Zinc alloy passivation treatment method and passivator

A passivation treatment and passivating agent technology, applied in the direction of metal material coating process and process efficiency improvement, can solve the problems of low decoration, short service life, poor bonding force of zinc alloy workpieces, etc., and achieve corrosion resistance. Good, improve the service life, the effect of uniform color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

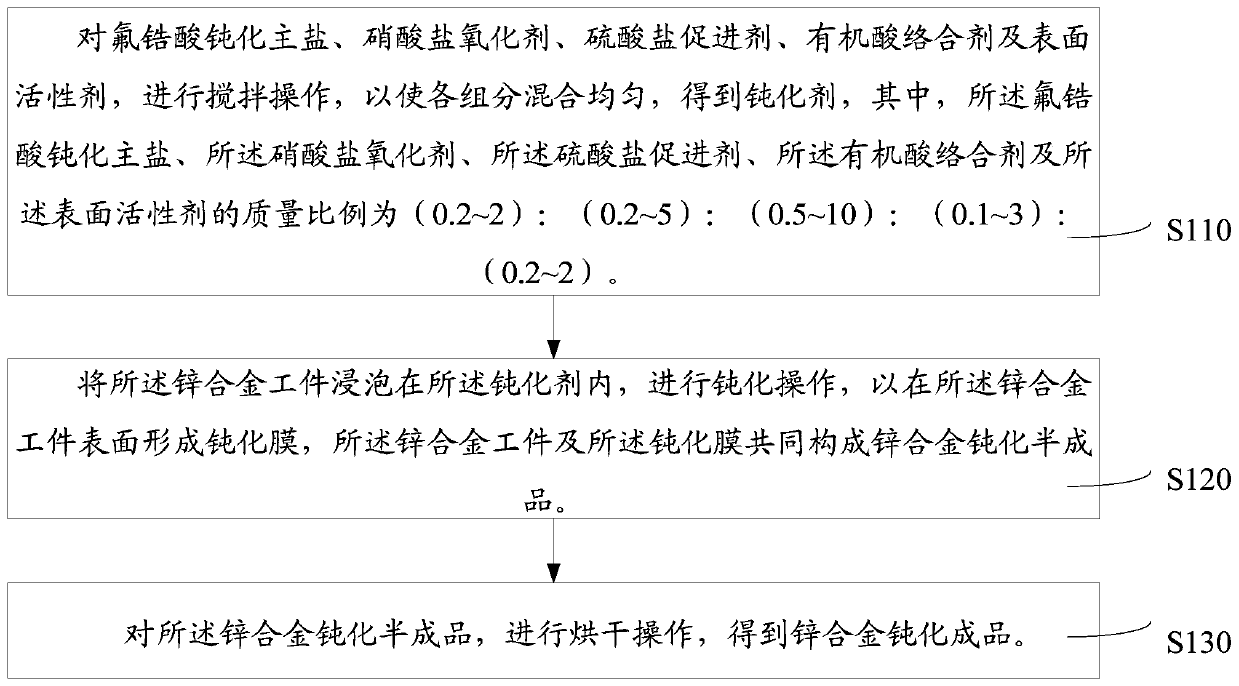

Method used

Image

Examples

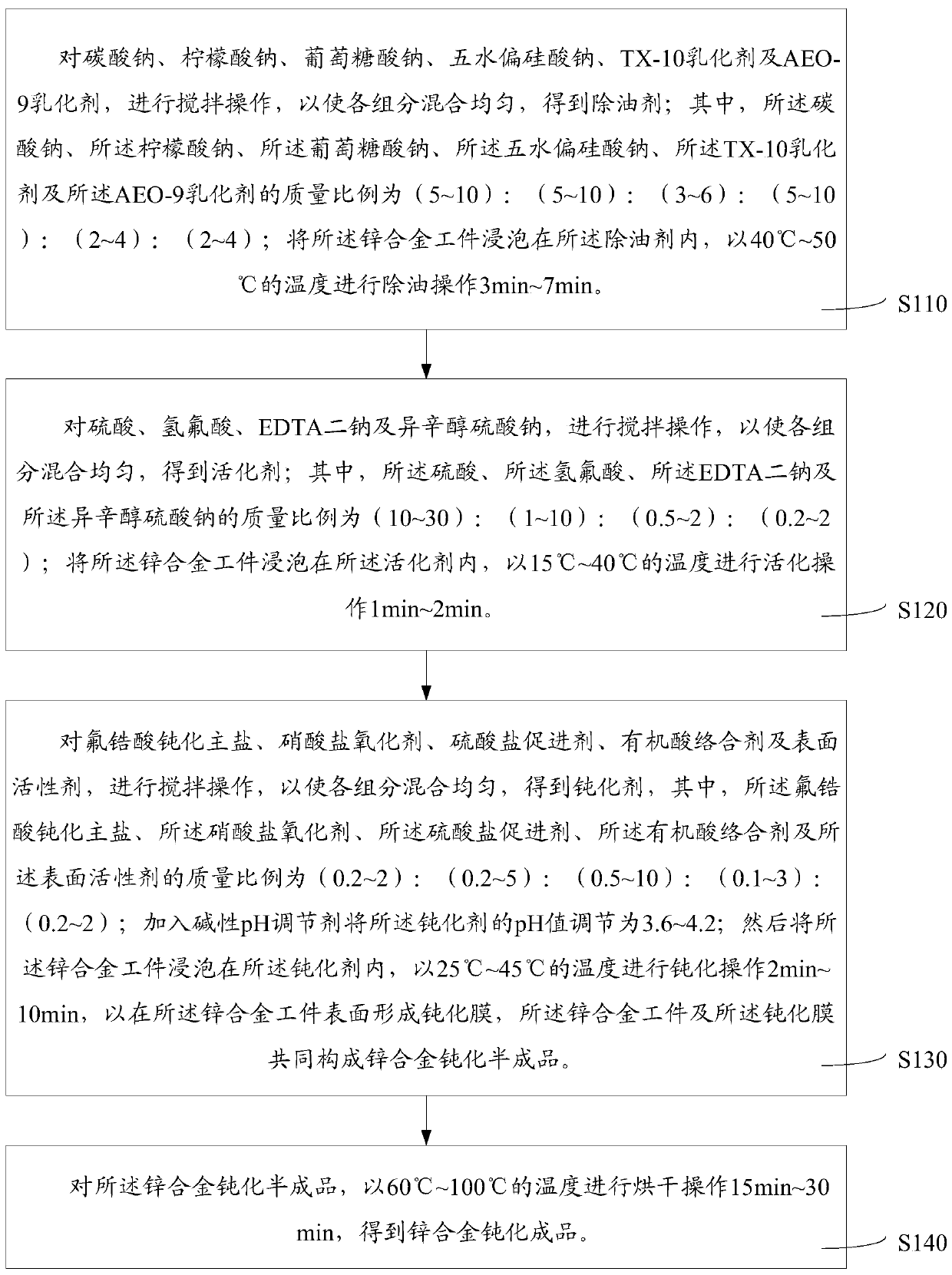

Embodiment approach

[0052] In one embodiment, before the operation of immersing the zinc alloy workpiece in the passivating agent, sulfuric acid, hydrofluoric acid, disodium EDTA and sodium isooctyl sulfate are also stirred, so that each component Mix uniformly to obtain an activator; wherein, the mass ratio of the sulfuric acid, the hydrofluoric acid, the disodium EDTA and the sodium isooctyl sulfate is (10~30):(1~10):(0.5 ~2): (0.2~2); immersing the zinc alloy workpiece in the activator to perform an activation operation.

[0053] It should be noted that the degreasing operation is one of the key procedures of the zinc alloy passivation treatment method. The sodium silicate remaining on the surface of the zinc alloy workpiece is removed through the activation operation, so as to avoid the reaction of sodium silicate and the acid in the passivation agent to form a colloid of silicic acid, which makes the passivation film foggy and causes the color of the passivation film Vividness and brightnes...

Embodiment 1

[0069] S111, dissolve 10g of sodium carbonate, 10g of sodium citrate, 3g of sodium gluconate, 5g of sodium metasilicate pentahydrate, 2g of TX-10 emulsifier and 3g of AEO-9 emulsifier in 1L of water, and perform a stirring operation so that each The components are mixed evenly to obtain a degreasing agent; the zinc alloy workpiece is soaked in the degreasing agent, and the degreasing operation is performed at a temperature of 45° C. for 5 minutes; washed with water for 3 times, each time for 20 seconds.

[0070] S121, 10g of 98% sulfuric acid, 6g of 55% hydrofluoric acid, 0.5g of disodium EDTA and 0.5g of sodium isooctyl sulfate are dissolved in 1L of water, and the stirring operation is carried out so that the components are uniformly mixed to obtain an activator; The zinc alloy workpiece was soaked in the activator, and activated at a temperature of 25° C. for 1.5 minutes; washed with water for 3 times, each time for 20 seconds.

[0071] S131, dissolve 0.5g potassium fluozir...

Embodiment 2

[0074] S112 is the same as step S111 in Embodiment 1.

[0075] S122 is the same as step S121 in Embodiment 1.

[0076] S132, dissolve 0.8g potassium fluozirconate, 0.5g chromium nitrate, 1g magnesium sulfate, 2g chromium sulfate, 0.5g hydroxyethylidene diphosphonic acid and 1g isooctyl sodium sulfate in 1L of water, and perform stirring operation so that each Mix the components evenly to obtain a passivating agent; add ammonia water to adjust the pH value of the passivating agent to 3.8; then soak the zinc alloy workpiece in the passivating agent and perform passivation at a temperature of 40°C 4min, to form a passivation film on the surface of the zinc alloy workpiece, the zinc alloy workpiece and the passivation film together constitute a zinc alloy passivation semi-finished product; wash with water 3 times, 20 seconds each time.

[0077]S142, same as step S141 of embodiment 1, see passivation effect Figure 5 , in the figure, the product on the right is the zinc alloy wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com