Mask plate and method for exposing wafer with protrusions

A technology of mask plate and convex part, which is applied in the field of mask plate for wafer exposure with convex part, can solve the problems of expensive price, resolution not meeting the process requirements, wafer alignment and other problems, and achieve saving Cost, High Resolution Requirements, Effects of Improving Alignment Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

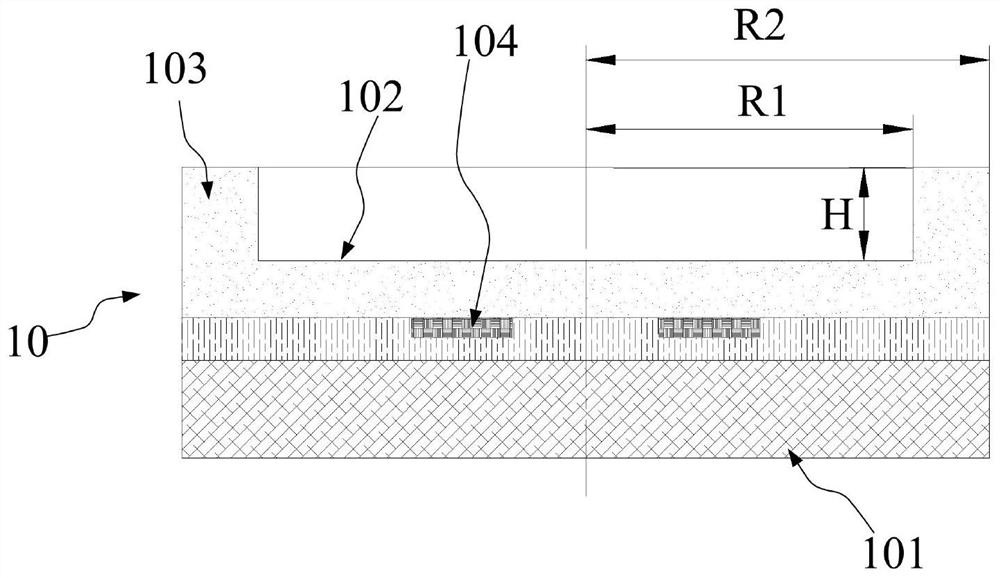

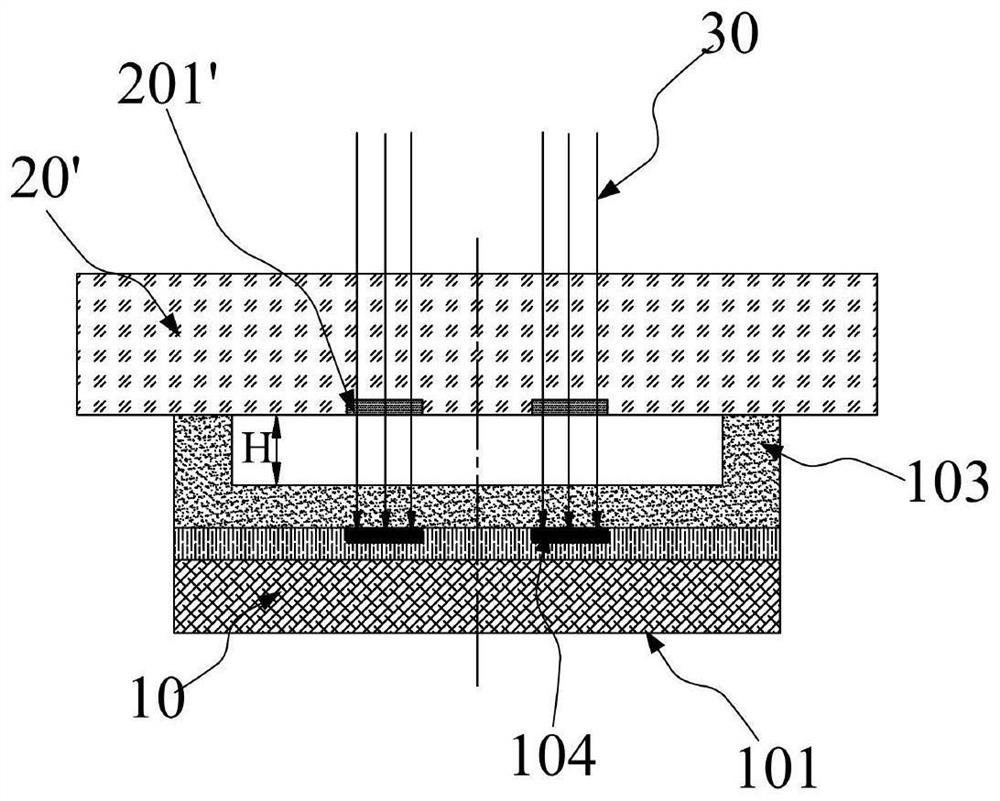

[0052] This embodiment provides a Figure 4-5Reticles for exposure of bumped wafers are shown, which are used as Figure 6-7 Exposure of a wafer 10 with a raised portion on the exposure surface shown in , the side of the wafer 10 facing the mask 20 is provided with a plurality of raised portions 103 (can also be one), the mask A graphic layer (not shown) and an alignment mark 104 are arranged on the mask plate 20, and a hole capable of receiving the protrusion 103 is provided on the side of the mask plate 20 facing the wafer 10. Notch 202.

[0053] Such as Figure 8 As shown, before exposure, insert all the protrusions 103 of the wafer 10 into the corresponding notches 202 of the mask 20, and adjust the insertion of the protrusions 103 to the corresponding positions according to the required resolution. After the depth in the above-mentioned notch 202 is reached so that the predetermined exposure gap requirement is reached between the mask plate 20 and the exposure surface ...

Embodiment 2

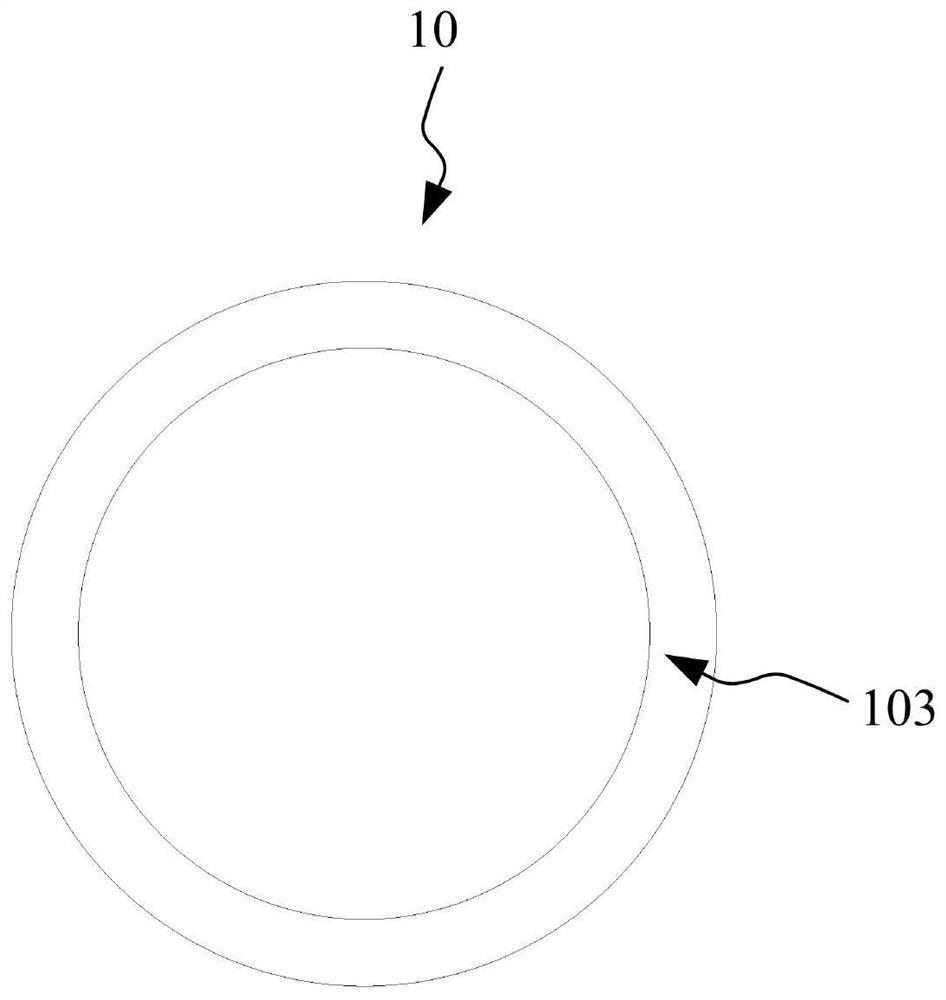

[0058] This embodiment provides a Figure 9-10 The mask plate 20 shown for wafer exposure with bumps can also realize the Figure 6-7 In the high-resolution exposure of the wafer 10 shown, the difference between the mask plate in this embodiment and the mask plate in Embodiment 1 is that the notch 202 of the mask plate 20 in this embodiment is an annular groove 2021. A plurality of protrusions 103 that are discretely distributed around the circumference are all inserted into the annular groove 2021 .

Embodiment 3

[0060] This embodiment provides a Figure 12-13 The mask plate 20 shown for wafer exposure with bumps can also realize the Figure 6-7 In the high-resolution exposure of the wafer 10 shown, the difference between the mask plate in this embodiment and the mask plate in Embodiment 1 is that the mask plate 20 in this embodiment is provided with a plurality of Figure 6-7 In the independent notch 202 corresponding to the plurality of raised parts 103, the plurality of raised parts 103 distributed in a discrete shape during exposure are respectively inserted into the corresponding notch 202 to reduce the distance between the mask plate 20 and the exposure surface. exposure gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com