Wood veneer composite material and its production process

A composite material and veneer technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, paper coating, special paper, etc., can solve the problems that the performance is not as good as that of products using special veneer composite materials, and meet the processing suitability Requirements, solve the problem of transverse cracking, and the effect of strong bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

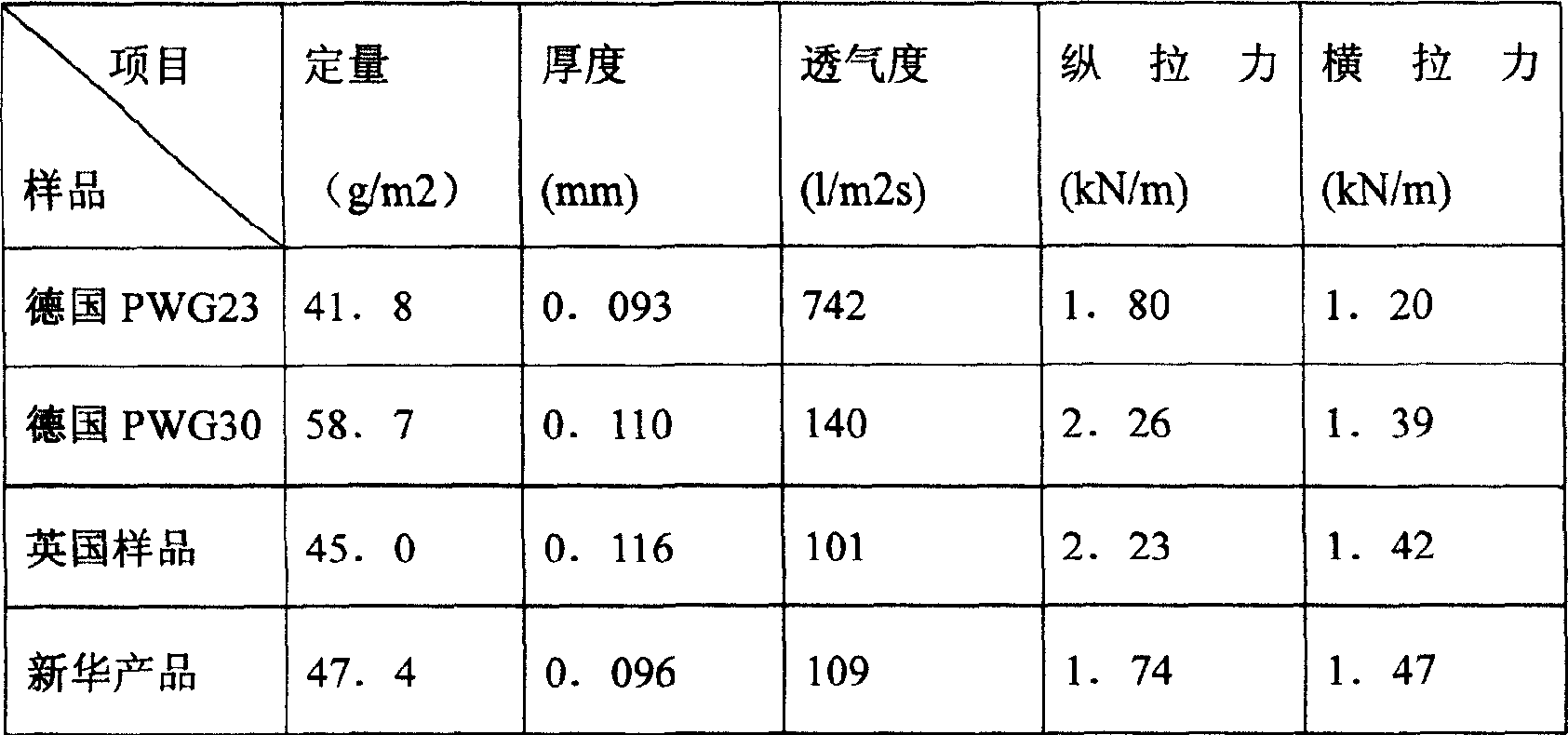

Image

Examples

Embodiment 1

[0016] Embodiment 1: this veneer composite material, it is made by the raw material of following weight ratio, Manila hemp pulp 20%, wood pulp 40%, chemical fiber 35%, bonding fiber 5%. The bonding fiber is water-soluble PVA, and the chemical fiber refers to vinylon.

[0017] The production technology of this veneer composite material mainly comprises the following steps;

[0018] 1) Beating with a beater: the beating concentration of wood pulp is 4-5%, the beating ampere is 65-70A, the beating time is 40-60 minutes, and the pulp quality requirements: percussion degree 15---18 (°SR), wet weight 14---16 (grams); the beating concentration of Manila hemp pulp is 3-4%, the beating amp is 60-65A, and the beating time is 30-50 minutes; the pulp quality requirements: percussion degree 14---16(°SR), The wet weight is 16---18 (grams); the chemical fiber is mainly loosened, and the fiber must be completely dispersed, and no drawing phenomenon is allowed;

[0019] 2) In the pulp storag...

Embodiment 2

[0039] Embodiment 2: The difference with Embodiment 1 is that this veneer composite material is made of the raw materials of the following weight ratio, Manila hemp pulp 40%, wood pulp 20%, chemical fiber 30%, bonding Fiber 10%, wherein said bonding fiber is water-soluble PVA, and chemical fiber refers to vinylon.

Embodiment 3

[0040] Embodiment 3: The difference with Embodiment 1 is that this veneer composite material is made of the raw materials of the following weight ratio, Manila hemp pulp 30%, wood pulp 20%, chemical fiber 40%, bonding Fiber 10%, wherein said bonding fiber is water-soluble PVA, and chemical fiber refers to vinylon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com