Phase change heat storage type electric heating floor

An electric heating floor, phase change heat storage technology, applied in the field of building decoration, can solve the problems of poor waterproof sealing, poor heat transfer effect, complex structure and installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

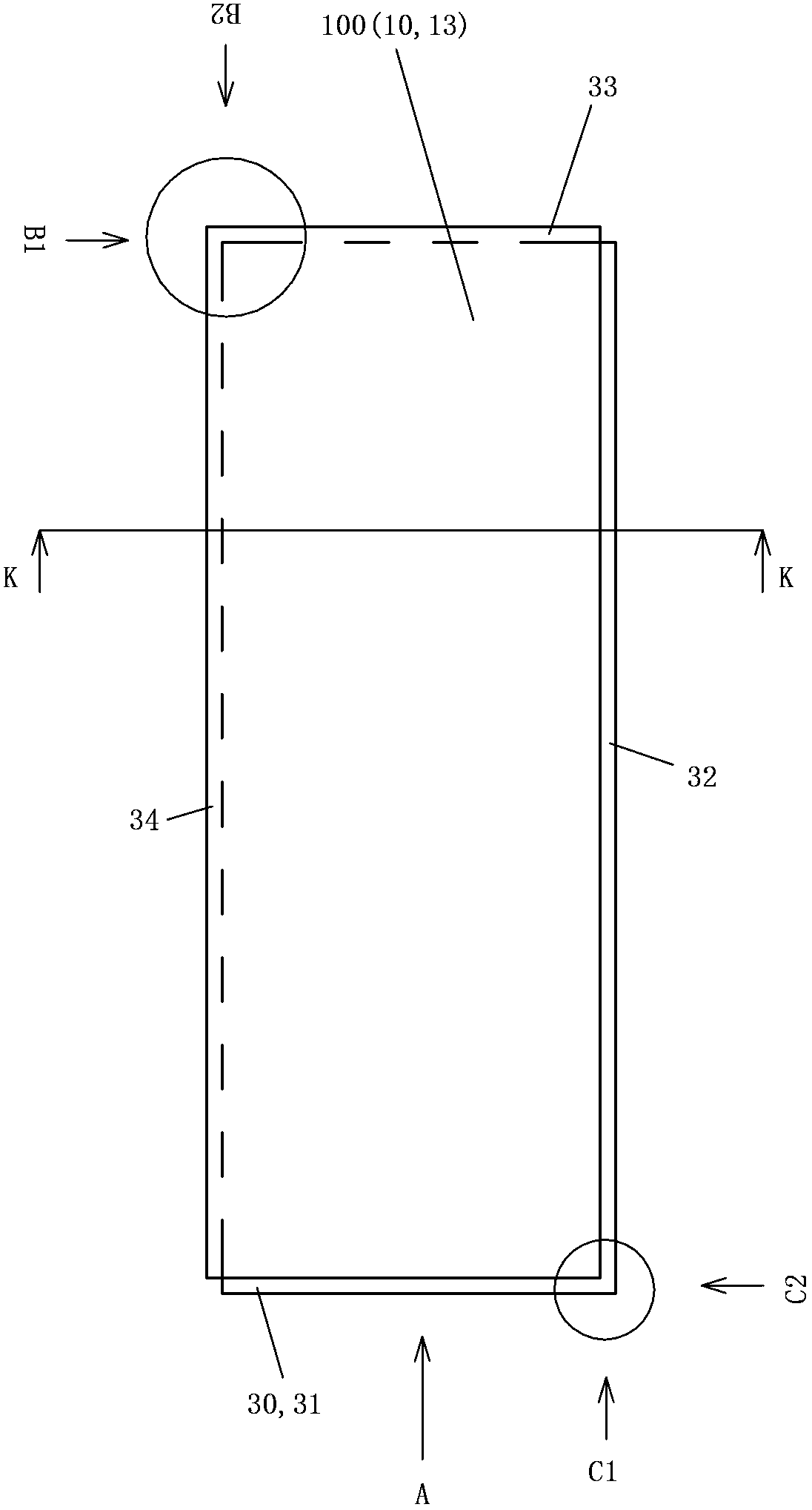

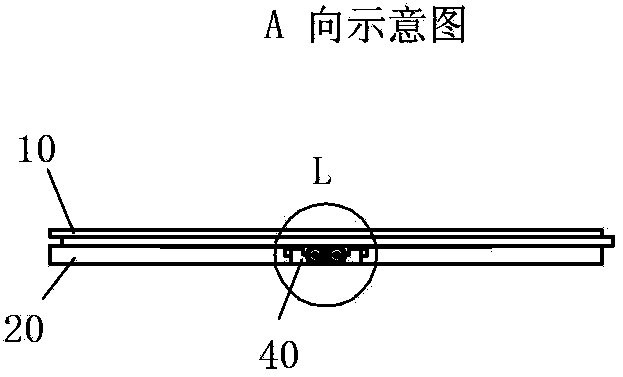

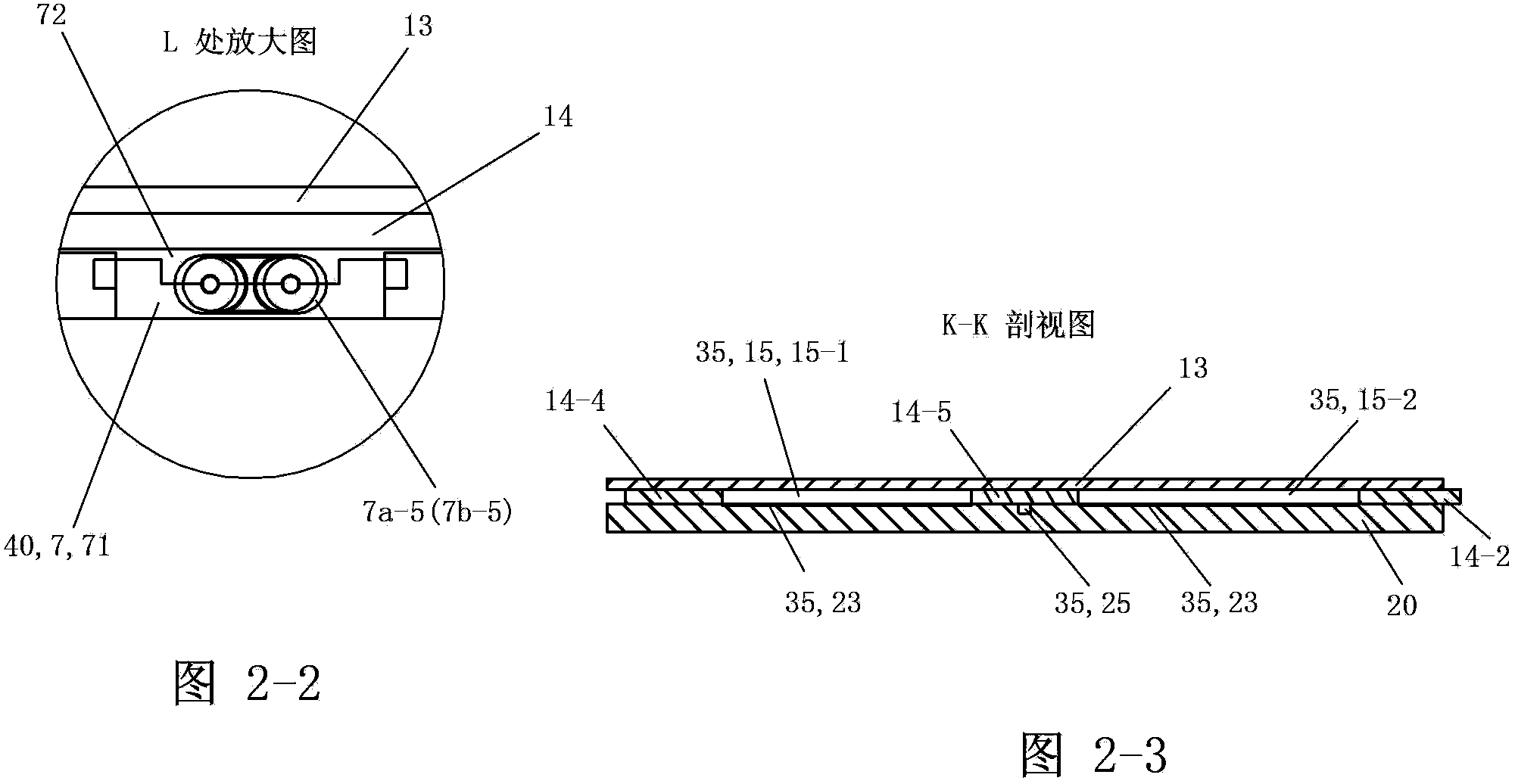

[0126] (Example 1, phase change heat storage type electric heating floor)

[0127] See Figure 1 to Figure 2-3 , The phase change thermal storage type electric heating floor 100 of the present invention is mainly composed of the floor main body 3 , the electric heating assembly 40 and the phase change unit 90 . The floor main body 3 is substantially in the shape of a plate-like cuboid, and is composed of a panel member 10 and a bottom plate 20 that are bonded and fixed together in the up and down direction at the peripheral parts. The interior of the floor main body 3 has a first installation space 35, and the first installation space The space 35 is jointly formed by the panel member 10 and the bottom plate 20 . The electric heater 5 and the phase change unit 90 of the electric heating assembly 40 are fixedly arranged in the first installation space 35 of the floor body 3 , and the overall shape formed by the electric heater 5 and the phase change unit 90 is consistent with ...

Embodiment 2)

[0195] The rest of this embodiment is the same as that of Embodiment 1, the difference being that there is no connection between the two inserting bars 81 of the double inserting bars 8 used to electrically connect two adjacent phase-change heat storage type electric heating floors. pieces, all of which are separate rods 81 (see Figure 20 ). The structural shapes of the two plungers 81 are basically the same.

Embodiment 3)

[0197] The rest of this embodiment is the same as that of Embodiment 1. The difference is that the plugging part 30 of this embodiment is formed during machining, and all the cut parts are cut on the bottom plate 20 to form a phase change heat storage type electric heating floor. The socket part 30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com