Patents

Literature

101results about How to "Improve color vibrancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color image enhancement method based on color constancy

The invention relates to a color image enhancement method based on color constancy, which comprises the following steps: firstly, the brightness gain of each pixel is calculated in a self-adapting manner by utilizing a quadratic function according to the brightness mean value of the color images; secondly, the color gain and proportion parameter are calculated, the brightness gain effect is reinforced, and the color brightness is improved at the same time; and finally, margin specific information is extracted, the translational parameter is calculated, the enhanced image is subject to margin restoration, and the final color enhancement image is obtained through utilizing the proportion parameter and the translational parameter. According to the invention, under the condition of ensuring the color constancy, the contrast degree and brightness are effectively improved, the favorable specific integrity is maintained, better enhancement effect of images under various lighting conditions can be obtained, and preferable universality is realized.

Owner:WUHAN UNIV

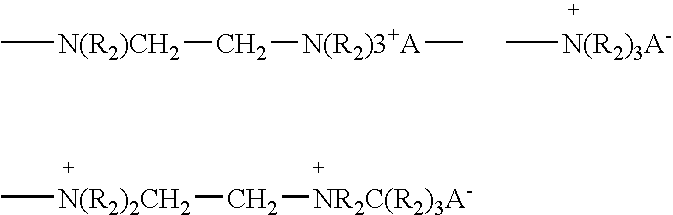

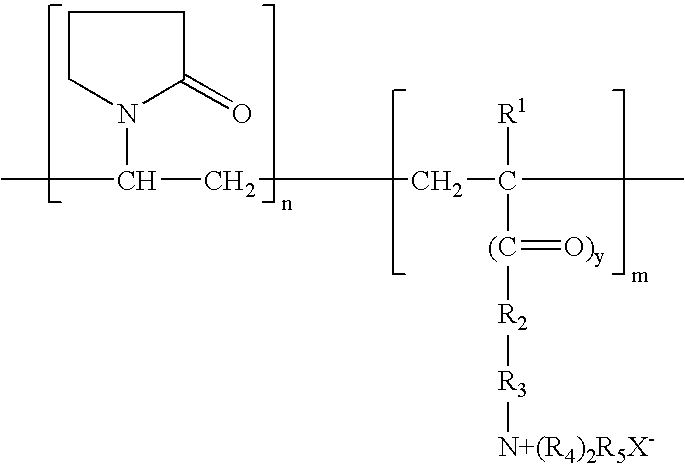

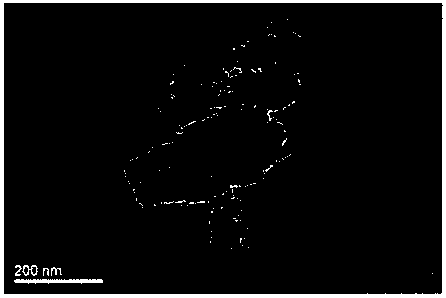

Pigment ink for inkjet printing of high fastness textile and preparation method thereof

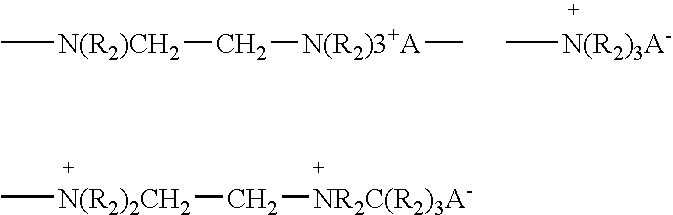

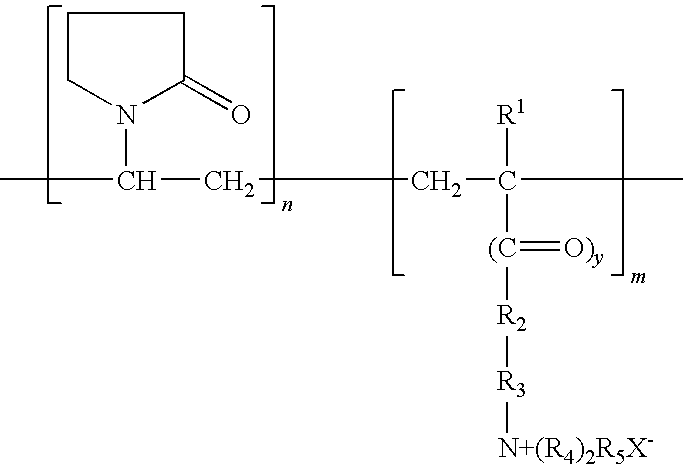

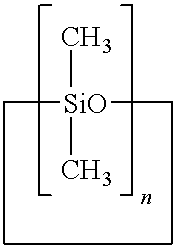

The invention discloses a pigment ink for inkjet printing of high fastness textile and a preparation method thereof. The ink comprises the following components by mass percent: 30-50% of pigment / branched polymer nano composite particle dispersoid, 10-50% of water soluble cosolvent, 1-5% of non-ionic surfactant, and the balance of deionized water. The preparation method comprises the following steps: sequentially adding the pigment / branched polymer nano composite particle dispersoid, a water-soluble cosolvent and a non-ionic surfactant into the deionized water in proportion, mixing uniformly, stirring by a stirrer at a speed of 500-1000rpm (revolutions per minute) for 20-40 minutes, regulating pH value of the ink to be 7-9, and filtering by virtue of a 500nm microfiltration membrane so as to obtain the coating ink. The ink needs no adhesive, the grain size of the pigment particle in the ink is less than 200nm, and the ink has good storage stability; after jet printing, the textile is baked so as to obtain good color fastness, thus improving the brightness.

Owner:JIANGSU GEMEIGAO DEV CO LTD

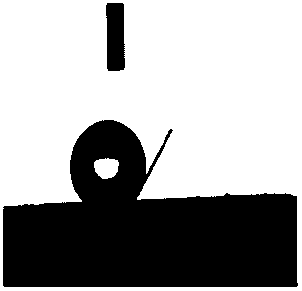

Normal-pressure low-temperature plasma preprocessing technique of textile for digital inking printing

InactiveCN101100808AImprove clarityImprove color vibrancyUltrasonic/sonic fibre treatmentDyeing processEngineeringPre treatment

The invention relates to fabric plasma surface modification processing technology used in dye ink digital inking printing. The fabric is processed inking printing by dye ink in the digital inking printing machine after processing by impulse normal pressure air low temperature plasma, then baking to form the finished product. Compared with the traditional preprocessing technology, the invention has the advantages of fast, convenient, saving water and energy, low cost, no social effects of pollution, suiting for industrialization continuous production etc.

Owner:JIANGNAN UNIV

Method for coloring hair

InactiveUS20070169286A1Easy to liftImprove color vibrancyCosmetic preparationsHair removalColored hairHue

A two step high lift method for oxidatively coloring hair comprising a first step of applying to the hair a lifting mixture comprised of an aqueous oxidizing agent composition and a lifting composition to the hair for a period of time sufficient to lift the hair, followed by a second step of applying an inactivated oxidative dye composition for a period of time sufficient to color the hair, and a method for improving color vibrancy and tone, evenness of color, and reducing brassiness in high lift oxidatively colored hair.

Owner:REVLON CONSUMER PROD CORP

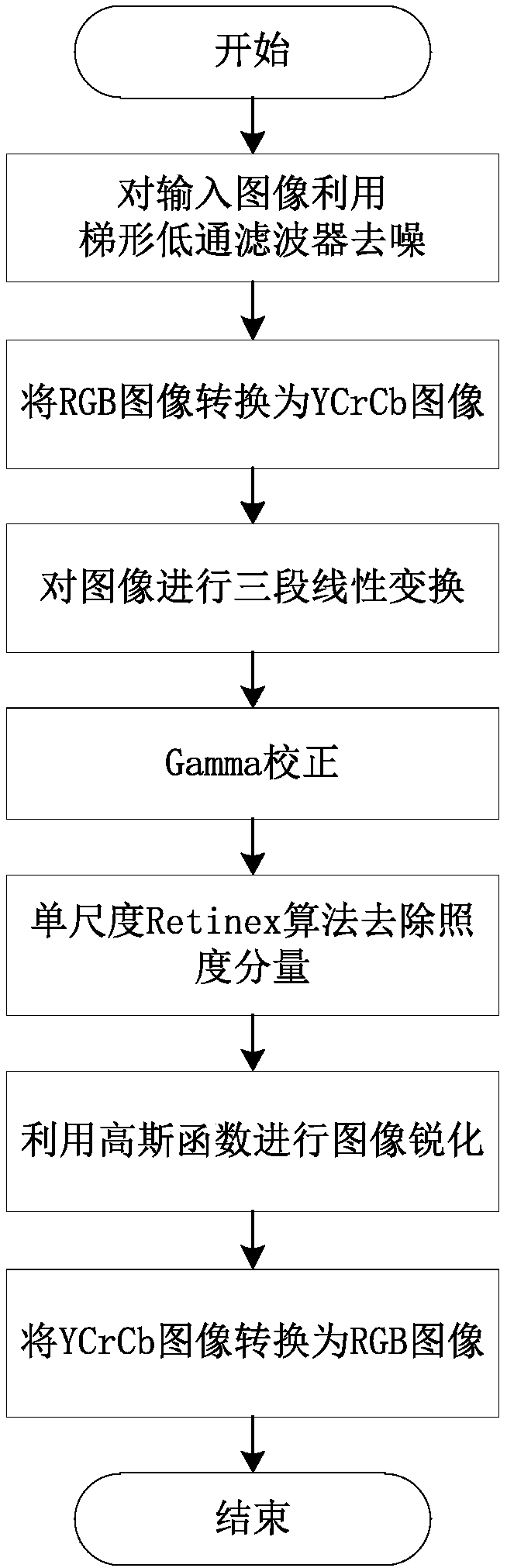

Low-contrast image enhancement method based on YCrCb

ActiveCN108122213AImprove darkLarge dynamic rangeImage enhancementImage analysisLow-pass filterRetinex algorithm

The invention relates to a low-contrast image enhancement method based on YCrCb. The low-contrast image enhancement method comprises the following steps: (1) performing image de-noising on an obtainedoriginal image by utilizing a trapezoidal low-pass filter; (2) performing conversion between a RGB color space and a YCrCb color space on the de-noised image to obtain an image brightness component;(3) performing piecewise linear transformation on a brightness component image by adopting a traditional spatial domain linear transformation method; (4) performing Gamma correction on the transformedimage; (5) performing Gaussian filtering on the corrected image by utilizing a single-scale Retinex algorithm and estimating illumination component and reflection component images; (6) performing image sharpening by utilizing a Gaussian sharpening algorithm aiming at the reflection component image; and (7) performing conversion between the YCrCb color space and the RGB color space on the sharpened image.

Owner:BEIHANG UNIV

High efficiency soap cleaning agent compsn. for textile dyeing soap cleaning and prepn. process

InactiveCN1834216AComply with environmental standardsImprove color vibrancyNon-ionic surface-active compoundsDetergent compounding agentsSulfonateCoconut diethanolamide

This invention provides a method for manufacturing a high-efficiency environment-friendly soaping agent composition for cleaning printed fabrics. The soaping agent composition is manufactured by mixing and adequately stirring C12 fatty alcohol polyoxyethylene ether, coconut diethanolamide, sodium secondary alkane sulfonate (SAS), dyeing-proof salt (S), sodium tripolyphosphate and water. The soaping agent composition has good soaping and anti-contaminating effects on printed fabrics, and can improve the strength of printed fabrics.

Owner:东莞市德能化工有限公司

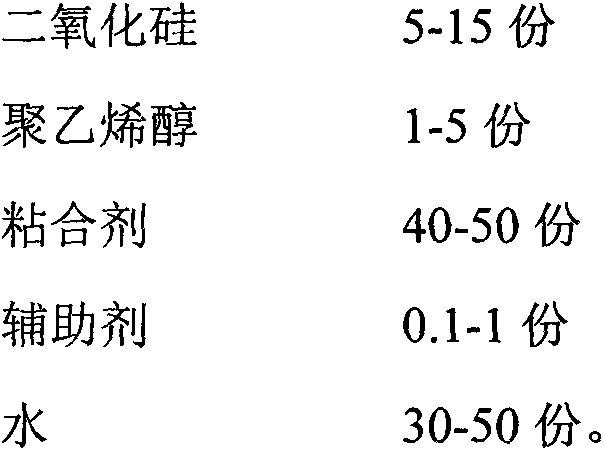

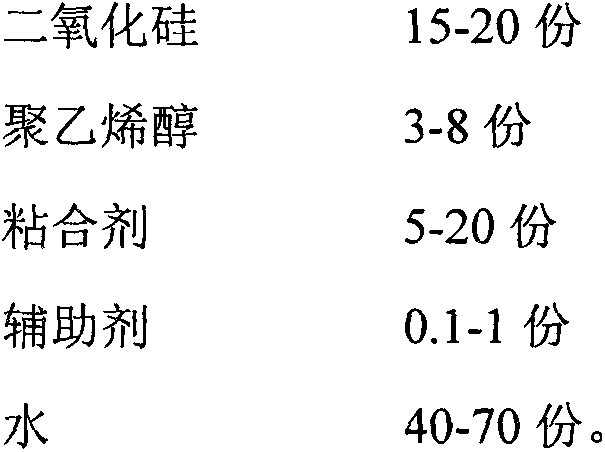

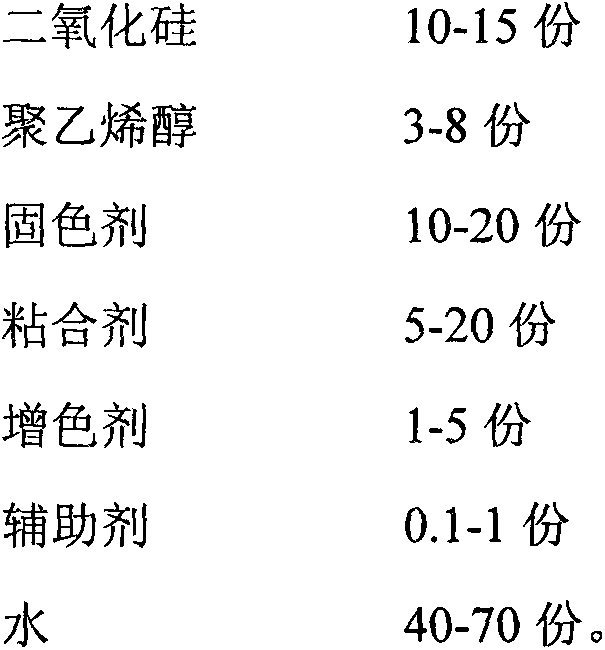

Water-borne matte water-proof ink jet canvas and preparation method thereof

InactiveCN103395337AGood sealingStrong ink absorptionOther artistic work equipmentsCoatingsCoated surfaceMoisture

The invention discloses water-borne matte water-proof ink jet canvas and a preparation method thereof. The canvas is formed by a substrate, a base coat, an ink absorption layer and a fixation layer. The preparation method comprises the steps that the substrate is coated with base coat paint after the substrate is dried and shaped, the paint is dried, the substrate is repeatedly coated two to three times, and the base coat paint is dried; then the substrate is repeatedly coated with the ink absorption layer paint one to two times, and the paint is dried; finally, the substrate is coated with fixation layer paint, the paint is dried, the substrate is rolled, cut and packed, and the water-borne matte water-proof ink jet canvas is obtained. According to the water-borne matte water-proof ink jet canvas and the preparation method of the water-borne matte water-proof ink jet canvas, a base paint formula is with a scientific ratio, the porous fabric substrate is good in base seal performance, ink for jet ink printing is prevented from permeating, meanwhile the ink absorption layer and the fixation layer are optimized and designed, the ink absorption layer is used for absorbing large amount of moisture in the ink and avoiding ink spreading and sinking during printing, the fixation layer is used for fixing dyes in the ink and enables the dyes to be remained in the surface of a coating, so that the canvas has strong ink absorbing capacity while being further endowed with high color brightness.

Owner:李娟

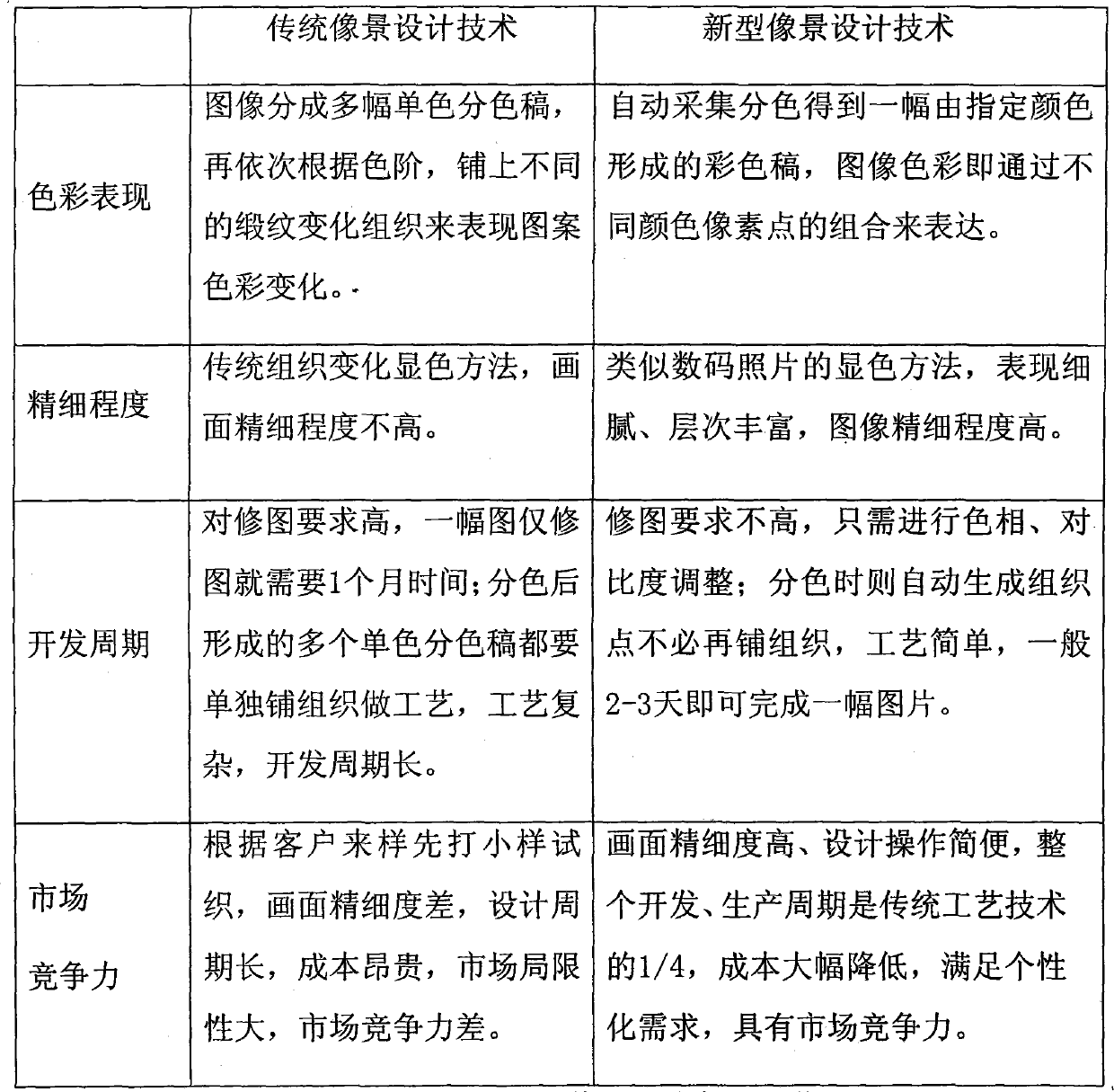

Manufacturing process of full-digital high-fineness image brocade fabrics

InactiveCN102560807AImprove color vibrancyHigh saturationSwivel-woven fabricsLappet-woven fabricsEngineeringDigital printing

A manufacturing process of full-digital high-fineness image brocade fabrics includes the following steps of scanning, image rectifying, color separating and processing. The manufacturing process has the advantages that design and development period is short, production time of conventional jacquard image fabric products is shortened, cost is reduced, expensive individual jacquard fabrics can be popularized in ordinary family, and the requirements of vast customers are met. Meanwhile, the full-digital high-fineness image brocade fabric has more layers and more exquisite styles as compared with conventional image fabrics, solves the problems of few layers and colors and poor fineness of conventional image jacquard fabrics, can be used for developing full-true-color picture works, has simulation effect as digital printing, breaks through limits of original products and can represent original appearance of pictures vividly and record time, events and characters with historical values by a unique presenting manner, thereby making permanent storage of wedding pictures, portraits and historical paintings come true. Further, application field of textiles is expanded and domestic demands of the market can be stimulated.

Owner:TIANJIN TEXTILE ENG RES INST

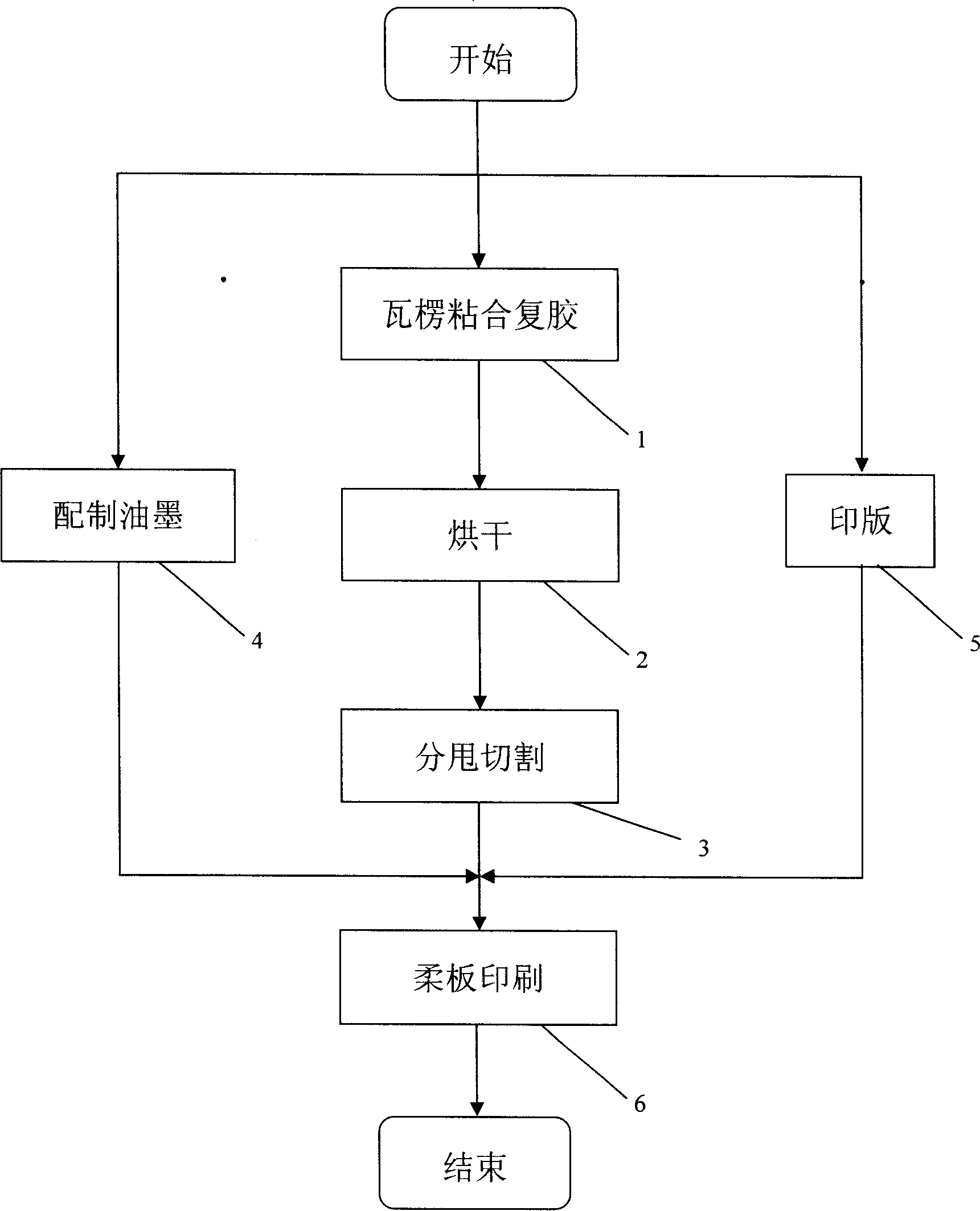

Method for manufacturing colorful flexible printing corrugated paper box

InactiveCN101186123AKeep clearImprove overprint accuracyMechanical working/deformationBox making operationsCardboardEngineering

The invention discloses a manufacture method of a colorful flexible printing corrugated box, comprising six steps such as corrugated bonding, drying, throwing and cutting, preparing ink, forme and flexible printing. A corrugated cardboard with special standard is taken as a printing material, thus leading no settlement phenomenon between the corrugated peak and corrugated valley of the corrugated cardboard to occur and ensuring clear printed patterns. By adopting no-shaft transmission flexible printing, overprinting precision of each color group can be independently adjusted, thus improving the overprinting precision of the printed products, and greatly improving the printing quality. By adopting knurled rolls in grid shape and ceramic material spayed on the surface of the knurled rolls, the surface performance of the knurled rolls is improved, the flexible printing quality is improved, the service life of the knurled rolls is prolonged, and the printing cost is saved. The content of the connecting material in ink is increased and the consistency of dye is increased, thus reaching required ink film thickness under low ink transmission quantity, and reaching the requirement of stable and full colors, high vividness of the printed product and good glossiness.

Owner:俞建虎

Method for finishing cotton-nylon elastic woven fabrics

InactiveCN101845735AImprove color vibrancyWrinkle freeTextile storage in superimposed formFibre treatmentEngineeringAmmonia

The invention provides a method for finishing cotton-nylon elastic woven fabrics, and the process flow comprises singeing, desizing, mercerizing, dry setting and preshrinking, which is characterized in that a step of cold batching yarding is added between the steps of singeing and desizing, and the steps of liquefying ammonia and pre-tendering are added between the steps of mercerizing and dry setting, therefore the whole process flow is as follows: singeing, cold batching yarding, desizing, mercerizing, liquefying ammonia, pre-tendering, dry forming and preshrinking. The invention has scientific and easily-operated process, compared with conventional cotton-nylon elastic woven fabrics, the cotton-nylon elastic woven fabrics obtained by the invention has better gloss, greatly improved fabric color brightness, no fold and turned edge on surface fabric, uniform fabric width, good tendering and setting effects, favorable elasticity up to 20-30% and the first-rate product rate above 99%, can further perfect the stability of product quality and satisfies high quality requirement on top grade fabrics.

Owner:LUTAI TEXTILE

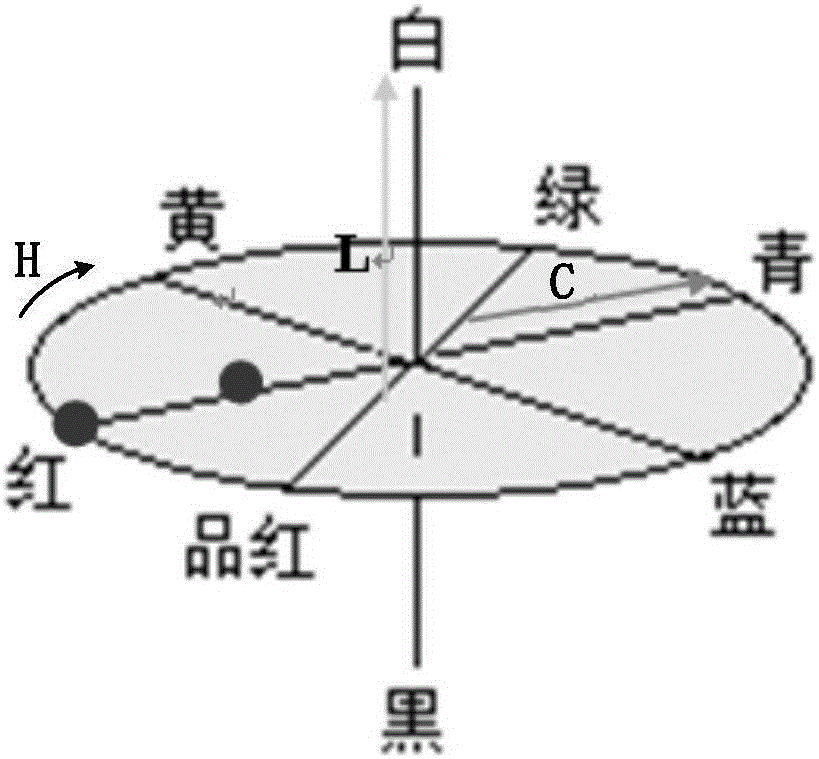

Image processing method

ActiveCN105096910AImprove color vibrancyImprove the display effectCathode-ray tube indicatorsImaging processingGamut

The invention relates to an image processing method which comprises the following steps: (a), obtaining an original image and a degraded image obtained by adding ambient light base color into the original image; (b), obtaining a chromaticity difference between the original image and the degraded image; and (c), carrying out chromaticity compensation on the original image by using the chromaticity difference so as to obtain a compensated image. According to the invention, chromaticity compensation such as color saturation compensation or color gamut range expanding is carried out on the original image according to ambient light conditions, therefore, color brightness of the image displayed under the ambient light is improved and a display effect of display equipment is improved greatly.

Owner:XIAN NOVASTAR TECH

Method for preparing amphiphilic modified organic pigment based on discontinuous deposition of silica sol

Owner:ZHEJIANG SCI-TECH UNIV

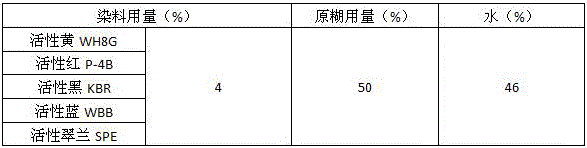

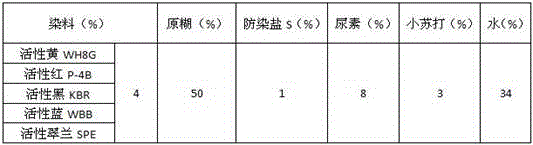

Reactive dye cold pad-batch printing method

ActiveCN105970698ASolve the color matching problemReduce dosageDyeing processTextile printerBuffering agent

The invention discloses a reactive dye cold pad-batch printing method and belongs to the technical field of textile printing and dyeing. A fabric is directly printed through color paste mixed through pure sodium alga acid and reactive dyes, after being dried, the fabric is subjected to pad-batch through a cold pad-batch printing fixation alkaline agent and then piled for 2-4 hours at the temperature of 30-40 DEG C, and then fixation can be finished. Compared with a traditional reactive dye printing method, the reactive dye cold pad-batch printing method has the advantages that steaming fixation is not needed, the energy source is saved, the fixation rate is increased by 7-20%, and dye is saved. The fixation alkaline agent is prepared from, by weight, 5-20% of an alkaline supply agent, 5-20% of a buffering agent, 3-10% of a chelating agent, 3-10% of dispersion abluent, 1-3% of alkali-resisting penetrant and the balance water.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Method for coloring hair

InactiveUS7566348B2Improve color vibrancyReducing brassinessCosmetic preparationsHair removalColored hairTwo step

A two step high lift method for oxidatively coloring hair comprising a first step of applying to the hair a lifting mixture comprised of an aqueous oxidizing agent composition and a lifting composition to the hair for a period of time sufficient to lift the hair, followed by a second step of applying an inactivated oxidative dye composition for a period of time sufficient to color the hair, and a method for improving color vibrancy and tone, evenness of color, and reducing brassiness in high lift oxidatively colored hair.

Owner:REVLON CONSUMER PROD CORP

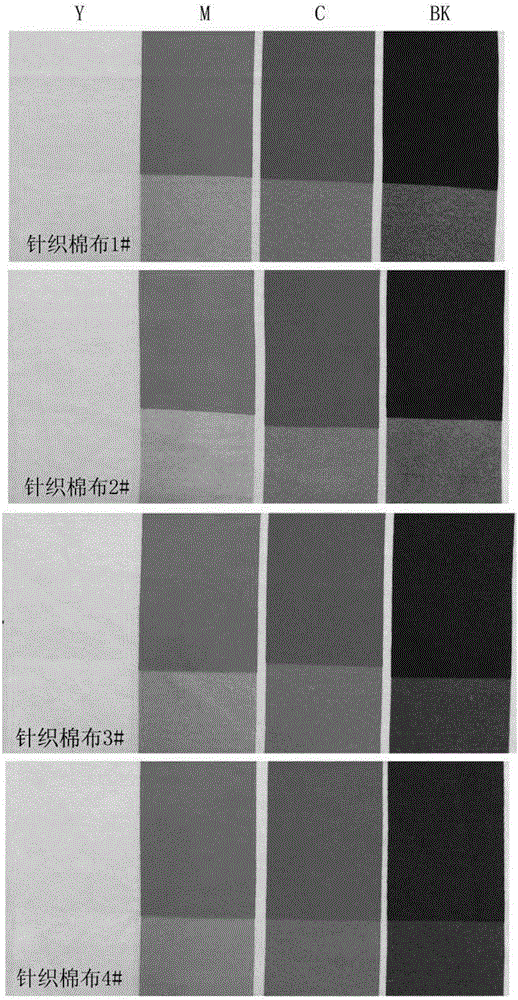

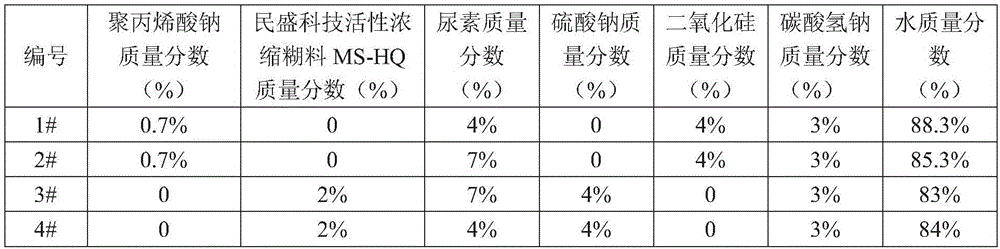

Environmental-friendly active dye digital printing pretreatment prime pulp and preparation method thereof

The invention discloses an environmental-friendly active dye digital printing pretreatment prime pulp and a preparation method of the environmental-friendly active dye digital printing pretreatment prime pulp. The prime pulp is prepared from, by mass, 0.2-4.5 parts of thickening agent, 3-15 parts of cellulosic fiber swelling agent, 0-5 parts of hygroscopic agent, 0.5-4 parts of alkaline agent, 1-6 parts of accelerating agent, 0-1 part of preservative, 0-2 parts of anti-reducing agent, and 70-90 parts of water. Sodium polyacrylate is good for reaction between the active dye and the cellulosic fiber, thus the prime pulp has high paste rate; the usage and cost of pre-treatment prime pulp are reduced; sodium polyacrylate can be used for reducing the dosage of urea or liquid ammonia, and still can keep high color yield and color brilliance; the environmental-friendly active dye digital printing pretreatment prime pulp has high printing and coloring rate for various cotton fabrics and real silk fabrics; the outline definition of the printing pattern is high, the permeation is moderate, color is fresh; hand feeling and whiteness of the printing cloth are not influenced; besides, the prime pulp has very good universality.

Owner:深圳市墨库图文技术有限公司

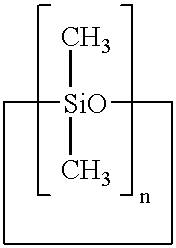

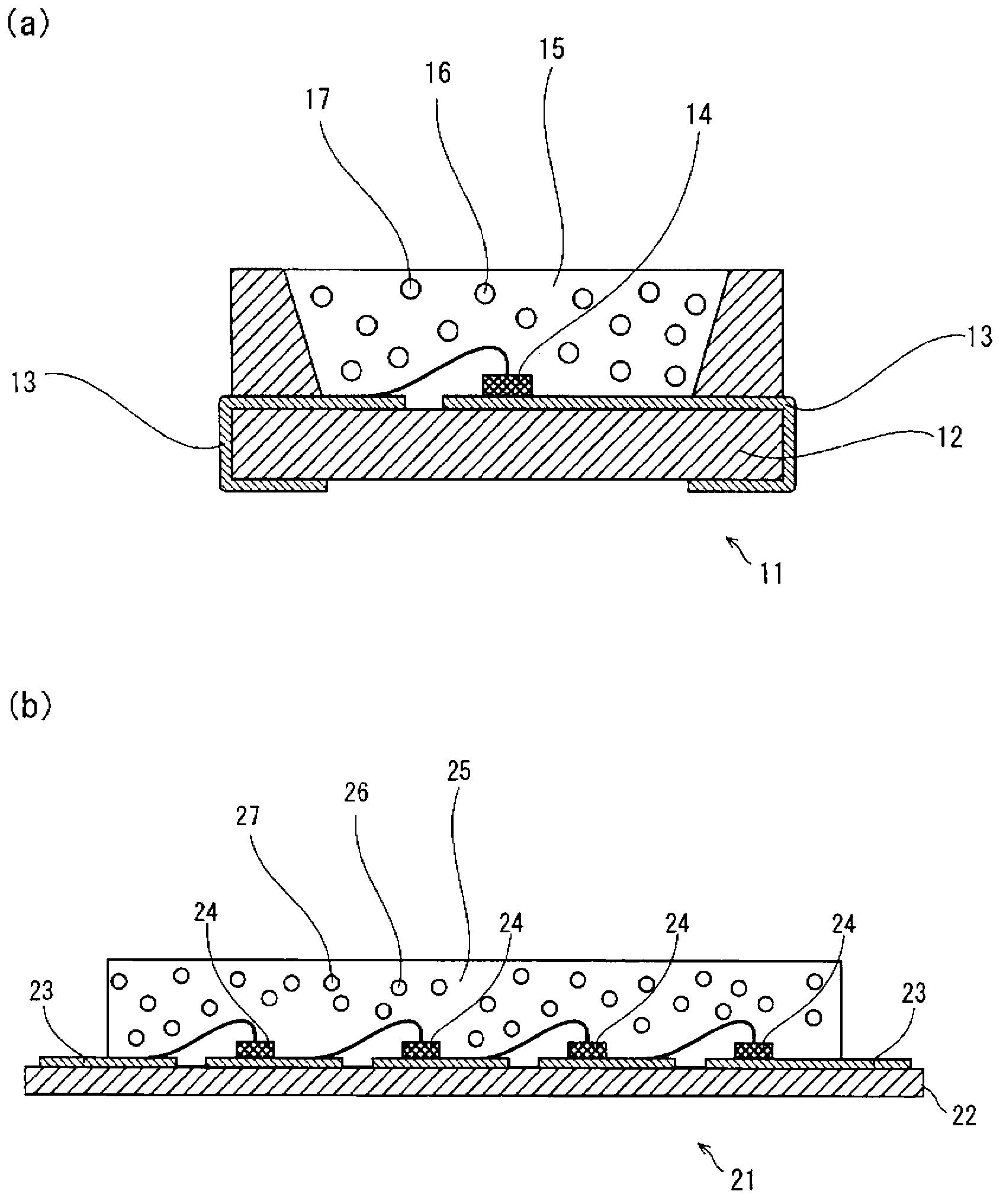

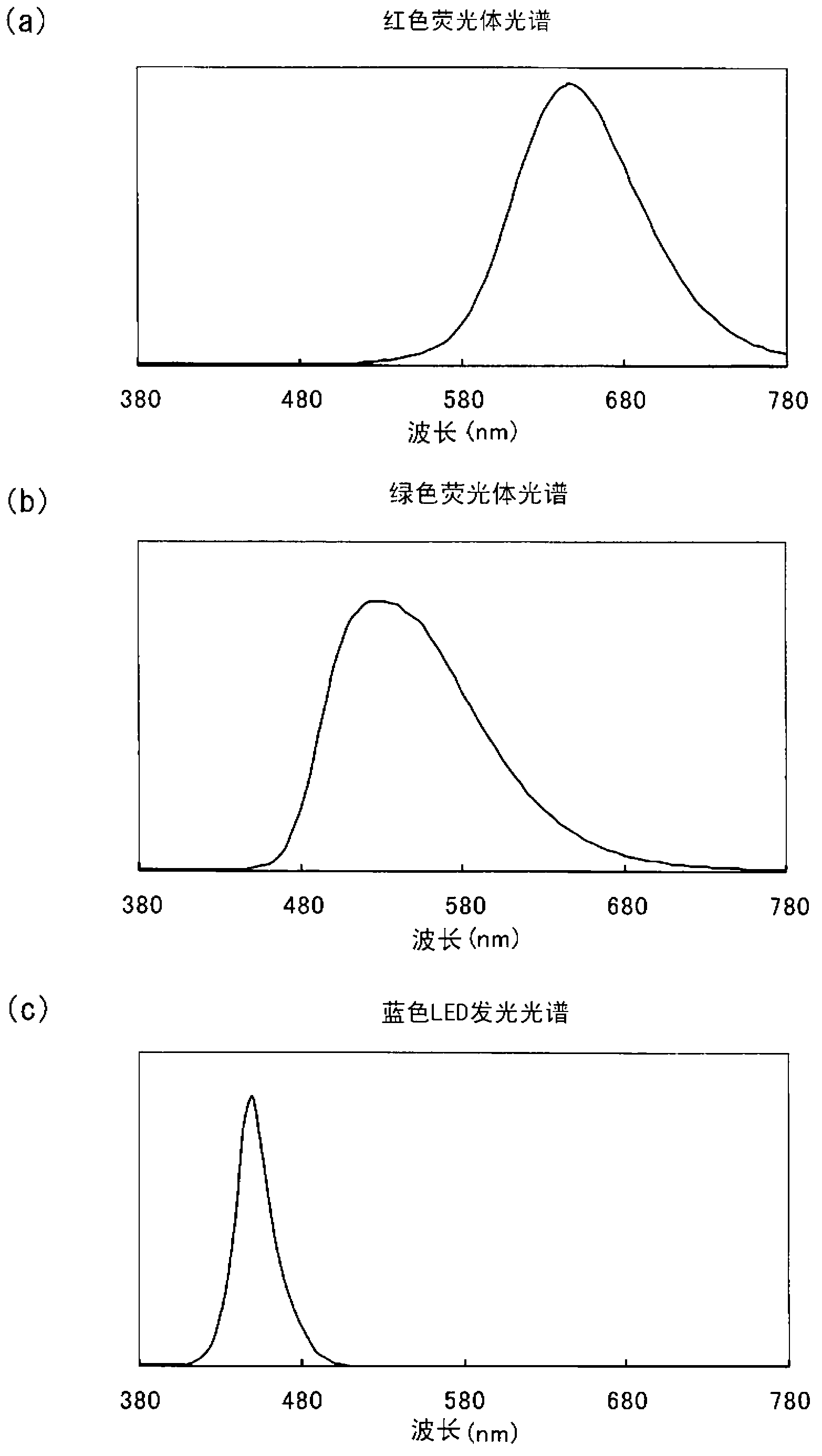

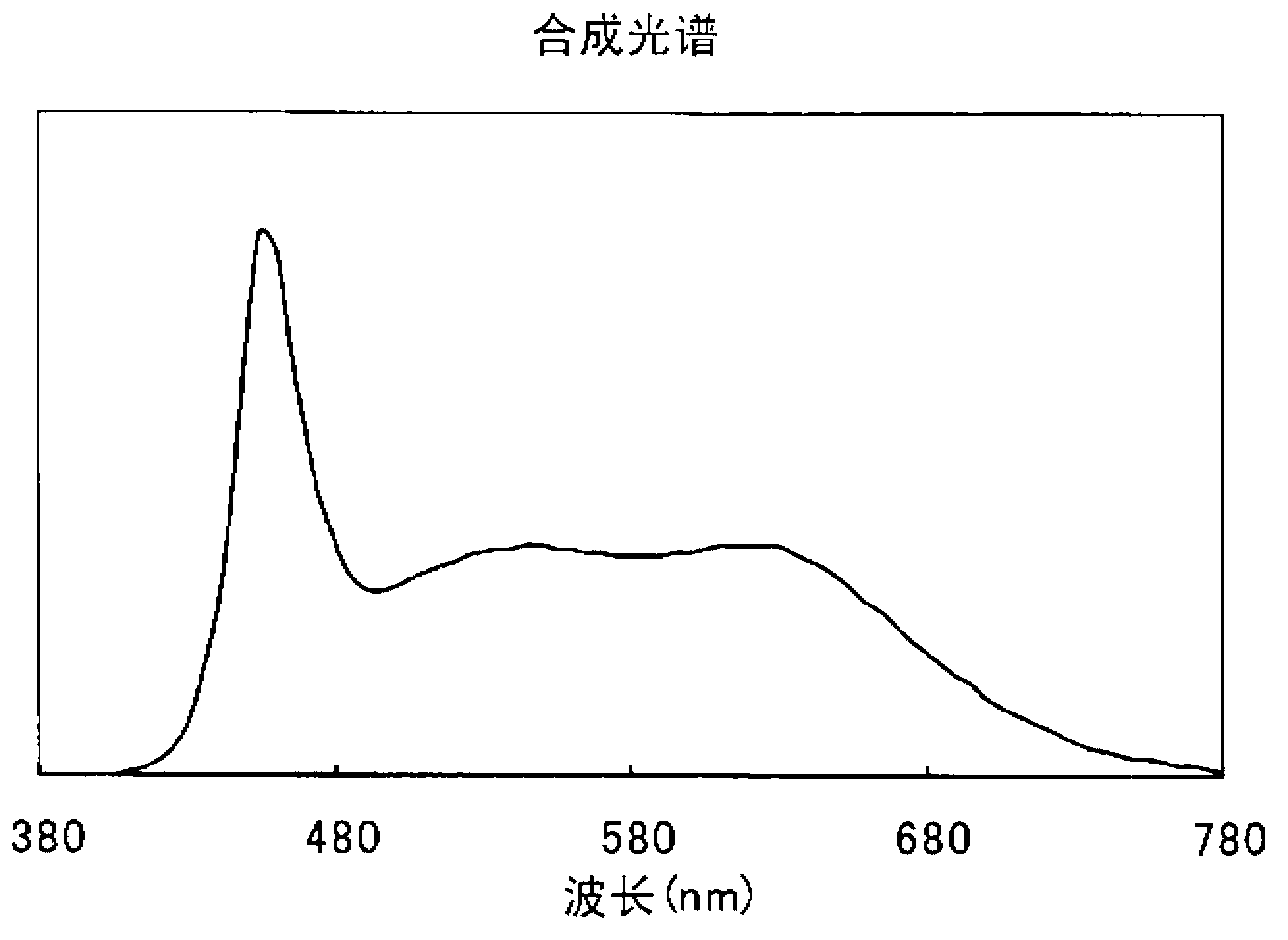

LED module and illumination device

InactiveCN103329293AIncreased red componentImprove color vibrancyPoint-like light sourceElongate light sourcesPhosphorFull width at half maximum

Provided is a high color saturation LED module and an illumination device which improve vividness of color of an illuminated object even if the color temperature of the ambient light is high, and as a result, are capable of optimally reproducing colors. The peak wavelength of the emission spectrum of blue LEDs is 420 nm-470 nm, and the half width thereof is greater than 0 nm and not greater than 50 nm. The peak wavelength of the emission spectrum of green phosphors is 500 nm-535 nm, and the half width thereof is 100 nm-110 nm. The peak wavelength of the emission spectrum of red phosphors is 610 nm-670 nm, and the half width thereof is 85 nm-95 nm. The correlated color temperature Tc of mixed light of the blue light, green light and red light is 4,600K-7,200K, and the duv thereof from -12 to -6.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

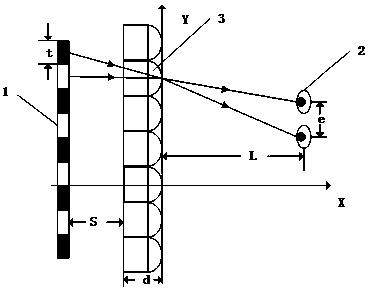

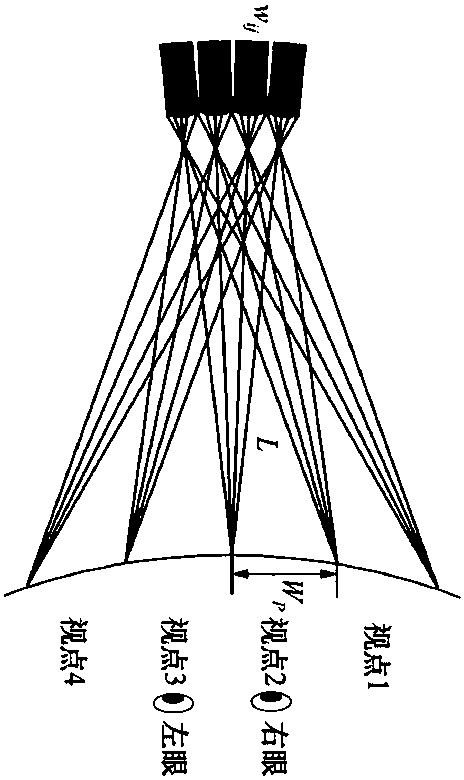

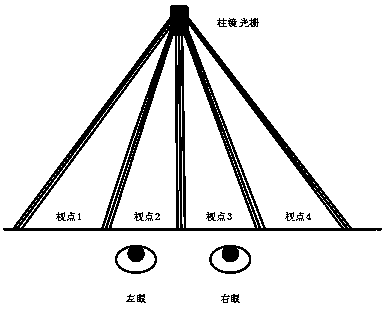

Lenticular grating based LED stereoscopic display screen device with great many of viewpoints

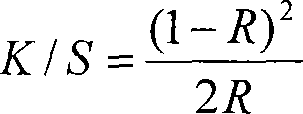

The invention provides a lenticular grating based LED stereoscopic display screen device with a great many of viewpoints. The display screen device comprises an LED planar display screen and human-eye watching viewpoints, an arc lenticular grating is arranged between the LED planar display screen and human-eye watching viewpoints, the LED planar display screen is arranged along the axis x and symmetric by taking the axis x as the center, the vertex of a cylindrical lens of the intermediate arc lenticular grating is positioned in the coordinate origin, an image side of the LED planar display screen is positioned in the focal plane of the cylindrical lens of the arc lenticular grating, the width of sub-pixel is t, the lenticular thickens of the arc lenticular grating is d, distance between the cylindrical lens of the arc lenticular grating and the LED planar display screen is s, the human-eye watching viewpoints are positioned in positions whose distance to the cylindrical lens of the arc lenticular grating is L, and the distance between the eyes is set as e. A 3D structure with a static effect as well as a 3D image with a dynamic effect can be realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

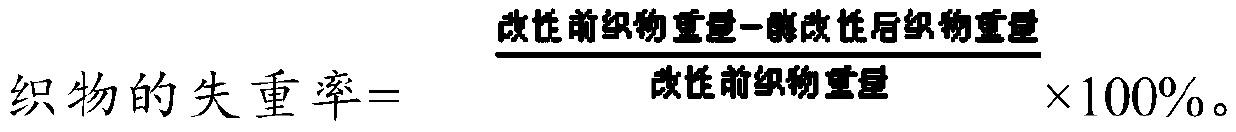

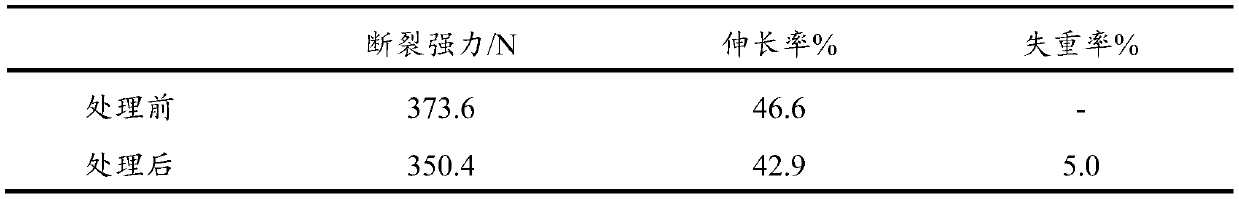

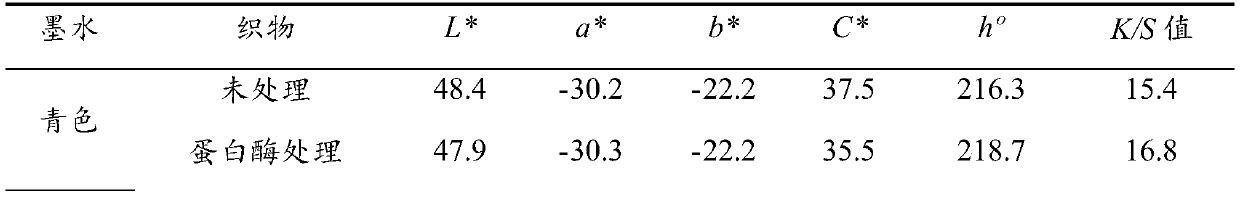

Enzyme treatment method of wool fabric and method for ink-jet printing of wool fabric

The invention provides an enzyme treatment method of a wool fabric. The enzyme treatment method comprises the steps that alkaline protease and an activating agent are applied to the wool fabric simultaneously, wherein the activating agent is selected from one or more of tricarboxylic ethyl phosphine, sodium pyrosulfite, sodium hydrogen sulfite and mercaptoethanol, the fabric is treated under an alkaline condition at the temperature of 40-65 DEG C, and protease inactivation is carried out to obtain the wool fabric after enzyme treatment. The invention provides a method for ink-jet printing of the wool fabric. The method comprises the steps that printing paste modification is carried out on the wool fabric obtained through the enzyme treatment method to obtain the modified wool fabric; ink-jet printing is carried out on the modified wool fabric by using reactive dye ink or acidic dye ink, the fabric is steamed after being dried, the fabric is washed with water, and the ink-jet printed fabric is obtained. The wool fabric modified through the enzyme treatment method is subjected to ink-jet printing, so that an obtained ink-jet printing pattern is clearer, the color is brighter, the process flow is short, and the fiber damage is small.

Owner:TIANJIN POLYTECHNIC UNIV

Carbon fiber-based thermochromic fabric and preparation method thereof

InactiveCN113201806AImprove uniformityImprove breathabilityCarbon fibresElectro-spinningElectrospinningViscose

The invention discloses a carbon fiber-based thermochromic fabric and a preparation method thereof. The thermochromic fabric comprises a thermochromic film and a basic fabric, wherein the thermochromic film is prepared from the following raw materials in parts by weight of 12 to 18 parts of polyethylene glycol, 35 to 45 parts of polyurethane, 5 to 8 parts of boron nitride nanosheets and 12 to 15 parts of thermochromic microcapsules. The thermochromic fabric has the beneficial effects that a thermochromic coating is encapsulated in a microcapsule formed by a polymer shell layer, so that the service life and the dispersion uniformity of the coating are effectively protected; reactive glyceryl borate is introduced into the shell layer of the microcapsule, so that the oxidation resistance is improved, pigment is inhibited from being oxidized, and meanwhile, the flame retardance is improved; the microcapsule is subjected to electrostatic spinning to form the film, so that the dispersity of the microcapsule on the fabric is improved; the humidity in the spinning process is controlled to form thicker nanofibers, so that a film layer has higher air permeability; and the basic fabric is pretreated, so that the adhesive force between the fabric and the film layer is increased, and an adhesive is not used.

Owner:王香玉

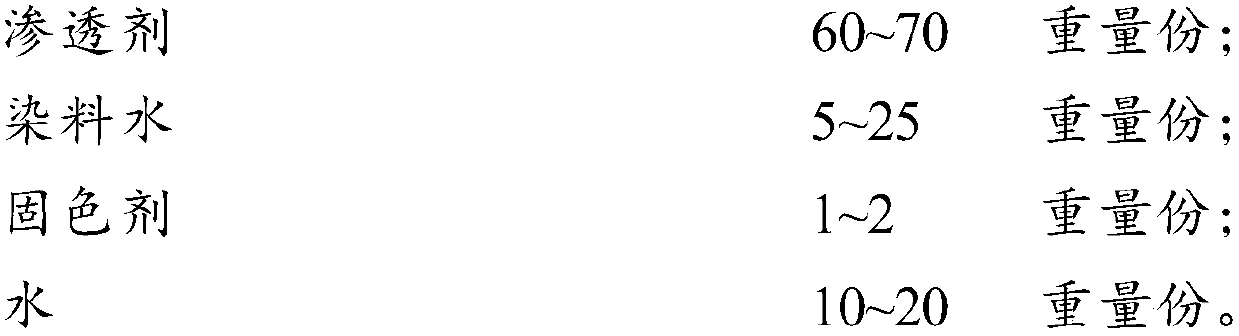

Dye for comprehensive color repairing process of double-faced leather and comprehensive color repairing process of double-faced leather

InactiveCN107916582AGood coloring effectFeel lubricatedDyeing processWastewaterBrightness perception

The invention provides a dye for a comprehensive color repairing process of double-faced leather. The dye comprises, by weight, 60-70 parts of penetrating agents, 5-25 parts of dye water, 1-2 parts ofcolor fixing agents and 10-20 parts of water. The invention further provides a comprehensive color repairing process of the double-faced leather. By the aid of the dye of a specific formula and the corresponding comprehensive color repairing process, according to dyed leather, particularly, the leather with large rough board discoloration, a dyed hair surface and an undyed leather board surface,the leather board surface is dyed, the color of the leather board surface is repaired and improved, coloring effects are greatly improved, a leather board is lubricating in hand feeling and high in oil feeling, color brightness and plumpness of fabric surface can be improved, and the fabric surface has comfortable silk feels. The comprehensive color repairing process is simple, easy to operate andless in sewage discharge, dyes are sufficiently absorbed, chemical materials are saved, and discharge of waste gas, wastewater and solid waste is reduced.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

Wet-state dyeing finishing and fixation method for leathers based on zirconium-aluminum-titanium complex

ActiveCN105155307ABright and uniform colorImprove coloringDyeing processLeather impregnationFiberWastewater

The invention relates to the technical field of leather making techniques and provides a wet-state dyeing finishing and fixation method for leathers based on a zirconium-aluminum-titanium complex. The zirconium-aluminum-titanium complex is added in a later period of dyeing and fat-liquoring; the zirconium-aluminum-titanium complex is a multi-metal cation tanning agent which may combine with leather fibers so as to increase positive charge on leather surface, to improve tinting strength of the leather surface and color brightness and to basically solve the shading problem, color fullness of cationic crust leathers is improved, consumption of dyes and formic acid in traditional fixation methods is lowered, dyeing rate and fastness of dyes are increased, the content of dyes in spent dye liquor is further decreased, wastewater treatment is easier, and a leather making process is greener.

Owner:XINGYE LEATHER TECH CO LTD

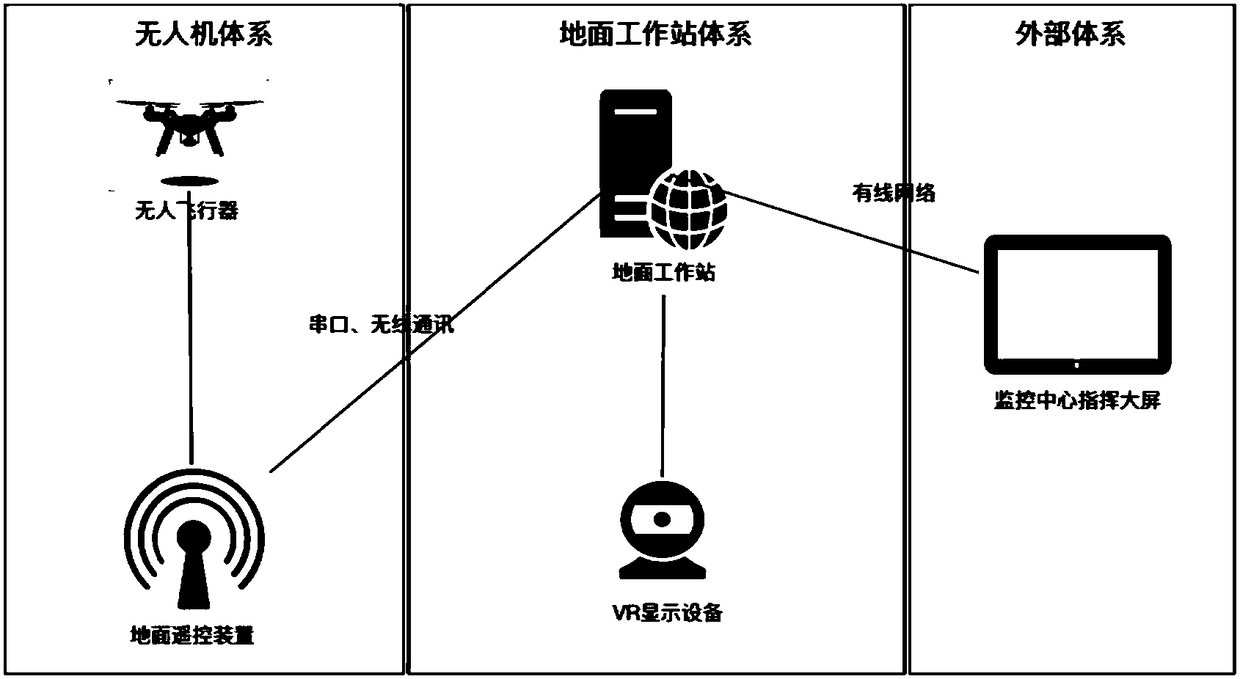

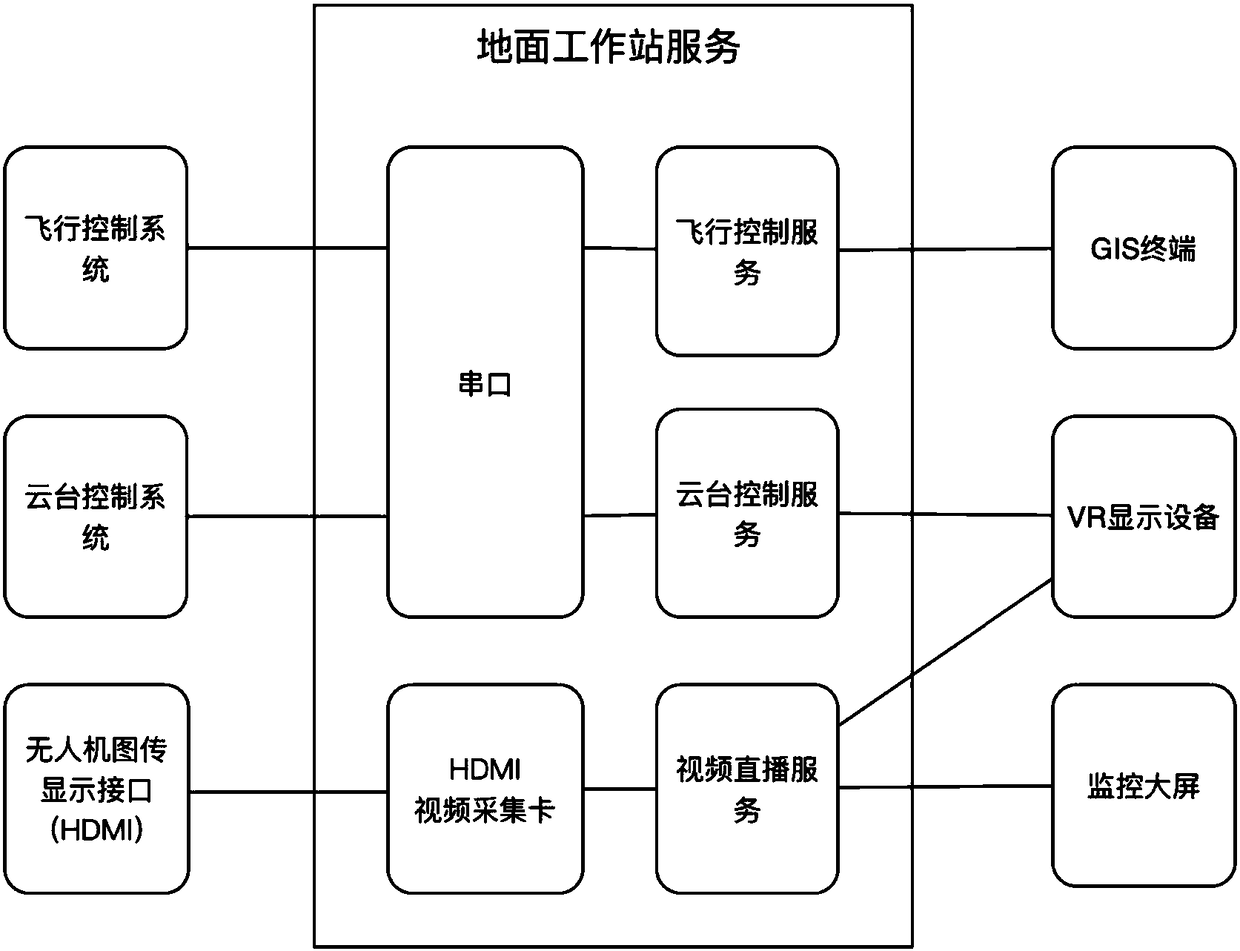

Intelligent power transmission line inspection method

InactiveCN108234953AReduce the burden onLiberating abilityTelevision system detailsColor television detailsTransceiverImaging quality

The invention provides an intelligent power transmission line inspection method. The method comprises the steps that an HDMI interface is adopted to transmit an acquired HDMI video in unmanned aerialvehicle image transmission, and a high-definition video output and generated from high-definition materials is acquired in a completely uncompressed mode in HDMI video acquisition; transceiver equipment is arranged to receive an analog remote control signal and an image transmission signal which are sent by an unmanned aerial vehicle, convert the analog remote control signal and the image transmission signal into digital signals and transmit the digital signals to VR equipment or a digital-to-analog converter (DAC) through a WIFI signal; and unmanned aerial vehicle images are displayed on theVR equipment. The original image quality can be completely kept, and compared with a compressed video, the higher sharpness and definition are achieved; and meanwhile, due to the fact that image processing such as consumed CPU time shortening and deinterlacing are completed in a chip, the burden of a CPU is greatly reduced, the capacity of the CPU is efficiently freed through a PCI-E DMA transmission mode, and then the CPU concentrates on work designated by a user.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

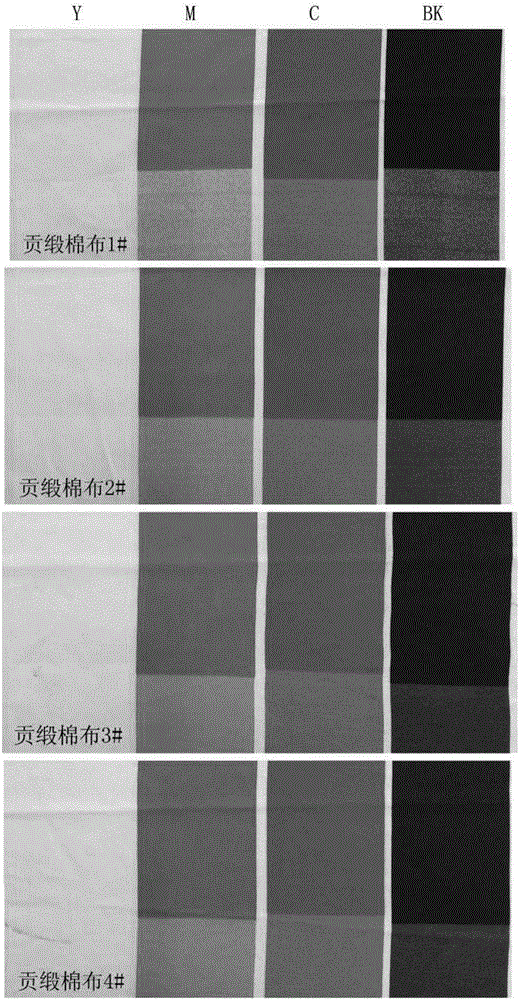

Production method of double-layer high-definition digital printing towel

ActiveCN106592276AImprove clarityImprove color vibrancyDry-cleaning apparatus for textilesDyeing processEngineeringDigital printing

The invention relates to a production method of a double-layer high-definition digital printing towel. A terry pile structure with double-layer gauze is designed and developed, and the double-layer high-definition digital printing towel is prepared through the combination of the terry pile structure and a digital printing technology. According to the production method of the double-layer high-definition digital printing towel, color brilliance and printing definition of a product are sharply improved, the disadvantages that a loop-velvet type fabric is poor in printing effect, prone to dry plate, low in definition and the like are effectively solved, flower-type definition can be sharply improved, the effect of the product on the whole is more fine and smooth, and the advantages of being exquisite in flower-type and rich in color of the digital printing are given full play.

Owner:LOFTEX INDS

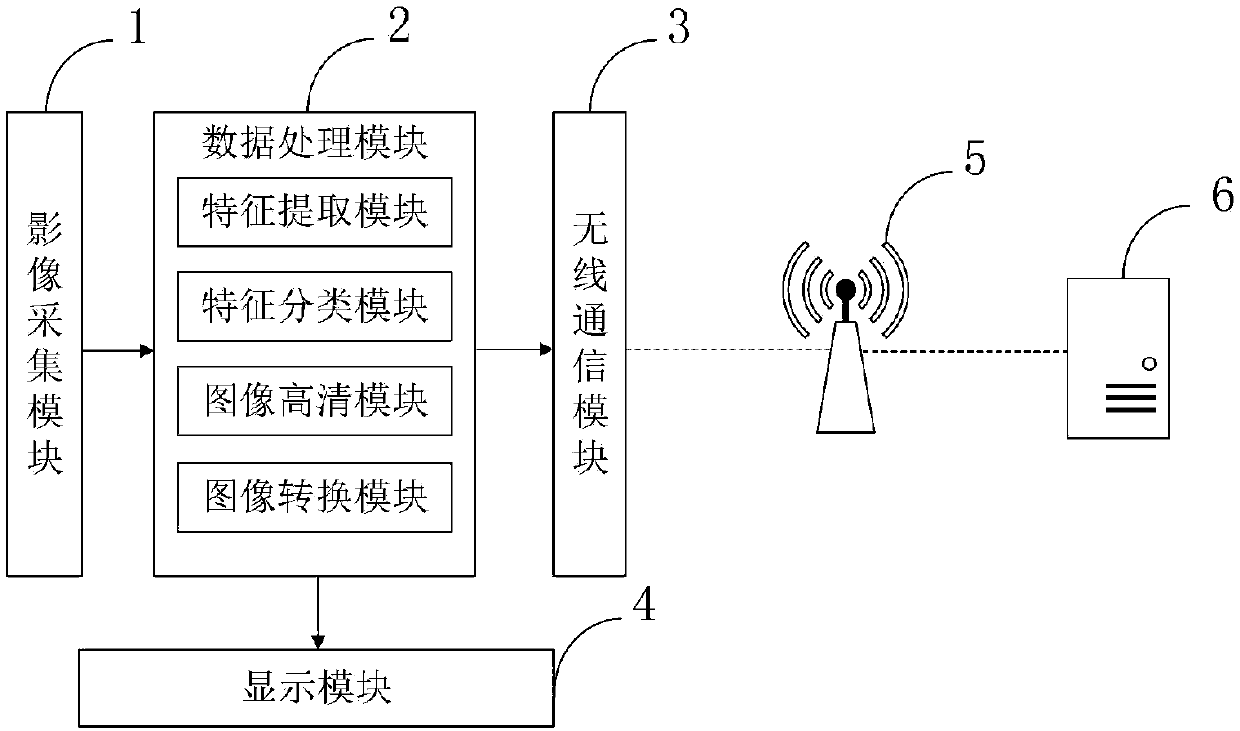

High-resolution remote sensing image road information extraction system

InactiveCN107862278AImprove color vibrancyImprove the display effectCharacter and pattern recognitionImage acquisitionChrominance

The invention belongs to the technical field of road image information extraction, and discloses a high-resolution remote sensing image road information extraction system. The high-resolution remote sensing image road information extraction system comprises an image acquisition module, a data processing module, a wireless communication module, a display module, a wireless base station and a remoteserver. The image acquisition module is connected with the data processing module through a circuit line. The data processing module is connected with the wireless communication module and the display module through circuit lines. The high-resolution remote sensing image road information extraction system performs chroma compensation on an original image through an image high-resolution module, such as compensation on color saturation or expansion on an original image color gamut range, and therefore can performs functions of improving image color brightness and greatly improving displaying effect of displaying equipment. The image can be extracted and classified through a characteristic extraction module and a characteristic classification module, thereby greatly improving processing efficiency of the acquired image.

Owner:HUANGGANG NORMAL UNIV

Cloth dyeing technology

The invention discloses a cloth dyeing technology. By improving a traditional cloth dyeing method, a dyeing method with simple process and low cost is obtained. Cloth dyed by the dyeing method has good dye uniformity and high color vividness. By the dyeing technology, yield of products is greatly raised.

Owner:ZHANGJIAGANG HUAYUAN DYEING & WEAVING

Coating tungsten product

InactiveCN101195285AImprove antioxidant capacityEasy to prepareMetal layered productsPerspirationTungsten

The invention discloses a coating tungsten material, including tungsten substrate. A coating layer with the thickness of 3-30 mu m, comprising TiN or alloy with Cu (residue)-15-45% Zn-0.1-1.5% Ni-0.5-1% Al2O3 is coated on the tungsten substrate. The tungsten substrate is compose of pure tungsten or alloy with W (residue)-2% Ni-1% Fe. The relative density of the tungsten substrate is 97-99% as large as the theoretical density of the pure tungsten. The coating tungsten material of the invention effectively improves the comprehensive usage properties of the surface of the tungsten substrate, such as oxidation resistance, wear resistance, perspiration and corrosion resistance and color brilliance on the condition of keeping the high relative density of the tungsten substrate, and thereby the tungsten substrate with high density is applied widely. The invention has the advantages of simple product process, low cost, adaptability for regular manufacture technique.

Owner:CENT SOUTH UNIV

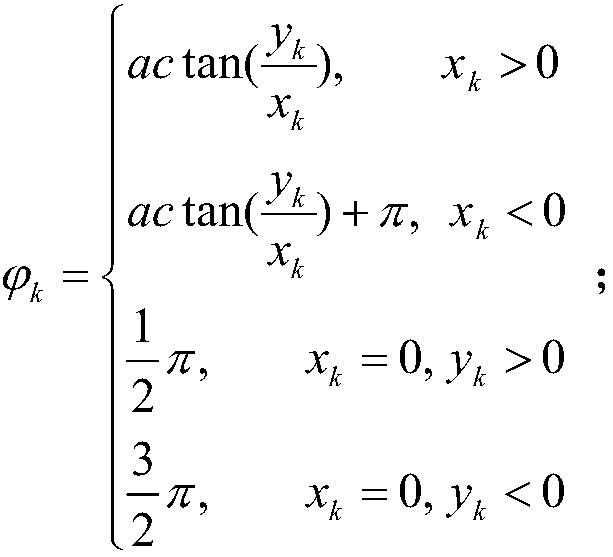

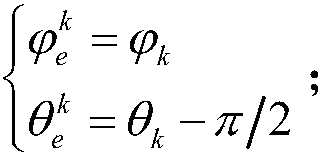

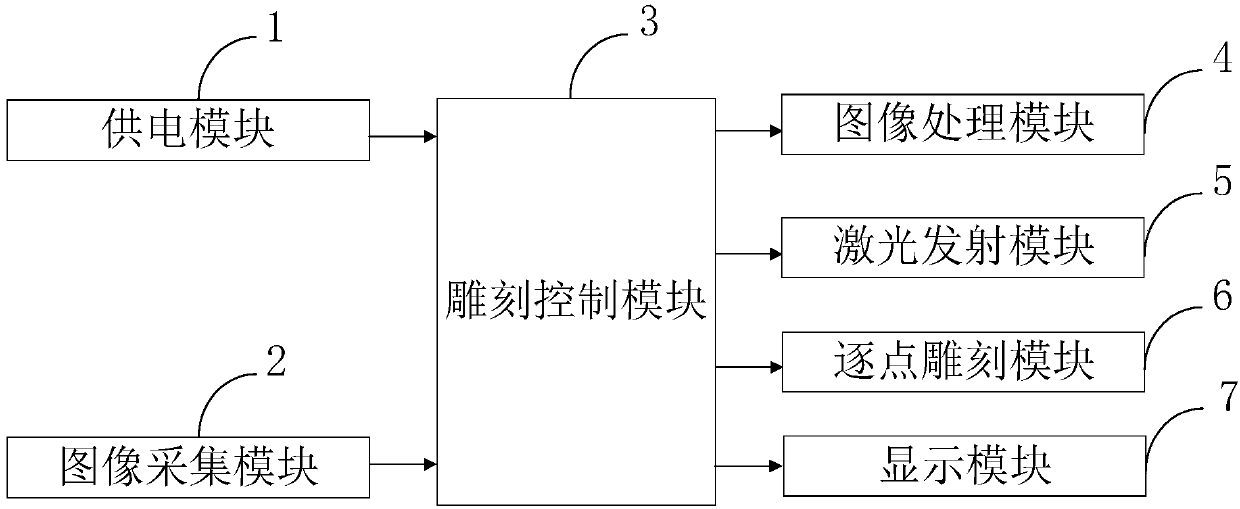

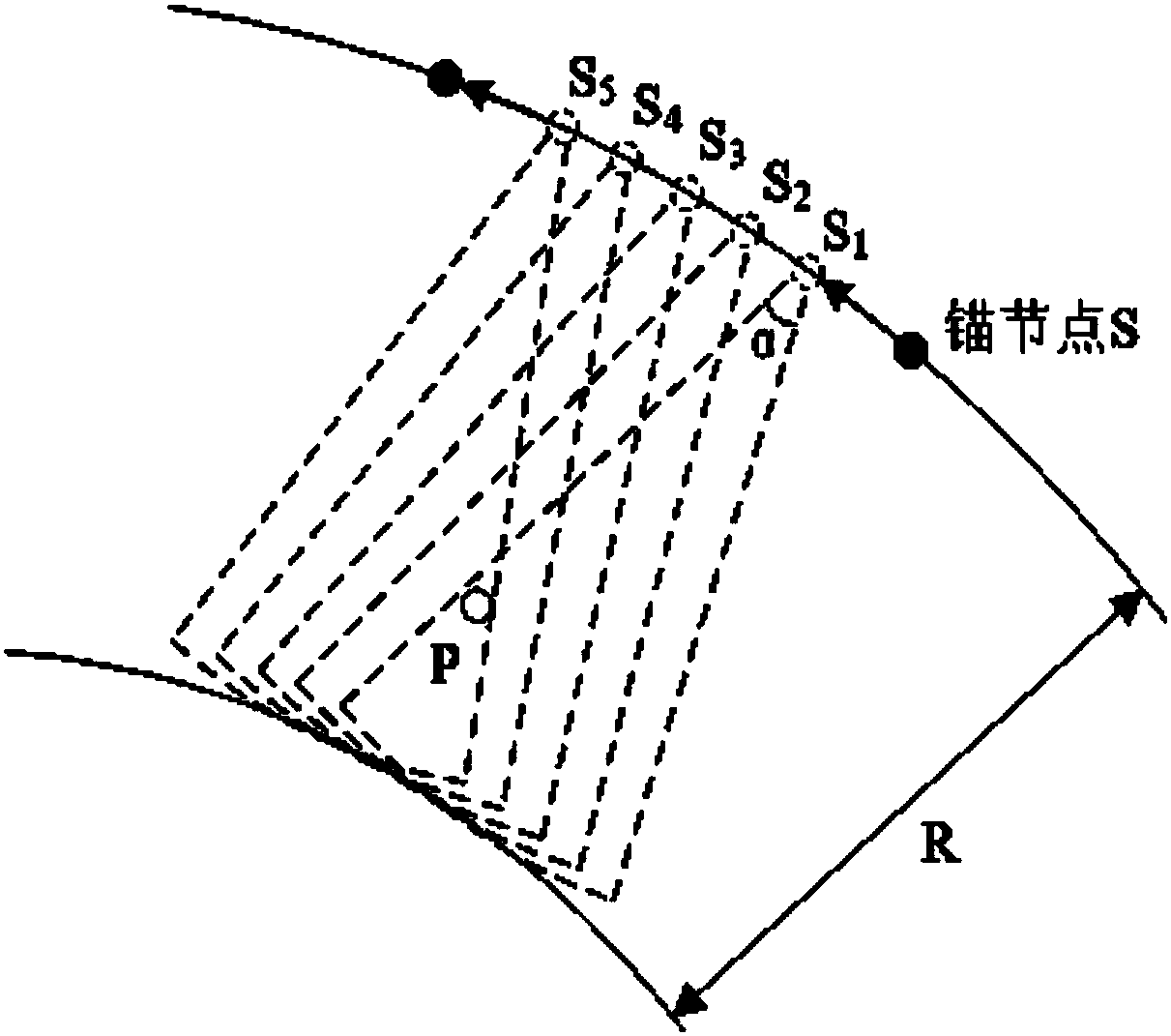

Novel laser engraving unit equipment control system

InactiveCN108515262AImprove color vibrancyComplete efficientlyLaser beam welding apparatusImaging processingGamut

The invention belongs to the technical field of laser engraving, and discloses a novel laser engraving unit equipment control system. The novel laser engraving unit equipment control system comprisesa power supply module, an image acquiring module, an engraving control module, an image processing module, a laser transmission module, a point-by-point engraving module and a display module. According to the novel laser engraving unit equipment control system, the image processing module carries out chrominance compensation on an image to be engraved according to ambient light conditions, for example, color saturation is compensated, or the color gamut range of the image to be engraved is expanded, in consequence, color vividness of the image displayed in ambient light can be improved, and the display effect of display equipment can be greatly improved; and meanwhile, engraving can be completed more efficiently through the point-by-point engraving module.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

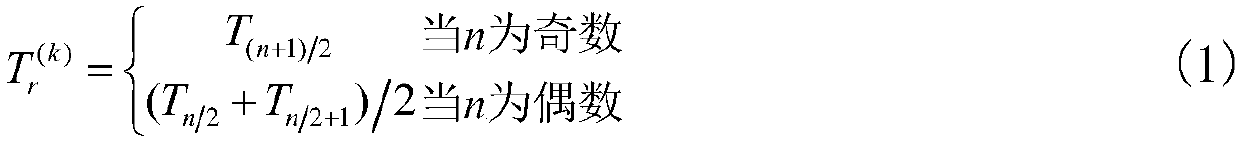

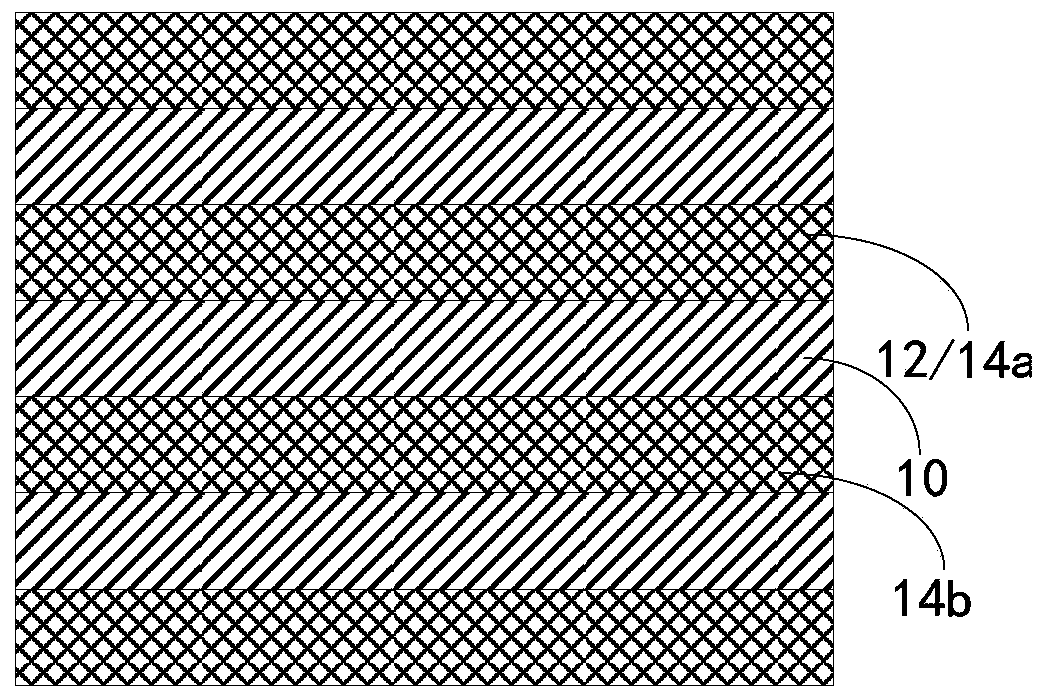

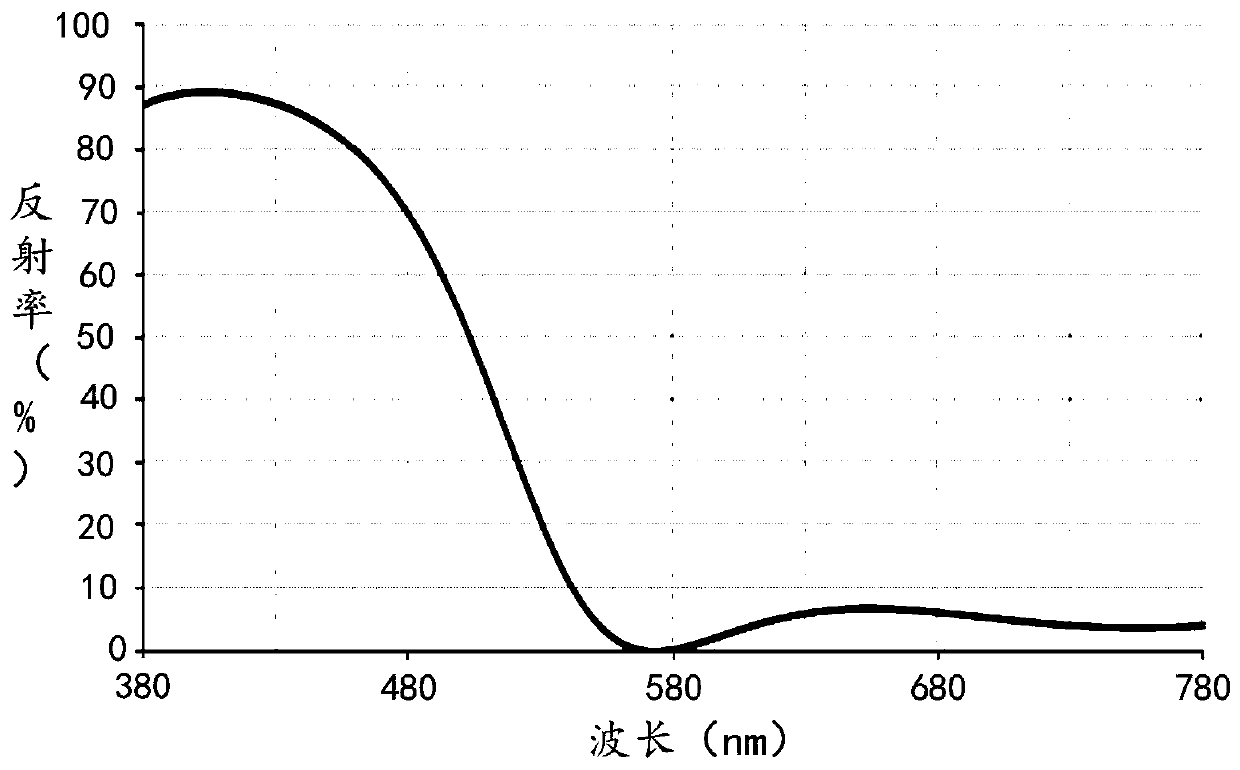

Optical thin film, structural color pigment and preparation method of optical thin film

ActiveCN110749945AIncrease brightnessSimple structurePigmenting treatmentNon-macromolecular adhesive additivesRefractive indexPhotopigment

The application discloses an optical thin film, a structural color pigment and a preparation method of the optical thin film. The optical thin film comprises a plurality of film layers with two high and low refractive indexes, wherein the plurality of film layers are laminated in a mode that two high and low refractive indexes are alternative; the plurality of film layers comprise an intermediatefilm layer; and in the intermediate film layer and other film layers positioned on one side of the intermediate film layer, the film layers with the same refractive indexes are different or not completely the same in optical thickness. In the mode, according to the application, brightness of the optical thin film can be improved.

Owner:NINGBO INLIGHT TECH CO LTD

PBAT fiber and preparation method thereof

ActiveCN113122952AFast crystallizationAvoid stickingMonocomponent copolyesters artificial filamentMelt spinningIsophthalic acid

The invention relates to a PBAT fiber and a preparation method. Molecular chain segments of the PBAT fiber comprise a butylene terephthalate chain segment, a butylene adipate chain segment and an isophthalic acid-5-sodium sulfoisophthalic acid butanediol ester chain segment, the molar content of the butylene adipate chain segment is 50%-150% relative to the molar content of the butylene terephthalate chain segment, and the molar content of the isophthalic acid-5-sodium sulfoisophthalic acid butanediol ester chain segment is 0.5%-4% relative to the molar content of the terephthalic acid butanediol ester chain segment; and the breaking strength of the PBAT fiber is 2.0-5.5 cN / dtex, the elongation at break is 15%-60%, and the AA rate is greater than or equal to 98%. The preparation method comprises the following steps that terephthalic acid and adipic acid are correspondingly esterified and then subjected to pre-polycondensation, then two prepolymers are mixed, an isophthalic acid-5-sodium sulfonate ester is added, then final polycondensation is carried out, and finally the PBAT fiber is prepared by a melt spinning method. According to the PBAT fiber, the balance relation between the crystallization capacity and the performance of PBAT is regulated and controlled through the length of the chain segment, and the performance of the fiber is improved by introducing SSIPA into the chain segment.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK +1

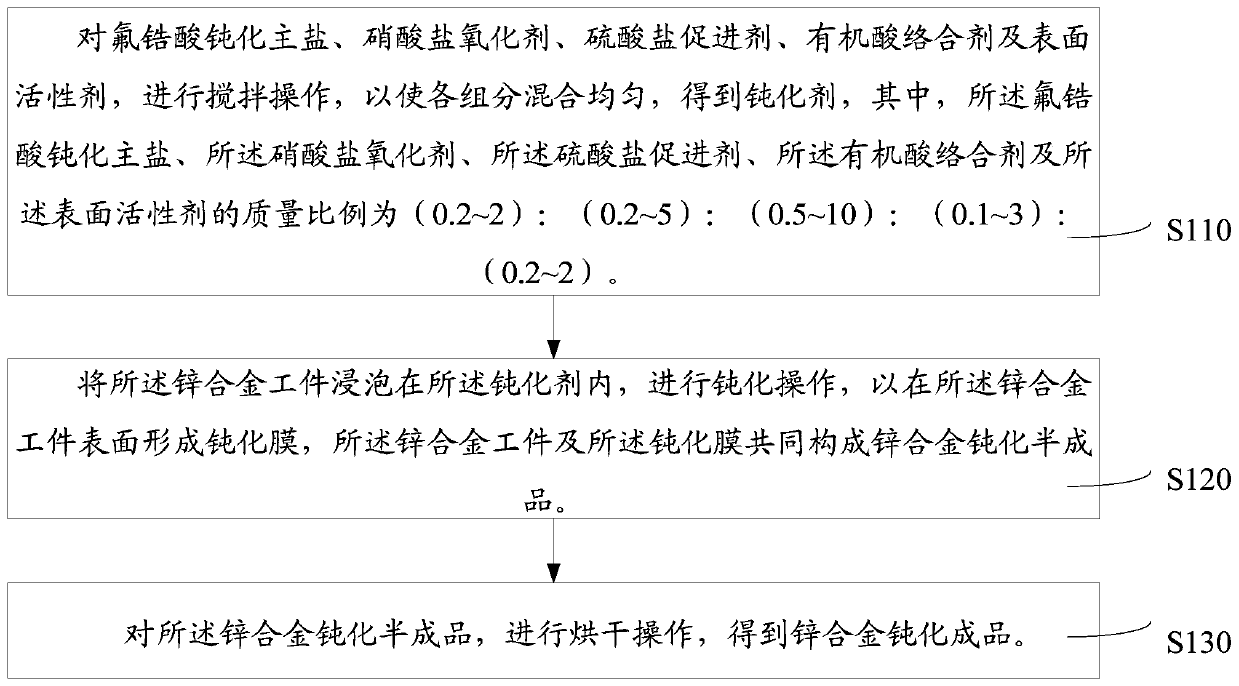

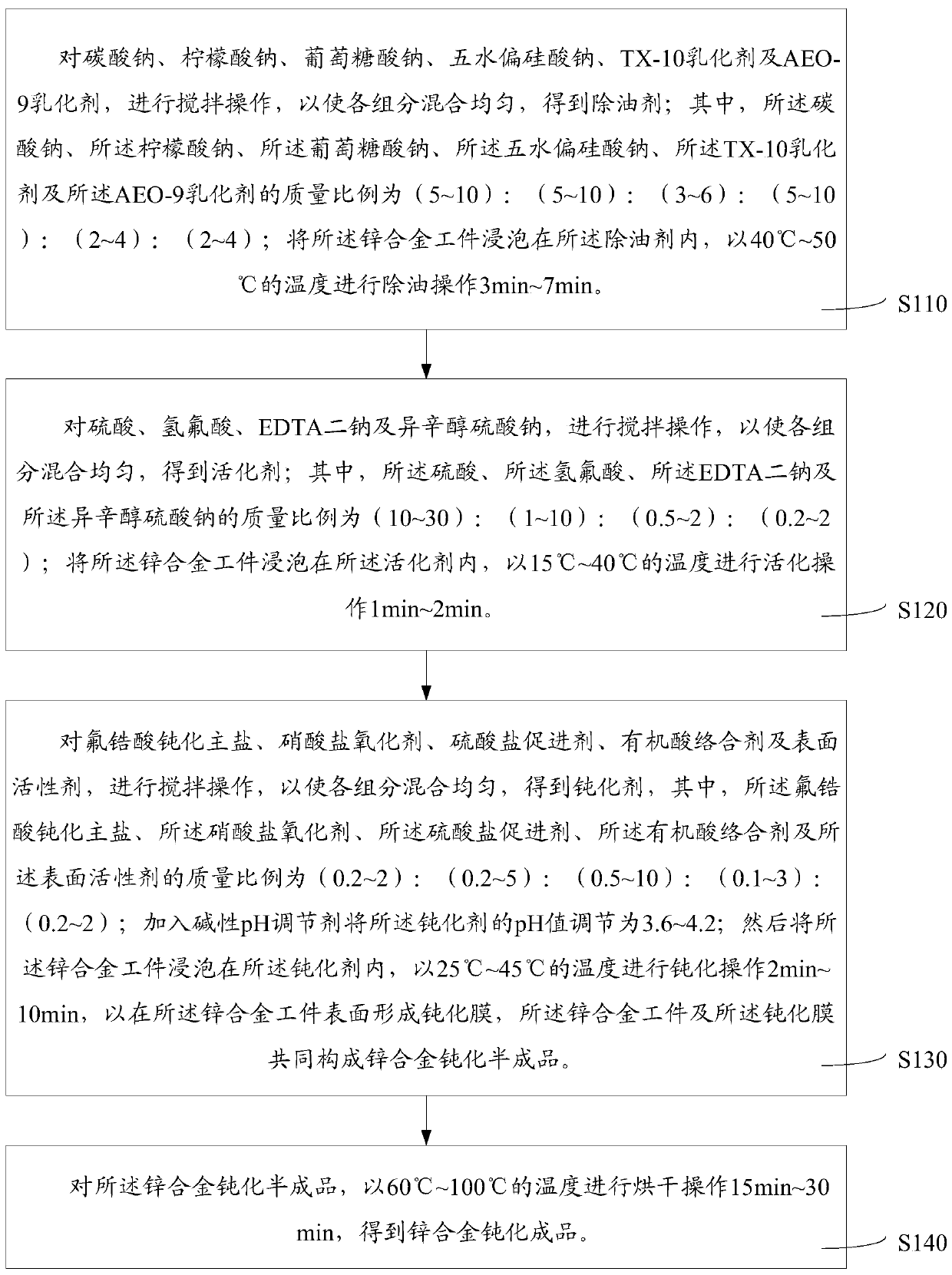

Zinc alloy passivation treatment method and passivator

ActiveCN110904445AAvoid problems prone to precipitationImprove color vibrancyMetallic material coating processesProcess efficiency improvementActive agentZinc alloys

The invention relates to the technical field of metal passivation, and discloses a zinc alloy passivation treatment method and a passivator. The passivator includes the following components in parts by weight: 0.2 to 2 parts of fluorozirconic acid passivation main salt, 0.2 to 5 parts of nitrate oxidant, 0.5 to 10 parts of sulfate accelerator, 0.1 to 3 parts of organic acid complexing agent and 0.2 to 2 parts of surfactant. The zinc alloy passivation treatment method includes steps such as degreasing, activation, passivation, drying and the like to form a passivation film on the surface of a zinc alloy workpiece to obtain a zinc alloy passivation product. The zinc alloy passivation treatment method uses no phosphorus and hexavalent chromium, the obtained passivation film has the characteristics of high film formation uniformity, high color vividness and high brightness, good bonding force with zinc alloy workpieces, high corrosion resistance, and high adhesion to coatings.

Owner:广东东明新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com