Productive technology of automobile pressure casting part

A production process and parts technology, which is applied in the production process field of aluminum alloy automotive die-casting parts, can solve problems such as low performance of aluminum alloy die-casting parts and cannot meet the performance requirements of key parts and high-quality requirements, and achieve good mechanical properties and meet Performance requirements, high product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

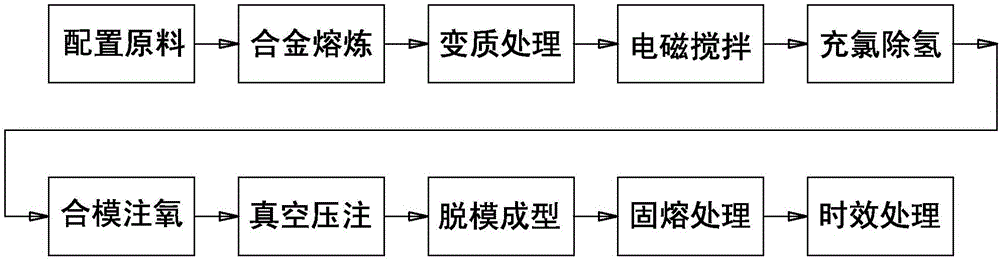

[0023] exist figure 1 In the shown embodiment 1, a kind of production technology of automobile die-casting part comprises the following steps:

[0024] a. Configuration raw materials: in parts by weight, including 80-82 parts of aluminum, 8.5-9.5 parts of silicon, 2.5-3.5 parts of copper, 0.5-0.6 parts of iron, 0.1-0.15 parts of molybdenum, 0.3-0.4 parts magnesium and 0.3-0.4% manganese.

[0025] b. Alloy smelting: Preheat aluminum, silicon, copper, iron, molybdenum, magnesium and manganese to 260-270°C, first add aluminum to the melting furnace to melt, after all the aluminum is melted, heat the melt to 720-730°C, Add silicon, copper, iron, molybdenum, magnesium and manganese, and control the alloy melt at 760-780°C after complete integration;

[0026] c. Modification treatment: in parts by weight, put 0.3-0.5 parts of modification agent strontium in the form of master alloy Al-10%Sr into the melting furnace, and perform modification treatment when the temperature of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com