Patents

Literature

660results about How to "Improve quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

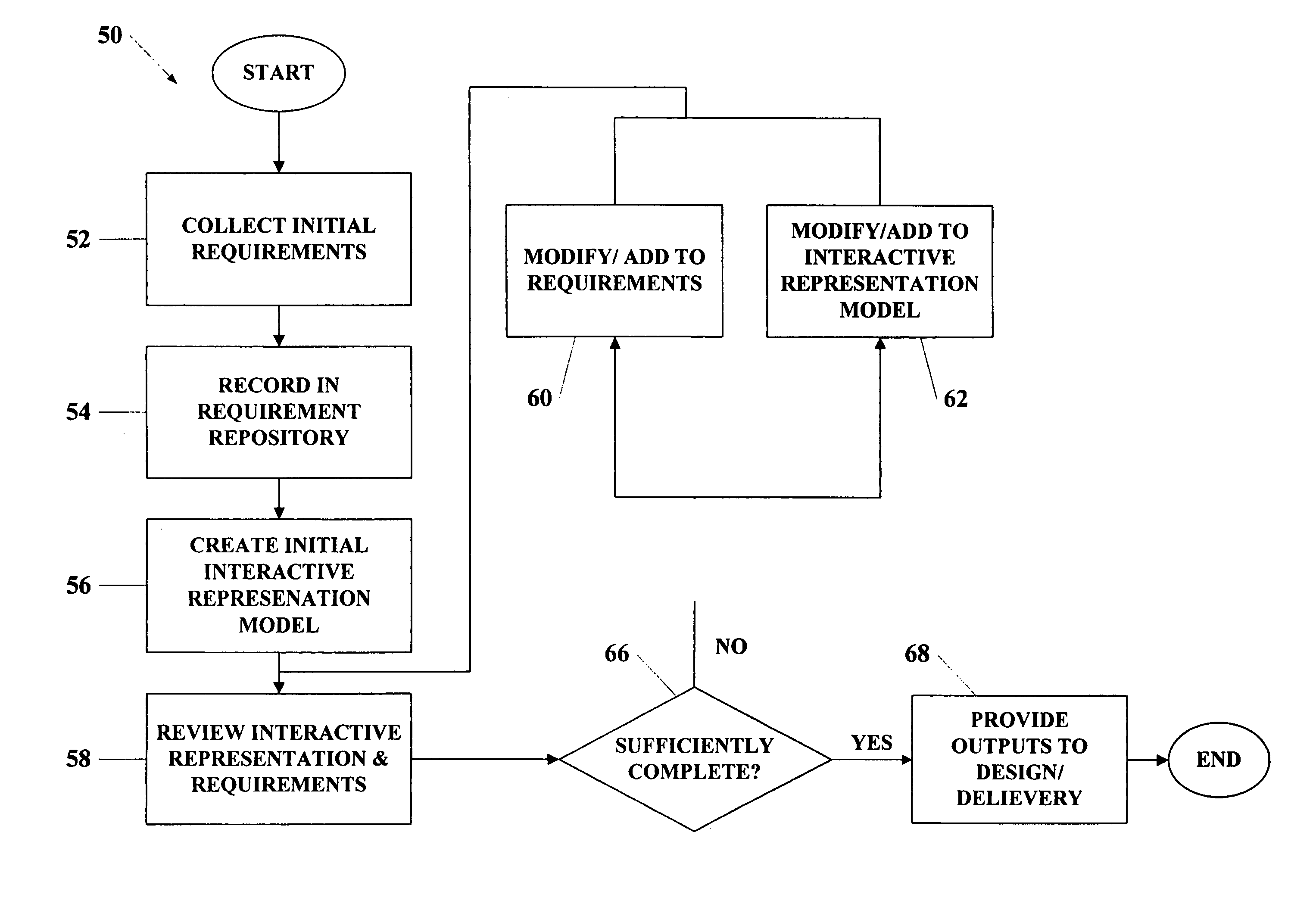

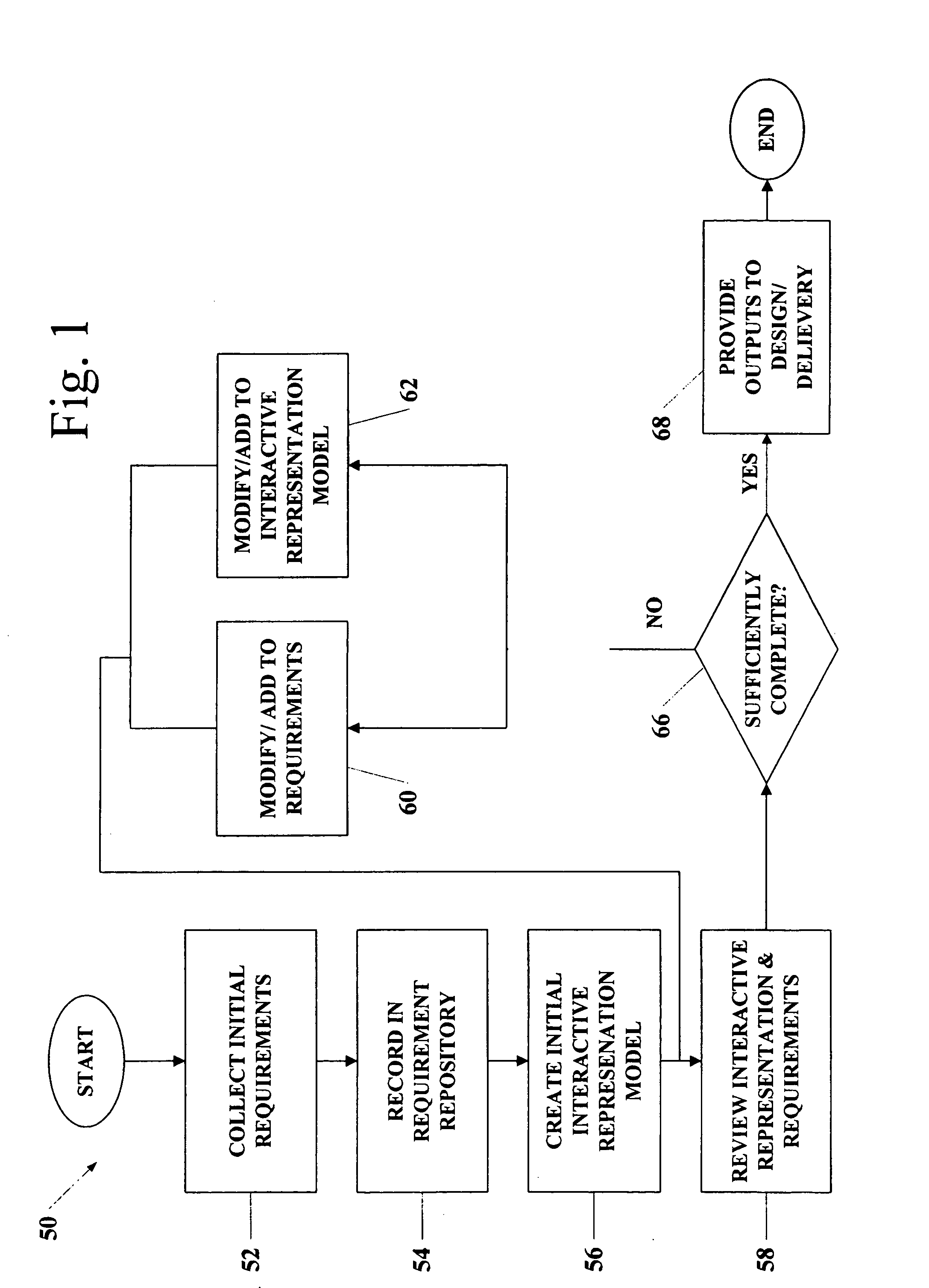

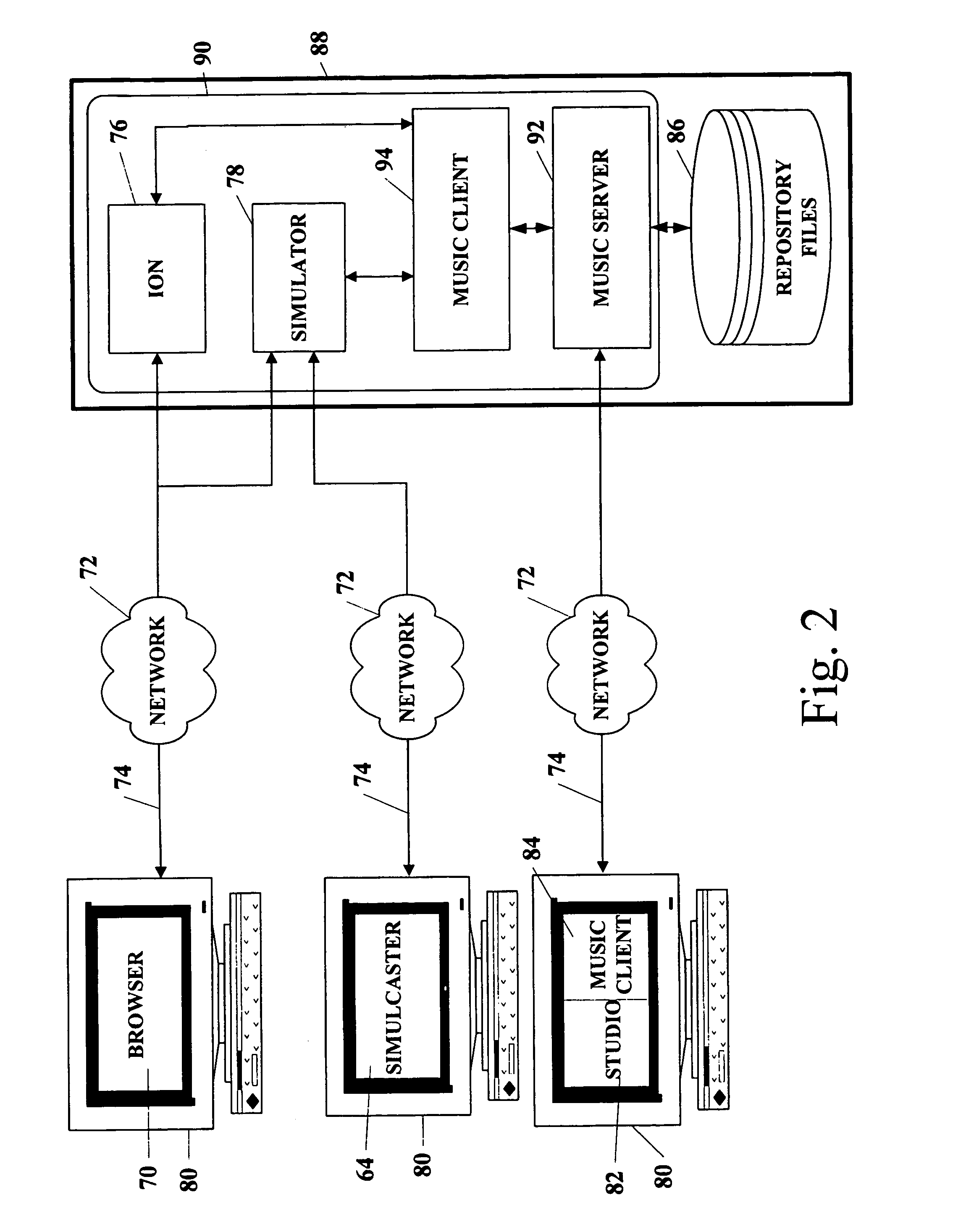

Systems and methods for defining a simulated interactive web page

InactiveUS7174286B2Reduce ambiguityPromote effective communicationData processing applicationsNatural language data processingApplication softwareWeb page

The system includes a novel software application interactive representation modeling language, a software application (82) operative to use the modeling language to create, read and modify interactive representation models of the proposed applications, a memory (86) to store requirement data and interactive representation model data, a software application (92) operative to read and update the interactive representation model data across a computer network, a software application (76) operative to maintain a record of the requirements and to administer operation of the system, a software application (78) operative to render interactive representations of the proposed applications in browser readable format, a software application (82) operative to allow multiple instances of other applications to access interactive representation data and requirement data residing in the memory and a software application (84) operative to allow an individual user's interactions with the system to be broadcast across a networked system to other users.

Owner:AXURE SOFTWARE SOLUTIONS

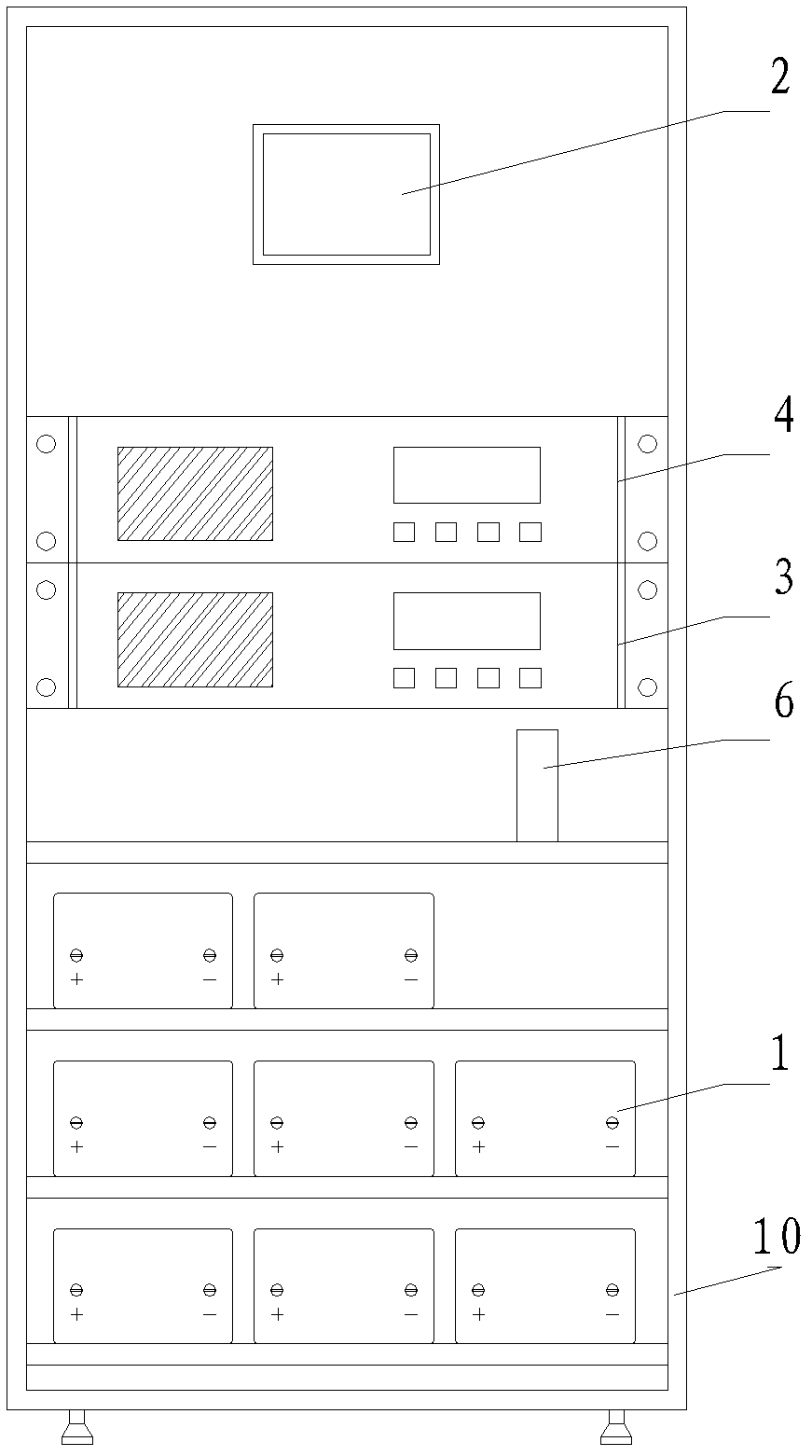

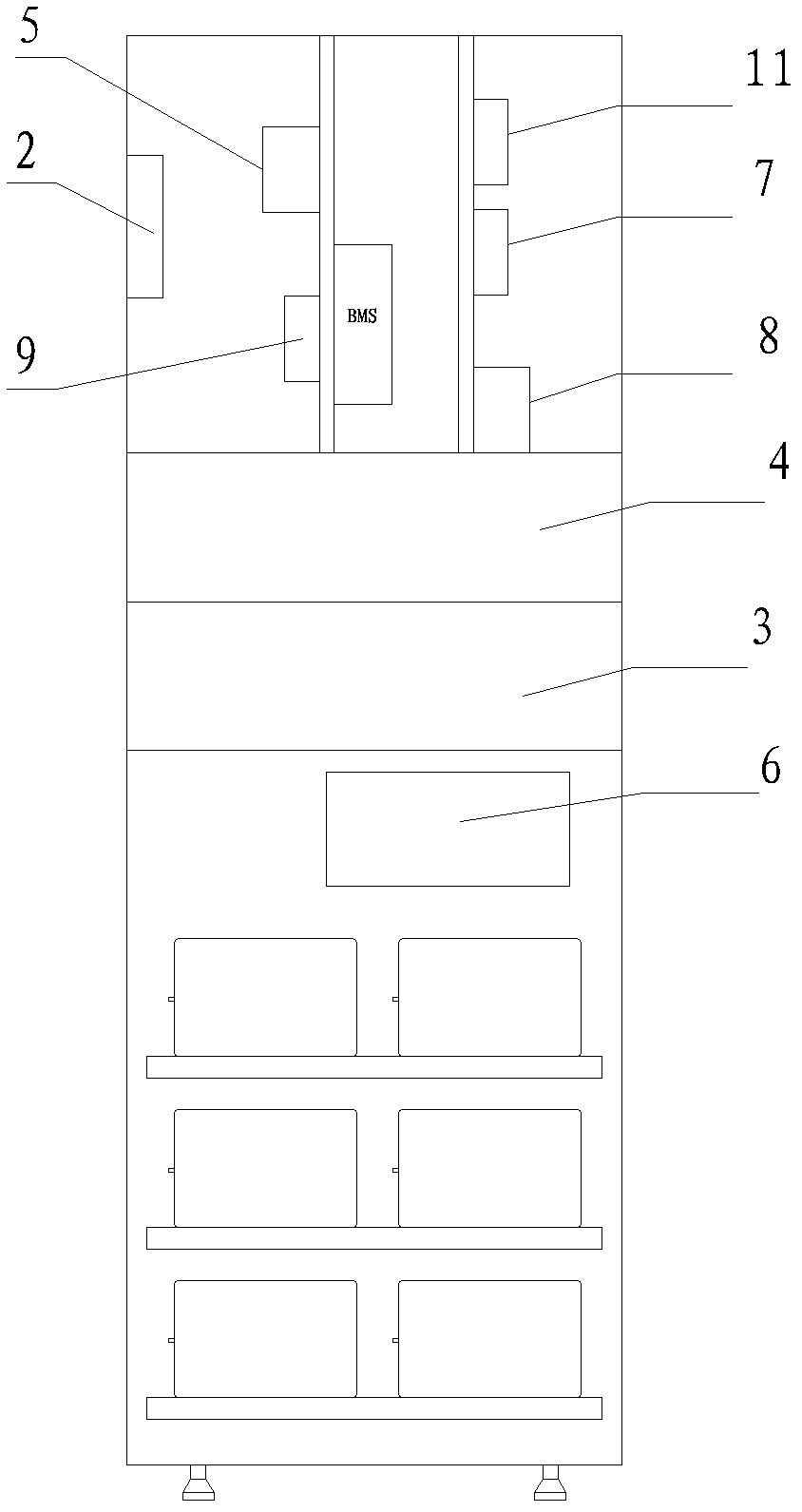

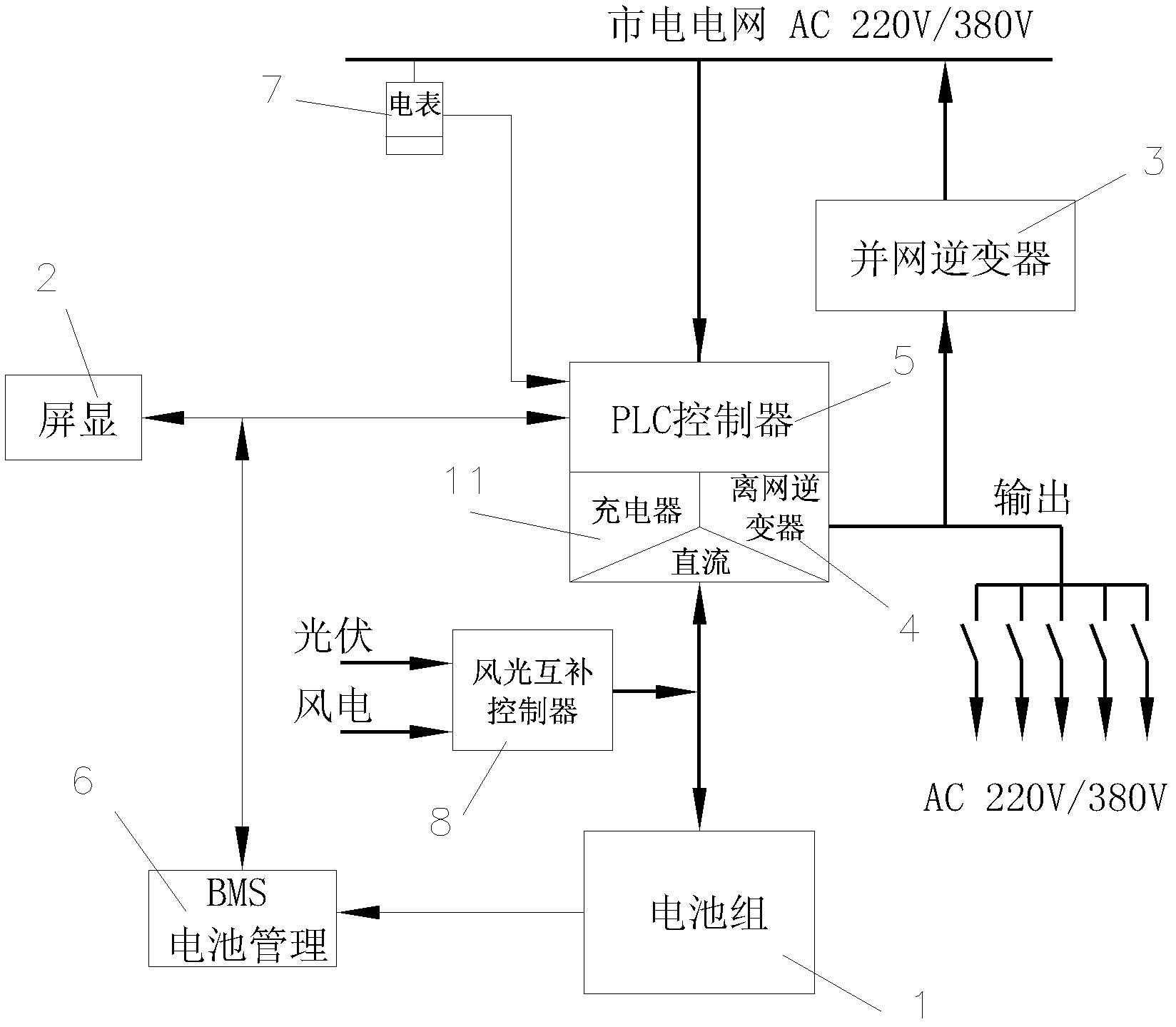

Intelligent energy storage machine and operating method thereof

ActiveCN102882237AAdd grid-connected power feed functionStable electricity loadBatteries circuit arrangementsAc network load balancingElectric power systemNew energy

The invention provides an intelligent energy storage machine and an operating method thereof. The intelligent energy storage machine is used in a large scale, so that the electrical load of a power grid is relatively stable, the electrical load for the daytime and night is balanced, and the peak load shifting function is realized; and the energy storage machine comprises a miniature wind power and photovoltaic power generation input interface, and a new energy access power system is easily realized. The intelligent energy storage machine comprises a cabinet shell, a control system, an energy device and an energy storage device, wherein the energy device is used for providing energy for the load and comprises a solar energy device, a wind energy device and a mains supply; the electric energy generated by the solar energy device and the wind energy device is stored in the energy storage device; the energy storage device is an energy storage battery pack; the energy storage battery pack is used for storing the energy generated by the solar energy device and the wind energy device and the energy charged by the mains supply; and the control system comprises a wind and photovoltaic complementary controller, a grid-connected inverter, an off-grid inverter, a programmable logic controller (PLC), a battery management system and a bidirectional intelligent electric meter.

Owner:YINLONG ENERGY CO LTD

Camellia oil preparation method for cosmetics

ActiveCN101305974AImprove quality requirementsCrystal clear appearanceCosmetic preparationsToilet preparationsCamellia oleiferaFiltration

The invention relates to a preparation method of cosmetics camellia oil. High-quality camellia seeds are selected to be used as the raw material; the camellia seeds are roasted under the negative pressure and at the lower temperature, and are husked after natural cooling and are squeezed at the room temperature to obtain high-quality crude oil with low acid value and pale yellow color; impurities are removed through filtration under the heating condition, alkali refining and ethanolic extracting two-stage process is utilized for acid stripping and de-coating; then the mixture composed of active carbon and floridin is used as de-coloring agent for de-pigmentation; peroxide and unclean flavor are removed through deodorization; then the drying winterization is acted; finally, the cosmetics camellia oil is obtained, wherein, the acid value is less than 0.1 mgKOH / g, the peroxide value is less than 0.5 mmol / kg, the appearance is colourless approximately as well as clear and translucent, and no unclean flavor exists. The cosmetics camellia oil reaches or exceeds the requirement of the national standard GB11765-2003 on first level expressed tea-seed oil, and can be directly used for manufacturing the cosmetic such as skin care oil for babies; in addition, an edible camellia oil fabrication plant can be improved for production, thereby lowering the investment cost greatly.

Owner:广东新大地生物科技股份有限公司

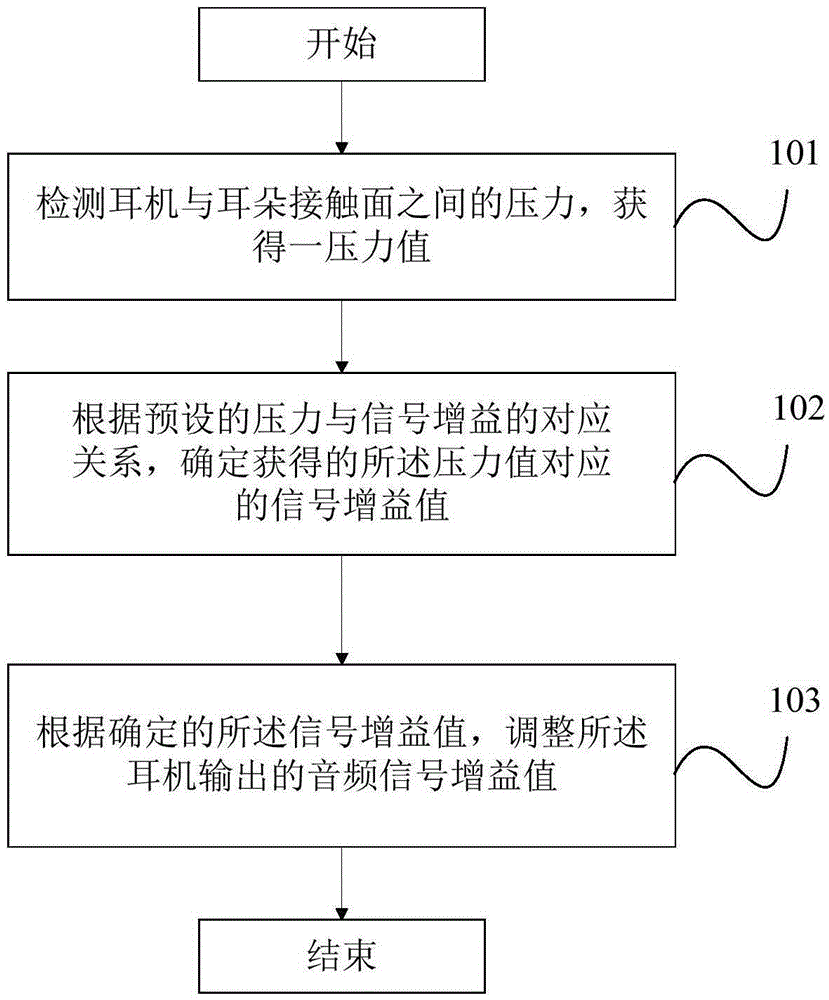

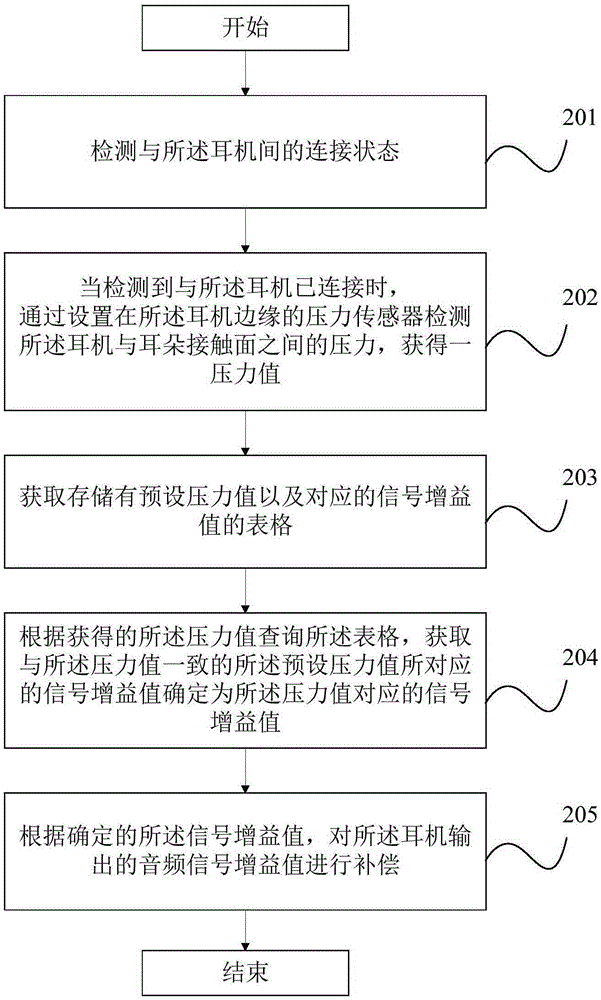

Method for improving sound quality of headset and mobile terminal

InactiveCN105246000AImprove headphone sound qualityImprove hearingEarpiece/earphone attachmentsTransducer circuitsVIT signalsAudio signal

The invention provides a method for improving sound quality of a headset. The method comprises the following steps: detecting a pressure between contact surfaces of the headset and ears so as to obtain a pressure value; determining a signal gain value corresponding to the obtained pressure value according to a corresponding relationship between a preset pressure and a signal gain; and adjusting an audio signal gain value output by the headset according to the signal gain value. The invention also provides a mobile terminal. According to the method provided by the invention, the signal gain value corresponding to the detected pressure value can be determined according to the corresponding relationship between the preset pressure and the signal gain, and the audio signal gain value output by the headset is adjusted according to the signal gain value in order to improve the sound quality of the headset. The aim of performing compensation on audio leakage generated due to an insufficient fit degree between the headset and human ears is fulfilled; an ideal sound quality effect can be achieved in different wearing states of a user; the auditory feeling is improved; and wearing discomfort due to a structural sealing design is avoided.

Owner:VIVO MOBILE COMM CO LTD

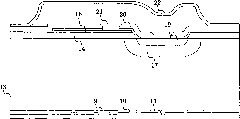

Method for the production of a sandwich component having a honeycomb core and the sandwich component obtained in this way

InactiveUS20090252921A1Improve adhesionEnhance layeringLamination ancillary operationsSynthetic resin layered productsShell moldingAdhesive

The invention relates to a method for the production of a fiber reinforced sandwich component (10) having a honeycomb core (12), the honeycombs of which are closed on both sides. The honeycomb core is closed at least on one side by a cover layer (14) made of fiber material, which is embedded in matrix material. The method comprises the following steps: —Producing a fabric comprising the honeycomb core and at least on one side of the honeycomb core, disposed from the inside to the outside, a curable adhesive layer (20), a barrier layer (16) and a fiber layer (14); —Locking the fabric on a one-sided molding tool (30) in a gastight chamber, which is formed up by a vacuum foil (48) on the one-sided molding tool; —Creating a vacuum in this gastight chamber, —After creating the vacuum, hardening or partial hardening of the adhesive layer between the honeycomb core and barrier layer in this vacuum such that the honeycomb cells (18) are evacuated at least partially before they are closed off by the barrier layer; —After hardening or partially hardening of the adhesive layer, infusion of the fiber layer in a vacuum with a matrix material; and —Hardening of the matrix material in a vacuum.

Owner:EURO COMPOSITES

Mixed frozen food of fresh fruit and vegetable and concentrated fruit and vegetable juice and processing method thereof

InactiveCN101803671AMake full use of functional complementarityNutritional diversityFrozen sweetsQuick FreezeFruit juice

The invention relates to mixed frozen food of fresh fruits and vegetables and concentrated fruit and vegetable juice and a processing method thereof, belonging to the field of the quick-frozen fresh fruit and vegetable beverage product and the production method thereof. The method comprises the following steps: directly selecting fresh fruits and eatable vegetables collected from pollution-free planting bases as main raw materials, obtaining clean solid materials after cleaning, peeling, seed removal and slitting pretreatment, mixing with such components as concentrated fruit juice and / or concentrated vegetable juice, white granulated sugar, honey, pectin, drinking water and the like according to a proportion, vacuum packaging to form a semi-finished product, and quickly freezing, thereby obtaining the finished quick-frozen fresh fruit and vegetable mixed food which can be stored, transported and sold under low-temperature conditions. The raw materials comprise the following components by weight percentage: 55-77 percent of solid clean materials of fresh fruit or / and eatable vegetables, 7-16 percent of concentrated fruit juice or / and concentrated vegetable juice, 0.2-1 percent of pectin, 2.5-5 percent of white granulated sugar, 0.3-3 percent of honey and 20-30 percent of drinking water. Therefore, the processed product is a novel frozen fruit and vegetable mixed food product with a high solid content.

Owner:WUHAN EAST YONGTAI BEVERAGE

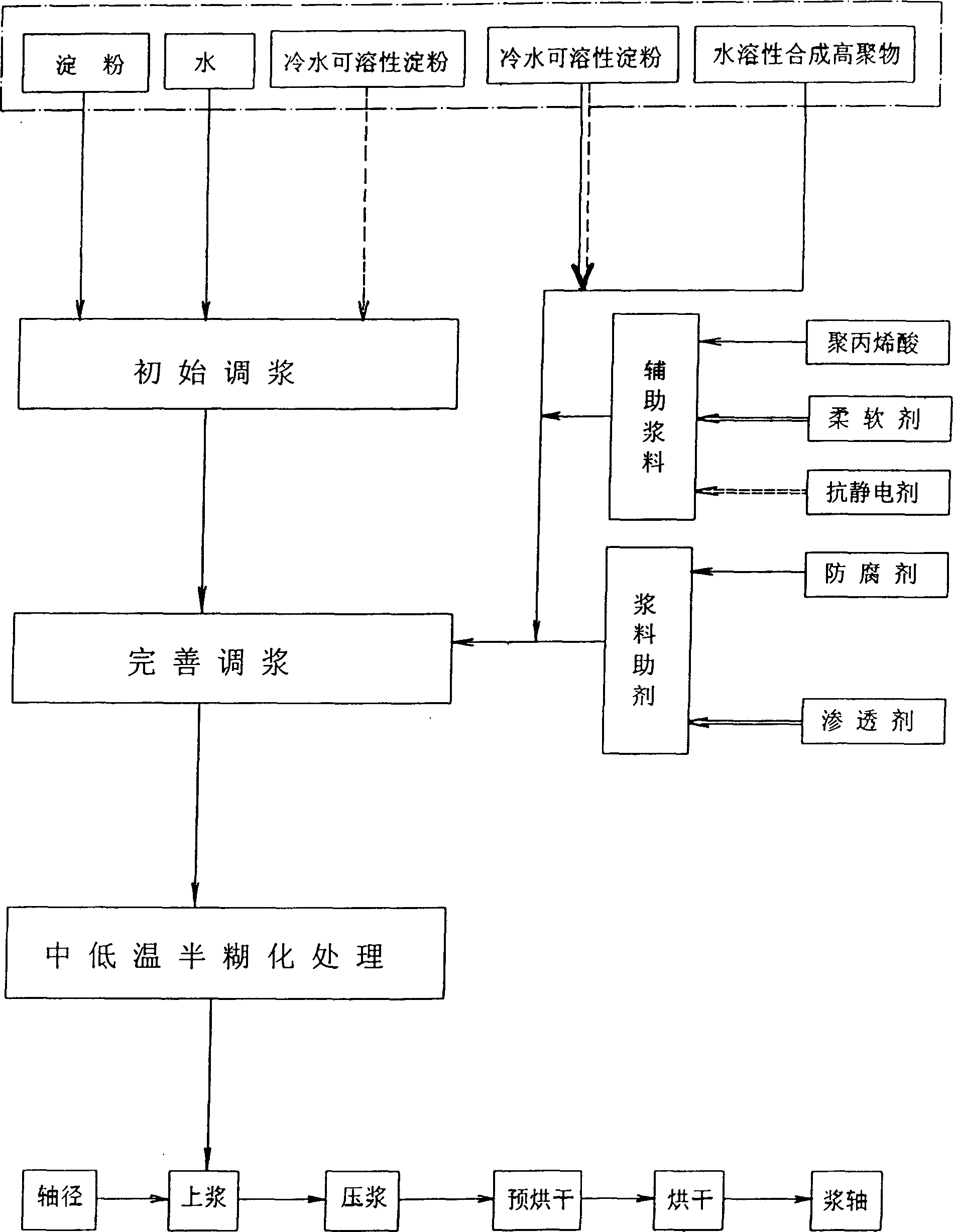

Middle and low temperature semi-pasted warp sizing method

The invention discloses a middle low-temperature gelatinization warp sizing method. Using 70-90 wt% starch, 0-20 wt% cold water soluble starch, 5-25 wt% soluble synthetic polymer, 1-5 wt% polyacrylic acid, 1-5 wt% softening agent, 1-5 % antistatic agent, 0.1-0.5 wt% preservative, 0.1-0.5 wt% penetrant of all slurry and 5-8 times water of all slurry as raw material; Slowly agitating starch and water for 5-15min to initialize plasm, adding cold water soluble starch, soluble synthetic polymer, polyacrylic acid, softening agent, antistatic agent, preservative, penetrant and slowly agitating for 5-15min to perfect plasm, heating to 45-60DEG C, pH 6.5-7.5, viscosity 5-10 seconds under rapid agitation for half gelatinization of starch, sizing in room temperature -60DEG C, squeezing in 3-20KN, prebaking in 85-95DEG C, drying in 115-130DEG C. Using in warp sizing. The effect of energy and time saving is good.

Owner:苏州泰和特科技有限公司

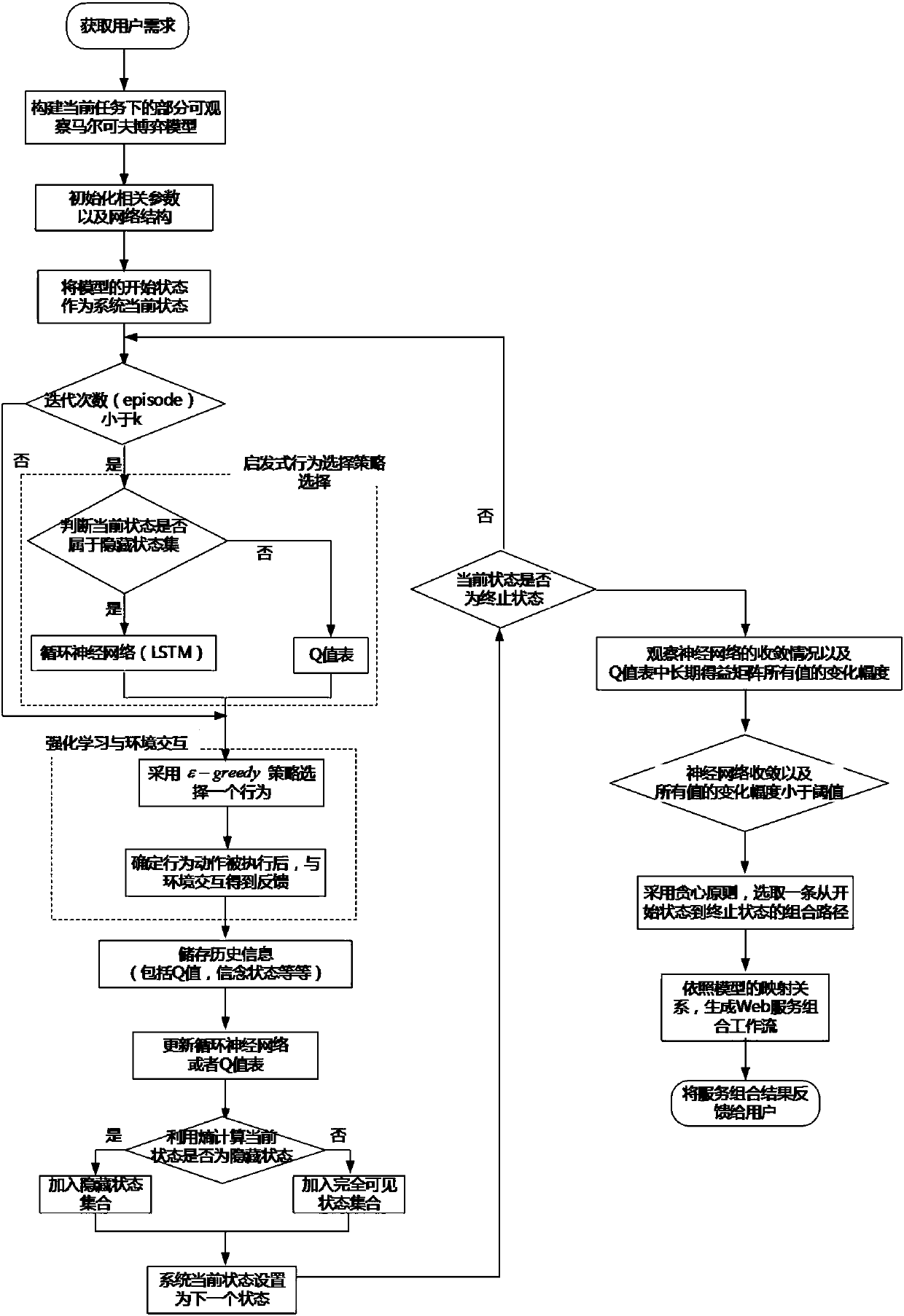

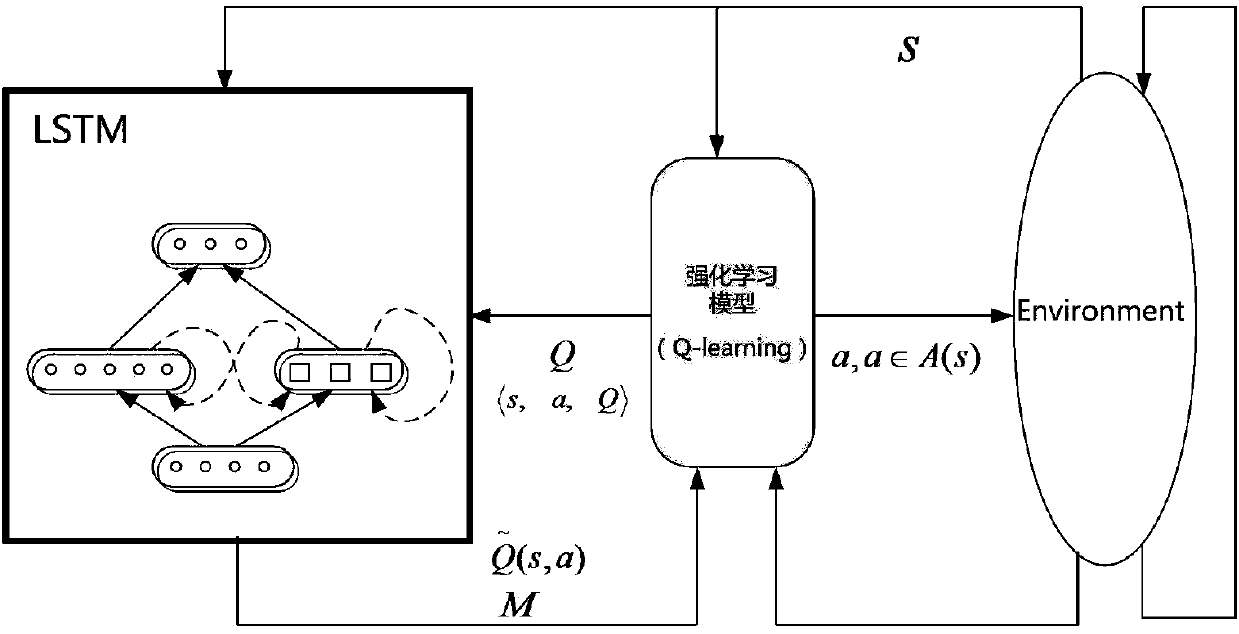

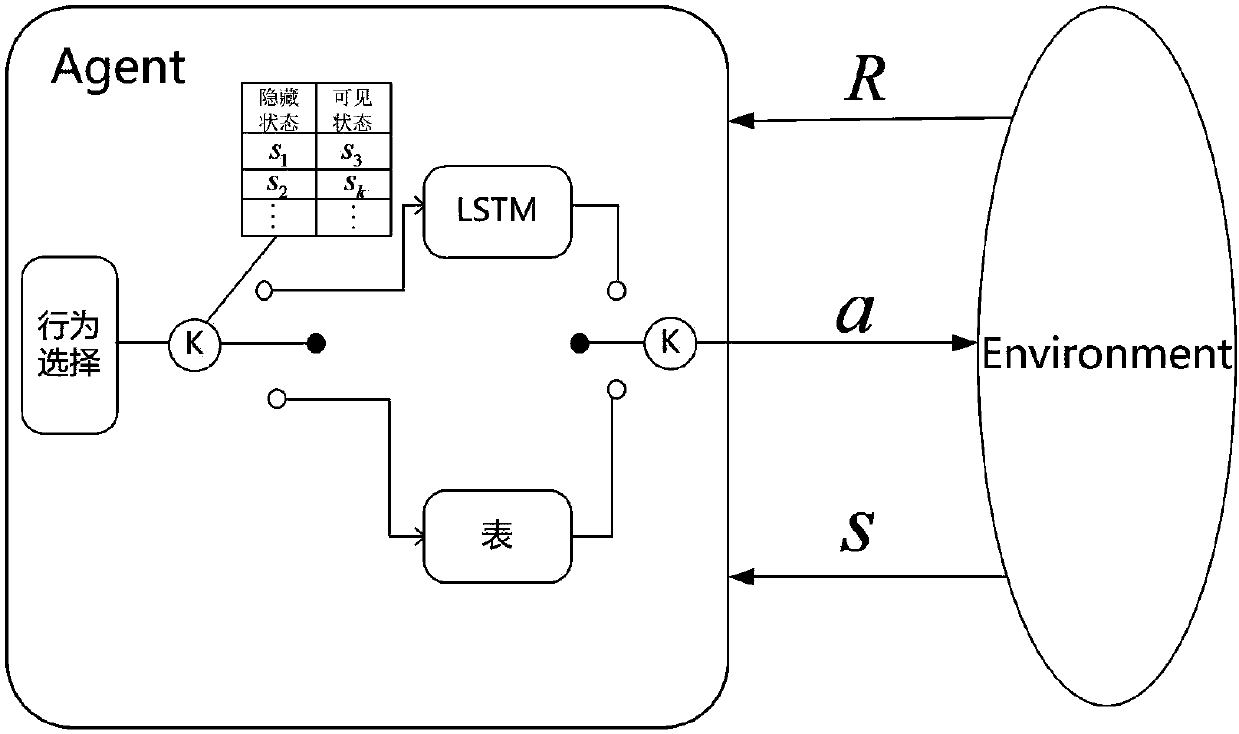

Web service combination method based on depth reinforcement learning

ActiveCN107241213ASolving Partial ObservabilityAccurately combine resultsData switching networksNeural learning methodsService compositionCurse of dimensionality

The invention discloses a web service combination method based on depth reinforcement learning for overcoming the problems of long time consumption, poor flexibility and non-ideal combination effect of the traditional service combination method in large-scale service scenes. The depth reinforcement learning technology and the heuristic thought are applied to the service combination problem. In addition, by considering the partial observability of the real environment, the service combination process is converted into a partially-observable Markov decision process POMDP, the solution problem of the POMDP is solved by using a recurrent neural network, and the method still expresses high efficiency encountering the challenge of curse of dimensionality. By adoption of the method provided by the invention, the solution speed can be effectively improved, the dynamic service combination environment is automatically adapted on the basis of ensuring the quality of the service combination scheme, and the adaptability and the flexibility of the service combination efficiency is effectively improved in a large-scale dynamic service combination scene.

Owner:SOUTHEAST UNIV

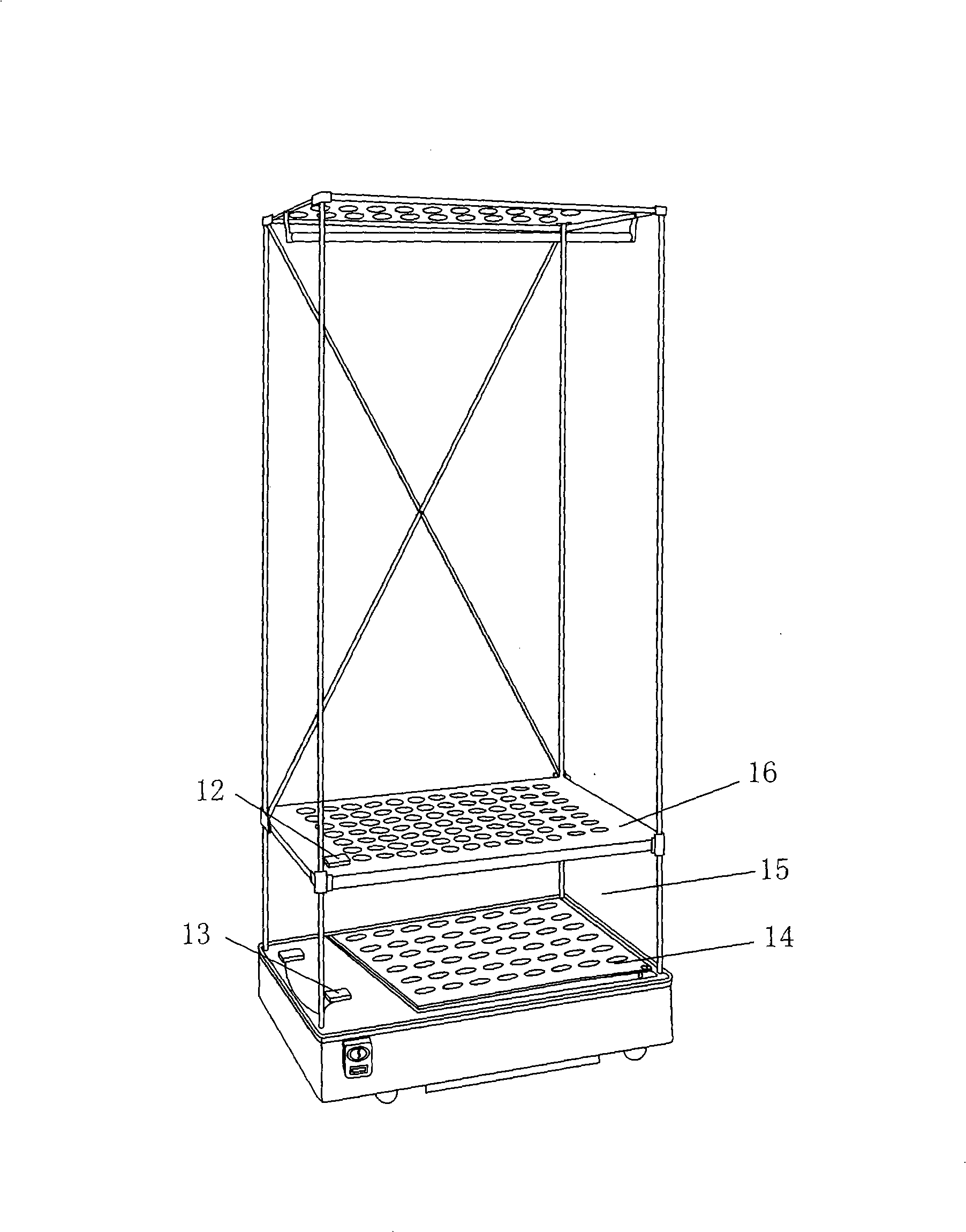

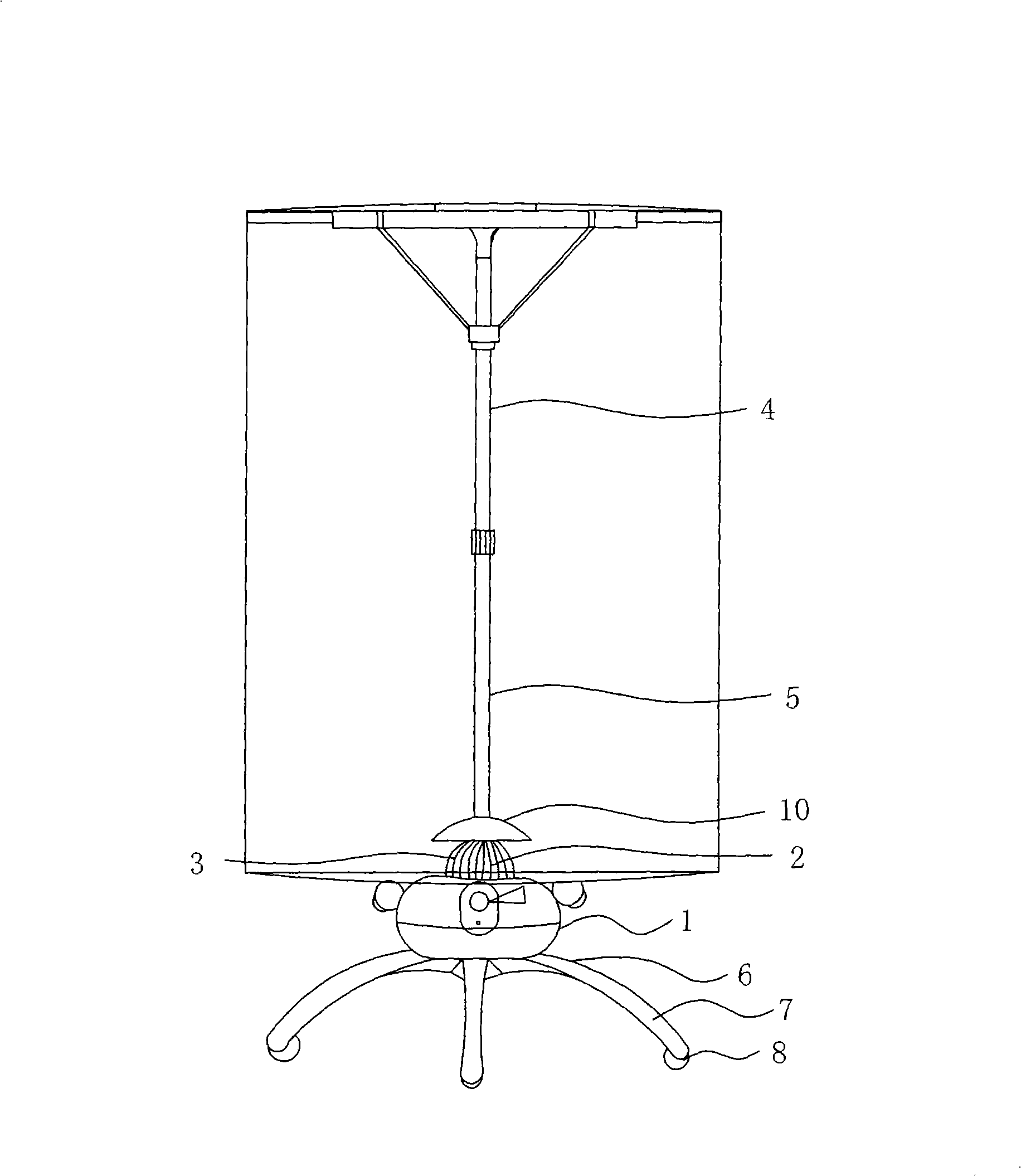

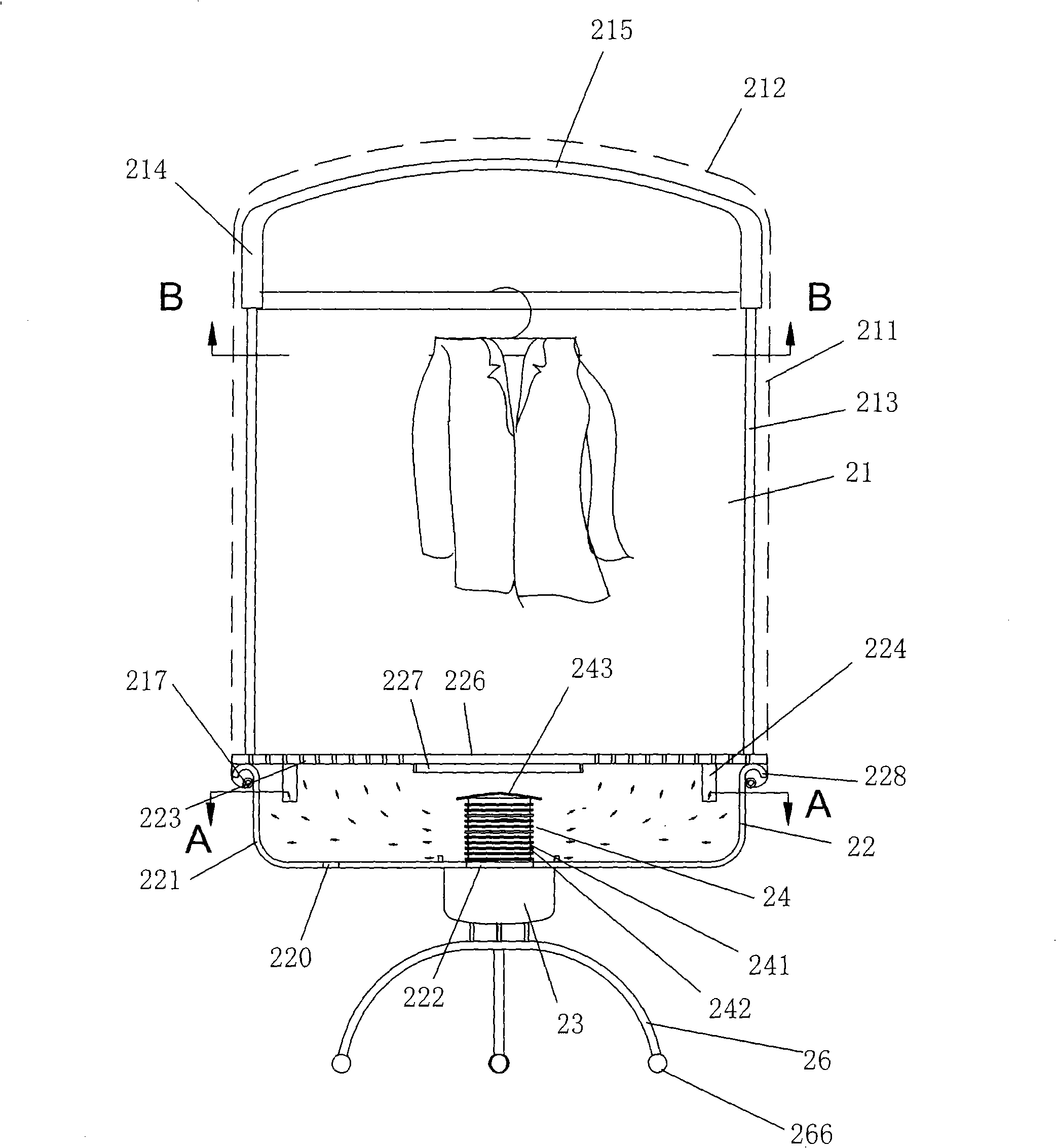

Safe clothes dryer having large spatial structure

ActiveCN101280510ASimple structureEasy to disassembleTextiles and paperLaundry driersEngineeringMechanical engineering

The invention relates to a clothes dryer, in particular to a safety clothes dryer with large-space structure , which comprises a clothes drying room, a hot air abating room, a hot air making room and a controller, wherein the clothes drying room, the hot air abating room and the hot air making room are respectively an independent part and are assembled in sequence from top to bottom. The hot air abating room is arranged below the clothes drying room and is a basin-shaped box with top opening, the bottom of the basin-shaped box is provided with an air intake connected with the hot air making room, an air-guiding safety cover is arranged at the top opening of the basin-shaped box and a clothes drying room installation device is arranged at the top opening of the basin-shaped box. The clothes drying room is composed of a bucket-shaped cloth cover, a support rack for supporting the bucket-shaped cloth cover, a basin-shaped box for forming the hot air abating room, a support member that is inserted connectively at the peripheries of the basin-shaped box and the support rack, a hot air making room, and bottom support feet. The clothes dryer has the advantages of large space, safety use, simple structure, convenient assembly / disassembly, transportation and installation, and that consumer can finish installation only in short time.

Owner:胡杰波

Low-temperature-resistant ultra-toughness modified nylon alloy material and preparation method thereof

ActiveCN102766330AGood compatibilityChange low temperature impact resistanceCoatingsAntioxidantUv absorber

The invention discloses a low-temperature-resistant ultra-toughness modified nylon alloy material and a preparation method thereof. The low-temperature-resistant ultra-toughness modified nylon alloy material is prepared from the following raw materials: PA (poly A) 66, PA6, a main flexibilizer, an auxiliary flexibilizer, a compatilizer, a main ultraviolet absorption agent, an auxiliary ultraviolet absorption agent, a main antioxidant, an auxiliary antioxidant and a lubricating agent. The preparation method comprises the following steps of: mixing the raw materials in a high mixing machine uniformly; putting the mixture into a dual-screw extrusion pelletizer for heating and fusing, vacuumizing, slicing and pelletizing; drying materials after pelletization in a vacuum box, so as to obtain the product granulate low-temperature-resistant ultra-toughness modified nylon alloy material provided by the invention. The product low-temperature-resistant ultra-toughness modified PA66 alloy material provided by the invention has high comprehensive performances and excellent temperature-resistant performance, achieves the advanced level of similar products abroad, can replace imported materials, and meets the high-quality requirement of the domestic market on the ultra-toughness PA66 alloy.

Owner:LUOHE KELAIBAO TECH CO LTD

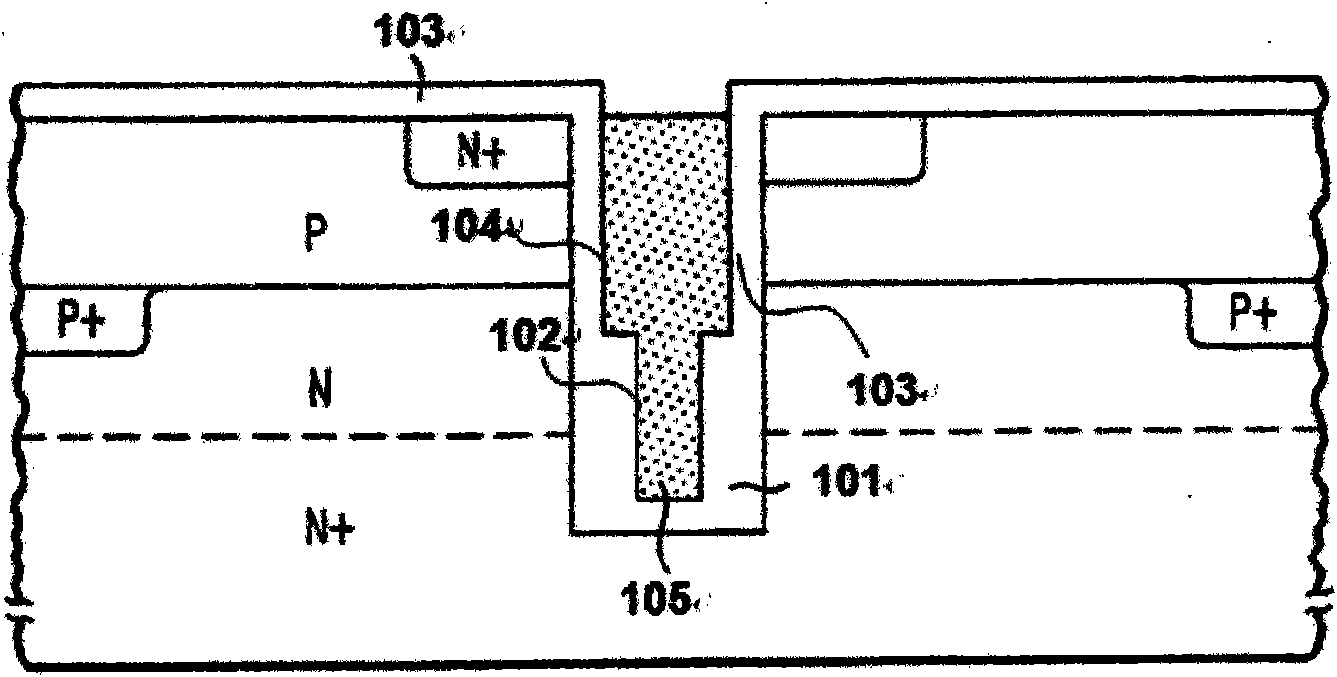

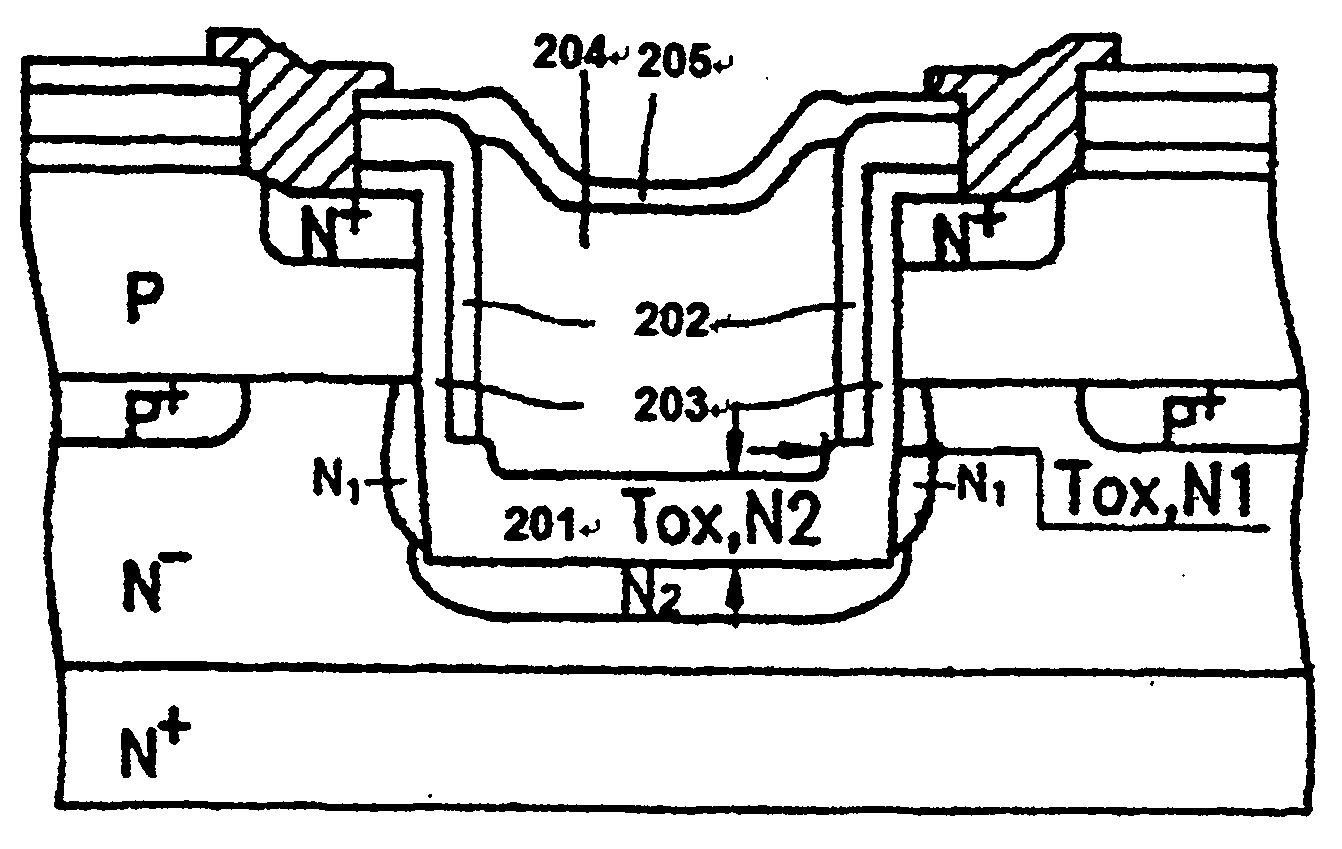

Non-punch-through deep trench IGBT with field stop structure and manufacturing method thereof

InactiveCN101826552ALow costEasy to implementSemiconductor/solid-state device manufacturingSemiconductor devicesElectromagnetic interferenceEngineering

The invention discloses a non-punch-through deep trench IGBT with a field stop structure and a manufacturing method thereof. The IGBT is equivalent to one NMOS field-effect tube driving one PNP bipolar transistor or one PMOS field-effect tube driving one NPN bipolar transistor. The NMOS tube or the PMOS tube in the invention realizes a vertical gate and a vertical trench through a deep trench technology and a high voltage-resistant trench gate technology is adopted; the NMOS tube or the PMOS tube and the PNP tube or the NPN tube are directly manufactured on a polished wafer to form a non-punch-through IGBT structure; and a field stop layer with the same doping type as a base region and with doping concentration higher than the base region is formed in the base region of the PNP tube or the NPN tube at a position close to a collector region through ion implantation or diffusion. The invention has the advantages that the cost of the manufacturing method is low and the implementation is easy; and the area of the manufactured IGBT is small, the switching loss is small, the short-circuit tolerance is high, the anti-electromagnetic interference capacity and the radiation resistance are enhanced and the like. Thereby, the demand of the market on the high quality of IGBT products is satisfied.

Owner:TIANJIN HUANXIN TECH DEV

Manufacture method of cold-rolled electrolytic tin substrate

ActiveCN102794301AStable productionReduce manufacturing costWork treatment devicesFurnace typesHydrogenPush pull

The invention discloses a manufacture method of a cold-rolled electrolytic tin substrate. The manufacture method comprises the steps of: (1) processing the produced molten iron by converter smelting, vacuum treatment, continuous casting and hot rolling after desulfuration to obtain a cold-rolled material; (2) pickling by a shallow-trench turbulent push-pull hydrochloric acid pickling set; (3) carrying out cold rolling for the first time by using a six-roller HC reversing mill, and rolling to a semi-product with a thickness of 0.5 to 0.6 mm after passing through 4 to 7 rolling passes; (4) cleaning by an electrolytic degreasing set; (5) carrying out annealing for the first time in a full-hydrogen shine-cover annealing furnace; (6) carrying out cold rolling for the second time by using the six-roller HC reversing mill; (7) carrying out annealing for the second time in the full-hydrogen shine-cover annealing furnace; (8) leveling by using a four-roller leveling machine, wherein the rolling force is controlled between 3000 to 4500kN; and (9) trimming by a re-reeling set, oiling, packaging and storing in a warehouse. The manufacture method disclosed by the invention has the advantages of stable production and low production cost, and can meet the requirement for high-quality electrolytic thin substrate in the food package industry.

Owner:山东泰山轧钢有限公司

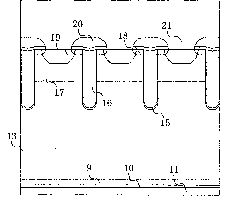

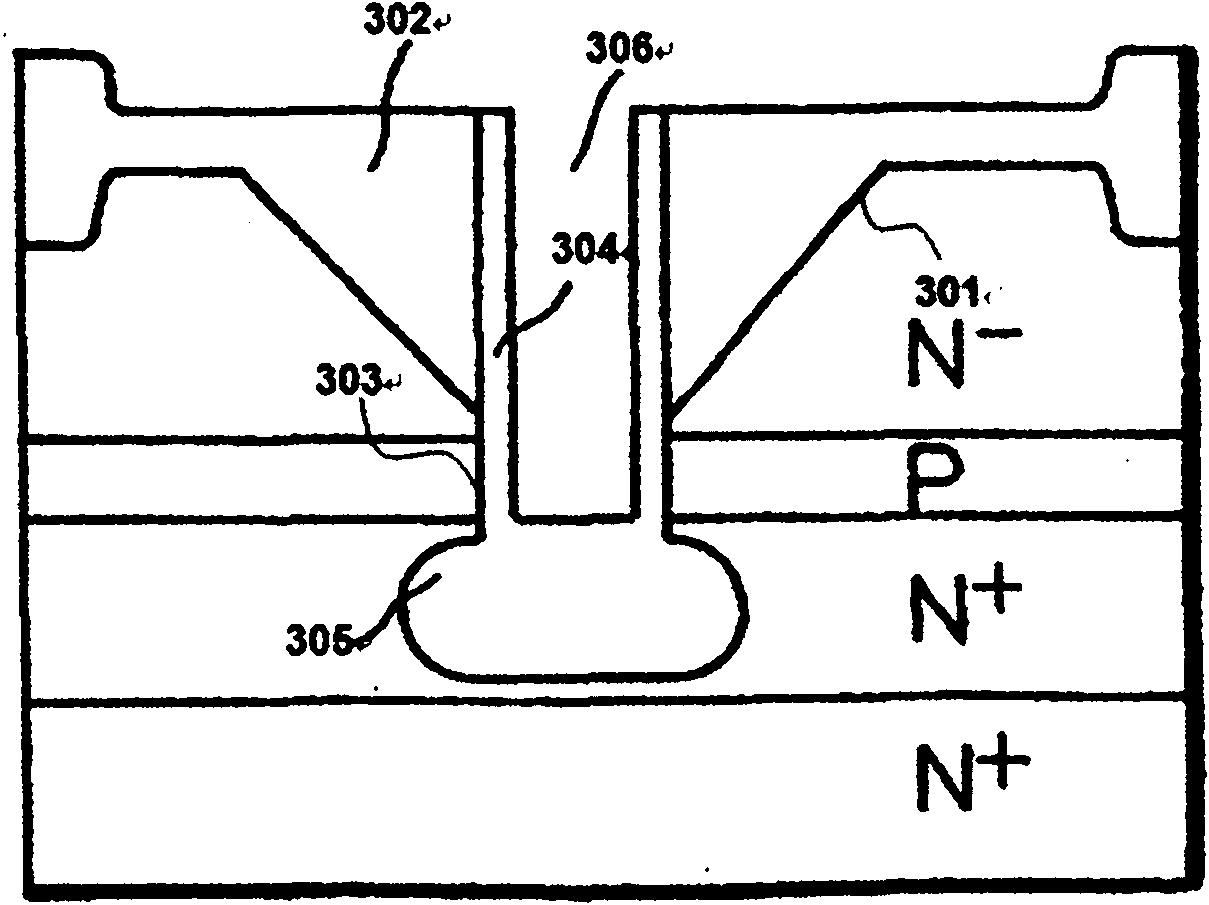

Trench structure for power device and manufacturing method thereof

InactiveCN102024848AQuality improvementImprove conductivitySemiconductor devicesSilicon oxideDry etching

The invention discloses a trench structure for a power device and a manufacturing method thereof. The trench structure has the characteristics that: a side wall is vertical and provided with a thin silicon oxide film or a side wall is provided with a slight slope (theta=80-90 degrees) and a thin silicon oxide film; the bottom is smooth and is provided with a thick silicon oxide film; doped polycrystals are filled without gaps; boundary defects are eliminated; and the surface of a wafer at a trench position does not have any step or has a small step. The manufacturing method for the trench structure comprises the following steps of: forming the trench through dry etching; removing surface defects of the trench by using an oxidation process; forming the side wall of the trench by using a silicon nitride film; and forming a silicon oxide film with a thick bottom and a thin side wall in the trench through selective oxidation, wet etching and reoxidation; filling a good-conductivity polysilicon film without gaps; and removing the excessive polysilicon film outside the trench through etching or a chemically mechanical polishing process to form the trench structure required by a trench type power device. The manufacturing method is simple and stable in process, and is easy to implement; and the manufactured device has the advantages of small area, good electrical characteristics and the like.

Owner:TIANJIN HUANXIN TECH DEV

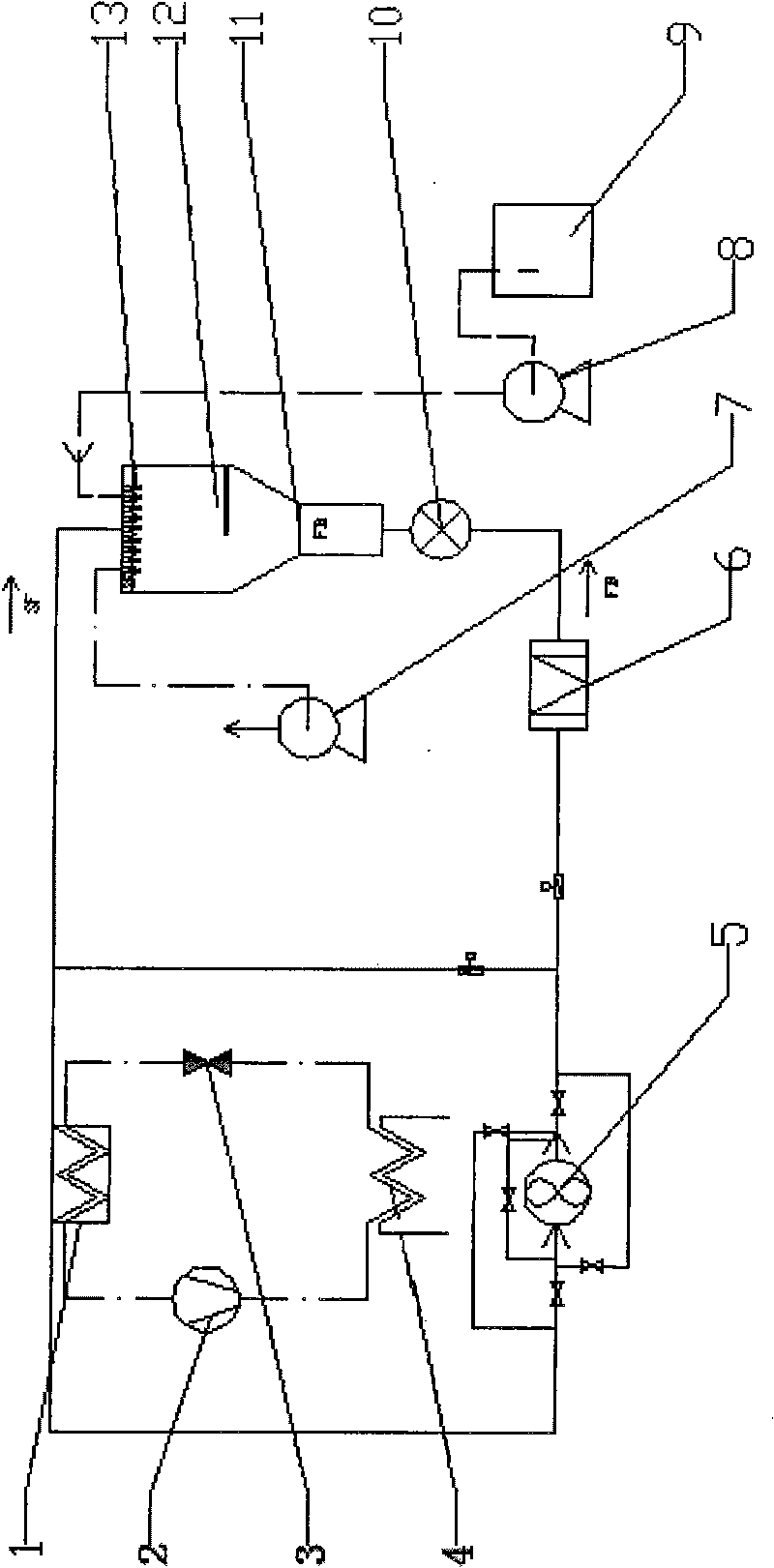

Intermittent drying system and method of multifunctional fluidized bed for freezing, spraying and pelleting

ActiveCN101738063AReduce damageReduce quality degradationDrying solid materials without heatProcess engineeringLiquid food

The invention discloses intermittent drying system and method of a multifunctional fluidized bed for freezing, spraying and pelleting, which has the advantages of flexible structure, variety methods, low use cost and the like. The structure is characterized by comprising a refrigeration system and a fluidized bed drying system for spraying and freezing in vacuum, wherein a vacuum spraying drying system is connected with a feeding system, the refrigeration system is connected with the feeding end of the vacuum spraying drying system, the other path of pipeline of the refrigeration pipeline is connected with a fluidized device of the vacuum spraying drying system through a pulse adjusting device to form a closed ring system, thereby flexible switch among different drying methods can be realized, and intermittent operation is carried out. The invention is mainly used for dewatering storage of products with high additional value, such as liquid foods, medicines, biological products and the like and development operation of new techniques of dewatering products such as liquid foods, medicines and biological products.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

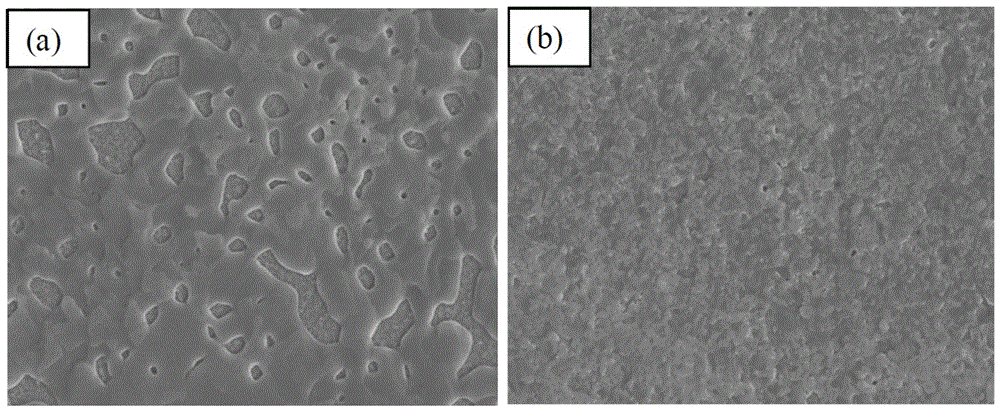

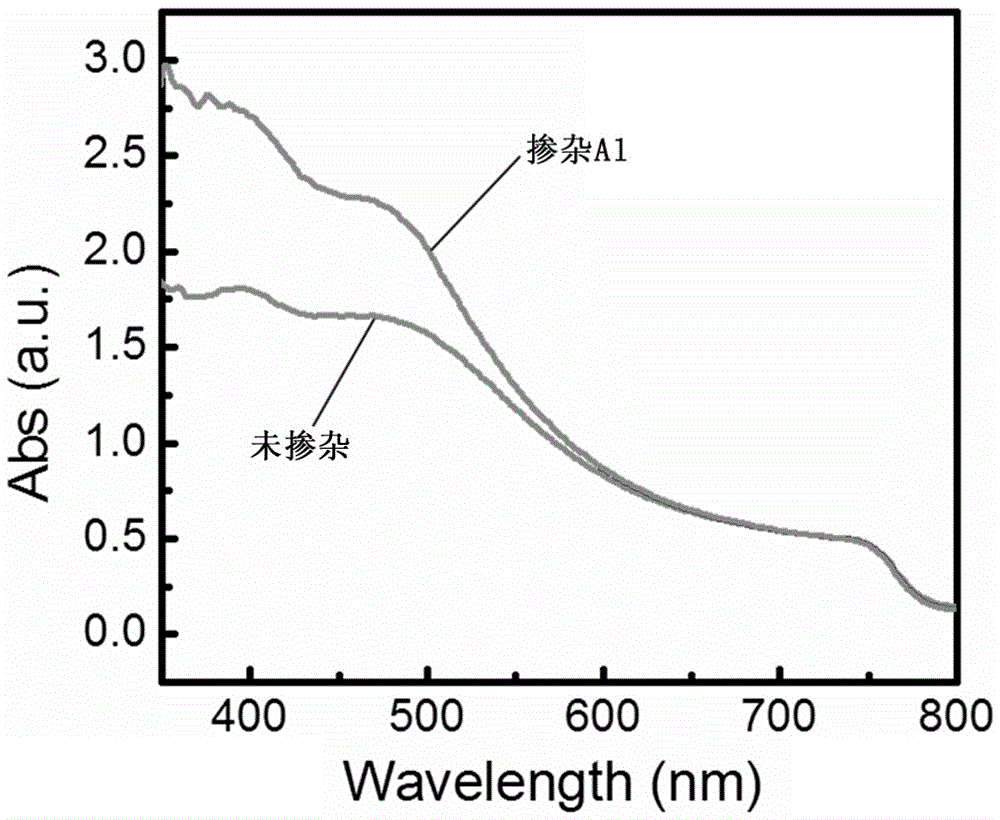

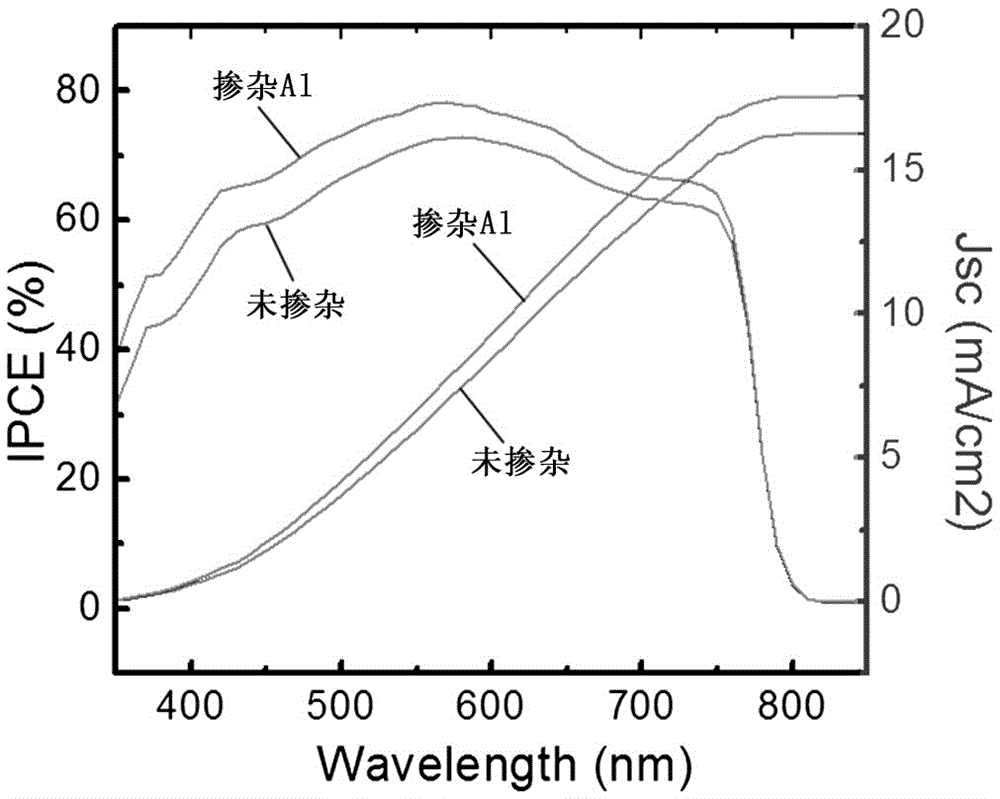

Metal-ion-doped perovskite thin film, preparation method and application therefor

ActiveCN105702865AGood coverageFew grain boundariesSolid-state devicesSemiconductor/solid-state device manufacturingIonPerovskite solar cell

The invention discloses a metal-ion-doped perovskite thin film, a preparation method and an application therefor. The preparation method for the metal-ion-doped perovskite thin film comprises the specific steps of dissolving metal powder into an HX solution to form the HX solution containing metal ions, wherein X is Cl, Br or I; enabling the HX solution containing metal ions to be mixed with an methylamine solution, and drying to prepare metal-ion-doped MAX powder; enabling the metal-ion-doped MAX powder to be mixed with the a lead salt, and dissolving the mixture into dimethylformamide to prepare a perovskite precursor liquid, wherein the lead salt is PbBr<2>, PbI<2> or PbCl<2>; and preparing the metal-ion-doped perovskite thin film from the perovskite precursor liquid through a rotary coating process. The metal-ion-doped perovskite thin film is prepared through a liquid phase one-step method; the cover degree of the prepared perovskite thin film is greatly improved; and the requirement of a perovskite solar cell on the high quality of the perovskite thin film can be fully satisfied.

Owner:HEBEI UNIVERSITY

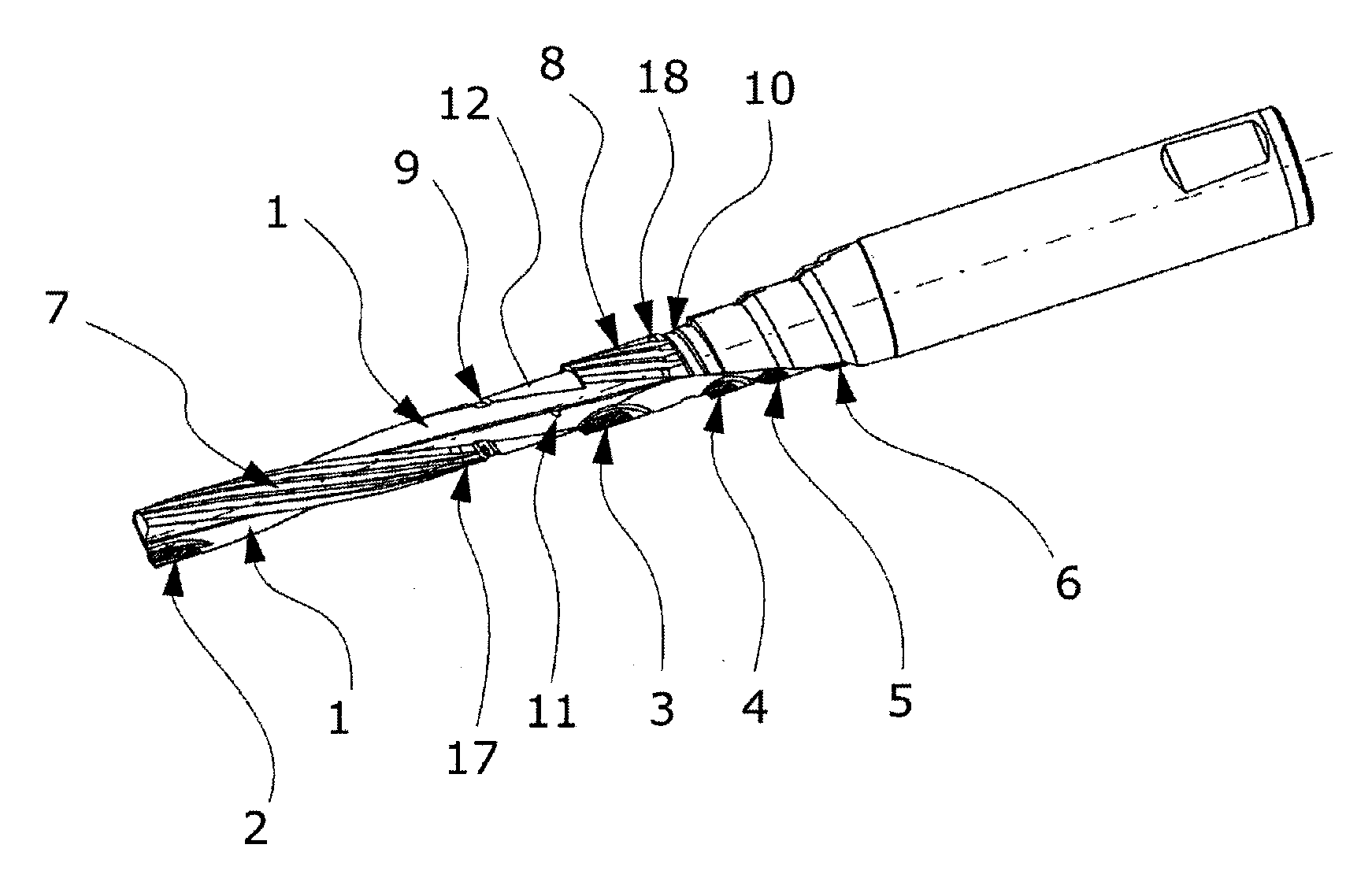

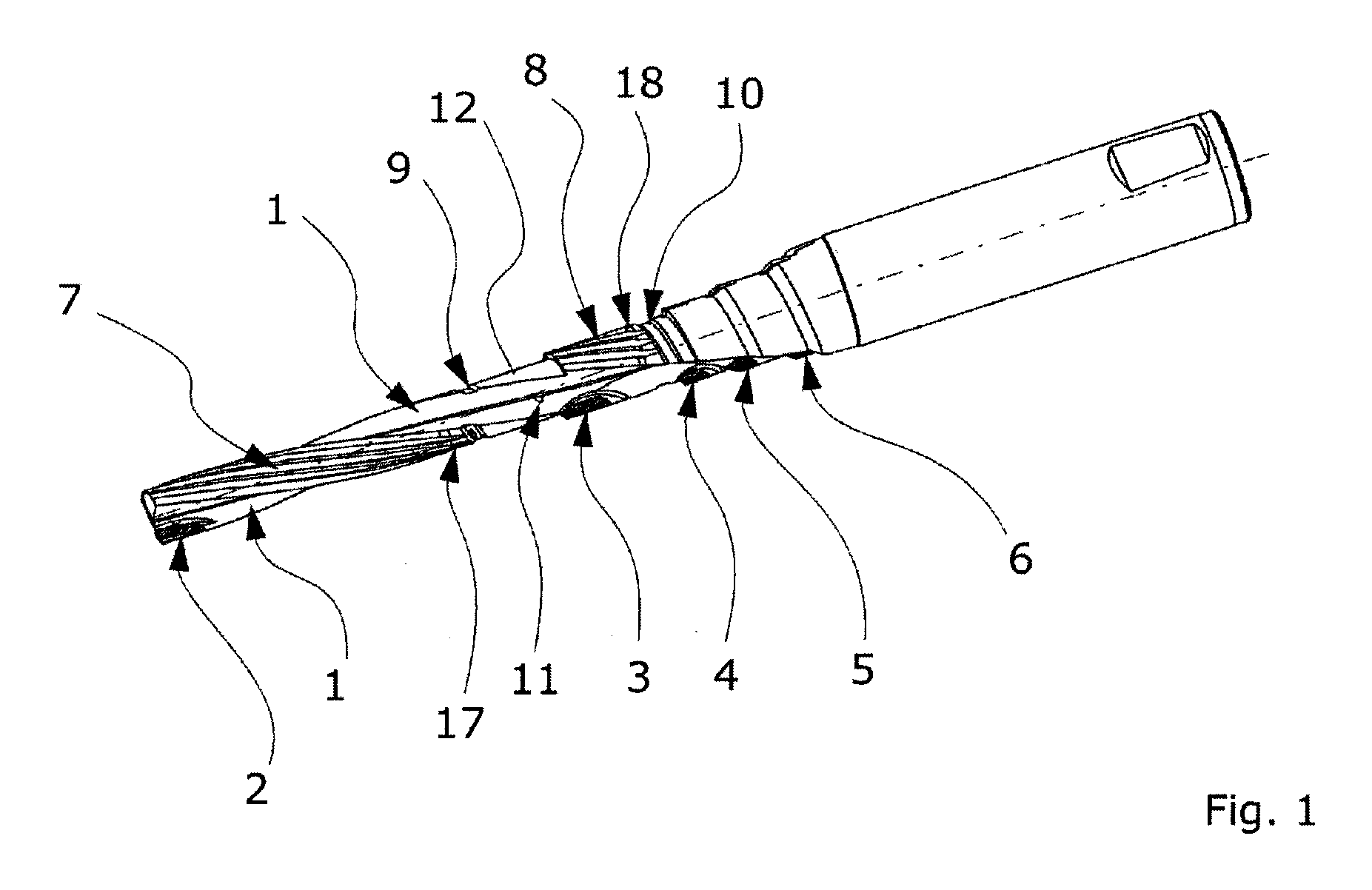

Reaming tool and a process for manufacturing such reaming tool

InactiveUS20080152445A1Cost-effective to manufactureHigh quality requirementThread cutting toolsWood turning toolsHardnessMetal

The invention relates to a reaming tool which has on its enveloping surface substantially helical flutes. High hardness cutting materials are brazed or soldered to the base material of the reaming tool. Thus, a cost-favourable manufacture of a reaming tool is provided. The invention makes it possible for the shaft and the head of the reaming tool to be made of solid carbide metal, the shaft and the head preferably constituting the one and same integrate body. A considerable improvement is obtained as regards the processing quality, the speed, and also the durability of the tool. This is based on the fact that the chip removal elements are sintered or brazed into the base body of the head initially shaped with the helical flutes, so that a material joint of high quality is provided compared to other joints.

Owner:UNIMERCO

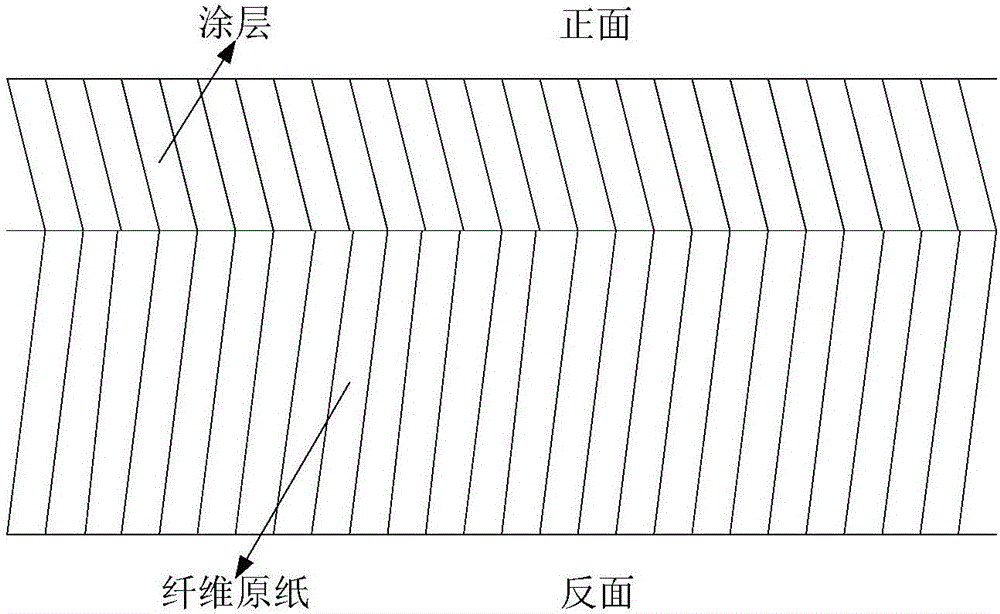

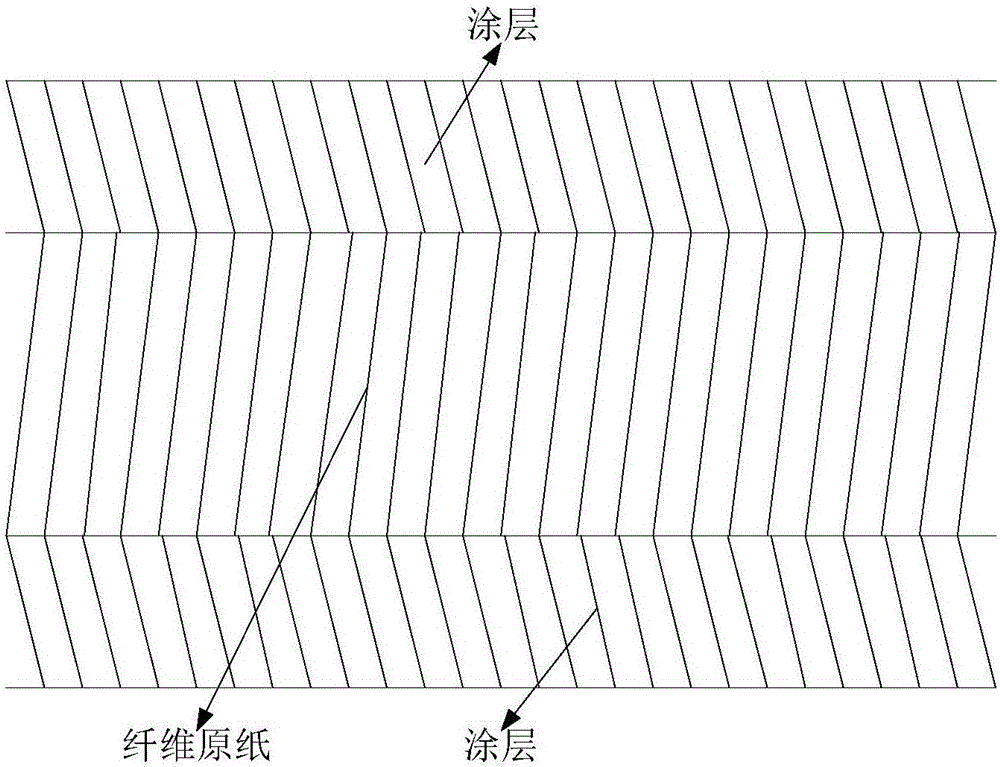

High-temperature-resistant non-combustion cigarette paper and preparation method thereof

ActiveCN106480773AMeet high quality requirementsTo achieve the purpose of high temperature resistanceInorganic fibres/flakesWater-repelling agents additionCombustionTar

The invention discloses high-temperature-resistant non-combustion cigarette paper and a preparation method thereof. The preparation method of the high-temperature-resistant non-combustion cigarette paper comprises the following steps: (1) glue application in pulp: a glue application agent is added into the pulp after pulping, and the solid content is controlled to be 1 to 5 percent of the specified quantity of raw paper; (2) surface glue application after papermaking; (3) single-side or two-side coating after glue application, wherein the coating quantity is 5 to 50g / m<2>; fixed quantity before paper sheet coating is 30 to 120g / m<2>. On the basis of the existing cigarette paper production process, the goal of resisting high temperature is achieved through performing glue application and coating treatment on the cigarette paper, so that the cigarette paper can be applied to the heating on non-combustion cigarettes. The high-temperature-resistant non-combustion cigarette paper obtained by the preparation method can be used at 300 to 500 DEG C; in the use process, the cigarette paper hardly generates color change, avoids tar penetration and does not deform; the high-quality requirement of heating non-combustion paper for cigarettes is met.

Owner:中烟摩迪(江门)纸业有限公司

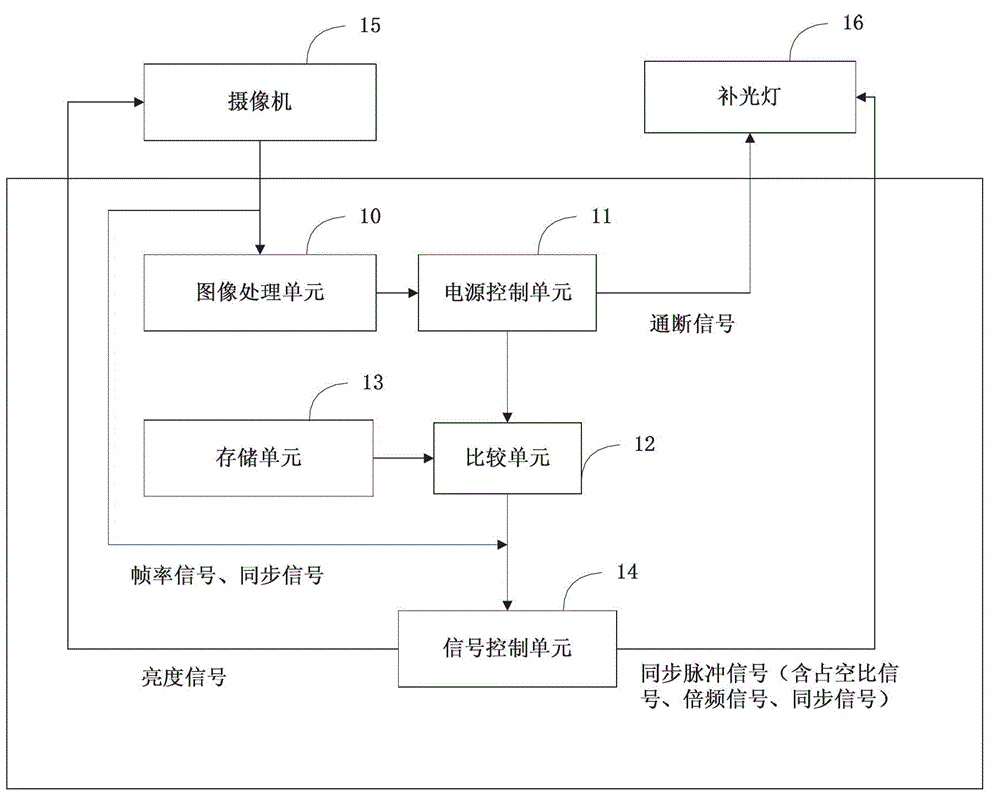

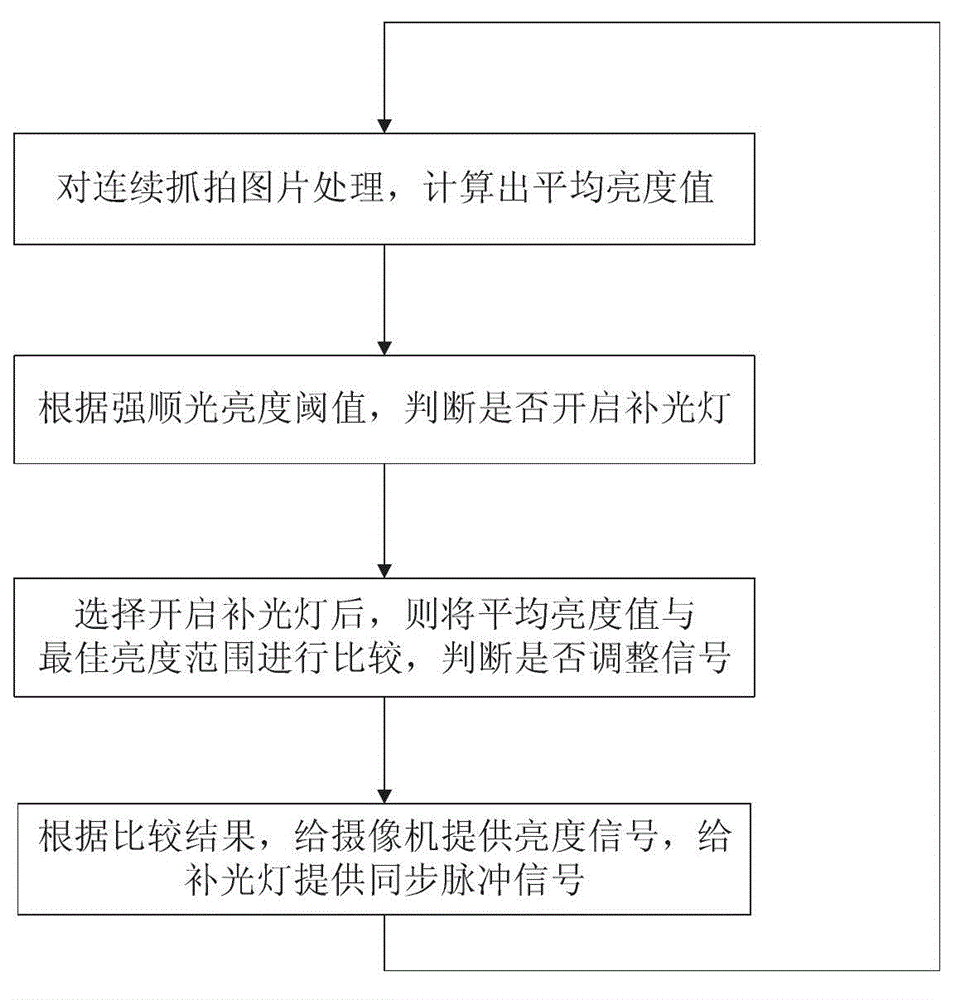

Intelligent control strobe light supplementing method and device of camera

InactiveCN102946517ASimple structureImprove work efficiencyTelevision system detailsColor television detailsIntelligent controlLightness

The invention discloses an intelligent control strobe light supplementing method and a light supplementing device of a camera. The method includes that step one, a luminance signal of continuous snapshot images is calculated by the camera according to a snapshot signal to obtain an average luminance value, whether a light supplementing lamp is switched on or not is determined according to high front lighting luminance threshold value, if the average luminance value is higher than the threshold value, an on-off signal is output to the light supplementing lamp, a power source of the light supplementing lamp is automatically turned off, and if the average luminance value is lower than or equal to the threshold value, the power source of the light supplementing lamp is automatically turned on; and step two, when the light supplementing lamp is switched on, the average luminance value of the snapshot images is calculated again, if the average luminance value is in the optimal luminance range of the snapshot images, the luminance signal of the camera and a synchronization pulse signal of the light supplementing lamp are not required to be adjusted, if the average luminance value is lower or higher than the optimal luminance range of the snapshot images, the output increased or decreased luminance signal of the camera and the increased or decreased synchronization pulse signal of the light supplementing lamp are adjusted, and the adjusted average luminance value is in the optimal luminance range of the snapshot images. By means of the intelligent control strobe light supplementing method and the light supplementing device of the camera, the light supplementing effect and efficiency are improved.

Owner:ZHEJIANG YINJIANG ZHIHUI TRAFFIC GRP CO LTD

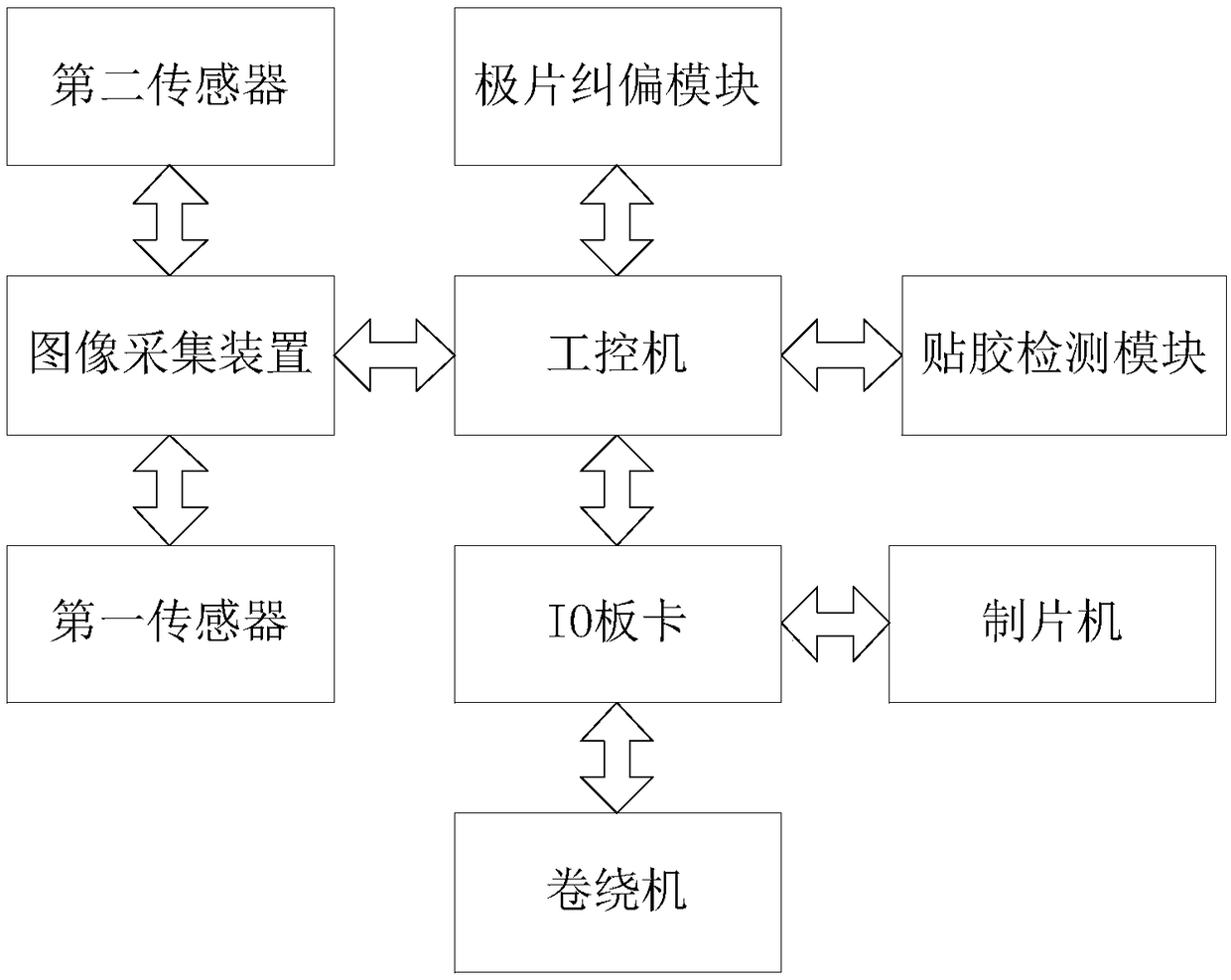

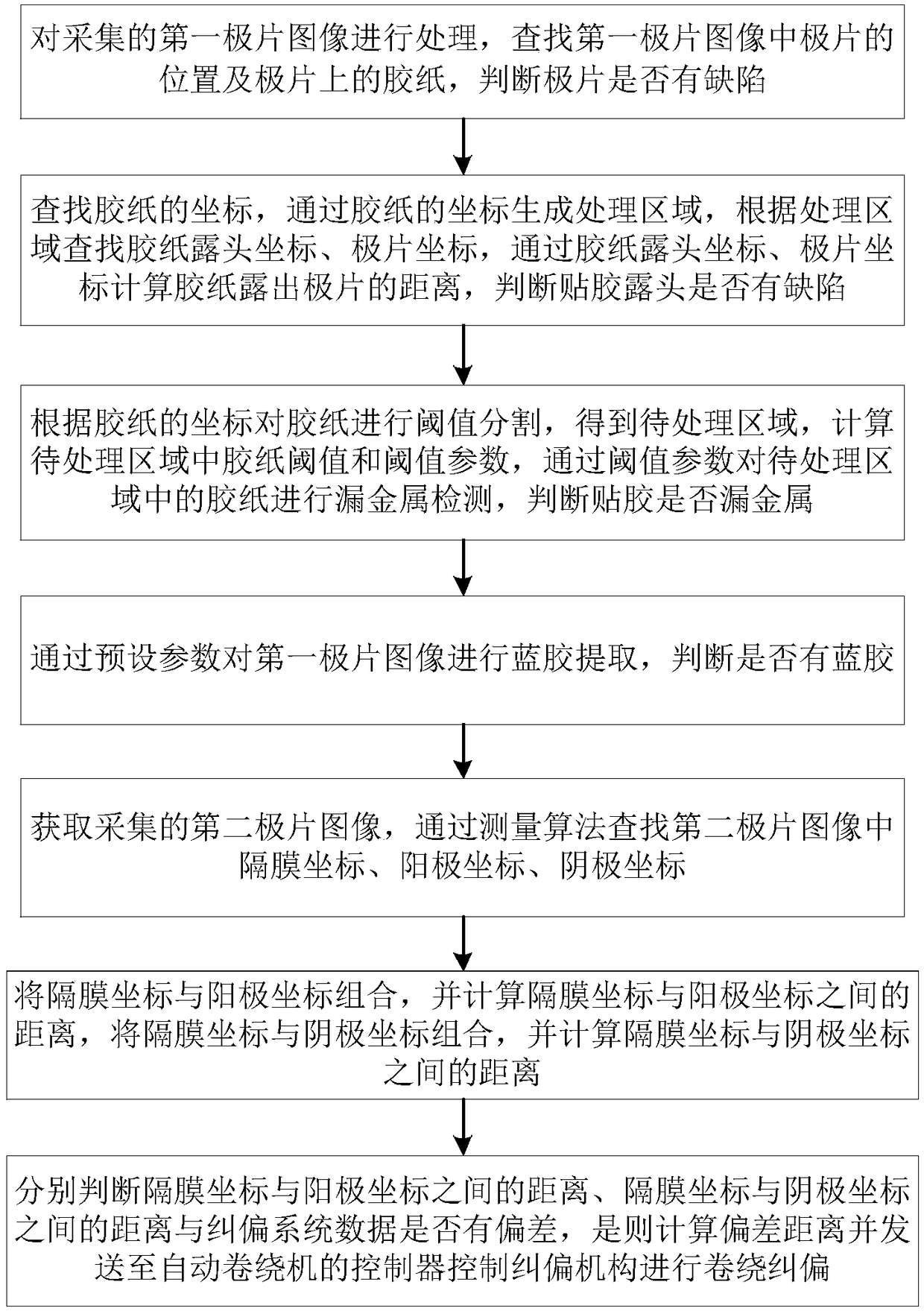

Pole piece making and rubberizing and pole piece correction detection method, equipment, medium and system

PendingCN109444145ASolve the problem of glue defectsImprove efficiencyFinal product manufactureSecondary cellsPole pieceAnode

The invention provides a pole piece making and rubberizing and a pole piece correction detection method. The method includes detecting the position of a pole piece; measuring the size; detecting rubberizing defects; detecting blue glue; searching a parameter coordinate; calculating a coordinate distance; and correcting the pole piece. The invention relates to electronic equipment and a readable storage medium for executing the above method. The invention further relates to the pole piece making and rubberizing and the pole piece correction detection system. The method realizes automatic detection of the position of the pole piece, gummed paper on the pole piece, rubberizing outcrop, rubberizing metal leakage and the blue glue, solves the problem of rubberizing defects of the pole piece, has high efficiency and small error, and can meet the huge requirements of consumers on lithium batteries and high quality requirements; The method realizes the detection of an anode-cathode spacing andan anode-diaphragm spacing of the pole piece, carries out single winding on the pole piece with defects, and carries out winding correction on the pole piece without defects but with correction in the spacings, and thus the problems of detection and correction of the anode-cathode spacing and the anode-diaphragm spacing of the pole piece in the winding process is solved, and the winding quality of battery cores is guaranteed.

Owner:GUANGZHOU SUPERSONIC AUTOMATION TECH

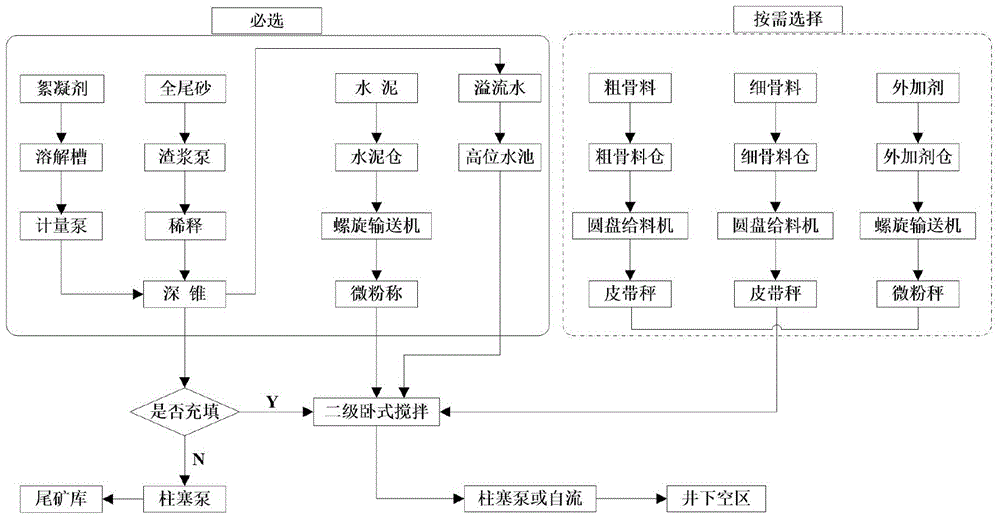

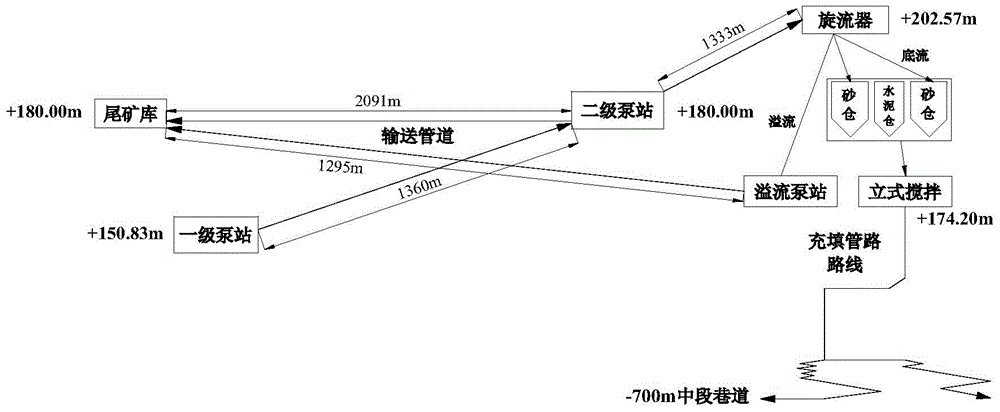

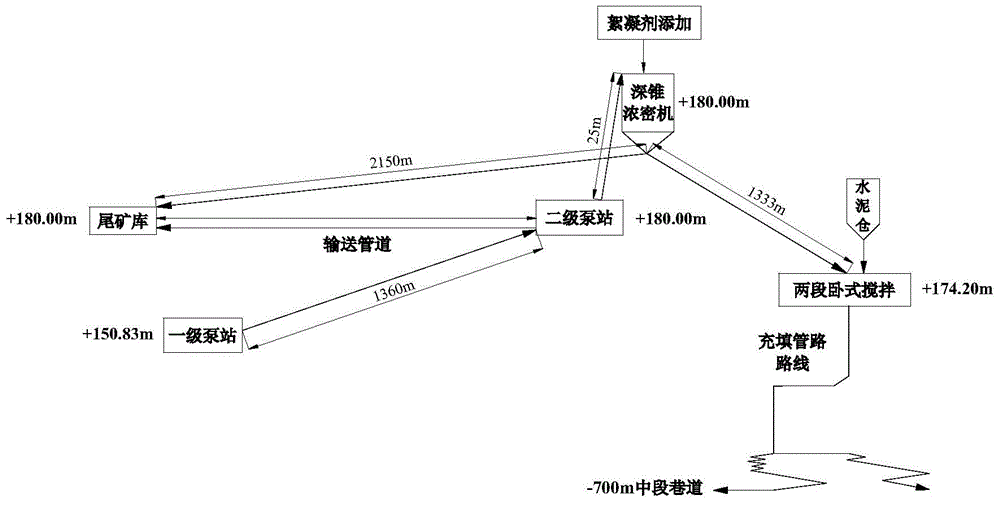

Total-tailings paste filling and stockpiling combined treatment method based on deep-cone thickener

ActiveCN104929683AHigh emission concentrationImprove security levelMaterial fill-upMining engineeringCombined treatment

The invention relates to a total-tailings paste filling and stockpiling combined treatment method based on a deep-cone thickener. A combined treatment system is composed of a one-stage or multi-stage pump station, the deep-cone thickener and a two-segment horizontal stirring device. The deep-cone thickener is arranged near the multi-stage pump station. A continuous feeding and discharging mode is adopted for achieving the continuous concentration process, and the two functions of filling and tailings stockpiling are both taken into consideration. In the running process of a filling system, total tailings of a concentration plant are completely thrown into the deep-cone thickener through the one-stage or multi-stage pump station. When filling is needed, deep-cone bottom flow is pumped to the two-segment stirrer through a mortar pump and is mixed with cement, and qualified paste is prepared and flows to or is pumped to a stope. When filling is not needed, the bottom flow is pumped by a plunger pump to a tailings pond by means of the pump station, and stockpiling of paste is performed. The method can well solve the filling problem of a gob and the stockpiling problem of tailings at the same time, filling cost is greatly reduced, the strength of filling bodies is improved, discharge of the tailings is reduced to the maximum extent, and meanwhile tailings paste is discharged.

Owner:UNIV OF SCI & TECH BEIJING +1

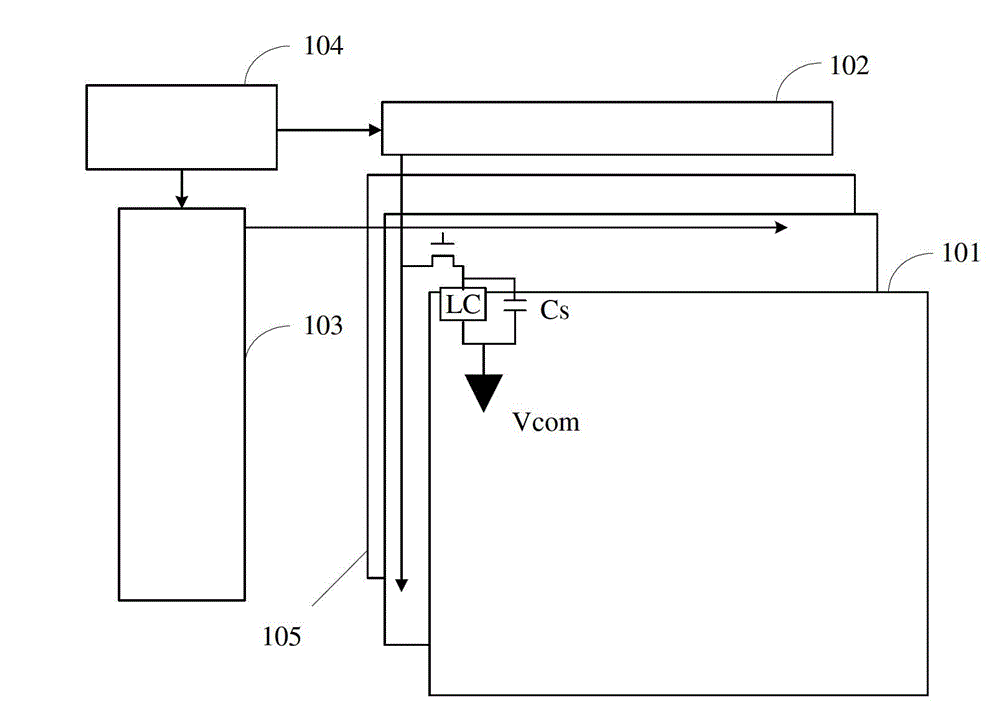

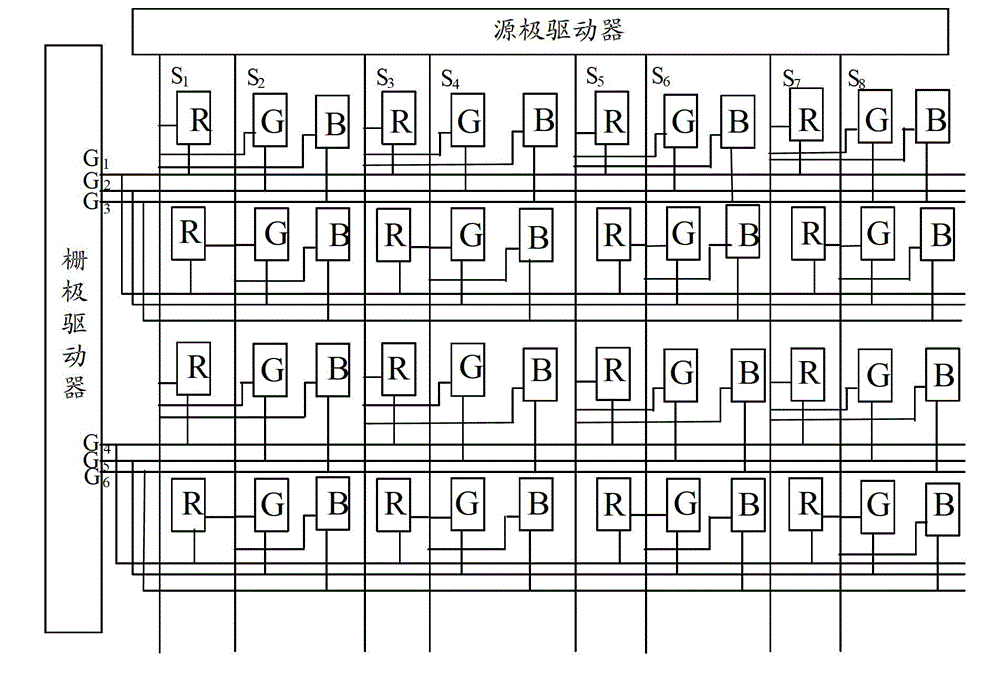

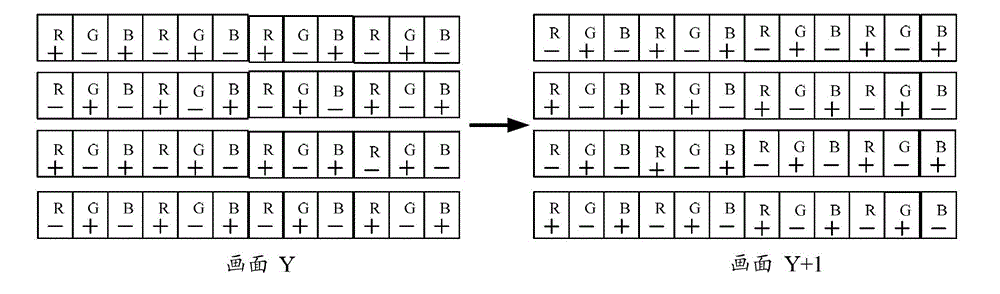

Display and display panel

ActiveCN102799036AIncrease charging timeLow costStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a liquid crystal display and a liquid crystal display panel. The liquid crystal display panel comprises a plurality of data lines, a plurality of scanning lines and a plurality of sub-pixels arranged in a matrix form; three rows of scanning lines are arranged between each two rows of the sub-pixels; and a line of data lines are arranged between each line or each two lines of the sub-pixels. According to the technical scheme of the invention, the pixel charging time can be prolonged when the high-quality requirement is met.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

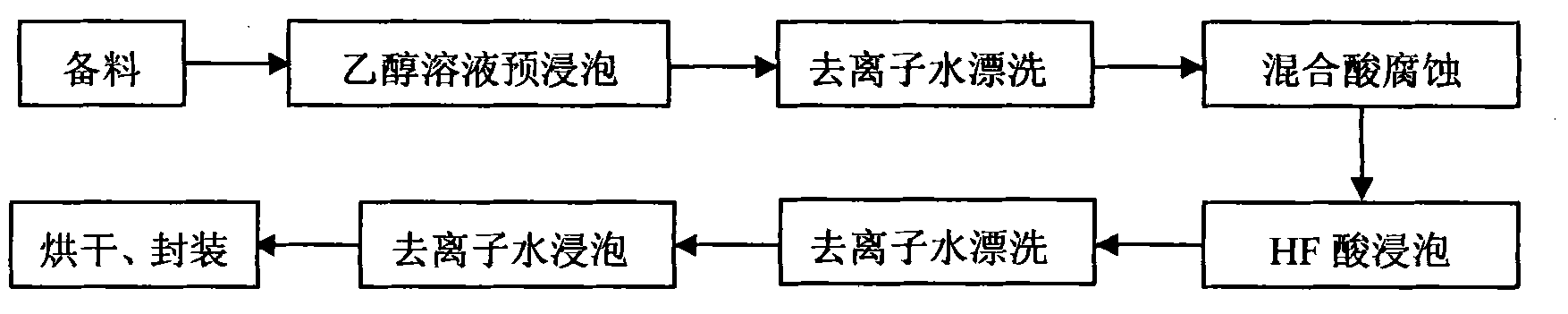

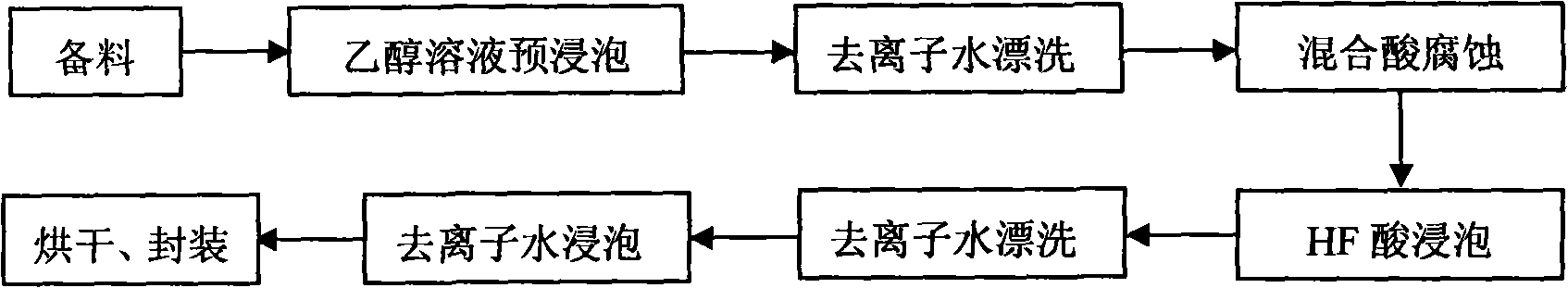

Cleaning method of policrystalline silicon raw material

InactiveCN101974785ALow impurity contentImprove quality requirementsAfter-treatment detailsHydrofluoric acidCleaning methods

The invention discloses a cleaning method of a policrystalline silicon raw material. The method comprises the following steps: 1) placing the policrystalline silicon raw material in ethanol solution for presoaking; 2) rinsing the presoaked policrystalline silicon raw material with deionized water; 3) placing the rinsed policrystalline silicon raw material in a mixed acid liquor of HNO3 and HF to corrode; 4) placing the corroded policrystalline silicon raw material in hydrofluoric acid to soak; 5) after soaking, placing the policrystalline silicon raw material in a deionized water tank with the overflow function to rinse; and 6) placing the rinsed policrystalline silicon raw material in deionized water to perform soaking treatment. The policrystalline silicon raw material cleaned and treated by the method of the invention has no spot on the surface, no oxidation layer and low impurity content, thus the problems of the existing cleaning process of the policrystalline silicon raw material that nonuniform corrosion is easy to cause and an oxidation layer or spots are easy to generate on the surface, can be overcome and the high quality requirement of the policrystalline silicon raw material can be met.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

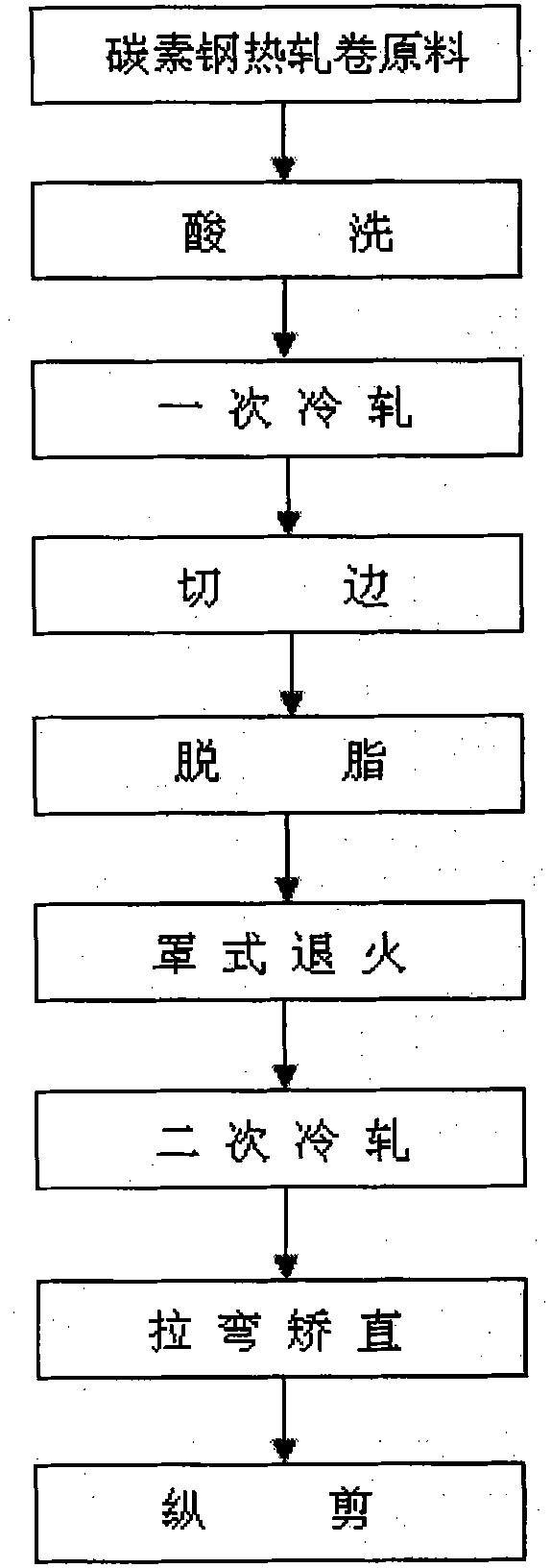

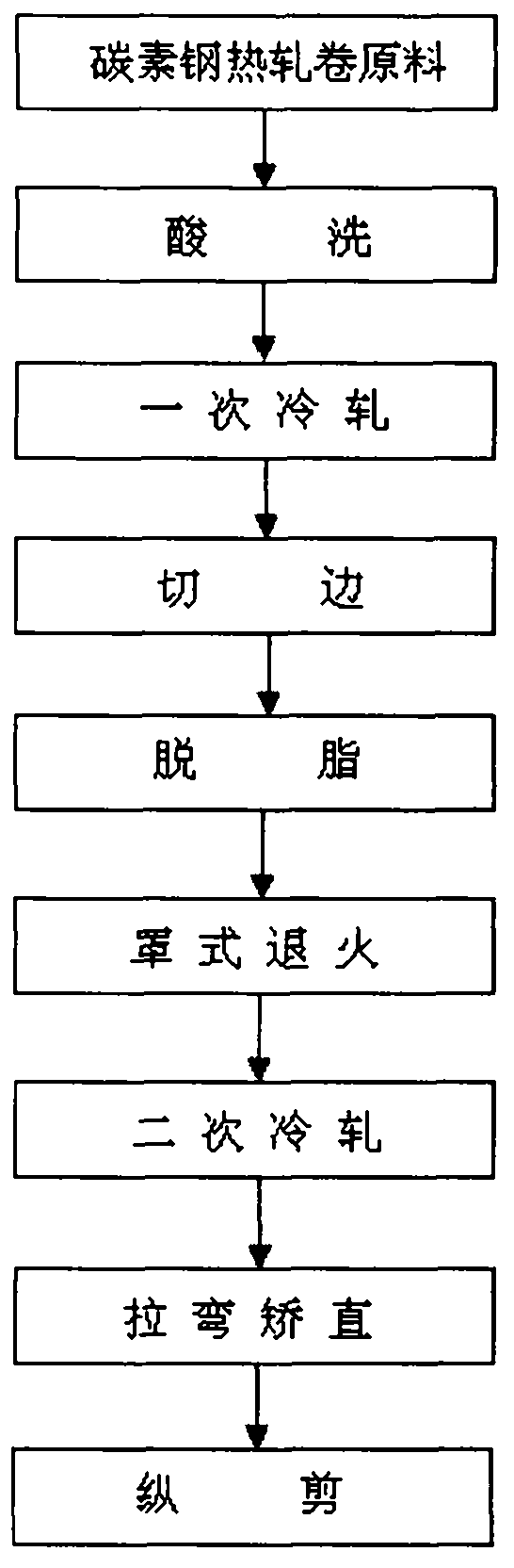

Production technique of high-accuracy cold-rolling carbon-steel steel belt for electronic industry

InactiveCN101871105AThickness tolerance fluctuations are smallStable performanceTemperature control deviceMetallic material coating processesCarbon steelSlip line

The invention relates to a production technique of a high-accuracy cold-rolling carbon-steel steel belt for the electronic industry, comprising the following steps: pickling the raw materials, cold rolling primarily, cutting edges, spraying and degreasing, annealing in a cover type manner, cold rolling secondarily, stretching crookedly and straightening and cutting into a finished product. The production technique adopts a four-roller high-accuracy reversing rolling machine and a unique rolling technique to conduct cold rolling, leads the product to has little thickness tolerance fluctuation, stable performance, uniform and consistent surface color, and no defects of color difference, scratching, slip line and the like, good plate-shaped flatness and straightness by the techniques of degreasing, annealing in a cover type manner, stretch bending and straightening, and the like, remarkably improves the product quality, is suitable for industrialized production, meets the high-quality requirements of the electronic industry, replaces stainless steel materials, and reduces the cost.

Owner:YONGXIN PRECISION MATERIAL WUXI

Preparation method of nano calcium carbonate capable of improving bonding strength of oxime-removing silicone sealant

ActiveCN103756366AImprove thixotropyHigh bonding strengthMaterial nanotechnologyNon-macromolecular adhesive additivesCrystal morphologyCarbonization

The invention relates to a preparation method of nano calcium carbonate capable of improving bonding strength of an oxime-removing silicone sealant. The preparation method has the characteristics that in the preparation process, the crystal morphology and growth rate of the crystal face are controlled according to the principle of crystallization to realize required crystal morphology and grain size; a certain amount of a dispersant is added into the carbonization process, and then strong stirring is performed, so that surface charge and steric hindrance are effectively controlled after nano calcium carbonate carbonization is terminated; surface treatment is carried out on nano calcium carbonate slurry under a certain process condition after particles in the nano calcium carbonate slurry are uniformly dispersed to further improve the steric hindrance and more uniformly disperse the particles; excellent nano calcium carbonate capable of improving bonding strength of the oxime-removing silicone sealant can be produced on an industrial device.

Owner:宣城新威华化工科技有限公司

Medical photography system and photography method implemented by same

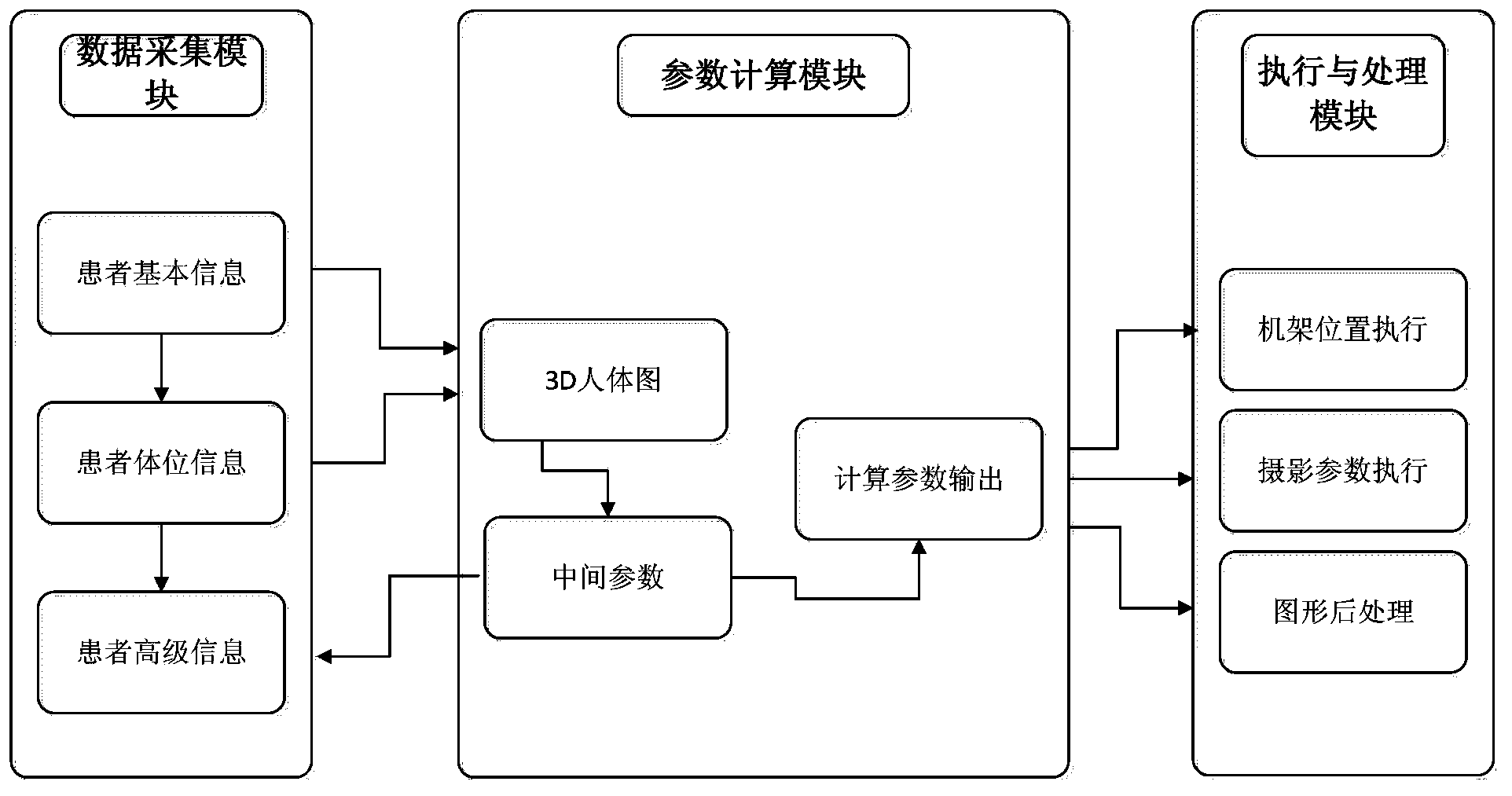

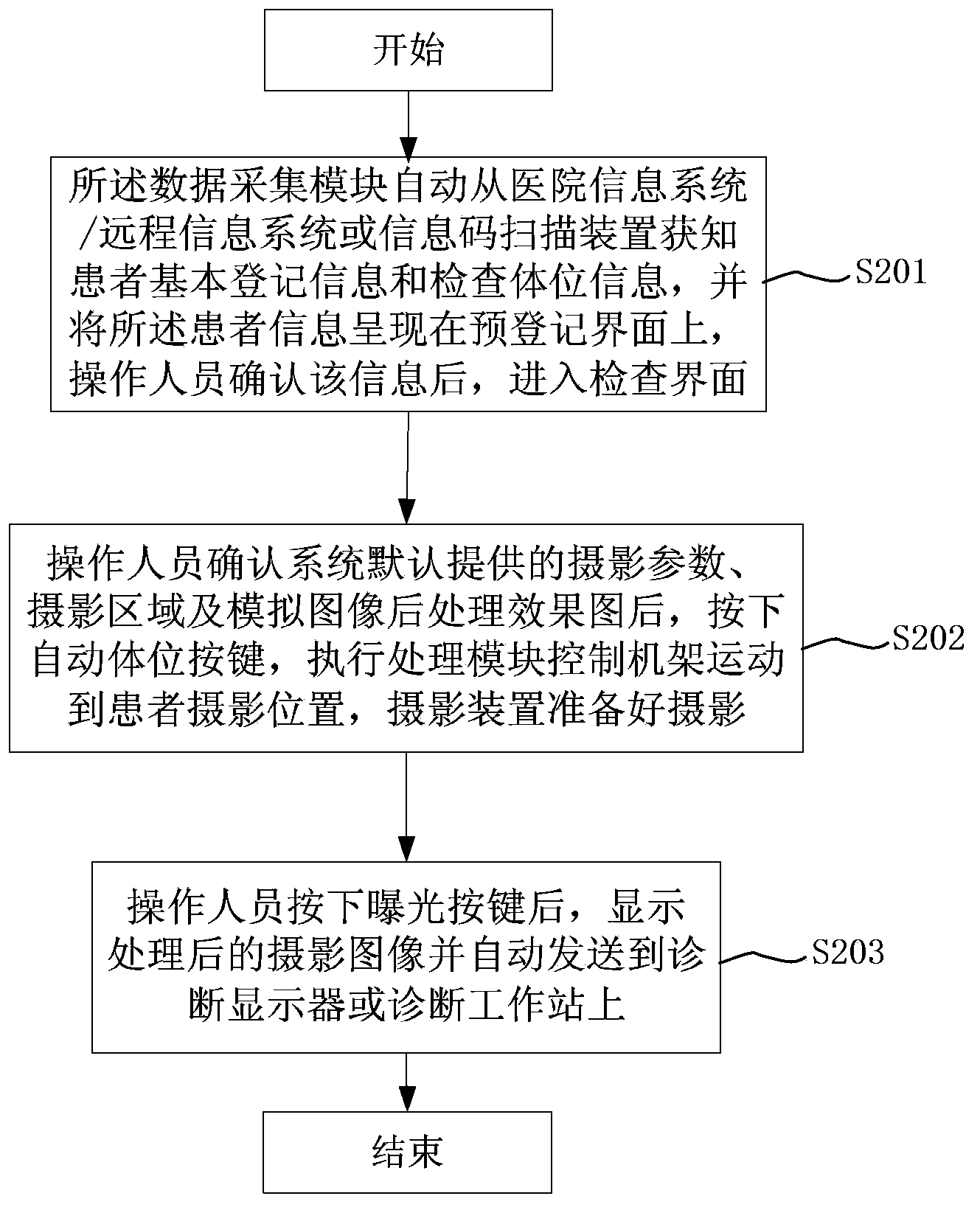

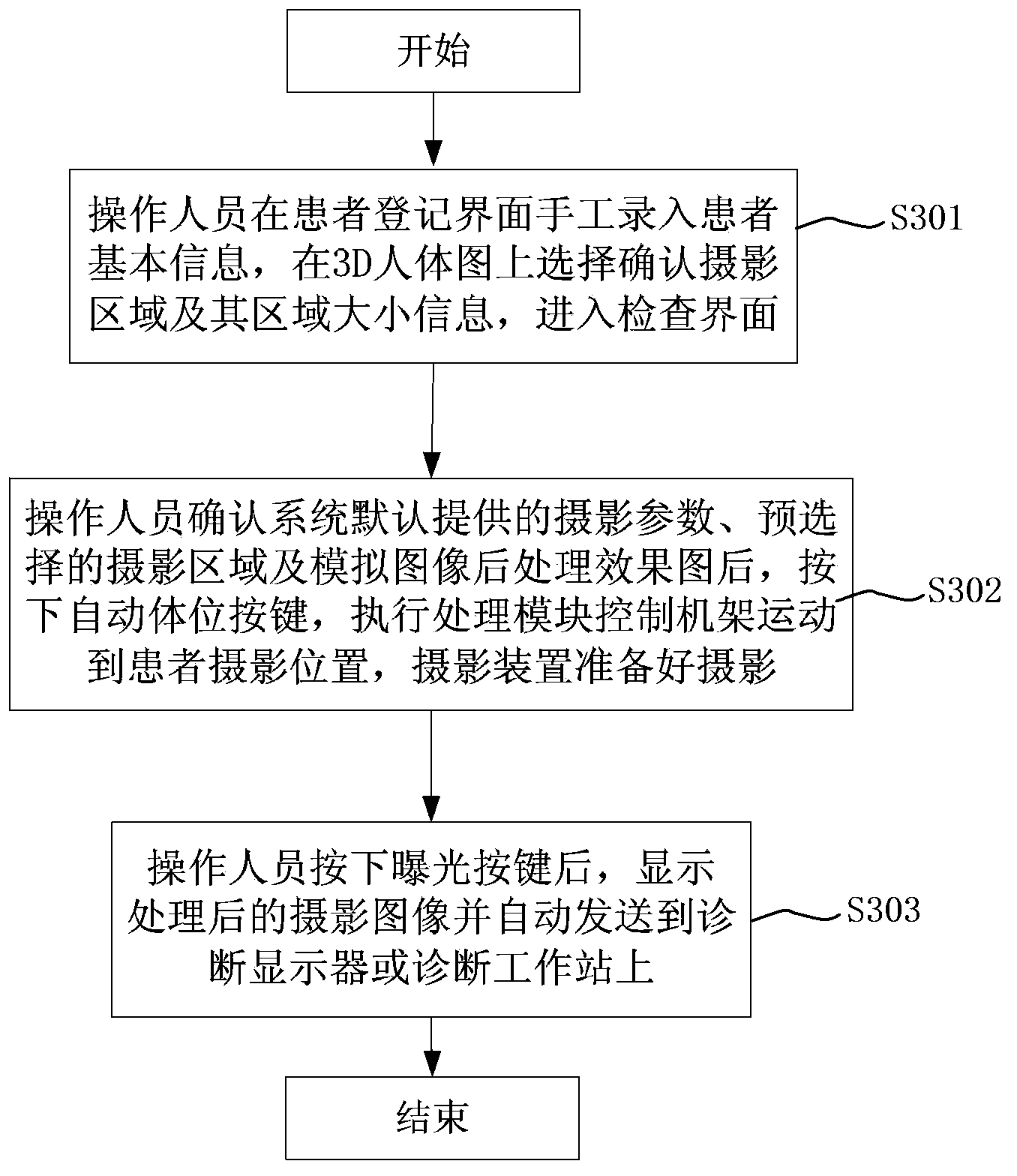

ActiveCN104068886ALower skill requirementsReduce workloadComputerised tomographsTomographyProcess moduleImage post processing

The invention discloses a medical photography system and a photography method implemented by the same. The medical photography system comprises a data acquiring module, a parameter calculating module and an executing and processing module. The data acquiring module is used for acquiring information of patients; the parameter calculating module determines framework location parameters, photography parameters and image post-processing parameters according to the information of the patients; the executing and processing module controls framework locations according to the framework location parameters, controls photography devices to carry out photography on the positions of the patients according to the photography parameters and processes acquired photography images according to the image post-processing parameters. The medical photography system and the photography method have the advantages that working processes can be simplified, skill requirements on operators can be lowered, the clinical training efficiency can be improved, and the operators can effectively concentrate on medical image diagnosis.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

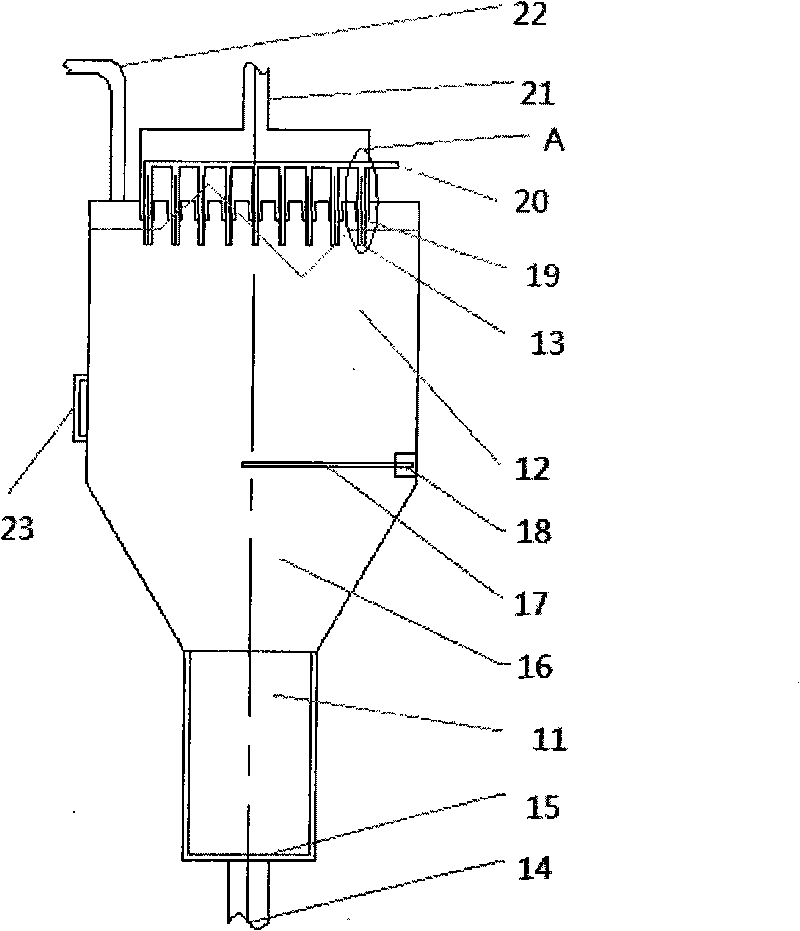

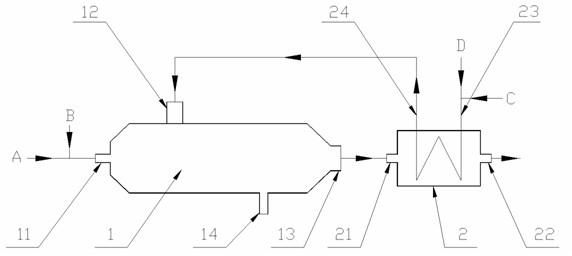

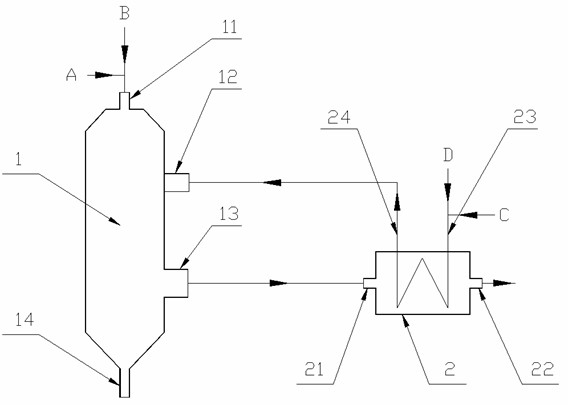

Cyclone melting device and method for fly ash preheating

InactiveCN102620299AImprove leaching rateLow melting slag collection rateIncinerator apparatusThermodynamicsLiquid slag

The invention discloses a cyclone melting device and a cyclone melting method for fly ash preheating, particularly relates to a device and a method for fly ash melting treatment. The device comprises a cyclone furnace and a fly ash preheater, wherein a smoke outlet of the cyclone furnace is connected with a hot smoke inlet of the fly ash preheater, and a working medium outlet of the fly ash preheater is communicated with a secondary air tangential inlet of the cyclone furnace. The method comprises the steps as follows: mixing the primary air with coal powders; spraying into the front end of the cyclone furnace from a primary air inlet of the cyclone furnace; carrying fly ashes into the fly ash preheater through the secondary air for the combustion of the coal powders through adopting the pneumatic transmission technology, enabling high-temperature smoke generated by combustion in the cyclone furnace to enter the fly ash preheater for heating the secondary air and the fly ashes, enabling the fly ashes after heated through the high-temperature smoke to enter the cyclone furnace, quickly heating the fly ashes to reach the fly ash melting temperature, rotating the secondary air in the cyclone furnace at a high speed, throwing the fly ashes to the wall surface of the cyclone surface under the action of a centrifugal force, quickly melting the fly ashes through the high-temperature wall surface, and discharging the molten fly ashes in the form of liquid slags from a liquid deslagging hole at the bottom of the cyclone furnace.

Owner:NANJING XINYE ENERGY TECH

Method for finishing cotton-nylon elastic woven fabrics

InactiveCN101845735AImprove color vibrancyWrinkle freeTextile storage in superimposed formFibre treatmentEngineeringAmmonia

The invention provides a method for finishing cotton-nylon elastic woven fabrics, and the process flow comprises singeing, desizing, mercerizing, dry setting and preshrinking, which is characterized in that a step of cold batching yarding is added between the steps of singeing and desizing, and the steps of liquefying ammonia and pre-tendering are added between the steps of mercerizing and dry setting, therefore the whole process flow is as follows: singeing, cold batching yarding, desizing, mercerizing, liquefying ammonia, pre-tendering, dry forming and preshrinking. The invention has scientific and easily-operated process, compared with conventional cotton-nylon elastic woven fabrics, the cotton-nylon elastic woven fabrics obtained by the invention has better gloss, greatly improved fabric color brightness, no fold and turned edge on surface fabric, uniform fabric width, good tendering and setting effects, favorable elasticity up to 20-30% and the first-rate product rate above 99%, can further perfect the stability of product quality and satisfies high quality requirement on top grade fabrics.

Owner:LUTAI TEXTILE

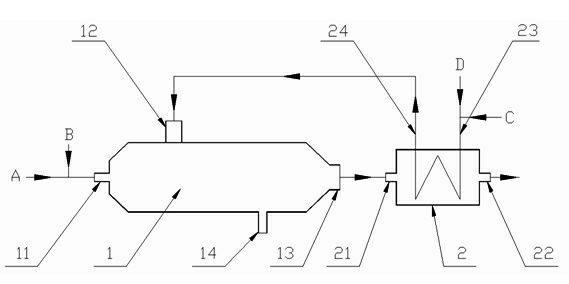

Productive technology of automobile pressure casting part

The invention discloses a productive technology of an automobile pressure casting part. The productive technology comprises the technological steps of raw material configuration, alloy smelting, modification, electromagnetic stirring, chlorine filling and hydrogen removing, die assembling and oxygen filling, vacuum pressure injection, demoulding forming, solution treatment and ageing and the like. The automobile pressure casting part produced by adopting the productive technology disclosed by the invention is excellent in mechanical property and high in quality and can meet the performance requirement of a key automotive part and the high-quality requirement of the part of a high-grade automobile.

Owner:宁波环亚机械制造有限公司

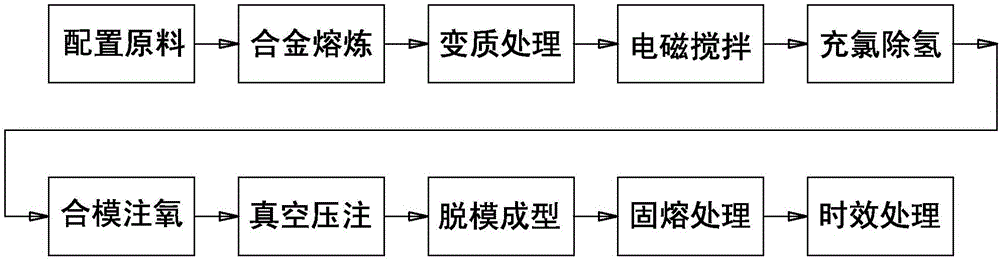

Partially-etched precision stainless steel strip used in communication industry as well as production process and application thereof

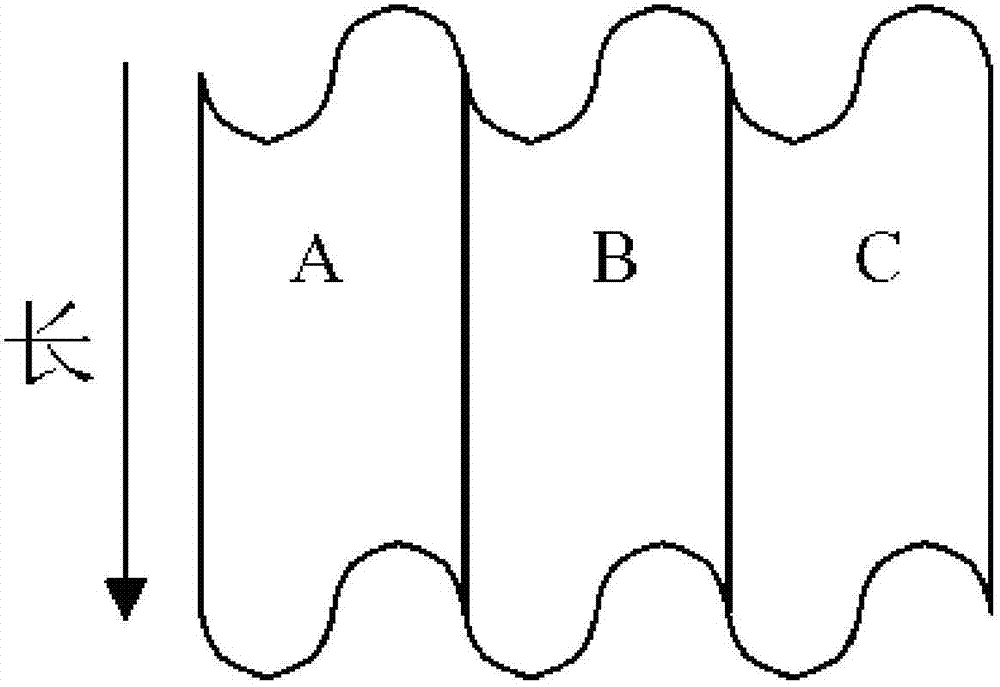

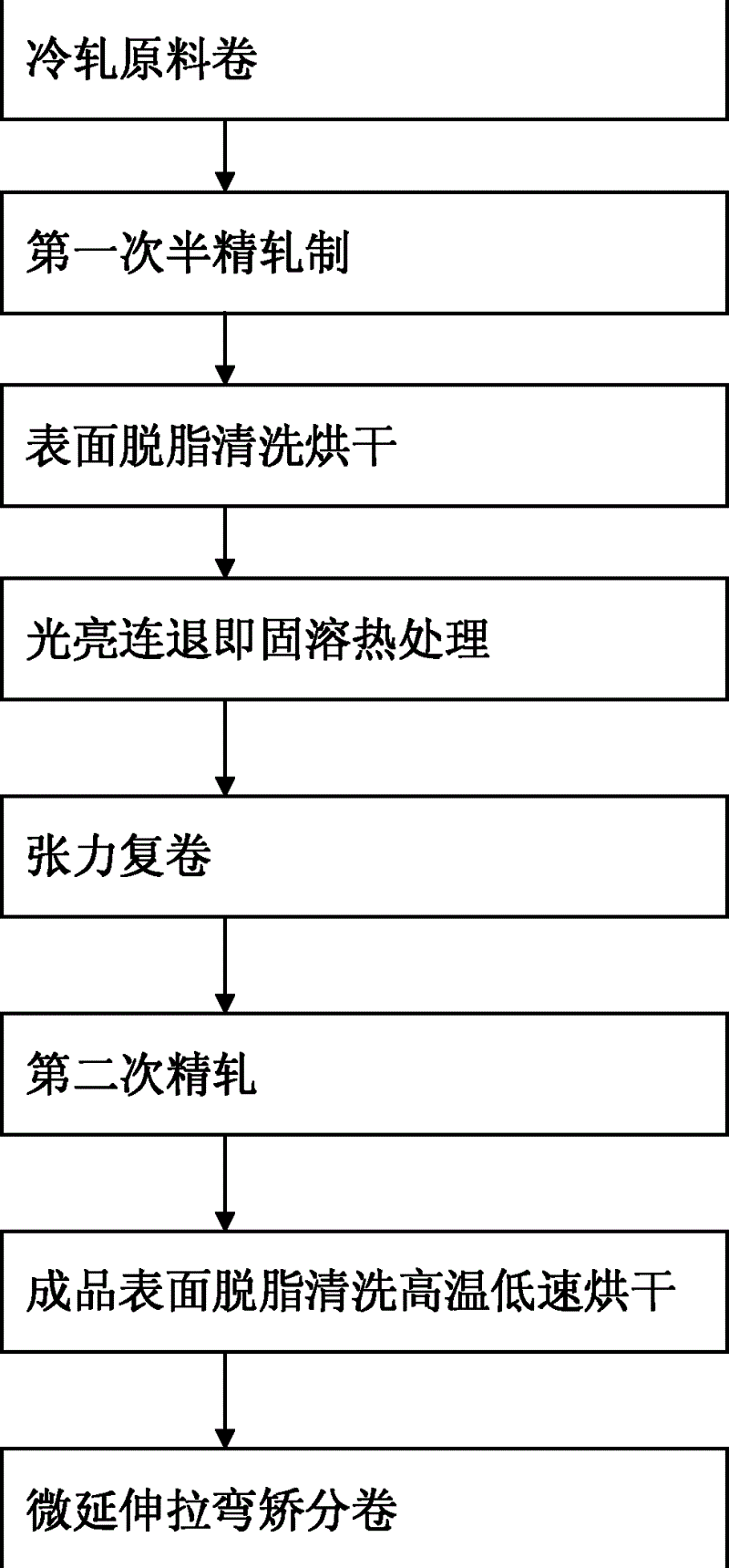

ActiveCN102699019AAvoid deformationMeet production requirementsTension/compression control deviceMetal rolling arrangementsCommunication industrySurface roughness

The invention relates to a production method of a partially-etched precision stainless steel strip, which comprises the following steps: semi-finish rolling; degreasing, washing and drying; solution heat treatment; tension rewinding; finish rolling; degreasing, cleaning and drying; micro extending, straightening and bundling. Due to the implementation of the technical scheme of the production process, the product has high thickness tolerance precision, low fluctuation, smooth surface, uniform surface roughness and no surface color difference. The plate is flat, has stable mechanical performance, is not easy to deform after being partially etched and can met the needs of producing the intelligent mobile phones in the communication industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

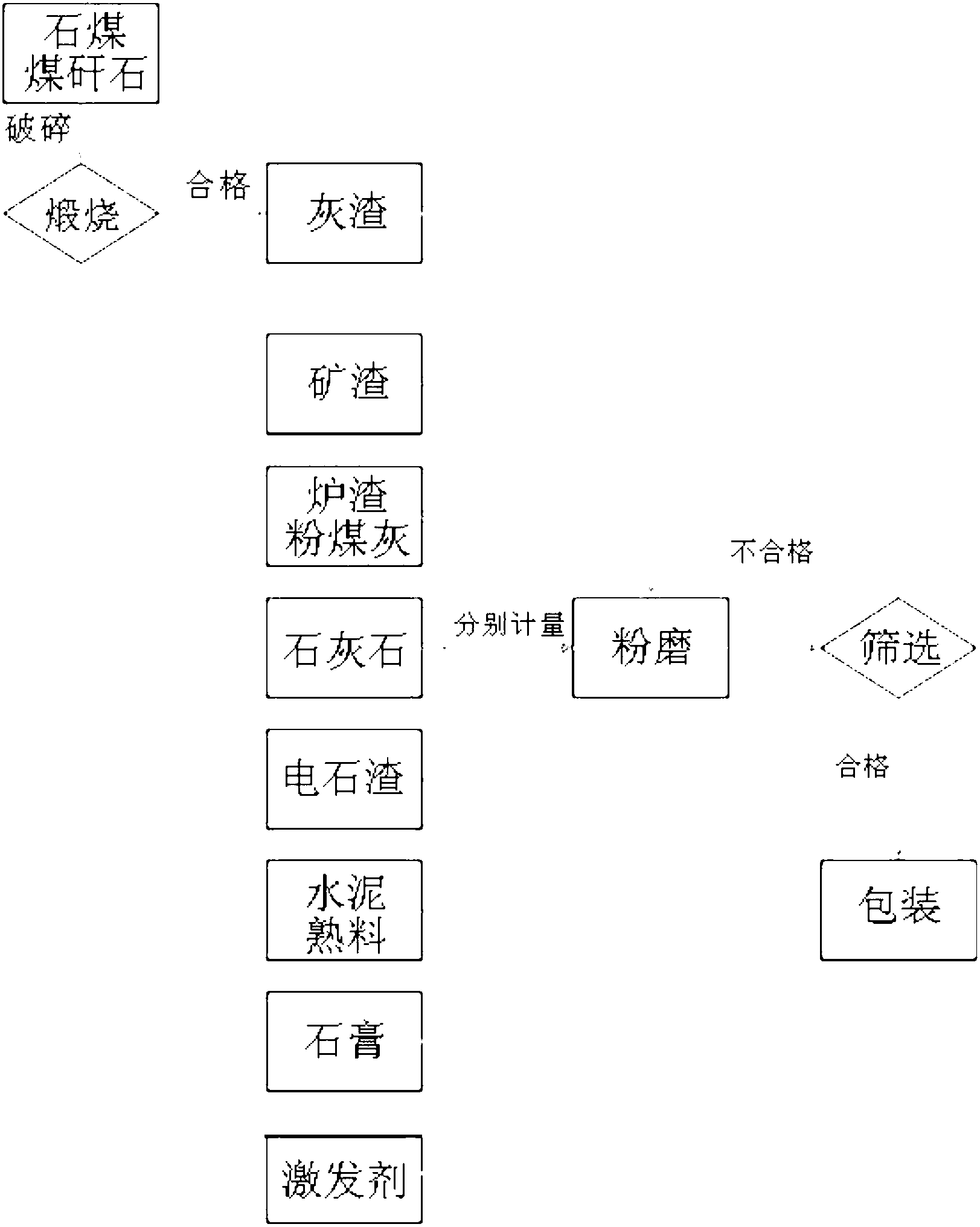

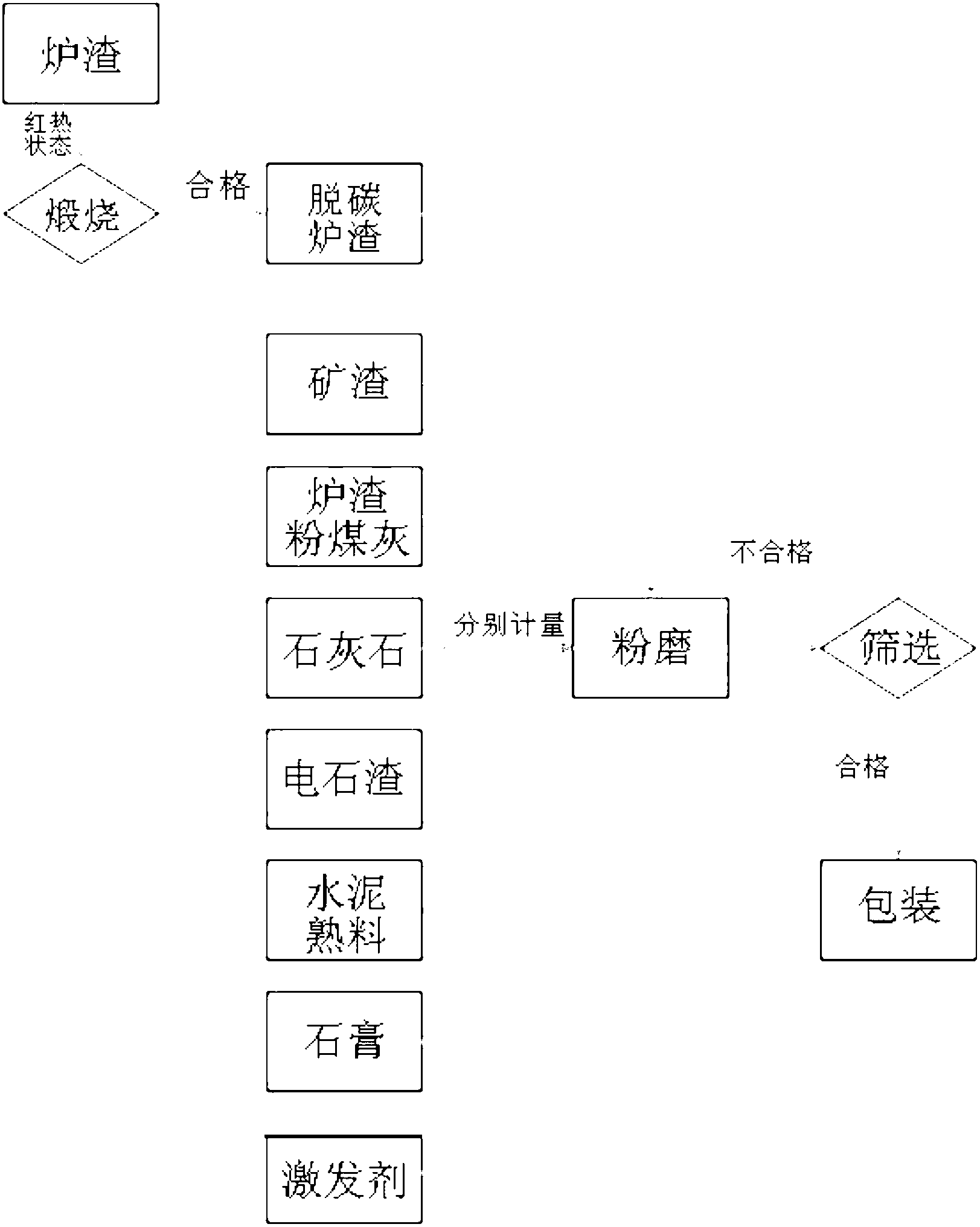

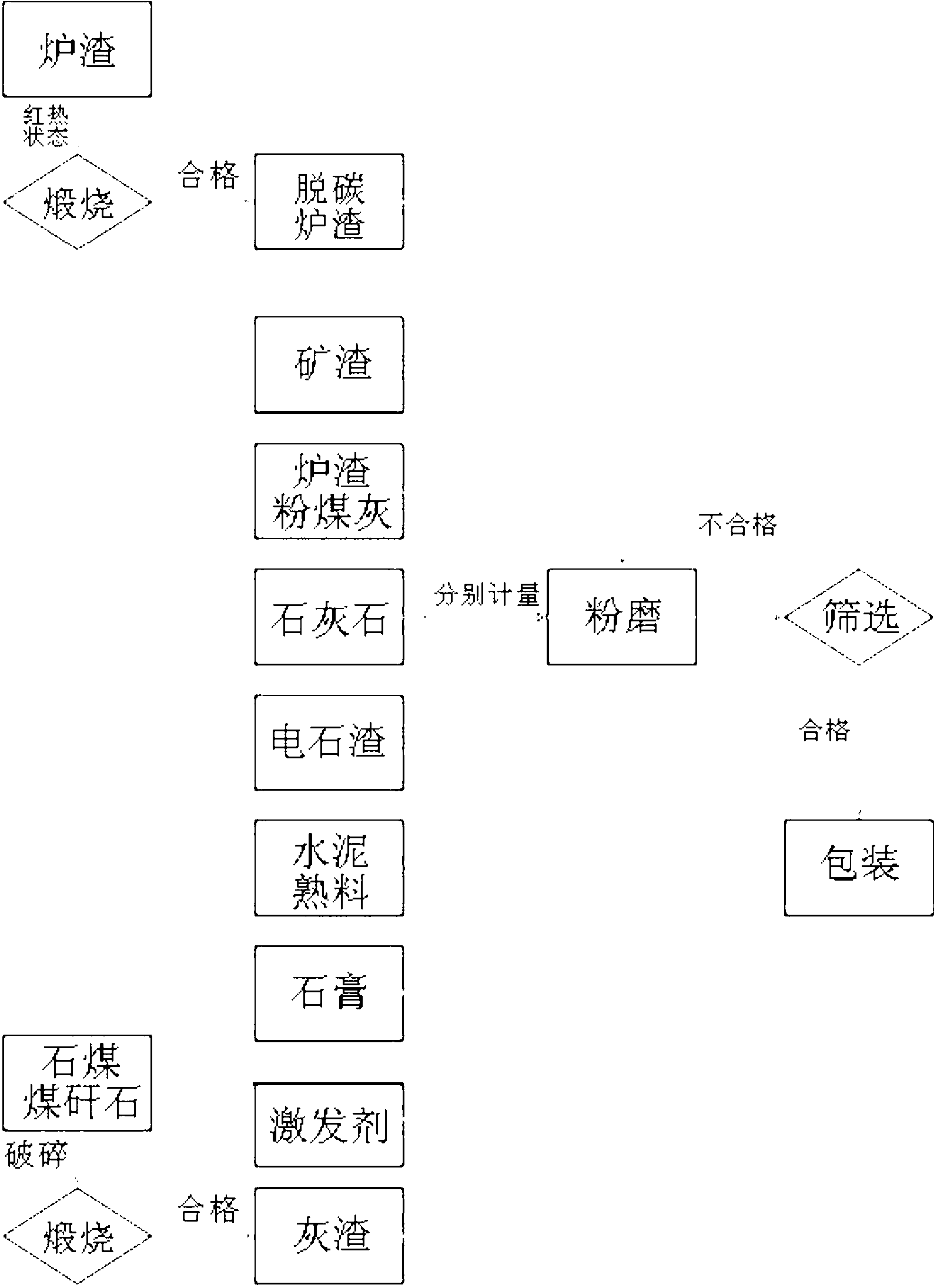

Inorganic waterproof cementitious material and preparation method thereof

The invention discloses an inorganic waterproof cementitious material. The inorganic waterproof cementitious material is characterized by comprising the materials in parts by weight: 35-55 parts of ash and / or decarburized slag, 10-30 parts of blast furnace slag / mineral powder, 8-16 parts of slag and / or coal ash, 4-8 parts of carbide slag, 0-10 parts of cement clinker, 4-8 parts of gypsum, 0-5 parts of lime stone and 0.5-5 parts of booster. All materials adopted by the inorganic waterproof cementitious material are inorganic materials, and aim at overcoming the defects generated by organic matters contained in polymer waterproof mortar. Thus, the inorganic waterproof cementitious material is good in weather fastness, not easy to age, good in affinity with a base layer, convenient to construct, and long in service life; and no harmful gas is released in the constructing and using processes.

Owner:溆浦大盛建材有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com