Method for preparing amphiphilic modified organic pigment based on discontinuous deposition of silica sol

An organic pigment and silica sol technology, applied in the direction of organic dyes, etc., can solve the problems of slow processing, aggregation and precipitation of adhesive film, insufficient lipophilicity, etc., and achieve the effect of strong bonding fastness.

Active Publication Date: 2014-12-17

ZHEJIANG SCI-TECH UNIV

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The above-mentioned research has successfully carried out hydrophilic modification to the surface of the lipophilic organic pigment, but there are still some problems in the above-mentioned research: (1) what is realized is the complete coating of the whole organic pigment particle, which often leads to the modification of the pigment. Excessive hydrophilicity and insufficient lipophilicity, so that in practical application, large-scale aggre

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

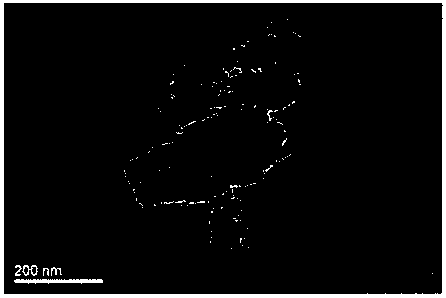

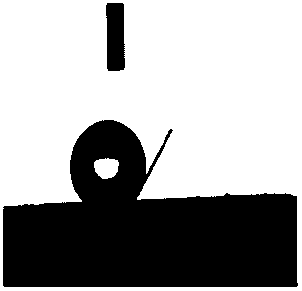

The invention discloses a method for preparing an amphiphilic modified organic pigment based on discontinuous deposition of silica sol. The method concretely comprises the following steps: adding an organic pigment into an ethanol solution containing an electrostatic adsorbent, and ball-milling for 30-90min to obtain a pigment/ethanol dispersion; and adding the silica sol, an inorganic precursor tetraethyl orthosilicate (TEOS), ammonia water (NH3.H2O) and a stabilizer into the pigment/ethanol dispersion, adjusting the pH value of a reaction system to 9.0-12.0, carrying out a modifying reaction, and drying to obtain the amphiphilic organic pigment. A modification technology used in the invention makes inorganic matters deposited on parts of the surfaces of the particles of the pigment, wherein the inorganic deposition part is hydrophilic and the deposition-free part is lipophilic. The obtained modified pigment is amphiphilic, can be moistened and dispersed in water, and can also be well dispersed in oily solvents and polymers. The pigment obtained in the invention is especially suitable for coloring coatings of textiles in wet processing environment.

Description

technical field [0001] The invention relates to the field of preparation of surface-modified organic pigments, in particular to a method for preparing amphiphilic modified organic pigments based on silica sol discontinuous deposition. Background technique [0002] Organic pigments have a wide spectrum, bright colors, bright hues, and various varieties. They have been widely used in many fields such as coatings, printing and dyeing, papermaking, and printing ink. However, organic pigments have low surface energy and strong hydrophobicity, so it is difficult to infiltrate in water without adding additives, let alone achieve uniform and stable dispersion in it. Therefore, it must be commercially processed on a large scale before being used in printing and dyeing wet processing. For example, European and American companies such as BASF and Ciba Fine Chemicals abroad have used a large number of pigment particle surface modification technologies to successfully develop a series o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09B67/08C09B67/20

Inventor 戚栋明陈智杰高翔曹志海

Owner ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com