Patents

Literature

33results about How to "Strong bond fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite cloth for curtain roller shutter and preparation method of composite cloth

ActiveCN109397806AWaterproof and breathableReduce tensionSynthetic resin layered productsLow-density polyethyleneUltraviolet protection

The invention discloses a composite cloth for a curtain roller shutter and a preparation method of the composite cloth. The composite cloth comprises a plasma-treated base cloth and a polyurethane TPUfilm attached to the base cloth, wherein the polyurethane TPU film is prepared by the following method that 70-80 parts of polyurethane TPU, 4-6 parts of low-density polyethylene (LDPE), 4-6 parts ofcarbon black, 4-6 parts of titanium oxide, 4-6 parts of nano glass micro-beads and 4-6 parts of phenyl salicylate are mixed evenly, then extruded and subjected to tape casting to form the film. By modifying the polyurethane TPU, the obtained composite cloth is soft and comfortable in hand feeling, environmental protection, shading, strong light irradiation resisting, ultraviolet protection, washing and dry-cleaning resisting and aging resistance are achieved, excellent light resistance and aging resistance are achieved, the adhesion fastness of a product is high, and the quality-guarantee service life is ten years or above. After the surface of the base cloth is activated, the modified polyurethane TPU film is composited in a hot-pressed mode, glue is not used, and thus real energy savingand environmental protection are achieved.

Owner:浙江鸿圣纺织科技有限公司

Manufacturing method of multifunctional film pasted fabric

InactiveCN106346887AImprove waterproof performanceEasy fit operationDomestic upholsterySynthetic resin layered productsEnvironmental resistanceCompound a

The invention discloses a manufacturing method of a multifunctional film pasted fabric. The multifunctional film pasted fabric is a seamless wall covering fabric or a full shading curtain fabric. The specific manufacturing method comprises the following steps: (1) compounding a surface fabric and a polyurethane TPU (thermoplastic polyurethane) water-resistant air-permeable film or polyurethane TPU black full shading waterproof film: sizing the surface of the film in a point transfer manner by using a special compounding machine, wherein an environment-friendly PU (polyurethane) or PUR (polyurethane resin) adhesive is used for sizing, and the compounding temperature is 125-135 DEG C; (2) curing: standing for 6-8 hours; (3) compounding with a base fabric: after compounding and curing the surface fabric and the polyurethane TPU water-resistant air-permeable film or polyurethane TPU black full shading waterproof film, sizing the other surface of the polyurethane TPU water-resistant air-permeable film or polyurethane TPU black full shading waterproof film by using the special compounding machine, wherein the environment-friendly PU or PUR adhesive is used for sizing, and the compounding temperature is 130-140 DEG C; and (4) finishing, and packaging. The manufacturing method disclosed by the invention is simple, has a favorable required effect and is environment-friendly.

Owner:浙江鸿圣纺织科技有限公司

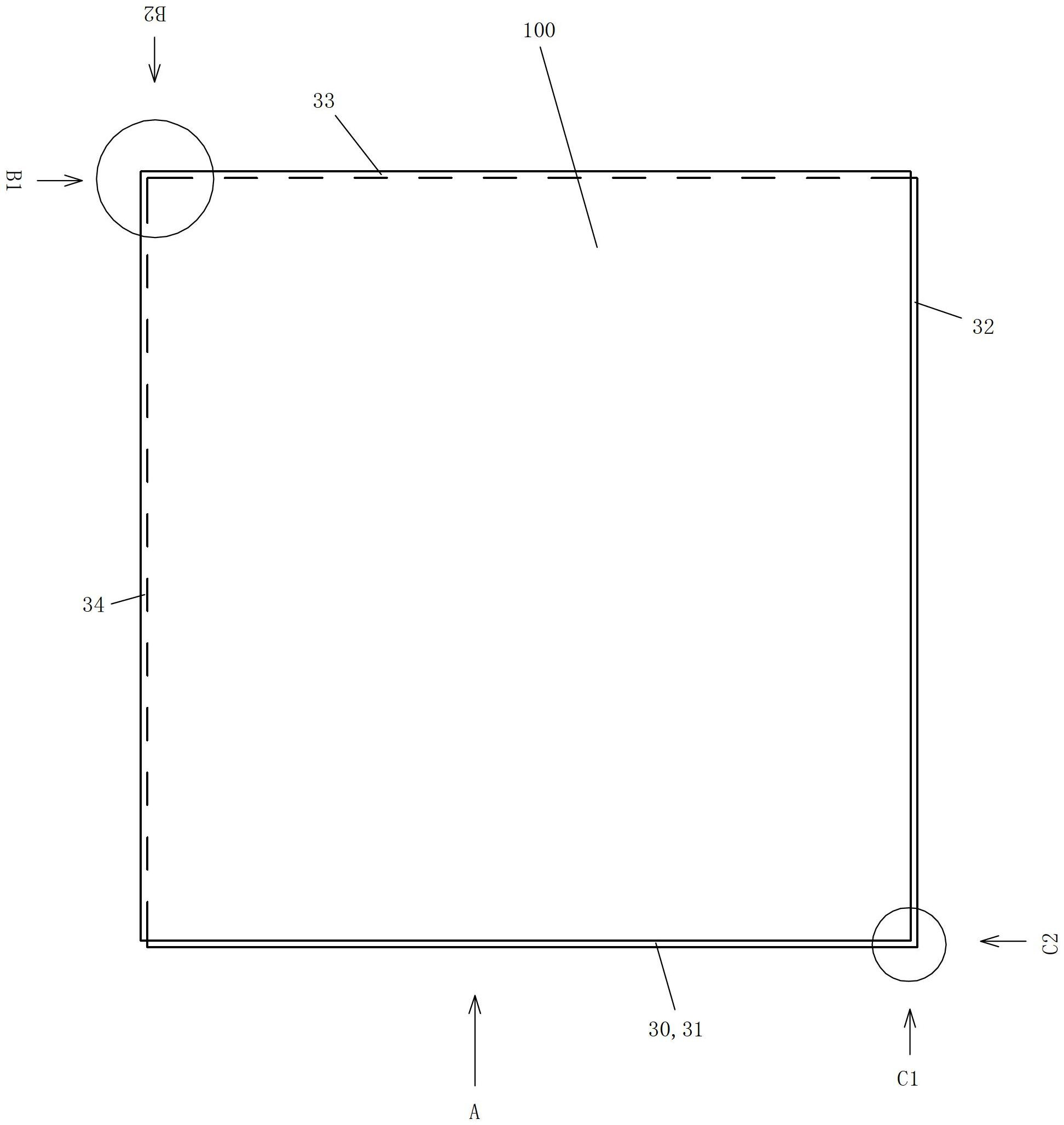

Phase change heat storage type electric heating floor

InactiveCN103776080ACompact and reasonable structureImprove securityLighting and heating apparatusElectric heating systemElectricityElectrical connection

The invention discloses a phase change heat storage type electric heating floor. The phase change heat storage type electric heating floor comprises a floor main body and an electric heating assembly. Socket positions which are connected with the adjacent electric heating floor portions during usage are formed on the periphery of the floor. The phase change heat storage type electric heating floor is characterized by also comprising a flat phase change unit; the floor main body comprises a panel component and a base plate; the corresponding positions of the panel component and the base plate in the vertical direction are bonded and fixed together to form the floor main body, wherein the inside of the floor main body comprises the first installation space; the electric heating assembly comprises an electric heating piece, a transmission unit and connection sockets which are located at the front end and the rear end of the electric heating piece respectively and used for performing electrical connection externally; the electric heating piece and the phase change unit are fixedly arranged in the first installation space of the floor main body; the panel component, the electric heating piece, the phase change unit and the base plate are arranged in turn from top to bottom and are in close contact with each other in turn in the vertical direction.

Owner:江苏德威木业有限公司

Spray-painting advertisement cloth and production process thereof

InactiveCN104057684ASimple production processComplete processLaminationLamination apparatusEngineeringPolymer coating

The invention relates to an advertisement-displaying and decorative material carrier, and especially relates to spray-painting advertisement cloth and a production process thereof. The spray-painting advertisement cloth comprises base cloth, coatings at the two sides, and PVC films at two sides of the coatings; the production process comprises the following steps: 1) unreeling a PVC light-color film, coating the PVC light-color film with a polymer coating by an anilox roller; 2) attaching the PVC light-color film to base cloth; 3) treating a PVC dark-color film according to the step 1), coating the polymer coating, attaching the PVC dark color film to the other side of the base cloth; 4) preheating another PVC light-color film, and attaching to the PVC dark-color film; 5) reeling and packaging. The production process is concise, and the process flow is complete; the coating is thin and light in mass, which greatly improves the production efficiency and raw material utilization rate, and saves cost; the coating is flat and uniform; the product has good spray-painting performance, excellent ink absorption performance, high color rendition degree, and wide applications.

Owner:SHANGHAI NAR INDAL

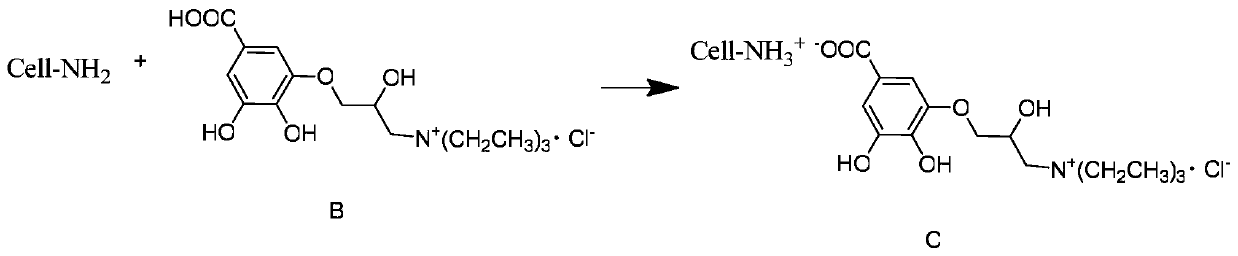

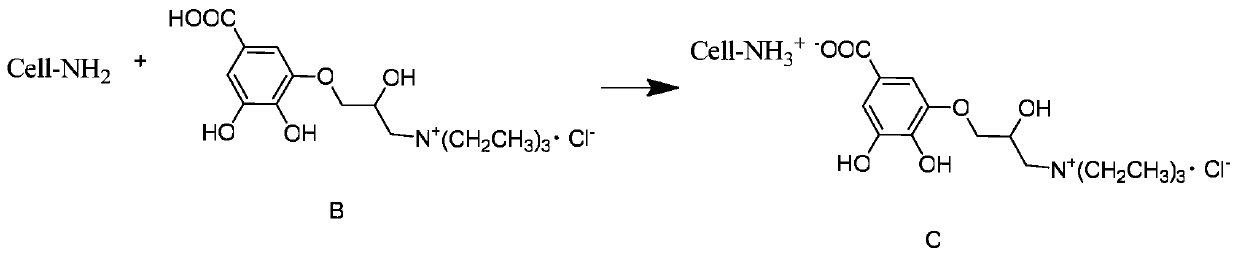

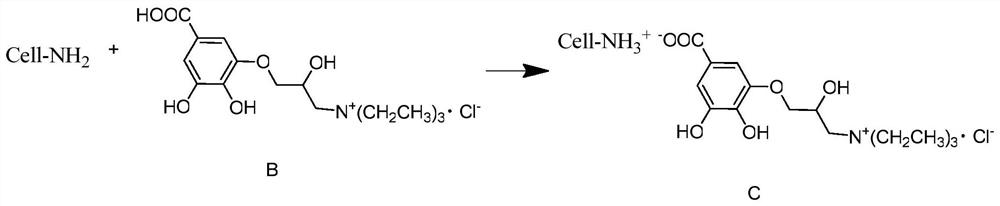

Preparation process of fluffy, warm-keeping and anti-mildew down quilt

ActiveCN110004728AIncrease warmthImprove bulkBiochemical fibre treatmentDry-cleaning apparatus for textilesFiberImpurity

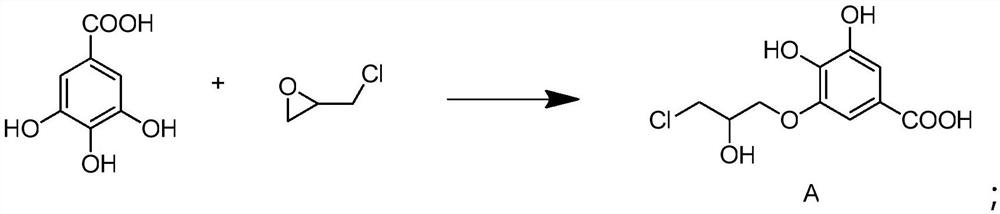

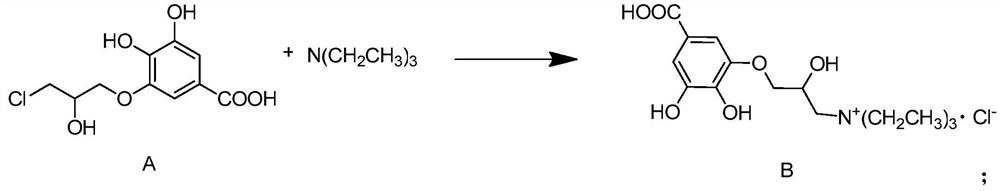

The invention discloses a preparation process of a fluffy, warm-keeping and anti-mildew down quilt. The preparation process has the advantages that filling down feather fibers are preprocessed to remove impurities and dust on the down feather fibers, then the down feather fibers are modified, sterilizing and antibacterial active N<+> is introduced into the down feather fibers, the pre-modified down feather fibers is mixed with metal ions, phenolic hydroxyl groups and alcoholic hydroxyl groups on the pre-modified down feather fibers can complex with Ni<2+> and Fe<3+>, and the antibacterial andanti-mildew performance of the down fibers is further increased; in addition, the warm-keeping performance of the down feather can be increased by introducing the Ni<2+> and the Fe<3+> which have goodfar infrared radiation ability into the down feather fibers, and the introduced Ni<2+> and Fe<3+> can generate a static effect to increase the fluffiness of the down feather; the preparation processis scientific and reasonable, the defect that existing down feather fibers are not resistant to mildew is improved, the down feather fibers can still have good antibacterial and anti-mildew performance after repeated washing, and the prepared down quilt is good in washability.

Owner:宁波博洋家纺集团有限公司

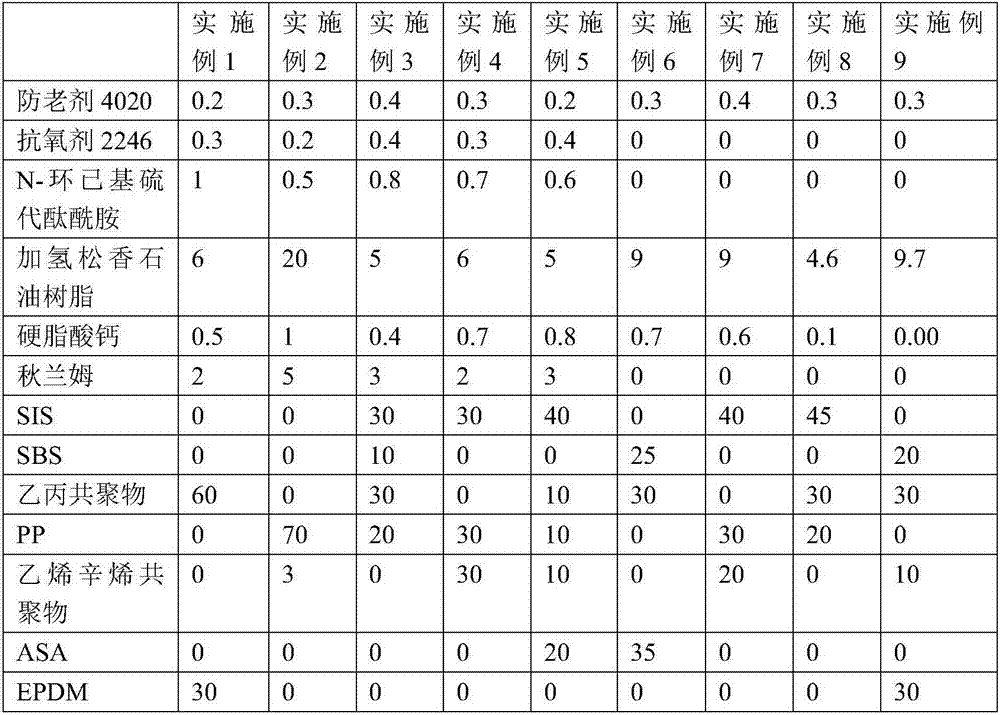

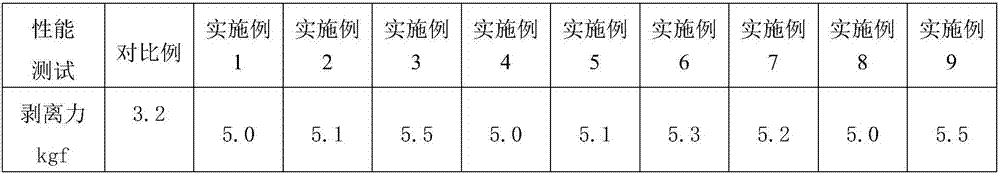

Novel hot melt adhesive membrane, preparation method and application

InactiveCN107418459ALow costLow priceNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAntioxidant

The invention discloses a hot melt adhesive membrane which is prepared from antioxidants, petroleum resin and engineering plastics. The invention further discloses a preparation method of the hot melt adhesive membrane and an application of the hot melt adhesive membrane to EVA (ethylene vinyl acetate) pressing rubber sheet forming soles. The hot melt adhesive membrane prepared by the method is low in cost, simple in process and environmentally friendly, and resources are saved.

Owner:江苏和和新材料股份有限公司

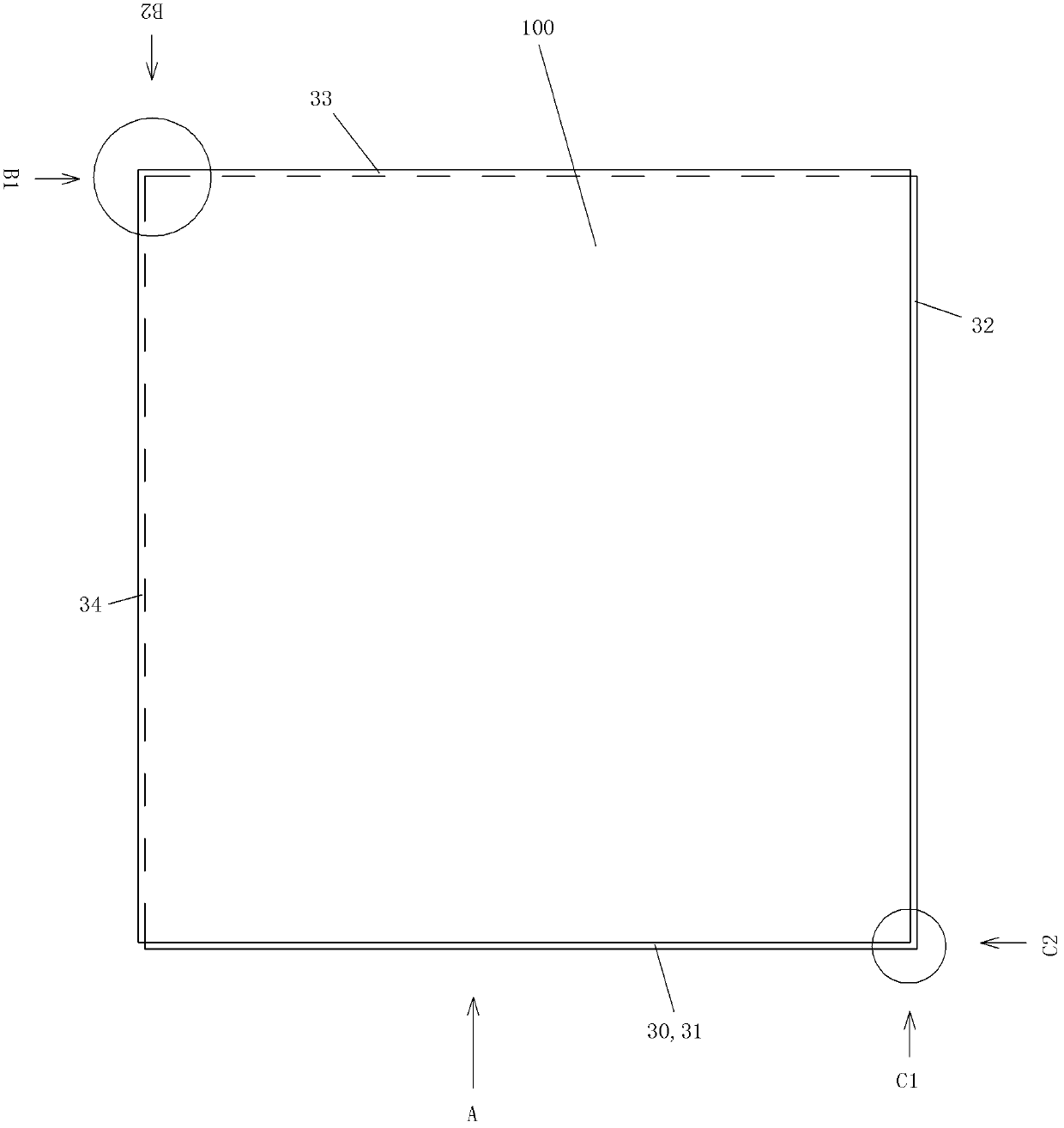

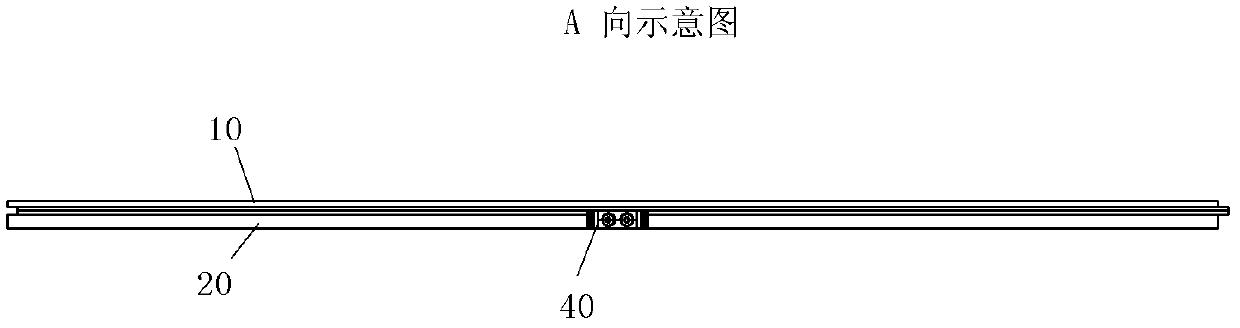

Spontaneous heating floor

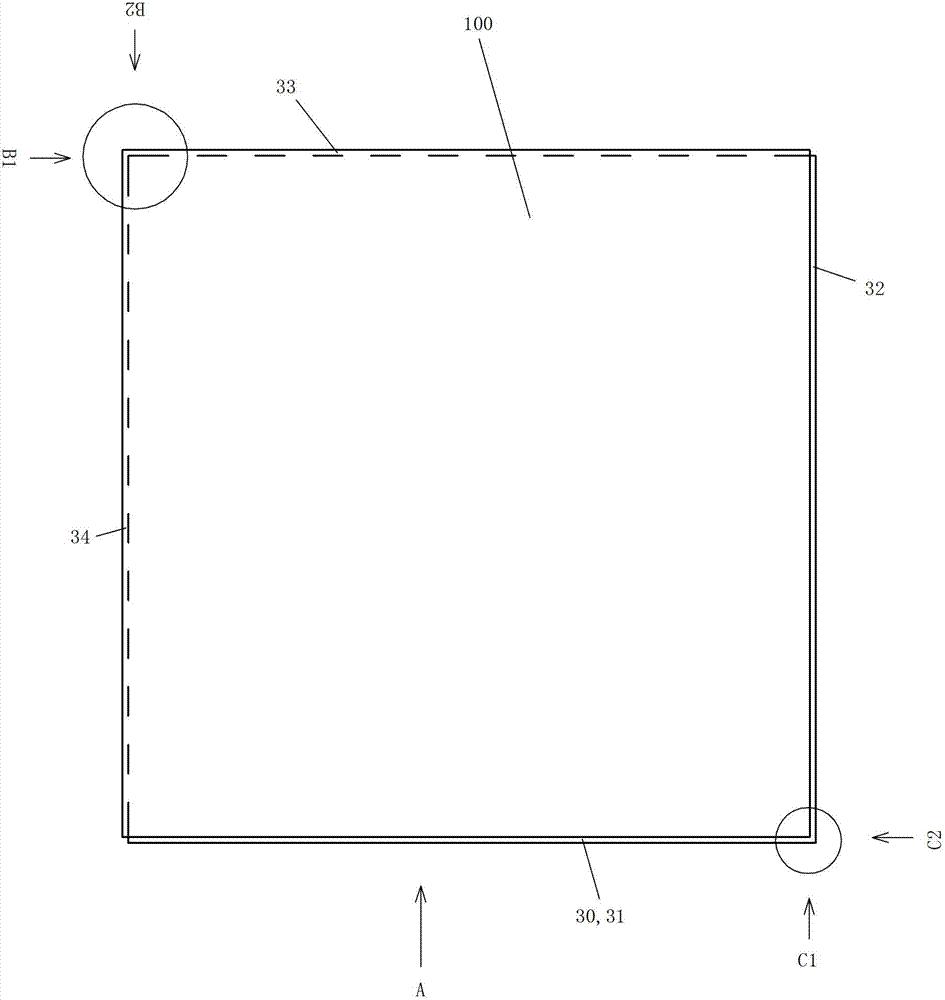

ActiveCN102607096AEasy to installImprove thermal efficiencyLighting and heating apparatusElectric heating systemElectricityPower flow

The invention discloses a spontaneous heating floor, which is characterized by comprising a panel, a soleplate and a spontaneous heating component. The heating body of the spontaneous heating component is an electric heating plate. The panel is adhered on the soleplate from above to form a main floor body with an inner cavity. The electric heating plate of the spontaneous heating component is arranged in the inner cavity of the main floor body. Power supply plug connectors belonging to the spontaneous heating components are arranged on the front and back sides of the main floor body. The power supply plug connectors are reliably limited and fixed in the main floor body and are capable of realizing electric connection and current transmission with an adjacent spontaneous heating floor at an insertion hole position exposed outwards from the power supply plug connectors and provided with copper inserting pins by means of a corresponding electric connecting component; and in the invention, the spontaneous heating floor is installed simply and conveniently, and a technical guarantee for safe and reliable application, high heat efficiency and durable structure is provided.

Owner:枣庄高新区利民供热服务有限公司

Wood veneer composite material and its production process

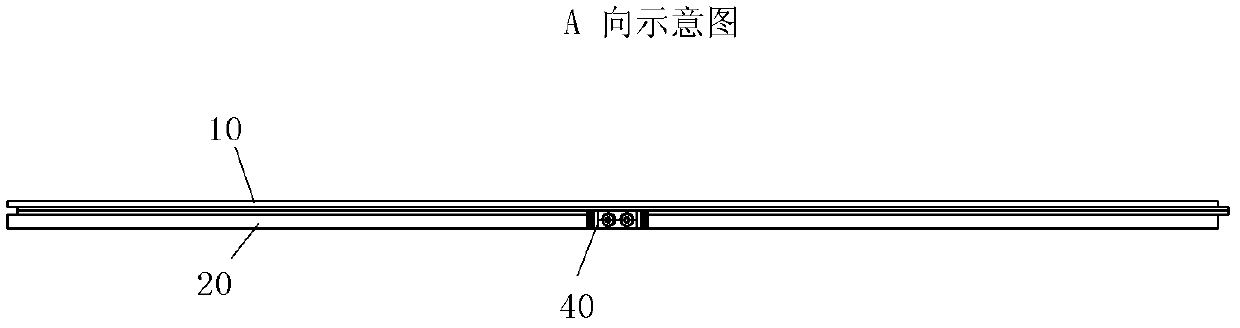

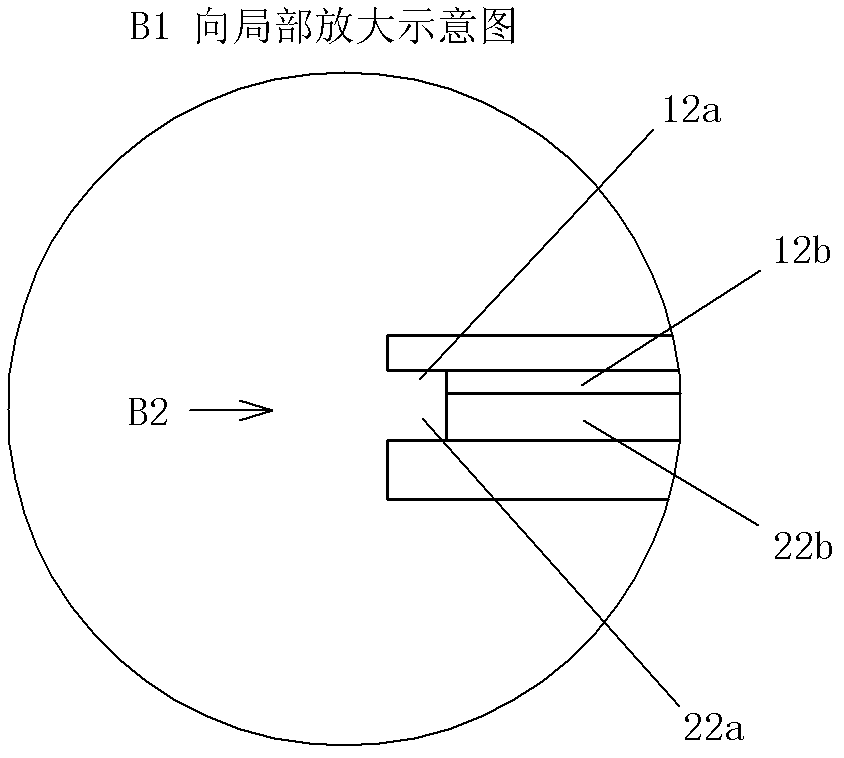

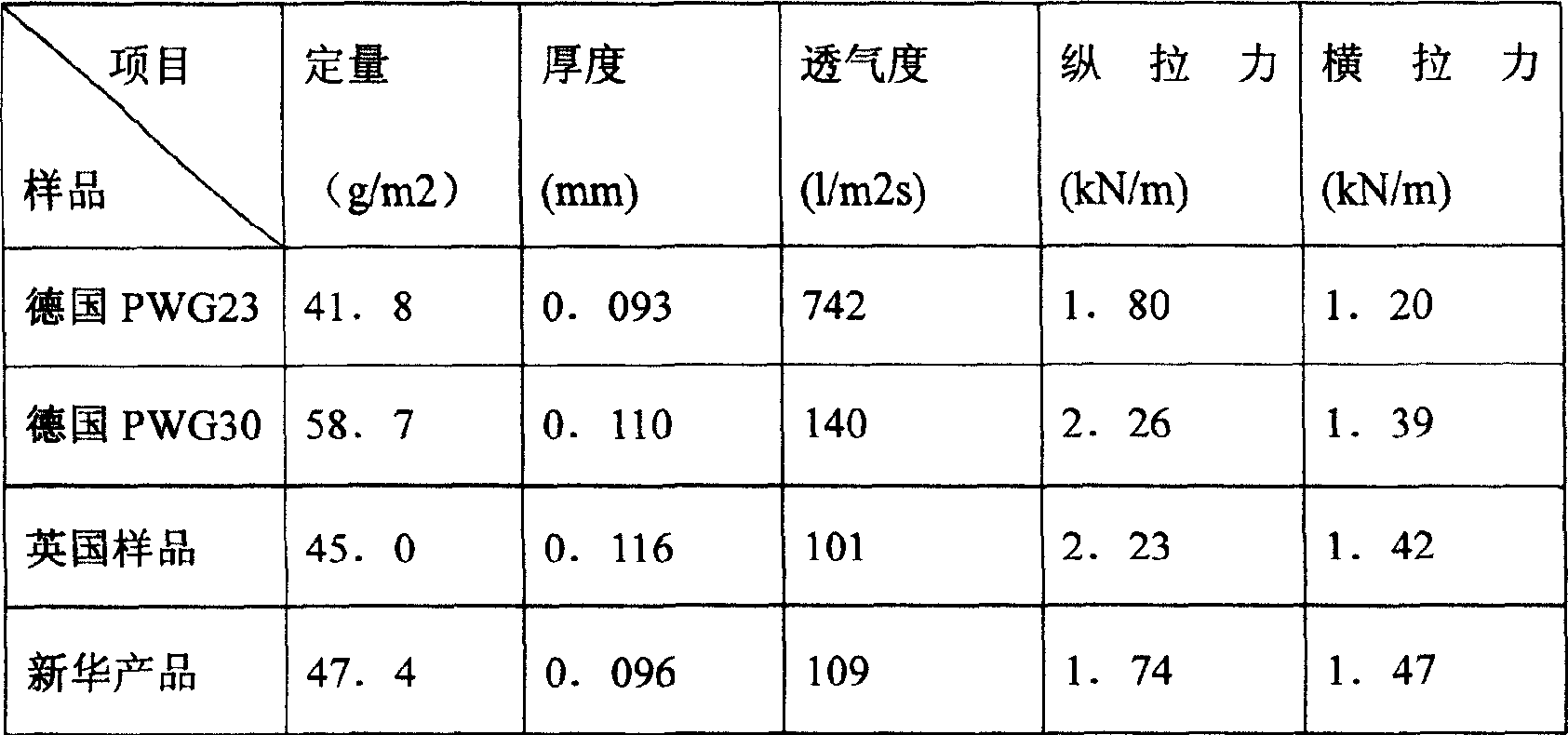

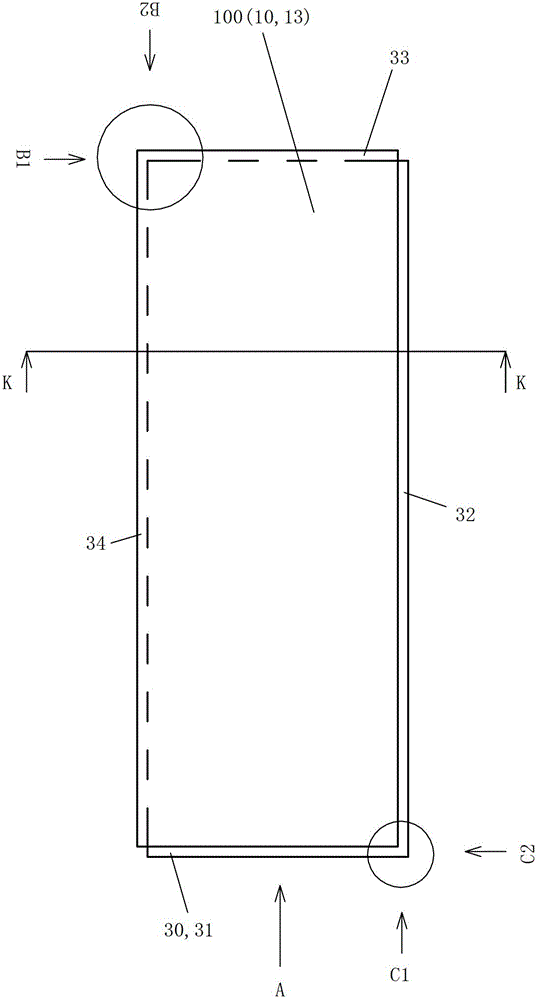

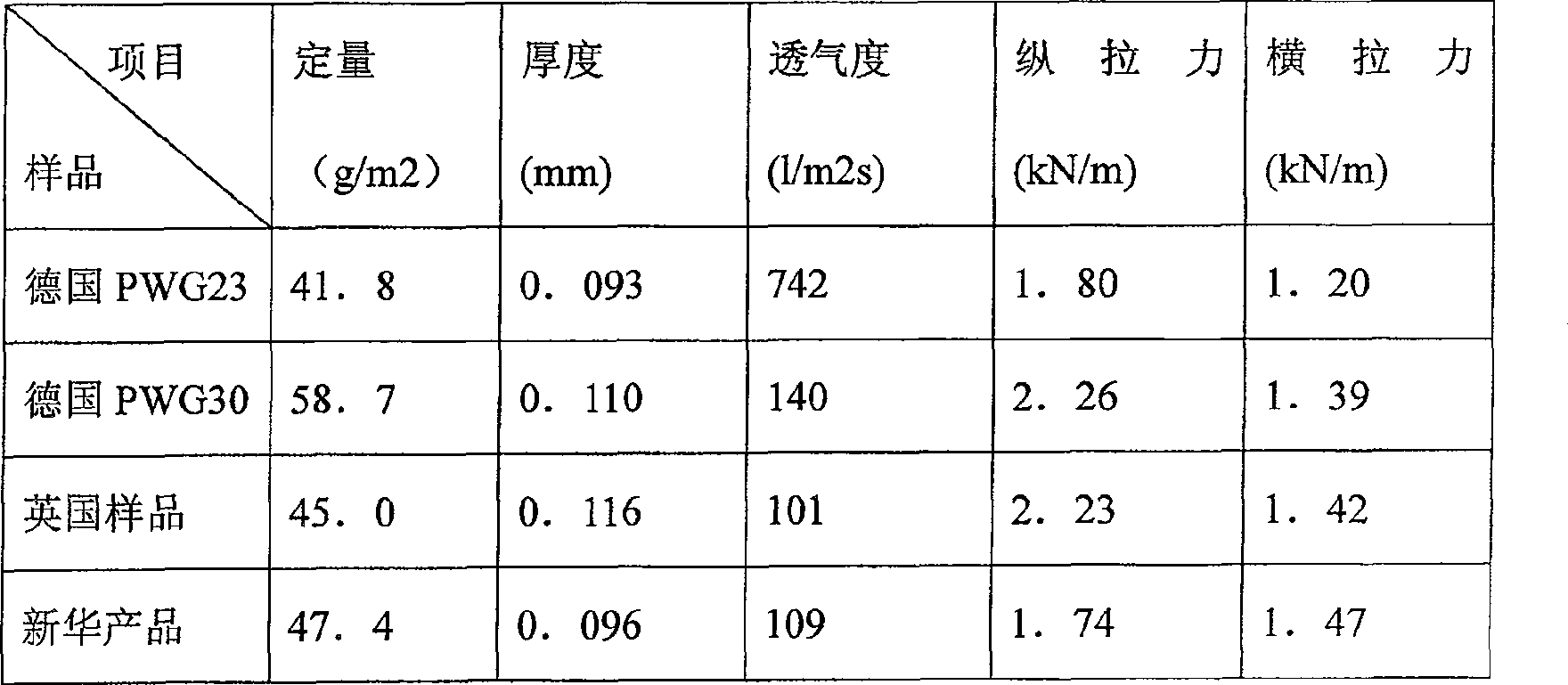

ActiveCN1928222AStrong bond fastnessSolve the transverse fracture problemNon-fibrous pulp additionSpecial paperFiberWood veneer

The invention relates to a wood compounded material, comprising by weight 20-40% of Manila sand slurry, 20-40% of wood slurry, 20-40% of chemical fiber which is vinylon and 3-10% of bonding fibre which is water miscible PVA. The production technology of the wood compounded material contains 1) beating by beater, 2) joining 1-% of PEO in drainer, 3) drying that original paper is formed by drying in dryer after forming in oblique graticule forming container, 4) coating by coater two times after loosening and it is cut into finish product by splitting machine. There are the merits that it is provided with adjacent crossbar strength ratio so as to solve the problem of wood strobilation and certain air permeability.

Owner:HANGZHOU XINHUA GROUP

Finishing method for improving washing resistance and cold and flexing resistance of leather coatings

ActiveCN110565389AImprove washing resistanceImprove cold resistance twists and turnsTextiles and paperPre treatmentCopolymer

The invention relates to the technical field of leather finishing, and provides a finishing method for improving the washing resistance and cold and flexing resistance of leather coatings. The methodcomprises the following steps of crust leather pretreatment finishing, primer coating, ironing, oscillation staking, embossing, standing, milling, toggling, middle coating, ironing, top coating, ironing, standing, milling, oscillation staking and ironing; a finishing agent main body material in the crust leather pretreatment finishing process is aromatic polyurethane copolymer; a finishing agent main body material of primer coating is polyurethane copolymer containing an active group and polyacrylate copolymer, and a finishing agent main body material of middle coating is the same as the finishing agent main body material of primer coating; a finishing agent main body material of top coating is polyurethane copolymer. According to the specific requirements of the washing resistance and cold and flexing resistance of the leather coatings, finishing materials are selected, the finishing process is reasonably matched and designed, and the disadvantages that the washing resistance and coldand flexing resistance of the leather coatings are poor are effectively solved.

Owner:宏兴汽车皮革(福建)发展有限公司

High temperature resistant inorganic binder for water-based paint and preparation method thereof

InactiveCN109777165AImprove high temperature resistanceImprove thermal shock resistanceCoatingsWater basedPhosphate

The invention relates to a high temperature resistant inorganic binder for water-based paint and a preparation method thereof. The invention is characterized in that the binder is prepared from the following raw materials: 10-80 wt% of solid aluminium dihydrogen phosphate, 10-80 wt% of quartz powder, 5-30 wt% of borax glass powder, 5-30 wt% of titanium sol, 10-80 wt% of nano-sized zirconium sol and 10-80 wt% of aluminum sol. The preparation method comprises the following steps: 1. mixing 1.10-80 wt% of solid aluminum dihydrogen phosphate, 10-80 wt% of quartz powder and 5-30 wt% of boron glasspowder, and pulverizing by airflow to obtain nanoscale mixed powder; 2. uniformly stirring 2.5-30 wt% of titanium sol, 10-80 wt% of nano-sized zirconium sol and 10-80 wt% of aluminum sol, and uniformly stirring to obtain a mixed liquid material; 3. adding the mixed powders according to the mass ratio of 1: 1-6 into the mixed liquid material, controlling temperature to 40-110 DEG C, adding while stirring, and uniformly mixing. The invention has the following beneficial effects: 1. good high temperature resistance; 2. good thermal shock resistance; 3. strong bonding fastness; 4. simple application; and 5. the preparation method is simple and easy to operate.

Owner:SHENZHEN TRIUMPH TECH ENG

Phase change heat storage type electric heating floor

InactiveCN103776080BCompact and reasonable structureImprove securityLighting and heating apparatusElectric heating systemElectricityElectrical connection

The invention discloses a phase change heat storage type electric heating floor. The phase change heat storage type electric heating floor comprises a floor main body and an electric heating assembly. Socket positions which are connected with the adjacent electric heating floor portions during usage are formed on the periphery of the floor. The phase change heat storage type electric heating floor is characterized by also comprising a flat phase change unit; the floor main body comprises a panel component and a base plate; the corresponding positions of the panel component and the base plate in the vertical direction are bonded and fixed together to form the floor main body, wherein the inside of the floor main body comprises the first installation space; the electric heating assembly comprises an electric heating piece, a transmission unit and connection sockets which are located at the front end and the rear end of the electric heating piece respectively and used for performing electrical connection externally; the electric heating piece and the phase change unit are fixedly arranged in the first installation space of the floor main body; the panel component, the electric heating piece, the phase change unit and the base plate are arranged in turn from top to bottom and are in close contact with each other in turn in the vertical direction.

Owner:江苏德威木业有限公司

Polypropylene decorative film for furniture surface facing

InactiveCN113249043AStrong adhesionGood compatibilityFilm/foil adhesive primer layersInksPolymer scienceUltraviolet lights

The invention relates to the technical field of decorative facing materials, and discloses a polypropylene decorative film for furniture surface facing. The polypropylene decorative film consists of a polypropylene base film layer, a printing layer, a coating layer and a back gum layer, and the polypropylene base film layer is a sheet-shaped base film formed by mixing and melting polypropylene resin, light calcium carbonate, nano titanium dioxide, color master batch, polyurethane, polyethylene wax and the like and then extruding the mixture. According to the polypropylene decorative film for furniture surface facing, polymerization and cross-linking between low-molecular prepolymers or oligomers and active monomers in a photocureable coating are initiated through the energy of ultraviolet light to obtain a cured paint film, the paint film is high in adhesive force, the hardness can reach 1H, and due to the compact surface structure, the paint film is good in scratch resistance and pollution resistance; and a back gum has good compatibility with polypropylene, is non-toxic, does not absorb water, and has hot melting viscosity, and the formed back gum layer can promote the bonding strength when the back gum layer is attached to a base material plate, has good fluidity at high temperature, and has good water resistance, acid and alkali resistance and weather resistance.

Owner:大正新型材料(肇庆)有限公司

Self-heating type floor decoration tile

ActiveCN102677862AEasy to installImprove thermal efficiencyLighting and heating apparatusElectric heating systemElectricityPower flow

The invention discloses a self-heating type floor decoration brick, and is characterized by comprising a floor tile panel, a floor tile lower seat and a self-heating assembly. A heating unit of the self-heating assembly is an electric heating piece. The floor tile is stuck and fixed above the floor tile lower seat to form a floor tile main body provided with an inner cavity. The electric heating piece of the self-heating assembly is arranged in the inner cavity of the floor tile main body. Power supply plug connectors of the self-heating assembly are arranged on the front side and the back side of the floor tile main body. The power supply plug connectors are reliably limited and fixed in the floor tile main body and can be used for electric connection with an adjacent electric heating floor tile and transmission of current by externally protruded spliced eye positions provided with copper contain pins through corresponding electric connection assemblies, so that the electric heating floor tile has the advantages of being simple and convenient to install, safe and reliable to use, higher in heat efficiency, durability and structurally providing technical supports.

Owner:枣庄高新区利民供热服务有限公司

Adhesive for metal glue joint

InactiveCN104212378ANot volatileStrong bond fastnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane elastomerAdhesive

The invention discloses an adhesive for metal glue joint. The adhesive comprises, by weight, 20-30 parts of butadiene rubber based magneto-rheological elastomers, 10-20 parts of fully-vulcanized superfine powder butadiene styrene rubber, 10-20 parts of 4, 4'-diphenyl-methane-diisocyanate, 6-12 parts of polytetrahydrofuran polyether, 12-18 parts of organic attapulgite / polyurethane elastomer nanocomposite, 8-15 parts of plant glue, 2-5 parts of coupling agents and 1-3 parts of initiating agents. By means of the adhesive for the metal glue joint, the adhesion is highly firm, the adhesion time is short, and the volatilization of harmful substances can not occur.

Owner:WUXI HITXINCHENG POLYMER TECH

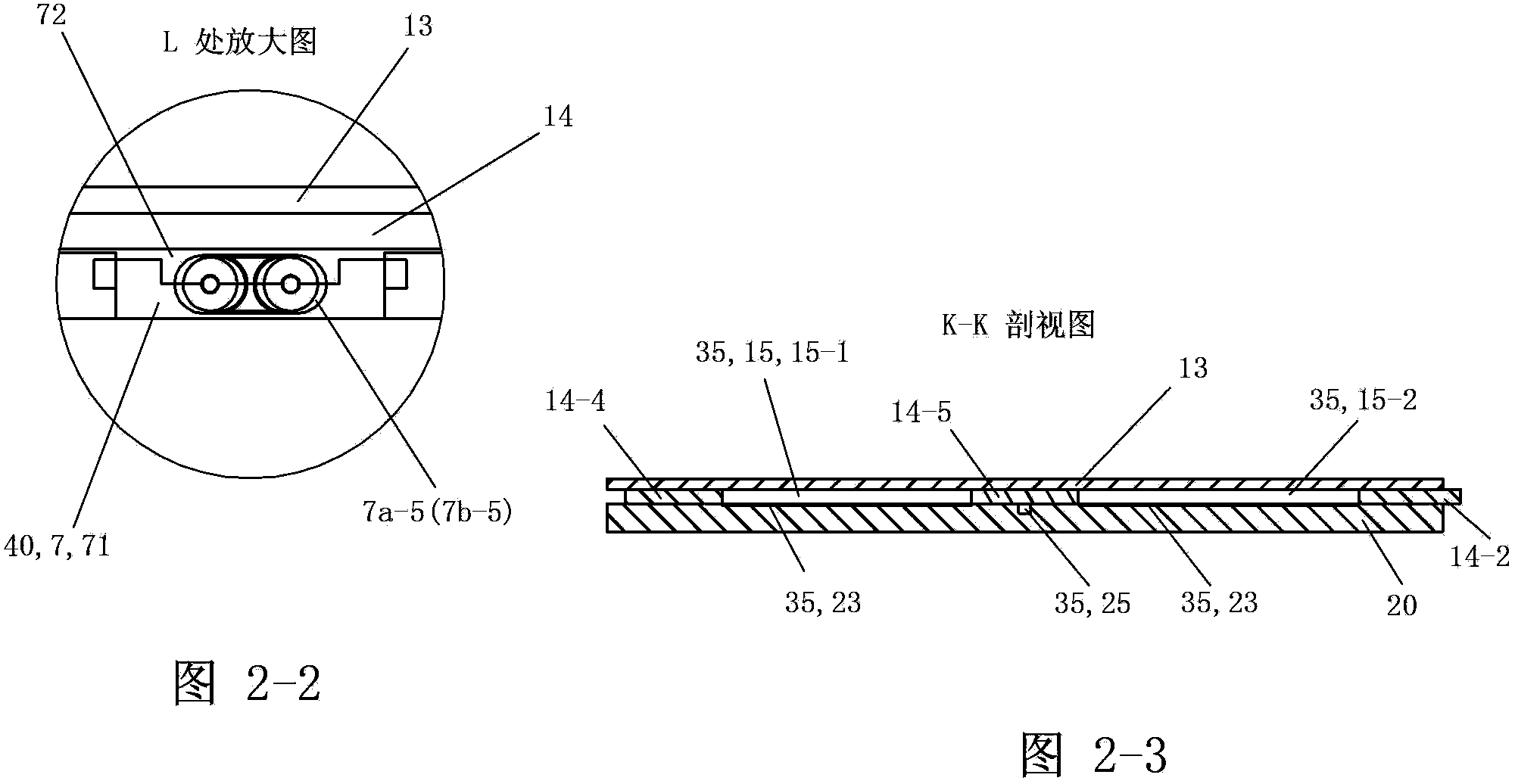

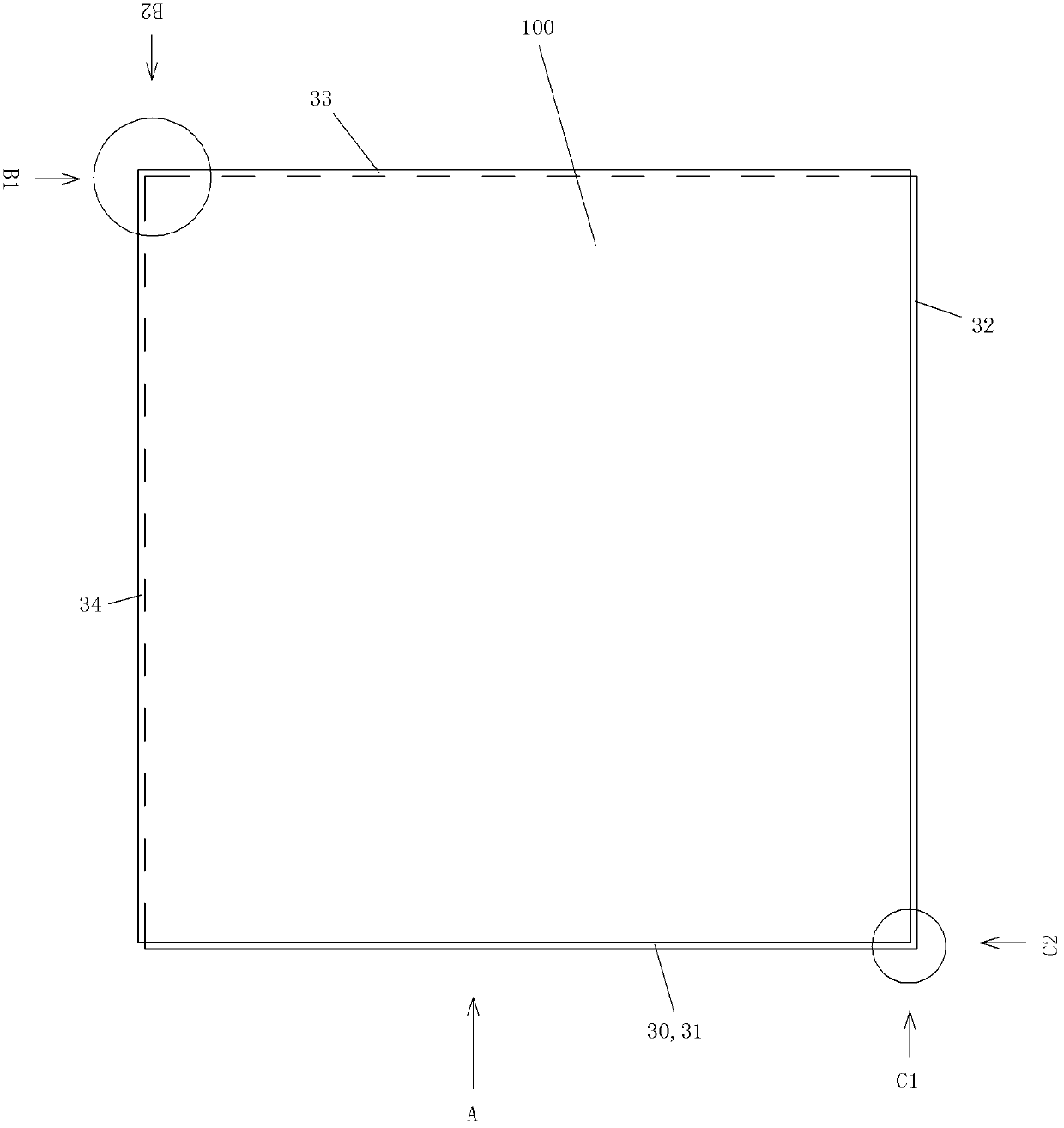

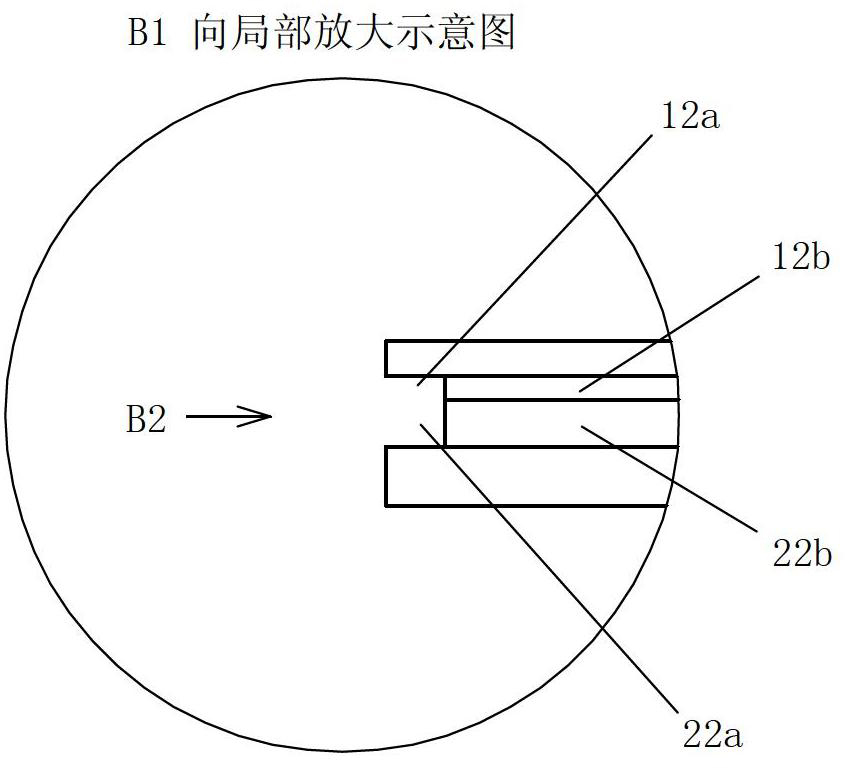

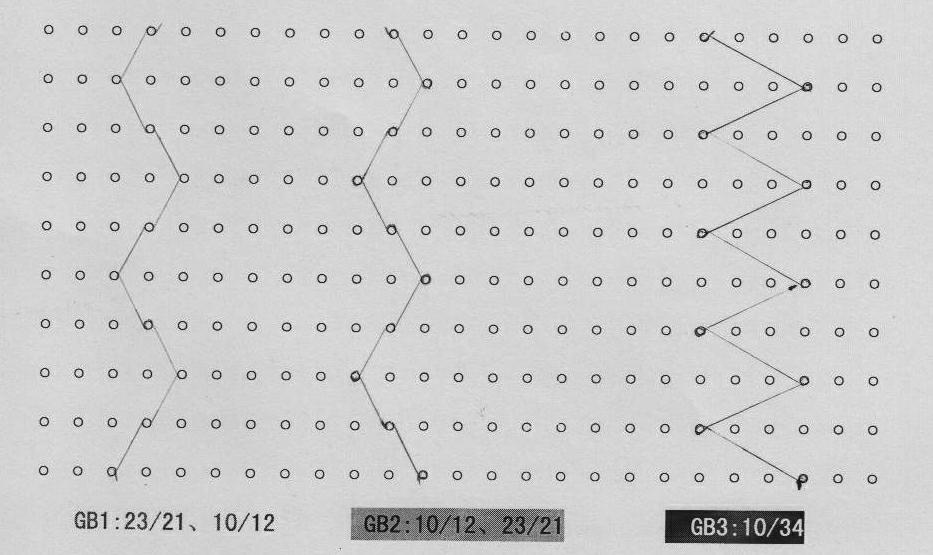

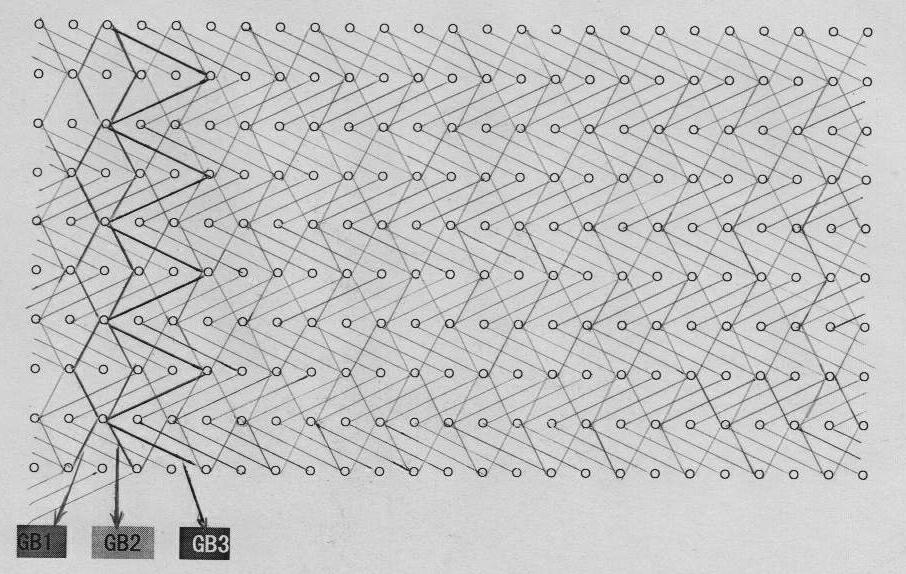

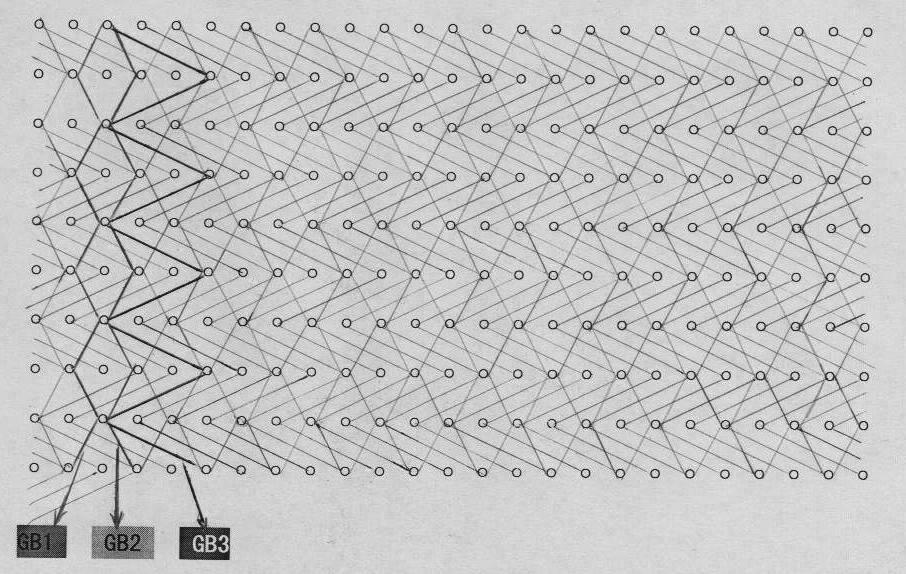

Production process of warp-knitting automobile interior trim composite material for film bonding

ActiveCN102555401AFlat surfaceStrong bond fastnessWarp knittingLaminationManufactured materialMechanical engineering

The invention relates to a production process of a warp-knitting automobile interior trim composite material for film bonding. The production process comprises the steps of raw material selection, warping, weaving, preshrinking, dyeing, shaping and compounding. The fabric tissue structure is characterized in that: GB1 is 10 / 12 and 23 / 21, GB2 is 23 / 21 and 10 / 12, and GB3 is 10 / 34; in the weaving step, the positions of a sinking sheet and a knitting needle are controlled to be 2.5 to 3.5mm through regulating the eccentric position of a sinking sheet shaft, so a circle pillar of a wire circle is increased during the knitting into circles, the wire circle has enough retraction space, and the elasticity is increased; and in the compounding step, fabrics are sequentially compounded with poly urethane (PU) foam and diaphragms. Products produced by the process have the proper elongtation, the requirements of interior trims in various molded surface structures produced through film bonding are met, the manufactured interior trims have flat surface, fullness and high bonding firmness, and the production process conforms to the requirements of individuation, diversification, environment protection and energy saving of the automobile interior trims.

Owner:HONGDA HIGH TECH HLDG CO LTD

Environmentally-friendly organic inorganic hybridized paint and preparation method and application thereof

InactiveCN101649152BImprove wear resistanceHigh hardnessLiquid surface applicatorsCoatingsSolventSuperhydrophobic coating

The invention discloses an environmentally-friendly organic inorganic hybridized paint and preparation method and application thereof. The preparation method includes that acrylosilane microemulsion is taken as binder, 2-35 parts of acrylosilane microemulsion containing hydroxyl is dissolved into 10-80 parts of alcohols solvent, 1-15 parts of tetraethoxysilane, 2-30 parts of organosiloxane and 0.5-10 parts of basic catalyst are added, hydrolysis and polycondensation are carried out in organic polymer emulsion to form hydrophobic inorganic network, so as to obtain organic inorganic hybridized acrylosilane paint. The paint is coated on the surface of water poly(methyl) acrylic ester primer and is dried, thus obtaining the organic inorganic hybridized super-hydrophobic coating with favourable mechanic performances. The adhesive force of the super-hydrophobic coating can achieve 1-2 level, water static contact angle is more than 150 degrees, and rolling angle is less than 10 degrees. The invention is simple in technology, available in raw materials and low in cost and overcomes the defects of the existing preparation technology and the disadvantage of poor mechanical performances of the super-hydrophobic coating.

Owner:SOUTH CHINA UNIV OF TECH

Wood veneer composite material and its production process

ActiveCN100526553CStrong bond fastnessSolve the transverse fracture problemNon-fibrous pulp additionSpecial paperWood veneerFiber

The invention relates to a wood compounded material, comprising by weight 20-40% of Manila sand slurry, 20-40% of wood slurry, 20-40% of chemical fiber which is vinylon and 3-10% of bonding fibre which is water miscible PVA. The production technology of the wood compounded material contains 1) beating by beater, 2) joining 1-% of PEO in drainer, 3) drying that original paper is formed by drying in dryer after forming in oblique graticule forming container, 4) coating by coater two times after loosening and it is cut into finish product by splitting machine. There are the merits that it is provided with adjacent crossbar strength ratio so as to solve the problem of wood strobilation and certain air permeability.

Owner:HANGZHOU XINHUA GROUP

Emergency exit internal sound insulation sponge foaming adhesive

InactiveCN104293230ALow costEasy to storeNon-macromolecular adhesive additivesMacromolecular adhesive additivesEnvironmental resistanceEngineering

The invention discloses an emergency exit internal sound insulation sponge foaming adhesive, and relates to the technical field of regenerated sponge. The emergency exit internal sound insulation sponge foaming adhesive comprises the following raw materials in parts by weight: 30-50 parts of a surfactant, 0.1-0.3 part of a defoaming agent, 2-8 parts of a dispersant, 2-6 parts of a cosolvent, 1-4 parts of a brightening agent and 6-8 parts of a flame retardant. The foaming adhesive is low in cost, the raw materials are environmentally friendly and non-toxic and free of pungent smell, the adhesive is convenient to store, not easy to cure and convenient to use and operate, the sponge produced by using the foaming adhesive is good in toughness, not easy to tear off and hard to combust due to addition of a great amount of flame retardant, a fire source can be effectively insulated, the fire hazard is avoided, a good sound insulation effect is achieved, and the adhesion strength is high.

Owner:ANHUI HAPPYANG CHILDRENS ARTICLES

A finishing method for improving the washing resistance and cold resistance of leather coating

ActiveCN110565389BInterleaved structure with hard and soft segmentsIncrease polarityTextiles and paperPolymer scienceAcrylate ester

The invention relates to the technical field of leather finishing, and provides a finishing method for improving the washing resistance and cold resistance of the leather coating. Softening→stretching→middle coating→ironing→top coating→ironing→standing→softening→oscillating and softening→ironing; the main material of the finishing agent in the pretreatment and finishing process of the raw leather is aromatic polyurethane copolymer The main material of the finishing agent of the primer is polyurethane copolymer and polyacrylate copolymer containing active groups, and the main material of the finishing agent of the middle coating is the same as the main material of the finishing agent of the primer; the The main material of the finishing agent for the top coating is a polyurethane copolymer; the present invention selects the finishing materials according to the specific requirements of the leather coating's resistance to water washing and cold tortuousness, and rationally matches the design of the finishing process, so as to effectively solve the problems of poor water-washing resistance and poor cold and tortuous resistance of the leather coating. disadvantages.

Owner:宏兴汽车皮革(福建)发展有限公司

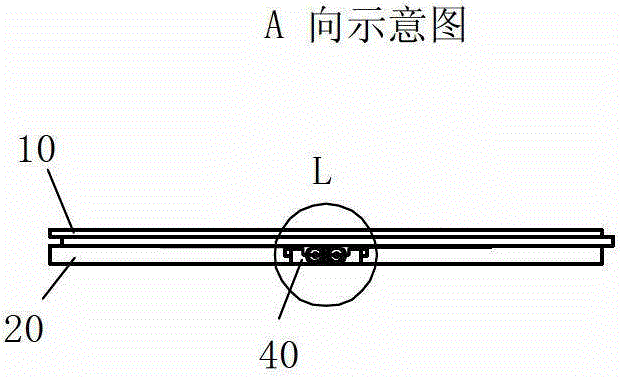

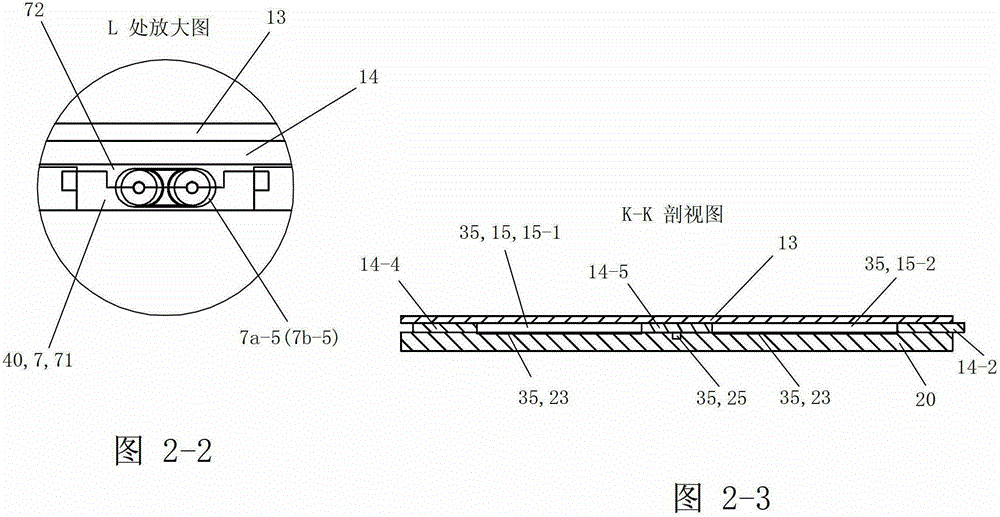

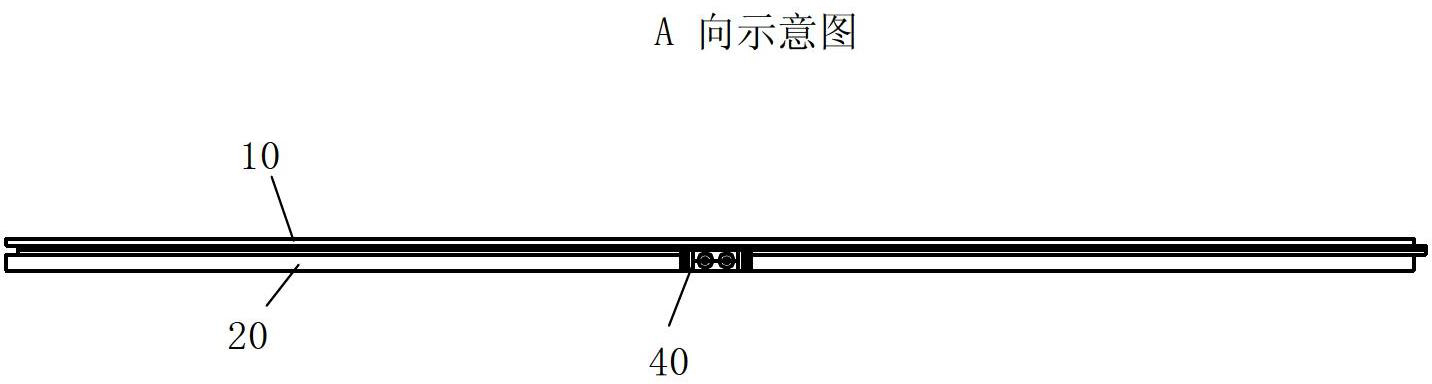

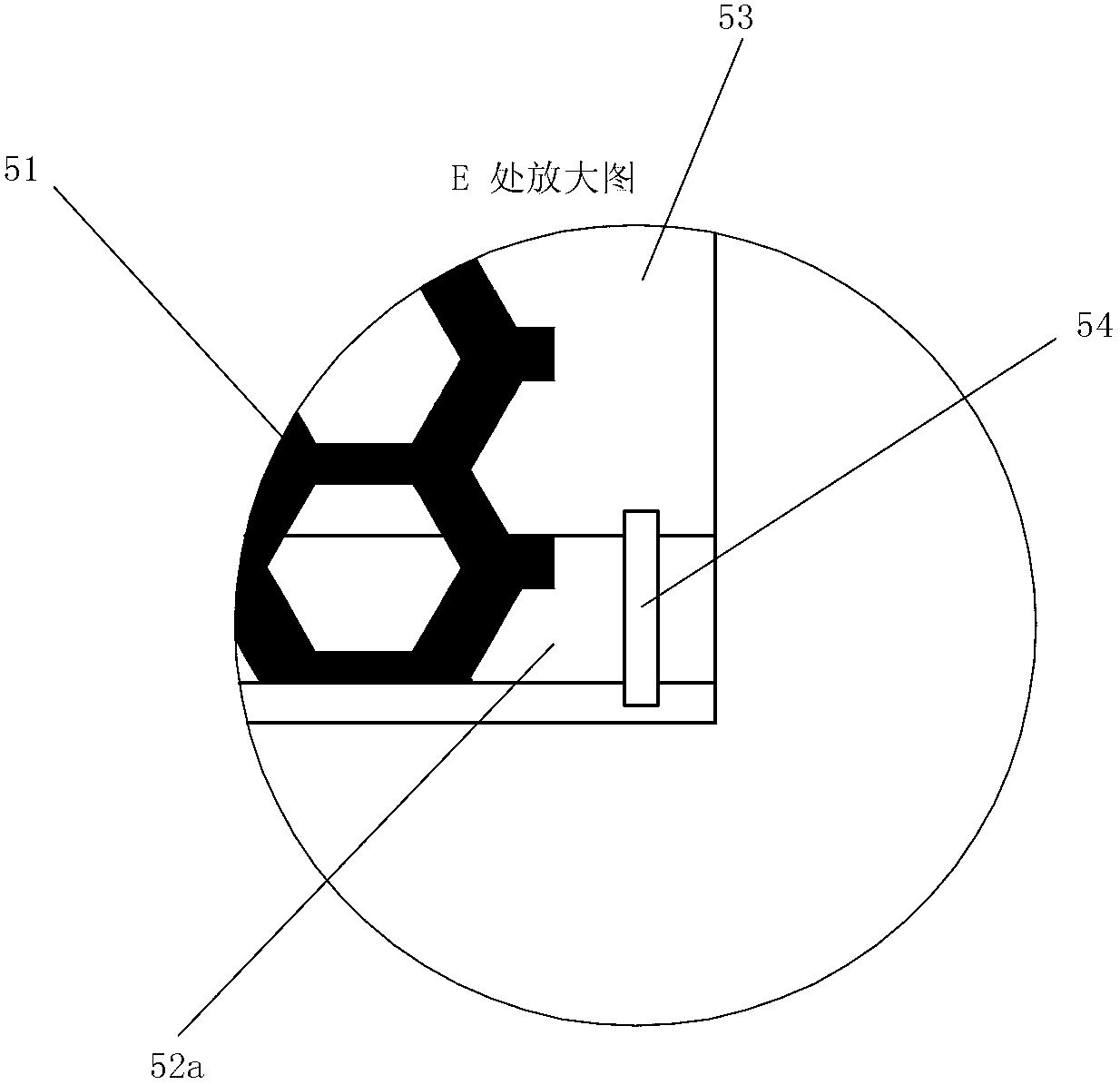

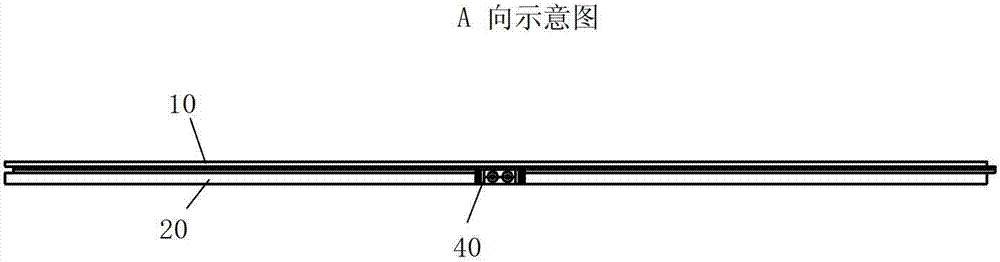

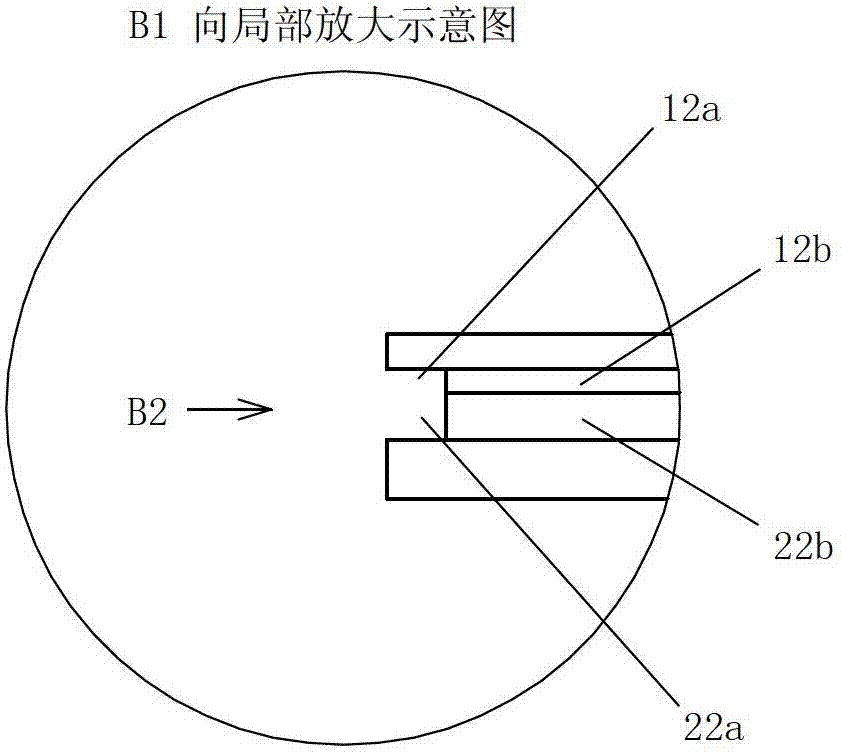

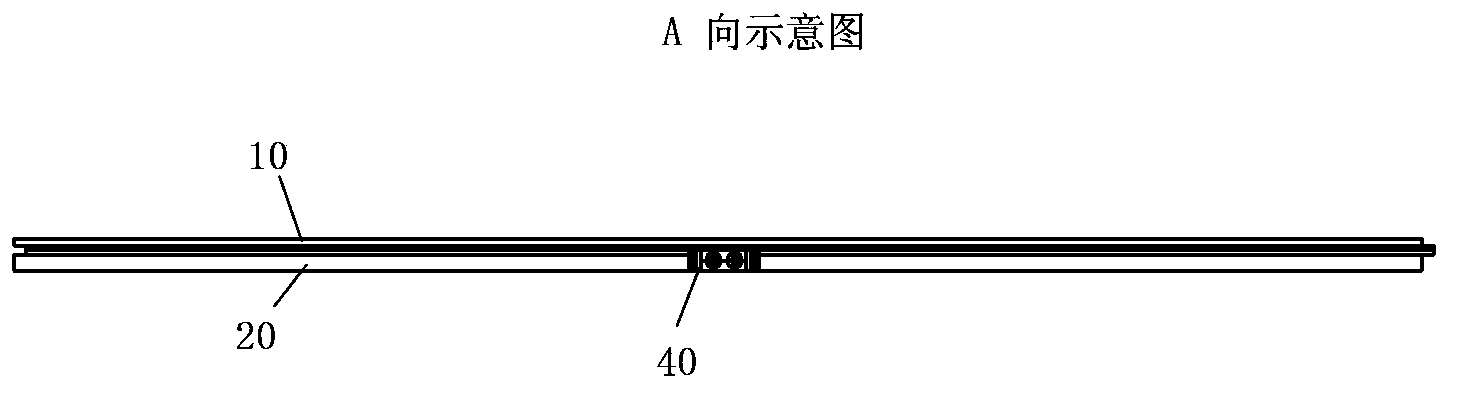

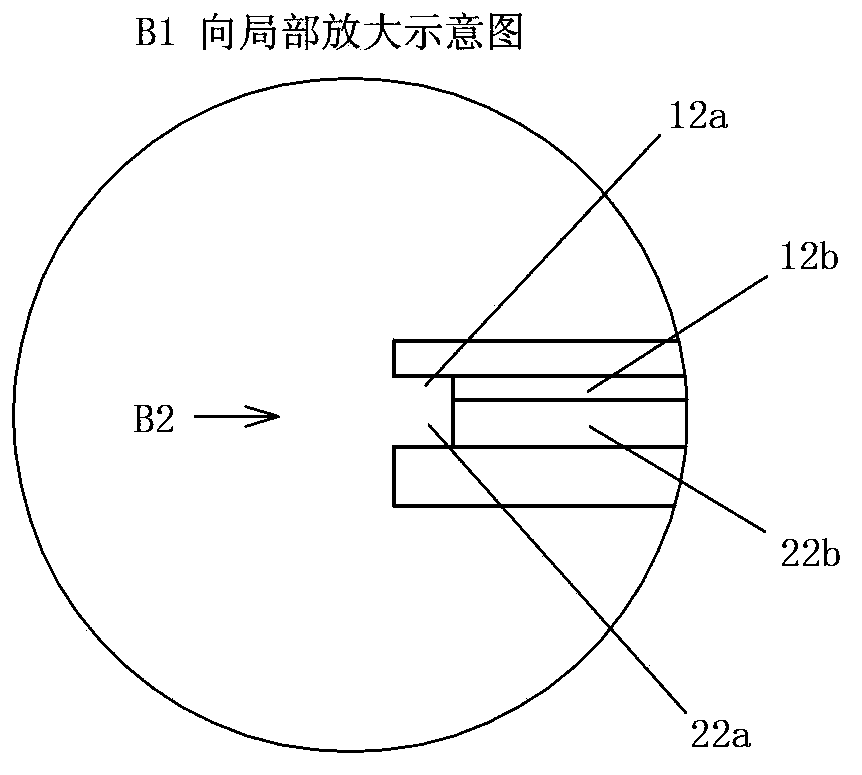

Self-heating assembly

ActiveCN102704648AImprove bonding fastnessImprove heating efficiencyLighting and heating apparatusElectric heating systemElectricityEngineering

The invention discloses a self-heating assembly, which is characterized by being a waterproof electric heating assembly. The self-heating assembly comprises an electric heating piece, a transmission unit and two mounting seats respectively located on the front and rear ends of the electric heating piece. The front end and the rear end of the electric heating piece are respectively provided with a flaked sealed waterproof electric heating device of an electrode. A fire wire unit of the transmission unit is penetrated by a first penetrating connector thereof and electrically connected to one electrode of the electric heating piece, and a zero wire unit is penetrated by a second penetrating connector thereof and electrically connected to the other electrode of the electric heating piece. Two mounting seats are divided into a front side mounting seat and a rear side mounting seat according to the different locations. Each mounting seat comprises a lower mounting seat located beneath and a cover plate inserted into the lower mounting seat from top to bottom. A part where components of the transmission unit are electrically connected to each other and a part where the transmission unit is electrically connected with the electric heating piece in a penetrating way are respectively arranged in the corresponding mounting seat hermetically.

Owner:泰州市海通资产管理有限公司

Self-heating assembly

ActiveCN102704648BImprove bonding fastnessImprove heating efficiencyLighting and heating apparatusElectric heating systemElectricitySelf heating

The invention discloses a self-heating assembly, which is characterized by being a waterproof electric heating assembly. The self-heating assembly comprises an electric heating piece, a transmission unit and two mounting seats respectively located on the front and rear ends of the electric heating piece. The front end and the rear end of the electric heating piece are respectively provided with a flaked sealed waterproof electric heating device of an electrode. A fire wire unit of the transmission unit is penetrated by a first penetrating connector thereof and electrically connected to one electrode of the electric heating piece, and a zero wire unit is penetrated by a second penetrating connector thereof and electrically connected to the other electrode of the electric heating piece. Two mounting seats are divided into a front side mounting seat and a rear side mounting seat according to the different locations. Each mounting seat comprises a lower mounting seat located beneath and a cover plate inserted into the lower mounting seat from top to bottom. A part where components of the transmission unit are electrically connected to each other and a part where the transmission unit is electrically connected with the electric heating piece in a penetrating way are respectively arranged in the corresponding mounting seat hermetically.

Owner:泰州市海通资产管理有限公司

Preparation process of a fluffy, warm, mildew-resistant down quilt

ActiveCN110004728BIncrease warmthImprove bulkBiochemical fibre treatmentDry-cleaning apparatus for textilesFiberAlcohol

Owner:宁波博洋家纺集团有限公司

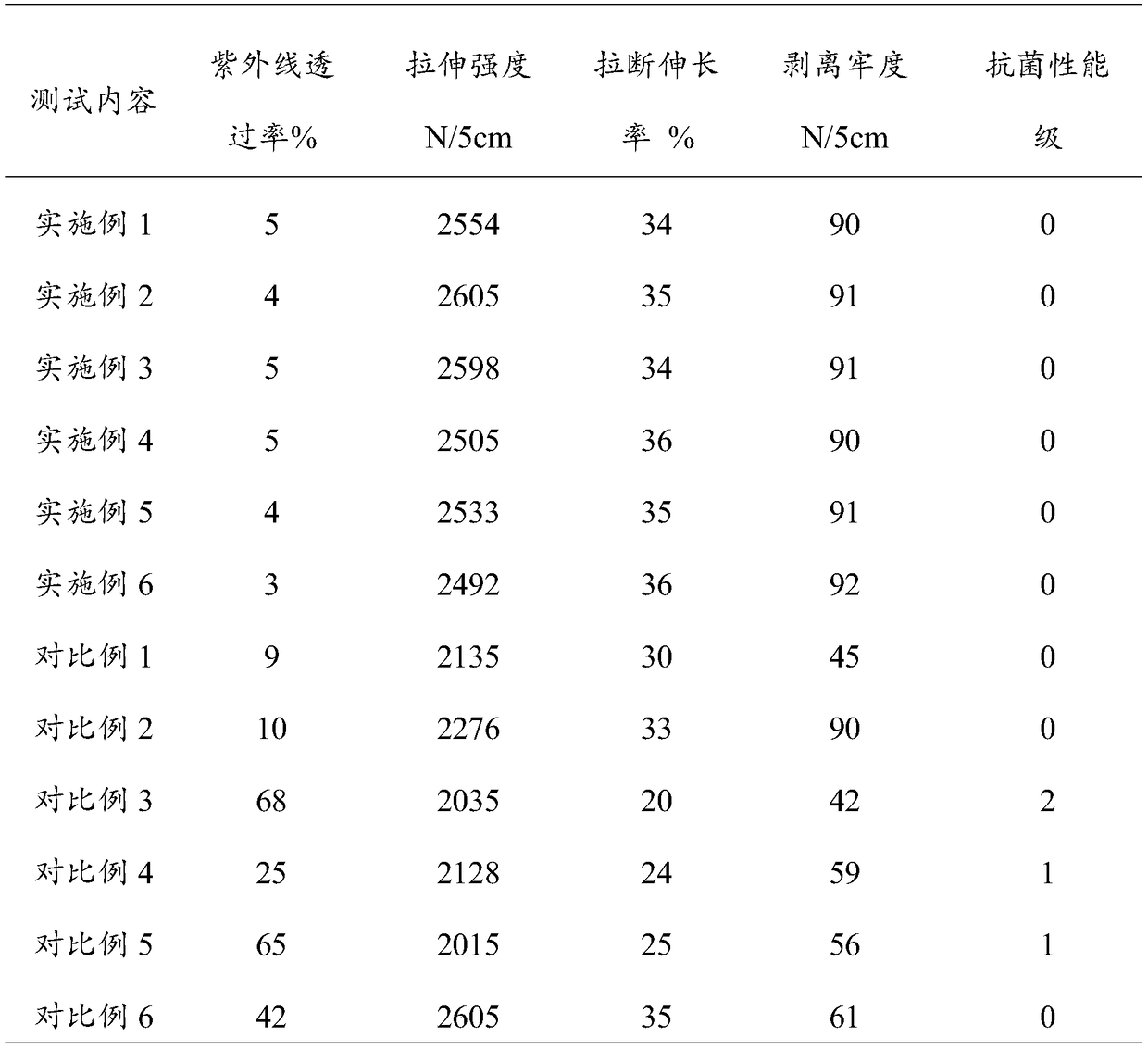

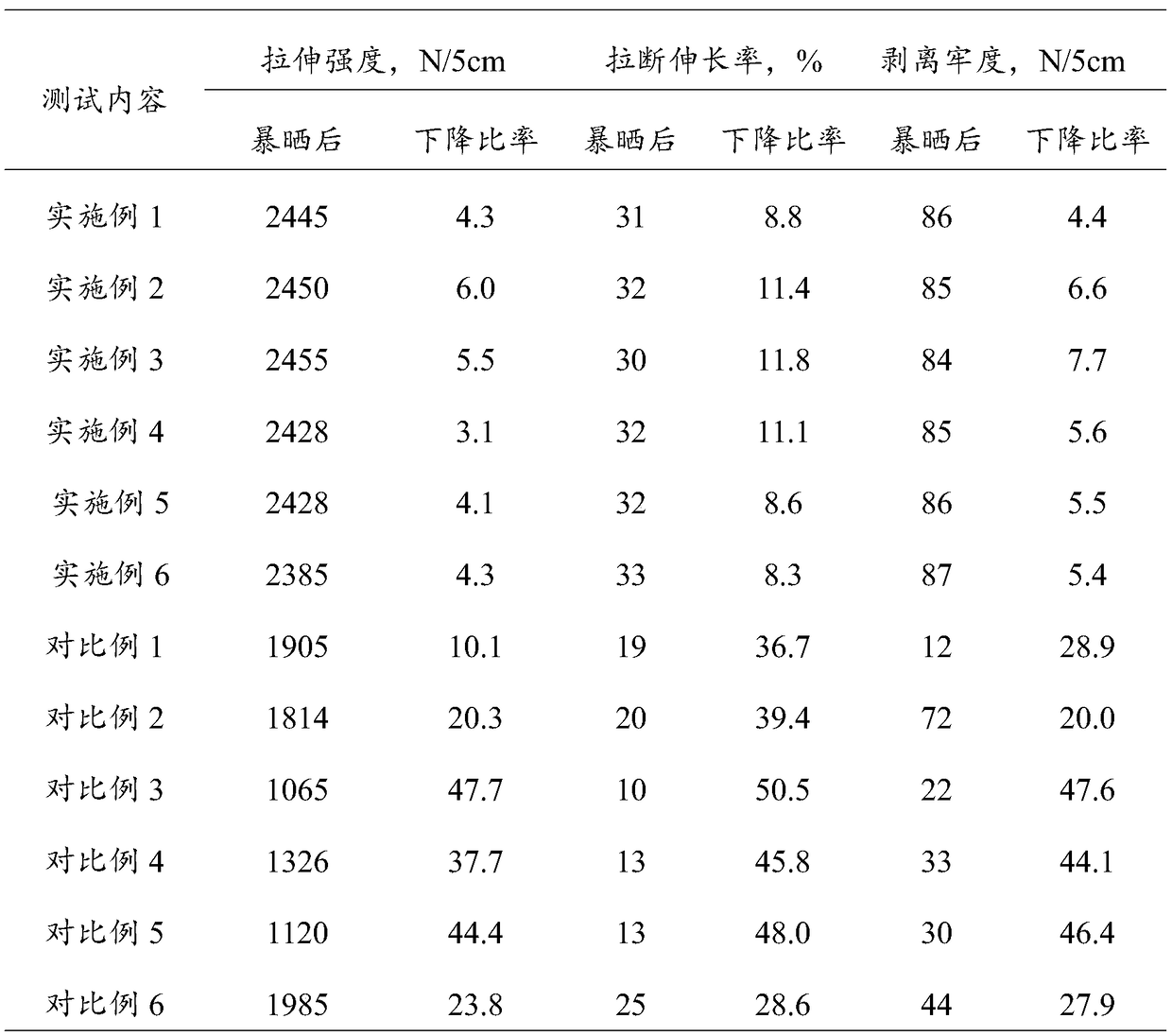

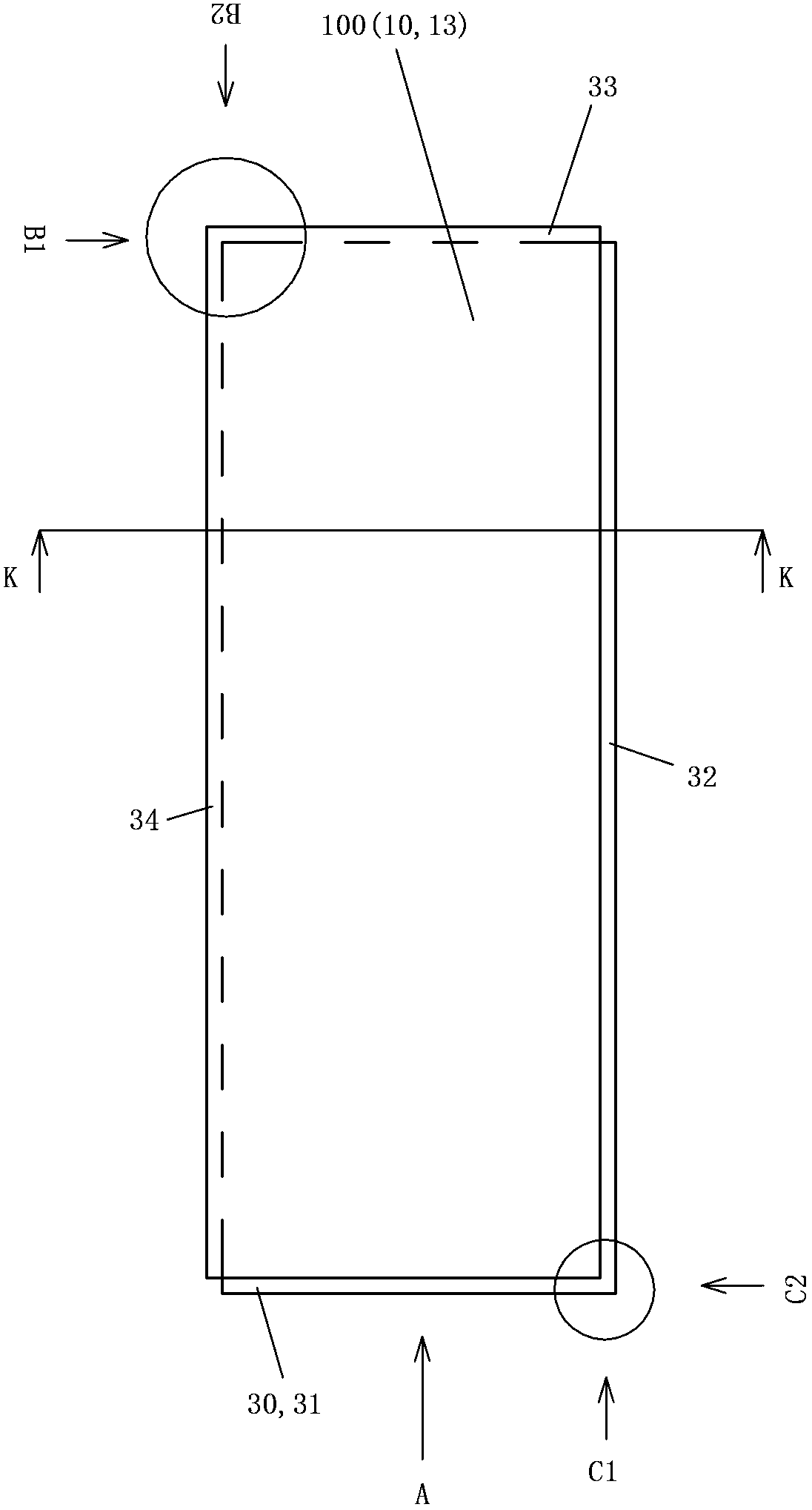

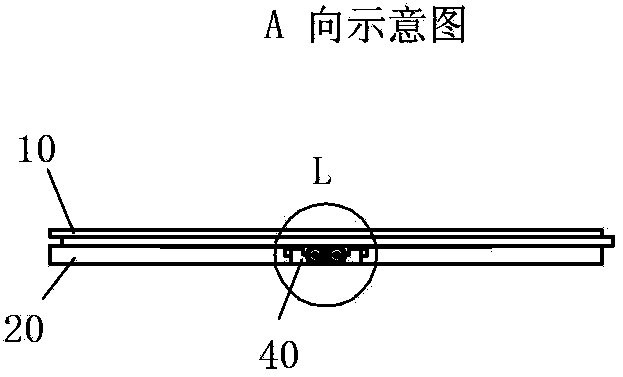

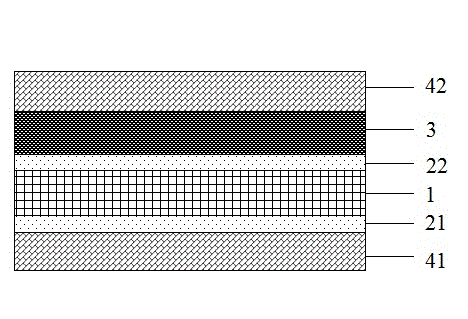

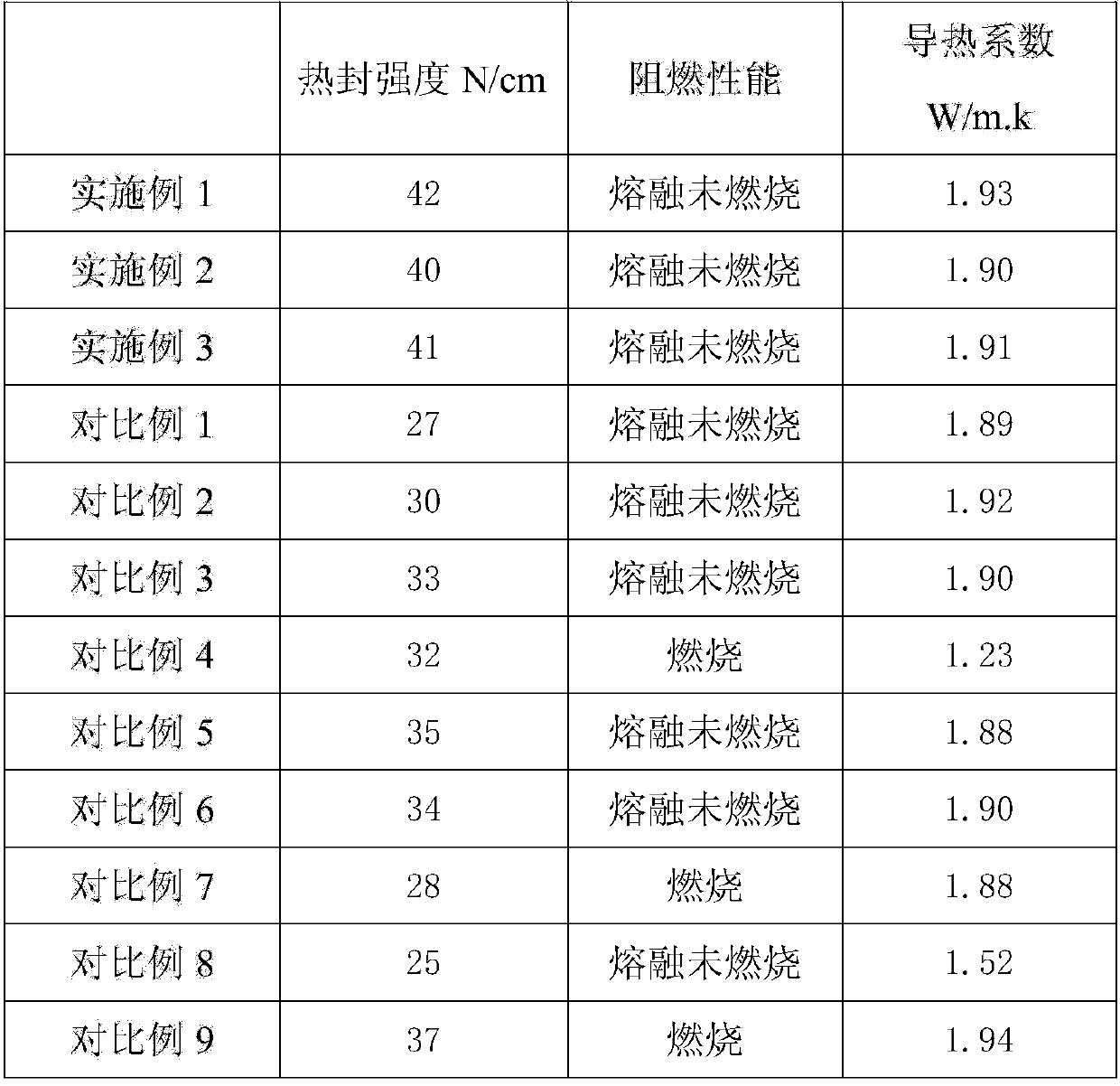

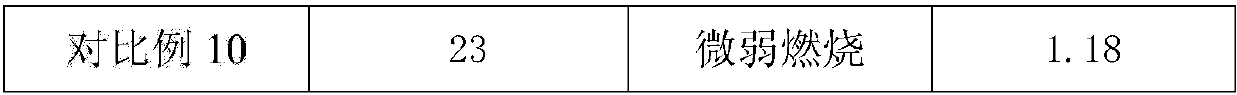

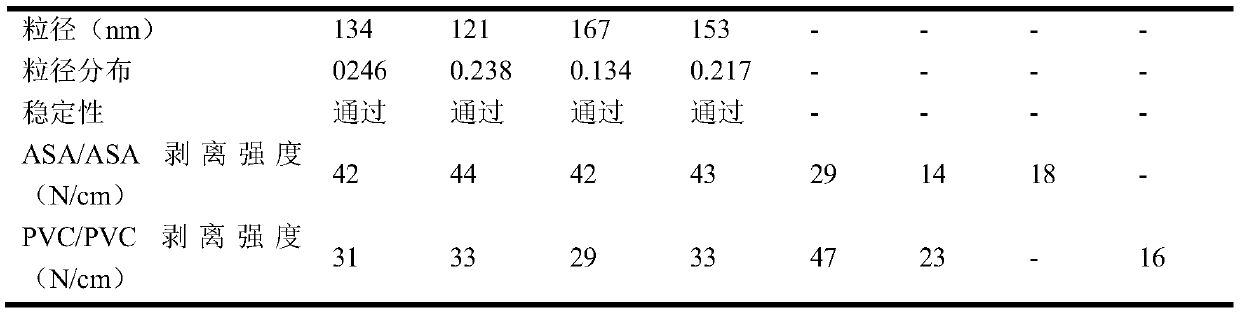

Flexible packaging material for lithium battery of new energy automobile and preparation method of flexible packaging material

ActiveCN110077043AImprove ductilityGood mechanical propertiesNon-macromolecular adhesive additivesSynthetic resin layered productsAcetic anhydrideEngineering

The invention discloses a flexible packaging material for a lithium battery of a new energy automobile and a preparation method of the flexible packaging material. The flexible packaging material forthe lithium battery is of a layered structure, the middle layer is an aluminum base layer, and the outer side of the aluminum base layer is divided into an upper side and a lower side; an adhesive resin layer, a PET layer, an adhesive resin layer and a copolymerized polypropylene layer are sequentially distributed from inside to outside on the lower side; an adhesive resin layer, a PET layer, an adhesive resin layer and a homopolypropylene layer are sequentially distributed from inside to outside on the upper side; the adhesive resin layer is binding resin of a grid structure, and alpha-Al2O3nanopowder is distributed in grids; the binding resin comprises homopolypropylene, a copolymer of styrene-maleic anhydride, dicumyl peroxide, acetic anhydride and hydroxy silicone oil. The heat-sealing strength, flame-retardant performance and heat-dissipating performance of the flexible packaging material for the lithium battery of the new energy automobile are comprehensively improved by adopting a specific structure and adding acetic anhydride and hydroxy silicone oil.

Owner:重庆迅昌汽车零部件有限公司

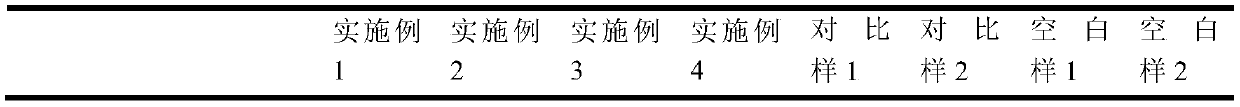

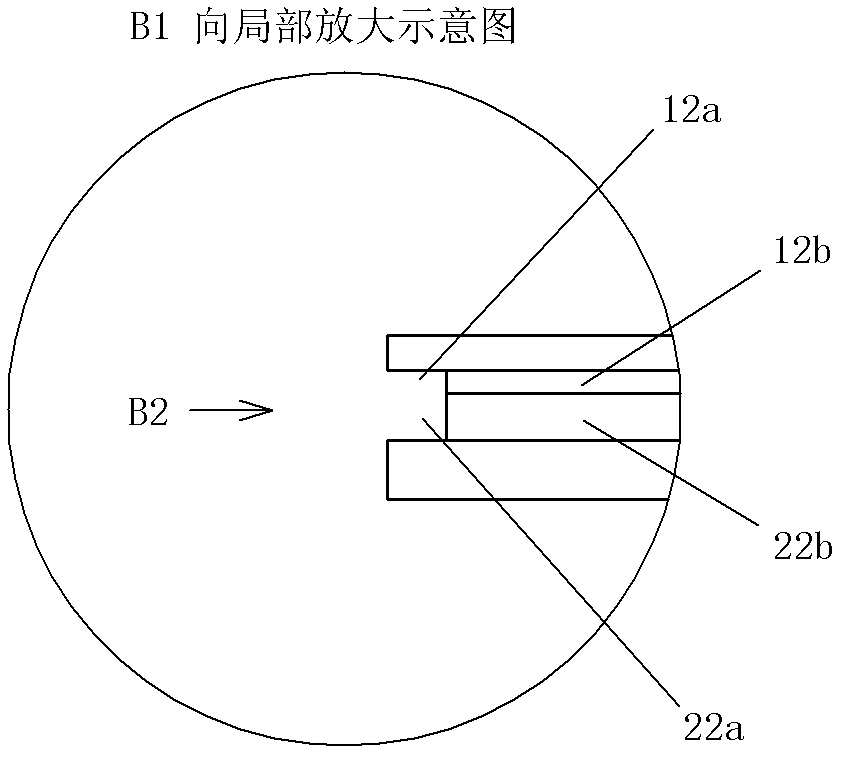

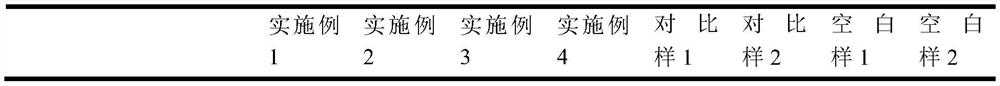

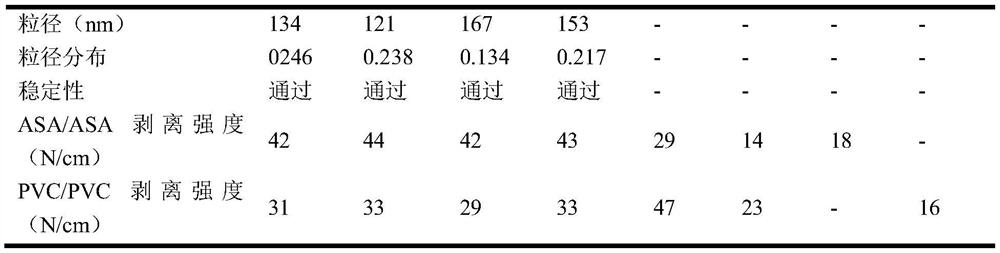

ASA plastic film ink resin and preparation method thereof

ActiveCN110776597AThe polymerization process is stable and controllableAddressing Aggregation Stability IssuesInksPolymer scienceAcrylonitrile

The invention provides water-based ink emulsion resin and a preparation method thereof. Through a special optimized emulsification scheme and process control, the emulsion polymerization process is stable and controllable, no filter residues are left after a reaction, and problem in polymerization stability of emulsions with high acrylonitrile monomer contents are solved. An emulsion obtained in the invention is fine in particle size and narrow in particle size distribution, which is beneficial for the preparation of subsequent intaglio printing water-based ink; the emulsion has very strong bonding fastness to an ASA / ASA composite system, and the peeling strength of a blank film sample can be improved to two times or more; and the emulsion has good adhesion to a PVC / PVC composite system, and the peel strength of the blank film sample can be improved to a level close to 2 times;. The fine-particle-size emulsion resin of the invention is expected to be applied to preparation of intaglioprinting water-based ink for ASA plastic films or PVC furniture films.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Spontaneous heating floor

ActiveCN102607096BEasy to installImprove thermal efficiencyLighting and heating apparatusElectric heating systemElectricityPower flow

The invention discloses a spontaneous heating floor, which is characterized by comprising a panel, a soleplate and a spontaneous heating component. The heating body of the spontaneous heating component is an electric heating plate. The panel is adhered on the soleplate from above to form a main floor body with an inner cavity. The electric heating plate of the spontaneous heating component is arranged in the inner cavity of the main floor body. Power supply plug connectors belonging to the spontaneous heating components are arranged on the front and back sides of the main floor body. The power supply plug connectors are reliably limited and fixed in the main floor body and are capable of realizing electric connection and current transmission with an adjacent spontaneous heating floor at an insertion hole position exposed outwards from the power supply plug connectors and provided with copper inserting pins by means of a corresponding electric connecting component; and in the invention, the spontaneous heating floor is installed simply and conveniently, and a technical guarantee for safe and reliable application, high heat efficiency and durable structure is provided.

Owner:枣庄高新区利民供热服务有限公司

Shaping waist seal and production process thereof

The invention discloses a shaping corset and a production process thereof, and belongs to the technical field of underwear production, and the production process comprises the following steps: material selection: selecting materials for making the corset; selecting waist seal processing machinery equipment, wherein the waist seal processing machinery equipment comprises a specific gluing machine, a mould pressing reinforcing machine and a tension detection device; a processing flow: carrying out inspection and shrinkage processing on the waist sealing material; pattern design, wherein raw materials used by the waist seal are cut according to the proportion of the waist seal; gluing: gluing and coating glue on the back surface of the cloth, pressing the cloth into a specified shape by using a mould pressing reinforcing machine, then installing the reinforcing rib positioning sheet between the inner side sheet and the outer side sheet, combining the inner side sheet and the outer side sheet, and then carrying out mould pressing reinforcing, the mould pressing temperature is 95-105 DEG C, and the mould pressing time is 35-45 seconds. The garment is seamlessly attached, more comfortable to wear and more close-fitting; the silica gel material is environment-friendly, harmless, high in fitting fastness and washable; gluing is conducted in a silica gel operation mode, seamless fitting design is achieved, and the appearance is simpler.

Owner:安徽省脉思图内衣科技有限公司

A kind of ASA plastic film ink resin and preparation method thereof

ActiveCN110776597BThe polymerization process is stable and controllableAddressing Aggregation Stability IssuesInksPolymer scienceAcrylonitrile

The invention provides a water-based ink emulsion resin and a preparation method thereof. Through a specially optimized emulsification scheme and process control, the emulsion polymerization process of the invention is stable and controllable, and there is no filter residue after the reaction, which solves the problem of high acrylonitrile monomer content. The problem of emulsion polymerization stability, the particle size of the emulsion of the present invention is fine, and the particle size distribution is very narrow, which is beneficial to the configuration of the subsequent gravure printing water-based ink, the emulsion has strong adhesion fastness to the ASA / ASA composite system, and the blank film sample The peel strength of the film is increased to more than 2 times, and the PVC / PVC composite system also has good adhesion performance, and the peel strength of the blank film sample can be raised to nearly 2 times. The fine particle size emulsion resin of the present invention is expected to be applied to ASA Preparation of water-based ink for gravure printing on plastic film or PVC furniture film.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Fire-proof sealant for wooden door component

InactiveCN104212401AImprove fire resistanceImprove wear resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesTriethoxysilane

The invention discloses a fire-proof sealant for a wooden door component. The fire-proof sealant for the wooden door component comprises 9-15 parts of phenol glycol and 2, 2-dimethylolpropionic acid benzyl ester, 12-21 parts of isophorone diisocyanate, 4-7 parts of 4, 4' diphenylmethane bismaleimide, 2-5 parts of gamma-aminopropyl triethoxy silane, 2-5 parts of 3, 3'-diamido-sulfobenzide, 3-6 parts of fillers and 3-6 parts of compatilizer. By means of the fire-proof sealant for the wooden door component, the fire resistance and the abrasion resistance are good, and the adhesion is highly firm.

Owner:WUXI HITXINCHENG POLYMER TECH

Self-heating type floor decoration tile

ActiveCN102677862BEasy to installImprove thermal efficiencyLighting and heating apparatusElectric heating systemElectricityPower flow

The invention discloses a self-heating type floor decoration brick, and is characterized by comprising a floor tile panel, a floor tile lower seat and a self-heating assembly. A heating unit of the self-heating assembly is an electric heating piece. The floor tile is stuck and fixed above the floor tile lower seat to form a floor tile main body provided with an inner cavity. The electric heating piece of the self-heating assembly is arranged in the inner cavity of the floor tile main body. Power supply plug connectors of the self-heating assembly are arranged on the front side and the back side of the floor tile main body. The power supply plug connectors are reliably limited and fixed in the floor tile main body and can be used for electric connection with an adjacent electric heating floor tile and transmission of current by externally protruded spliced eye positions provided with copper contain pins through corresponding electric connection assemblies, so that the electric heating floor tile has the advantages of being simple and convenient to install, safe and reliable to use, higher in heat efficiency, durability and structurally providing technical supports.

Owner:枣庄高新区利民供热服务有限公司

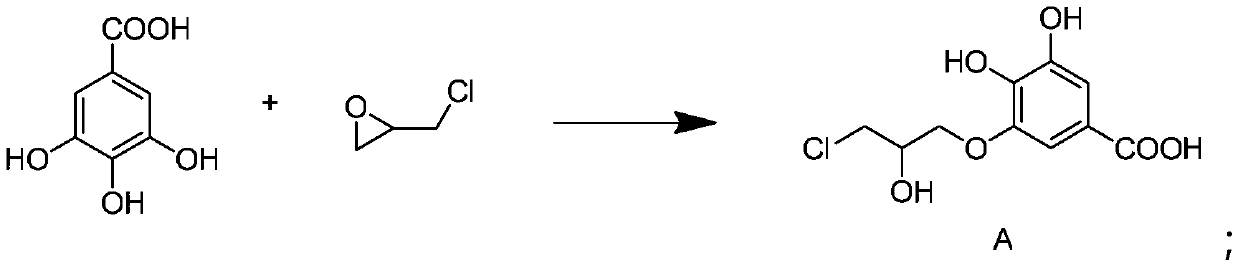

Glue for producing phenolic compact laminate plate and phenolic compact laminate plate production method using the same

InactiveCN106497466AAntifreezeIncrease contact areaNon-macromolecular adhesive additivesLaminationPolymer scienceDiethylene glycol

The invention relates to glue for producing a phenolic compact laminate plate and a phenolic compact laminate plate production method using the same. The glue comprises an agent A and an agent B. The agent A comprises 900-1100 parts of formaldehyde, 1500-1800 parts of phenol, 1800-2000 parts of epichlorohydrin, 90-110 parts of a coupling agent, 130-170 parts of diethylene glycol, and 25 -35 parts of tert-butyl peroxybenzoate. The glue has the advantages of good flexibility, anti-freezing stability, bonding fastness and short compression cycle.

Owner:意禾新材料科技(常州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com