Self-heating assembly

A technology of self-heating components and components, which is applied in the field of architectural decoration, can solve the problems of heat conduction plate damage, heavy maintenance workload, and technical solutions that cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] (Example 1, self-heating component)

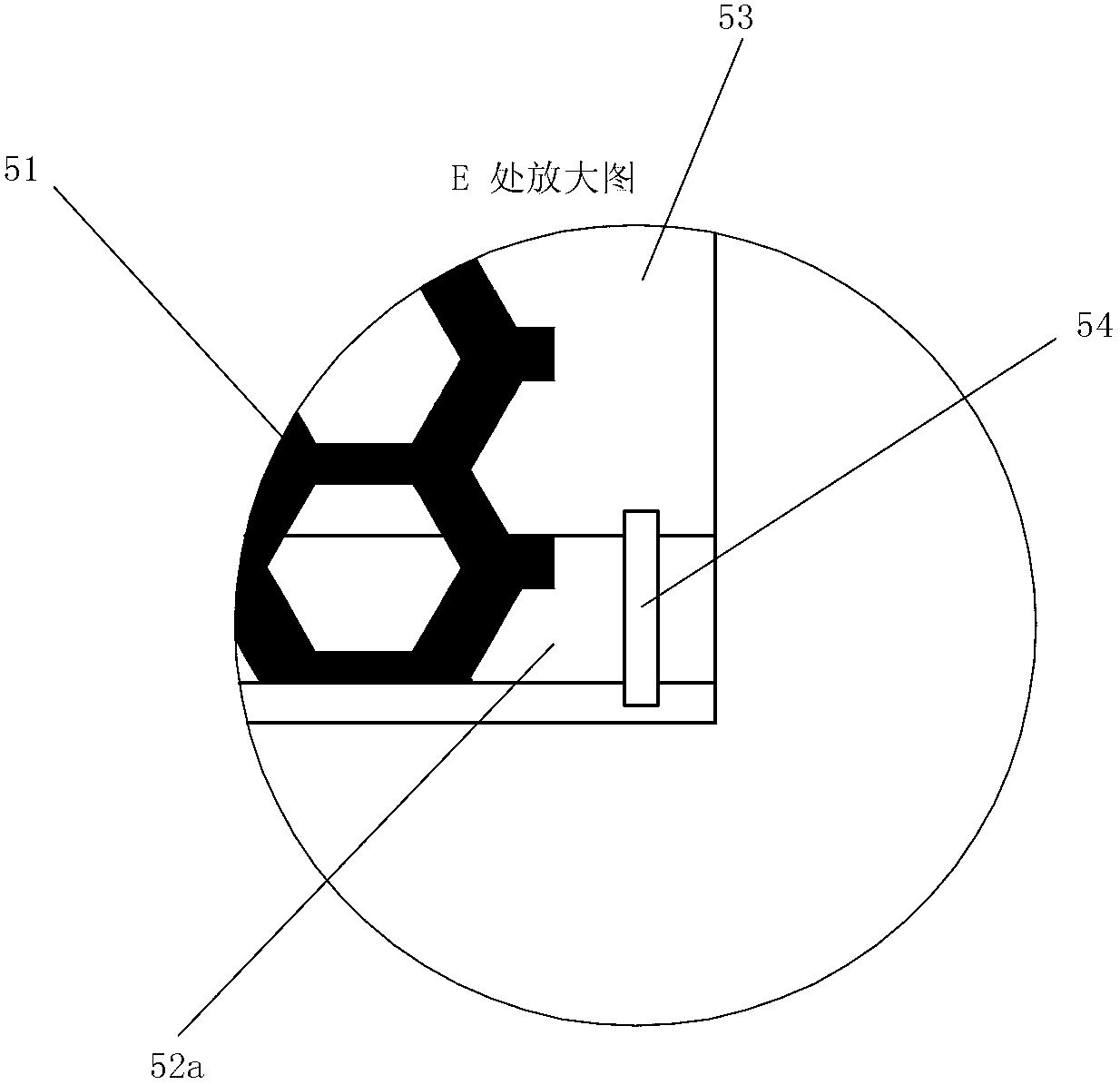

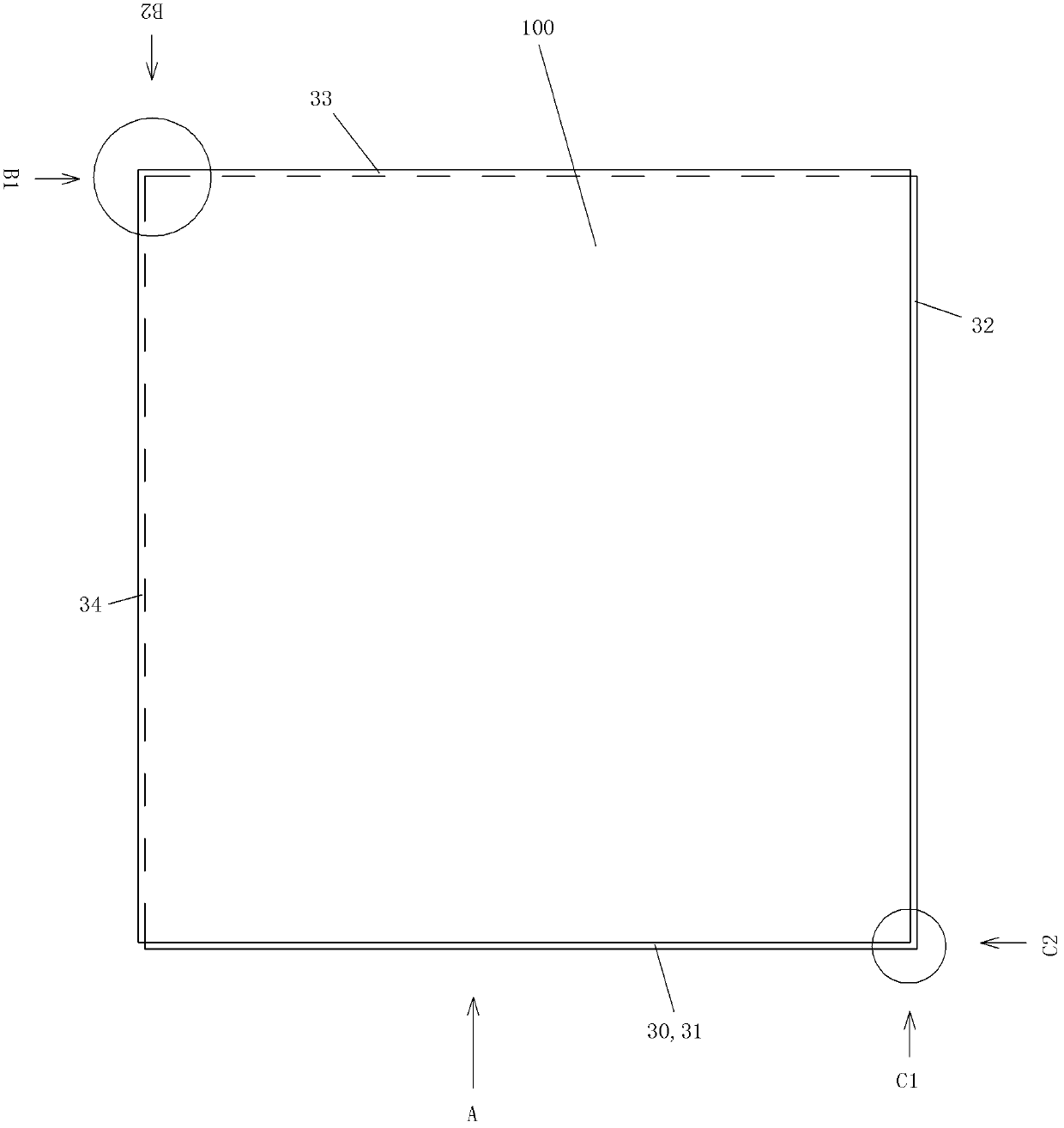

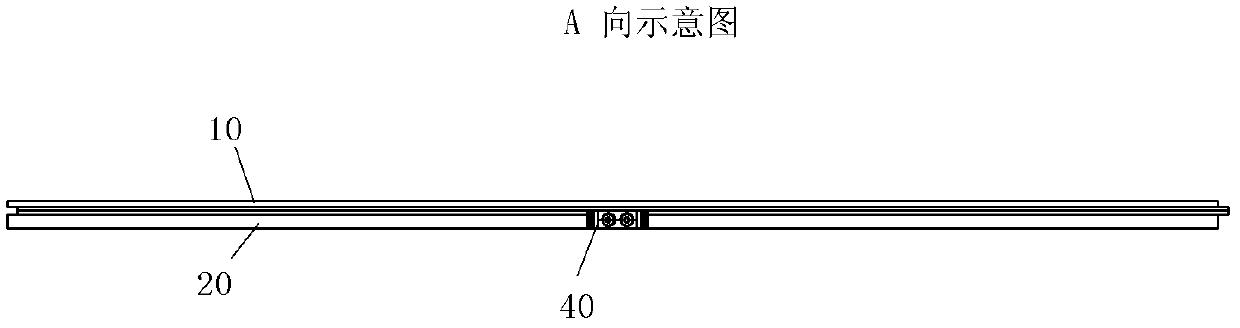

[0119] See Figure 7-1 , The self-heating component 40 is a waterproof electric heating component, and the self-heating component 40 includes a heating plate 5 , a transmission unit 6 and two installation seats 7 located at the front and rear ends of the heating plate 5 .

[0120] The transmission unit 6 is composed of two transmission connectors 61 , two wires 62 and two piercing connectors 63 . The structure and shape of the two transmission connectors 61 are the same, and they are divided into the first transmission connector 61a and the second transmission connector 61b; the two electric wires 62 are all the same, and are divided into the first electric wire 62a and the second The electric wire 62b; the two puncture connectors 63 have the same structure and shape, and are divided into a first puncture connector 63a and a second puncture connector 63b. The first transmission plug 61a, the first electric wire 62a and the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com