Aqueous polyurethane adhesive and preparation thereof

A water-based polyurethane and adhesive technology, which is applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of not meeting the adhesive force requirements of shoe adhesives, low cross-linking degree, small molecular weight of polyurethane, etc. problem, to achieve the effect of stable and controllable polymerization process, excellent anti-aging ability, and improved initial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

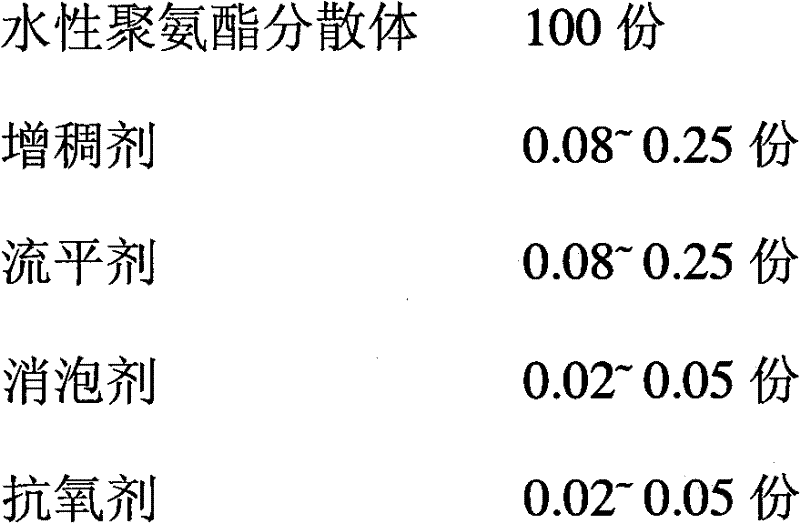

[0037] Prepare the water-based polyurethane adhesive in the following parts by weight ratio:

[0038] 100 parts of water-based polyurethane dispersion

[0039] Thickener acrylic acid copolymer 0.25 parts

[0040] Leveling agent polyether modified polyorganosiloxane 0.08 parts

[0041] Defoamer Glycerin polyoxyethylene-polyoxypropylene copolymer 0.05 parts

[0042] Antioxidant tris(2,4-di-tert-butylphenyl) phosphite 0.02 parts

[0043] The preparation steps are as follows:

[0044](1) Preparation of polyurethane prepolymer: Add an excess of the first polyol polycaprolactone diol with a molecular weight of 1000 to a single-necked flask, dry it in vacuum at 100° C. for 3 hours, cool down to 50° C., and set aside. Add 100 parts of the first polyol to a four-necked flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen inlet, keep the temperature at 50 ° C, add 0.08 parts of stannous octoate catalyst, and dropwise add diisocyanate monomer isofor 55 par...

Embodiment 2

[0050] Prepare the water-based polyurethane adhesive in the following parts by weight ratio:

[0051] 100 parts of water-based polyurethane dispersion

[0052] Thickener acrylic acid copolymer 0.10 parts

[0053] Leveling agent polyether modified polyorganosiloxane 0.25 parts

[0054] Defoamer Glycerin polyoxyethylene-polyoxypropylene copolymer 0.02 parts

[0055] Antioxidant tris(2,4-di-tert-butylphenyl) phosphite 0.05 parts

[0056] The preparation steps are as follows:

[0057] (1) Preparation of polyurethane prepolymer: Add an excess of the first polyol polybutylene adipate diol with a molecular weight of 1000 to a single-necked flask, dry it in vacuum at 110° C. for 2 hours, cool down to 70° C., and set aside. Add 100 parts of the first polyol to a four-necked flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen inlet, keep the temperature at 70°C, add 0.08 parts of stannous octoate catalyst, and dropwise add diisocyanate monomer isofor 55 ...

Embodiment 3

[0063] Prepare the water-based polyurethane adhesive in the following parts by weight ratio:

[0064] 100 parts of water-based polyurethane dispersion

[0065] Thickener acrylic acid copolymer 0.15 parts

[0066] Leveling agent polyether modified polyorganosiloxane 0.15 parts

[0067] Defoamer Glycerin polyoxyethylene-polyoxypropylene copolymer 0.03 parts

[0068] Antioxidant tris(2,4-di-tert-butylphenyl) phosphite 0.03 parts

[0069] The preparation steps are as follows:

[0070] (1) Preparation of polyurethane prepolymer: Add an excess of the first polyol polybutylene adipate diol with a molecular weight of 1000 to a single-necked flask, dry it in vacuum at 120° C. for 1 hour, cool down to 90° C., and set aside. Add 100 parts of the first polyol to a four-neck flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen inlet, keep the temperature at 90°C, add 0.08 parts of stannous octoate catalyst, and dropwise add diisocyanate monomer bicyclic 65 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com