Flexible packaging material for lithium battery of new energy automobile and preparation method of flexible packaging material

A new energy vehicle, lithium battery technology, applied in battery box/sleeve materials, batteries, electronic equipment, etc., can solve problems such as difficulty in ensuring quality, high requirements for solvent bonding layers, etc., and achieve tensile and compressive strength and hardness. Good performance, good flame retardant effect, high heat sealing strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

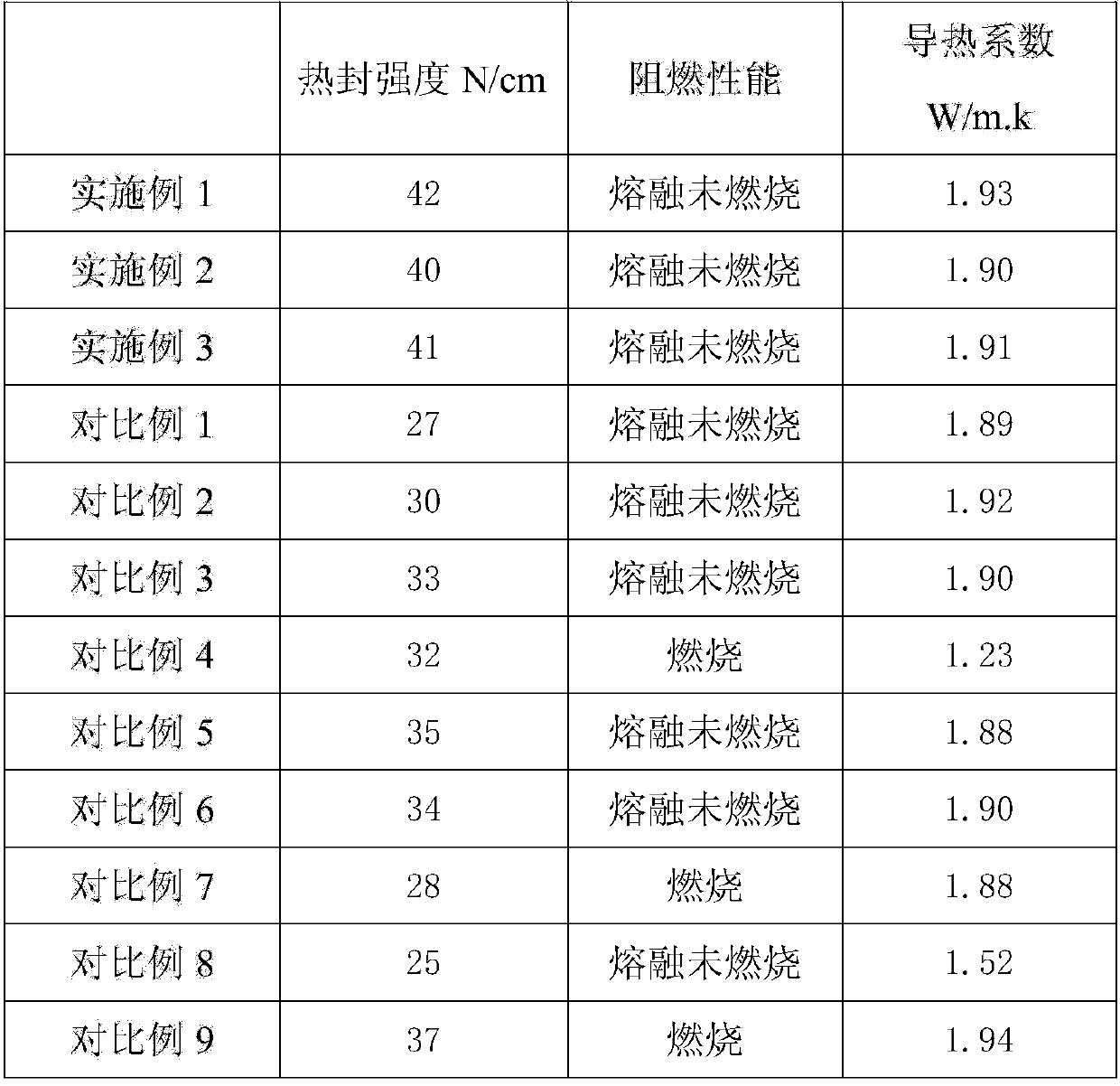

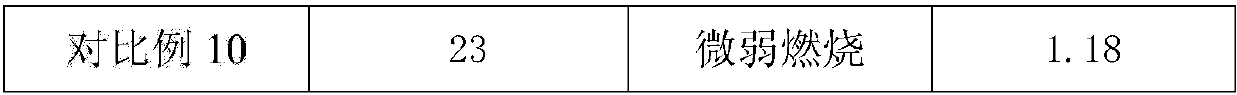

Embodiment 1

[0022] A flexible packaging material for lithium batteries of new energy vehicles, the flexible packaging material for lithium batteries has a layered structure, the middle layer is an aluminum base layer, the outer side of the aluminum base layer is divided into upper and lower sides, and the lower side is distributed sequentially from the inside to the outside. Adhesive resin layer, PET layer, adhesive resin layer and co-polypropylene layer, the upper side is distributed as adhesive resin layer, PET layer, adhesive resin layer and homopolypropylene layer from inside to outside in turn; the adhesive resin layer It is an adhesive resin with a grid structure, and α-Al is distributed in the grid 2 o 3 Nano powder, described binding resin comprises by mass parts: 90 parts of homopolypropylene, 10 parts of styrene-maleic anhydride copolymers, 0.2 parts of dicumyl peroxide, 4 parts of hydroxyl silicone oil, 0.3 parts of acetic anhydride; the PET layer, the co-polypropylene layer, ...

Embodiment 2

[0026] Substantially the same as Example 1, except that the adhesive resin includes by mass parts: 85 parts of homopolypropylene, 15 parts of styrene-maleic anhydride copolymers, 0.1 parts of dicumyl peroxide, 5 parts Parts of hydroxy silicone oil, 0.2 parts of acetic anhydride.

Embodiment 3

[0028] It is basically the same as Example 1, except that the binder resin includes by mass parts: 95 parts of homopolypropylene, 5 parts of styrene-maleic anhydride copolymers, 0.3 parts of dicumyl peroxide, 3 parts Parts of hydroxy silicone oil, 0.4 parts of acetic anhydride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com