A color filter substrate

A color filter, color photoresist technology, applied in the direction of filters, optics, opto-mechanical equipment, etc., can solve the problems of oblique color shift, design, high film thickness of color photoresist, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

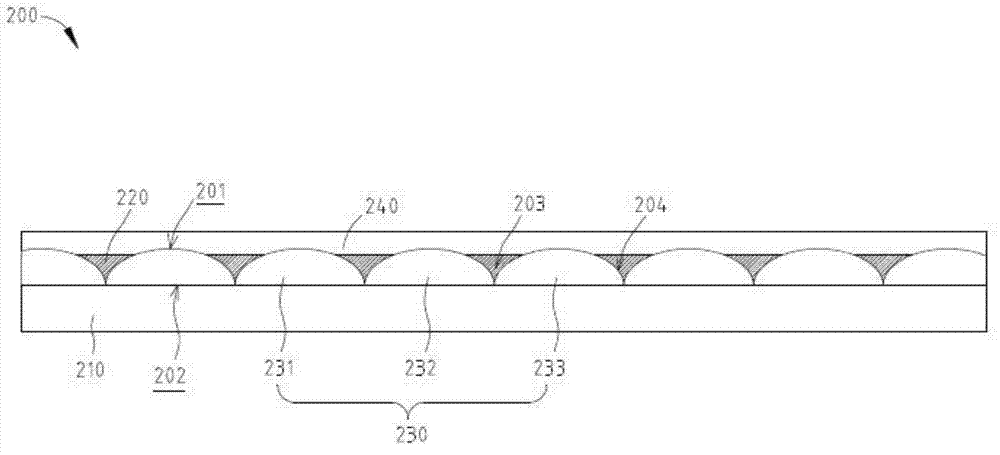

[0021] image 3 It is a cross-sectional view of the color filter substrate in the present invention. Such as image 3 As shown, the color filter substrate 200 in the present invention includes a substrate 210, wherein the substrate 210 is made of a light-transmitting material; a color photoresist 230 is arranged on the substrate 210, wherein the colored light The resistance 230 is an arc shape, its lower surface 202 is in contact with the substrate 210, and its upper surface 201 is arc-shaped. The color photoresist 230 has an edge portion 204, and adjacent color photoresist 230 are in contact with each other. A concave portion 203 is formed between adjacent color photoresists 230; a black matrix 220 is arranged between two adjacent color photoresists 230, that is, the black matrix 220 is arranged between adjacent color photoresists 230 to form The concave portion 203 ; a flat layer 240 is disposed above the color photoresist 230 and the black matrix 220 .

[0022] Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com