A kind of ASA plastic film ink resin and preparation method thereof

A technology of plastic film and ink, applied in ink, household utensils, applications, etc., can solve the problems of inability to print in color and restrict the application of ASA film, etc., achieve strong adhesion fastness, stable and controllable emulsion polymerization process, and good adhesion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

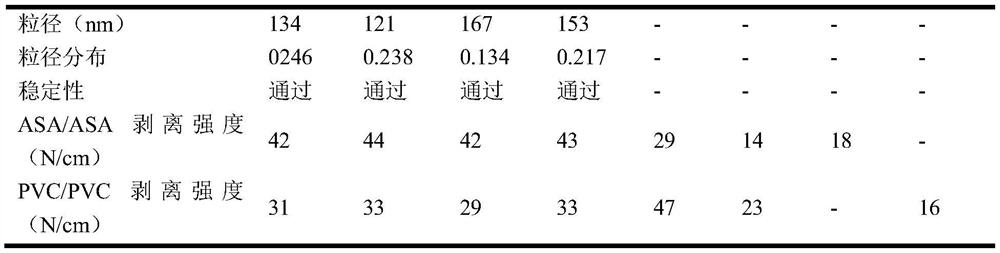

Embodiment 1

[0030] (1) At room temperature, 10kg of acrylonitrile monomer (Chengdu Huana Chemical Co., Ltd.), 11kg of styrene monomer (Jinan Chuangshi Chemical Co., Ltd.), 0.5kg of S8115 (SOLVAY company) primary emulsifier, 0.2kg of TRITON X-705 (DOW company) co-emulsifier and 20kg of pure water were mixed and stirred and dispersed at a speed of 600rpm for 40min to prepare the core layer monomer pre-emulsion;

[0031] (2) At room temperature, 2kg of HCM206 hydroxypropyl methacrylate monomer (Hechuang Chemical Company), 10kg of n-butyl acrylate monomer (Sinopharm Chemical Reagent Co., Ltd.), 0.5kg of S8115 (SOLVAY company) main emulsifier was mixed and stirred and dissolved at a speed of 400rpm for 30min to obtain a shell monomer liquid;

[0032] (3) under room temperature, the ammonium persulfate (Wujiang Weitong Chemical Co., Ltd.) initiator of 0.23kg is dissolved in the pure water of 6kg, makes initiator aqueous solution;

[0033] (4) At room temperature, add 19.69kg of pure water to...

Embodiment 2

[0035] (1) At room temperature, 10kg of acrylonitrile monomer (Chengdu Huana Chemical Co., Ltd.), 11kg of styrene monomer (Jinan Chuangshi Chemical Co., Ltd.), 1kg of S8115 (SOLVAY company) main emulsifier, 0.4kg of TRITON X-705 (DOW company) co-emulsifier and 22kg of pure water were mixed and stirred and dispersed at a speed of 800rpm for 20min to prepare the core layer monomer pre-emulsion;

[0036] (2) At room temperature, 5kg of HCM206 hydroxypropyl methacrylate monomer (Hechuang Chemical Company), 7kg of n-butyl acrylate monomer (Sinopharm Group Chemical Reagent Co., Ltd.), 0.6kg of S8115 (SOLVAY company) main emulsifier was mixed and stirred and dissolved at a speed of 600rpm for 10min to obtain a shell monomer liquid;

[0037] (3) under room temperature, the ammonium persulfate (Wujiang Weitong Chemical Co., Ltd.) initiator of 0.3kg is dissolved in the pure water of 7.5kg, makes initiator aqueous solution;

[0038] (4) At room temperature, add 17.324kg of pure water ...

Embodiment 3

[0040] (1) At room temperature, 7kg of acrylonitrile monomer (Chengdu Huana Chemical Co., Ltd.), 13kg of styrene monomer (Jinan Chuangshi Chemical Co., Ltd.), 0.8kg of S8115 (SOLVAY company) primary emulsifier, 0.2kg of TRITON X-705 (DOW company) co-emulsifier and 21kg of pure water were mixed and stirred and dispersed at a speed of 750rpm for 30min to prepare the core layer monomer pre-emulsion;

[0041] (2) At room temperature, 4kg of HCM206 hydroxypropyl methacrylate monomer (Hechuang Chemical Company), 10kg of n-butyl acrylate monomer (Sinopharm Chemical Reagent Co., Ltd.), 0.4kg of S8115 (SOLVAY company) main emulsifier was mixed and stirred and dissolved at a speed of 550rpm for 20min to obtain a shell monomer liquid;

[0042] (3) under room temperature, the ammonium persulfate (Wujiang Weitong Chemical Co., Ltd.) initiator of 0.28kg is dissolved in the pure water of 7kg, makes initiator aqueous solution;

[0043] (4) At room temperature, add 16.22kg of pure water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com