Preparation method of polyimide film

A polyimide film and diamine monomer technology, applied in the field of polyimide film preparation, can solve the problems of difficult process control, improve material mechanical properties, narrow processing window, etc., and achieve gel and insoluble content Low, wide film processing window, and the effect of improving processability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

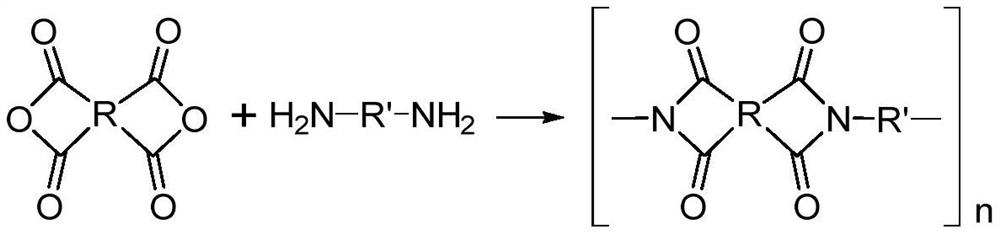

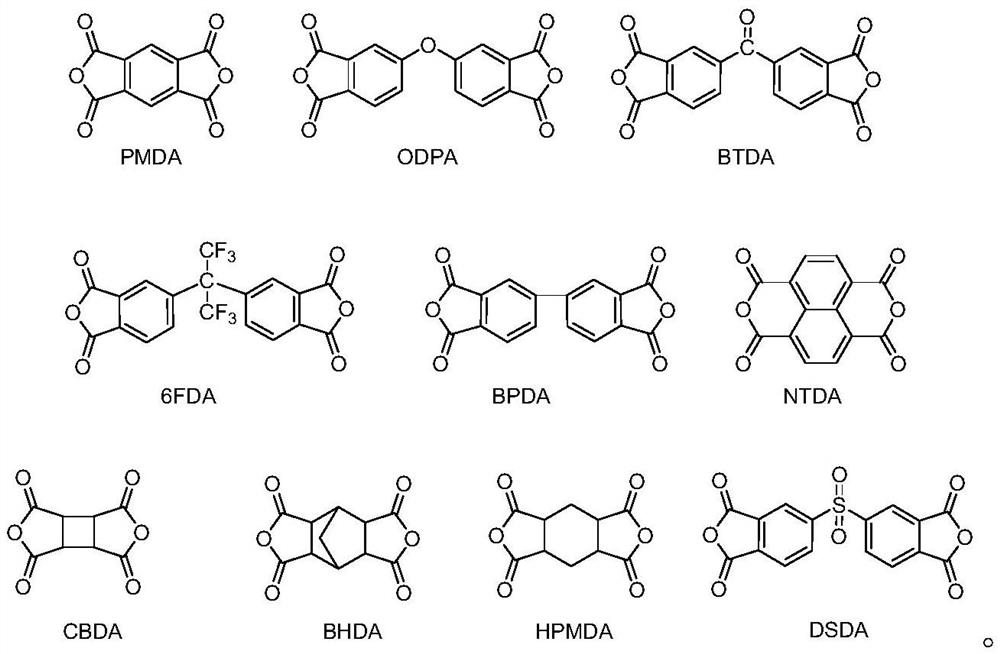

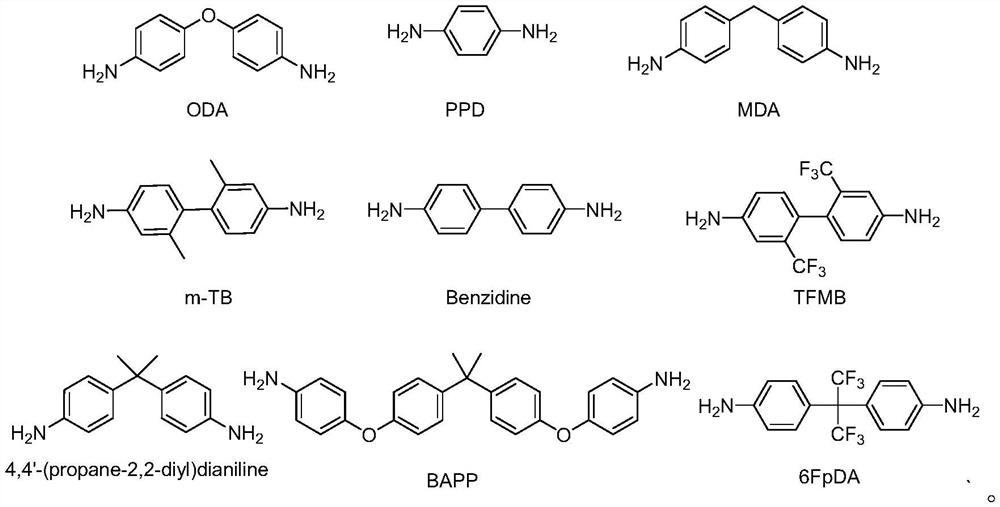

Method used

Image

Examples

Embodiment 1

[0047] 300 g of NMP (75% by mass in the total amount of the solvent), 1-ethyl-3-methylimidazolyl acetic acid were added as a solvent to a glass reaction vessel with an inner volume of 500 mL equipped with a stirrer and a nitrogen introduction and discharge pipe. Salt ([EMIM] + [Ac] - ) 100g of ionic liquid (accounting for 25% by mass in the total solvent), to which PPD 26.88g (0.249 mol), BPDA 73.12g (0.249 mol) were added, and the stirring was completely dissolved at room temperature. The reaction was stirred at 50° C. for 10 hours to obtain In the polyamic acid solution composition having a solid content concentration of 18.5% by weight, a solution viscosity of 58.0 Pa·s, and a logarithmic viscosity of 1.10, no flocs and insolubles were formed in the reaction product.

[0048] The polyamic acid solution composition was coated on a glass substrate with a doctor blade, the coating film was degassed and pre-dried at 25° C. under reduced pressure for 30 minutes, and then placed...

Embodiment 2

[0051] It was prepared in the same manner as in Example 1, except that 320 g of DMF (80 mass % of the total solvent) and 80 g of 1-ethyl-3-methylimidazolium acetate ionic liquid (20 mass % of the total solvent) were used Polyimide film.

[0052] The thermal decomposition temperature of the obtained polyimide film was 485° C., and the tensile strength was 295 MPa.

Embodiment 3

[0054] In addition to using DMF 160 g (40 mass % of the total solvent) and DEF 160 g (40 mass % of the total solvent), 1-ethyl-3-methylimidazolium acetate ionic liquid 80 g (accounting for the total solvent) A polyimide film was formed in the same manner as in Example 1 except for 20% by mass in the above.

[0055] The thermal decomposition temperature of the obtained polyimide film was 493° C., and the tensile strength was 310 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com