Novel hot melt adhesive membrane, preparation method and application

A hot-melt adhesive film, a new technology, applied in the direction of chemical instruments and methods, adhesives, rubber layered products, etc., can solve the problems of high production cost, time-consuming consumables, time-consuming and laborious, etc., and achieve strong bonding fastness and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] 1. Hot melt adhesive film:

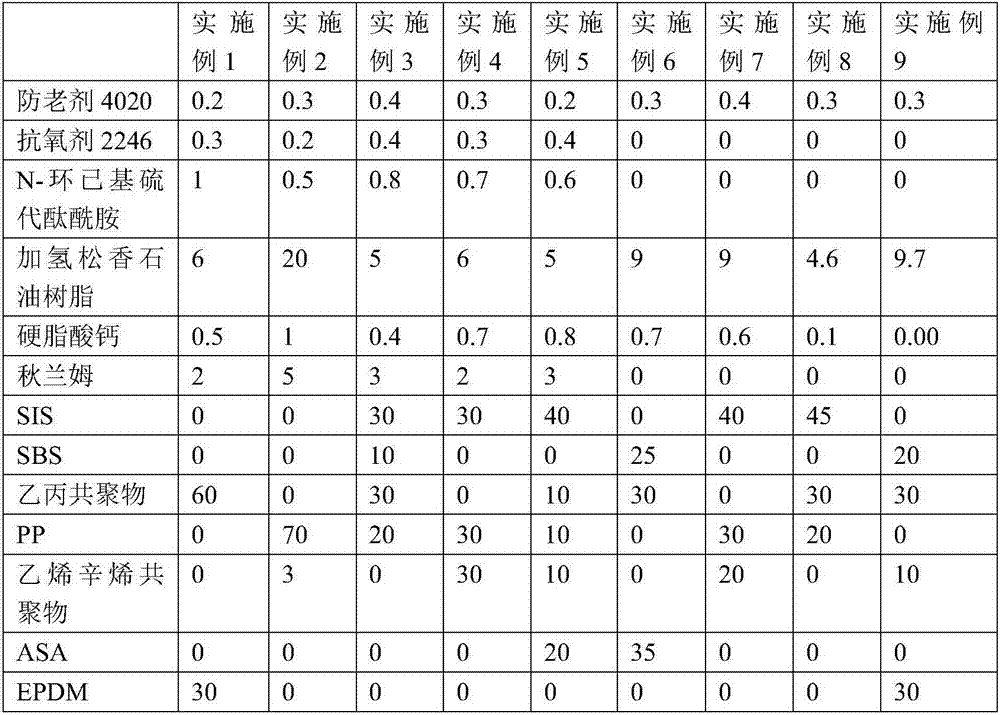

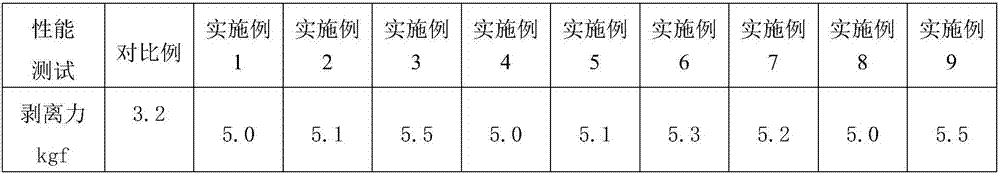

[0031] As shown in Table 1, nine different hot-melt adhesive films of Examples 1-9 are listed, and the specific components are shown in Table 1.

[0032] Among them, the ratio of raw and auxiliary materials (unit: wt%).

[0033]

[0034] Table 1

[0035] 2. Preparation of hot melt adhesive film:

[0036] (1) Put the main material and auxiliary materials into the mixing device, heat up to 30-100°C, and mix for 30 minutes;

[0037] (2) The twin-screw extruder is heated up to 120 to 180 degrees, and the resulting mixture is extruded and granulated;

[0038] (3) The temperature of the casting machine is raised to 120 to 180 degrees, and the film is formed after casting and extrusion.

[0039] 3. Application of hot melt adhesive film

[0040] Place the hot melt adhesive film made above between the primary foamed EVA layer and the raw film layer to form a three-layer covering structure, then heat the mold to 180°C, then put the above three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com