor is connected by metal wires to form a Wheatstone bridge, and the four lead terminals of the Wheatstone bridge are connected to the pressure welding block. The sensor makes the terminal matching resistors on the double-layer film structure with different thermal expansion coefficients, and uses the terminal matching resistors to absorb microwave power to generate heat, resulting in differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com